Page 1

No.SFOD-OMT0010-B

Product name

4-axis Step Motor Controller

(Parallel I/O type)

MODEL/ Series/ Product Number

JXC73/83 Series

Page 2

- 1 -

No.SFOD-OMT0010-B

Contents

1. Safety Instructions ........................................................................ 5

2. Product Outline .............................................................................. 7

2.1 Features ............................................................................................................ 7

2.2 How to Order .................................................................................................. 8

2.3 Product configuration ............................................................................... 9

3. Procedures to Trial run ............................................................... 10

3.1 Checking the contents of the package .......................................... 10

3.2. Mounting the controller ........................................................................ 11

3.3 Install the setting software and the driver ................................... 11

3.4 Wiring and connection ............................................................................ 11

3.5 Power supply, Start-up of controller setting software, and Alarm check 11

(1) Supplying power ................................................................................ 11

(2) Start-up of controller setting software .................................. 12

(3) Alarm check.......................................................................................... 13

3.6 Parameters and Step data ..................................................................... 14

(1) Select the actuator............................................................................ 14

(2) Setting parameters ........................................................................... 17

(3) Step data settings ............................................................................. 19

3.7 Check using JOG operation ................................................................ 20

(1) Change to Remote mode .............................................................. 20

(2) Return to origin .................................................................................. 21

(3) JOG or Inching ................................................................................... 22

3.8 Operation test using Test Drive ......................................................... 23

(1) Test Drive setting .............................................................................. 23

(2) Change to Remote mode .............................................................. 23

(3) Return to origin .................................................................................. 24

(4) Test drive starts ................................................................................. 24

4. Product Specifications ................................................................ 25

4.1 Basic Specifications ................................................................................ 25

4.2 Parts Description ....................................................................................... 26

4.3 Dimensions ................................................................................................... 27

(1) Direct mounting ................................................................................... 27

(2) DIN rail mounting .............................................................................. 27

4.4 Mounting ........................................................................................................ 28

(1) Mounting ................................................................................................ 28

(2) Grounding ............................................................................................. 29

Page 3

- 2 -

No.SFOD-OMT0010-B

(3) Mounting location ............................................................................. 30

5. Power supply connector ............................................................. 31

5.1 Connector specifications ...................................................................... 31

(1) Main control power supply connector: C PWR ................. 31

(2) Motor drive power connector: M PWR ................................... 31

(3) Motor control power supply connector: CI ......................... 32

5.2 Wiring ............................................................................................................... 33

(1) Wiring of the power supply connector .................................. 33

(2) Wiring of the stop switch .............................................................. 34

6. Details of parallel I/O connector ................................................. 36

6.1 Parallel I/O specifications ..................................................................... 36

6.2 Parallel I/O circuit (NPN, PNP) ............................................................ 36

(1)Parallel I/O input circuit ................................................................... 36

(2)Parallel I/O output circuit ............................................................... 37

6.3 Parallel I/O signals .................................................................................... 38

(1) I/O1 ............................................................................................................ 39

(2) I/O2 ............................................................................................................ 42

6.4 Parallel I/O Wiring Example.................................................................. 44

(1) NPN type ................................................................................................ 44

(2) PNP type ................................................................................................. 46

7. Setting Data Entry ....................................................................... 48

7.1 Profile parameter ....................................................................................... 48

7.2 Basic parameter ......................................................................................... 49

7.3 Return to origin parameter ................................................................... 51

7.4 Step data ........................................................................................................ 52

(1) ABS ........................................................................................................... 54

(2) INC ............................................................................................................. 54

(3) LIN-A / LIN-I........................................................................................... 54

(4) CIR-R / CIR-L ........................................................................................ 55

(5) SYN-I ........................................................................................................ 55

8. Description of operation ............................................................. 56

8.1 Return to origin ........................................................................................... 56

8.2 Positioning Operation ............................................................................. 57

8.3 Pushing Operation .................................................................................... 60

8.4 Linear interpolation .................................................................................. 64

8.5 Circular interpolation ............................................................................... 67

8.6 Speed tuning control ..................................................................................... 71

8.7 Controller input signal response time............................................ 73

Page 4

- 3 -

No.SFOD-OMT0010-B

8.8 Methods of interrupting operation ................................................... 73

9. Operation Instructions ................................................................ 74

9.1 Outline of the Operation instruction ............................................... 74

9.2 Operation procedure of parallel I/O signals ................................ 74

(1) From power on to Return to origin .......................................... 74

(2) Positioning operation ..................................................................... 75

(3) Pushing operation .................................................................................. 76

(4) HOLD ........................................................................................................ 77

(5) RESET ..................................................................................................... 77

(6) STOP ......................................................................................................... 79

(7) Area output ........................................................................................... 80

10. Accessories ................................................................................ 81

10.1 Power cable for main control ............................................................ 81

10.2 DIN rail mounting bracket................................................................... 81

10.3 Actuator cable (5m or less) ................................................................ 82

10.4 Actuator cable (8-20m) ......................................................................... 82

10.5 Actuator cable [For sensor/ with lock (5m or less)] ............. 83

10.6 Actuator cable [For sensor/ with lock (8m to 20m)] ............. 83

10.7 ParallelI/O cable......................................................................................... 84

10.8 Controller Set up kit ............................................................................... 85

11. Alarm detection .......................................................................... 86

11.1 Parallel output Alarm group .............................................................. 86

11.2 Alarms and countermeasures .......................................................... 87

12. Common Precautions for wiring and cable ............................ 95

13. Electric Actuators / Common Precautions .............................. 96

13.1 Design and Selection ............................................................................ 96

13.2 Mounting ...................................................................................................... 97

13.3. Handling Precautions .......................................................................... 98

13.4 Operating environment ........................................................................ 99

13.5 Maintenance and Precautions ....................................................... 100

13.6 Precautions for actuator with lock ............................................. 100

14. Controller and Peripheral Devices / Specific Product Precautions 101

14.1 Design and selection .......................................................................... 101

14.2 Handling Precautions ........................................................................ 101

14.3 Mounting ................................................................................................... 103

14.4 Wiring ......................................................................................................... 103

Page 5

- 4 -

No.SFOD-OMT0010-B

14.5 Power supply .......................................................................................... 104

14.6 Grounding ................................................................................................ 104

14.7 Maintenance ............................................................................................ 104

15. Troubleshooting ...................................................................... 105

15.1 Operation Errors ................................................................................... 105

15.2 Position / Speed problems .............................................................. 108

Supplement 1. Actuator Specifications ........................................ 110

Supplement 1.1 Initial setting of LEY/LEYG series ................................. 110

Supplement 1.2 Initial setting of LEFS series ............................................ 110

Supplement 1.3 Initial setting of LES(H) series ............................. 111

Supplement 1.4 Initial setting of LEP series .................................... 111

Supplement 1.5 Initial setting of LEFB series ................................. 112

Supplement 1.6 Initial setting of LER series ................................... 112

Supplement 1.7 Initial setting of LEH series ................................... 112

Page 6

- 5 -

No.SFOD-OMT0010-B

JXC73/83 Series / Controller

1. Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or

“Danger.”

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1) , and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could result in minor or

moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided, could result in

death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will result in death or

serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

1.The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2.When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

be used in any of the following conditions:

1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4.Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

Page 7

- 6 -

No.SFOD-OMT0010-B

JXC73/83 Series / Controller

1. Safety Instructions

Caution

1.The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and provide specifications

or a contract, if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited Warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

1.The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered,whichever is first. *2)

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility,

a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers

noted in the specified catalog for the particular products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum

pad or failure due to the deterioration of rubber material are not covered by the limited

warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of mass

destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by the

relevant security laws and regulation of the countries involved in the transaction. Prior to the

shipment of a SMC product to another country, assure that all local rules governing that export

are known and followed.

Page 8

- 7 -

No.SFOD-OMT0010-B

2. Product Outline

2.1 Features

This controller uses predefined "step data" in which multiple data such as position or speed are

included together as operation instructions to the actuator. An external PLC specifies the step data

number to the controller and will start the operation based on the step data.

Feature of the controller.

4 axes speed tuning control

Up to 4 axes speed tuning control is available for specifying step data.

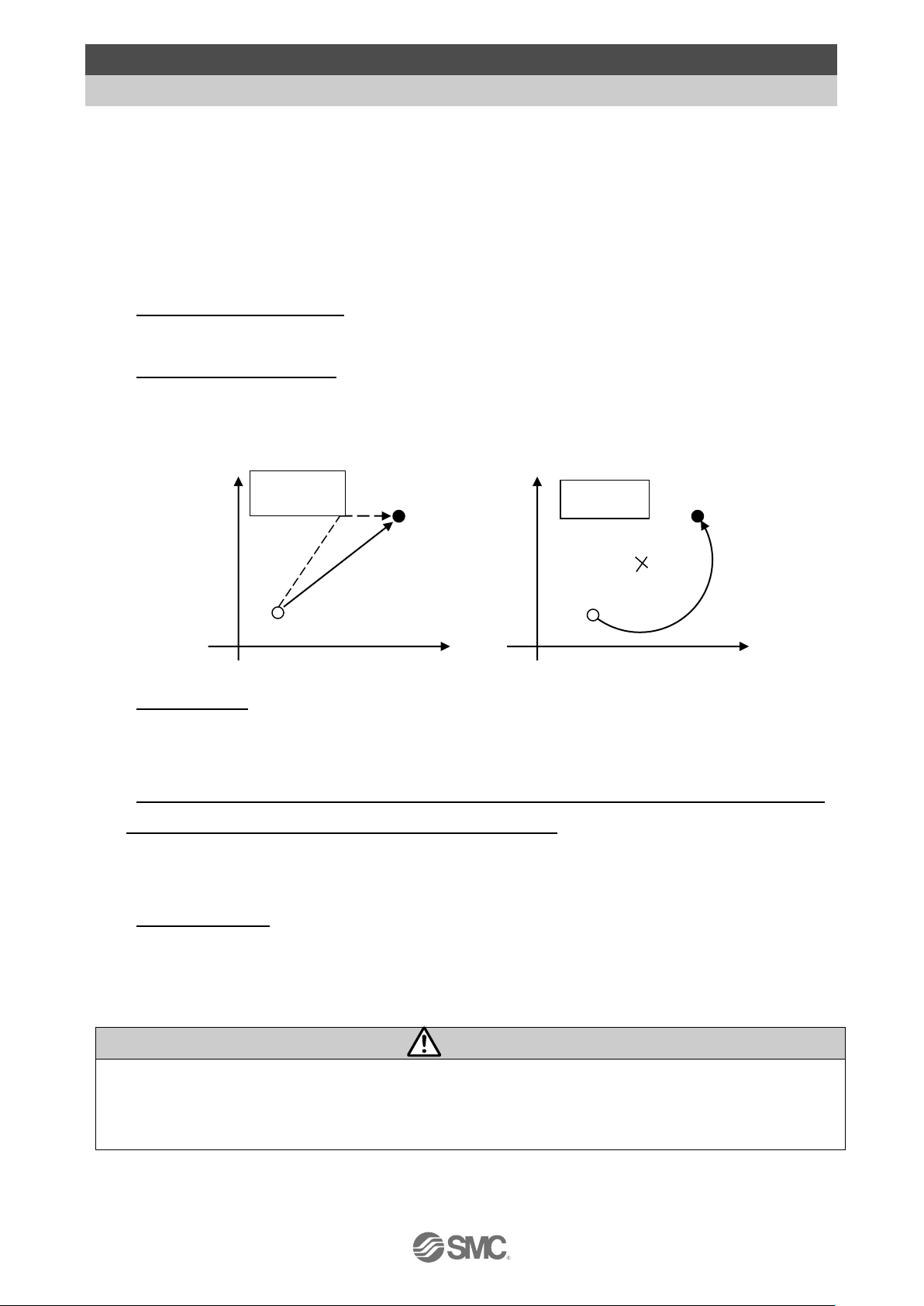

Linear/ circular interpolation

Linear interpolation for up to 3 axes and circular interpolation between 2 axes are possible.

Linear interpolation is possible by setting the target position and travel speed of the locus. For

circular interpolation, the travel speed of the locus and the centre position must be set.

Return to origin

All axes are possible to return to origin by using one “return to origin” signal (SETUP). The

order of the return to origin operation is possible to specify by the parameters.

