SMC Networks LESH16L, LESH16R, LESH25R, LESH8R, LESH25L Operation Manual

...

Doc. no. LES-OM00210

PRODUCT NAME

Electric Slide Table

MODEL / Series / Product Number

LES Series

Applicable models: LESH[]R, LESH[]L,LESH[]D

R T ype

●Standard

/LESH[]R Series

D T ype

●Standard

/LESH[]D Series

L Type

●Standard

/LESH[]L Series

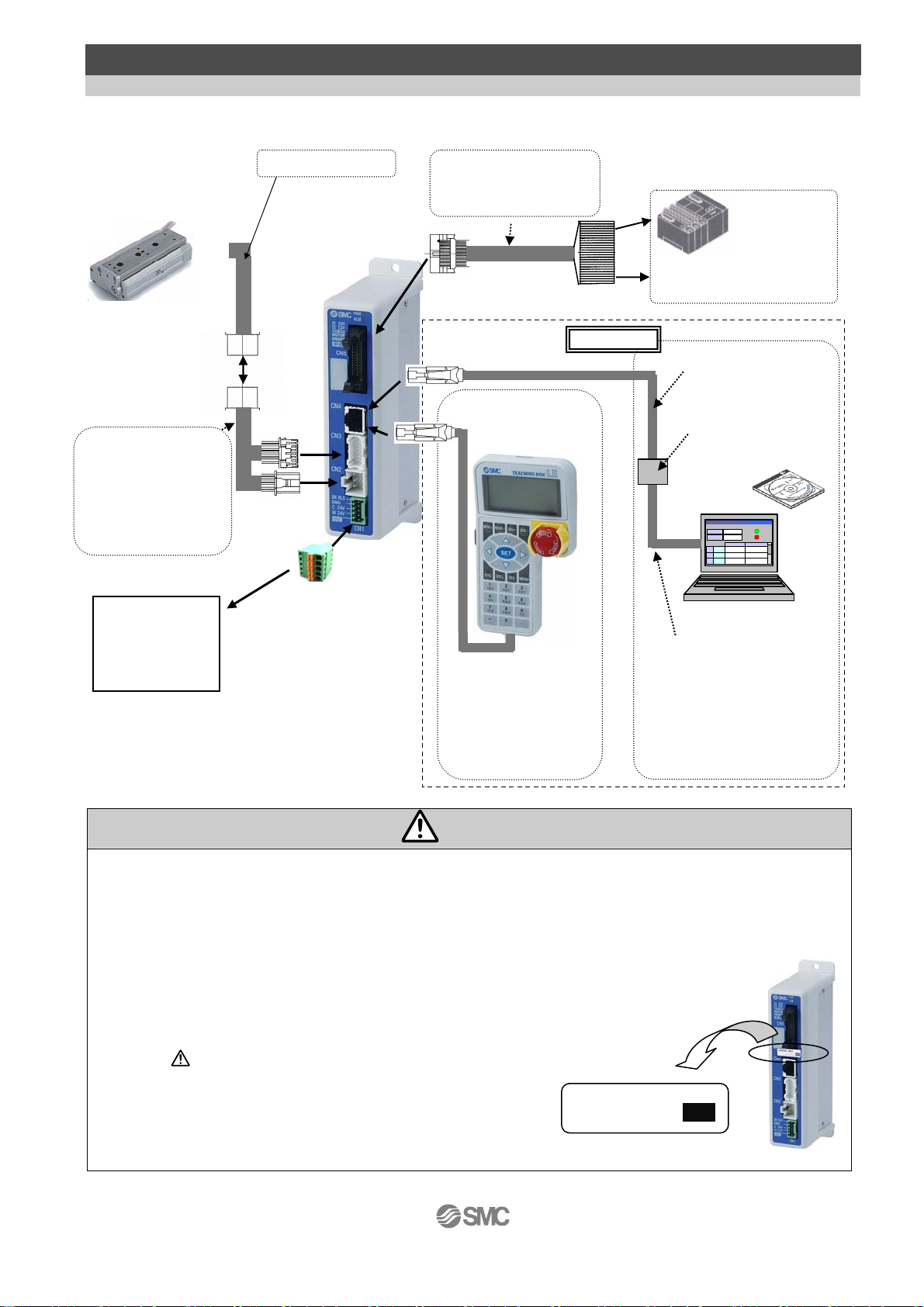

<Controller>

LEC Series

This manual describes the actuators operation in combination with the LEC*6 series controllers.

Refer to the manual relevant to the controller being used for full operating instructions.

Contents

Safety Instructions............................................................................. 2

1. Procedure before operation/simple setting to use straight away4

1.1 Preparation................................................................................ 4

1.2 Controller setting software version......................................... 5

1.3 Teaching box ............................................................................. 7

2. Electric Slide table /LES Series..................................................... 9

2.1 Specification.............................................................................. 9

2. 2 How to Order .......................................................................... 13

2.3 Construction ........................................................................... 14

3. Product Outline ............................................................................ 16

3.1 System construction .............................................................. 16

3.2 Setting Function...................................................................... 17

3.3 Step data setting ..................................................................... 20

3.4 Parameter setting.................................................................... 31

4. Wiring of cables / Common precautions.................................... 35

5. Electric actuators / Common precautions ................................. 36

5.1 Design and selection .............................................................. 36

5.2 Mounting.................................................................................. 37

5.3 Handling .................................................................................. 37

5.4 Operating environment .......................................................... 39

5.5 Maintenance ............................................................................ 39

5.6 Precautions for actuator with lock ........................................ 40

6. Electric actuators / Common precautions ................................. 41

6.1 Design and selection .............................................................. 41

6.2 Handling .................................................................................. 41

6.3 Precaution on maintenance ................................................... 45

6.4 Replacement of belt ( LESH*R / LESH*L )............................. 46

6.5 How to spreading grease ....................................................... 48

7. Troubleshooting ........................................................................... 49

- 1 –

LES Series / Electric Slide table

Safety Instructions

These safety instructions are intended to prevent hazardous situations and /or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition to International Standards (ISO

/IEC), Japan Industrial Standards (JIS)*1) and other safety regulations*2).

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety. etc.

*2) Labor Safety and Sanitation Law, etc.

Caution

Warning

Danger

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor or

moderate injury.

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in

death or serious injury.

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death or

serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery /equipment until safety is confirmed.

The inspection and maintenance of machinery /equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

Before machinery /equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

be used in any of the following conditions.

1) Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other

applications unsuitable for the standard specifications described in the product catalog.

3) An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4) Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

- 2 -

LES Series / Electric Slide table

Safety Instructions

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange specifications

or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer /Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

The warranty period of the product is 1 year in service or 1.5 years after the product is delivered.*3)

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

Prior to using SMC products, please read and understand the warranty terms and disclaimers noted

in the specified catalog for the particular products.

*3)

Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure

due to the deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements

When the product is exported, strictly follow the laws required by the Ministry of Economy, Trade and

Industry (Foreign Exchange and Foreign Trade Control Law).

- 3 -

1. Procedure before operation/simple setting to use straight away

The controller is already set with the data of the actuator.

With the simple setting “easy mode”, it can be operated and running parameters can be changed easily.

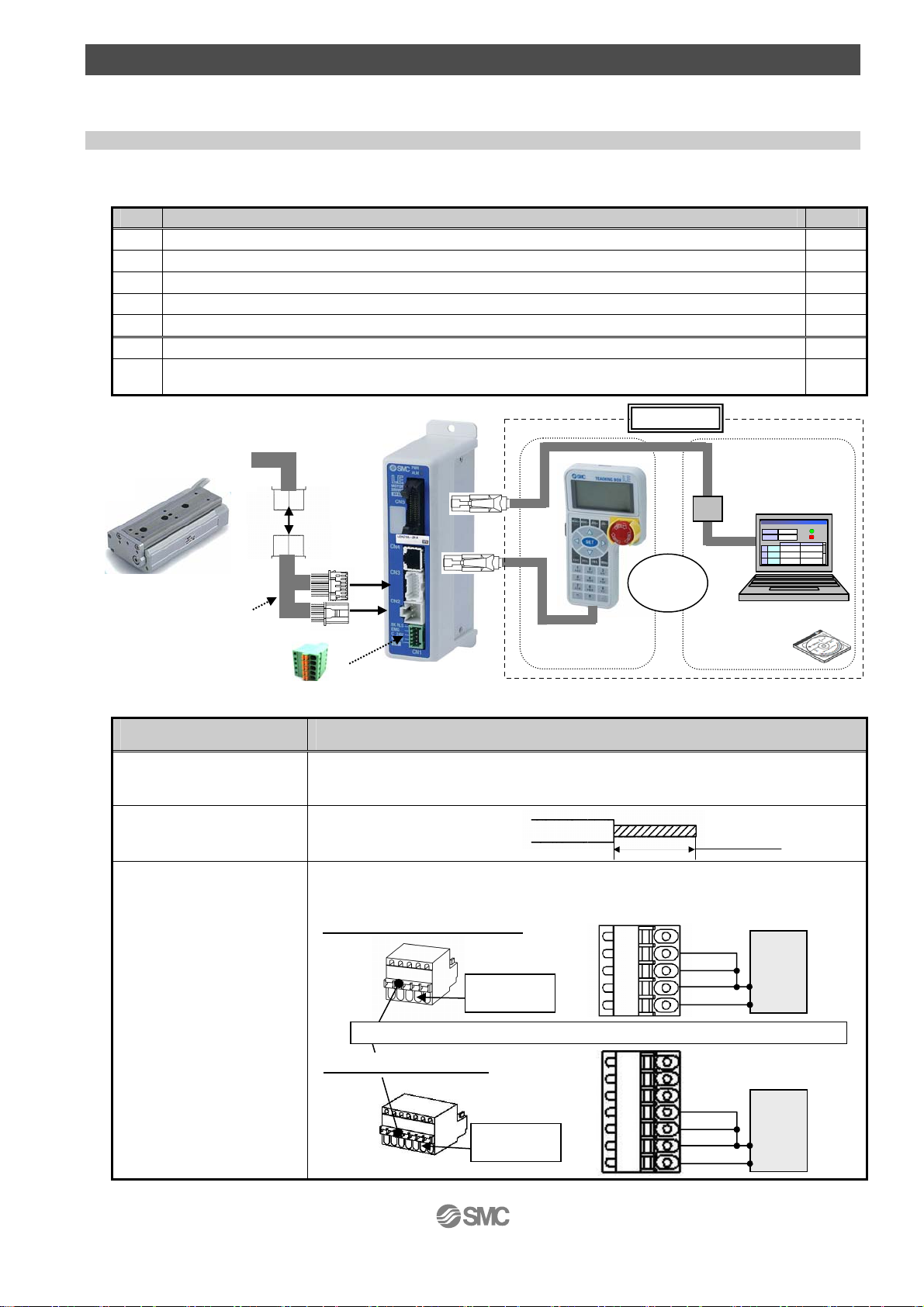

1.1 Preparation

(1) Items to be prepared

Please check the label, and the quantity of accessories, to confirm that it is the product that was ordered.

