Page 1

Doc.no. LEC-OM03403

Product name

Electric actuator controller

Gateway (GW) unit (Profibus type)

Model / Series

LEC-GPR1

Page 2

Contents

1. Safety Instructions.................................................................. 4

2. Outlines of Product ................................................................ 7

2. 1 Features................................................................................................................ 7

2. 2 How to Order ...................................................................................................... 7

2. 3 Structure of

2. 4 Procedure (How to start the actuator) ................................................... 9

(1) Checking the conte

(2) Mounting the unit....................................................................................... 9

(3) Initial setting of the

(4) Setting the unit........................................................................................... 9

(5) Unit wiring /

(6) Power su

(7) Operation .................................................................................................... 10

the product ................................................................................ 8

nt of the package ................................................ 9

connect controller ............................................. 9

Connection......................................................................... 9

pply ............................................................................................. 10

3. Specifications .............................................................................11

3. 1 Specifica

3. 2 Details

3.3 Outside dimension diagram............................................................................14

(1) Screw mount ty

(2) DIN rail mount typ

3.4 How to install......................................................................................................15

tions.................................................................................................... 11

of parts................................................................................................. 13

pe (LEC-GPR1)......................................................... 14

e (LEC-GPR1D) ................................................... 14

(1) How to i

(2) Installation l

nstall............................................................................................. 15

ocation ................................................................................. 15

4. Initial Setting...............................................................................16

4. 1. Switch (Addr

4. 2. Setting the switch to change the communication (CN2SW)........... 17

4. 3. Setting of co

4. 4 SIEMENS PLC S7 C

ess, B RATE).......................................................................... 16

ntroller (LEC)..........................................................................18

onnection Method ................................................... 21

5. External connection .................................................................23

5. 1 CN4: Power supply connector ....................................................................23

5. 2 CN3: Bus connector

5. 3 CN1: CONT connector...................................................................................23

5. 4 CN2: PC/TB connector.................................................................................24

.......................................................................................23

6. CN4: Power supply connector .............................................25

- 1 -

Page 3

6.1 Power supply connector................................................................................. 25

6.2 Power line............................................................................................................ 25

6.3 Wiring of the shutdown circuit......................................................................26

【Shutdown circuit Example】 ...................................................................... 28

7. CN3: Bus conecter ...................................................................29

8. CN1: Controller IF communication connector (CONT)30

8. 1 Connection......................................................................................................... 30

8. 2 Wiring diagram................................................................................................... 32

9. CN2: TB/PC connector..........................................................33

9. 1 How to use......................................................................................................... 33

10. LED display................................................................................34

10. 1 LED display...................................................................................................... 34

10. 2 Controller IF communication status and LED display......................35

11. Mode.............................................................................................36

11. 1 Outline............................................................................................................... 36

11. 2. Step data i

11. 3. Numerical data

11. 4. Data writing mode ........................................................................................38

nput mode ................................................................................. 36

input mode.......................................................................36

12. Memory map .............................................................................39

12. 1 Memory assignment...................................................................................... 39

12. 2 Controller IF sta

12. 3 Gateway unit stat

12. 4 Gateway unit contr

tus flag(IN Data)..........................................................43

us flag(IN Data)......................................................... 43

ol flag(OUT Data) .................................................. 45

13. Precautions for controlling the controller (LEC)....46

13. 1. Communication delay between the gateway unit unit and the

13. 2. Guideline of the Response delay between the Gateway and the

........................................................................................................................................ 47

controller(LEC) 46

Motor Control Unit

14. Wiring of cables/Common precautions..........................48

15. Electric actuators/Common precautions .....................49

15.1 Design and selection ..................................................................................... 49

15.2 Mounting.............................................................................................................50

15.3 Handling.............................................................................................................. 51

15.4 Operating environment ................................................................................. 52

- 2 -

Page 4

15.5 Maintenance ..................................................................................................... 53

15.6 Precautions for a

16.

Gateway unit and its peripheral devices /Specific product precautions

16.1 Design and selection ..................................................................................... 54

16.2 Handling.............................................................................................................. 54

16.3 Mounting.............................................................................................................55

16.4 Electrical wiring ............................................................................................... 56

16.5 Power supply.................................................................................................... 56

16.6 Grounding...........................................................................................................56

16.7 Maintenace........................................................................................................ 57

ctuator with lock...........................................................53

54

- 3 -

Page 5

LEC-G Series/Gateway unit

1. Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions are categorized into three groups, "Caution", "Warning" and "Danger" depending on

the level of hazard and damage, and the degree of emergency. They are all important notes for safety

and must be followed in addition to International Standards (ISO/IEC), Japan Industrial Standards

(JIS)*1) and other safety regulations*2).

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

JIS B 8370: Pneumatic fluid power - General rules relating to systems

JIS B 8361: Hydraulic fluid power - General rules relating to systems

JIS B 9960-1: Safety of machinery - Electrical equipments of machines (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety, etc/

*2) Labor Safety and Sanitation Law, etc.

Caution

Warning

Danger

Caution indicates a hazard with a low level of risk which, if not avoided, could result in

minor or moderate injury.

Warning indicates a hazard with a medium level of risk which, if not avoided, could result

in death or serious injury.

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death

or serious injury.

Warning

(1) The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with

specific equipment must be decided by the person who designs the equipment or decides its

specifications based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the

person who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest

catalog information, with a view to giving due consideration to any possibility of equipment failure

when configuring the equipment.

(2) Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment must be performed by an

operator who is appropriately trained and experienced.

(3) Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures

to prevent dropping of driven objects or run-away of machinery/equipment have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the

specific product precautions of all relevant products carefully.

3.

Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

- 4 -

Page 6

Warning

(4) Contact SMC beforehand and take special consideration of safety measures if the product is

to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a location

exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space,

shipping, vehicles, military, medical treatment, combustion and recreation, or equipment in contact

with food and beverages, emergency stop circuits, clutch and brake circuits in press applications,

safety equipment or other applications unsuitable for the standard specifications described in the

product catalog.

3. An application which could have negative effects on people, property, or animals requiring special

safety analysis.

Use in an interlock circuit, which requires the provision of double interlock for possible failure by using

a mechanical protective function, and periodical checks to confirm proper operation. Check the

product regularly in order to confirm normal operation.

- 5 -

Page 7

LEC-G Series/Gateway unit

Safety Instructions

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

[Limited warranty and Disclaimer]

(1) The warranty period of the product is 1 year in service or within 1.5 years after the product is

delivered.

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

(2) For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to SMC product independently, and not to any other damage

incurred due to the failure of the product.

(3) Prior to using SMC products, please read and understand the warranty terms and disclaimers

noted in the specified catalog for the particular products.

[Compliance Requirements]

When the product is exported, strictly follow the laws required by the Ministry of Economy, Trade and

Industry (Foreign Exchange and Foreign Trade Control Law).

- 6 -

Page 8

2. Outlines of Product

2. 1 Features

The gateway unit (GW unit, hereafter) is the unit to connect the electric actuator controller (LEC

series) to Profibus. One unit can control up to 5 same type of controllers.

Caution

When the device is set up or failure occurs, please refer the operation manual of the controller, the

actuator, and the teaching box as well as this operation manual.

※Keep this operation manual accessible so it can be referred when necessary.

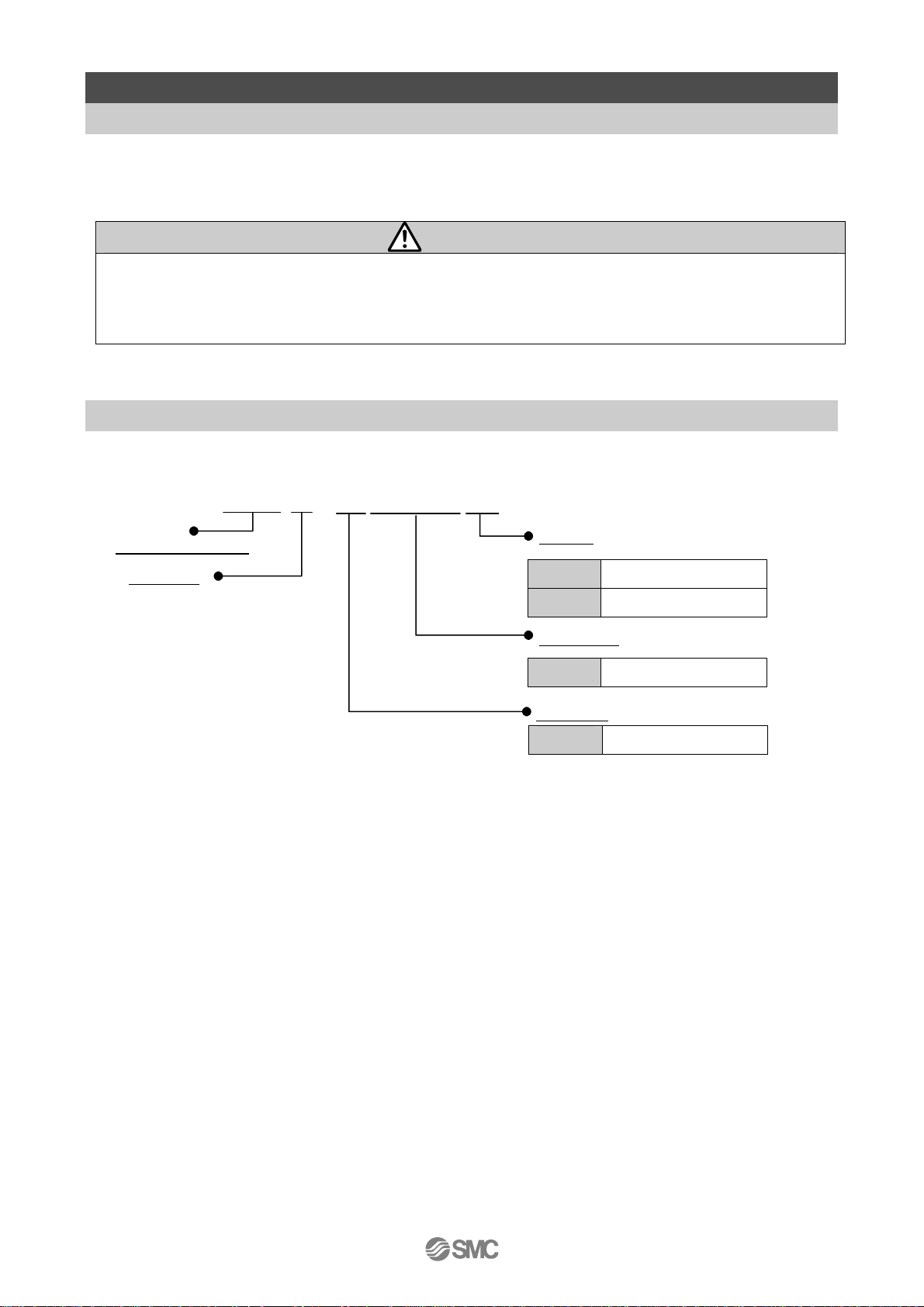

2. 2 How to Order

How to order is shown below.

LEC-GPR1□

Electric equipment

Controller

DIN rail

Nil Not mountable.