It is possible to set 512 steps of positioning or pushing operation in normal mode, and 2048

steps of positioning or pushing operation in extended mode.

Control the actuator according to the step data specified by the input of parallel I/O. It is

possible to operate all axes by using 1 step.

Data input method

It is possible to set the step data, parameters, monitor conditions, and reset alarms by

communication via the USB port from a PC inwhich the controller setting software is installed.

Caution

Please keep this manual safe for future use. It will be necessary to refer to this manual along with the

operation manuals for other actuators and controller setting software at installation and fault finding.

Keep this operation manual accessible for reference.

Circular

interpolation

Current

position

Target

position

Center

Linear

interpolation

Current position

Target position

Linear interpolation

Individual

operation of

the axis

Page 9

- 8 -

No.SFOD-OMT0010-B

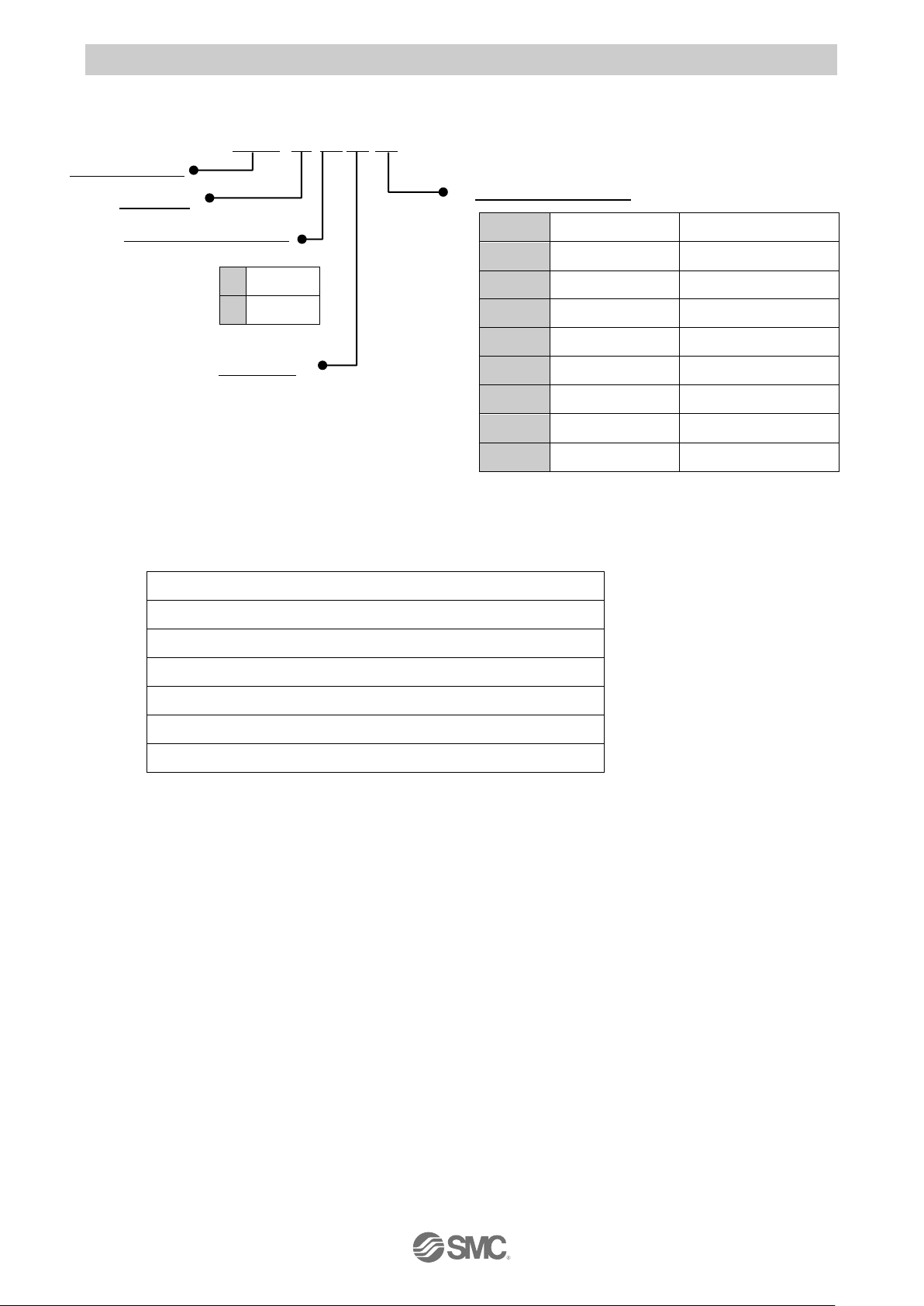

2.2 How to Order

How to order is shown below.

Applicable Actuator

Electric Actuator Rod Type LEY Series

Electric Actuator Rod Type with Guide LEYG Series

Electric Actuator Slider Type LEF Series

Electric Slide Table LES/LESH Series

Electric Rotary Table LER Series

Note2)

Electric Actuator Miniature Type LEPY/LEPS Series

Electric Gripper (2-Finger Type, 3-Finger Type) LEH Series

Note 2) The continuous rotation (360°) type is excluded.

J X C 3

I/O cable or mounting

Input/Output specifications

Controller

4 axis type

Electric equipment

7

NPN

8

PNP

Symbol

I/O cable

Note1)

Mounting

1

1.5m

Direct mounting

2

1.5m

DIN rail

3

3m

Direct mounting

4

3m

DIN rail

5

5m

Direct mounting

6

5m

DIN rail

7

--

Direct mounting

8

--

DIN rail

Note 1) When I/O cable (1.5 to 5m) is selected,

two I/O cables are included.

Page 10

- 9 -

No.SFOD-OMT0010-B

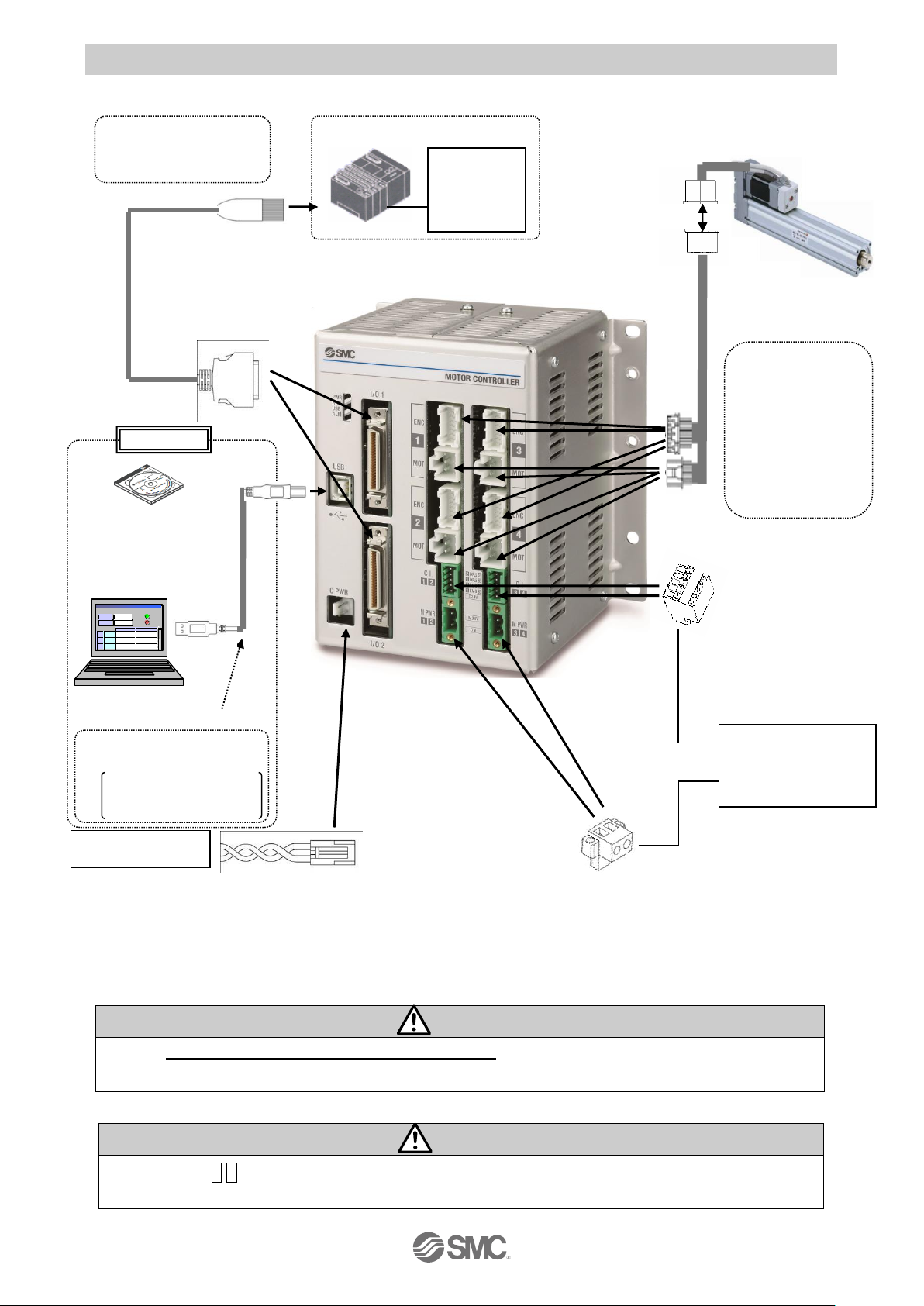

●Motor control power

supply connector

(Accessory)

<Applicable wire size>

AWG20 (0.5mm2)

● Motor drive power connector

(Accessory)

<Applicable wire size>

AWG16 (1.25mm2)

PC

● USB cable

Product No.: JXC-W1-2

位置 速度

100 500

200

1000

50

200

1

2

3

テスト

テスト

テスト

現在位置

120.3

現在速度

200

mm

mm/s

動作中

アラーム

モニタ

設定

位置 速度

100 500

200

1000

50

200

1

2

3

テスト

テスト

テスト

現在位置

120.3

現在速度

200

mm

mm/s

動作中

アラーム

モニタ

設定

●Controller set up kit

Contents

-Controller Setting Kit

-USB cable

Product No.: JXC-W1

PLC

Main control power

supply 24VDC

Motor control and

motor drive power

supply

24 VDC

●Power cable for main control

Cable length: 1.5m (Accessory)

Product No.: JXC-C1

Note2)

Note2)

Note2)

Note2)

●Controller setting software

Product No.: JXC-W1-1

Input/output

signal power

supply

24VDC

2.3 Product configuration

Structure of the controller.

Note 1) Connected actuators should be ordered separately.

Note 2) PLC, PC and 24VDC power supply should be prepared by theuser.

Wirning

Refer to 12. Common Precautions for wiring and cable.

Use “USB cable (JXC-W1-2)” when communicating with a PC.

Caution

Connector “CI3 4” must be connected even when axis 3 and 4 are not used. If not, a “Modbus

Error” alarm will be generated.