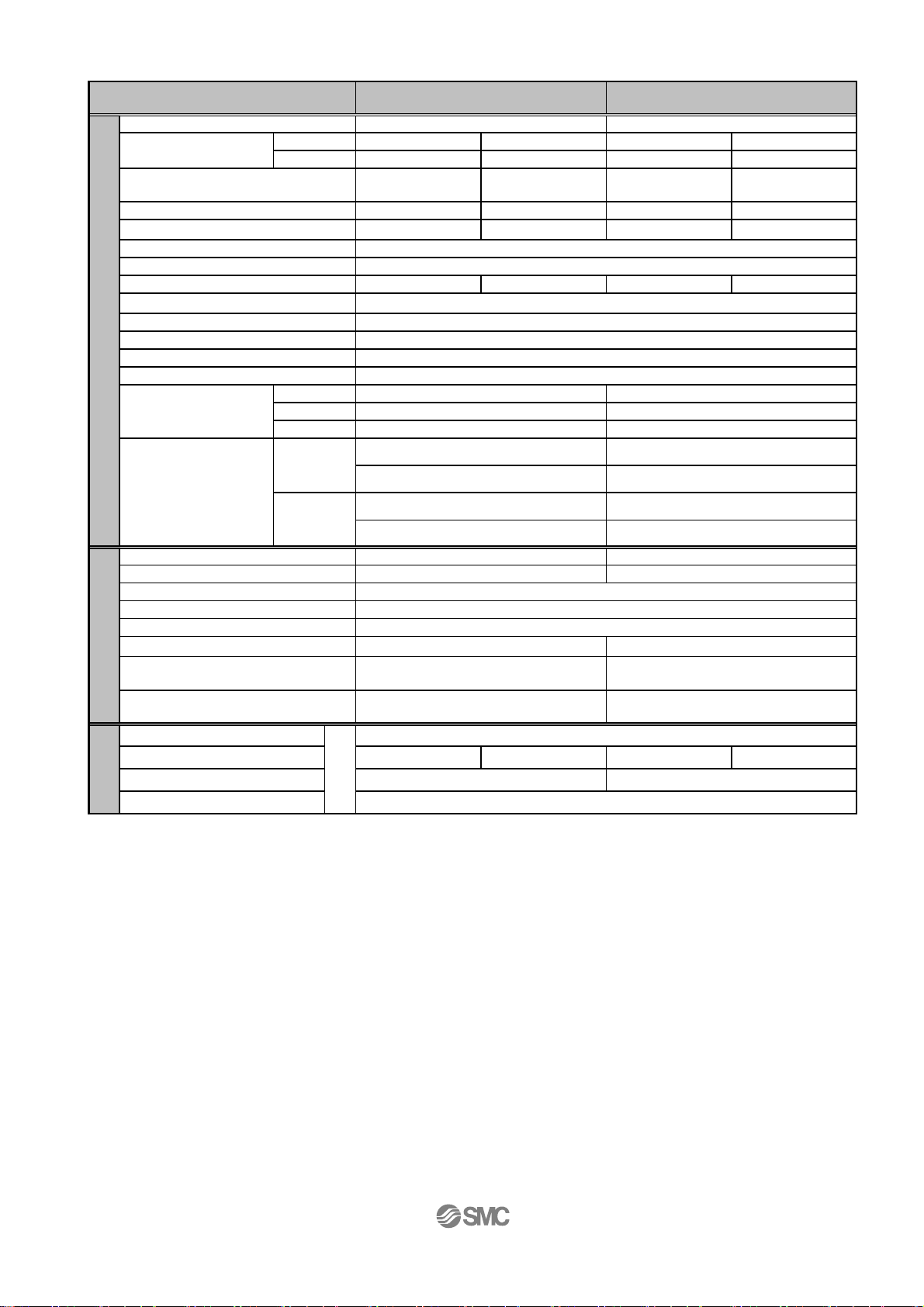

Table 1. Components

No. Part name Qty

(1)

(2)

(3)

(4)

(5)

(6)

(7)

[The controller setting software, The communication cable, USB cable and conversion unit are included.]

(1)Electric slide teble

(2) Controller

To CN3

(4)Actuator cable

(3)Power supply plug

To CN2

Table 2. Items to be prepared by the customer

I/O cable (Not use in this section)

To CN1

Electric slide teble

Controller

Power supply plug

Actuator cable

Teaching box

Controller setting kit

To CN4

(6)Teaching box

Option

or

(7)Controller

●Communication

cable

To USB port

モニタ

モニタ

現在位置

mm

現在位置

mm

120.3

120.3

現在速度

現在速度

mm/s

mm/s

200

200

設定

設定

位置 速度

位置 速度

100 500

1

テスト

100 500

1

テスト

2

テスト

2

テスト

200

200

3

テスト

3

テスト

50

50

PC

Setting kit

動作中

動作中

アラーム

アラーム

1000

1000

200

200

1

1

1

1

1

1

1

Part name Conditions

Power supply 24VDC

Do not use the power supply

with “Inruch-restraining type”

Wire AWG20 (0.5mm2)

Power supply plug

Wiring

Refer to power consumption of each actuator

/ See 2.1 Specification on p.9-12

(Prepare the power supply that has capacity of “Moment max.power consumption” or more.)

Stripped wire length

8mm

Connect the plus side of 24VDC to the C24V, M24V and EMG terminals of the power

supply plug, and the minus side to the 0V terminal.When conformity to UL is required,

the electric actuator and controller should be used with a UL1310 Class 2 power supply.

Step motor (servo 24VDC)

24VDC

power

suppiy

24V

0V

Electrical

wire entry

EMG

C24V

M24V

0V

Push the open/clese lever and insert the wire into the electrical wire entry

Servo motor (24VDC)

