SMC Networks LECSB Series, LECSB*-S5 Series, LECSB*-S7 Series, LECSB*-S8 Series Operation Manual

Doc. no. JXC※-OMT0021-B

PRODUCT NAME

AC Servo Motor Driver

MODEL/ Series

LECSB Series

LECSB□-□ Series / Driver

which, if not avoided, could result in minor or

moderate injury.

indicates a hazard w it h a medi um level o f ri sk which , if no t avoid ed, cou ld resul t in death

or serious injury.

k which, if not avoided, will result in death or

serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

ntact SMC beforehand and take special consideration of safety measures if the product is to be

1. Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important not es f or safety and m ust be followed in add ition to Inter nation al Standards (ISO/IEC)

*1), and other safety regulations.

*1) ISO 4414: Pneumatic flu id power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218: Manipulating industrial robots -- Safety

etc.

Caution

Caution indicates a hazard with a low level of risk

Warning

Danger

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment mus t be decided b y the per son who designs the equipm ent or dec ides its specific ations bas ed on

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product an d mac h inery/equipment until safety is confirmed.

The inspection and maintenance of machinery/equipment should only be performed after measures to prevent

falling or runaway of the driven objects have been confirmed.

When the product is to be r emoved, confir m that the safety meas ures as m entioned above ar e implem ented

and the power from any appropriate source is cut, and read and understand the specific product precautions of

all relevant products carefully.

Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Co

used in any of the following conditions.

1) Conditions and envir onments outside of the given s pecifications , or use outdoors or in a place expos ed to

direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergenc y stop circuits, clutch and lock circuits in press ap plications, saf ety equipment or other

applications unsuitable for the standard specifications described in the product catalog.

3) An application whic h could have negative ef fects on people, proper ty, or animals r equiring special safet y

analysis.

4) Use in an interlock circuit, which requires the pro vision of double interlock f or possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

Warning

Danger indicates a hazard with a high level of ris

A - 1

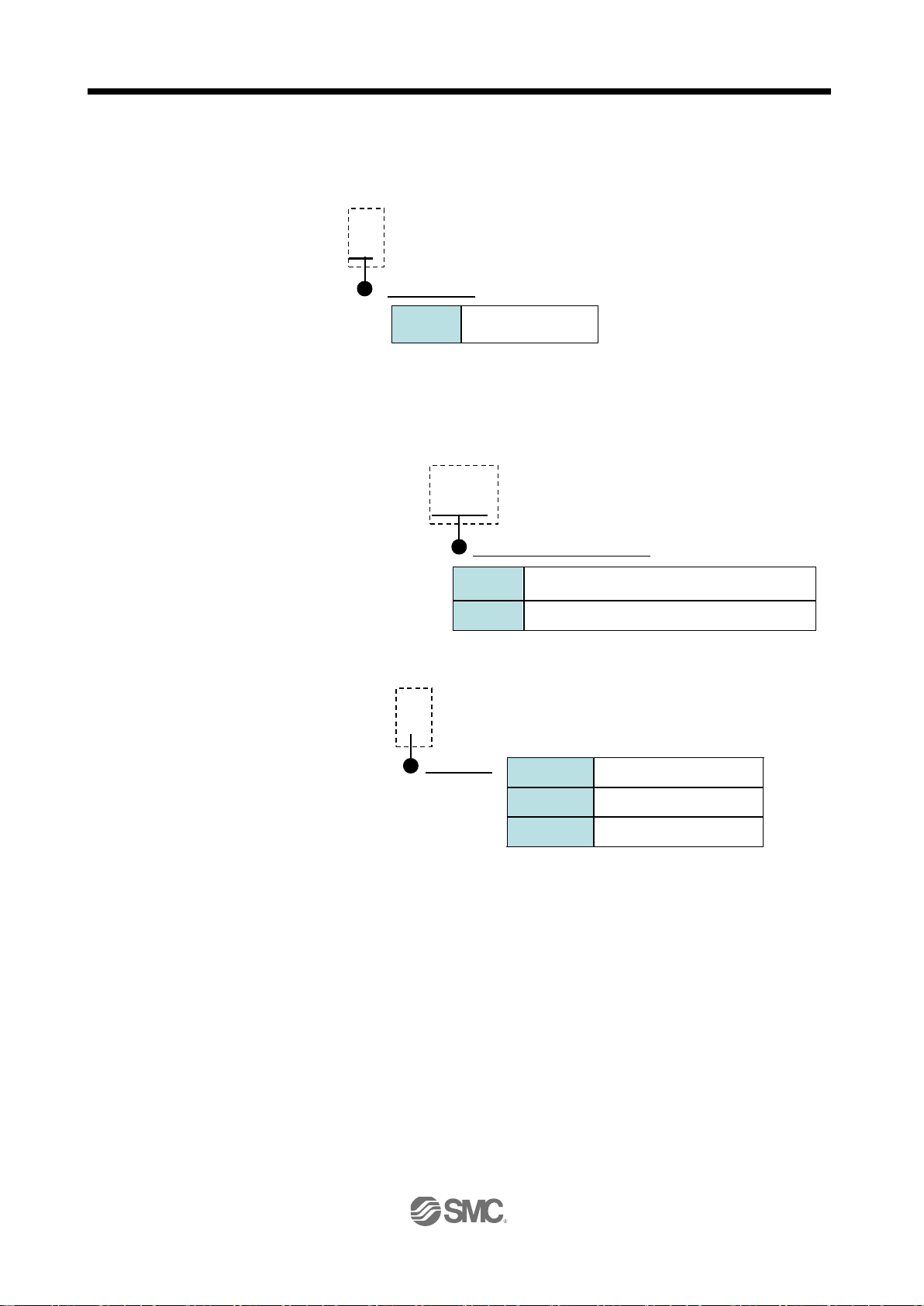

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Prohibition

Indicates what must not be done. For example, "No Fire" is indicated by

Compulsion

Indicates what must be done. For example, grounding is indicated by

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so on

are classified into "POINT".

After reading this installation guide, always keep it accessible to the operator.

A - 2

Caution

If anything is unclear, contact your nearest sales branch.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or

failure due to the deterioration of rubber material are not covered by the limited warranty.

LECSB□-□ Series / Driver

1. Safety Instructions

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using th e product in other indus tries, consult SMC bef orehand and exchang e specifications or a

contract if necessary.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warran ty and Disclaime r

The warranty period of the product is 1 year in service or 1.5 years after the product is delivered,

whichever is first.*3)

Also, the product may have specified durability, running distance or replacement parts. Please consult

your nearest sales branch.

For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage incurred

due to the failure of the product.

Prior to using SMC products, please read and understand the warranty terms and disclaimers noted in

the specified catalog for the particular products.

*3) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Compliance Requirem e nt s

When the product is exported, str ictly follow the laws requ ired by the M inistry of Econom y, Trade and I ndustry

(Foreign Exchange and Foreign Trade Control Law).

A - 3

WARNING

CAUTION

1. To prevent electric shock, note the following

Before wiring or inspection, turn off the power and wait for 15 minutes or more (20 minutes or for drive unit

30kW or more) until the charge lamp turns off. Then, confirm that the voltage between P(

and L for drive unit 30kW or more) is safe with a voltage tester and others. Otherwise, an electric

(L

shock may occur. In addition, always confirm from the front of the driver, whether the charge lamp is off or

not.

Connect the driver and servo motor to ground.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the driver and servo motor until they have been installed. Otherwise, you may get

an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, you may get an electric

shock.

During power-on or operation, do not open the front cover. You may get an electric shock.

Do not operate the driver with the front cover removed. High-voltage terminals and charging area are

exposed and you may get an electric shock.

Except for wiring or periodic inspection, do not remove the front cover even if the power is off. The driver is

charged and y ou may ge t an ele ct r i c sho c k.

) and N( )

2. To prevent fire, note the following

Install the driver, servo motor and regenerative resistor on incombustible material. Installing them directly

or close to combustibles will lead to a fire.

Always connect a magnetic contactor between the main circuit power supply and L1, L2, and L3 of the

driver, and configure the wiring to be able to shut down the power supply on the side of the driver power

supply. If a magnetic contactor is not connected, continuous flow of a large current may cause a fire when

the driver malfunctions.

When a regenerative resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative transistor fault or the like may overheat the regenerative resistor, causing a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the driver, and servo motor.

Always connect a no-fuse breaker to the power supply of the driver.

A - 4

CAUTION

CAUTION

3. To prevent injury, note the follow

Only the voltage specified in the Instruction Manual should be applied to each terminal, Otherwise, a burst,

damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

Take safety measures, e.g. provide covers, to prevent accidental contact of hands and parts (cables, etc.)

with the driver heat sink, regenerative resistor, servo motor, etc. since they may be hot while pow er i s on or

for some time after power-off. Their temperatures may be high and you may get burnt or a parts may

damaged.

During operation, never touch the rotating parts of the servo motor. Doing so can cause injury.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric shock,

etc.

(1) Transportation and installation

Transport the products correctly according to their mass.

Stacking in excess of the specified number of products is not allowed.

Do not carry the servo motor by the cables, shaft or encoder.

Do not hold the front cover to transport the driver. The driver may drop.

Install the driver in a load-bearing place in accordance with the Instruction Manual.

Do not climb or stand on servo equipment. Do not put heavy objects on equipment.

The driver and servo motor must be installed in the specified direction.

Leave specified clearances between driver and control enclosure walls or other equipment.

Do not install or operate the driver and servo motor which has been damaged or has any parts missing.

Do not block the intake and exhaust areas of the driver and servo motor which has a cooling fan. Doing so

may cause faults.

Do not drop or strike driver or servo motor. Isolate from all impact loads.

Securely attach the servo motor to the machine. If attach insecurely, the servo motor may come off during

operation.

The servo motor with reduction gear must be installed in the specified direction to prevent oil leakage.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotating parts of the servo

motor during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. The encoder

may become faulty.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

A - 5

CAUTION

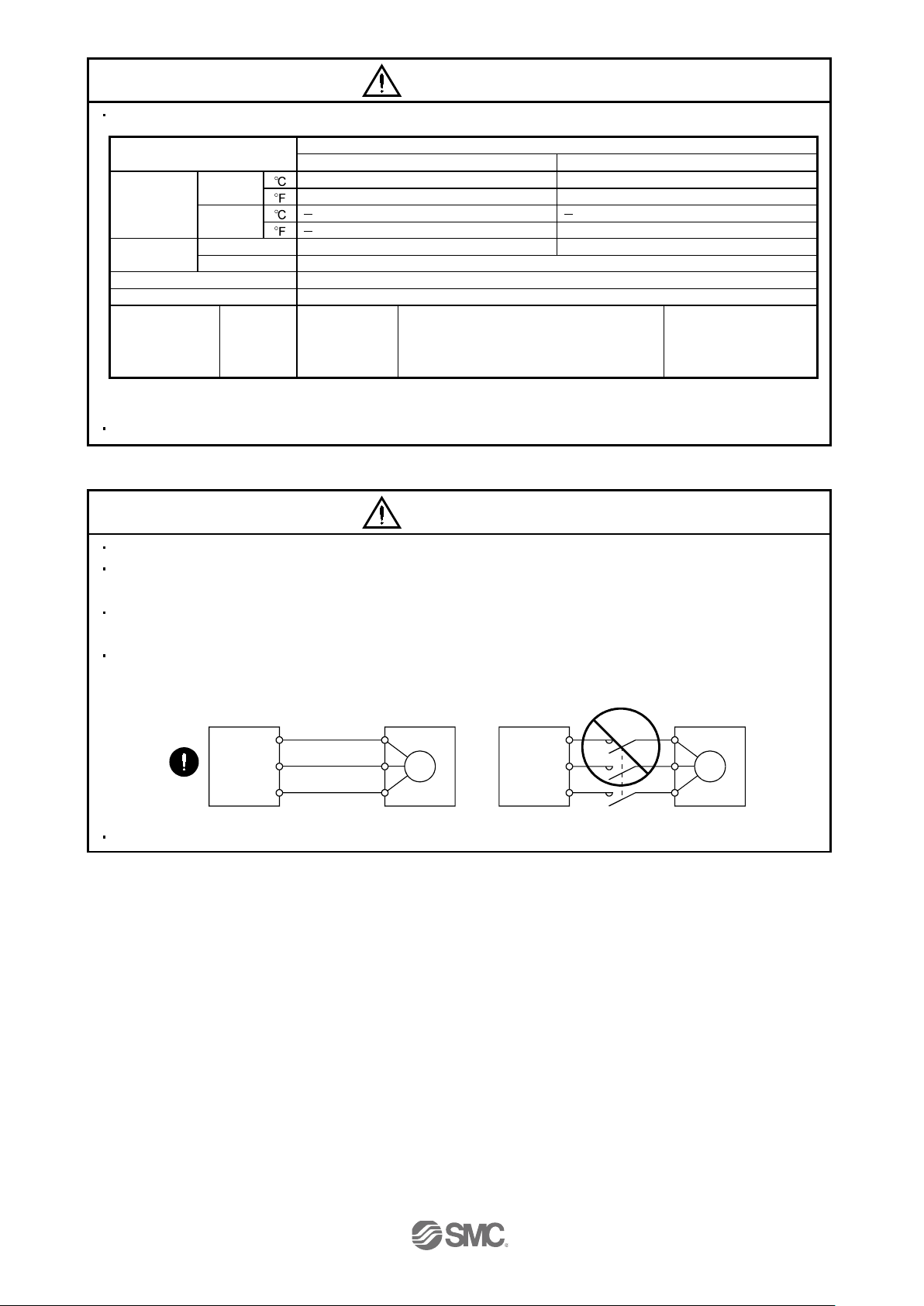

Environmental conditions

Driver

Servo motor

In

operation

[ ]

0 to 55 (non-freezing)

0 to 40 (non-freezing)

[ ]

32 to 131 (non-freezing)

32 to 104 (non-freezing)

[ ]

20 to 65 (non-freezing)

15 to 70 (non-freezing)

[ ]

4 to 149 (non-freezing)

5 to 158 (non-freezing)

Ambient

humidity

In operation

90%RH or less (non-condensing)

80%RH or less (non-condensing)

In storage

90%RH or less (non-condensing)

Ambience

Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude

Max. 1000m (3280 ft) above sea level

series

Note. Except the servo motor with redu cti on ge ar.

CAUTION

U

Servo motor

M

V

W

U

V

W

Servo amplifier

(drive unit)

U

M

V

W

U

V

W

Servo motor

Servo amplifier

(drive unit)

When you keep or use it, please fulfill the following environmental conditions.

Item

Ambient

temperature

In storage

LECS□□-S5

LECS□□-S7

LECS□□-S8

X, Y: 49 m/s2

(Note)

Vibration

[m/s

2

]

5.9 or less at 10 to

55Hz (directions of

X, Y and Z axes)

When the equipment has been stored for an extended period of time, contact your local sales office.