To M PWR

To I/O

●Controller

● Electric actuator

Note1)

Options

To CI

To ENC

To MOT

● I/O cable

Product No: JXC-C2-

To USB

Note1)

●Actuator cable

Part No:

LE-CP--

(Robotic type cable)

LE-CP---S

(Standard cable)

To C PWR

Page 11

- 10 -

No.SFOD-OMT0010-B

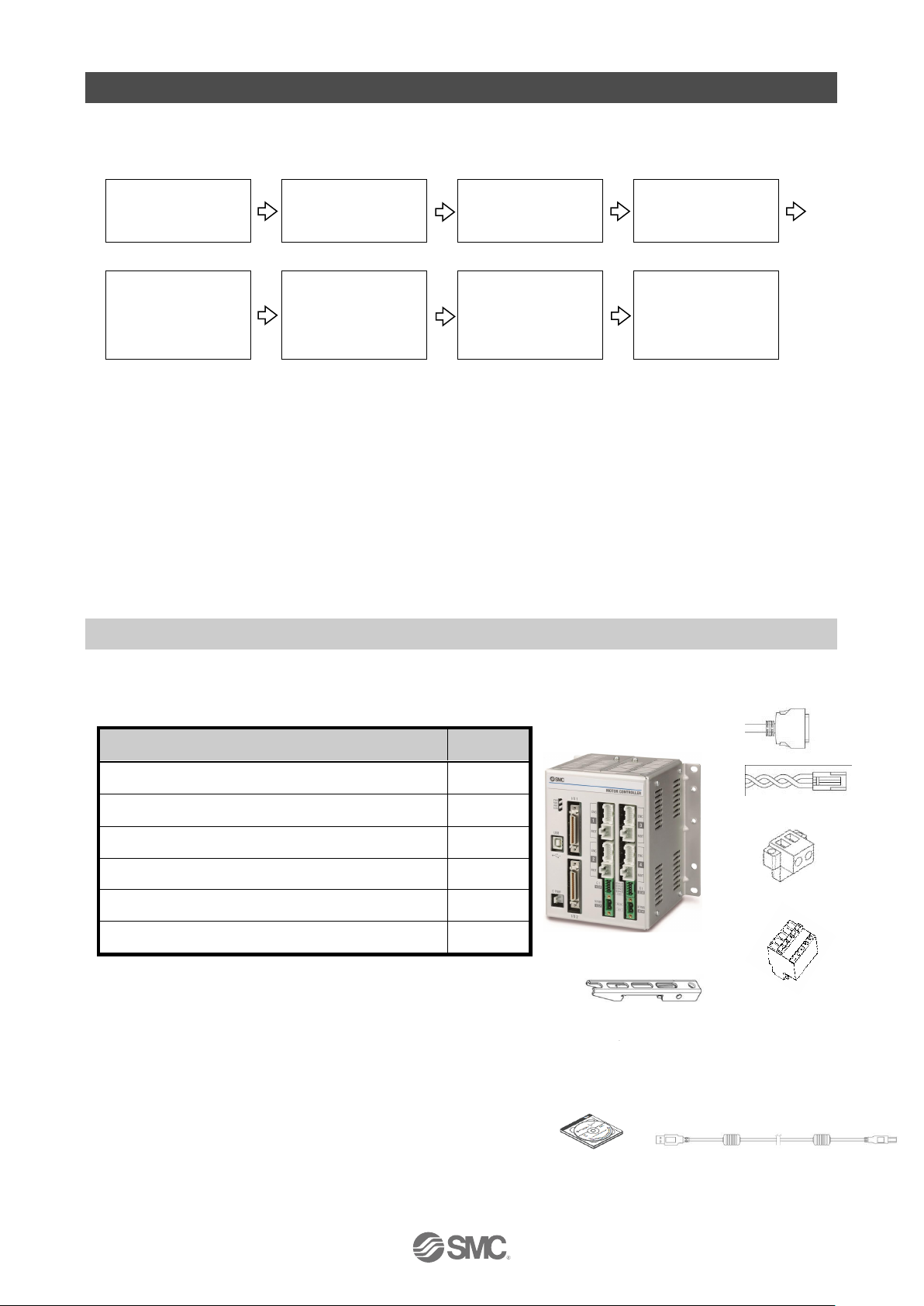

3. Procedures to Trial run

Install, wire, set and perform a trial run for the controller referring to the procedure below when using

the product for the first time.

Check the contents of

the package

Mounting the controller

Software Installation

Wiring and connecting

Supply power.

Start-up of controller

setting software

Parameters and

Step data

Check using JOG

operation

Operation test using

Test Drive.

For “Installation of the software”, refer to this operation manual and the Installation Manual for the

controller setting software (No.SFOD-OMT0008). For “Start-up of controller setting software”,

“Parameters and step data”, “Check using JOG operation” and “Operation test using Test Drive”,

please refer to the setting software operation manual (No.SFOD-OMT0012).

When this controller is used for the first time after purchase, do not upload the default values in the

controller.

Please download the information which has been set by the controller setting software and use it.

3.1 Checking the contents of the package

After unpacking everything, check the description on the label to identify the controller and the

number of accessories.

Note1) These items are included if you ordered by the

part number for a set of controller.

[Options]

Controller setting kit (Product model No.: JXC-W1)

(Controller setting software and USB cable are included.)

If any parts are missing or damaged, please contact your distributor.

Product name

Quantity

Controller (JXC3)

1 pc.

Power cable for main control (Length 1.5m)

1 pc.

Motor drive power connector

2 pcs.

Motor control power supply connector

2 pcs.

DIN rail mounting bracket

Note 1)

1 set

I/O cable

Note1)

2 pcs.

Controller Setting Kit

Controller

Power cable for main control

I/O cable

Note1)

Motor control power supply

connector

Motor drive power connector

USB cable

DIN rail mounting bracket

Note 1)

Mounting screw M5 x8 (4pcs.),

Holding screw M5 x14 (2pcs.) included

Page 12

- 11 -

No.SFOD-OMT0010-B

3.2. Mounting the controller

Refer to

4.4 Mounting

for instructions on how to mount the controller.

3.3 Install the setting software and the driver

Install the controller setting software and driver software on the PC to be used.

For details, refer to the Installation Manual for the controller setting software (No.SFOD-OMT0008).

3.4 Wiring and connection

Connect the cables to the controller.

Refer to section

2.3 Product configuration, 5.2 Wiring

and

6.4 Parallel I/O Wiring Example

for

wiring details.

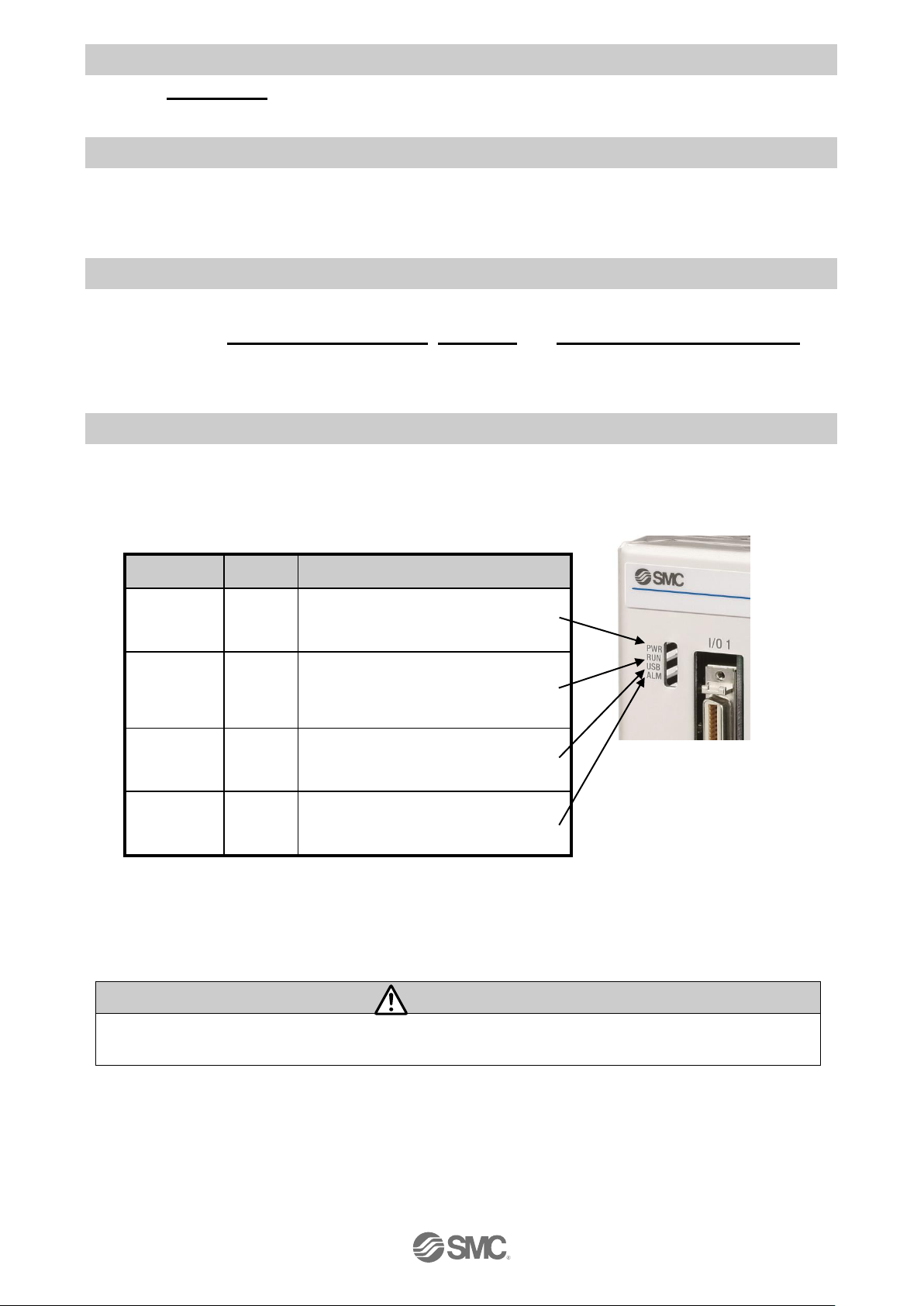

3.5 Power supply, Start-up of controller setting software, and Alarm check

(1) Supplying power

After supplying power for the motor control and motor drive, turn on the power supply for the main

control.

LED

Colour

Status

PWR

Green

ON: Power ON

OFF: Power OFF

RUN

Green

ON: Operating

Flashing: Operation by the setting

software

OFF: Not operated

USB

Green

ON: USB connected

OFF: USB not connected

ALM

Red

ON: Alarm is generated

OFF: Alarm is not generated

Check that thePWR LED is ON.

If the green PWR LED is not ON, check the wiring of the power supply and the power supply

voltage.

Caution

After supplying power for the motor control and motor drive, turn on the power supply for the

main control. Otherwise a“Modbus Error”alarm will be generated.

Page 13

- 12 -

No.SFOD-OMT0010-B

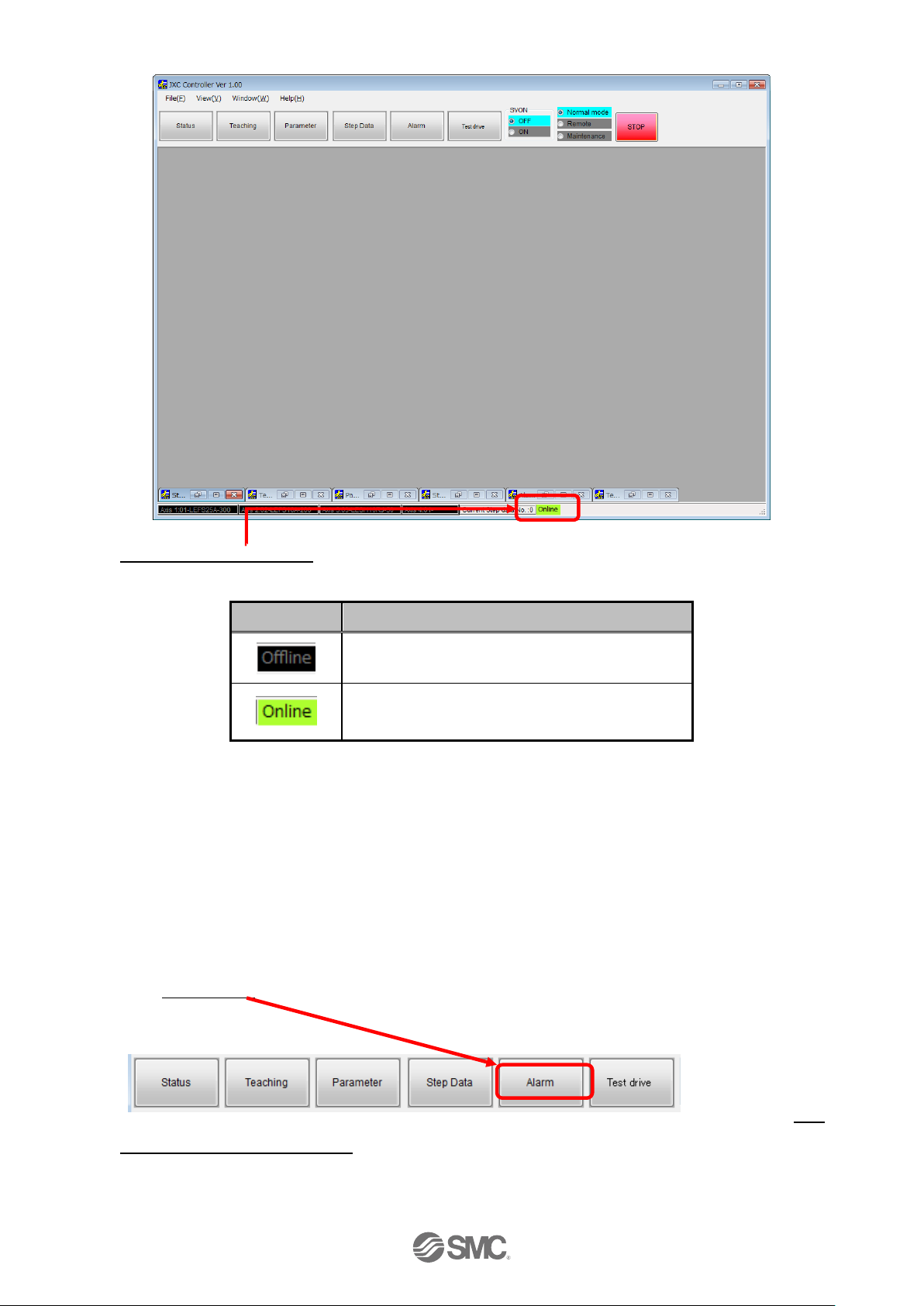

(2) Start-up of controller setting software

Using a PC with the controller setting software installed, start the application “SMC / JXC

Controller” to start the setting software.