24VDC

power

suppiy

24V

0V

Electrical

wire entry

EMG

C24V

M24V

0V

- 4 -

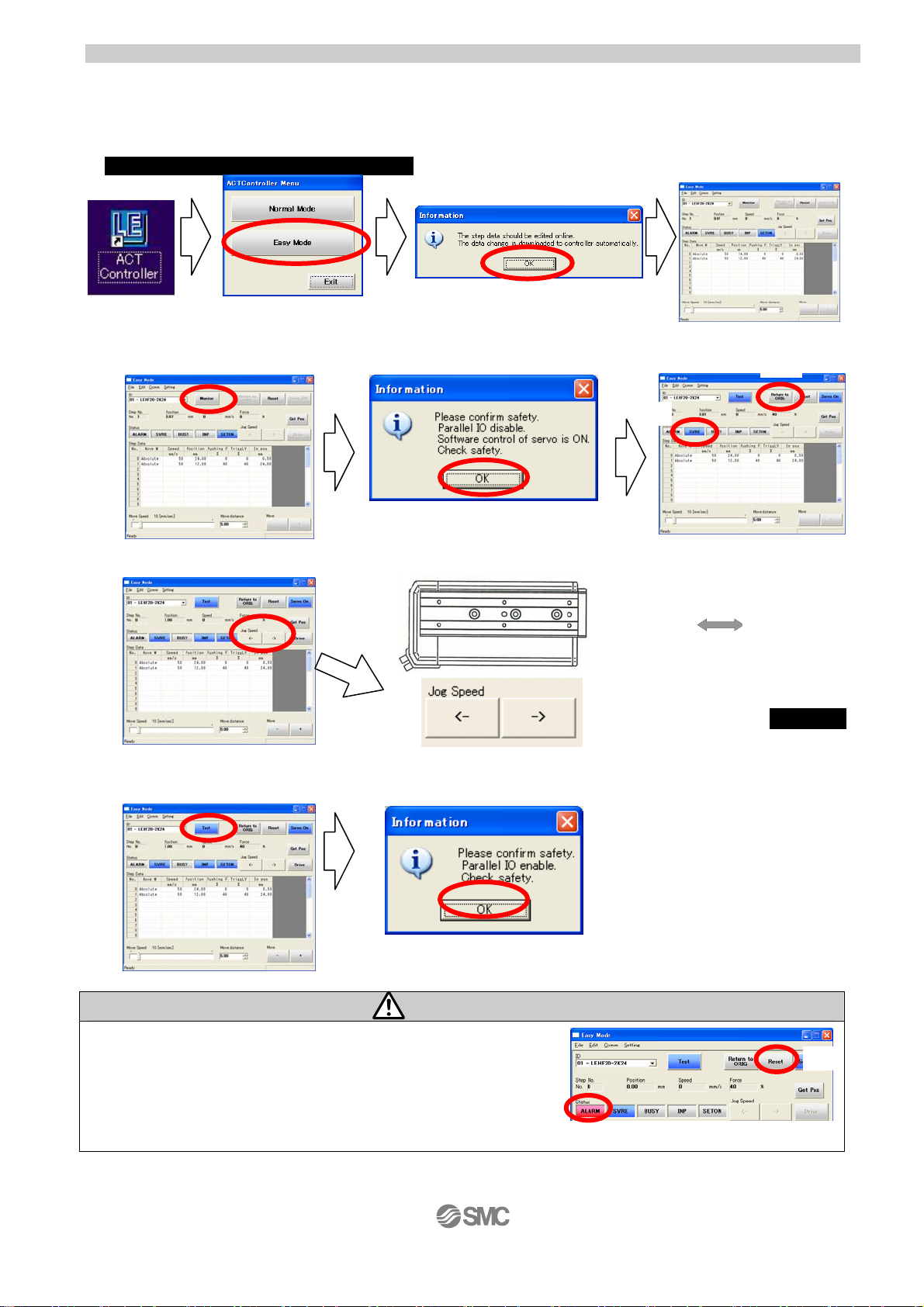

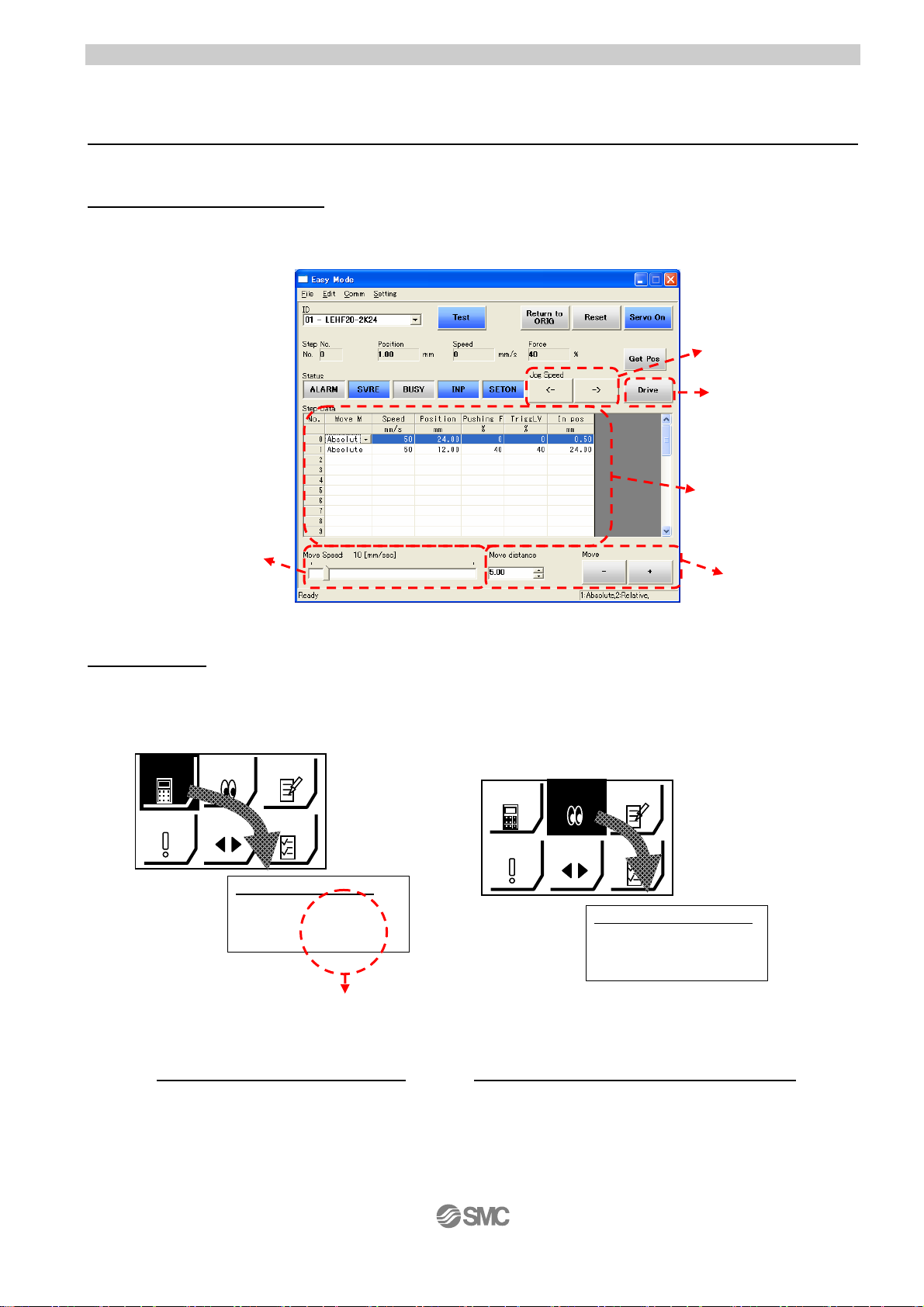

1.2 Controller setting software version

1. Installation of software

With the controller setting software CD-ROM, install the communication unit software, following the

“Software Installation procedure” (PDF)

2. Startup of software

After turning on the controller power supply, start up the ACT Controller setting soft ware.

3. JOG Drive

a. Driving preparation: Servo On → Return to ORIG

Select “Monitor” Select “OK” (1)”SVRE” lighting is confirmed

b.JOG Drive (2) Select “Return to ORIG”

c. Driving stop: Servo Off

Select “Test” Select “OK”

Select “Easy Mode” Select “OK”

(2)

(1)

ExtendedRetracted

Cli

Clicking arrow button→Operation

Retracted

Extended

Caution

If an alarm is generated

(1) When ”ALARM” is generated, release it by selecting (2) Reset.

In the case of an alarm code that cannot be released with

“Reset”, turn the power supply OFF and ON again.

Note) For details of alarm codes, refer to the Controller Operation Manual.

- 5 -

(1)

(2)

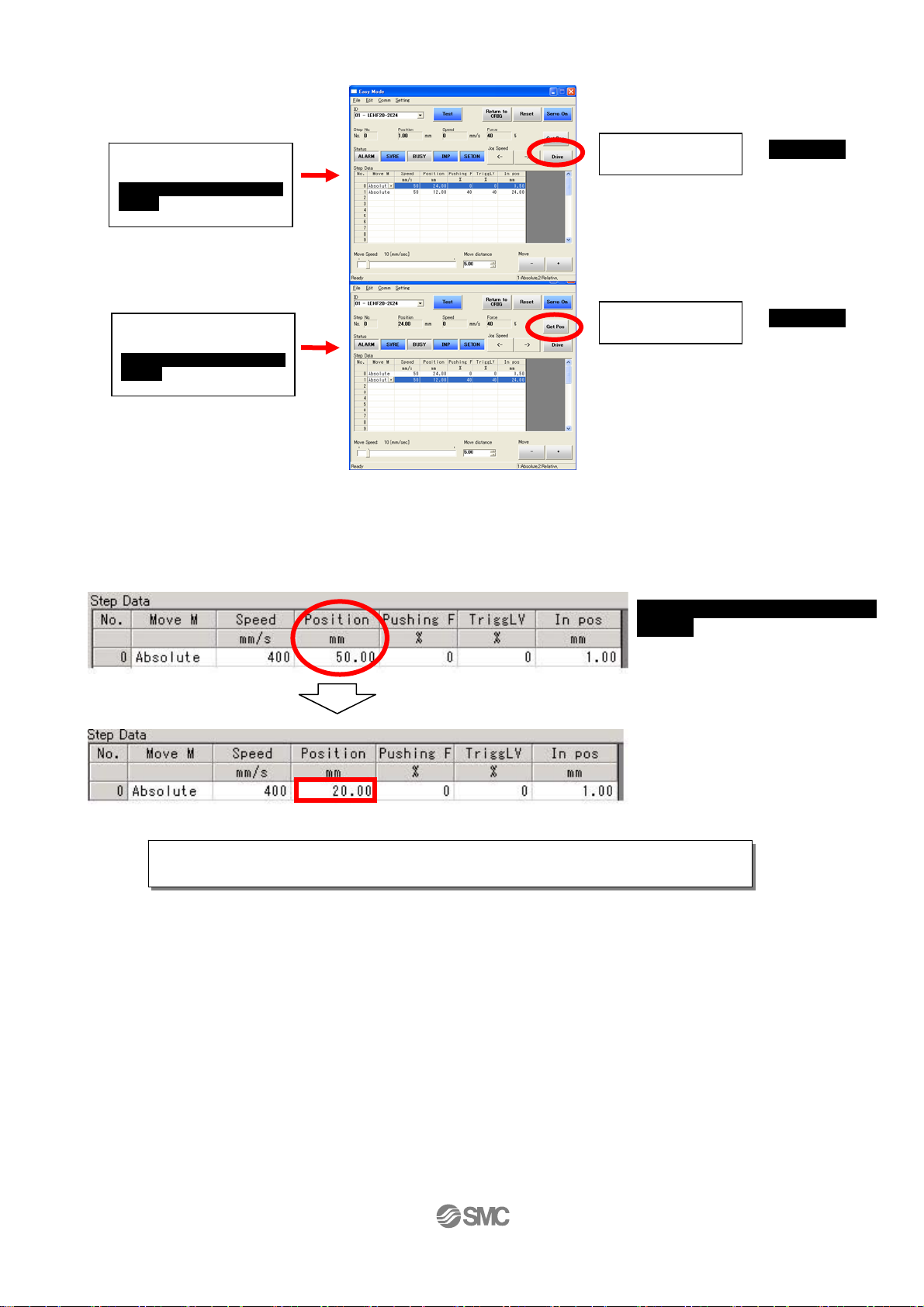

4. TEST Drive / Step No.0 → No.1 → No.0・・・

a. Driving preparation: Servo On → Return to ORIG / Refer to “3.JOG Drive”.

b.TEST Drive

“Step No.0” Operation

→ Operation

Procedure 1:

Select “Step No.0”

You can select anywhere in

the row

Procedure 2:

Select “Drive”

“Step No.1” Operation

→ Operation

Procedure 3:

Select “Step No.1”

You can select anywhere in

the row

Procedure 4:

Select “Drive”

c.Driving stop : Servo Off / Refer to “3.JOG Drive”.

5. Step data change

Ex) “Step No.0” / Positioning operation / At the time of shipment, Step No.0 is set to positioning operation

Change of positioning stop

position

Position: 50mm → 20mm

Input ”20”

For details of operation, and relationship between operation procedure and input/

output signals, refer to“3.3 Step Data” setting method p. 20 to 30.

6. Controller setting software screen explanation

Refer to the “Help / Easy mode” menu in the “ACT Controller” setting software.