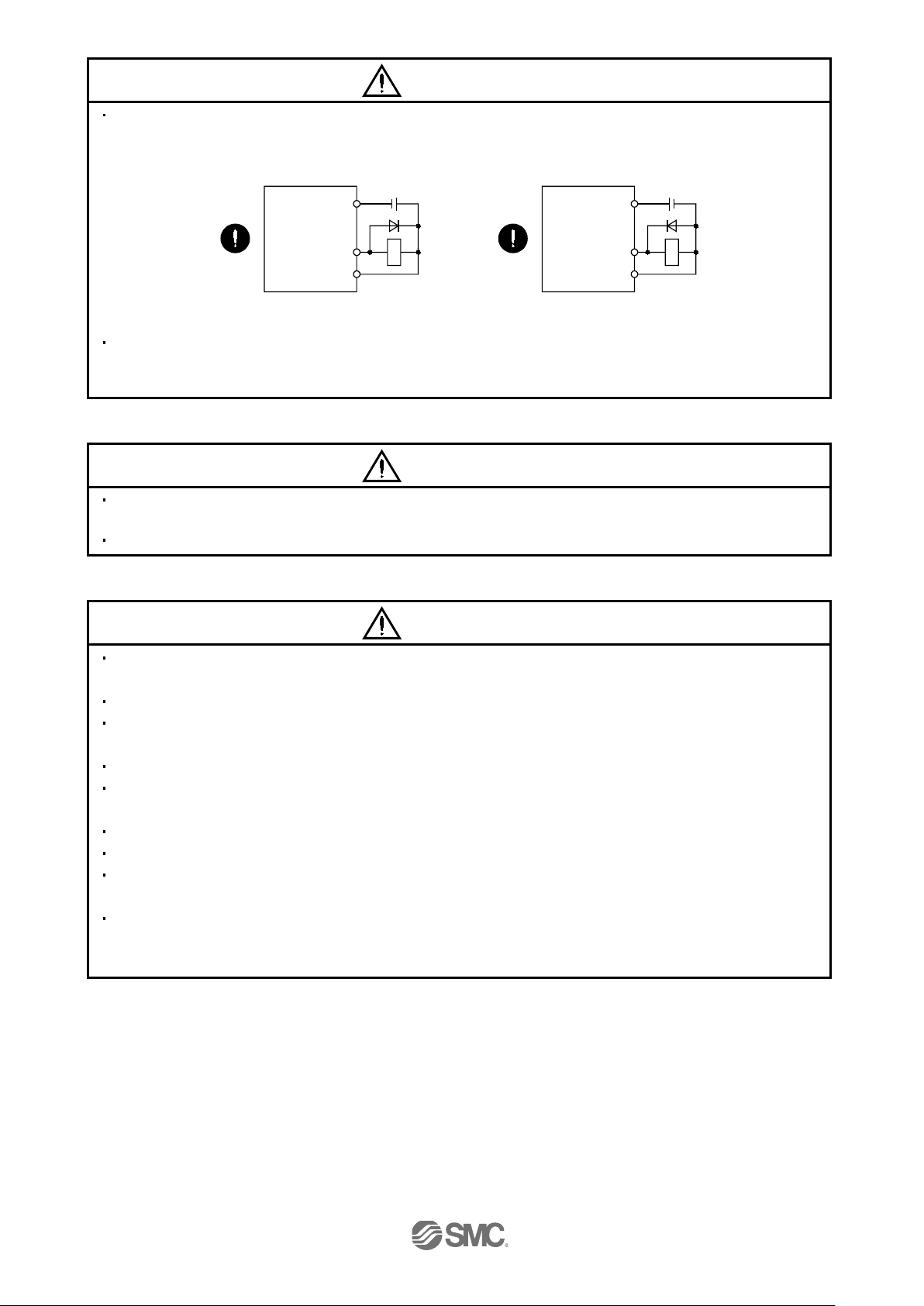

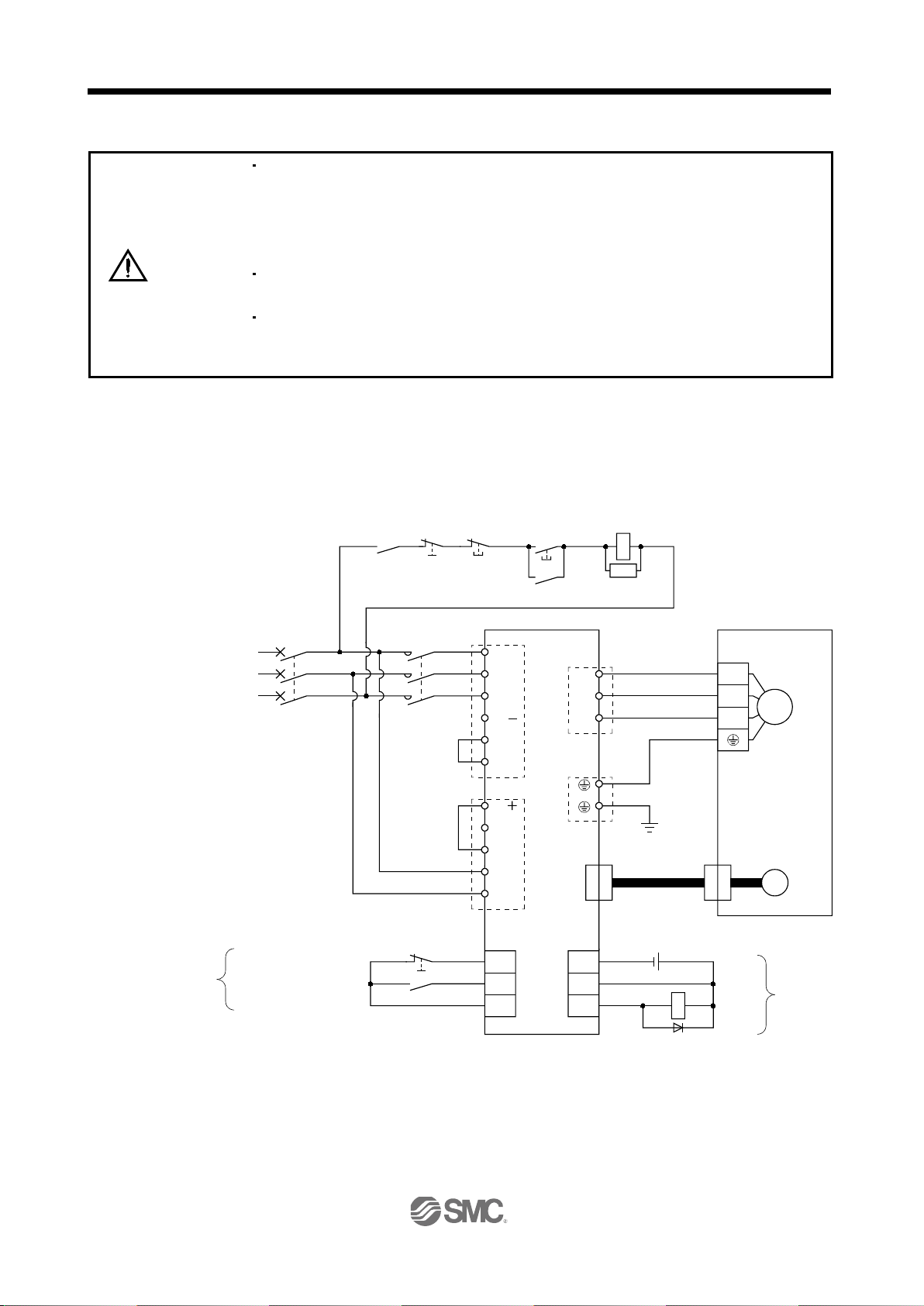

(2) Wiring

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Do not install a power capacitor, surge absorber or radio noise filter (FR-BIF-(H) : Mitsubishi Electric

Corporation) between the servo motor and driver.

Connect the wires to the correct phase terminals (U, V, W) of the driver and servo motor.

Not doing so may cause unexpected operation.

Connect the servo motor power terminal (U, V, W) to the servo motor power input terminal (U, V, W)

directly. Do not let a magnetic contactor, etc. intervene.

Driver

Driver

Do not connect AC power directly to the servo motor. Otherwise, a fault may occu r.

A - 6

CAUTION

DOCOM

Control output

signal

DICOM

24VDC

Servo amplifier

(drive unit)

RA

For sink output interface

DOCOM

Control output

signal

DICOM

24VDC

Servo amplifier

(drive unit)