D Mountable

Applicable

PR1 Profibus DP V1

Unit types

G Gateway unit

- 7 -

Page 9

2. 3 Structure of the product

The system aplies this unit consists of the unit below.

System structure drawing.

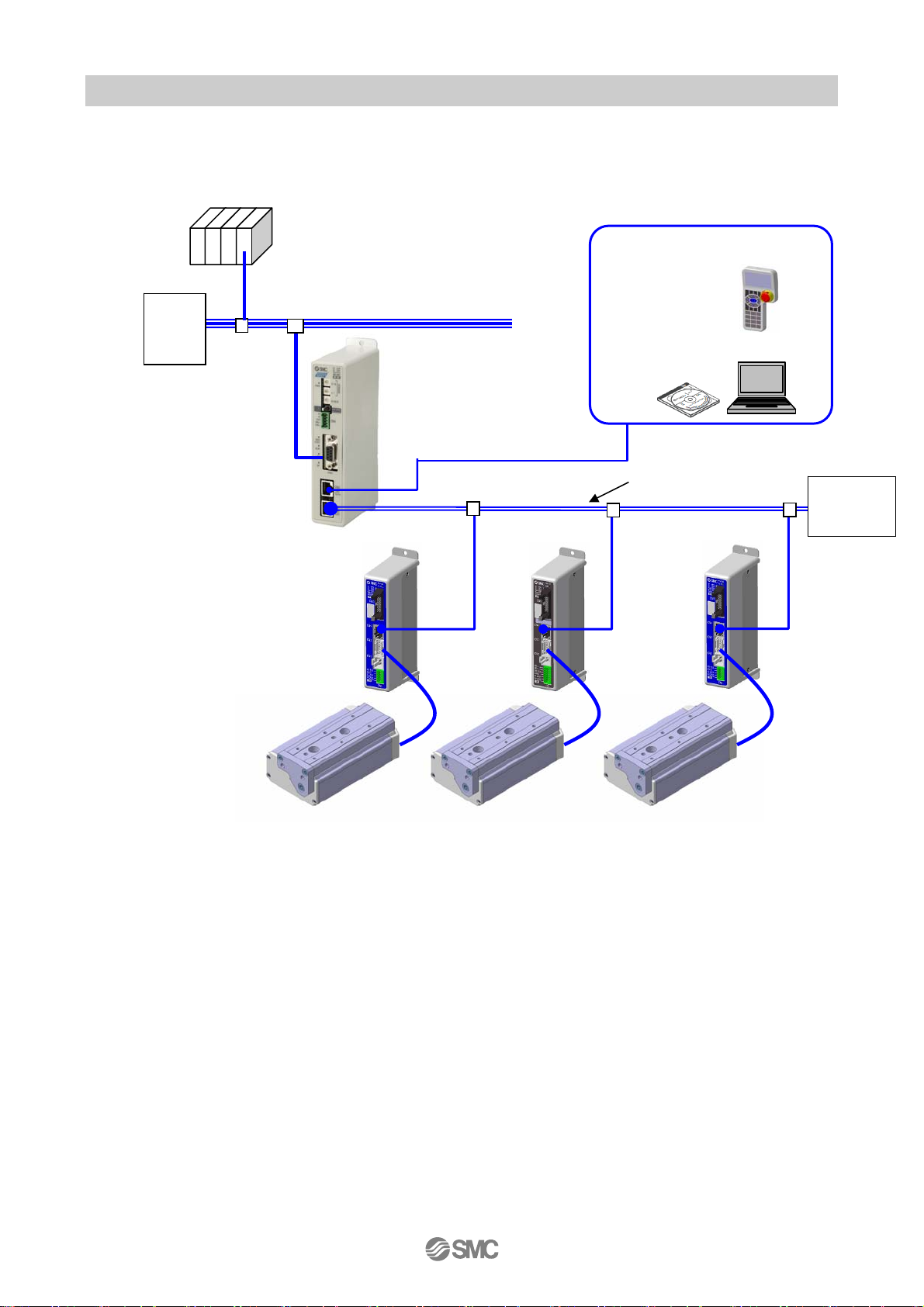

PLC

Profibus

Ter m

Teaching box

LEC-T1-3G

inati

Motor controller

LEC Series

Electric actuator

LE Series

Gateway unit

LEC-GPR1

Controller setting software

LEC-W2

LEC serial communication (RS485)

Modbus communication

Termination

Resistor

・

- 8 -

Page 10

2. 4 Procedure (How to start the actuator)

Install, wire, set and operate the gateway unit referring to the procedure below when the product is

used for the first time.

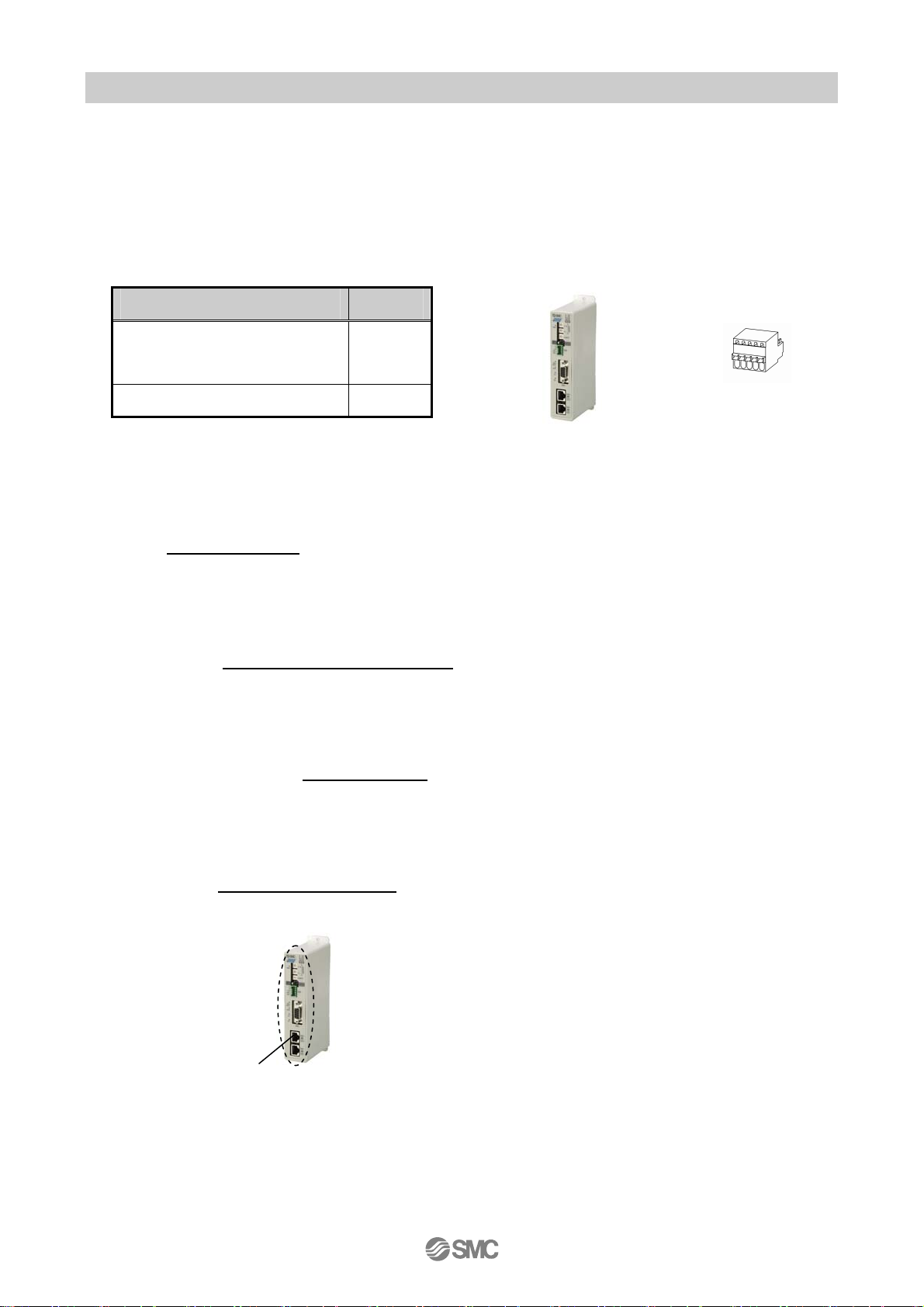

(1) Checking the content of the package

ter unpacking, check the description of the label to identify the gateway unit and the quantity of

Af

accessories.

Part’s name Quantity

Gateway unit

LEC-GPR1)

(

Power supply connector 1 pc.

1 pc.

Gateway unit

Power supply connector

(*)

These items are included if you ordered by the part number for a set of controller and actuator.

(2) Mounting the unit

Refer to 3.4

How to install

for the mounting of the gateway unit.

(3) Initial setting of the connect controller

The p

arameters of the controller’s, that are is connected to the gateway unit need to be set.

Refer to section 4.4 Setting of controller (LEC)

(4) Setting the unit

It

is necessary to set the node address and the communication speed by the rotary switch of the

gateway unit. Refer to section 4. Initial Setting

(5) Unit wiring / Connection

Conn

ect cables to the connectors(CN1 to CN3) of the gateway unit.

Refer to section 5. External connection

for the wiring of connectors.

Connector

- 9 -

Page 11

(6) Power supply

Supply po

wer 24V DC.

Caution

0V line of the gateway unit and the motor controller (LEC) have to be common.

When power is supplied in order of the gateway unit, then the controller (LEC), reset the data link

after supplying power to the controller (LEC).

(Refer to

If the condition is normal, LED on the front of the gateway unit turns on as the table below when power

is supplied.

12.4 Gateway unit control flag

Functions LED

condition

PWR Green On Supply of power

BUS STAT Green

Controller IF is communicating

for the details of data link reset).

Condition

flashing

ALM Green

flashing

CN2 STAT Off CN2 (TB/PC terminal) invalid

SF Green On

BF Green On

Refer to

If LED [ALM] on the front panel of the gateway unit shows red, an alarm conditions has occured.

(7) Operation

Refer to

series as well.

10. LED display

12. Memory

map

No alarm

System fault

BUS fault

for the explanation of LED lamps.

for the assignment of the memory. Read the operation manual of LEC

normal

normal

- 10 -

Page 12

3. Specifications

3. 1 Specifications

Basic specifications of the product.

Item Specifications

Rated voltage 24 VDC±10%

Current consumption 200mA or less (When teaching box is not connected)

300mA or less (When teaching box is connected)

Applicable controller Electric actuator controller (LEC series)

Product to be connected Max. 5pcs.

I/O occupation area

(Input/Output)

When conformity to UL is required, the electric actuator and controller should be used with a UL1310

Class 2 power supply.