- 6 -

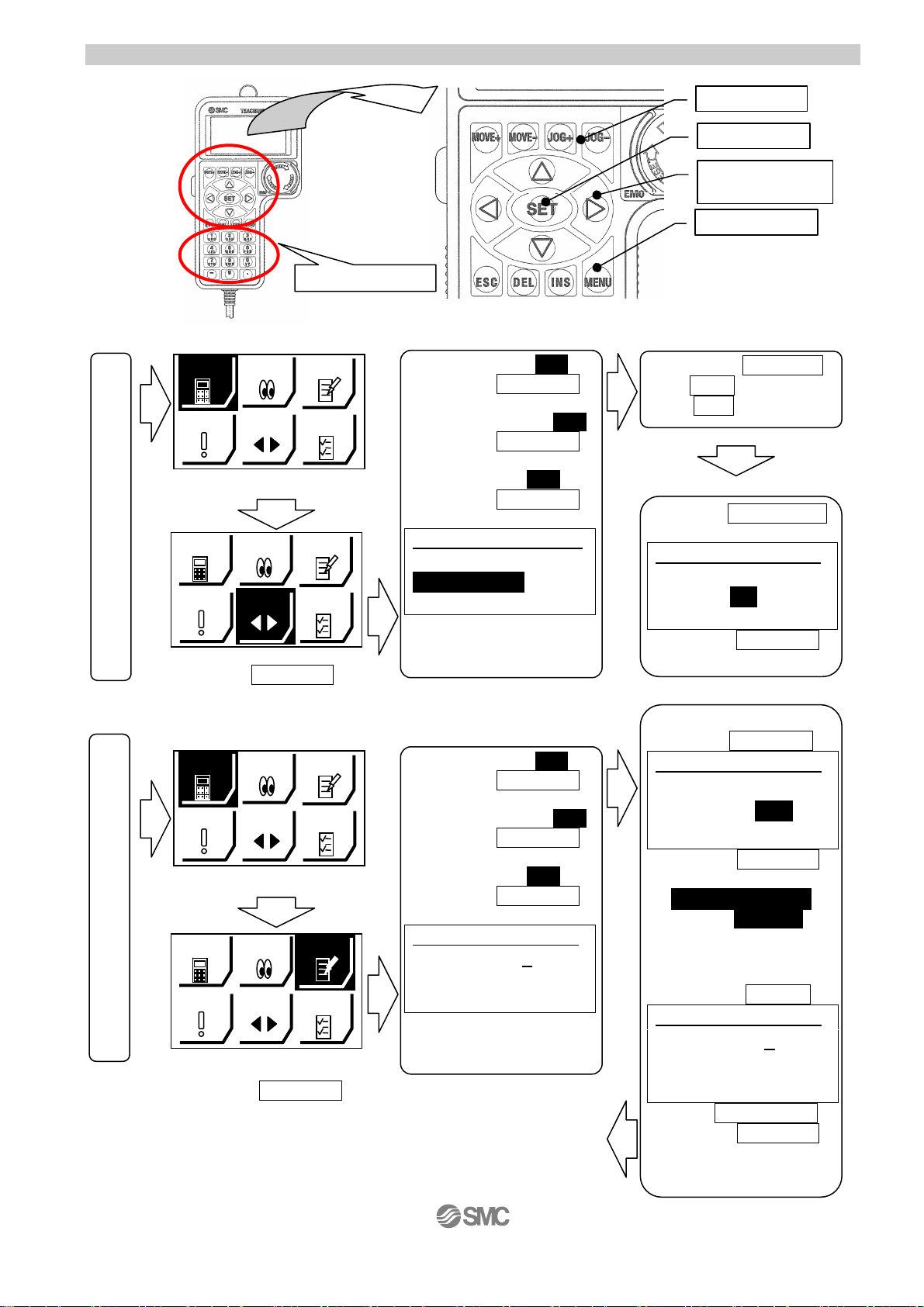

1.3 Teaching box

ジョグ

デ

ジョグ

デ

r

r

ジョグ

デ

ジョグ

デ

1. Name

(1) Number key

2. JOG Drive

ータ

DATA

モニタ

MONITOR

アラーム

ALARM

JOG

Select “JOG” Method of ending “JOG Drive”

supply is turned on.

ータ

DATA

モニタ

MONITOR

The powe

アラーム

ALARM

JOG

テスト

TEST

設定

SETTING

テスト

TEST

設定

SETTING

EXT Inp OFF:YES

Press the (3)SET key

↓

Servo ON,Ready?:YES

Press the (3)SET key

↓

RTN ORIG:Start

Press the (3)SET key

↓

AX

JOG 1

IS.

RTN ORIG Done

“JOG±”:Move

Posn 123.45mm

Operates by (2) JOG key

Press the (5)MENU key

Check 1

EXT Inp ON

Press the (3)SET key

3. TEST Drive / Step No.0 → No.1 → No.0・・・

ータ

DATA

モニタ

MONITOR

テスト

TEST

アラーム

ALARM

JOG

設定

SETTING

Servo ON,Ready?:YES

Select “TEST”

supply is turned on.

The powe

ータ

DATA

アラーム

ALARM

モニタ

MONITOR

JOG

テスト

TEST

設定

SETTING

Test 1

Step No. 0

Test Start

Posn 10.00mm

Press the (3)SET key

EXT Inp OFF:YES

Press the (3)SET key

↓

Press the (3)SET key

↓

RTN ORIG:Start

Press the (3)SET key

↓

<Work 1: Driving>

Press the

Test 1

Step No. 0

Test Start

Posn 10.00mm

<Work 2

Test 1

Step No. 1

Test Start

Posn 50.00mm

Press the (1)Number key”1”

Method of ending “TEST Drive”

It is the same as the Method

of ending “JOG Drive”

<Work 1: Driving>Repetition

- 7 -

(2) JOG key

(3)SET key

(4) Up and down,

right and left key

(5)MENU key

JOG+: extract

JOG-: retract

↓

AX

IS.

OK

Press the (3)SET key

(4)Down key

Press the (3)SET key

↓

Step No.0(Open)

Test Complete

↓

:Select Step No.>

Press the

(4)Up key

Press the (3)SET key

↓

4. Step data change

r

ジョグ

デ

“Step No.0” / Positioning operation

ータ

DATA

モニタ

MONITOR

テスト

TEST

アラーム

ALARM

JOG

SETTING

設定

supply is turned on.

Select “DATA”

Press the (3)SET key

The powe

Press the (5)MENU key

For details of operation, and relationship between operation procedure and input/

output signals, refer to“3.3 Step Data” setting method p. 20 to 30.

5. Teaching box detailed explanation

Please refer to the teaching box manual.

Screen to stop at

50mm position

Step 1

Step No. 0

Posn 50 .00mm

Force 0%

Press the (4)Down key

Select “Posn”

Method of ending “DATA”

Change of positioning

stop position

Posn 50 mm → 20mm

Step 1

Step No. 0

Posn 50 .00mm

Force 0%

Press the (1)Number key”20”

Press the (3)SET key

“Complete”

Step 1

Step No. 0

Posn 20 .00mm

Force 0%

- 8 -

2. Electric Slide table /LES Series

g

p

]

n

2.1 Specification

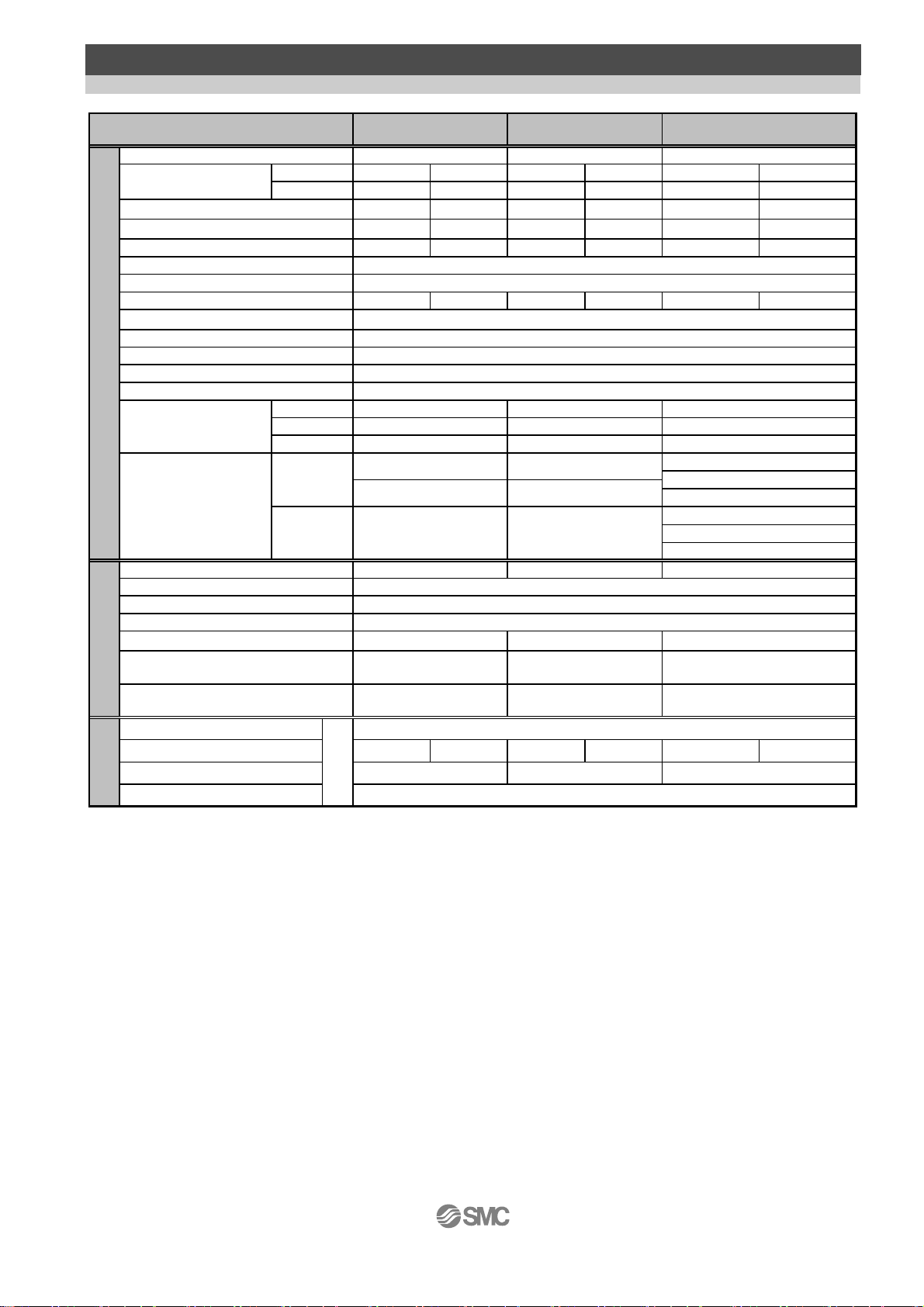

Step Motor (Servo 24VDC) / R,L Type

Size

Stroke [mm]

Work load

Note1)2)3)