RA

For source output interface

CAUTION

CAUTION

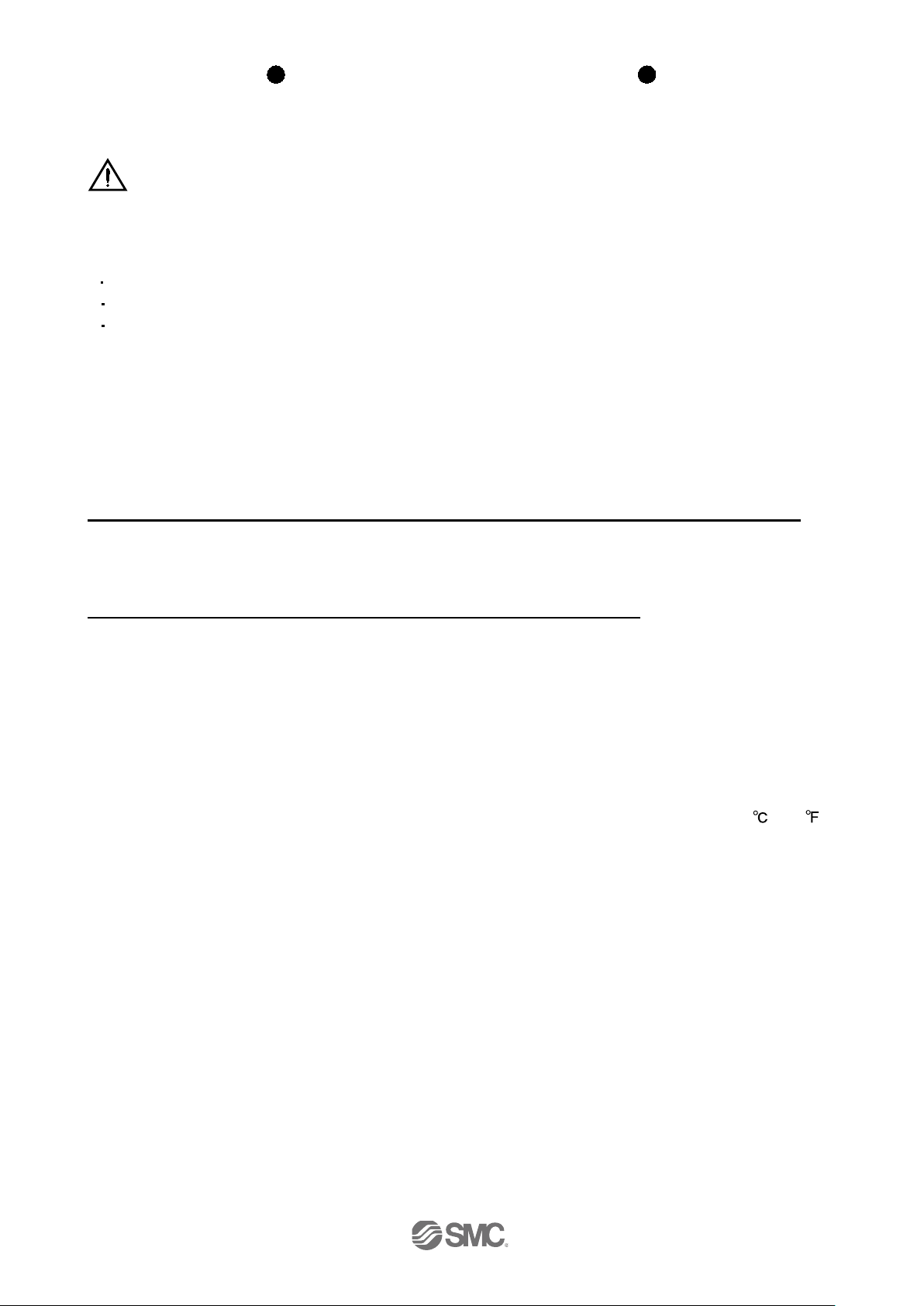

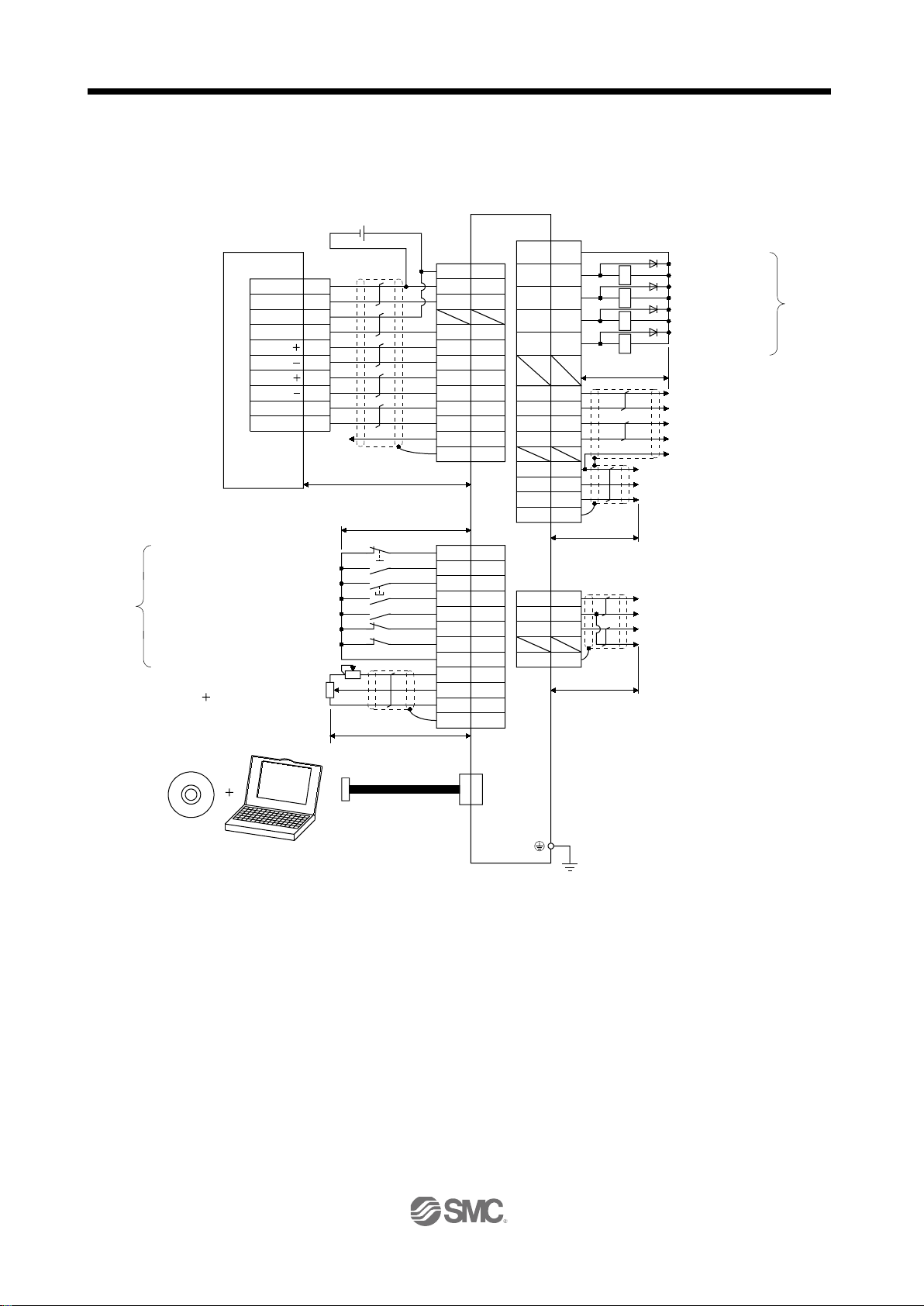

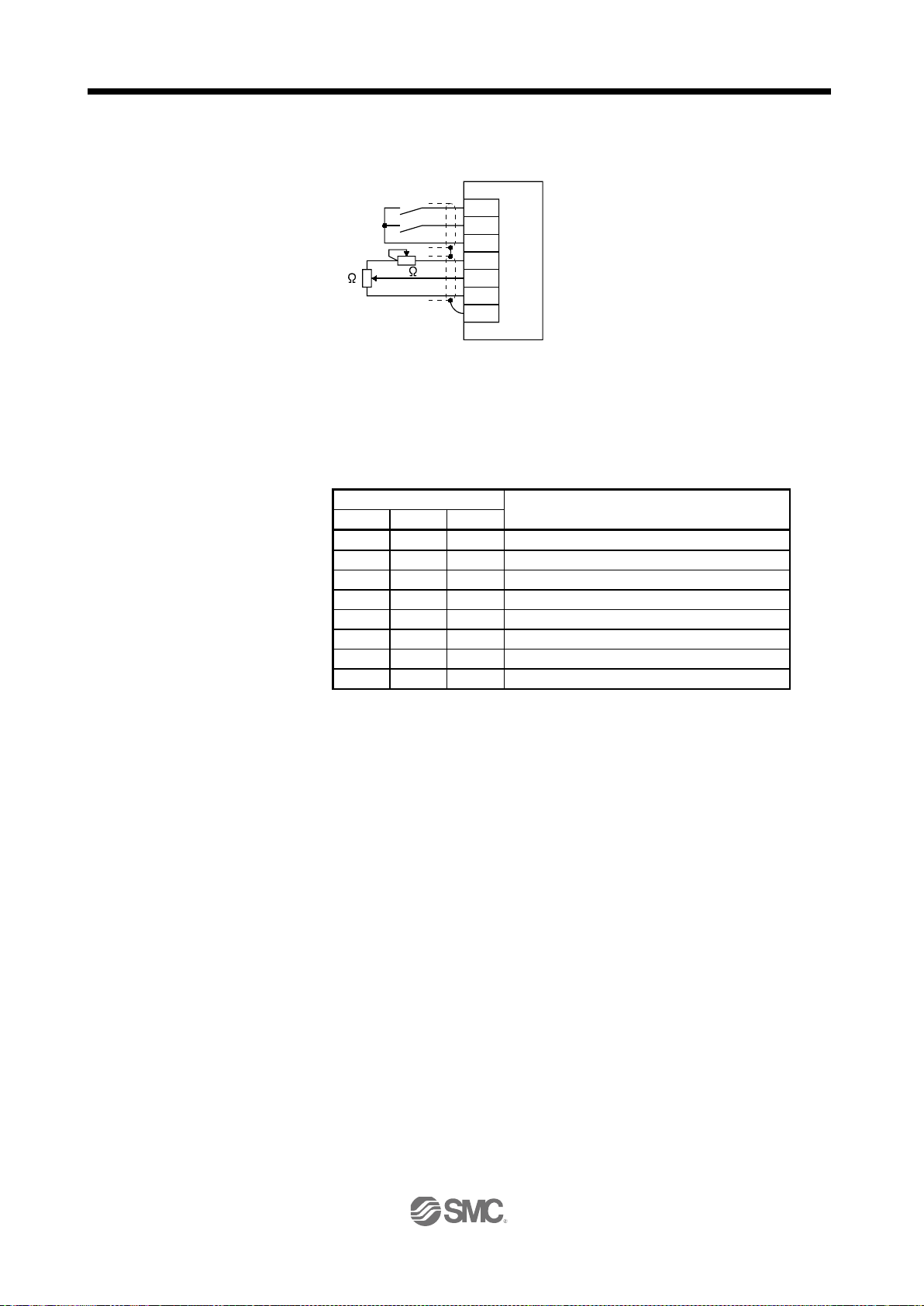

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Driver

Driver

When the cable is not tightened enough to the terminal block (connector), the cable or terminal block

(connector) may generate heat because of the poor contact. Be sure to tighten the cable with specified

torque.

(3) Test run adjustment

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be insatiable.

(4) Usage

Provide an external emergency stop circuit to ensure that operation can be stopped and power switched

off immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resetting an alarm, make sure that the run signal of the driver is off to prevent an accident. A

sudden restart is made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise filter, etc. to minimize the influence of electromagnetic interference, which may be caused by

electronic equipment used near the driver.

Burning or breaking a driver may cause a toxic gas. Do not burn or break a converter unit and driver.

Use the driver with the specified servo motor.

The lock on the servo motor is designed to hold the motor shaft and should not be used for ordinary

braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor are

coupled via a timing belt), the lock may not hold the motor shaft. To ensure safety, install a stopper on the

machine side.

A - 7

CAUTION

Servo motor

Electromagnetic brake

B

RA

Contacts must be opened

with the EMG stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

24 V DC

CAUTION

Lock

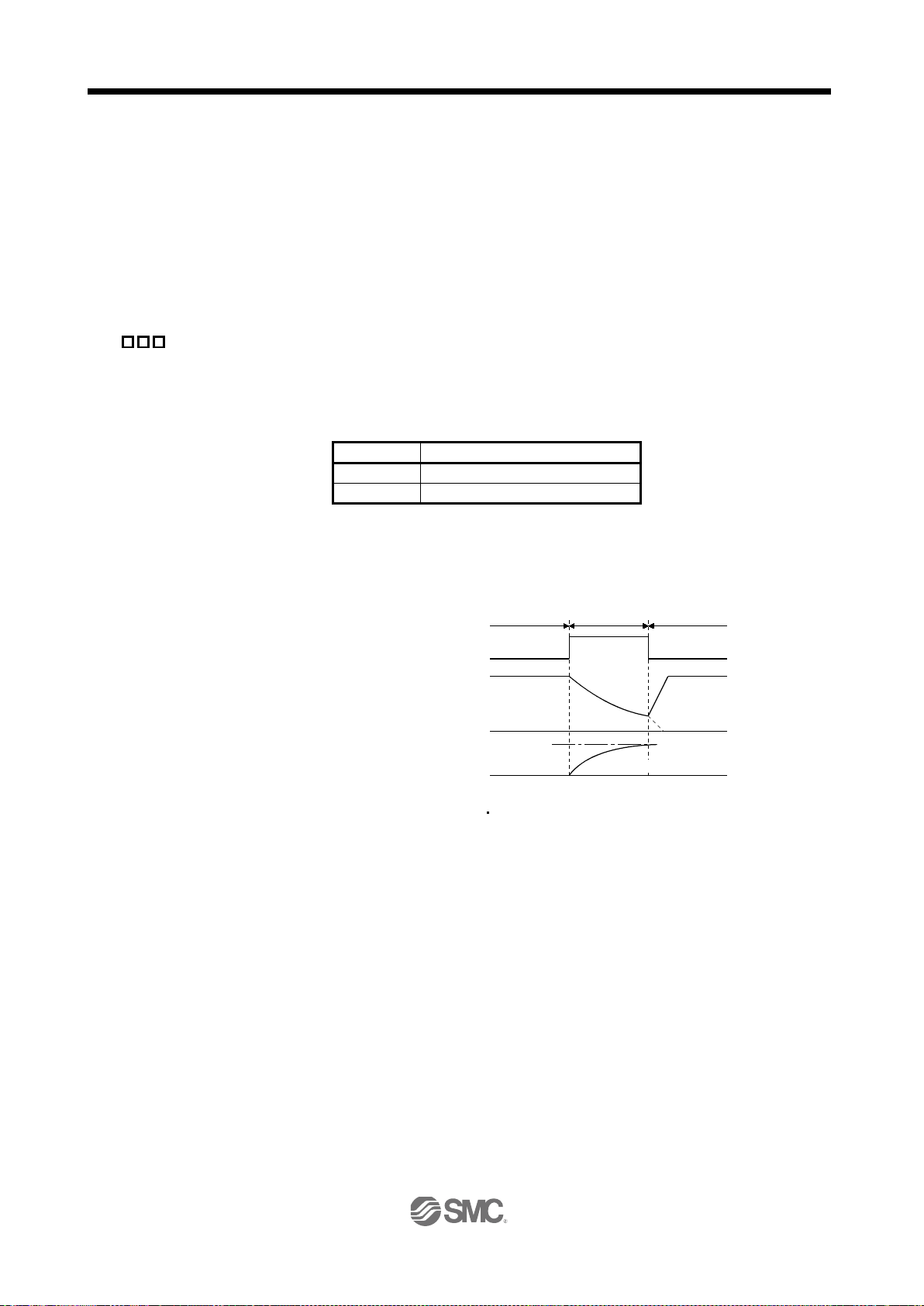

(5) Corrective actions

When it is assumed that a hazardous condition may take place at the occur due to a power failure or a

product fault, use a servo motor with a lock or an external lock mechanism for the purpose of prevention.

Do not use the 24VDC interface for the lock. Always use the power supply designed exclusively for the lock.

Otherwise, a fault may occur.

Configure a lock circuit so that it is activated also by an external emergency stop switch.

Contacts must be opened when ALM (Malfunction) and

MBR (Electromagnetic brake interlock) turns off.

Lock

Refer to section 3.11.4 when wiring for the circuit configuration.

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

When power is restored after an instantaneous power failure, keep away from the machine because the

machine may be restarted suddenly (design the machine so that it is secured against hazard if restarted).

(6) Maintenance, inspection and parts replacement

With age, the electrolytic capacitor of the driver will deteriorate. To prevent a secondary accident due to a

fault, it is recommended to replace the electrolytic capacitor every 10 years when used in general

environment. Please contact your local sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Specifications and Instruction Manual may have

been drawn without covers and safety guards. When the equipment is operated, the covers and safety

guards must be installed as specified. Operation must be performed in accordance with this Specifications

and Instruction Manual.

A - 8

DISPOSAL OF WASTE

Please dispose a driver battery (primary battery) and other options according to your local laws and regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the

total number of the following operations exceeds 100,000, the converter unit, driver and/or converter unit may

fail when the EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Home position setting in the absolute position detection system

Write to the EEP-ROM due to device changes

Precautions for Choosing the Products

SMC will not be held liable for damage caused by factors found not to be the cause of SMC; machine

damage or lost profits caused by faults in the SMC products; damage, secondary damage, accident

compensation caused by special factors unpredictable by SMC; damages to products other than SMC

products; and to other duties.

COMPLIANCE WITH THE EUROPEAN EC DIRECTIVES

Refer to Appendix 9 f or the com plianc e with EC Dir ect ives .

COMPLIANCE WITH UL/ C-UL STANDARD

Refer to Appendix 10 for the compliance with UL/C-UL standard.

<<About the manuals>>

This Instruction Manual are required if you use the General-Purpose AC servo LECSB□-□ for the first time.

Always purchase them and use the LECSB□-□ safely.

<<Wiring>>

Wires mentioned in this instruction manual are selected based on the ambient temperature of 40

(104 ).

A - 9

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1 - 1 to 1 -13

1.1 Summary .................................................................................................................................................. 1 - 2

1.2 Function block diagram ............................................................................................................................ 1 - 3

1.3 Driver standard specifications .................................................................................................................. 1 - 4

1.4 Function list .............................................................................................................................................. 1 - 5

1.4.1 Applicable control mode for each actuator. ...................................................................................... 1 - 7

1.5 Model code definition ............................................................................................................................... 1 - 8

1.6 Combination with servo motor ................................................................................................................ 1 -10

1.7 Structure .................................................................................................................................................. 1 -11

1.7.1 Parts ide nt i fi cati on ............................................................................................................................ 1 -11

1.8 Configuration including auxiliary equipment........................................................................................... 1 -12

2. INSTALLATION 2 - 1 to 2 - 6

2.1 Installation direction and clearances ....................................................................................................... 2 - 3

2.2 Keep out foreign materials ....................................................................................................................... 2 - 4

2.3 Cable stress ............................................................................................................................................. 2 - 5

2.4 Inspection items ....................................................................................................................................... 2 - 5

2.5 Parts having service lives ........................................................................................................................ 2 - 6

3. SIGNALS AND WIRING 3 - 1 to 3 -64

3.1 Input power supply circuit ........................................................................................................................ 3 - 3

3.2 I/O signal connection example ................................................................................................................ 3 - 6

3.2.1 Position control mode ........................................................................................................................ 3 - 6

3.2.2 Speed control mode .......................................................................................................................... 3 - 8

3.2.3 Torque control mode ........................................................................................................................ 3 -10

3.3 Explanation of power supply system ...................................................................................................... 3 -12

3.3.1 Signal ex pl an at io n s .......................................................................................................................... 3 -12

3.3.2 Power-on sequence ......................................................................................................................... 3 -13

3.3.3 CNP1, CNP2, CNP3 wiring method ................................................................................................ 3 -15

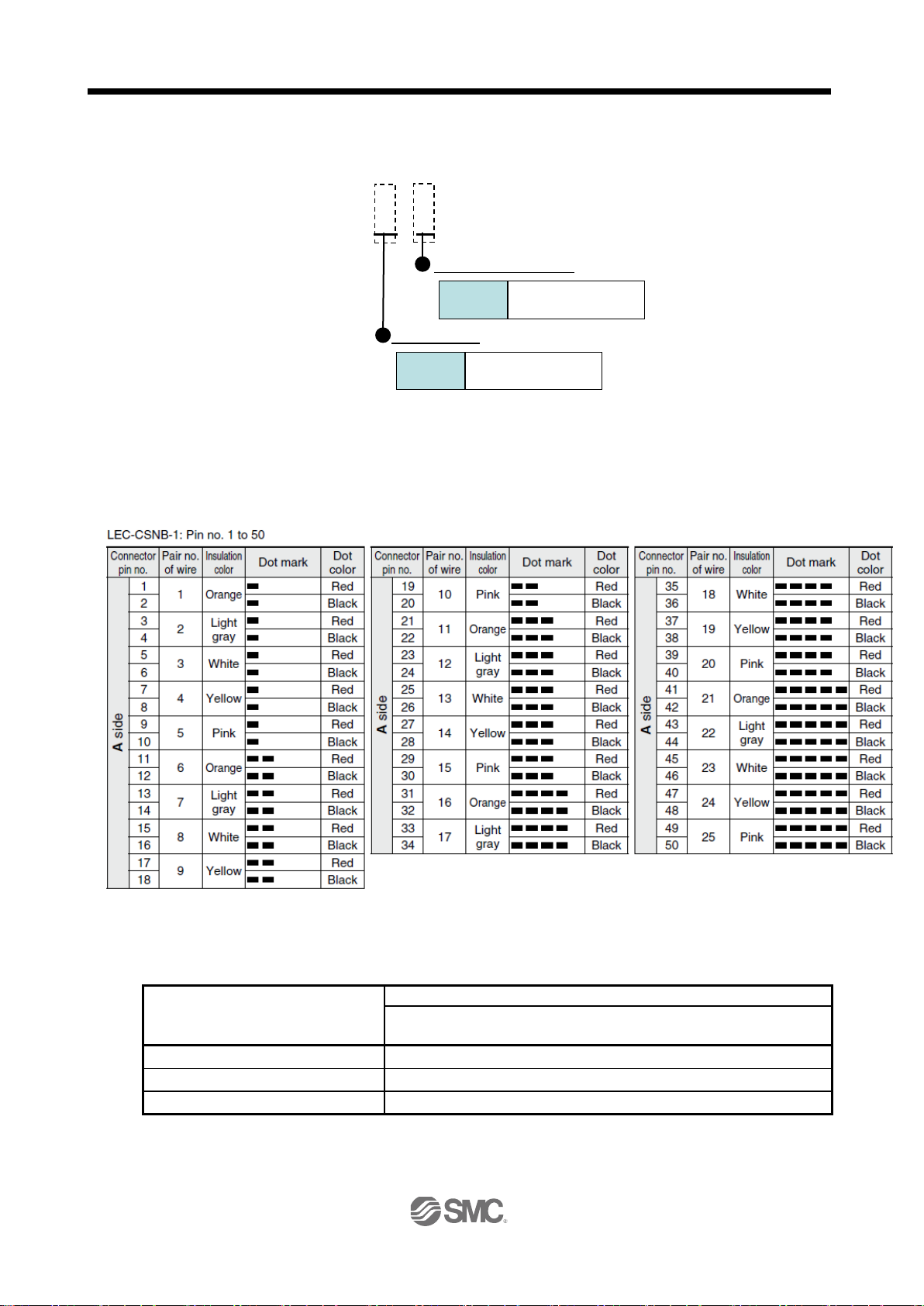

3.4 Connectors and signal arrangements .................................................................................................... 3 -20