【Profibus spec】

Item Specifications

Fieldbus Profibus DP –V1

Device type DP slave

Communication speed Auto baud rate

Address setting range 0 to 125

ID Number 1414

Configuration file GSD

Terminating resistor None

Connecter type D-sub

Input 57words / Output 57 words

【Controller IF communication spec. 】

Item Specifications

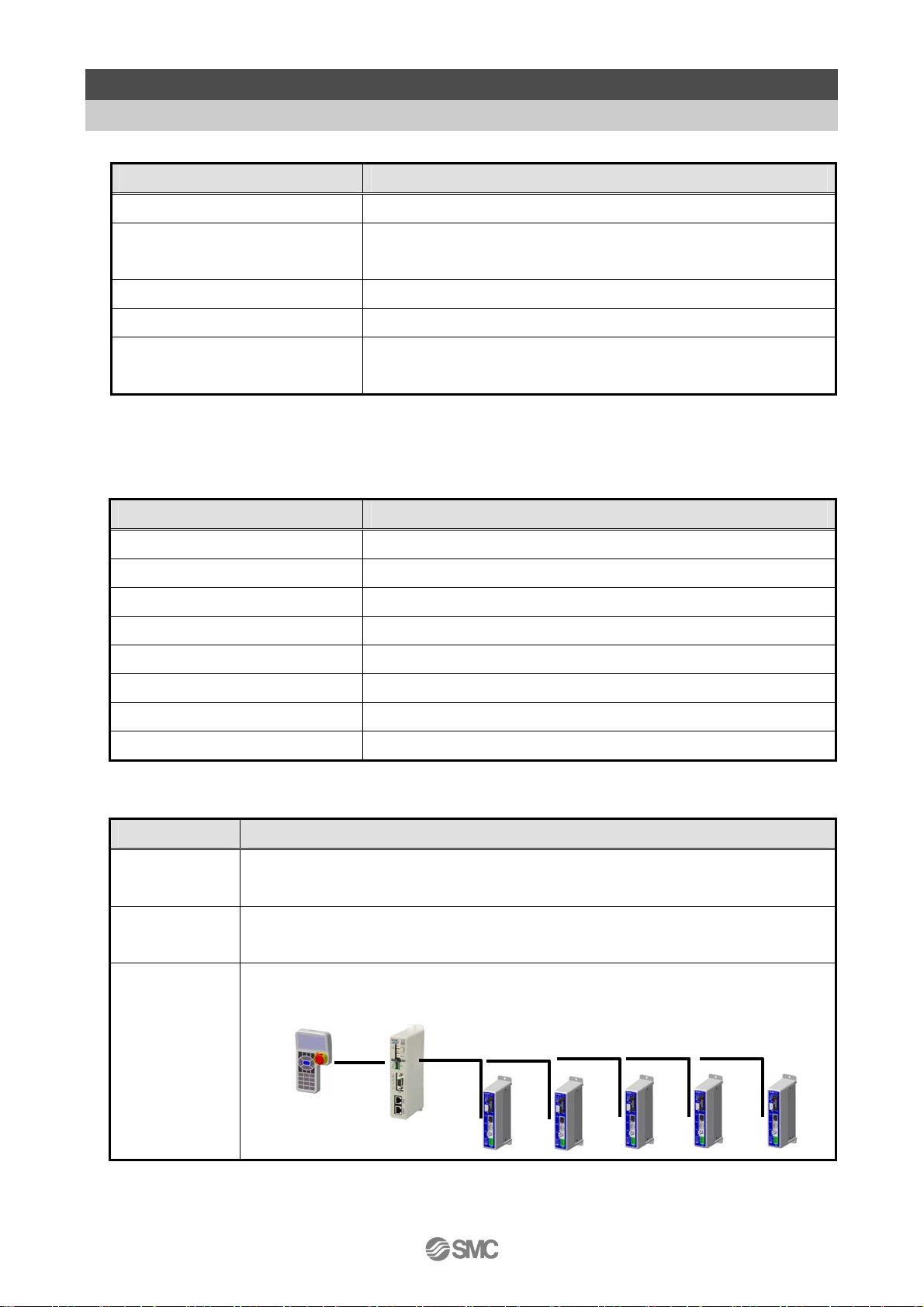

Serial

communication

Communication

speed

Cable length The cable for the teaching box (3m) and the electric actuator controller (5m x 5)

RS485 (Modbus protocol compliant)

115.2k or 230.4kbps (Select 115.2kbps when the teaching box is connected)

makes 28m of cable length. This is the maximum cable length.

3m

5m

- 11 -

5m

5m

5m 5m

Page 13

【Conditions of environment 】

Item Specifications

Applicable ambient temperature 0~40℃(No freezing)

Applicable ambient humidity 90%RH or less (No condensation)

Atmosphere No corrosive gas, flammable gas, oil mist, or particles.

Storage temperature -10~60℃(No freezing)

Storage humidity 90%RH or less (No condensation)

Vibration 4.9m/s2 (0.5G) or less

Enclosure IP20

Mass

200g (screw mount type)

220g (DIN rail mount type)

- 12 -

Page 14

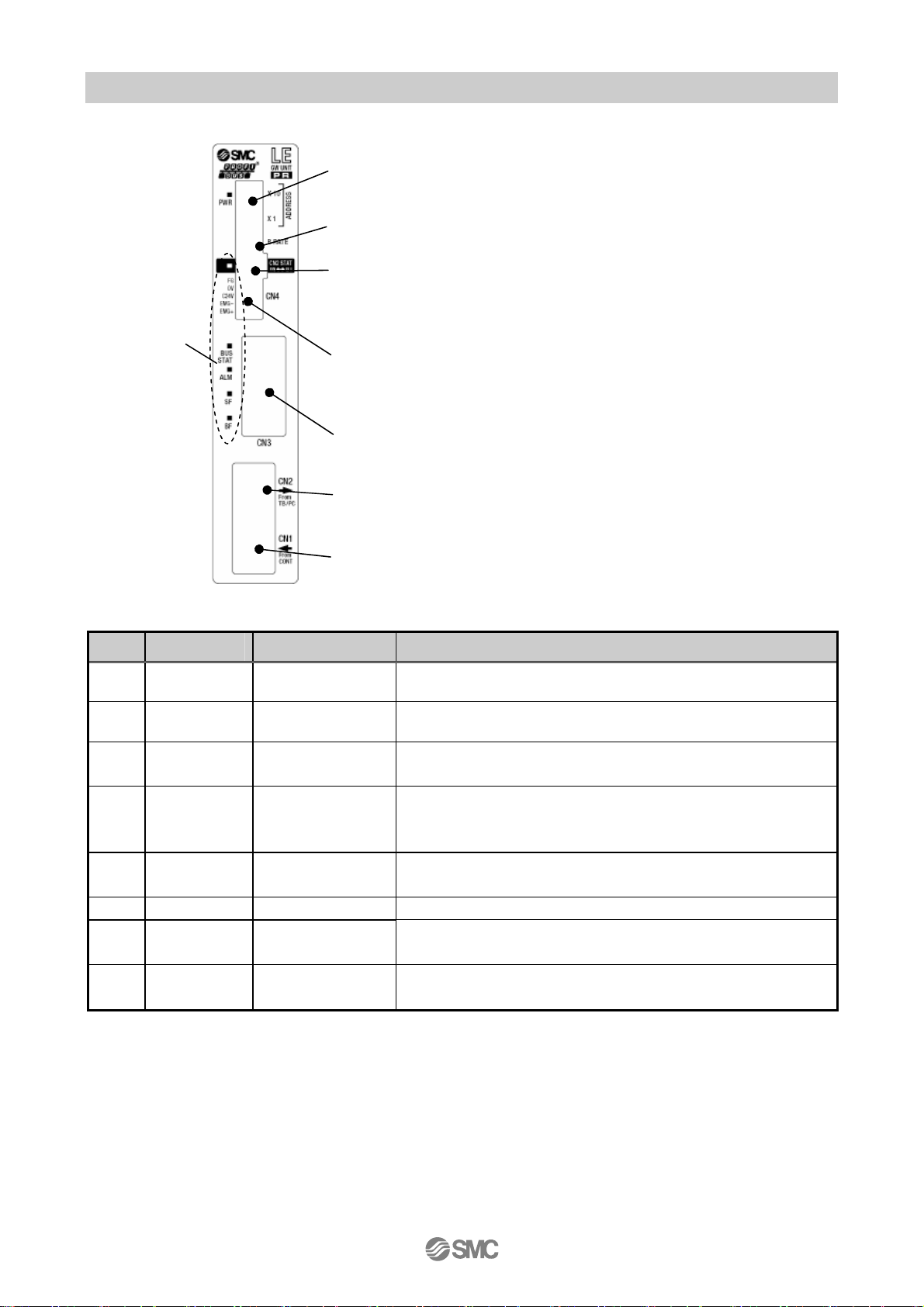

3. 2 Details of parts

Details of parts of the gateway unit

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

No. Display Description Detail

1 - LED lamp LED to indicate the condition of the gateway unit

2 ADDRESS Address switch This switch sets X1 and X10 in the address.

3 B RATE

4 CN2 SW

5 CN4

6 CN3 Bus connector Connect Profibus line.

7 CN2 TB/PC connector

8 CN1 CONT connector

Communication

speed

Communication

switch

Power supply

connector

The switch to set the communication speed of the

controller IF communication line.

Disables the communication with the controller IF

communication line, and ables the communication with the

equipment which are connected to CN2.

Connect the power supply and EMG.

The connector which connect LEC teaching box (LEC-T1)

or the ACT software Controller for setting (LEC-W2)

The connector for the controller IF communication line.

Connect the motor controller (LEC series).