[kg]

Pushing force [N] 30to70%

Speed [mm/s]

Pushing speed [mm/s]

Acceleration/Deceleration [mm/s

Positioning repeatability [mm] +/-0.05

Screw lead [mm]

Impact / vibration resistance [m/sec2]

Actuation type Slide screw + belt

Guide type Linear guide (circulating type)

Operating temp. range [℃] 5 to 40

Operating humidity range [%RH] 90 or less (No condensation)

Static Allowable

Actuator specification

Moment

[Nm]

Weight

[kg]

Motor size [mm] 20 28

Motor type HB type 2-phase step motor (Unipolar connection)

Encoder

Rated voltage [VDC] 24+/-10%

Power consumption [W]

Standby power consumption when

operatin

Moment max. power

Electric specification

consum

Type

Holding force [N] 24 2.5 300 48 500 77

Power consumption [W]

Rated voltage [VDC] 24+/-10%

Lock unit specificatio

[W]

tion[W

Note1)3)

Note6)

Note7)

Horizontal

Vertical

Note2)3)

2

]

Note4)

Pitching

Yawing

Rolling

Without lock

With lock 75st : 0.79 100st : 1.71

Note5)

Note9)

Note8)

50 , 75

2164 9 6

0.5 0.25 2 1 4 2

6 to 15 4 to 10 23.5 to 55 15 to 35 77 to 180 43 to 100

10 to 200 20 to 400 10 to 200 20 to 400 10 to 150 20 to 400

10 to 20 20 10 to 20 20 10 to 20 20

48510 8 16

50st : 0.55 50st : 1.15

75st : 0.70 100st : 1.60

R

LESH8

L

11

11

12

Incremental A/B phase (800 pulse/rotation)

20 43

715 13

35 60

43.6 5

LESH16 LESH25

50 , 100

5,000 or less

50st:26 / 100st:43

50st:26 / 100st:43 50st: 77/100st:112/150st:154

No excitation operating type

R

L

50 , 100 , 150

50 / 20

50st: 77/100st:112/150st:154

49 50st:146/100st:177/150st:152

50st : 2.50

100st : 3.30

150st : 4.26

50st : 2.84

100st : 3.64

150st : 4.60

Note 1) The speed is dependent on the workload. Check the “Speed-workload graphs” for the selected model in the catalogue

or the operation manual.

Note 2) The accuracy of the pushing force is ±20% of the max. pushing force.

The max. setting for the pushing force is 70% of the max. pushing force.

Note 3) The speed and force may change depending on the cable length, load and mounting conditions.

Furthemore, if the cable length exceeds 5m then it will decrease by up to 10% for each 5m.(At 15m : Reduced by up

to 20%)

Note 4) Impact resistance:

No malfunction occurred when the actuator was tested with a drop tester in both an axial direction and a perpendicular

direction to the lead screw. (The test was performed with the actuator in the initial state)

Vibration resistance:

No malfunction occurred in a test ranging between 45 to 2000 Hz when the actuator was tested in both an axial

direction and a perpendicular direction to the lead screw. (The test was performed with the actuator in the initial state)

Note 5) The "Power consumption" (including the controller) is for when the actuator is operating.

Note 6) The "Standby power consumption when operating" (including the controller) is for when the actuator is stopped in the

set position with no applied force in the direction of the actuator movement.

Note 7) The "Momentary max. power consumption" (including the controller) is for when the actuator is operating.

This value can be used for the selection of the power supply.

Note 8) Only applies to actuators supplied with a lock.

Note 9) For the actuator with lock, please add the power consumption for the lock.

R

L

42

67

74

- 9 -

g

n

p

(

)

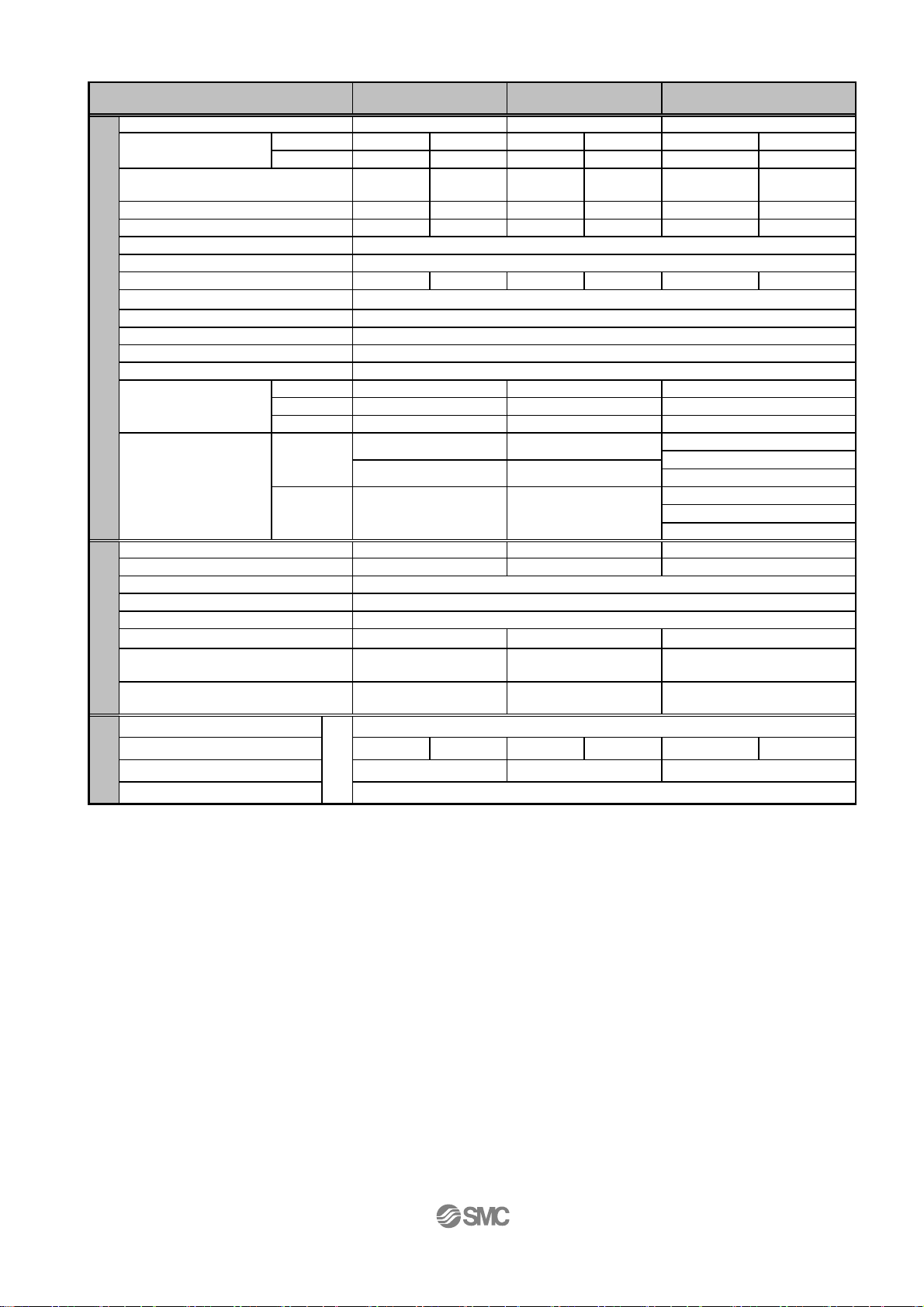

Servo Motor(24VDC) / R,L Type

Size LESH8 A

Work load

[kg]

Pushing force [N] 50to100%

LESH8[ ]A:50 to 75%

Speed [mm/s]

Pushing speed [mm/s]

Acceleration/Deceleration [mm/s2]

Positioning repeatability [mm] +/-0.05

Screw lead [mm]

Impact / vibration resistance [m/sec2]

Actuation type Slide screw + belt

Guide type Linear guide (circulating type)

Operating temp. range [℃] 5 to 40

Operating humidity range [%RH] 90 or less (No condensation)

Actuator specification

Static Allowable

Moment

[Nm]

Weight

[kg]

Motor size [mm]

Motor output [W] 10 30 36

Motor type

Encoder

Rated voltage [VDC]

Power consumption [W]

Standby power consumption

tion [W]

[W]

Note5)

when operatin

Electric specification

Moment max. power

consum

Type

Holding force [N]

Power consumption [W]

Rated voltage [VDC]

Lock unit specificatio

Horizontal

Vertical

Note1)

Note1)

Note2)

Pitching

Yawing

Rolling

Without lock

With lock

Note3)

Note4)

Note7)

2152.5 6 4

0.5 0.25 2 1 4 1.5

7.5 to 11 5 to 7.5 17.5 to 35 10 to 20 18 to 36 12 to 24

10 to 200 20 to 400 10 to 200 20 to 400 10 to 150 20 to 400

10 to 20 20 10 to 20 20 10 to 20 20

48510 8 16

Horizontal : 4

Vertical : 7

24 2.5 300 48 500 77

Note6)

R

L

50 , 75

11

11

12

50st : 0.55

75st : 0.70 100st : 1.60

75st : 0.79 100st : 1.71

20 28

Incremental A/B phase (800 pulse/rotation) / Z phase

58 84

84 124

4

LESH16 A LESH25 A

50st:26 / 100st:43

50st:26 / 100st:43 50st: 77/100st:112/150st:154

50st : 1.15

Servo motor (Servo 24VDC)

Horizontal : 2

Vertical : 15

No excitation operating type

R

L

50 , 100Stroke [mm]

5,000 or less

50 / 20

49 50st:146/100st:177/150st:152

24+/-10%

3.6 5

24+/-10%

50 , 100 , 150

50st: 77/100st:112/150st:154

100st : 3.30

150st : 4.26

100st : 3.64

150st : 4.60

Horizontal : 4

Vertical : 43

R

L

50st : 2.50

50st : 2.84

42

144

158

Note 1) The accuracy of the pushing force is ±20% of the max. pushing force.

The setting for the pushing force is 50-75% of LESH8[]A pushing force.

Note 2) Impact resistance: No malfunction occurred when the actuator was tested with a drop tester in both an

axial direction and a perpendicular direction to the lead screw.

(The test was performed with the actuator in the initial state)

Vibration resistance: No malfunction occurred in a test ranging between 45 to 2000 Hz. Test was

performed in both an axial direction and a perpendicular direction to the lead screw.