If the controller setting software is installed with the default setting, an icon will be created on the

desk top. It is possible to start the setting software by double-clicking the icon.

When the setting software starts, the connection between the controller and PC is confirmed. The

screen below will be displayed when the communication is established correctly.

However, when the setting software is started for the first time, this window will not appear.

When power is supplied to the controller for the first time, the title window will be displayed.

The following window will be displayed after setting the parameters of the controller and the

connected actuator.

When selecting “No (N)”, the controller will start without uploading. The title window shown below

will be displayed.

When the PC is not able to communicate with the controller, the following screen is displayed.

When select “OK”, the title window will be displayed.

Page 14

- 13 -

No.SFOD-OMT0010-B

After the initial title window is displayed, the following main window will be displayed.

The communication status between the controller and PC is indicated at the bottom of the main

window.

Display

Details

Off-line state

On-line state

When the PC is able to communicate with the controller, "On-line" status is established

automatically.

If the communication is in the off-line state, the PC is not able to communicate with the controller.

Please check the following.

-

Check that power is supplied to the controller at the correct voltage.

- Check that the controller and the PC are connected to each other via the

communication cable.

- Check that the USB driver is installed correctly.

(3) Alarm check

If the Alarm button at the top of the main window of the setting software flashes red an alarm has

been generated.

It is possible to check the details of the generated alarm by clicking the Alarm button. Refer to

11.2

Alarms and countermeasures

for details of the countermeasures against the alarm, and reset

the alarm.

Page 15

- 14 -

No.SFOD-OMT0010-B

3.6 Parameters and Step data

When using for the first time or after changing the connected actuator, or when the settings of the

controller or connected actuator have been changed, it is necessary to review the set parameters and

step data.

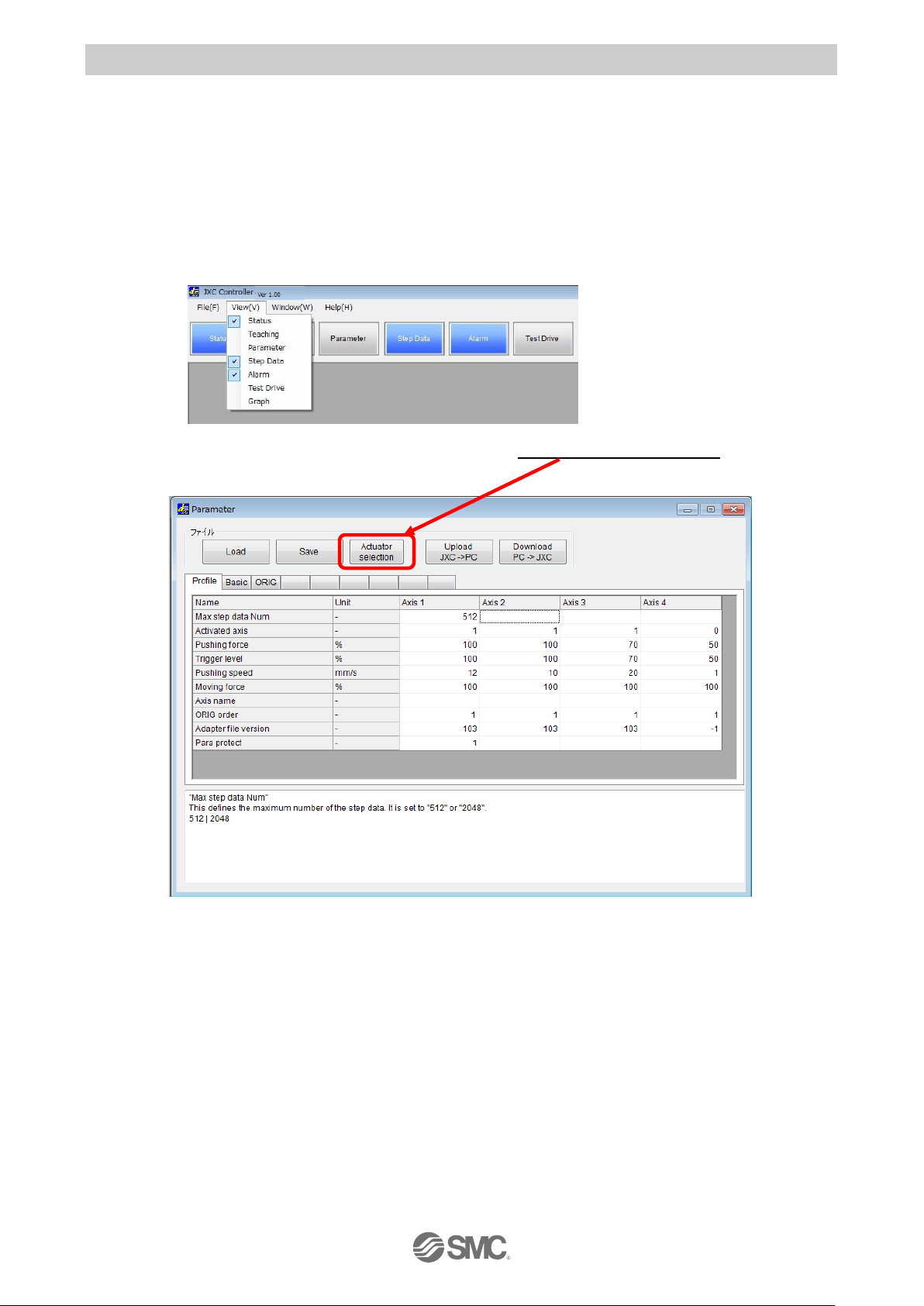

It is possible to display parameters and step data as shown below.

(1) Select the actuator

Select "View(V)" at the top of the main window, and check the parameters.

The Parameter window will be displayed.Select the "Actuator selection" button. The Actuator

selection window will be displayed.

Page 16

- 15 -

No.SFOD-OMT0010-B

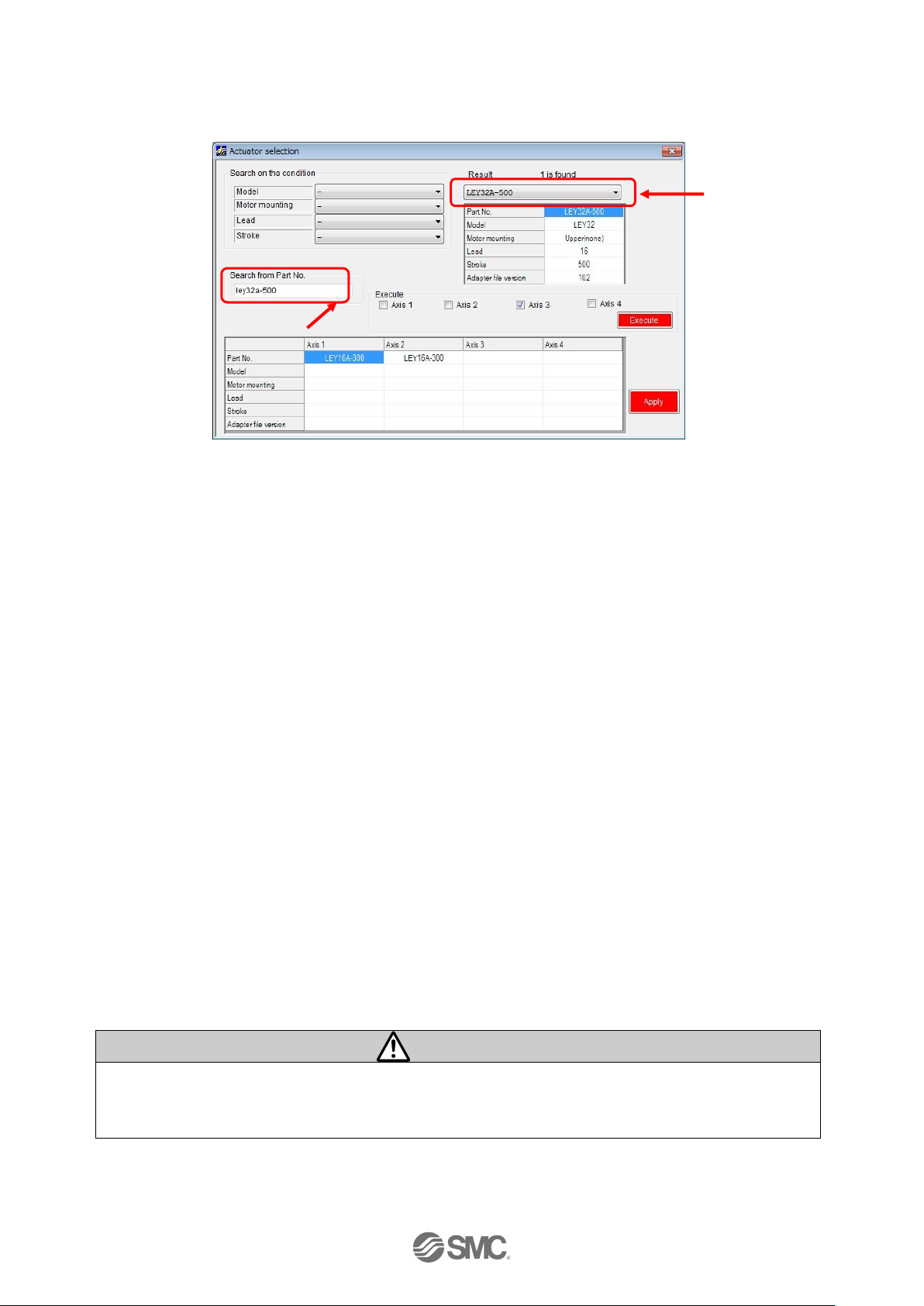

Input the partnumber of the actuator to be used in the “Search from Part No. area”.

A list of part numbers of the actuators matching the conditions will be displayed by clicking the

"Result" button. Select the actuator to be connected.

If the part number of the actuator to be used is already known, input the part number until stroke.

Example) When the LEY16RA-100BML is ordered, input ‘LEY16RA-100’.

When the LER series is used, input the part number including the rotation angle.

Example) When the LERH30K-3L is ordered, input ‘LERH30K-3’.

When there is no match in the results even when the stroke is input, the possible causes could

be :-.

(a) No applicable stroke

Input the part number without the stroke. Select the closest model to the actuator being used,

with a stroke which is longer than that of the actuator being used.

Example) When LEY16RA-75 is ordered, input ‘LEY16RA-100’.

(b) For LEFSH(High precision type)

Input LEFS to search.

Example) When LEFSH25RH-300 isordered, input ‘LEFS25RH-300’

(c) When a Clean type (11-) or Secondary battery type (25A-) is ordered.

Search without inputting 11- or 25A-, and find the actuator to which 11- or 25A- is applicable.