- 13 -

Page 15

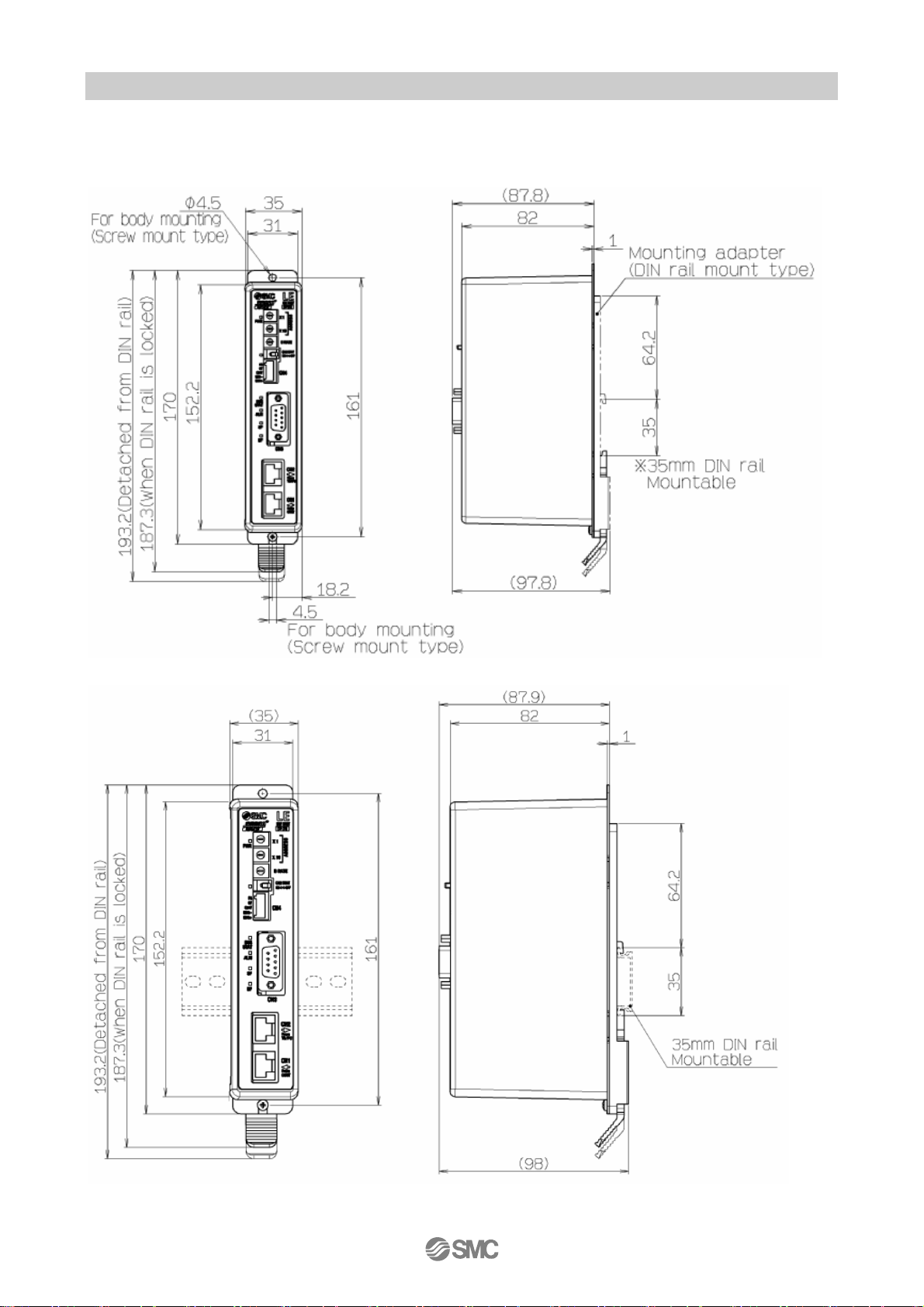

3.3 Outside dimension diagram

The outside view of this product is as shown in the diagram below:

(1) Screw mount type (LEC-GPR1)

(2) DIN rail mount type (LEC-GPR1

D)

- 14 -

Page 16

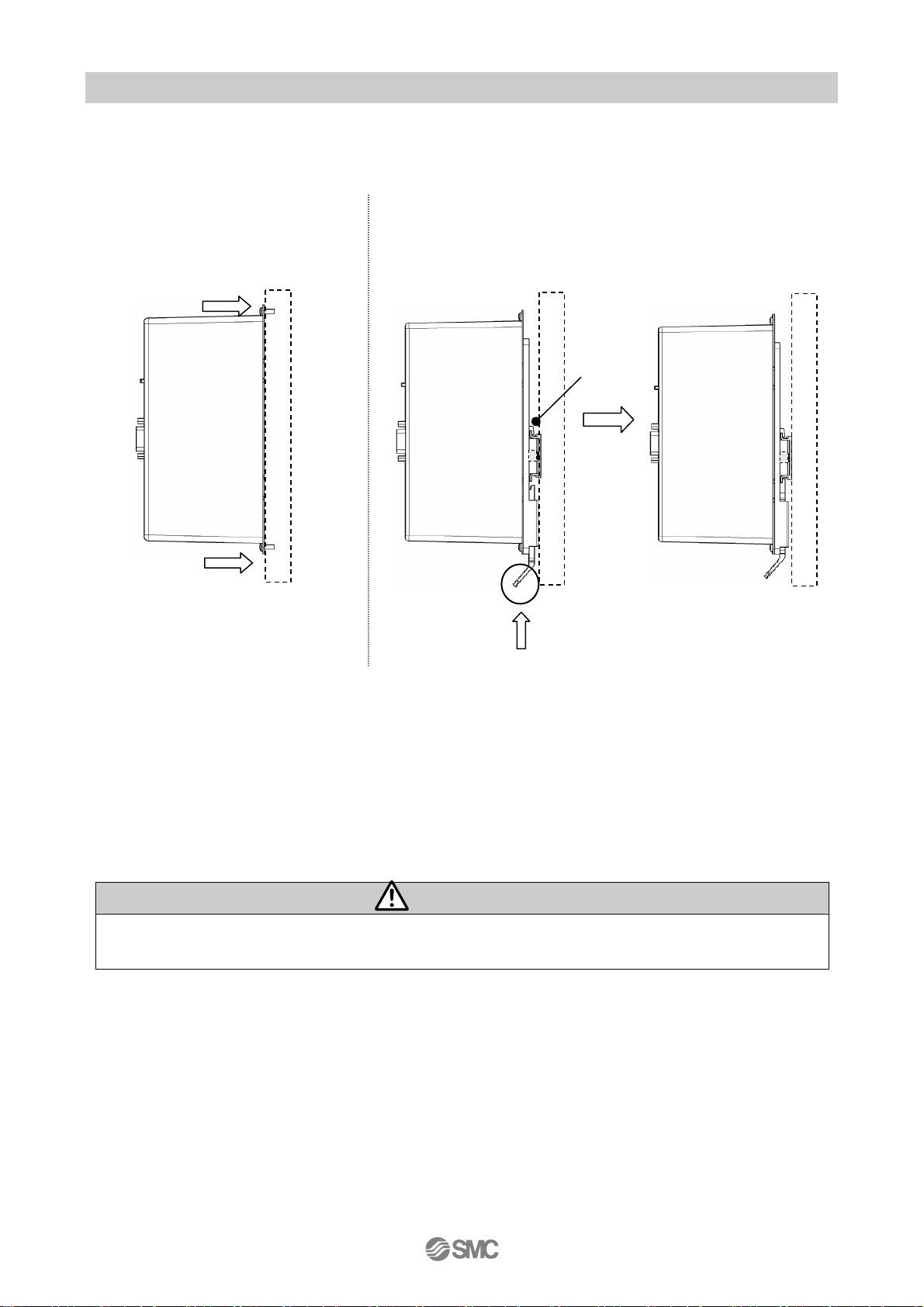

3.4 How to install

(1) How to install

There are two types of controllers; screw mount type and DIN rail mount type.

The followings are the descriptions on how to install each type:

[1] Screw mount type (LEC-GPR1)

(Installation with two M4 screws)

Screw direction

[2] DIN rail mount type (LEC-GPR1D)

(Installation with the DIN rail)

DIN rail is locked.

Screw direction

(2) Installation location

Please inst

not exceed 40

all this gateway unit at an appropriate place where the surrounding temperature will

o

C.

DIN rail

A

Hook the controller on the DIN rail and

press the lever of section A in the arrow

direction to lock it.

Caution

Install the gateway unit on a flat surface. Excessive pressure applied to the housing will damage the

gateway unit.

- 15 -

Page 17

)

4. Initial Setting

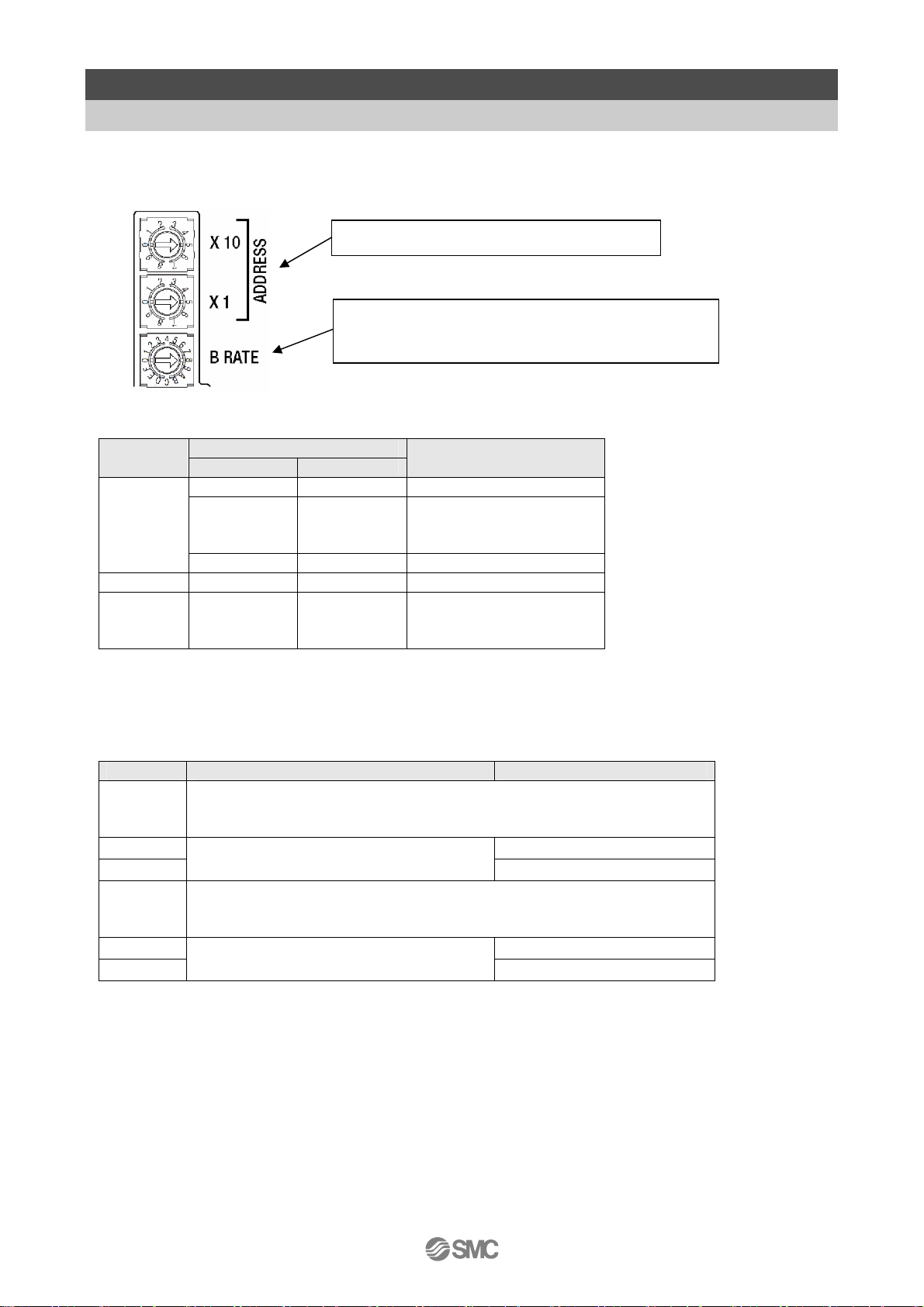

4. 1. Switch (Address, B RATE)

The address of the gateway unit, and the transmission rate of motor controller LEC are set. Table below

shows the setting of switches.

Node address setting

ADDRESS B RATE

X10 X1

0 or 8

1 or 9 0 0 100

0

※ Do not set B RATE to the value of "Unused"

0 0 0

0

:

9

9 9 99

:

2

The address is shown. (0~99

The treble is shown about the transmission rate of

controller IF

Node address

1

:

8

1

:

5

1

:

98

101

:

125

※ Node address becomes 125 when a setup of a node address is set as a larger value than 125.

B RATE switch

B RATE the transmission rate of controller IF Nod address (X100)

F

:

Do not use

A

9 100 ~ 125

8

230.4kbps

1 ~ 99

7

:

Do not use

2

1 100 ~ 125

0

Caution1: Set the controller IF communication speed at 115.2kbps to use the teaching box (LEC-T1-).

Caution 2: Turn off the power supply in order to change the switch setting.