(The test was performed with the slide table in the initial state.)

Note 3) The "Power consumption" (including the controller) is for when the actuator is operating.

Note 4) The "Standby power consumption when operating" (including the controller) is for when the actuator is

stopped in the set position with no applied force in the direction of the actuator movement.

Note 5) The "Momentary max. power consumption" (including the controller) is for when the actuator is operating.

This value can be used for the selection of the power supply.

Note 6) Only applies to actuators supplied with a lock.

Note 7) For the actuator with lock, please add the power consumption for the lock.

- 10 -

n

p

]

g

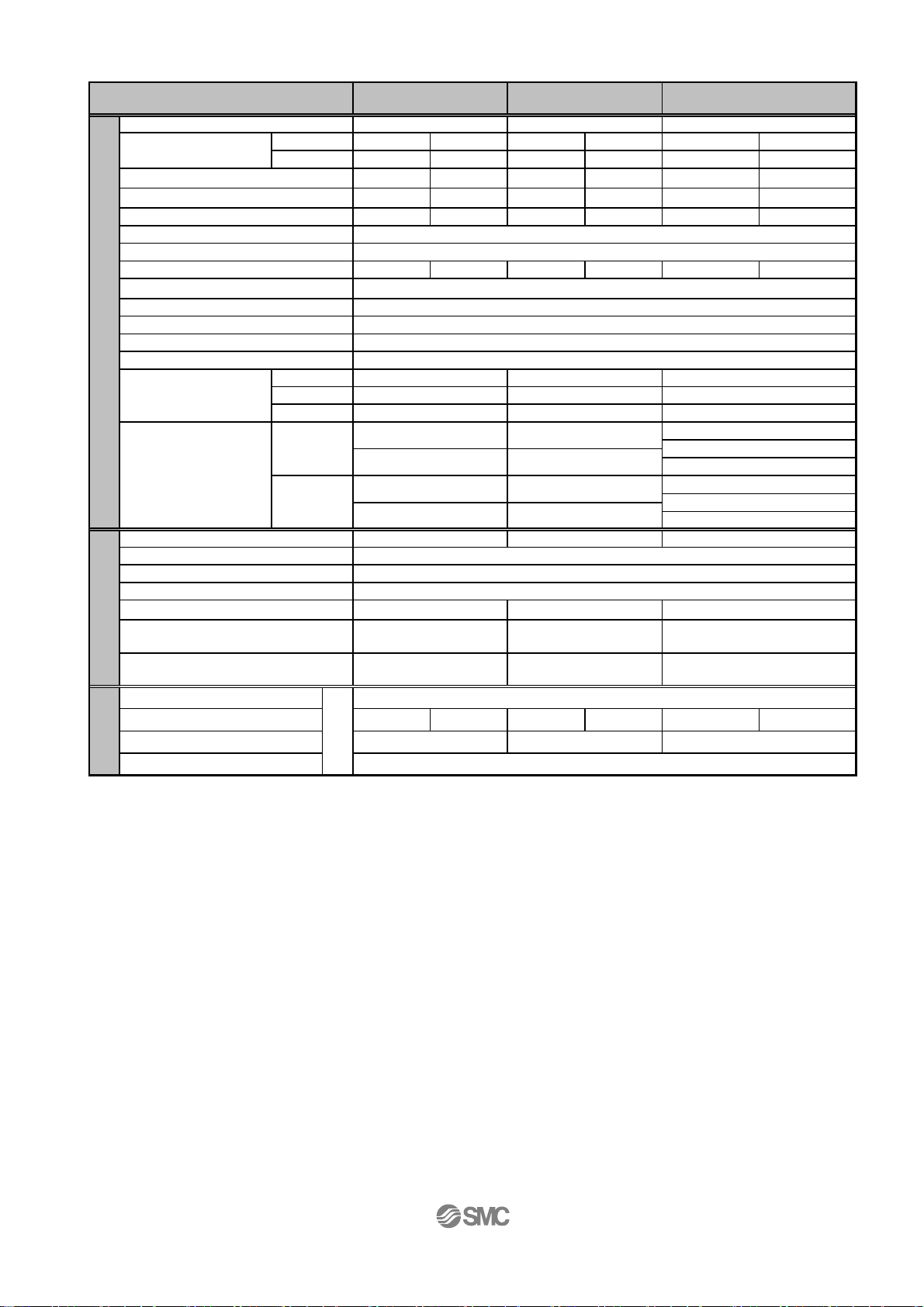

Step Motor (Servo 24VDC) / D Type

Size

Stroke [mm]

Work load

Note1)2)3)

[kg]

Pushing force [N] 30to70%

Speed [mm/s]

Pushing speed [mm/s]

Acceleration/Deceleration [mm/s

Positioning repeatability [mm] +/-0.05

Screw lead [mm]

Impact / vibration resistance [m/sec2]

Actuation type Slide screw

Guide type Linear guide (circulating type)

Operating temp. range [℃] 5 to 40

Operating humidity range [%RH] 90 or less (No condensation)

Static Allowable

Actuator specification

Moment

[Nm]

[kg]

Motor size [mm] 20 28

Motor type HB type 2-phase step motor (Unipolar connection)

Encoder

Rated voltage [VDC] 24+/-10%

Power consumption [W]

Standby power consumption when

operatin

Moment max. power

Electric specification

consum

Type

Holding force [N] 24 2.5 300 48 500 77

Power consumption [W]

Rated voltage [VDC] 24+/-10%

Lock unit specificatio

[W]

tion[W

Note1)3)

Note6)

Note7)

Horizontal

Vertical

Note2)3)

2

]

Note4)

Pitching

Yawing

Rolling

Without lock

With lock

Note5)

Note9)

Note8)

LESH8D LESH16D

50 , 75

2164 9 6

0.5 0.25 2 1 4 2

6 to 15 4 to 10 23.5 to 55 15 to 35 77 to 180 43 to 100

10 to 200 20 to 400 10 to 200 20 to 400 10 to 150 20 to 400

10 to 20 20 10 to 20 20 10 to 20 20

48510 8 16

11

11

12

50st : 0.57 50st : 1.25

75st : 0.70 100st : 1.70

50st : 0.66 50st : 1.36

75st : 0.79 100st : 1.81

Incremental A/B phase (800 pulse/rotation)

20 43 67

715 13

35 60 74

43.6 5

50 , 100

5,000 or less

50 / 20

50st:26 / 100st:43

50st:26 / 100st:43 50st: 77/100st:112/150st:154

49 50st:146/100st:177/150st:152

No excitation operating type

50st: 77/100st:112/150st:154

LESH25D

50 , 100 , 150

50st : 2.52

100st : 3.27

150st : 3.60Weight

50st : 2.86

100st : 3.61

150st : 3.94

42

Note 1) The speed is dependent on the workload. Check the “Speed-workload graphs” for the selected model in the catalogue

or the operation manual.

Note 2) The accuracy of the pushing force is ±20% of the max. pushing force.

The max. setting for the pushing force is 70% of the max. pushing force.

Note 3) The speed and force may change depending on the cable length, load and mounting conditions.

Furthemore, if the cable length exceeds 5m then it will decrease by up to 10% for each 5m.(At 15m : Reduced by up

to 20%)

Note 4) Impact resistance:

No malfunction occurred when the actuator was tested with a drop tester in both an axial direction and a perpendicular

direction to the lead screw. (The test was performed with the actuator in the initial state)

Vibration resistance:

No malfunction occurred in a test ranging between 45 to 2000 Hz when the actuator was tested in both an axial

direction and a perpendicular direction to the lead screw. (The test was performed with the actuator in the initial state)

Note 5) The "Power consumption" (including the controller) is for when the actuator is operating.

Note 6) The "Standby power consumption when operating" (including the controller) is for when the actuator is stopped in the

set position with no applied force in the direction of the actuator movement.

Note 7) The "Momentary max. power consumption" (including the controller) is for when the actuator is operating.

This value can be used for the selection of the power supply.

Note 8) Only applies to actuators supplied with a lock.

Note 9) For the actuator with lock, please add the power consumption for the lock.

- 11 -

r

g

(

)

Servo Motor(24VDC) /D Type

Size LESH8DA

LESH16DA

Stroke [mm]

Note1)

Note1)

Note4)

Horizontal

Vertical

2

]

Note2)

Pitching

Yawing

Rolling

Without lock

With lock

Note3)

Note7)

0.5 0.25 2 1

7.5 to 11 5 to 7.5 17.5 to 35 10 to 20

10 to 200 20 to 400 10 to 200 20 to 400

10 to 20 20 10 to 20 20

24 2.5 300 48

Note6)

Work load

[kg]

Pushing force [N] 50to100%

LESH8[ ]A:50 to 75%

Speed [mm/s]

Pushing speed [mm/s]

Acceleration/Deceleration [mm/s

Positioning repeatability [mm] +/-0.05

Screw lead [mm]

Impact / vibration resistance [m/sec2]

Actuation type Slide screw

Guide type

Operating temp. range [℃]5 to 40

Operating humidity range [%RH] 90 or less (No condensation)

Actuator specification

Static Allowable

Moment

[Nm]

Weight

[kg]

Motor size [mm]

Motor output [W]

Motor type

Encoder

Rated voltage [VDC]

Power consumption [W]

Standby power consumption

when operatin

Electric specification

Moment max. powe

consumption [W]

Type

Holding force [N]

Power consumption [W]

Rated voltage [VDC]

Lock unit specifica tion

[W]

Note5)

50 , 75

2152.5

5,000 or less

48510

50 / 20

Linear guide (circulating type)

11

11

12

50st : 0.57 50st : 1.25

75st : 0.70 100st : 1.70

50st : 0.66

75st : 0.79 100st : 1.81

20 28

10 30

Servo motor (Servo 24VDC)

Incremental A/B phase (800 pulse/rotation) / Z phase

24+/-10%

58 84

Horizontal : 4

Vertical : 7

84 124

No excitation operating type

4

24+/-10%

50 , 100

50st:26 / 100st:43

50st:26 / 100st:43

49

50st : 1.36

Horizontal : 2

Vertical : 15

3.6

Note 1) The accuracy of the pushing force is ±20% of the max. pushing force.

The setting for the pushing force is 50-75% of LESH8[]A pushing force.

Note 2) Impact resistance: No malfunction occurred when the actuator was tested with a drop tester in both an

axial direction and a perpendicular direction to the lead screw.