3.5 Signal explanations ................................................................................................................................. 3 -23

3.6 Detailed description of the signals .......................................................................................................... 3 -34

3.6.1 Position control mode ....................................................................................................................... 3 -34

3.6.2 Speed control mode ......................................................................................................................... 3 -38

3.6.3 Torque control mode ........................................................................................................................ 3 -40

3.6.4 Position/speed control change mode .............................................................................................. 3 -43

3.6.5 Speed/torque control change mode ................................................................................................ 3 -45

3.6.6 Torque/position control change mode ............................................................................................. 3 -47

3.7 Alarm occurrence timing chart ................................................................................................................ 3 -48

3.8 Interfaces ................................................................................................................................................. 3 -49

3.8.1 Internal connection diagram ............................................................................................................ 3 -49

3.8.2 Detailed description of interfaces ..................................................................................................... 3 -50

1

3.8.3 Source I/O interfaces ....................................................................................................................... 3 -55

3.9 Treatment of cable shield external conductor ........................................................................................ 3 -56

3.10 Connection of driver and servo motor .................................................................................................. 3 -57

3.10.1 Connection instructions .................................................................................................................. 3 -57

3.10.2 Power supply cable wiring diagrams ............................................................................................. 3 -58

3.11 Servo motor with a lock......................................................................................................................... 3 -59

3.11.1 Safety precautions ......................................................................................................................... 3 -59

3.11.2 Setting ............................................................................................................................................. 3 -59

3.11.3 Timing charts .................................................................................................................................. 3 -60

3.11.4 Wiring diagrams (LE-□-□ series servo motor) ............................................................................ 3 -62

3.12 Grounding .............................................................................................................................................. 3 -64

4. STARTUP 4 - 1 to 4 -19

4.1 Switching power on for the first time ....................................................................................................... 4 - 2

4.1.1 Startup procedure .............................................................................................................................. 4 - 2

4.1.2 Wiring check ...................................................................................................................................... 4 - 3

4.1.3 Surrounding environment .................................................................................................................. 4 - 4

4.2 Startup in position control mode .............................................................................................................. 4 - 5

4.2.1 Power on and off procedures ............................................................................................................ 4 - 5

4.2.2 Stop .................................................................................................................................................... 4 - 5

4.2.3 Test operation.................................................................................................................................... 4 - 6

4.2.4 Parameter setting .............................................................................................................................. 4 - 7

4.2.5 Actual operation ................................................................................................................................ 4 - 8

4.2.6 Trouble at start-up ............................................................................................................................. 4 - 8

4.3 Startup in speed control mode ................................................................................................................ 4 -10

4.3.1 Power on and off procedures ........................................................................................................... 4 -10

4.3.2 Stop ................................................................................................................................................... 4 -11

4.3.3 Test operation................................................................................................................................... 4 -12

4.3.4 Parameter setting ............................................................................................................................. 4 -13

4.3.5 Actual operation ............................................................................................................................... 4 -14

4.3.6 Trouble at start-up ............................................................................................................................ 4 -14

4.4 Startup in torque control mode ............................................................................................................... 4 -15

4.4.1 Power on and off procedures ........................................................................................................... 4 -15

4.4.2 Stop ................................................................................................................................................... 4 -16

4.4.3 Test operation .................................................................................................................................. 4 -17

4.4.4 Parameter setting ............................................................................................................................. 4 -18

4.4.5 Actual operation ............................................................................................................................... 4 -19

4.4.6 Trouble at start-up ............................................................................................................................ 4 -19

5. PARAMETERS 5 - 1 to 5 -57

5.1 Basic setting parameters (No.PA ) .................................................................................................... 5 - 2

5.1.1 Parameter list .................................................................................................................................... 5 - 2

5.1.2 Parameter write inhibit ...................................................................................................................... 5 - 3

5.1.3 Selection of control mode ................................................................................................................. 5 - 4

5.1.4 Selection of regenerative option ....................................................................................................... 5 - 5

5.1.5 Using absolute position detection system ........................................................................................ 5 - 6

2

5.1.6 Using electromagnetic brake interlock (MBR) .................................................................................. 5 - 6

5.1.7 Number of command input pulses per servo motor revolution ........................................................ 5 - 7

5.1.8 Electronic gear................................................................................................................................... 5 - 8

5.1.9 Auto tuning ....................................................................................................................................... 5 -12

5.1.10 In-position range ............................................................................................................................ 5 -13

5.1.11 Torque limit ..................................................................................................................................... 5 -14

5.1.12 Selection of command pulse input form ........................................................................................ 5 -15

5.1.13 Selection of servo motor rotation direction .................................................................................... 5 -16

5.1.14 Encoder output pulse ..................................................................................................................... 5 -16

5.2 Gain/filter parameters (No. PB

5.2.1 Parameter list ................................................................................................................................... 5 -18

5.2.2 Detail li s t ........................................................................................................................................... 5 -20

5.2.3 Position smoothing ........................................................................................................................... 5 -31

5.3 Extension setting parameters (No. PC

5.3.1 Parameter list ................................................................................................................................... 5 -32

5.3.2 List of d et ail s ..................................................................................................................................... 5 -33

5.3.3 Analog monitor ................................................................................................................................. 5 -43

5.3.4 Alarm history clear ............................................................................................................................ 5 -46

5.4 I/O setting parameters (No. PD

5.4.1 Parameter list ................................................................................................................................... 5 -47

5.4.2 List of d et ail s ..................................................................................................................................... 5 -48

5.4.3 Using forward/reverse rotation stroke end to change the stopping pattern ................................... 5 -57

) ....................................................................................................... 5 -18

) .......................................................................................... 5 -32

)...................................................................................................... 5 -47

6. DISPLAY AND OPERATION SECTIONS 6 - 1 to 6 -23

6.1 Overview ................................................................................................................................................... 6 - 2

6.2 Display sequence ..................................................................................................................................... 6 - 3

6.3 Status display ........................................................................................................................................... 6 - 4

6.3.1 Display transition ............................................................................................................................... 6 - 4

6.3.2 Display examples .............................................................................................................................. 6 - 5

6.3.3 Status display list ............................................................................................................................... 6 - 6

6.3.4 Changi ng the s t atu s disp lay screen .................................................................................................. 6 - 7

6.4 Diagnostic mode ...................................................................................................................................... 6 - 8

6.5 Alarm mode ............................................................................................................................................. 6 -10

6.6 Parameter mode ..................................................................................................................................... 6 -12

6.6.1 Parameter mode transition............................................................................................................... 6 -12

6.6.2 Operation example ........................................................................................................................... 6 -13

6.7 External I/O signal display ...................................................................................................................... 6 -15

6.8 Output si gn al (D O) fo rced ou tp ut............................................................................................................ 6 -18

6.9 Test operation mode ............................................................................................................................... 6 -19

6.9.1 Mode cha ng e .................................................................................................................................... 6 -19

6.9.2 JOG operation .................................................................................................................................. 6 -20

6.9.3 Positioning operation ........................................................................................................................ 6 -21

6.9.4 Motor-less operation ........................................................................................................................ 6 -23

7. GENERAL GAIN ADJUSTMENT 7 - 1 to 7 -11

7.1 Different adjustment methods .................................................................................................................. 7 - 2

3

7.1.1 Adjustment on a single driver ........................................................................................................... 7 - 2

TM

7.1.2 Adjustment using software (MR Configurator2

)............................................................................ 7 - 3

7.2 Auto tuning ............................................................................................................................................... 7 - 4

7.2.1 Auto tuning mode .............................................................................................................................. 7 - 4

7.2.2 Auto tuning mode basis .................................................................................................................... 7 - 5

7.2.3 Adjustment procedure by auto tuning ............................................................................................... 7 - 6

7.2.4 Response level setting in auto tuning mode .................................................................................... 7 - 7

7.3 Manual mode 1 (simple manual adjustment) .......................................................................................... 7 - 8

7.4 Interpolation mode .................................................................................................................................. 7 -11

8. SPECIAL ADJUSTMENT FUNCTIONS 8 - 1 to 8 -18

8.1 Function block diagram ............................................................................................................................ 8 - 2

8.2 Adaptive filter

........................................................................................................................................ 8 - 2

8.3 Machine resonance suppression filter ..................................................................................................... 8 - 5

8.4 Advanced vib r ati o n supp re ss io n co nt rol ................................................................................................. 8 - 7

8.5 Low-pass filter ......................................................................................................................................... 8 -11

8.6 Gain chang in g fu n ction ........................................................................................................................... 8 -11

8.6.1 Applications ...................................................................................................................................... 8 -11

8.6.2 Funct io n bl o ck di ag ram .................................................................................................................... 8 -12

8.6.3 Parameters ....................................................................................................................................... 8 -13

8.6.4 Gain changing procedure ................................................................................................................. 8 -15

8.7 Vibration suppression control filter 2 ...................................................................................................... 8 -17

9. TROUBLESHOOTING 9 - 1 to 9 -26

9.1 Alarms and warning list ............................................................................................................................ 9 - 2

9.2 Remedies for alarms ................................................................................................................................ 9 - 3

9.3 Remedies for warnings ........................................................................................................................... 9 -16

9.4 Troubles without an alarm/warning ........................................................................................................ 9 -18

10. OUTLINE DRAWINGS 10- 1 to 10- 5

10.1 Driver ..................................................................................................................................................... 10- 2

10.2 Connector .............................................................................................................................................. 10- 4

11. CHARACTERISTICS 11- 1 to 11 - 7

11.1 Overload protection characteristics ...................................................................................................... 11- 2

11.2 Power supply equipment capacity and generated loss ....................................................................... 11- 3

11.3 Dynamic brake characteristics .............................................................................................................. 11- 5

11.3.1 Dynamic brake operation ............................................................................................................... 11- 5

11.3.2 The dynamic brake at the load inertia moment ............................................................................. 11- 6

11.4 Cable flexing life .................................................................................................................................... 11- 7

11.5 Inrush currents at power-on of main circuit and control circuit ............................................................ 11- 7

12. OPTIONS AND AUXILIARY EQUIPMENT 12- 1 to 12 -36

12.1 Cable/connector sets ............................................................................................................................ 12- 2

4

12.1.1 Combinations of cable/connector sets .......................................................................................... 12- 3

12.1.2 Encoder cable ................................................................................................................................ 12- 5

12.1.3 Motor cables ................................................................................................................................... 12- 7

12.1.4 Lock cables ..................................................................................................................................... 12- 9

12.2 Regenerative options ........................................................................................................................... 12-10

TM

12.3 Set up software(MR Configurator2

) ................................................................................................. 12-13

12.3.1 Specifications ................................................................................................................................ 12-13

12.3.2 System configuration ..................................................................................................................... 12-14

12.3.3 Precautions for using USB communication function .................................................................... 12-16

12.4 Battery unit LEC-MR-J3BAT ................................................................................................................ 12-17

12.5 Selection example of wires .................................................................................................................. 12-18

12.6 No-fuse breakers, fuses, magnetic contactors ................................................................................... 12-21

12.7 Noise reduction techniques ................................................................................................................. 12-22

12.8 Leakage current breaker ...................................................................................................................... 12-30

12.9 EMC filter (recommended) .................................................................................................................. 12-32

13. COMMUNICATION FUNCTION 13- 1 to 13-35

13.1 Configuration ......................................................................................................................................... 13- 2

13.2 Communication specifications .............................................................................................................. 13- 4

13.2.1 Communication overview ............................................................................................................... 13- 4

13.2.2 Parameter setting ........................................................................................................................... 13- 5

13.3 Protocol ................................................................................................................................................. 13- 6

13.3.1 Transmission data configuration .................................................................................................... 13- 6

13.3.2 Character codes ............................................................................................................................. 13- 7

13.3.3 Error codes ..................................................................................................................................... 13- 8

13.3.4 Checksum ....................................................................................................................................... 13- 8

13.3.5 Time-out.......................................................................................................................................... 13- 9

13.3.6 Retry ............................................................................................................................................... 13- 9

13.3.7 Ini ti al ization .................................................................................................................................... 13-10

13.3.8 Communication procedure example ............................................................................................. 13-10

13.4 Command and data No. list ................................................................................................................. 13-11

13.4.1 Read commands ........................................................................................................................... 13-11

13.4.2 Write commands ........................................................................................................................... 13-15

13.5 Detailed explanations of commands ................................................................................................... 13-17

13.5.1 Data processing ............................................................................................................................ 13-17

13.5.2 Status display ................................................................................................................................ 13-19

13.5.3 Parameters .................................................................................................................................... 13-20

13.5.4 External I/O signal statuses (DIO diagnosis) ............................................................................... 13-23

13.5.5 Input device ON/OFF .................................................................................................................... 13-26

13.5.6 Disable/enable of I/O devices (DIO) ............................................................................................. 13-26

13.5.7 Input devices ON/OFF (test operation) ........................................................................................ 13-27

13.5.8 Test operation mode ..................................................................................................................... 13-28

13.5.9 Output signal pin ON/OFF output signal (DO) forced output ....................................................... 13-31

13.5.10 Alarm history ............................................................................................................................... 13-32

13.5.11 Current alarm .............................................................................................................................. 13-33

13.5.12 Other commands ......................................................................................................................... 13-34

5

14. ABSOLUTE POSITION DETECTION SYSTEM 14- 1 to 14-66

14.1 Outline ................................................................................................................................................... 14- 2

14.1.1 Features.......................................................................................................................................... 14- 2

14.1.2 Restrictions ..................................................................................................................................... 14- 3

14.2 Specifications ........................................................................................................................................ 14- 4

14.3 Battery replacement procedure ............................................................................................................ 14- 5

14.3.1 When replacing battery with the control circuit power ON ............................................................ 14- 5

14.4 Battery installation procedure ............................................................................................................... 14- 5

14.5 Standard connection diagram ............................................................................................................... 14- 6

14.6 Signal explanation ................................................................................................................................. 14- 7

14.7 Startup procedure ................................................................................................................................. 14- 8

14.8 Absolute position data transfer protocol ............................................................................................... 14- 9

14.8.1 Data transfer procedure ................................................................................................................. 14- 9

14.8.2 Transfer method ............................................................................................................................ 14-10

14.8.3 Home position setting.................................................................................................................... 14-21

14.8.4 Use of servo motor with a lock...................................................................................................... 14-23

14.8.5 How to process the absolute position data at detection of stroke end ........................................ 14-25

14.9 Examples of use ................................................................................................................................... 14-26

14.9.1 MELSEC FX

(2N)-32MT (FX(2N)-1PG) ........................................................................................... 14-26

14.9.2 MELSEC A1SD75 ......................................................................................................................... 14-38

14.9.3 MELSEC QD75 ............................................................................................................................. 14-51

14.10 Absolute position data transfer errors ............................................................................................... 14-59

14.10.1 Corrective actions ....................................................................................................................... 14-59

14.10.2 Error resetting conditions ............................................................................................................ 14-61