115.2kbps

1 ~ 99

- 16 -

Page 18

4. 2. Setting the switch to change the communication (CN2SW)

Turn ON the communication switch (CN2SW) during Profibus control. If the communication switch

(CN2SW) is turned off during Profibus control, communication error (data link error) is generated in the

gateway unit. Turn OFF communication switch (CN2SW) when changing the setting of controller

(LEC) by connecting the teaching box (LEC-T1-) of setting software (LEC-W2) to PC/TB connector

(CN2).

In this case, the communication from Profibus to the controller (LEC) is cut.

- 17 -

Page 19

4. 3. Setting of controller (LEC)

Initial parameter setting is necessary for the controller (LEC) which is connected to the gateway unit.

Set the following by directly connecting the teaching box (LEC-T1-) or the setting software to the

controller (LEC) before connecting the gateway unit.

Check the operation manual of the controller (LEC) and the teaching box (LEC-T1-) when setting the

controller (LEC).

4. 3. 1 ID setting

ID setting is necessary when connecting two or more controllers (LEC) to the gateway unit.

Assign ID to each controller (LEC) in serial number so that the numbers do not overlap. The setting

range of ID is between 1 to 5.

[Example of ID change procedure using the ACT Controller Setting software (LEC-W2)]

Start the setting software in Normal mode.

Open the parameter window.

4. 3. 2 Setting of the communication speed

It is necessary to match the gateway unit controller IF communication speed with the controller (LEC)

communication speed. Set the controller IF communication speed at 115,2kbps to use the teaching

box (LEC-T1-)

[Communication speed change procedure Setting software (LEC-W2)]

(1) Set the controller ID.

(Letters are changed to blue)

(2) Select Download.

(Changed ID is sent to the controller. ID

set value turns to black)

Start the setting software with Normal mode.

(1) Select [HELP] - [Password] from the menu. Password input screen below appears. Enter "password".

- 18 -

Page 20

(3)

(5)

)

(2) Set the controller so that the communication speed can be changed.

Change "Parameter protect" setting so that "Communication speed" parameter can be changed.

View the parameters of the controller.

Select "Basic" Tab - Item "Parameter protect" to "3: Common + Extend + Step"

The changed data is sent by clicking the download button, and the parameter protect set value text

changes from blue to black.

(3) Select the "Motor" Tab of the parameter window to change item "Comm speed" to "115200" for when

using Teaching box or "230400" for when using ACT Controller software.

(2)-1 Change parameter protect

to [3: Common + Extend + Step].

(2)-2 Select Download.

-1 Select the tag "Motor".

The changed data is sent by clicking the download button, and "Communication speed" set value is

changed from blue to black.

(3)-2 Change the communication speed

to 「115200」

(3)-3 Select Download.

or 「230400」(6

- 19 -

Page 21

(4) Change item "Parameter protect" using “Basic” tab of the display of (2) to "1: Common + Step data"

and click download.

(5) Close the ACT Controller software (LEC-W2) and turn OFF the controller (LEC) power supply. The

changed communication speed will be valid from the next time the controller (LEC) is turned on.

Caution

The communication speed of the gateway unit and the controller (LEC) must match.

If the communication speed does not match, the gateway unit and the controller (LEC) cannot

communicate.

Set the controller IF communication speed to 115,2kbps when using the teaching box (LEC-T1-)

The defaults setting of communication speed in the setting software (LEC-W2) is 38.6kbps.

After changing the communication speed, set the ACT Controller software (LEC-W2)

communication speed to 115.2kbps for Teaching box or 230.4kbps for the ACT controller software.

Do not change any parameters other than "ID setting"/"Communication speed setting".

Otherwise, malfunction can result.

Change "ID setting" / "Communication speed setting" to use the controller (LEC) stand-alone.

- 20 -

Page 22

4. 4 SIEMENS PLC S7 Connection Method

Below is an explanation of the LEC-GPR1 connection method with a SIEMENS PLX STEP7TM.

4.4.1 GSD File Installation

After STEP7TM has been stated.

Open[Hardware Configuration] screen.

Select “Opton-Install New GSD” From the mwnu var.

Select GSD File, and click the Open button.

After completiong the above steps,” Anybus-CC PROFIBUS DP-V1”will automatically be added to the

Hardware Catalog under the STE7TM[PROFIBUS DP][Additional Field Device][General]Folder.

* Screen data used on this document is taken for STEP7TM software by Siemens AG.

4.4.2 Adding Stations

Drag and drop “Anybus-CC PROFIBUS DP-V1”from the Hardware Catalogue to the station window.

[Properties-PROFIBUS interface”dialogue box will be displayed.

Enter the unit address on the dialogue boz.Please make sure that the address entered is the same as

the address set, using the switches.

Pree the OK button to confirm the address setting. “Anybus-CC PROFIBUS DP-V1”will be shown on

the station window.

- 21 -

Page 23

4.4.3 Adding Units

Select “Anybus-CC PROFIBUS DP-V1” from the station window.

Drag and drop the connected unit from [Hardware Catalogue] Windws.

・Input16word

・Input16word

・Input16word

・Universal module

I/O Type: Input,Length: 9,Unit: Words,Consistent over: Total length

・Output16word

・Output16word

・Output16word

・Universal module

I/O Type: Output,Length: 9,Unit:Words,Consistent over: Total length

Please give "I Address" and "Q Address" to me with the crack so as not to overlap.

The figure below is an example to set by "I Address 0-113" and "Q Address 0-113".

It is set completion by downloading the configuration data to PLC.

Input Total 57words

Output Total 57words

- 22 -

Page 24

5. External connection

5. 1 CN4: Power supply connector

Connect the power supply. The gateway unit and the controller (LEC) should have the common 0V line.

Gateway

Unit

CN4

Power supply line

Power supply

(24 VDC)

(Cables, PLC and power supply are prepared by customer)

* Refer to 6. CN4: Power supply connector

5. 2 CN3: Bus connector

Connect the Profibus line and the controller (LEC) with the communication cable (LEC-CG□-□)

Gateway

Unit

CN3

* Refer to 7. CN3: Bus connector

Profibus line.

(Cables, PLC and power supply are prepared by customer)

PLC

5. 3 CN1: CONT connector

Connect the gateway unit and the controller (LEC) to communication cable (LEC-CG□-□).

Gateway

unit

Controller input power supply

24 VDC

CN1

Terminating Resistor

(120 1/4W)

CN4

* Refer to section 8. CN1: Controller IF communication connector (CONT)

Controller (LEC) Controller (LEC)

CN4

Controller (LEC)

- 23 -

CN4

Page 25

Caution

Do not pull out the cable between the gateway unit and the cable, or cut off the power

supply to the controller (LEC). Communication is interrupted.

5. 4 CN2: PC/TB connector

The connector which connects the tools teaching box (LEC-T1-3*G*) or PC (LEC-W2) for setting the

controller (LEC.

The data link of the gateway unit and the controller (LEC) data is cut by turning off CN2SW or

stopping data link, and communication with the tool teaching box (LEC-T1-3*G*) for setting the controller

or PC (LEC-W2) becomes possible.

(1) Connecting the teaching box

Gateway unit

CN2

Teaching box

(with 3m of cable)

(2) Connecting PC

(Communication cable, USB cable, conversion unit)

Gateway unit

CN2CN2

Conversion unit

USB cable

(A-miniB type)

Communication cable

※Refer to 9.CN2:TB/PC Power supply connector for usage.

Caution

Do not start the setting software during data link.

Controller setting software

モニタ

モニタ

現在位置

現在位置

現在速度

現在速度

設定

設定

1

テスト

1

テスト

2

テスト

2

テスト

3

テスト

3

テスト

mm

mm

120.3

120.3

mm/s

mm/s

200

200

位置 速度

位置 速度

100

100

200

200

50

50

動作中

動作中

アラーム

アラーム

500

500

1000

1000

200

200

PC

(PC is prepared by customer)

Otherwise, communication error (data link error) is generated with the gateway unit.

- 24 -

Page 26

6. CN4: Power supply connector

6.1 Power supply connector

Specifications of the communication connector in accessory

terminal Function Functional explanation

1 EMG + EMG signal output +

Output terminal of the emergency stop

2 EMG - EMG signal output -

switch of the teaching box.

3 C 24V Power supply + terminal

Power supply terminal of the Gateway unit

5 4 3 2 1

4 0V

Power supply - Terminal

5 FG FG Terminal Grounding terminal

(Power to the teaching box is supplied from

this terminal)

Caution

(1) 0V line of the gateway unit and the motor controller (LEC) have to be common.

(2) When conformity to UL is required, the electric actuator and controller should be used with a

UL1310 Class 2 power supply.

6.2 Power line

(Power lines are prepared by customer. Specifications below need to be satisfied)

Item Specifications

Applicable

wire

Size

Peeled wire

length

Do not connect multiple wires to one terminal.

Power terminal

(24V,0V)

EMG signal output

(EMG+,EMG-)

AWG20: Single line,No insulation sleeve, Twisted wire with

bar terminal.

*The rated temperature for the insulation coating: 60

degrees C or more.

AWG20: Single line,No insulation sleeve, Twisted wire with

bar terminal.

*Rated temperature of the insulation cover is 60 degrees C

or higher

8mm

Caution

- 25 -

Page 27

Caution

(1) The earthling should be the dedicated grounding point. It should be a functional ground with less

than 100 resistance.

(2) The ground point should be near this gateway unit to make the wire length shorter.

6.3 Wiring of the shutdown circuit

The gateway unit has the terminal (EMG+, EMG-) which outputs the stop switch signal of the teaching

Gateway unit

Recommended Functional grounding

Other device

Gateway unit

Not Recommended grounding

Other device

box when the communication switch (CN2SW) is turned on. Set the terminal to EMG terminal of the

controller (LEC) to use the teaching box.

Teaching

box

CN2

Internal

circuit

RY

Switch to change

the communication

(CN2SW)

Shutdown

circuit

CN4

EMG +

EMG-

24V

0V

Gateway unit

- 26 -

Page 28

Caution

T urn on the communication s witch (CN2SW) before install / removal of the teaching box to

/ from the gateway unit.

If EMG+ and EMG- terminals are connected to the controller (LEC) or a shutdown circuit and the

communication switch is turned off when the teaching box is not connected, connected controller

(LEC) or the shutdown circuit receives stop signal (Open between EMG+ and EMG-) and operation

stops

- 27 -

Page 29

【Shut

down circuit Example】

Shutdown circuit with gateway Check the circuit referring the controller (LEC) operation manual.

【Example of the circuit】ex. LEC6

DC24

Shutdown is lifted

Switch

Ry

0V

Stop

Gateway

Unit

EMG +

EMG -

Power supply plug (1st. unit)

BK RLS

EMG

C 24V

M 24V

0V

Switch

Ry

Ry

Surge suppressor

24V

0V

Controller

input power

Power supply plug (2nd. unit)

BK RLS

EMG

C 24V

M 24V

0V

Ry

24V

0V

Controller

input power

Power supply plug (3rd. unit)

BK RLS

EMG

C 24V

M 24V

0V

Ry

24V

0V

Controller

input power

Caution

When the stop signal is input, the controller (LEC) is stopped with max deceleration speed, and servo

motor is turned off.