Example) When 11-LEFSH16A-100BR is ordered, input ‘LEFS16A-100’

Caution

When the stroke parameter selected is longer than the stroke of the actuator to be used, the

"position" input to the step data must not exceed the actuator stroke range.

When there is no actuator match, consult SMC.

Search from Part No. area

Result

Page 17

- 16 -

No.SFOD-OMT0010-B

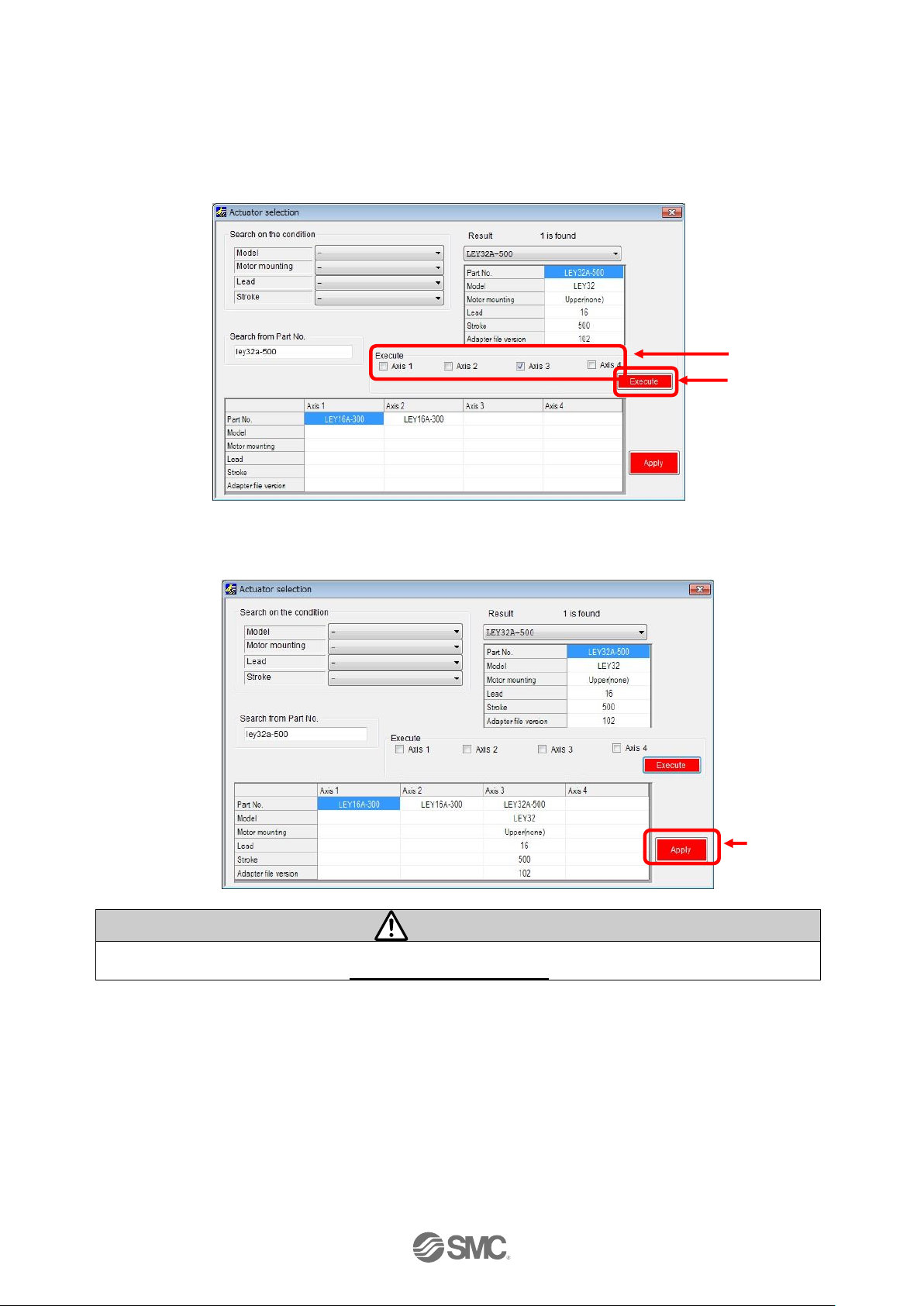

Select the check box for the axis for which parameters are to be input (one or more boxes are

possible to be selected).

Select the "Execute"

button.

Axis parameters will be displayed in the

Actuator selection window. The values input here are for display only, and are not written to

the controller.

Display the parameters for all axes.

Select the "Execute" button.

The parameters are copied to

the parameter window table.

Caution

Copying does not write parameters to the controller. Be sure to download the parameters

following the procedure in section 3.6 (2) Setting parameters.

Check box

Execute

Apply

Page 18

- 17 -

No.SFOD-OMT0010-B

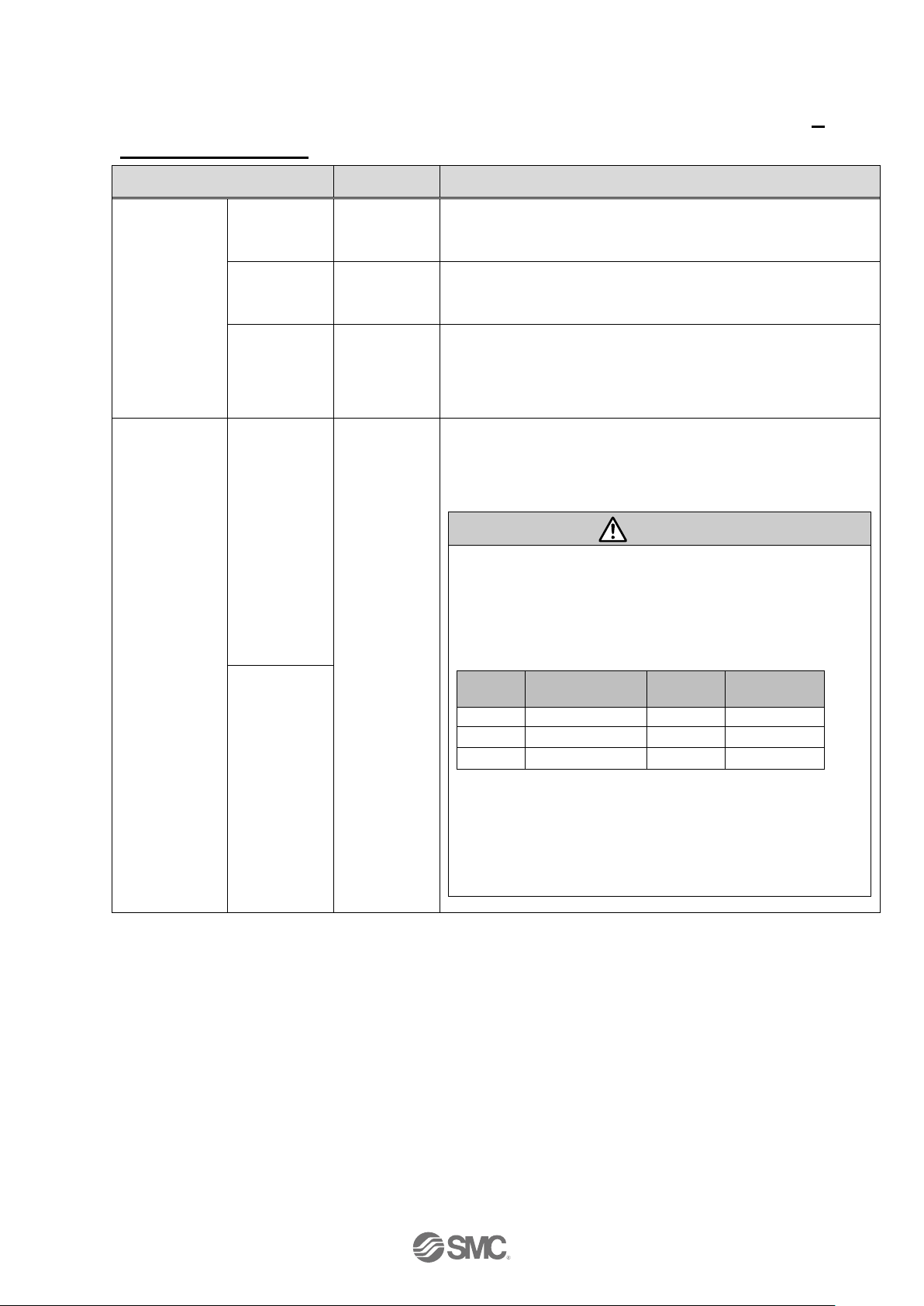

(2) Setting parameters

Set the parameters such as for valid axis and electronic gear.

Check the parameters below and change them if necessary. For other items, refer to section

7.

Settings and Data Entry

.

Parameter name

Input range

Outline

Profile

parameter

Max step

data Num

512 or

2048

Maximum step data. Change if necessary.

Activated

axis

0 or 1

Set the validity of the axes. Set "0" (invalid) when no

actuator is connected. Set "1" (valid) when connected.

ORIG

order

1 to 4

The order for axes to return to origin. The order is assigned

from 1 to 4. Multiple axes are possible to return to origin

simultaneously by setting the same order number.

Basic

parameter

Undefined

No.11

1 to 4096

Define the Electronic Gear.

Undefined parameter No.11: Electronic gear (numerator)

Undefined parameter No.12: Electronic gear (denominator)

Caution

When interpolation is performed for actuators of

different lead, the travel distance per pulse must be the

same. Otherwise do not change the distance.

Set the electronic gear for Axis 2, 3 or 4 so that the travel

distance for all of them are the same as Axis 1.

[Setting example]

Axis

Actuator

Lead

Electronic

gear ratio

Axis 1

LEY16C-300

2.5mm

1/ 1

Axis 2

LEY16B-300

5mm

25/ 50

Axis 3

LEY16A-300

10mm

25/ 100

Set Axis 2 and 3 so that the travel distance becomes

2.5mm per 800 pulse.

Electronic Gear ratio

= Lead of Axis 1/ Lead of Axis 2(or Axis 3)

=2.5mm/5mm (or 2.5mm/10mm)

=25/50 (or 25/100)

Undefined

No.12

Page 19

- 18 -

No.SFOD-OMT0010-B

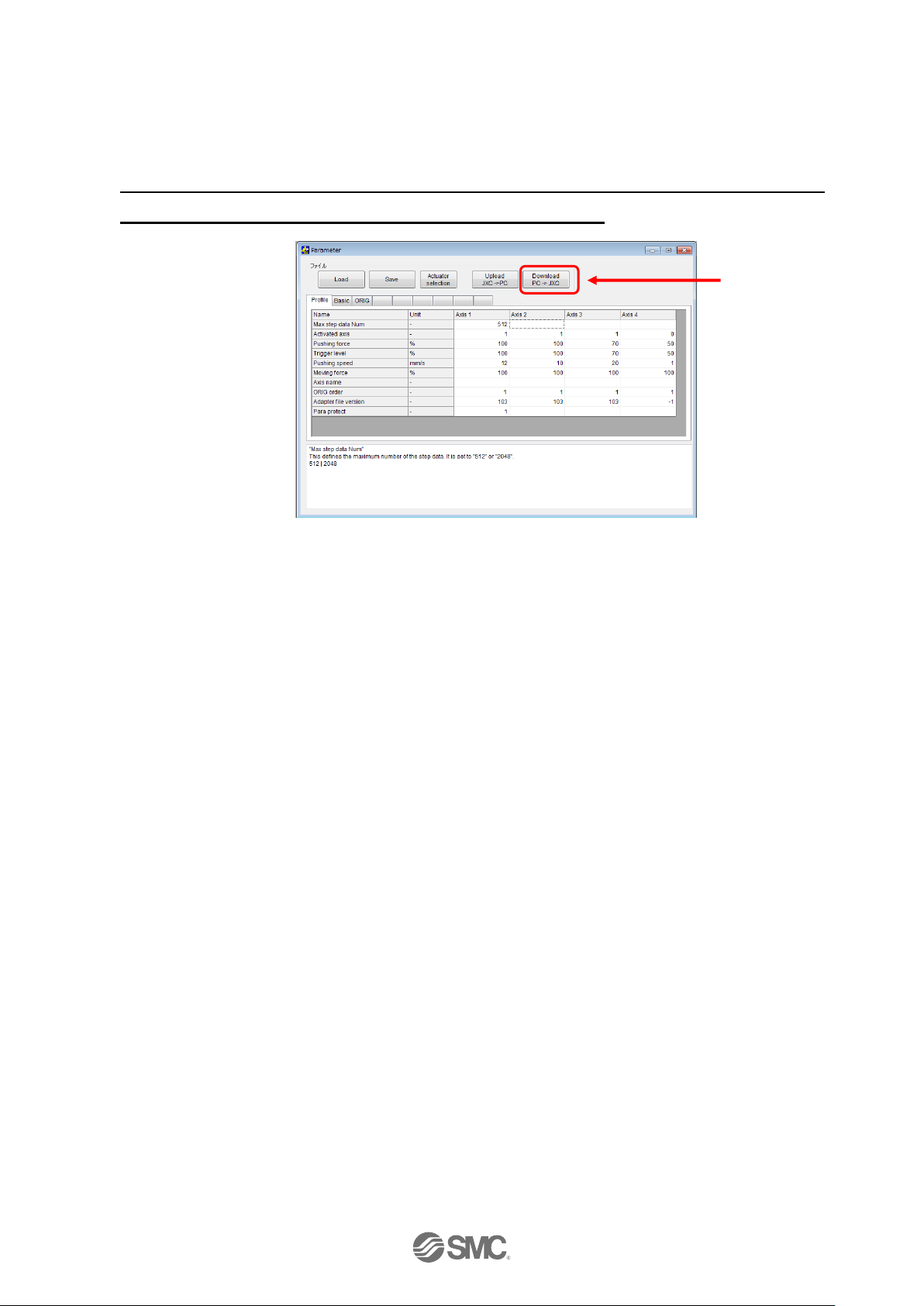

After setting parameters, select the "Download" button in the parameter window. Parameters in the