14.11 Communication-based ABS transfer system .................................................................................... 14-62

14.11.1 Serial communication command ................................................................................................ 14-62

14.11.2 Absolute position data transfer protocol ..................................................................................... 14-62

14.12 Confirmation of absolute position detection data .............................................................................. 14-66

15. SERVO MOTOR 15- 1 to 15- 6

15.1 Servo motor with a lock......................................................................................................................... 15- 2

15.1.1 Features.......................................................................................................................................... 15- 2

15.1.2 Characteristics of servo motor with a lock ..................................................................................... 15- 4

15.2 Protection from oil and water ........................................................................................................ 15- 5

15.3 Cable ............................................................................................................................................. 15- 5

15.4 Rated speed of servo motor ......................................................................................................... 15- 5

15.5 Mounting connectors .................................................................................................................... 15- 6

APPENDIX App.- 1 to App.-13

App. 1 Parameter list ..................................................................................................................................App.- 2

App. 2 Signal layout recording paper ........................................................................................................App.- 4

App. 3 Status display block diagram .........................................................................................................App.- 5

App. 4 Handling of AC driver batteries for the United Nations

Recommendations on the Transport of Dangerous Goods ..........................................................App.- 6

App. 5 Symbol for the new EU Battery Directive ......................................................................................App.- 6

6

App. 6 Compliance with the European EC directives ...............................................................................App.- 7

App. 7 Conformance with UL/C-UL standard .......................................................................................... App.-10

7

1. FUNCTIONS AND CONFIGURATI ON

1. FUNCTIONS AND CONFIGURATION .......................................................................................................... 2

1.1 Summary .................................................................................................................................................. 2

1.2 Function block diagram ............................................................................................................................ 3

1.3 Driver standard specifications .................................................................................................................. 4

1.4 Function list .............................................................................................................................................. 5

1.4.1 Applicable control mode for each actuator. ....................................................................................... 7

1.5 Model code definition ............................................................................................................................... 8

1.6 Combination with servo motor ............................................................................................................... 10

1.7 Structure ................................................................................................................................................. 11

1.7.1 Parts identification ........................................................................................................................... 11

1.8 Configuration including auxiliary equipment .......................................................................................... 12

1 - 1

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATIO N

1.1 Summary It has position control, speed control and torque control modes. Further, it can perform operation with the control modes changed, e.g. position/speed control, speed/torque control and torque/position control. Hence, it is applicable to a wide range of fields, not only precision positioning and smooth speed control of machine tools and general industrial machines but also line control and tension control. As this new series has the USB or RS-422 serial communication function, a set up software

TM

(MR Configurator2

operation, status display monitoring, gain adjustment, etc.

With real-time auto tuning, you can automatically adjust the servo gains according to the machine.

The LECSB□-□ series servo motor with an absolute position encoder which has the resolution of 262144

pulses/rev to ensure. Simply adding a battery to the driver makes up an absolute position detection system.

This makes home position return unnecessary at power-on or alarm occurrence by setting a home position

once.

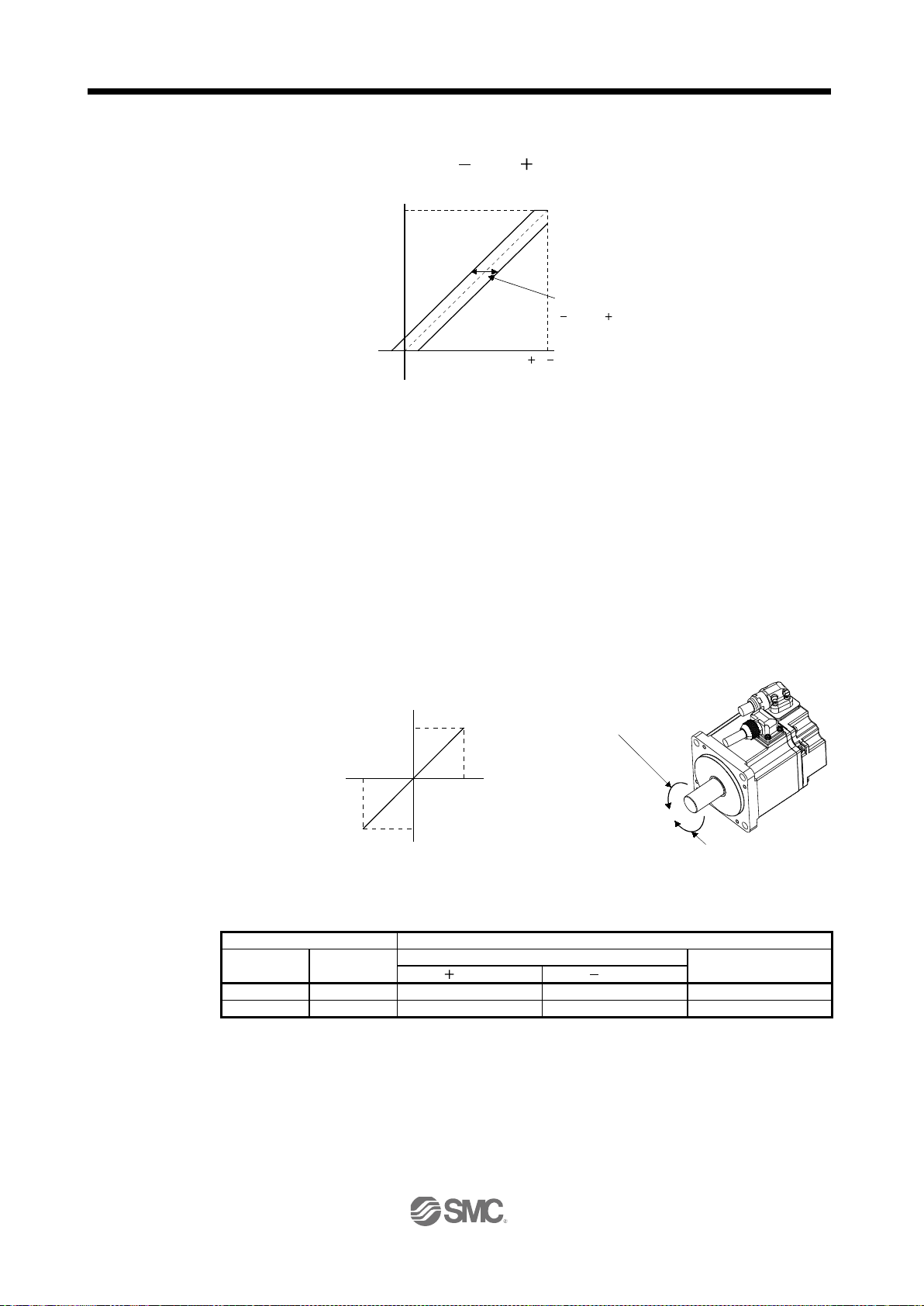

(1) Position control mode

An up to 1Mpps high-speed pulse train is used to control the speed and direction of a motor and execute

precision positioning of 262144 pulses/rev resolution.

The position smoothing function provides a choice of two different modes appropriate for a machine, so a

smoother start/stop can be made in response to a sudden position command.

A torque limit is imposed on the driver by the clamp circuit to protect the power transistor in the main circuit

from overcurrent due to sudden acceleration/deceleration or overload. This torque limit value can be

changed to any value with an external analog input or the parameter.

(2) Speed control mode

An external analog speed command (0 to

speeds) is used to control the speed and direction of a servo motor smoothly.

There are also the acceleration/deceleration time constant setting in response to speed command, the

servo lock function at a stop time, and automatic offset adjustment function in response to external analog

speed command.

(3) Torque control mode

An external analog torque command (0 to

To prevent unexpected operation under no load, the speed limit function (external or internal setting) is also

available for application to tension control, etc.

) installed personal computer or the like can be used to perform parameter setting, test

10VDC) or parameter-driven internal speed command (max. 7

8VDC) is used to control the torque output by the servo motor.

1 - 2

1. FUNCTIONS AND CONFIGURATION

C

D

L

11

CN5 CN3 CN6

I/F

USB RS-422 D/AA/D

USB RS-422

CN4

MR-J3BAT

CN1

P

1

P

2

P

(

) N

(

)

B

NFB

(Note 2)

Power

supply

MC

RA

24VDC

B1

B2

L

1

L

2

L

3

L

21

Servo amplifier

U

V

W

U

V

W

Diode

stack

Regenerative

option

Power factor

improving DC

reactor

CHARGE

lamp

Regenerative TR

(Note 1)

Current

detector

M

Servo motor

Dynamic

brake circuit

Electro-

magnetic

brake

Encoder

Base

amplifier

Voltage

detection

Overcurrent

protection

Current

detection

Control

circuit

power

supply

(Note 3) Cooling fan

Relay

Pulse input

Model position

control

Model speed

control

Virtual

encoder

Virtual

motor

Model

position

Model

speed

Model torque

Actual position

control

Actual speed

control

Current

control

Optional battery

(for absolute position

detection system)

Analog monitor

(2 channels)

Personal

computer

D I/O control

Servo on

Command pulse train input

Start

Failure, etc

.

Analog

(2 channels)

Controller

CN2

Lock

LEC-MR-J3BAT

Driver

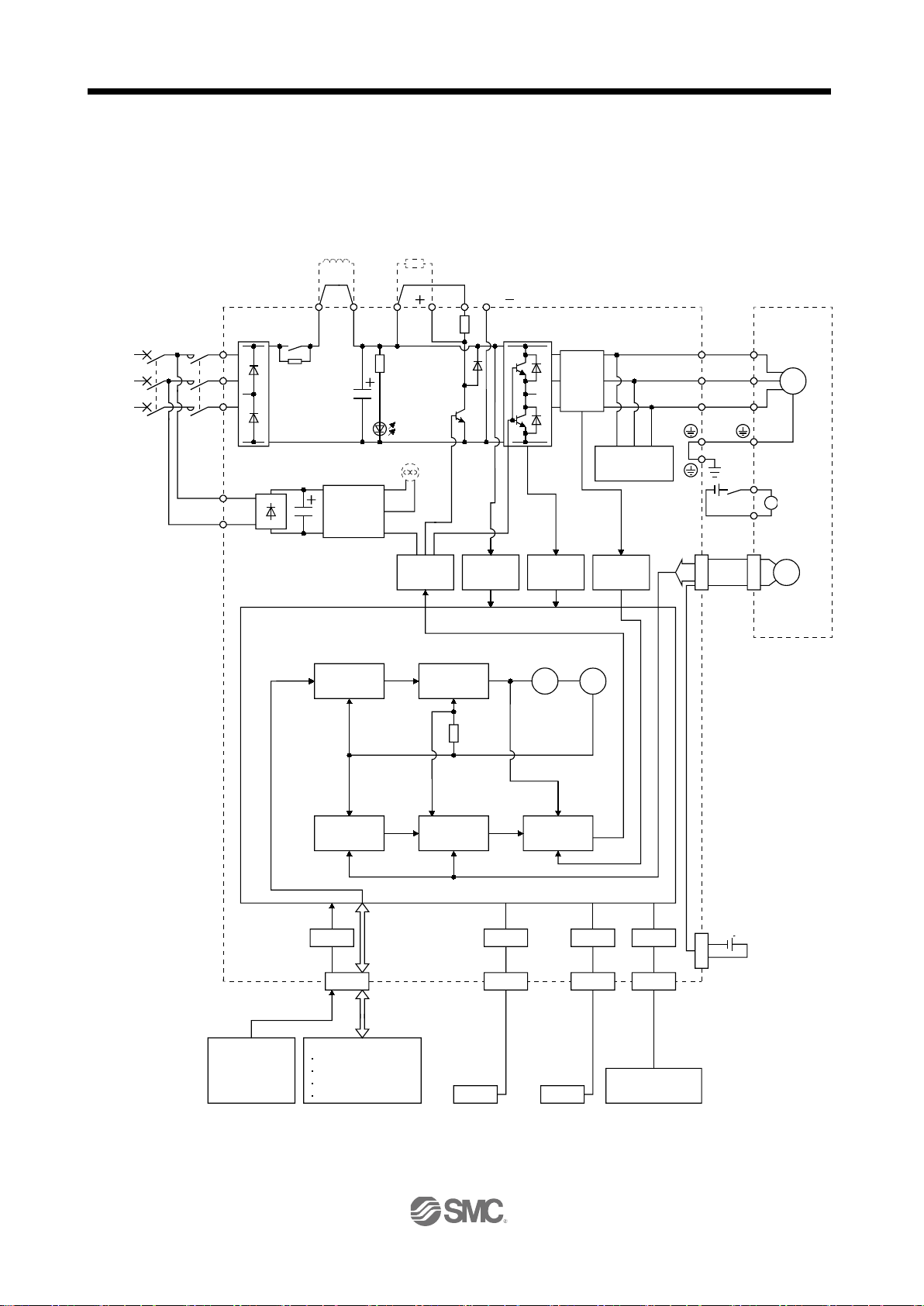

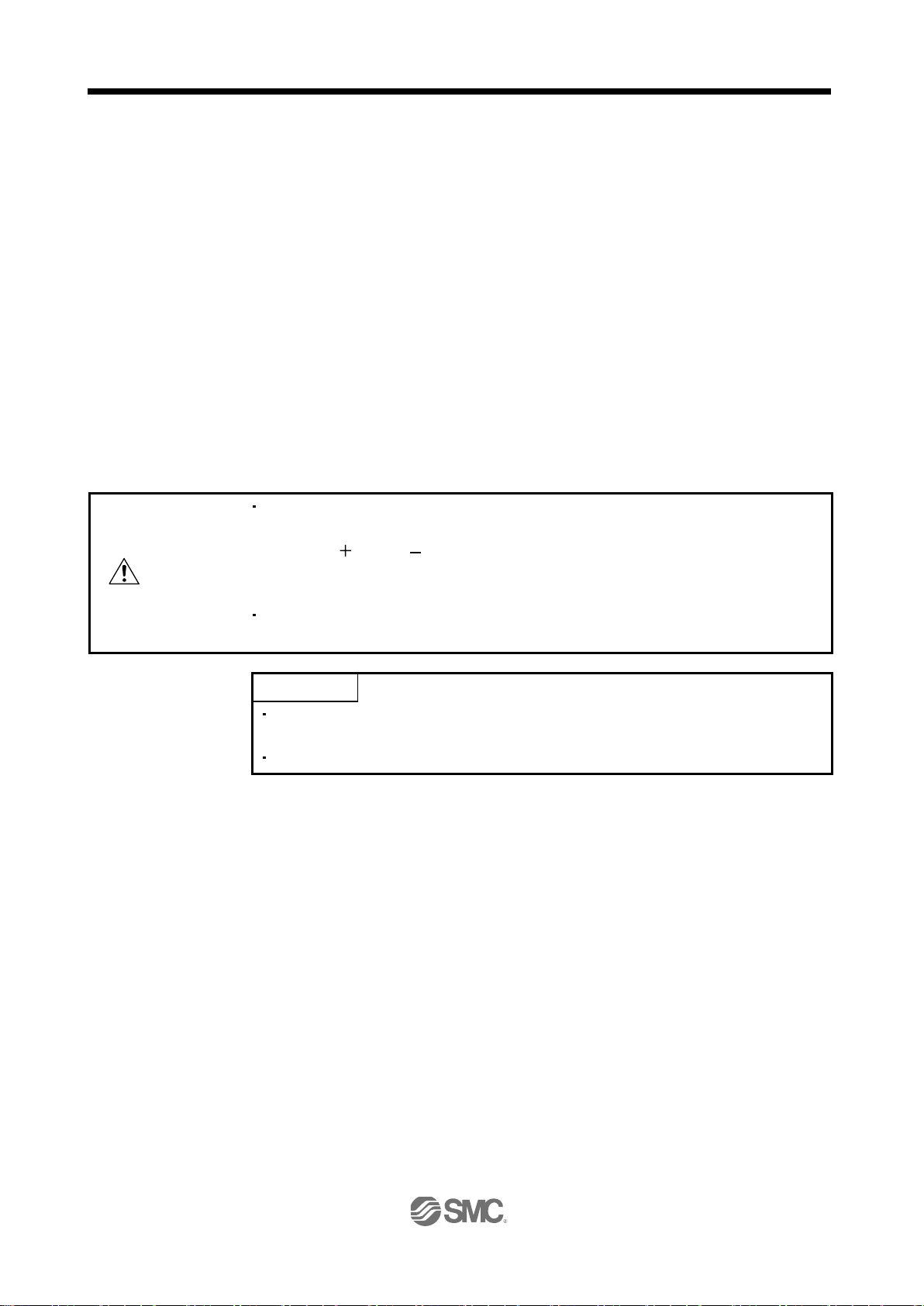

1.2 Function block diagram The function block diagram of this servo is shown below.

(1) LECSB□-□

Note 1. The built-in regenerative resistor is not provided for the LECSB1-S5.