- 28 -

Page 30

7. CN3: Bus conecter

BUS: D-sub 9-pin socket

No Designation Description

1 - Unused

9

8

7

6

Use the PROFIBUS DP connector with bus cable.

(e.g. 6GK1 500-0FC10,6ES7 972-0BA12-0XA0,manufactured by Siemens)

A shielded twisted pair valbe for PROFIBUS DP should be used.

5

4

3

2

1

2 - Unused

3 RXD・TXD-P Receive/transmit data,positive

4 - Unused

5 DGND Data ground(reference potential

to VP)

6 VP Power supply puluse (P5V)

7 - Unused

8 RXD/TXD-N Receive/transmit data,negative

9 - Unused

- 29 -

Page 31

8. CN1: Controller IF communication connector (CONT)

8. 1 Connection

One unit can control up to 5 pcs. of controllers (LEC).

The example of link connection which consists of telecommunication cable LEC-CG 1-1 and cable

LEC-CG 2-1 between branches is shown below.

5

1 LEC-CG1-

a) RJ45 male connector with a shield(8P)

b) M12 4pin

male connector

2 LEC-CGD

c) M12 4pin

female connector

b) M12 4pin

male connector

3 LEC-CG2-

b) M12 4pin

male connector

2 LEC-CGD

b) M12 4pin

male connector

4

1 LEC-CG1-

No Description Part number Content

1 Communication cable cable LEC-CG1-

2 Branch connector LEC-CGD The junction cable to connect the gateway and the controller.

3 Cable between branches LEC-CG2-

4 Terminating Resistor

a) RJ45 male connector with a shield(8P)

K 0.3m

L 0.5m

1 1m

K 0.3m

L 0.5m

1 1m

1 LEC-CG1-

a) RJ45 male connector with a shield(8P)

Cable to connect the gateway unit CN1 and the branch

connector, or controller (LEC) CN4 and the branch connector.

Cable to connect the branch connector.

Termination on RS-485 Bus (120 Ohms)

Recommended connector

:XS2C-D4** [OMRON Corporation]

5 RJ-45 connector dust cover

-

LEC-CAP-X22

- 30 -

Dust adhere when the RJ-45 connector is not connected with the

CN1 or CN2 connector.

Please attach a cover when you prevent the adhesion such as

dust.

120Ω 1/4W

Page 32

Recommended connector

No Description Part number

a) RJ45 male connector with a shield(8P) TM21P-88P [HIROSE ELECTRIC CO., LTD.]

b) M12 4pinmale connector HR24-8DJ4PE550A(73) [HIROSE ELECTRIC CO., LTD.]

XS2G-D4** [OMRON Corporation]

c) M12 4pin female connector HR24-8DP4S300(73) [HIROSE ELECTRIC CO., LTD.]

XS2C-D4** [OMRON Corporation]

- 31 -

Page 33

8. 2 Wiring diagram

For you reference, the example of wiring of the gateway unit CN1 is shown below.

The communication line from the gateway unit CN1 branches to each controller (LEC) by the branch

connector. It is recommended to connect the terminating resistor (120 1/4W) to the branch connector

at the terminal.

When connecting the cable, the shield of the cable becomes same potential as 0V of the controller

power supply.

When using it, do not contact it to conductive parts of switchboard, other instruments, wiring, etc.

Gateway unit CN1

Description Pin No.

N.C. 1

N.C. 2

SD+ 3

SD- 4

N.C. 5

N.C. 6

N.C. 7

N.C. 8

Shield

Branch

1 1

2 2

3 3

4 4

1234

Branch

1 1

2 2

3 3

4 4

1 2 3 4

Controller CN4

Description Pin No.

EMG+ 1

EMG- 2

SD+ 3

SD- 4

EN_SW+ 5

ON 6

DC24V 7

GND 8

Shield

Controller CN4

Description Pin No.

EMG+ 1

EMG- 2

SD+ 3

SD- 4

EN_SW+ 5

ON 6

DC24V 7

GND 8

Shield

- 32 -

Page 34

9. CN2: TB/PC connector

9. 1 How to use

This connector is for setting the controller (LEC) which is connected to the gateway unit by the teaching

box or the set software.

When the communication switch (CN2SW) is turned off, the communication from Profibus DP to the

controller is disconnected, and the signal line of CN2 and CN1 is connected. From now on, the setting of

each controller is possible.

The following is the setting procedure of the controller (LEC) when the teaching box or PC setting

software us connected to the gateway unit.

【Procedure to start setting】

(1) Connect the teaching box or PC to CN2 of gateway unit.

(2) Turn off the communication switch (CN2SW).

(3) Reset signal is sent to all controllers (LEC) which are connected to the gateway unit, and the

communication from Profibus to the controller (LEC) is disconnected. Reset signal stops all actuators.

(4) Communication from the teaching box or PC becomes available.

【Procedure to finish setting】

(1) Finish the PC setting software.

(2) Turn on the communication switch (CN2SW).

(In case of the teaching box, power supply is turned off at this point)

(3) Communication starts after the reset signal is sent from the gateway unit to the controller (LEC).

Reset signal stops all the actuators immediately after communication starts.

(4) Remove the teaching box or PC from the CN2 of gateway unit.

Caution

Do not start the setting software during data link (CN2SW turn on).

Otherwise, communication error (data link error) is generated with the gateway unit.

Use the teaching box and the setting software after finishing startup process of the gateway

unit (After ALM lamp green blinks). (CN2SW turn off etc.)

The gateway unit communicates with controller (LEC) as startup processing immediately

after turning on of the power supply.

At this time, if the teaching box or the setting software communicate to controller (LEC),

communication error is generated.

- 33 -

Page 35

10. LED display

10. 1 LED display

LED name Content

Off Power is not supplied PWR Power supply

status is displayed

SN2SW

Controller IF

STAT

ALM

BF Bus fault

status

The alarm status.

(Profibus)

(Profibus)

Green On Power is supplied

Off When switch ON CN2STAT ON, OFF status of

Green ON When switch OFF

Green flashing Communicating BUS

Off Communication

disconnected

Green flashing Normal status

Orange flashing Warning generated

Red On When alarm is

generated or

communication data link

is disconnected.

Green ON Normal status SF System fault

Off Error status

Green ON Normal status

Green flashing Stop status

Off Error status

- 34 -

Page 36

10. 2 Controller IF communication status and LED display

Gateway unit status PWR BUS STAT ALM CN2 STAT

Supply of power Green On Off Off Off

Controller (LEC) and normal

communication

Command to interrupt data link is being

given

CN2SW ON Command to interrupt data

link is being given

Contr

oller

IF

Communication error with

some controllers (LEC) is

detected.

Communication error is

detected for all controllers

(LEC), or IF communication

speed of the controller is

incorrect.

Green On Green

flashing

Green On Off Green

Green On Off Green

Green On Green

flashing

Green On Green

flashing

Green

flashing

flashing

flashing

Orange

flashes

Red On Off

Off

Off

Green On

Off

- 35 -

Page 37

11. Mode

11. 1 Outline

This unit has 3 types of operation mode. These modes can be switched by mode change. Current mode

can be checked by mode return

Refer to “12.4(1) Return of the mode” for “Return of the Mode”.

Step data input mode

Operating actuator by using the memory of the gateway unit which corresponds to parallel IO of

controller (LEC).

Numerical data input mode

Operating actuator by using the memory of the gateway unit which corresponds to parallel IO of

controller (LEC), and operating actuator by directly sending the parameters which like a position, a

speed etc., are available.

Step data writing mode

Operating actuator by using the memory of the gateway unit which corresponds to parallel IO of

controller (LEC), and editing step data of the LEC controllers through the gateway unit, are available.

Please confirm the setting method of "Mode chenge" and "Mode return" by "Gateway control flag" and

"Gateway unit state flag".

11. 2. Step data input mode

This is the mode that Operating actuator by using the memory of the gateway unit which corresponds

to parallel IO of controller (LEC).

In case that “ID” setting of the controller(LEC) is “1”, the memory which corresponds to the parallel IO

of controller can be operated by I Address 14,15 and Q Address 14,15.

Refer to the manual of controller (LEC) for detail of the function and the operation of parallel IO.

11. 3. Numerical data input mode

This is the mode that operating actuator by sending to controller (LEC) the data which is a position, a

speed etc.

The actuator moves with the position, the speed etc which is specified by sent data.

In this mode, the command by using parallel I/O is available.

Before operating the actuator by directly sending the data which like a position, a speed etc, SVON and

return to origin should be finished.

Please make same operation as performing SVON and return to origin with parallel IO by using the

corresponding memory.

And operating the actuator is availavle by using the memory which corresponds to parallel IO of

LEC6 controller.

Refer to the manual of controller (LEC) for detail of the function and the operation of parallel IO.

The data such as the current position can be read by “Setting numerical data”.

Refer to “12.4(5) Setting numerical data” for “Setting numerical data”.

- 36 -

Page 38

●Operation commanded by numerical data input mode (ID=1)

(1) Write “0” in Q_Address 16 .

(2) Write the motion profile (position, speed…) in Q_Address 17 to 33.

Refer to "7.1 Step data" of the operation manual of the controller(LEC).

(3) Write “1” in Q_Address 16. Then, the command of the driving is sent to the controller (LEC).

(4) When the sending to the controller(LEC) is completed, “Sending completed” (I_Address 33.1)

changes from “0” to “1” and the actuator starts driving.

(5) And, when the actuator completes driving, “INP” (I_Address 15.3) is changed from “0” to “1”.

Refer to "6.3 Parallel IO input" of the operation manual of the controller(LEC) for detail of INP

signal.

(6) Write “0” in Q_Address16.

Then, “Sending completed” (I_Address 33.1) is changed from “1” to “0”.

Operation command

Data (Position, speed)

Sending

Sending completed

Operation

INP

1

2

3

6

4

5

- 37 -

Page 39

11. 4. Data writing mode

This is the mode that the step data of the controller(LEC) can be changed through the gateway unit.

After changing it, the changed step data is reflected by commanding to drive the changed step data.

And the same functions as step data input mode are available in this mode.

The driving and the return to origin etc. are commanded by using the memory which corresponds to

parallel IO of LEC controller.

Refer to the manual of controller (LEC) for detail of the function and the operation of parallel IO.

●Writing step data method

(1)Write “0” in Q_Address 17.

(2)Write the motion profile (position, speed…) in Q_Address 18 to 33.

Refer to "7.1 Step data" of the operation manual of the controller(LEC).

(3)Write the step data number which is changed in Q_Address 16. (Setting data range is from 0 to 63.)

(4)Write “1” in Q_Address 17. Then, the data which is written in avobe (2) are sent to the

controller(LEC).

(5)When the sending to the controller(LEC) is completed, “Sending completed” (I_Address .33.1)

is changed from “0” to “1”.

(6)Write “0” in Q_Address 17 .

Then, “Sending completed ” (I_Address .33.1) changes from “1” to “0”.

- 38 -

Page 40

12. Memory map

12. 1 Memory assignment

Gateway unit --> Higher level device [IN]

I_Address Data name

0

1

2

3

4

5

…

13

Correspond-

I_Address

Ing ID

Gateway unit control flag

Unused (Do not use it.) -

Bit/Byte

No.