parameter window will be written to the controller. Writing is completed when the progress bar

disappears and then the setting software is ready to operate.

It is necessary to turn off the power to the controller and turn it on again. The downloaded

parameters will become valid after turning the power on again.

Download

Page 20

- 19 -

No.SFOD-OMT0010-B

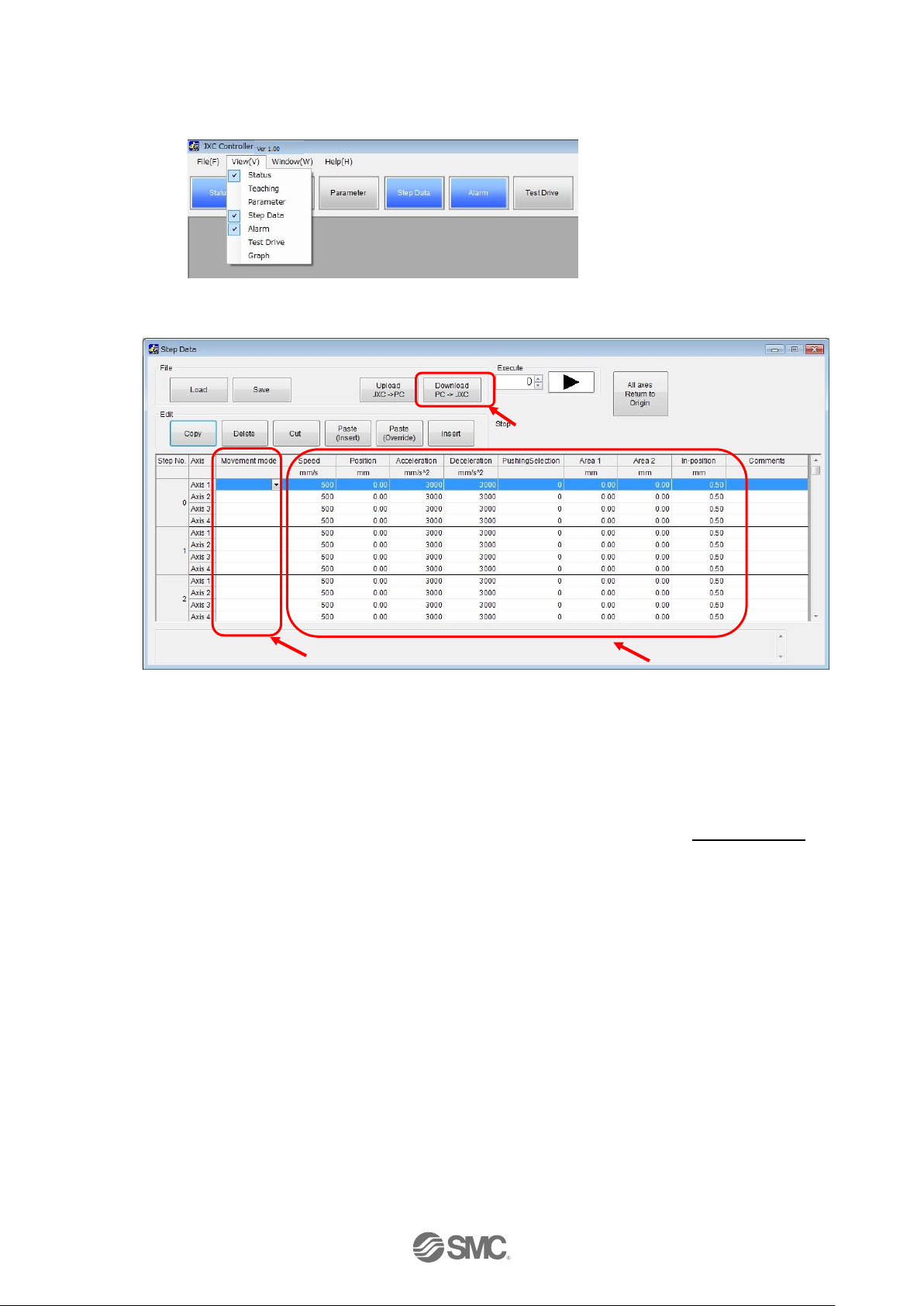

(3) Step data settings

Select "View(V)" at the top of the main window, and select "Step Data".

The Step data window will be displayed.

Select the “▼” button for the movement mode for the axis of the step number to be set. Select the

movement mode shown in the list. Enter the necessary numerical data according to the selected

movement mode.

The setting is different depending on the movement mode. Refer to section

7.4 Step Data

for

details.

After setting the step data, select the "Download" button in the step data window. The step data will

be written to the controller. Writing is completed when the progress bar disappearsand then the

setting software is ready to operate.

Movement mode

Area to input numerical data.

Download

Page 21

- 20 -

No.SFOD-OMT0010-B

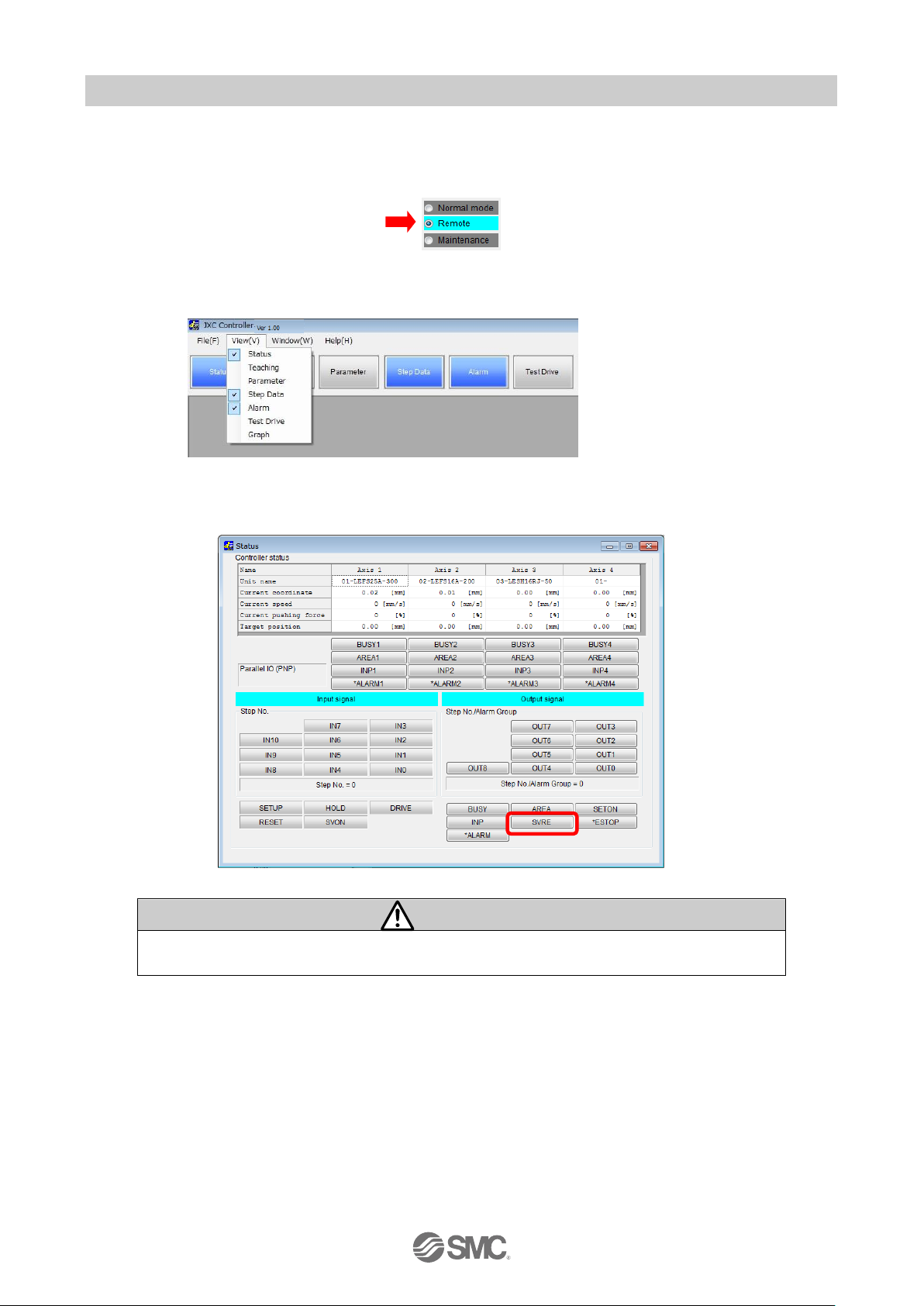

3.7 Check using JOG operation

(1) Change to Remote mode

Change the mode to Remote mode at the top of the main window. The Servo will be turned on by

selecting Remote mode.

Confirm that the Servo is ON. (Confirm SVRE ON in the status window.)

Select "View(V)" at the top of the main window, and select "Status".

The Status window will be displayed. When the Servo is ON, the SVRE box will turn blue in the

Output signal area.

Caution

When the power is supplied, it may take up to 20 seconds from servo ON input to SVRE

ON output, depending on the actuator position or the conditions.