(The test was performed with the actuator in the initial state)

Vibration resistance: No malfunction occurred in a test ranging between 45 to 2000 Hz. Test was

performed in both an axial direction and a perpendicular direction to the lead screw.

(The test was performed with the slide table in the initial state.)

Note 3) The "Power consumption" (including the controller) is for when the actuator is operating.

Note 4) The "Standby power consumption when operating" (including the controller) is for when the actuator is

stopped in the set position with no applied force in the direction of the actuator movement.

Note 5) The "Momentary max. power consumption" (including the controller) is for when the actuator is operating.

This value can be used for the selection of the power supply.

Note 6) Only applies to actuators supplied with a lock.

Note 7) For the actuator with lock, please add the power consumption for the lock.

- 12 -

2. 2 How to Order

(1)

LE

-5016 R J

-R 1 6NSH 1

Size

8

16

25

Type

R

R type

L

L type

D

D type

Motor type

Step motor

Nill

(Servo DC24V)

Servo motor

*

A

(DC24V)

*LESH25DA cannot correspond.

Screw read (mm)

記号

LESH8

LESH16

J

8

10

K

4

5

Stroke (mm)

*Applicable types

75 100●150

50

LESH8

LESH16

LESH25

○

:

○

●

○

●

R/L type alone cannot correspond.

LESH25

●

●

Controller mounting style

Screw mounting style

Nill

DIN rail mounting style

D

I/O cable length (m)

Without cable

Nill

1

33

5

Motor option

Without lock

Nill

With lock

B

Body option

(Refer to left table)

Nill

S

16

8

*

Basic type

Dust proof specification

Mounting style

Without side holder

Nill

With side holder (4pcs)

H

Actuator cable type

Nill

R

S

*Only "Step motor" can be selected. (Only "Robotic type cable" can be selected.)

Without cable

With robotic type cabe

*

Standard cable

Nill 8

1

3

55

*Produced upon receipt of order.

Controller type

Nill

6N

(Step data input type)

6P

*

1N

*

1P

*

AN

*

AP

*Only "Step motor" can be selected.

Actuator cable length (m)

Without cable

1.5

3

1.5

5

Without controller

LECP6/LECA6

LECP1

(Programless type)

LECPA

(Pulse input type)

A

B

C

8

10

15

20

NPN

PNP

NPN

PNP

NPN

PNP

*

*

*

*

Caution

The actuator body and controller are sold as a package.

If when only the actuator is purchased separately, confirm that the combination of the controller, which

you have and the actuator is compatible. / See 5.3 Caution(1) on p.38

<Be sure to check the following before use.>

(1) Check that actuator label for model number.

This matches the controller.

(2) Check Parallel I /O configuration matches (NPN or PNP).

LESH8RJ-50

NPN

(2)

- 13 -

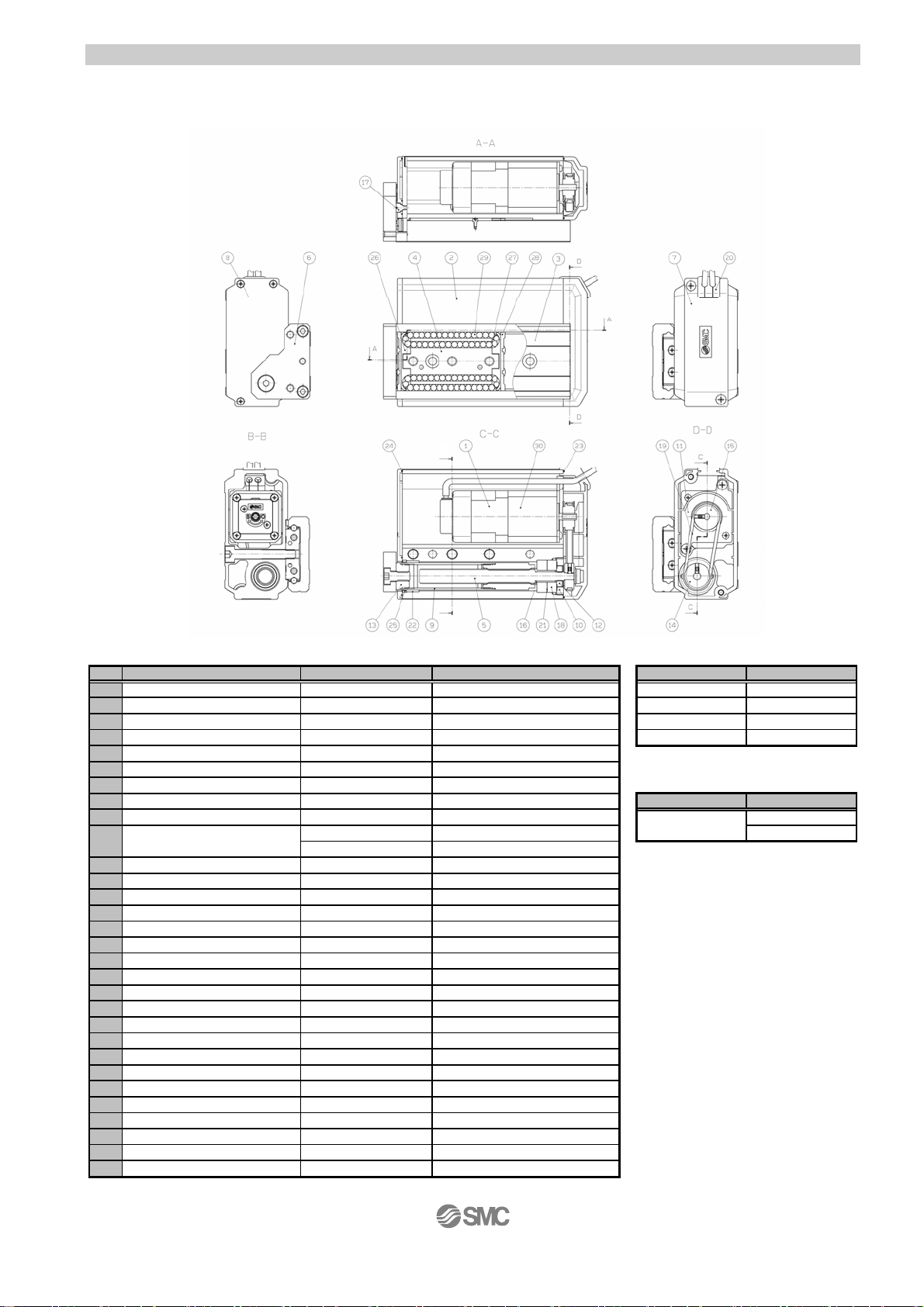

2.3 Construction

y

r

・LESH*R / LESH*L

Component parts

No. Description Material Remarks

1

Motor - - LESH8□ LE-D-1-1

Body Aluminum alloy Hard anodized LESH16

2

Teble Stainless steel Heat treated

3

4

Guide block Stainless steel Heat treated

Lead screw Stainless steel Special treatment

5

End plate Aluminum alloy Hard anodized

6

7

Pulle

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30 Lock - -

cove

End cover Plastic - Parts Order number

Rod Stainless steel

Bearing holder

Motor plate Aluminum alloy -

Lock nut

Socket Carbon steel Electroless nickel plated

Lead screw pulley Aluminum alloy Motor pulley Aluminum alloy Spacer Stainless steel

Stopper Carbon steel Electroless nickel plated

Bearing

Belt - Grommet Plastic -

Simring Steel

Bushing - Dust proof only

Pulley gasket NBR Dust proof only

End gasket NBR Dust proof only

Scraper NBR Dust proof only

cover Plastic

Return guide Plastic

Scraper

Steel ball

Plastic -

Carbon steel Electroless nickel plated GR-S-020(20g)

Copper alloy

Special steel Chromate

--

Stainless steel and NBR

High carbon chrome bearing steel

B

B

- GR-S-010(10g)

Electrol ess nickel plated(LES H25R/L* only)