Data name

Model/

Size

Value

range

Corresponding

mode

All modes

Corresponding

Unit

mode

0 OUT0 bit 0,1 -

1 OUT1 bit 0,1 -

2 OUT2 bit 0,1 -

14

ID1

15

3 OUT3 bit 0,1 -

4 OUT4 bit 0,1 -

5 OUT5 bit 0,1 -

6 - bit 0 -

7 - bit 0 -

All modes

0 BUSY bit 0,1 -

1 SVRE bit 0,1 -

2 SETON bit 0,1 -

3 INP bit 0,1 -

4 AREA bit 0,1 -

5 WAREA bit 0,1 -

6 ESTOP bit 0,1 -

7 ALARM bit 0,1 -

・Please refer the operation manual of the step motor controller (LECP6) and the servo motor controller

(LECA6) to check the detail of each signal.

- 39 -

Page 41

Correspond-

ing ID

I_

Address

Bit/Byte

No.

16 3

Data

name

Model/

Size

Value range Unit

Correspond-

Ing mode

ID1

17 2

18 1

19 0

20 H

21 L

22 H

23 L

24 3

25 2

26 1

27 0

28 - Alarm 0 to 255 -

29 - Alarm 0 to 255 -

30 - Alarm 0 to 255 -

Current

4 +/-2147483647 0.01mm

position

Current

2 0 to 65500 mm/s

speed

Current

2 0 to 300 %

Force

Target

4 +/-2147483647 0.01mm

position

4

Numerical data

input

Numerical data

input

ID2

ID3

ID4

ID5

31 - Alarm

32

Controller IF status flag (ID=1)

33

34 to 53

54 to 73

74 to 93

94 to 113

0 to 255 -

All modes

Same as ID1

Same as ID1

Same as ID1

Same as ID1

- 40 -

Page 42

Higher level device --> Gateway unit [OUT]

Q_Address Data name

0

1

Gateway unit status flag

2

3

4

Corresponding

mode

All modes

Correspond-

ing ID

ID1

5

…

13

Q_

Address

14

Bit/Byte

No.

0 IN0 bit 0,1 -

1 IN1 bit 0,1 -

2 IN2 bit 0,1 -

3 IN3 bit 0,1 -

4 IN4 bit 0,1 -

5 IN5 bit 0,1 -

6 - bit 0 -

7 - bit 0 -

0 HOLD bit 0,1 -

1 SVON bit 0,1 -

Unused (Do not use it.) -

Data name

Model/

Value range Unit

Size

Corresponding

All mode

mode

2 DRIVE bit 0,1 -

15

3 RESET bit 0,1 -

4 SETUP bit 0,1 -

5 - bit 0 -

6 - bit 0 -

7 - bit 0 -

- 41 -

Page 43

Correspond

-ing D

Q_

Address

Bit/Byte

No.

Data name

Model/

Size

Value range Unit

Correspond

-ing mode

ID1

16 -

Start flag

Step data No

Operation

17 -

Note)

18 H

Speed 2 0 to 65500 mm/s

19 L

20 3

21 2

Position 4 +/-2147483647 0.01mm

22 1

23 0

24 H

Acceleration 2 0 to 65500 mm/s

25 L

26 H

Deceleration 2 0 to 65500 mm/s

27 L

28 - Pushing force 1 0 to 30 10%

0: no send

1: send

1

0 to 63

1: Absolute

1

2: Relative

-

-

Numerical

data input

Data writting

2

2

Numerical

data input

Data writting

29 - Threshold 1 0 to 30 10%

30 - Pushing speed 1 0 to 255 mm/s

Positioning

1 0 to 30 10%

thrust

In pos 2 0 to 65500 0.01mm

Same as ID1

Same as ID1

Same as ID1

Same as ID1

ID2

ID3

ID4

ID5

31 -

32 H

33 L

34 to 53

54 to 73

74 to 93

94 to

113

Note) "0" is "no send" at mode of data writing. "1" and "2" contain "send" at mode of data writing.

- 42 -

Page 44

12. 2 Controller IF status flag(IN Data)

Controller IF flag is sent back to each ID ID=1 is shown below as an example

[ID=1]

I_Address

32

bit

7 6 5 4 3 2 1 0

- - - - -

-

Abnormal

station

Connect station

33

- - - - -

-

Sending

Sending

completed

(1) Connect station

1 (ON) appears when it is confirmed that the motor controller (LEC) is connected. 0 (OFF) appears

when the connection is not confirmed.

(2) Abnormal station

0 (OFF) appears when the communication with the motor controller is normal at the connect station. 1

(ON) appears when the communication is not normal.

(3) Sending

1 (ON) appears while the operation command from the motor controller (LEC) is given and the

sending of the operation data for the motor controller is completed at numerical data input mode. 0

(OFF) appears when the sending is completed.

(4) Sending completed

1 (ON) appears when the sending of the operation command data to the motor controller (LEC) is

completed at the numerical data input mode. 1 (ON) appears while the sending of the operation

command data to the motor controller when the operation command is (ID=1).

Start flag

Sending

Sending completed

Sending command

12. 3 Gateway unit status flag(IN Data)

The flag to indicate the gateway communication status.

I_Address

bit

0

1

2

3 Return of the final station number

(1) Return of the mode

Current mode is displayed

Address0

Bit1 Bit0

0 0 Step data input mode

0 1 Numerical data input mode

1 0 Data writing mode

7 6 5 4 3 2 1 0

Commu

Initial ALARM READY

nicating

Return of the read numerical data

Mode name

- 43 -

- -

Return of the mode

Page 45

(2) READY

1 (ON) appears when the gateway is activated.

(3) ALARM

1 (ON) appears when one or more abnormal station are present, and the alarm is generated. 0 (OFF)

appears when alarm is not generated.

(4) Initial

0 (OFF) appears during processing the initial for check the connect station. 1 (ON) appears when the

processing of the initial is completed.

(5) During communication

1(ON) appears when communication is made for one or more station. 0 (OFF) appears when not

communicated.

In one of following cases, communication is not made.

CN2SW is ON.

Stop[InputAddress0.7] is ON.

All the connect stations become abnormal and the communication is stopped.

(6) Return of the read numerical data (Valid only in numerical data input mode)

ON (1) appears in ID bit if numerical data can be read. OFF (0) appears when the data can not be read.

The command to read numerical data is given by “Setting numerical data”.

I_Address

bit

7 6 5 4 3 2 1 0

1 - - - ID5 ID4 ID3 ID2 ID1

2 - - - - - - - -

(7) Return of the final station number

Return the range of the ID of the controller (LEC) to communication when the initial is processed. ID

number is returned in binary digit.

ID

bit

3 2 1 0

1 0 0 0 1

2 0 0 1 0

3 0 0 1 1

: :

5 0 1 0 1

- 44 -

Page 46

12. 4 Gateway unit control flag(OUT Data)

The flag to control the gateway communication status.

bit

Q_Address

0 Stop - Restart Reset - - Mode command

7 6 5 4 3 2 1 0

1

Setting numerical data

2

3 - - - - Setting the final station number

(1) Mode command

Command the mode. Mode return is updated when the set mode becomes valid.

Address0

Mode name

Bit1 Bit0

0 0 Step data input mode

0 1 Numerical data input mode

1 0 Data writing mode

(2) Reset

Communication to the abnormal station restart when 0 (FF) is changed to 1 (ON). But, it is invalid when

Stop is 1(ON) or CN2SW is ON.

(3) Restart

Initial processing is executed again when 0 (OFF) is changed to 1 (ON). But, it is invalid when Stop is 1

(ON) or CN2SW is ON.

(4) Stop

All communications to the connected motor controller (LEC) are stopped when 0 (OFF) is changed to 1

(ON). Communication restart by chancing to 0 (OFF) from 1 (ON).

(5) Setting numerical data (Valid only in direct setting mode)

ON (1) appears in ID bit if numerical data can be read. OFF (0) appears when the data can not be read.

Q_Address

bit

7 6 5 4 3 2 1 0

1 - - - ID5 ID4 ID3 ID2 ID1

2 - - - - - - - -

(6) Return of the final station number

Indicates the range of the ID of the controller (LEC) to communication when the initial is processed. ID

number is set in binary digit.

Input range is from 1 to 5. If the set value is lower than 0 or larger than 5, 5 is set.

ID

bit

3 2 1 0

1 0 0 0 1

2 0 0 1 0

3 0 0 1 1

: :

5 0 1 0 1

- 45 -

Page 47

13. Precautions for controlling the controller (LEC)

13. 1. Communication delay between the gateway unit unit and the controller(LEC)

There is communication delay between the gateway unit and the controller (LEC). Please refer to the

procedure below for the control procedure taking the delay into consideration

For details of each signal, please refer to the operation manual of each motor controller (LEC) to be

connected.

Example of operation indication with step data input mode

Command

(Input signal)

(1) DRIVE input ON (1) ⇒ Confirm that all OUT0 to 5 in the

(2) DRIVE input OFF (0) ⇒ Confirmed that OUT0 to 5 in the

(3) INP is ON (1) and BUSY is OFF

Cautions for the above example

When the operation is ordered right after the operation shown below, the response of DRIVE above

are not recognized because OUT0 to 5 in the data information are all OFF (0) before turning ON (1) the

Response (Output signal)

data information are changed to

OFF (0) from values before

DRIVE input ON (1).

data information is the value

within IN0 to 5 in specified data.

(0)

- Confirm the

completion of

the operation.

DRIVE input. In this case, take measures against the communication delay by using the timer.

【Condition in which OUT0 to 5 in the data information is all OFF】

- Supply of power

- During and the right after the returning to origin position.

- RESET input ON

- After DRIVE input OFF(0) after commanding to start step data No.0

- 46 -

Page 48

13. 2. Guideline of the Response delay between the Gateway and the Motor Control Unit

The gateway unit communicates with the motor controller (LEC) to read the controller status and

commands the controller. The time for the communication causes delay in the response.

Please take this into consideration when selecting the PLC program.

PLC

Profi Bus

Gateway

Unit

Communication to read the motor controller status

The gateway unit communicates one by one in order. The communication time is approximately 30ms

per unit. When reading of numerical data is validated during Numerical data input mode or data rewrite

mode, it takes another 30ms for communicating with valid controller (LEC).

Communication for commanding the motor controller

When rewrite of the remote I/O and the register is commanded by Profibus master, it takes 30ms for

communicating with the target controller (LEC).

Response delay depends on the number of the connected motor controllers (LEC) and rewrite

frequency.

Ex. 1) Response time guideline when four controllers are connected in step data input mode.

4 pcs. × approx. 30ms = Approx. 120ms +

[:Communication time to rewrite the remote I/O and the register]

Ex. 2) Response time guideline when twelve controllers are connected in step data input mode.

5 pcs. × approx. 30ms = Approx. 150ms +

[:Communication time to rewrite the remote I/O and the register]

Ex. 3) Response time guideline when 5 controllers are connected in numerical data input mode (3

controllers are valid for reading numerical data).

5 pcs. × approx. 30ms + 3pcs. x approx. 30ms = Approx. 240ms +

[:Communication time to rewrite the remote I/O and the register]

※This response time does not include the response time of Profibus and motor controller (LEC), and

processing time of PLC.