Page 22

- 21 -

No.SFOD-OMT0010-B

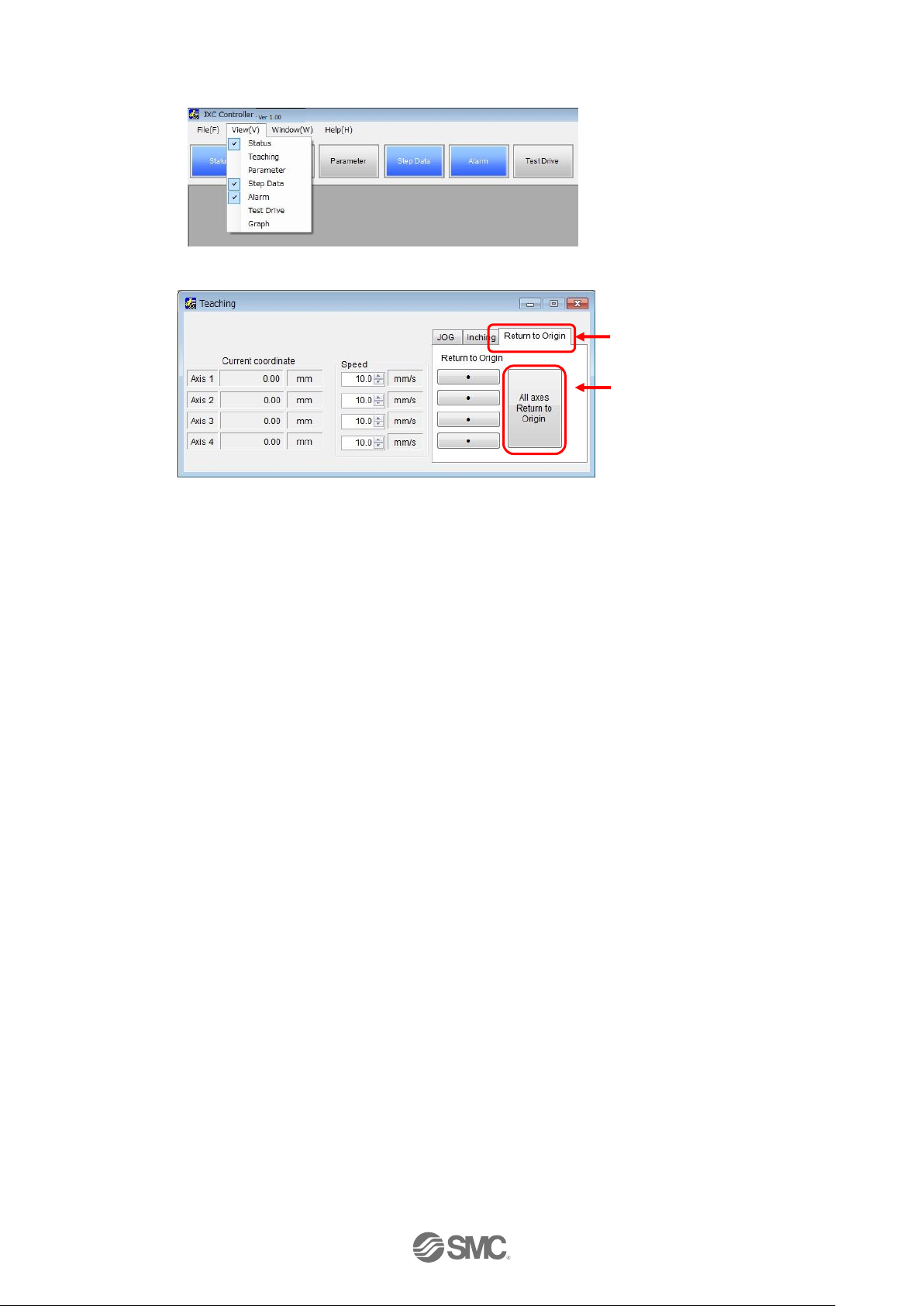

(2) Return to origin

Select "View(V)" at the top of the main window, and select "Teaching".

The teaching window will be displayed.

Select the “Return to Origin” tab. Select “Return to Origin(●)” or “All axes Return to Origin”.

When the return to origin setting is completed, SETON is ON. Confirm that the output signal

SETON turns blue in the status window.

All axes Return to Origin

Return to Origin tab

Page 23

- 22 -

No.SFOD-OMT0010-B

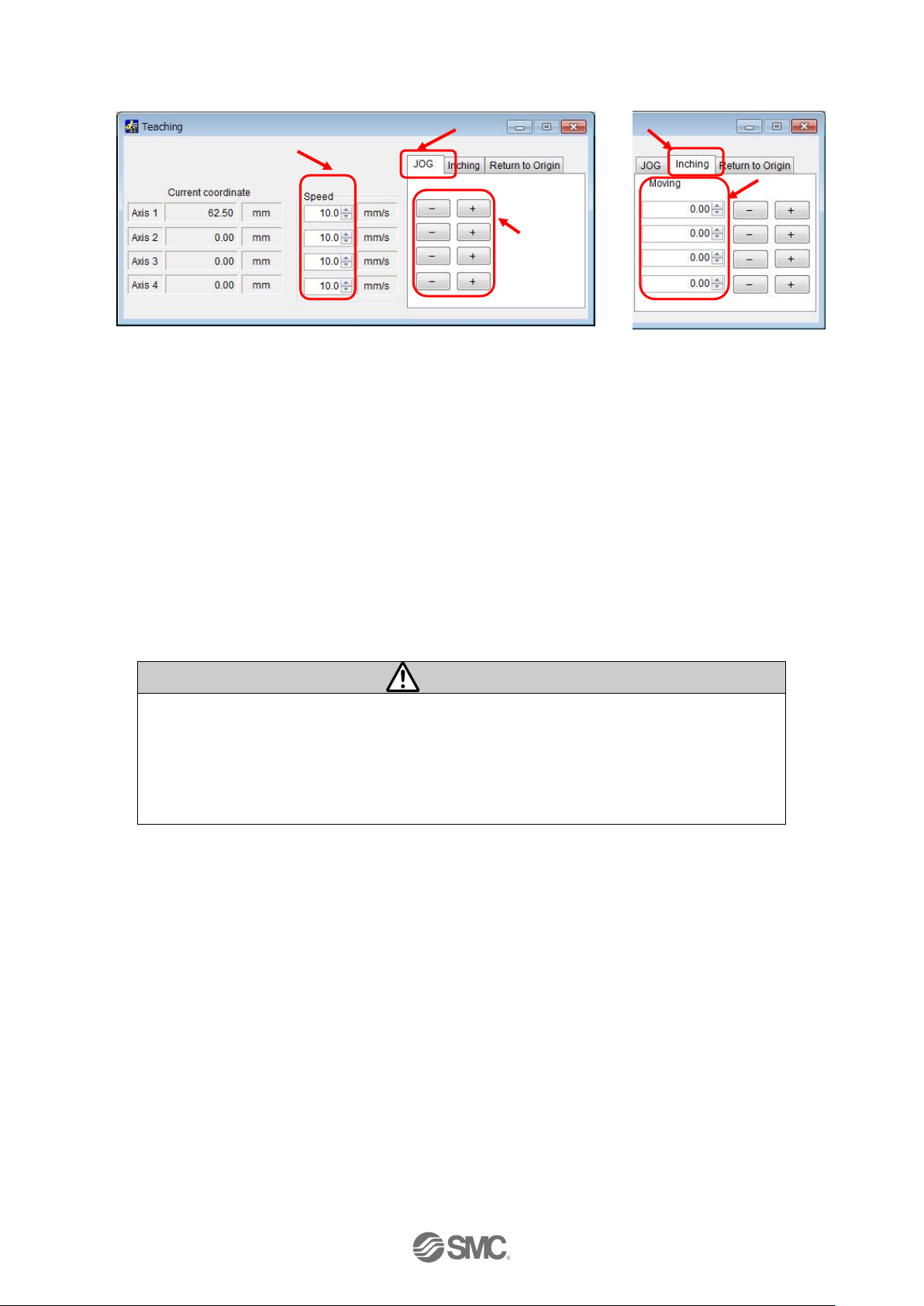

(3) JOG or Inching

Select the “JOG” or “Inching” tab.

(a) JOG

Set the "Speed". The Position will move in the "+" or "-" direction as long as the "+" or "-"

button is pressed.

(b) Inching

Set "Speed" for travel speed and "Moving" for travel distance. The Position will move in the "+"

or "-" direction during setting.

Confirm that the connected actuator travels at the speed or distance according to the connected

actuator setting.

Caution

When perform return to origin operation, JOG function and Inching function for the first

time, make sure that the parameter setting is correct.

When the electronic gear is set, make sure that the actuator travels for the set travel

distance by performing the inching function.

It is possible that unexpected operation will result in accidents, injury, or damage to the

system or actuator.

Speed

JOG tab

+/- button

Inching tab

Travel distance

Page 24

- 23 -

No.SFOD-OMT0010-B

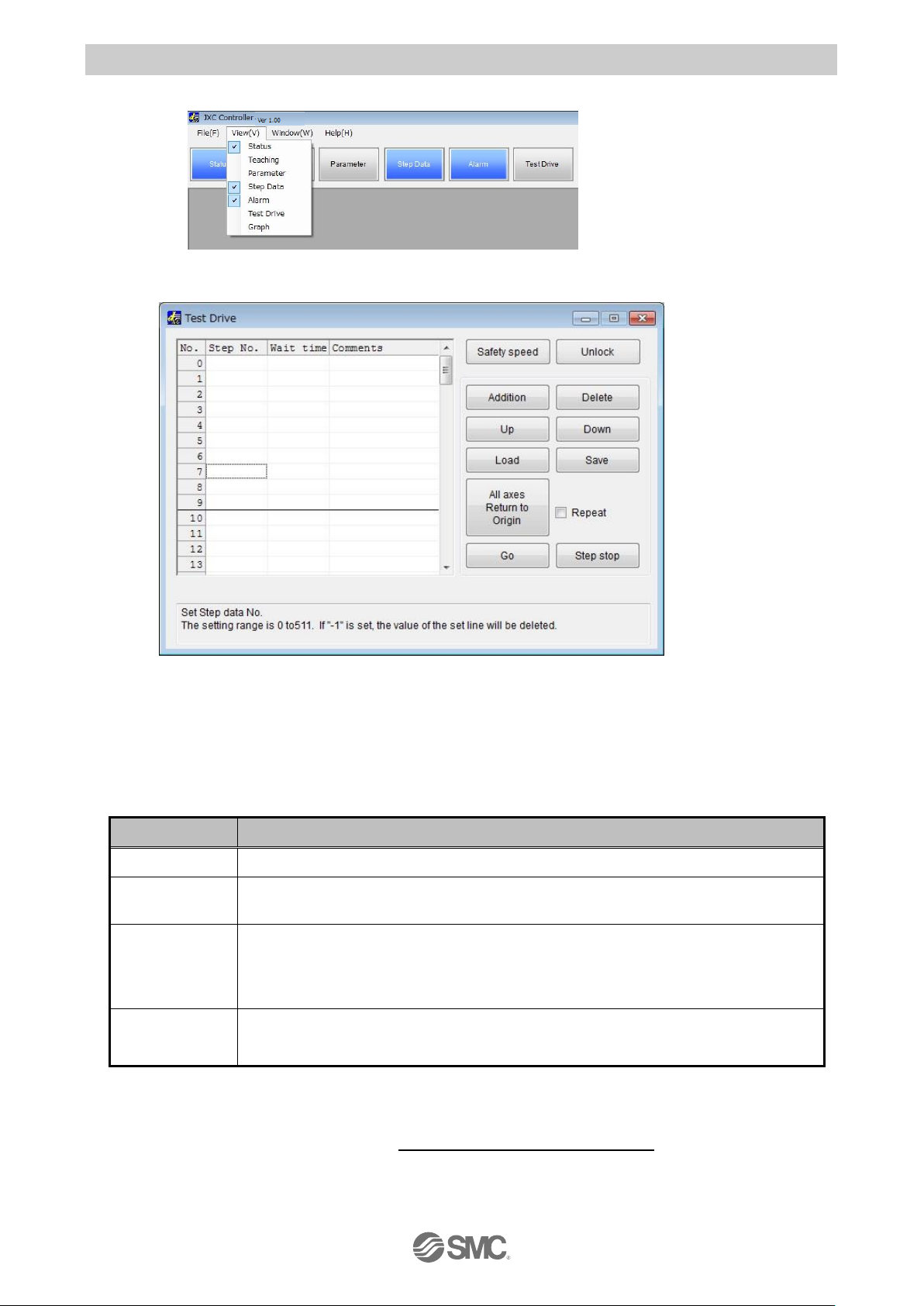

3.8 Operation test using Test Drive

Select "View(V)" at the top of the main window, and select "Test Drive".

The Test Drive window will be displayed.

It is possible to test the set step data in a specified order.

(1) Test Drive setting

Set the order of the step data number for testing in the test drive list window. The table below

shows details of the items required.

Items

Details

No.

Line number.

Step No.

Step number to be executed.

The set line is deleted by entering "-1".

Wait time

Wait time after the actuator has been operated by the step data, specified by

the step number. Unit is msec.

Setting range is 0 to 32767 msec.

Comments

Comments are possible to be entered. (Note that half-width comma "," cannot

be used).

(2) Change to Remote mode

Turn on the Servo, referring to section

3.7 (1) Change to Remote mode.

Page 25

- 24 -

No.SFOD-OMT0010-B

(3) Return to origin

Confirm that SVRE output is ON, refer to section

3.7 (1) Change to Remote mode

. Then, select

"All axes Return to Origin", and perform the “Return to origin” operation.