2. For 1-phase 200 to 230VAC, connect the power supply to L1, L2 and leave L3 open.

There is no L

3 for 1-phase 100 to 120VAC power supply. For the specification of power supply, refer to section 1.3.

1 - 3

1. FUNCTIONS AND CONFIGURATION

Driver

Item

Output

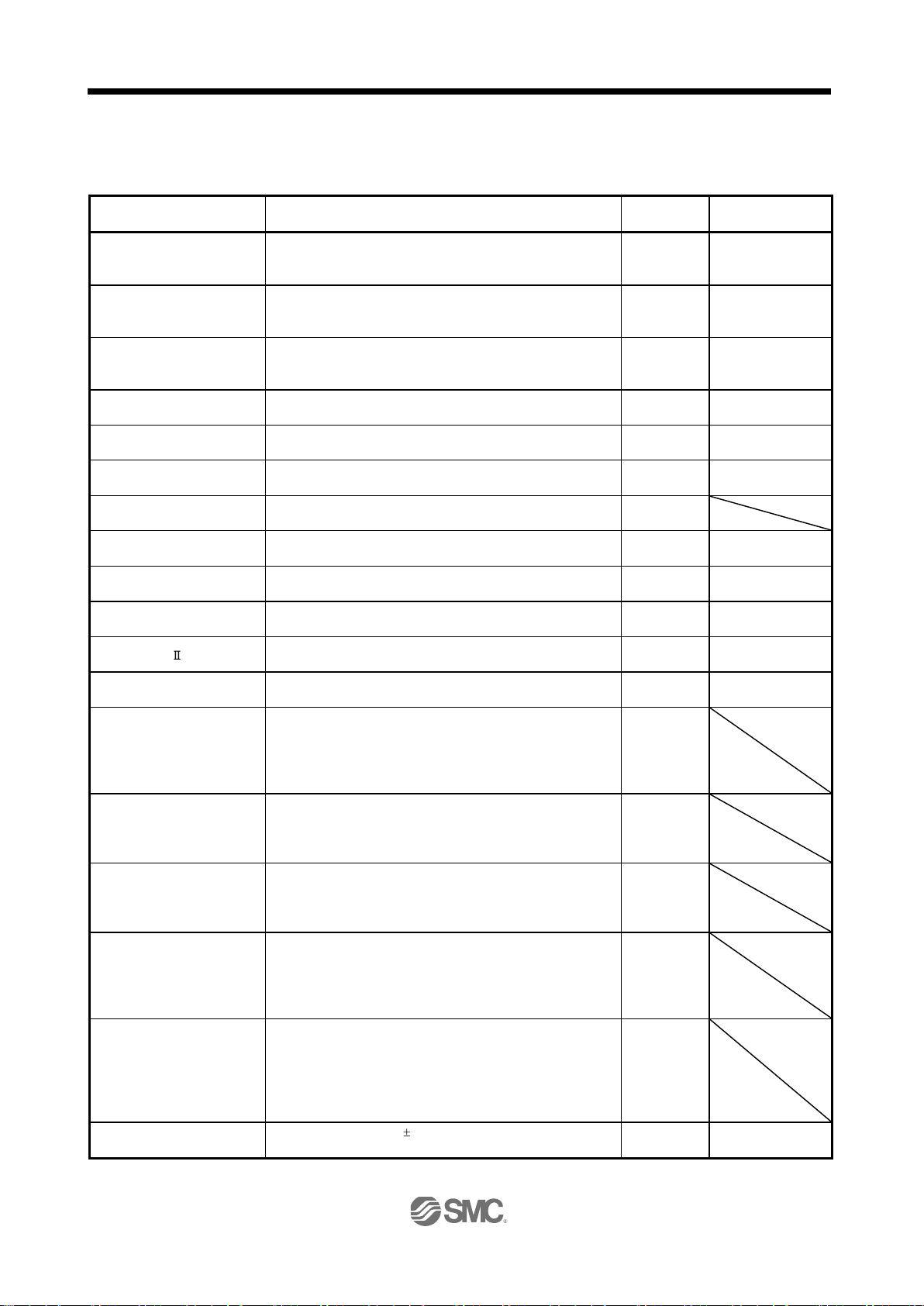

Rated voltage

3-phase 170VAC

Rated current [A]

1.1

1.5

2.8

Main circuit power

Voltage, frequency

3-phase or 1-phase 200 to 230VAC, 50/60Hz

Rated current [A]

0.9

1.5

2.6

3-phase or 1-phase

170 to 253VAC

Permissible frequency fluctuation

Within 5

Power supply capacity

Refer to section 11.2

Inrush current

Refer to section 11.5

Voltage, frequency

1-phase 200 to 230VAC, 50/60Hz

Rated current [A]

0.2

Permissible voltage

fluctuation

Permissible

fluctuation

Power

consumption [W]

Inrush current

Refer to section 11.5

Voltage

24VDC 10

Power supply

capacity

Control System

Sine-wave PWM control, current control system

Dynamic brake

Built-in

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic

protection, excessive error protection

Position control

Max. input pulse frequency

1Mpps (for differential receiver), 200kpps (for open collector)

Command pulse multiplying

factor

In-position range setting

0 to 10000 pulse (command pulse unit)

Error excessive

3 revolutions

Torque limit

Set by parameter setting or external analog input (0 to 10VDC/maximum torque)

Speed control range

Analog speed command 1: 2000, internal speed command 1: 5000

Analog speed command

input

0.01 or less (load fluctuation 0 to 100 )

0.2 or less (ambient temperature 25 10

(59 to 95 )

)

Torque limit

Set by parameter setting or external analog input (0 to 10VDC/maximum torque)

Torque control

Analog torque command

input

Speed limit

Set by parameter setting or external analog input (0 to 10VDC/Rated speed)

CE (LVD: IEC/EN 50178, EMC: IEC/EN 61800-3)

UL (UL 508C)

Structure

Natural-cooling, open

[ ]

(Note 2) 0 to 55 (non-freezing)

[ ]

(Note 2) 32 to 131 (non-freezing)

[ ]

20 to 65 (non-freezing)

[ ]

4 to 149 (non-freezing)

Ambient

humidity

In operation

In storage

Indoors (no direct sunlight),

Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude

Max. 1000m above sea level

Vibration

5.9m/s2 or less at 10 to 55Hz (directions of X, Y and Z axes)

[kg]

0.8

0.8

1.0

[lb]

1.76

1.76

2.21

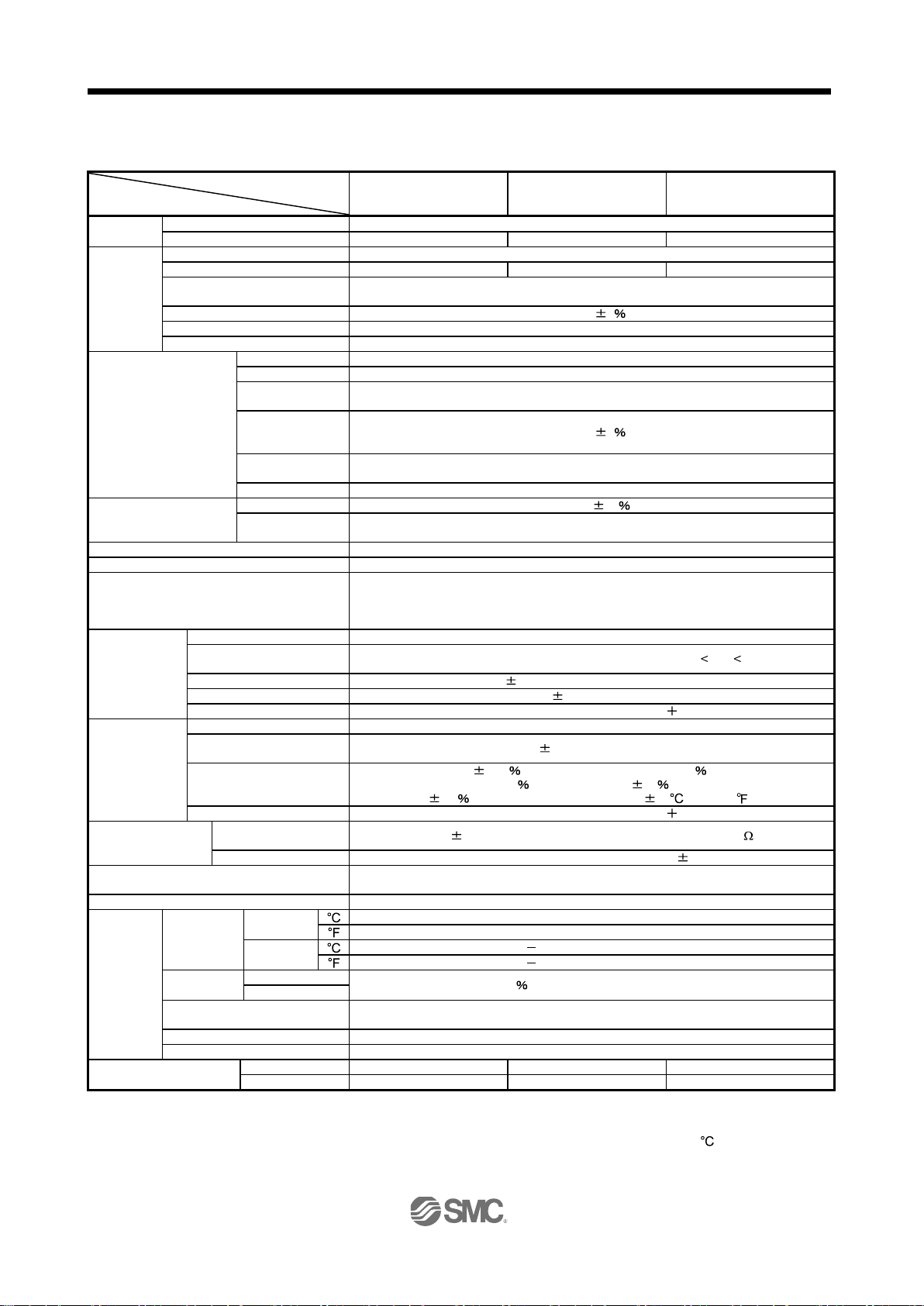

1.3 Driver standard specifications (1) 200V class

Permissible voltage fluctuation

supply

Control circuit power

supply

Interface power supply

Protective functions

frequency

LECSB□-□

LECSB□-S5 LECSB□-S7 LECSB-□-S8

1-phase 170 to 253VAC

Within 5

30

(Note 1) 0.3A

thermal relay), servo motor overheat protection, encoder error protection, regenerative

error protection, undervoltage, instantaneous power failure protection, overspeed

Electronic gear A:1 to 1048576, B:1 to 1048576, 1/10 A/B 2000

mode

0 to 10VDC / Rated speed

mode

Speed fluctuation ratio

Speed control

mode

Compliance to standards

Ambient

temperature

Ambient

Environmental conditions

Mass

Note 1. 0.3A is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of

I/O points.

2. When closely mounting the driver of 3.5kW or less, operate them at the ambient temperatures of 0 to 45

effective load ratio.

3. When a UL/C-UL-compliant servo motor is used in combination, the value is 2.9A.

In operation

In storage

0 to 8VDC / Maximum torque (input impedance 10 to 12k )

0 (power fluctuation 10 )

90 RH or less (non-condensing)

or at 75% or smaller

1 - 4

1. FUNCTIONS AND CONFIGURATION

(Note)

Control mode

Section 4.2

Section 4.3

Section 3.2.3

Section 4.4

change mode

control and speed control.

mode

control and torque control.

Torque/position control

change mode

Using input device, control can be switched between torque

control and position control.

High-resolution encoder of 262144 pulses/rev is used as a

servo motor encoder.

system

return unnecessary at every power-on.

stop or use an input device to change gains during operation.

suppression control

vibration.

characteristics automatically to suppress mechanical vibration.

system response is increased.

function.

function.

function.

function.

function.

control

stop.

No.PB24

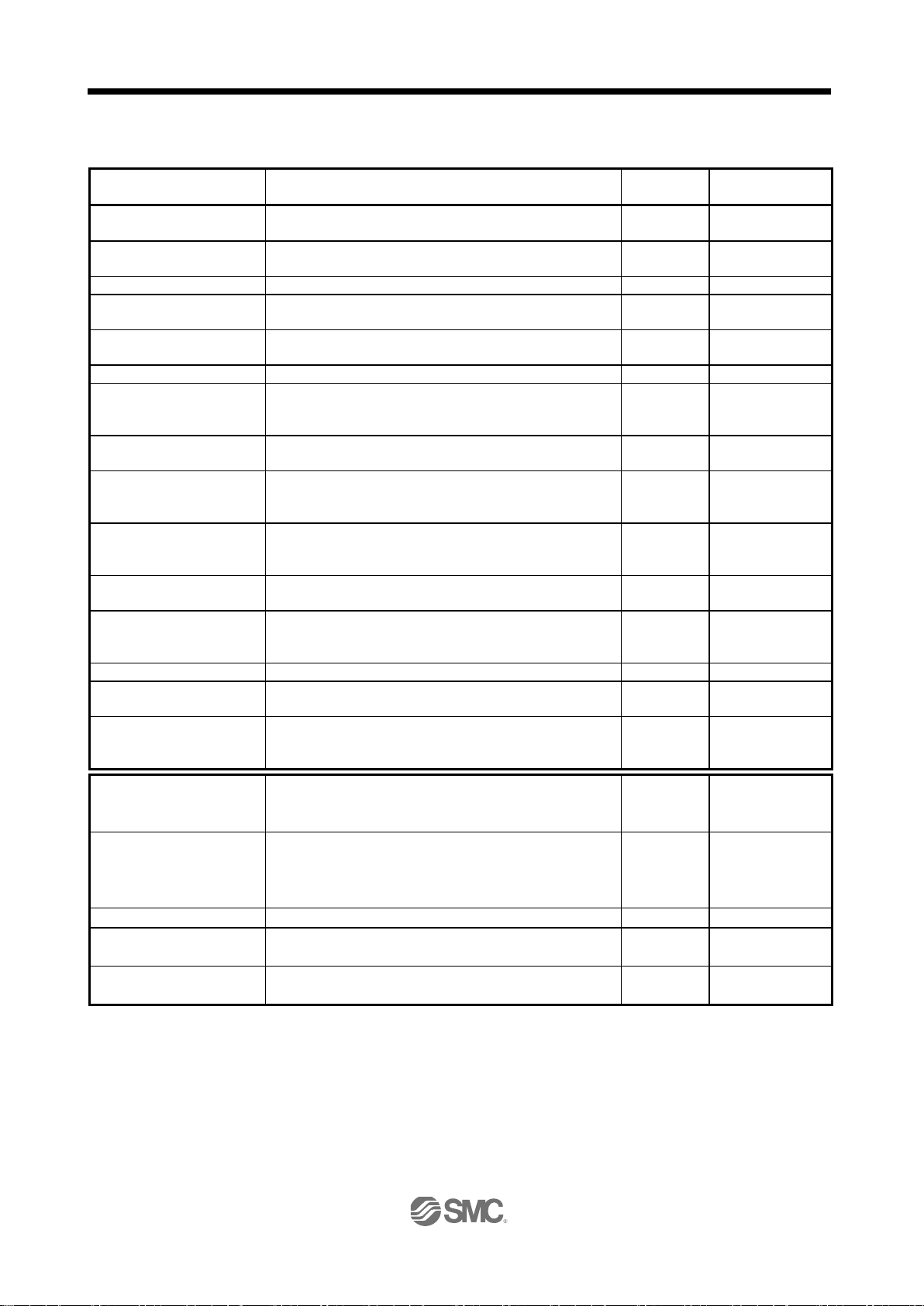

1.4 Function list The following table lists the functions of this servo. For details of the functions, refer to the reference field.