Communication between the

gateway unit and the controller

Motor controller

(LEC)

Motor controller

(LEC)

Motor controller

(LEC)

- 47 -

Page 49

14. Wiring of cables/Common precautions

Warning

1. Adjusting, mounting or wiring change should never be done before shutting off the power

supply to the product.

Electrical shock, malfunction and damaged can result.

2. Never disassemble the cable. Use only specified cables.

3. Never connect or disconnect the cable or connector with power on.

Caution

1. Wire the connector securely. Do not apply any voltage to the terminals other than those

specified in the product Manual.

2. Wire the connector securely.

Check for correct connector wiring and polarity.

3. Take appropriate measures against noise.

Noise in a signal line may cause malfunction. As a countermeasure, separate high voltage and low

voltage cables, and shorten wiring lengths, etc.

4. Do not route wires and cables together with power or high voltage cables.

The product can malfunction due to interference of noise and surge voltage from power and high

voltage cables to the signal line. Route the wires of the product separately from power or high

voltage cables.

5. Take care that actuator movement does not catch cables.

6. Operate with cables secured. Avoid bending cables at sharp angles where they enter the product.

7. Avoid twisting, folding, rotating or applying an external force to the cable.

Risk of electric shock, wire break, contact failure and lost of control for the product can happen.

8. Fix the motor cable protruding from the product in place before using.

The motor and lock cables are not robotic type cables and can be damaged when moved.Therefore

do not place it in a flexible moving tube.

9. The cable connecting the actuator and controller (LEC) is superior in bending resistance, but

should not be placed into a flexible moving tube with a radius smaller than the specified

value.

( Min. 50 mm)

10. Confirm proper wiring of the product.

Poor insulation (interference with other circuits, poor insulation between terminals and etc.) can

apply excessive voltage or current to the product causing damage.

11. The Speed / pushing force may vary, depending on the cable length, load and mounting

conditions etc..

If the cable length exceeds 5m, the speed / pushing force will be reduced by a maximum of 10% per

5m. (If cable length is 15m: Maximum 20% reduction.)

[Transportation]

Caution

1. Do not carry or sw ing the product by the motor or the cable

- 48 -

Page 50

15. Electric actuators/Common precautions

15.1 Design and selection

Warning

1. Be sure to read the Operation Manual.

Handling or usage/operation other than that specified in the Operation Manual may lead to

breakage and operation failure of the product.

Any damage attributed to the use beyond the specifications is not guaranteed.

2. There is a possibility of dangerous sudden action by the product if sliding parts of machinery

are twisted due to external forces, etc.

In such cases, human injury may occur, such as by catching hands or feet in the machinery, or damage to the

machinery itself may occur. Design the machinery should be designed to avoid such dangers.

3. A protective cover is recommended to minimize the risk of personal injury.

If a driven object and moving parts of the product are in close proximity, personal injury may occur.

Design the system to avoid contact with the human body.

4. Securely tighten all stationary parts and connected parts so that they will not become loose.

When the product operates with high frequency or is installed where there is a lot of vibration,

ensure that all parts remain secure.

5. Consider a possible loss of power source.

Take measures to prevent injury and equipment damage even in the case of a power source failure.

6. Consider behavior of emergency stop of whole system.

Design the system so that human injury and/or damage to machinery and equipment will not be

caused, when it is stopped by a safety device for abnormal conditions such as a power outage or a

manual emergency stop of whole system.

7. Consider the action when operation is restarted after an emergency stop or abnormal stop of

whole system.

Design the system so that human injury or equipment damage will not occur upon restart of

operation of whole system.

8. Disassembly and modification prohibited

Do not modify or reconstruct (including additional machining) the product. An injury or failure can result.

9. Do not use stop signal,"EMG" of the controller and stop switch on the teaching box as the

emergency stop of system.

The stop signal, "EMG" of controller and the stop switch on the teaching box are for decelerating

and stopping the actuator.

Design the system with an emergency stop circuit which is applied relevant safety standard separately.

10. When using it for vertical application, it is necessary to build in a safety device.

The rod may fall due to the weight of work. The safety device should not interfere with normal

operation of the machine.

Caution

1. Operate within the limits of the maximum usable stroke.

The product will be damaged if it is used with the stroke which is over the maximum stroke. Refer to

the specifications of the product.

2. When the product repeatedly cycles with partial strokes, operate it at a full stroke at least

once a day or every 1000 strokes.

Otherwise, lubrication can run out.

- 49 -

Page 51

3. Do not use the product in applications where excessive external force or impact force is

applied to it.

The product can be damaged. Each component that includes motor is made with accurate tolerance.

So even slightly deformed or miss-alignment of component may lead operation failure of the

product.

4. Refer to a common auto switch /matter (Best Pneumatics No 2) w hen an auto switch is built

in and used.

5. Return to origin cannot return while operating.

It cannot be done during positioning operation, pushing operation and pushing.

6. When conformity to UL is required, the electric actuator and controller should be used

with a UL1310 Class 2 power supply.

15.2 Mounting

Warning

1. Install and operate the product only after reading the Operation Manual carefully and

understanding its contents. Keep the manual in a safe place future reference.

2. Observe the tightening torque for screws.

Tighten the screws to the recommended torque for mounting the product.

3. Do not make any alterations to this product.

Alterations made to this product may lead to a loss of durability and damage to the product, which

can lead to human injury and damage to other equipment and machinery.

4. When using external guide, the guide axis should be parallel to the actuator axis.

There will be damage/excessive wear on the lead screw if the external guide is not parallel.

5. When an external guide is used, connect the moving parts of the product and the load in

such a way that there is no interference at any point within the stroke.

Do not scratch or dent the sliding parts of the product tube or piston rod etc., by striking or grasping

them with other objects. Components are manufactured to precise tolerances, so that even a slight

deformation may cause faulty operation.

6. Prevent the seizure of rotating parts.

Prevent the seizure of rotating parts (pins, etc.) by applying grease.

7. Do not use the product until you verify that the equipment can be operated properly.

After mounting or repair, connect the power supply to the product and perform appropriate functional

inspections to check it is mounted properly.

8. At the overhang mounted impeller fixation

There is a possibility that the power at the bending moment damages the actuator when moving it at

high speed.

The support metal fittings that suppress the vibration of the main body of the actuator are installed.

Lower and use speed for the state that the actuator doesn't vibrate.

9. When attaching work piece, do not apply strong impact or large moment.

If an external force over the allowable moment is applied, it may cause looseness in the guide unit,

an increase in sliding resistance or other problems.

10. Maintenance space.

Allow sufficient space for maintenance and inspection.

- 50 -

Page 52

15.3 Handling

Warning

1. Do not touch the motor while in operation.

The surface temperature of the motor can increase to approx. 90oC to 100oC due to operating

conditions. Energizing alone may also cause this temperature increase. As it may cause burns, do

not touch the motor when in operation.

2. If abnormal heating, smoking or fire, etc., occurs in the product, immediately shut off the

power supply.

3. Immediately stop operation if abnormal operation noise or vibration occurs.

If abnormal operation noise or vibration occurs, the product may have been mounted incorrectly.

Unless operation of the product is stopped for inspection, the product can be seriously damaged.

4. Never touch the rotating part of the motor or moving part of the actuator while in operation.

5. When installing, adjusting, inspecting or performing maintenance on the product, controller and

related equipment, be sure to shut off the power supply to each of them. Then, lock it so that no one

other than the person working can turn the power on, or implem ent measures such as a safety plug.

6.

In the case of the actuator that has a servo motor (24VDC), the “motor phase detection step"

is done by inputting the servo on signal just after the controller power is turned on. The

“motor phase detection step” operates the table/rod to the maximum distance of the lead

screw. (The motor rot ates in the reverse direction if the t able hits an obstacle such as the end

stop damper.) Take the “motor phase detection step” into consideration for the installation

and operation of this actuator.

Caution

1.

Keep the controller and product combined as delivered for use.

The product is set in parameters for shipment. If it is combined with a different parameter, failure can result.

2.

Check the product for the following points before operation.

a) Damage to electric driving line and signal lines

b) Looseness of the connector to each power line and signal line

c) Looseness of the actuator/cylinder and controller/driver mounting

d) Abnormal operation

e) Emergency stop of the total system

3. When more than one person is performing work, decide on the procedures, signals,

measures and resolution for abnormal conditions before beginning the work. Also,

designate a person to supervise work other than those performing work.

4. Actual speed of the product will be changed by the workload.

Before selecting a product, check the catalog for the instructions regarding selection and

specifications.

5. Do not apply a load, impact or resistance in addition to a transferred load during return to origin.

In the case of the return to origin by pushing force, additional force will cause displacement of the

origin position since it is based on detected motor torque.

6. Do not remove the name plate.

7. Operation test should be done by low speed. Start operation by predefined speed after

confirming there is no trouble.

[Earth]

Warning

1. Please give the earth of the actuator.

2. Please make it to the earth of the exclusive use. The earth construction is D seed.

(Below earth resistance 100)

3. Please shorten the distance until the actuator and earth.

- 51 -

Page 53

[Unpackaging]

Caution

1. Check the received product is as ordered.

If a different product is installed from the one ordered, injury or damage can result.

15.4 Operating environment

Warning

1. Avoid use in the following environments.

a. Locations where a large amount of dusts and cutting chips are airborne.

b. Locations where the ambient temperature is outside the range of the temperature specification

(refer to specifications).

c. Locations where the ambient humidity is outside the range of the humidity specification (refer to

specifications).

d. Locations where corrosive gas, flammable gas, sea water, water and steam are present.

e. Locations where strong magnetic or electric fields are generated.

f. Locations where direct vibration or impact is applied to the product.

g. Areas that are dusty, or are exposed to splashes of water and oil drops.

h. Areas exposed to direct sunlight (ultraviolet ray).

2. Do not use in an environment where the product is directly exposed to liquid, such as cutting oils.

If cutting oils, coolant or oil mist contaminates the product, failure or increased sliding resistance can

result.

3. Install a protective cover when the product is used in an environment directly exposed to

foreign matters such as dust, cutting chips and spatter.

Play or increased sliding resistance can result.

4. Shade the sunlight in the place where the product is applied with direct sunshine.

5. Shield the valve from radiated heat generated by nearby heat sources.

When there is a heat source surrounding the product, the radiated heat from the heat source can

increase the temperature of the product beyond the operating temperature range. Protect it with a

cover, etc.

6. Grease oil can be decreased due to external environment and operating conditions, and it

deteriorates lubrication performance to shorten the life of the product.

[Storage]

Warning

1. Do not store the product in a place in direct contact with rain or water drops or is exposed to

harmful gas or liquid.

2. Store in an area that is shaded from direct sunlight and has a temperature and humidity

within the specified range (-10oC to 60oC and 35 to 85% No condensation or freezing.

3. Do not apply vibration and impact to the product during storage.

- 52 -

Page 54

15.5 Maintenance

Warning

1. Do not disassemble or repair the product.

Fire or electric shock can result.

2. Before modifying or checking the wiring, the voltage should be checked with a tester 5

minutes after the power supply is turned off.

Electrical shock can result.

Caution

1. Maintenance should be performed according to the procedure indicated in the Operating

Manual.

Incorrect handling can cause injury, damage or malfunction of equipment and machinery.

2. Removal of product.