LESH25R/L* only

-

-

-

Linear guide

-

- 14 -

R type as shown

L type opposite as shown

Maintenance parts/belt

Size Part number

□

LESH25□ LE-D-1-3

LESH25□ALE-D-1-4

Maintenance parts/grease

Table

LE-D-1-2

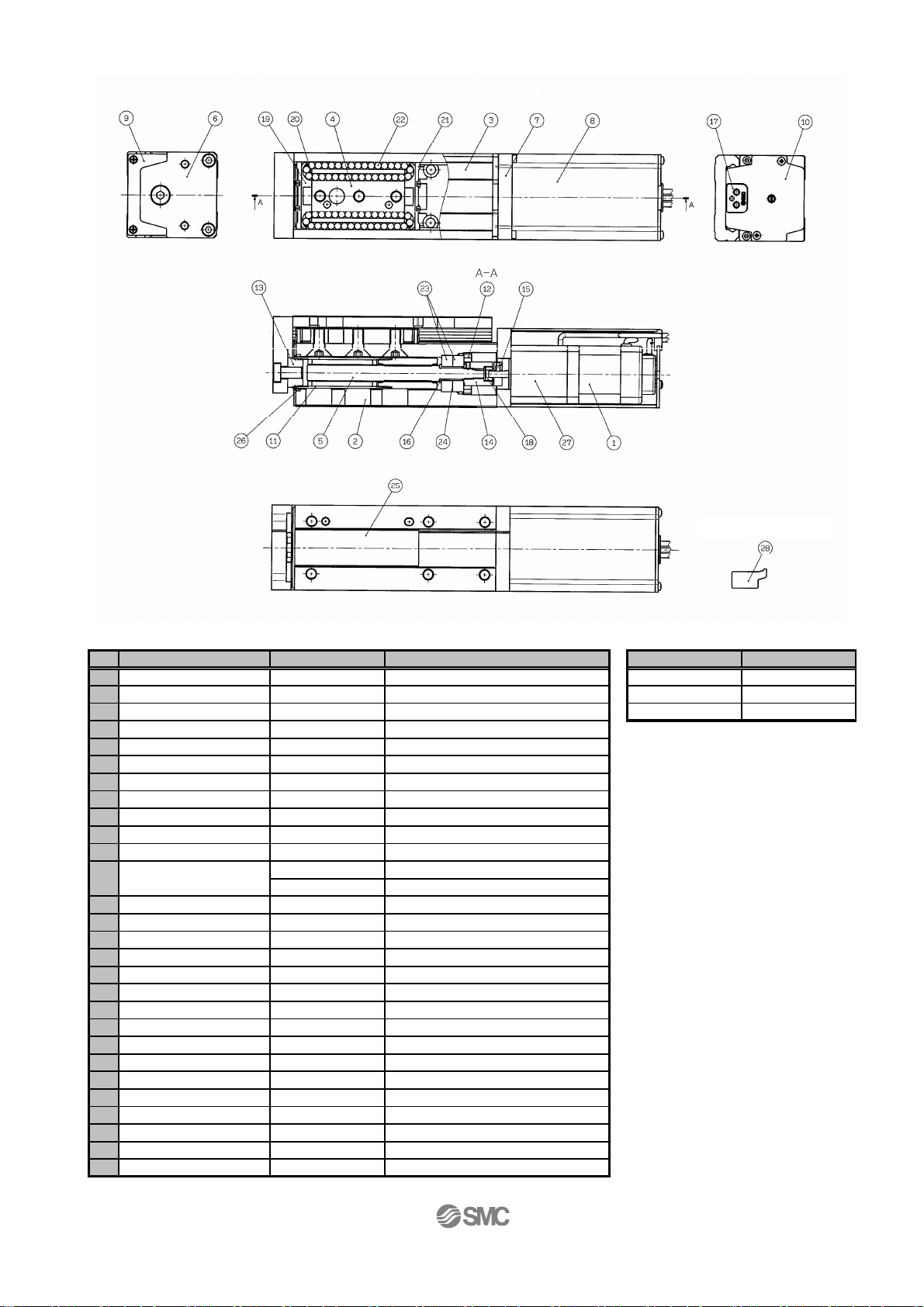

・LESH*D

Component parts

No. Description Material Remarks

1 Motor - 2 Body Aluminum alloy Hard anodized

3 Table Stainless steel Heat treatment + Electroless nickel

4 Guide block Stainless steel Heat treatment

5 Lead screw Stainless steel Heat treatment + Special plated

6 End plate Aluminum alloy Hard anodized

7 Motor flange Aluminum alloy Hard anodized

8 Motor cover Aluminum alloy Hard anodized

9 End cover Aluminum alloy Hard anodized

10 Motor end cover Aluminum alloy Hard anodized

11 Rod Stainless steel -

Bearing holder

12

13 Socket Carbon steel Electroless nickel plated

14 Hub(Screw side

15 Hub(Motor side

16 Spacer Stainless steel LESH25D* only

17 Grommet NBR 18 Spider NBR 19 Cover Plastic 20 Return guide Plastic 21 Scraper Stainless steel + Linear guide part

22 Steel ball Special steel 23 Bearing - 24 Shim ring Carbon steel 25 Masking tape - 26 Scraper NBR Dust proof only / rod part

27 Lock - 28 Side Holder Aluminum alloy Hard anodized

)

)

Carbon steel Electroless nickel plated

Copper alloy

Aluminum alloy Aluminum alloy -

Electroless nickel plated(LES H25R/ L* only)

- 15 -

Bundled shipment

Option parts/Side holder

Model Part number

LESH8D LE-D-3-1

LESH16D LE-D-3-2

LESH25D LE-D-3-3

3. Product Outline

)

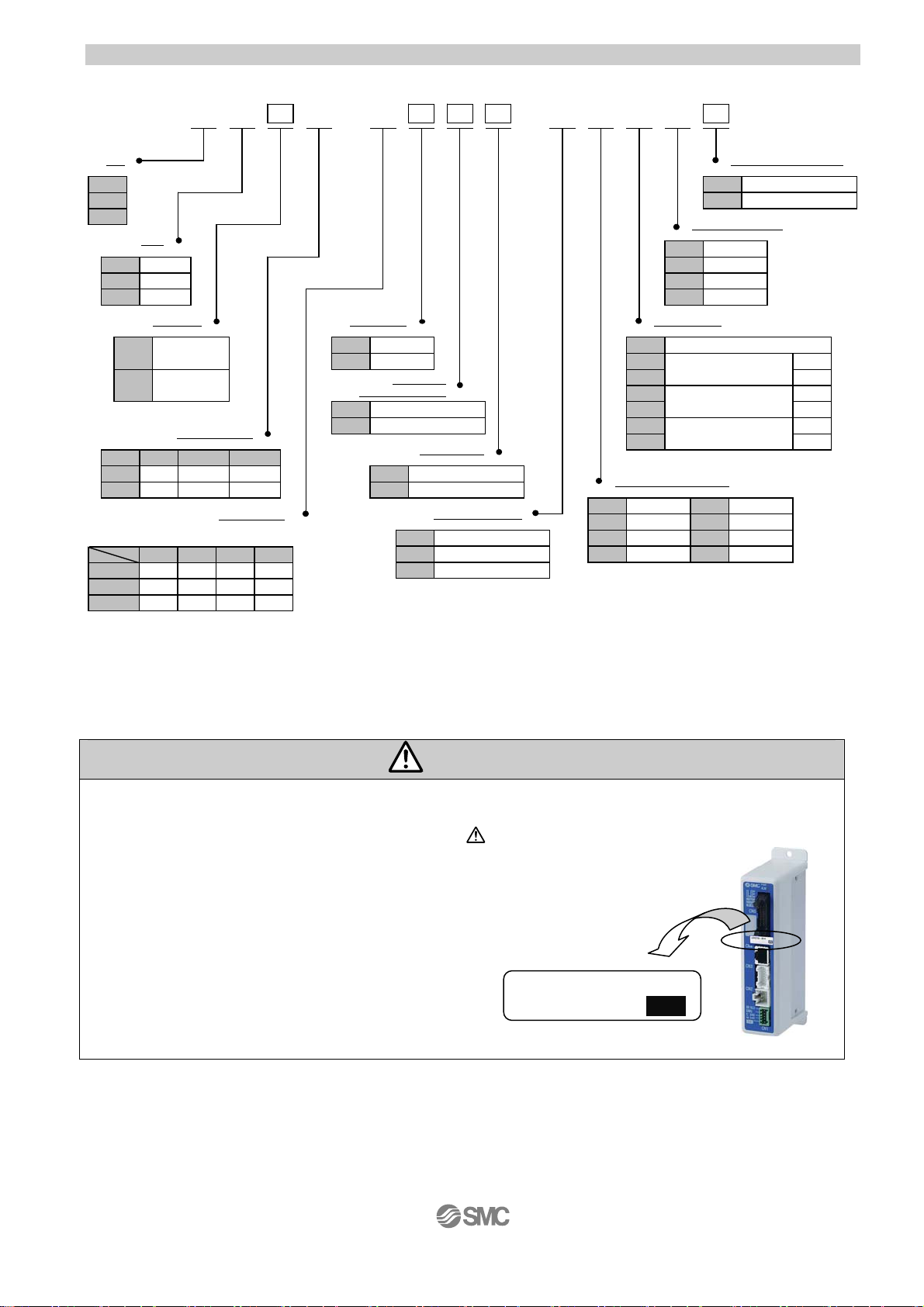

3.1 System construction

●Electric slide table

Note 1)

●Actuator cable

Part No:

-LE-C*-*-*

(Robotic type cable)

-LE-C*-*S-*

(Standard cable)

Note 2)

Controller

power supply

24VDC

●Power supply plug

<Applicable cable size>

Note 1): These items are included when it is selected

Note 2):

by ordering code.

When conformity to UL is required, the

electric actuator and controller should

be used with a UL1310 Class 2 power

supply.

Motor cable

Note 1)

●Controller

To CN3

To CN2

To CN1

AWG20 (0.5mm

Note 1

●I /O cable

Part No:LEC-CN5-

PLC

Note 2)

To CN5

Power supply

24VDC

Option

To CN4

●Communication

cable

●

Conversion

unit

or

モニタ

モニタ

現在位置

現在位置

現在速度

現在速度

設定

設定

1

1

2

2

3

3

動作中

動作中

mm

mm

120.3

120.3

アラーム

アラーム

mm/s

mm/s

200

200

位置 速度

位置 速度

100 500

テスト

100 500

テスト

1000

テスト

1000

テスト

200

200

200

テスト

200

テスト

50

50

PC

●USB cable

(A-miniB type)

2

)

●Teaching box

(with a cable of

3m long)

Part No:LEC-T1-3EG

●Controller setting kit

(

Controller setting software,

Communication cable,

Conversion unit and

USB cable are included.)

Part No:LEC-W2

Warning

Refer to the operation manual of the LEC (controller) for detailed wiring.

/ See “4 Wiring of cables” on p.35.

Communication cable is to be connected to PC by USB cable through conversion unit.

And do not connect teaching box to PC.

Do not connect the teaching box directly to the PC as there maybe

fire risk and damage to the PC or teaching box.

The actuator body and controller are sold as a package.

If when only the actuator is purchased separately, confirm that the combination

of the controller, which you have and the actuator is compatible.

/See 5.3 Caution(1) on p.38

<Be sure to check the following before use.>

(1) Check that actuator label for model number.

This matches the controller.

(2) Check Parallel I/O configuration matches (NPN or PNP).

- 16 -

(1)

LESH8RJ-50

NPN

(2)

3.2 Setting Function

ジョグ

デ

ジョグ

デ

Refer to the operation manual of the controller (LEC series) for the detail of the setting function.

Easy Mode for simple setting

>Select “Easy mode” for instant operation

Controller setting software

Setting and operation, such as the step data setting, test drive and JOG / fixed-distance moving, can

be performed on the same page.

JOG moving

Start testing

Positioning

data setting

Speed setting of JOG /

fixed distance

Teaching box

Setting and operation by the simple screen without scrolling.

Select function by the iconized menu at the first page.

Step data setting and monitoring at the second page.

SETTING

テスト

TEST

設定

1st screen

2nd screen

Data Axis 1

Step No. 0

Posn 123.45mm

speed 400mm/s

It can be registered by “SET”

after entering the values.

ータ

DATA

アラーム

ALARM

ータ

DATA

アラーム

ALARM

モニタ

MONITOR

JOG

1st screen

モニタ

MONITOR

JOG

テスト

TEST

設定

SETTING

Monitor Axis 1

Step No. 1

Posn 12.34mm

speed 50mm/s

Operation status can be

checked

Fixed distance

moving

2nd screen

Example of setting the step data

Example of checking the operation status

- 17 -

Loading...

Loading...