Function Description

Position control mode This servo is used as position control servo. P

Speed control mode This servo is used as speed control servo. S

Torque control mode This servo is used as torque control servo. T

Position/speed control

Speed/torque control change

High-resolution encoder

Absolute position detection

Gain changing function

Advanced vibration

Adaptive filter

Using input device, control can be switched between position

Using input device, control can be switched between speed

Merely setting a home position once makes home position

You can switch between gains during rotation and gains during

This function suppresses vibration at the arm end or residual

Driver detects mechanical resonance and sets filter

P/S Section 3.6.4

S/T Section 3.6.5

T/P Section 3.6.6

P, S, T

P, S Section 8.6

P, S, T Section 8.2

Reference

Section 3.2.1

Section 3.6.1

Section 3.2.2

Section 3.6.2

Section 3.6.3

P Chapter 14

P Section 8.4

Low-pass filter

Machine analyzer function

Machine simulation

Gain search function

Robust disturbance

compensation

Advanced Gain search

Suppresses high-frequency resonance which occurs as servo

Analyzes the frequency characteristic of the mechanical

system by simply connecting a personal computer installed Set

up software(MR Configurator2TM) with a driver.

Set up software(MR Configurator2

Can simulate machine motions on a personal computer screen

on the basis of the machine analyzer results.

Set up software(MR Configurator2

Personal computer changes gains automatically and searches

for overshoot-free gains in a short time.

Set up software(MR Configurator2

This function provides better disturbance response in case of

low response level due to high load inertia moment ratio for the

roll send axes.

Set up software(MR Configurator2

Advanced Gain search automatically searches for the optimum

parameter for settle time to be short.

The gain can be adjusted by setting sequentially in accordance

with wizard screens.

Set up software(MR Configurator2

TM

) is necessary for this

TM

) is necessary for this

TM

) is necessary for this

TM

) is necessary for this

TM

) is necessary for this

P, S, T Section 8.5

P

P

P

P, S, T

P

Slight vibration suppression

Suppresses vibration of 1 pulse produced at a servo motor

1 - 5

P

Parameters

1. FUNCTIONS AND CONFIGURATION

Control mode

Parameters

No.PA06, PA07

to the servo motor shaft varies.

Position smoothing

Speed can be increased smoothly in response to input pulse.

P

Parameter No.PB03

deceleration time constant

regenerative power.

Alarm history clear

Alarm history is cleared.

P, S, T

Parameter No.PC18

restarted by merely switching on the start signal.

different types.

Forward rotation start, reverse rotation start, servo-on (SON)

CN1 connectors.

Parameters

PD10 to PD12

connectors.

PD18

Section 5.1.11

No.PC05 to PC11

Status display

Servo status is shown on the 5-digit, 7-segment LED display

P, S, T

Section 6.3

display.

Use this function for output signal wiring check, etc.

analog speed limit (VLA) of 0V.

for positioning operation and program operation.

Analog monitor output

Servo status is output in terms of voltage in real time.

P, S, T

Parameter No.PC14

(MR Configurator2TM)

status display, etc. can be performed.

output in 3-bit code.

Note. P: Position control mode, S: Speed control mode, T: Torque control mode

P/S: Position/speed control change mode, S/T: Speed/torque control change mode, T/P: Torque/position control change mode

Function Description

Electronic gear Input pulses can be multiplied by 1/50 to 50. P

(Note)

Reference

Auto tuning

S-pattern acceleration/

Return converter

Restart after instantaneous

power failure

Command pulse selection

Input signal selection

(Device settings)

Output signal selection

(Device settings)

Torque limit Servo motor torque can be limited to any value. P, S

Speed limit Servo motor speed can be limited to any value. T

External I/O signal display

Automatically adjusts the gain to optimum value if load applied

Speed can be increased and decreased smoothly. S, T Parameter No.PC03

Used when the regenerative option cannot provide enough

If the input power supply voltage had reduced to cause an

alarm but has returned to normal, the servo motor can be

Command pulse train form can be selected from among three

and other input device can be assigned to certain pins of the

Trouble (ALM), dynamic brake interlock (MBR) and other

output device can be assigned to certain pins of the CN1

ON/OFF statuses of external I/O signals are shown on the

P, S Chapter 7

P, S, T Section 12.4

S Parameter No.PC22

P Section 5.1.12

P, S, T

P, S, T

P, S, T Section 6.7

No.PD03 to PD08,

Parameters

No.PD13 to PD16,

Section 3.6.1 (5)

Section 3.6.3 (3)

Parameter

Output signal (DO)

forced output

Automatic VC offset

Test operation mode

Set up software

Alarm code output

Output signal can be forced on/off independently of the servo

status.

Voltage is automatically offset to stop the servo motor if it does

not come to a stop at the analog speed command (VC) or

JOG operation, positioning operation, motor-less operation,

DO forced output and program operation.

However, Set up software(MR Configurator2

Using a personal computer, parameter setting, test operation,

If an alarm has occurred, the corresponding alarm number is

TM

) is necessary

P, S, T Section 6.8

S, T Section 6.4

P, S, T Section 6.9

P, S, T Section 12.8

P, S, T Section 9.1

1 - 6

1. FUNCTIONS AND CONFIGURATION

(

)

(○:Applicable

Inapplicable)

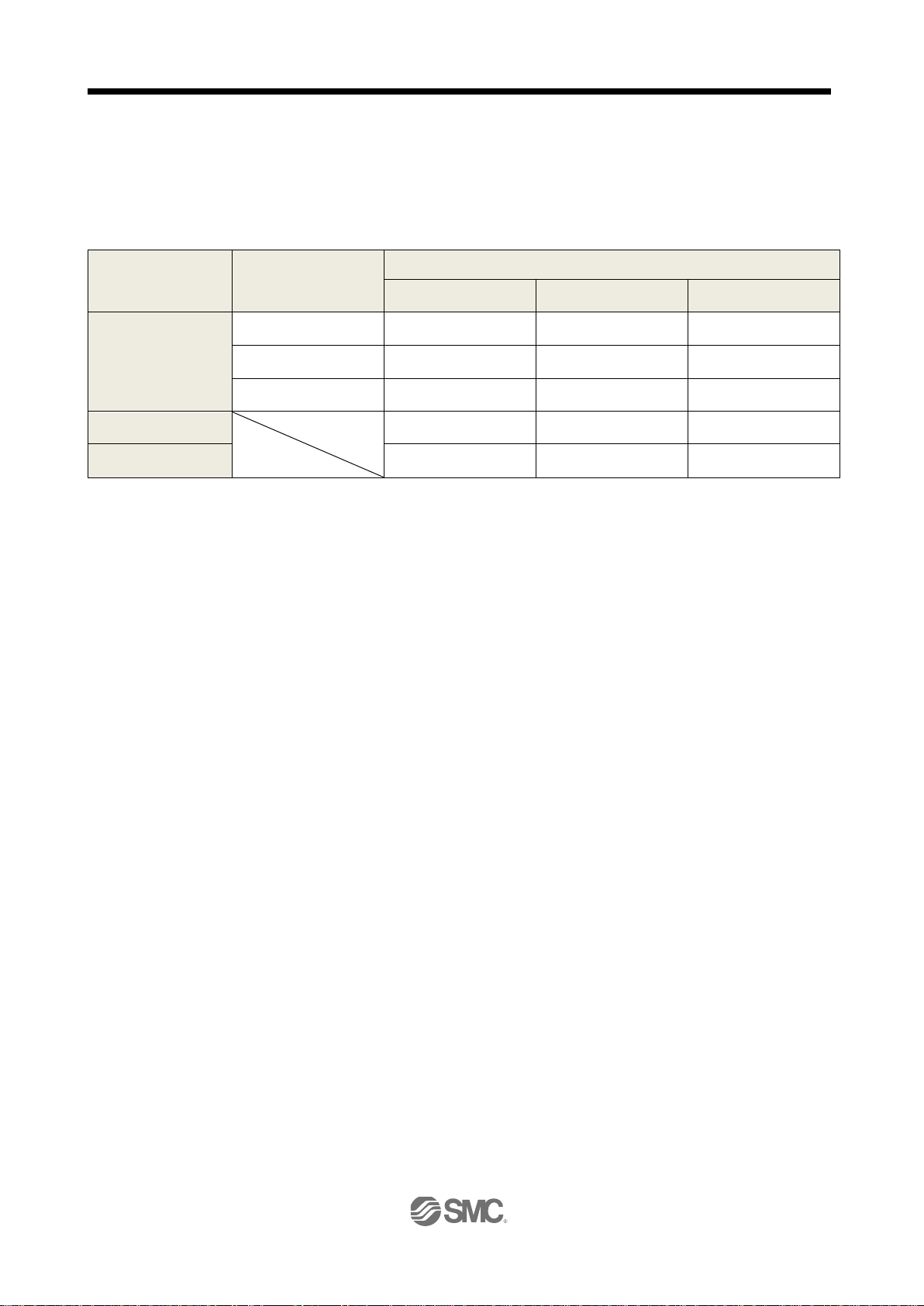

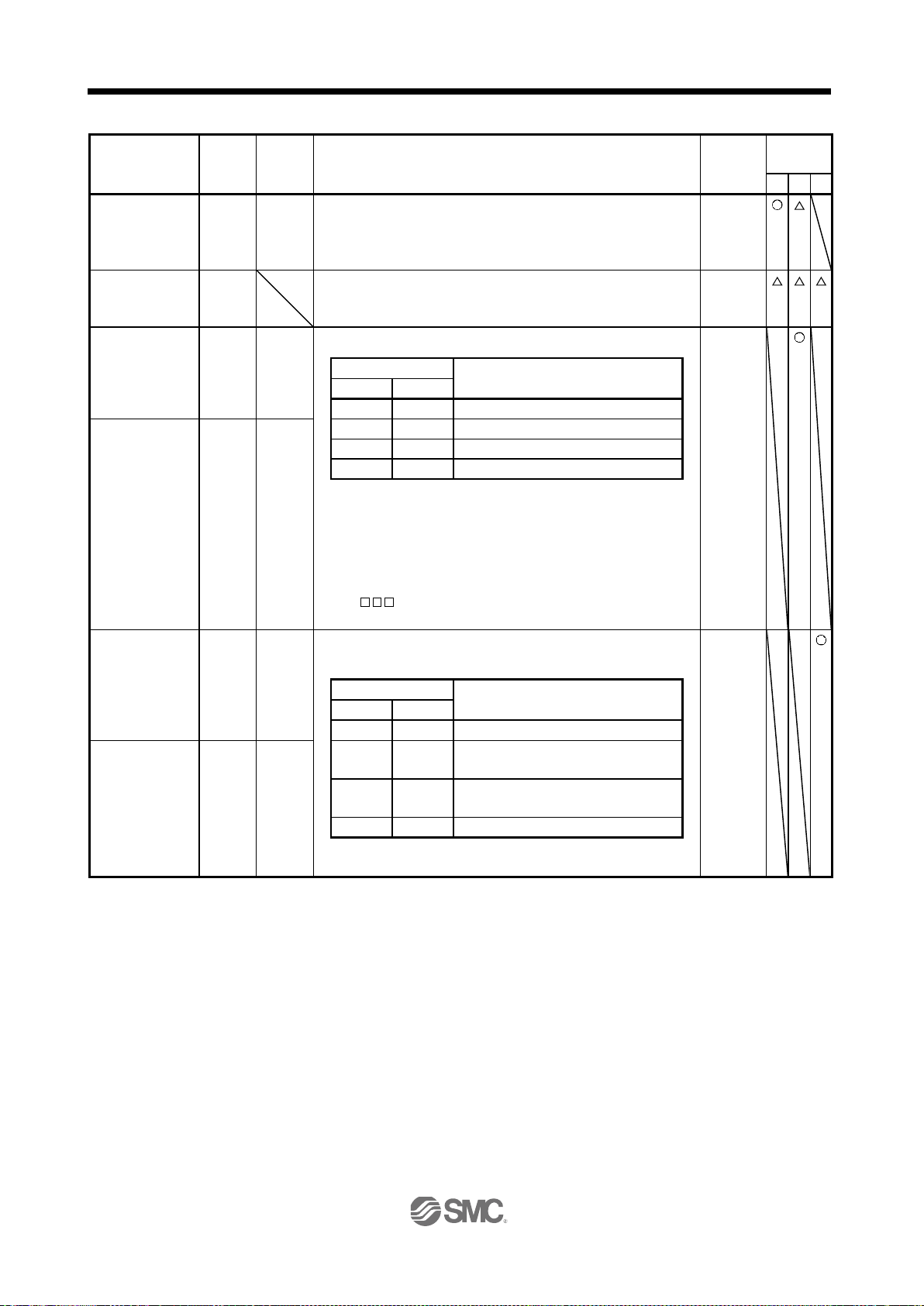

1.4.1 Applicable control mode for each actuator. The following control mode can be selected for applicable actuators. Please refer 「3. SIGNALS AND WIRING」and「5. PARAMETERS」about wiring and parameter setting.

Table. Applicable control mode.

Driver type Actuator type

Control mode

Position control Speed control Torque control

Note 1) 2)

Selected by parameter number PA1.

,×:

LECSB

(

Absolute

)

LEY ○ ○

LEF ○ × ×

Note 2)

○

Note2 )

LEJ ○ × ×

Command method

[Pulse train] [ON/OFF Signal] [ON/OFF Signal]

Operation method

Positioning operation Setting speed operation Setting t orque operation

Note 1. The control change mode cannot be used.

Note 2. Make the moving range limitation by external sensor etc to avoid actuator hitting to the work

piece or stroke end.

When using the thrush control, the following parameter should be set.

If not, it will cause malfunction.

LECSB : The value of the parameter value [PC13] “Analog torque maximum output command”

should be 30 (Maximum thrush of the product) or less. (LEY63 : 50% or less).

When the control equivalent to the pushing operation of the controller LECP series is performed,

select the LECSS / LECSS-T driver and combine it with the Motion or Simple Motion (manufactured

by Mitsubishi Electric Corporation) which has a pushing operation function.

1 - 7

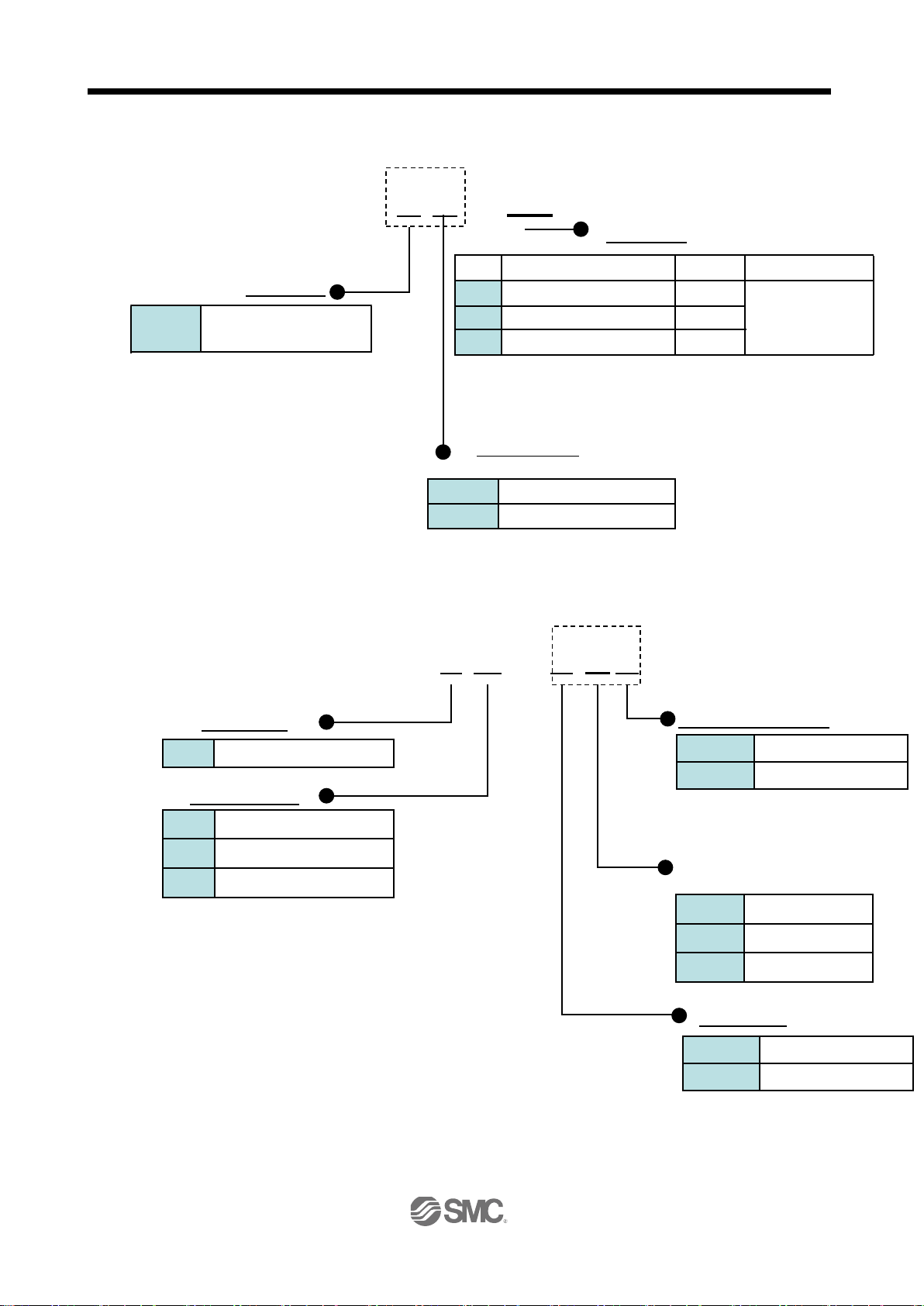

1. FUNCTIONS AND CONFIGURATION

LE

Cable Content

AC Servo motor

S

Encoder cable

E

Lock cable

B

Motor cable

M

Motor Type

2m

2

5m

10m

A

Cable Length (L) [m]

Opposite axis side

B

Axis side

A

Connector Direction

Robot cable

R

Standard cable

S

Cable Type

Motor type

S5

Driver Type

AC200~230V 50,60Hz

AC100~120V 50,60Hz

2

1

Power supply

B

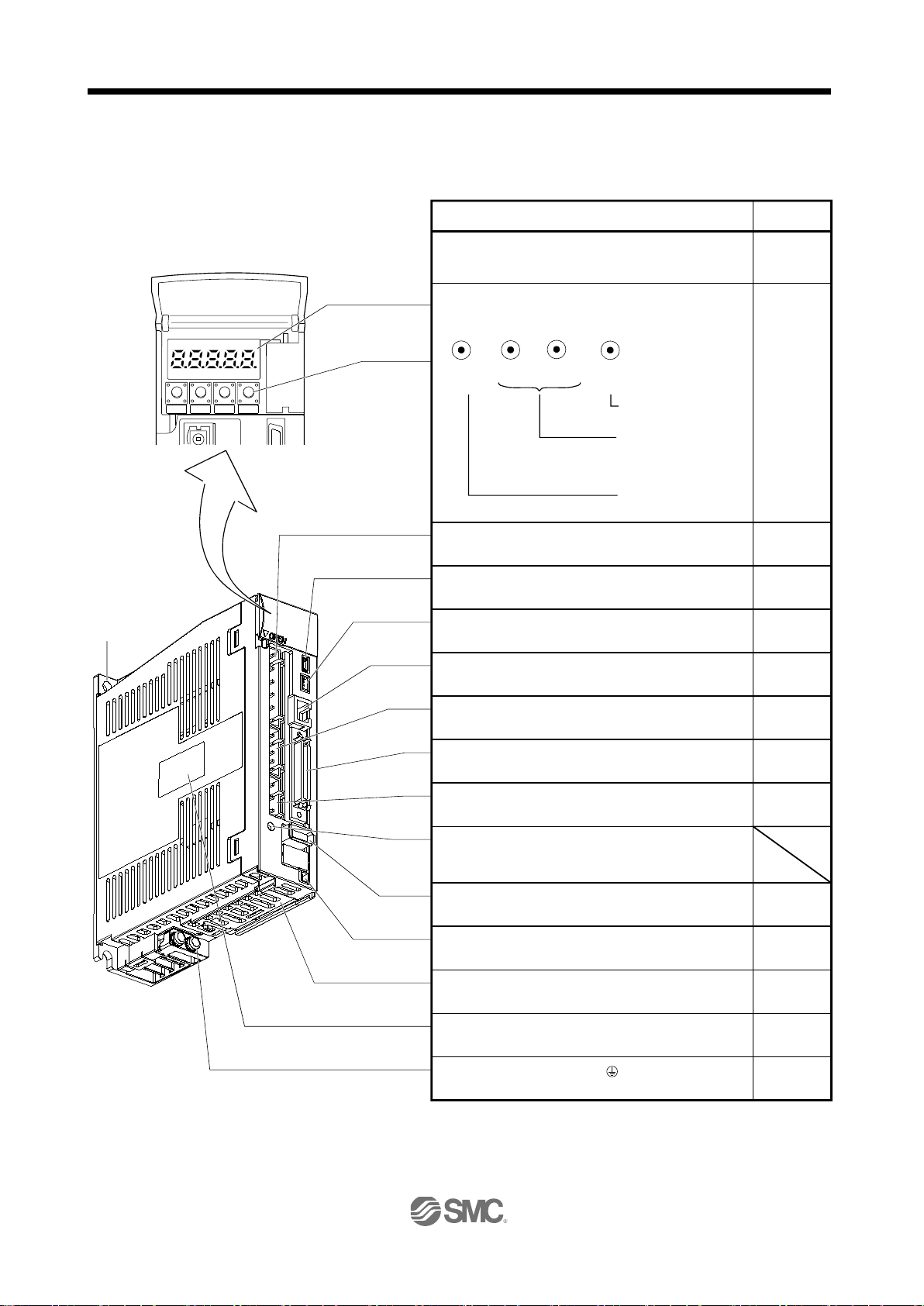

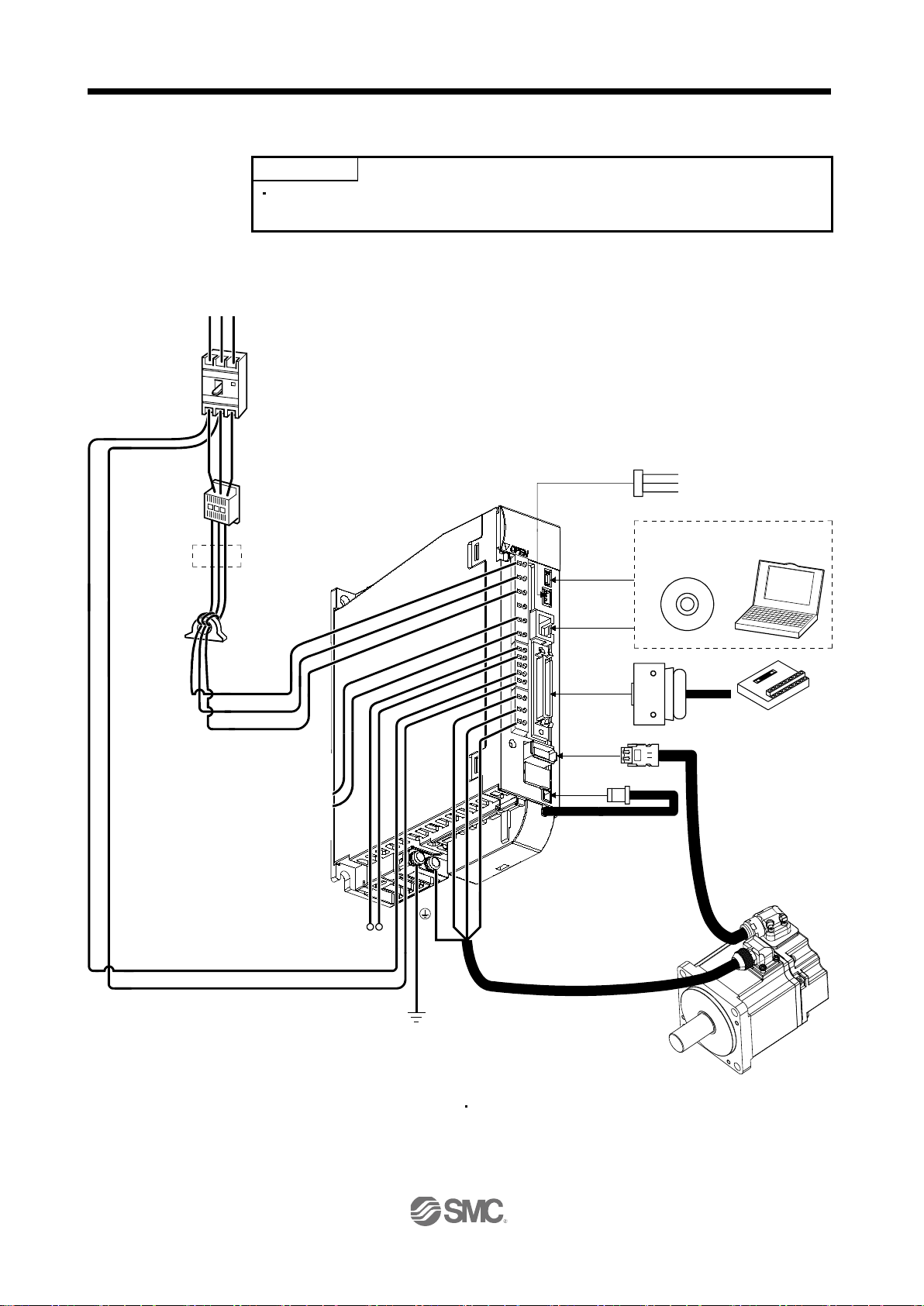

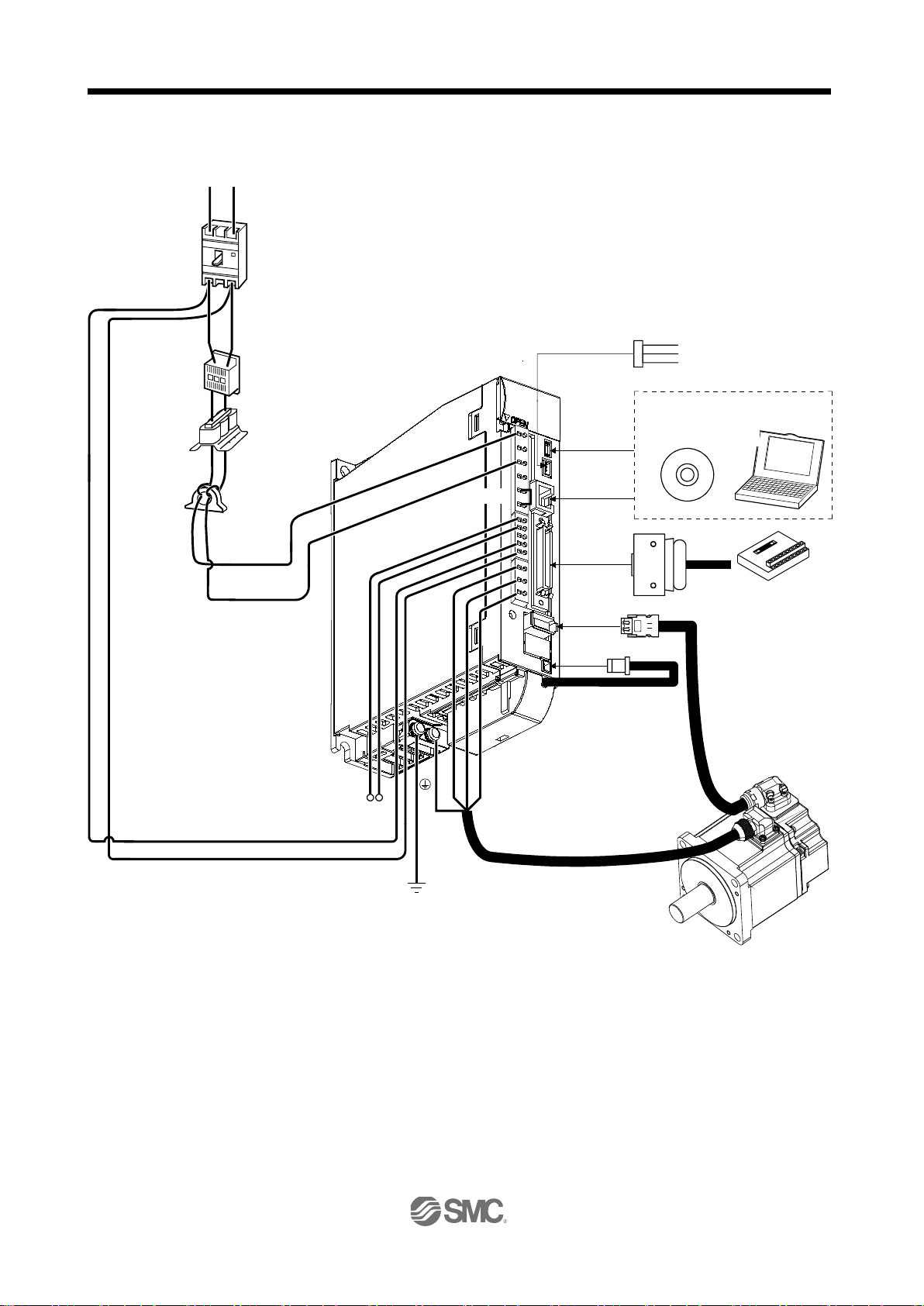

Pulse input type