(4) Test drive starts

Confirm that SETON output is ON, refer to section

3.7 (2) Return to origin

.

Test drive starts by pressing the "Go" button, based on the test drive list.

Test drive is completed when the correct operation is confirmed. If the operation was not as

expected, then refer to section

3.6 (3) Step data settings

to revise the settings.

Caution

Do not disconnect the USB cable while executing step data.

The actuator will stop.

Page 26

- 25 -

No.SFOD-OMT0010-B

4. Product Specifications

4.1 Basic Specifications

Basic specifications of the product.

Item

Specifications

Number of axes per

controller

Max. 4 axis

Controlled motor

Step motor (servo 24 VDC )

Controlled encoder

Incremental phase A / B (Encoder resolution 800 pulse / rotation)

Power supply

specification

Note1)

Main control power supply

Power supply voltage: 24VDC+/-10%

Max. current consumption: 300mA

Motor drive and motor control power supply

Power supply voltage: 24VDC+/-10%

Max. current consumption: Depends on connected actuator.

Note2)

Parallel input

16 inputs (Optically isolated)

Parallel output

32 outputs (Optically isolated)

Serial

communication

USB2.0 (Full Speed 12Mbps)

Memory

Flash ROM and EEPROM

LED indicator

PWR (green), RUN (green), USB (green), ALM (red)

Lock control

With forced lock-release terminal

Note3)

Cable length

I/O cable: 5 m maximum

Actuator cable: 20 m maximum

Cooling method

Natural air cooling

Operating

temperature range

0 to 40oC (No freezing)

Operating humidity

range

90% RH or less (No condensation)

Storage

temperature range

-10 to 60oC (No freezing)

Storage humidity

range

90% RH or less (No condensation)

Insulation

resistance

Between the external terminals and case

50MΩ (500 VDC)

Weight

1050 g (Direct mounting)

1100 g (DIN rail mounting)

Note 1) Do not use a power supply with "inrush currentprotection" for the motor drive power

and motor control power supply.

Note 2) Power consumption depends on the actuator connected.Refer to the actuator

specifications for further details.

Note 3) Applicable to non-magnetizing lock.

Page 27

- 26 -

No.SFOD-OMT0010-B

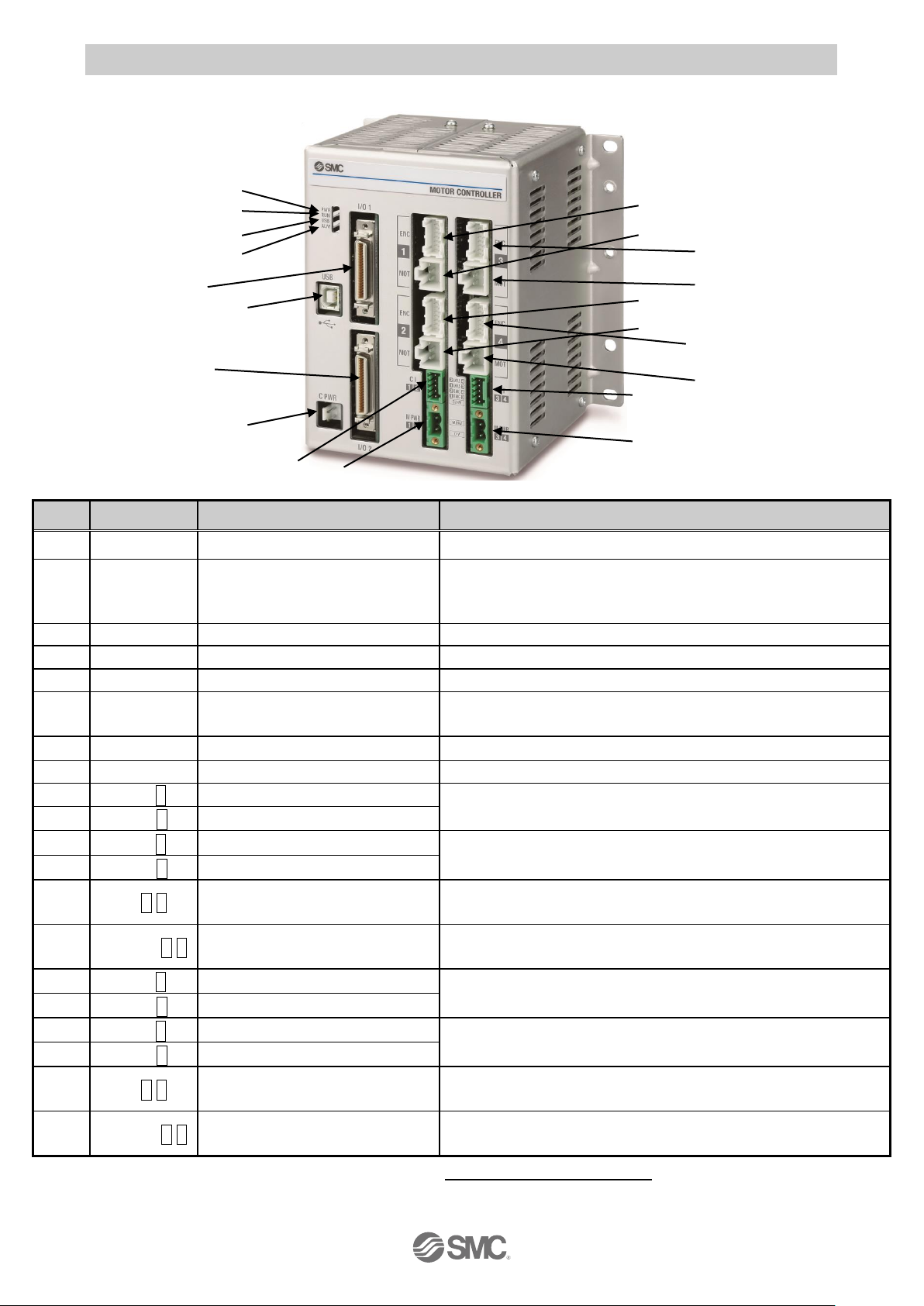

4.2 Parts Description

Detail of the controller parts.

No.

Display

Description

Details

1

PWR

Power supply LED (green)

Power supply ON: LED is ON Power supply OFF: LED is OFF

2

RUN

Operating LED (green)

Operation by parallel I/O: LED is ON

Operation by USB communication: LED is Flashing

Stop: LED is OFF

3

USB

USB LED (green)

USB connected: LED is ON USB not connected: LED is OFF

4

ALM

Alarm LED (red)

Alarm condition: LED is ON No alarm: LED is OFF

5

USB

Serial communication

Connect to a PC using a USB cable.

6

C PWR

Main control power supply

connector (2 pin)

Note)

Main control power supply (+)(-)

7

I/O 1

Parallel I/O connector (40 pins)

Connect to the PLC using an I/O cable.

8

I/O 2

Parallel I/O connector (40 pins)

Connect to the PLC using an I/O cable.

9

ENC1

Encoder connector (16 pins)

Axis 1: Connect the actuator cable.

10

MOT1

Motor power connector (6 pins)

11

ENC2

Encoder connector (16 pins)

Axis 2: Connect the actuator cable.

12

MOT2

Motor power connector (6 pins)

13

CI 1 2

Motor control power supply

connector

Note)

Motor control power supply(+), Axis 1 stop(+), Axis 1 unlock(+), Axis 2

stop(+), Axis 2 unlock (+)

14

M PWR 1 2

Motor drive power connector

Note)

Axis 1, Axis 2 Motor drive power (+), common(-)

15

ENC3

Encoder connector (16 pins)

Axis 3: Connect the actuator cable.

16

MOT3

Motor power connector (6 pins)

17

ENC4

Encoder connector (16 pins)

Axis 4: Connect the actuator cable.

18

MOT4

Motor power connector (6 pins)

19

CI 3 4

Motor control power supply

connector

Note)

Motor control power supply(+), Axis 3 stop(+), Axis 3 unlock(+), Axis

4 stop(+), Axis 4 unlock (+)

20

M PWR 3 4

Motor drive power connector

Note)

Axis 3, Axis 4 Motor drive power (+), common(-)

Note) The connector is included. Refer to section

5. Power supply connector

.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(20)

(19)

(17)

(18)

Page 28

- 27 -

No.SFOD-OMT0010-B

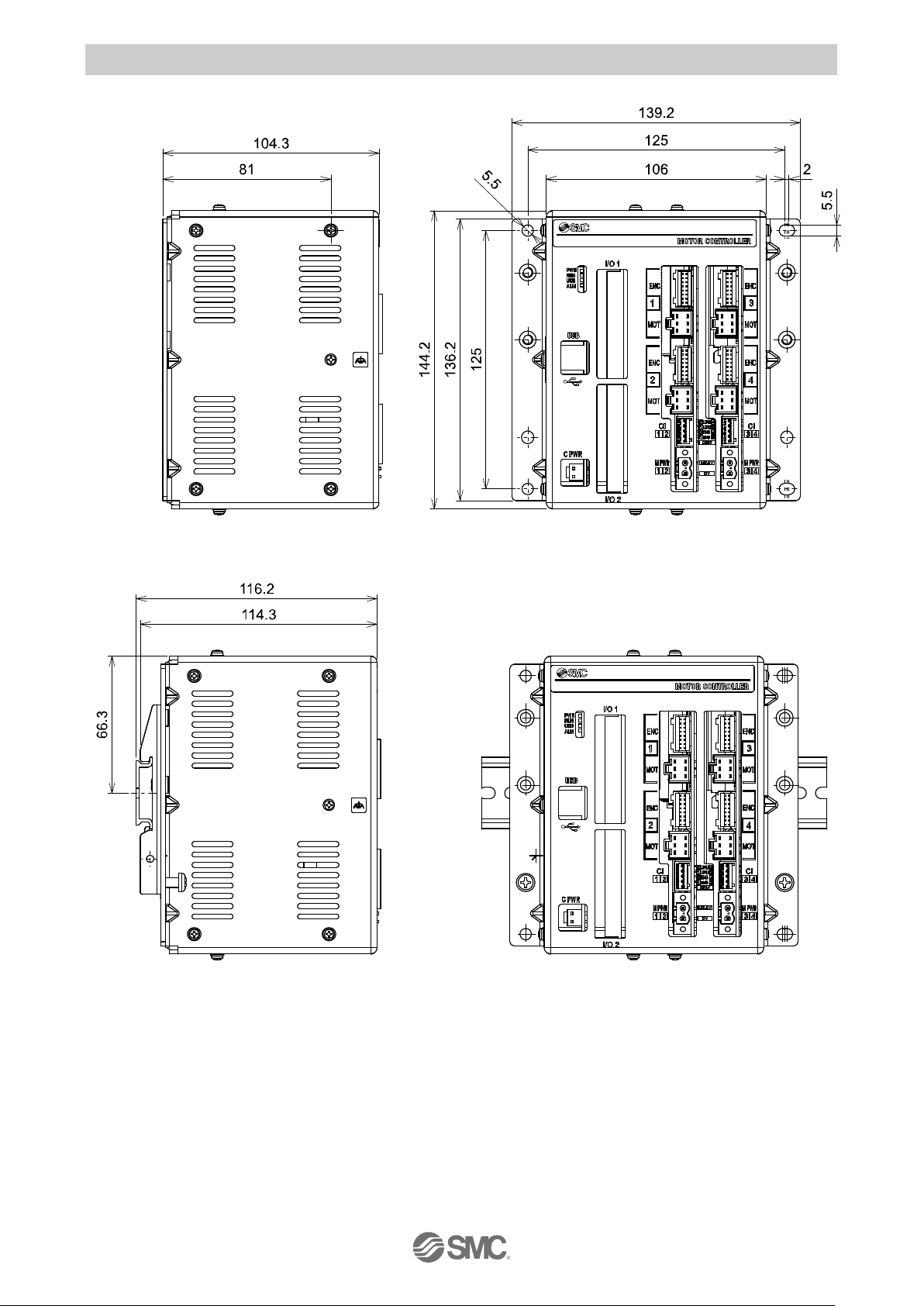

4.3 Dimensions

(1) Direct mounting

(2) DIN rail mounting

Page 29

- 28 -

No.SFOD-OMT0010-B

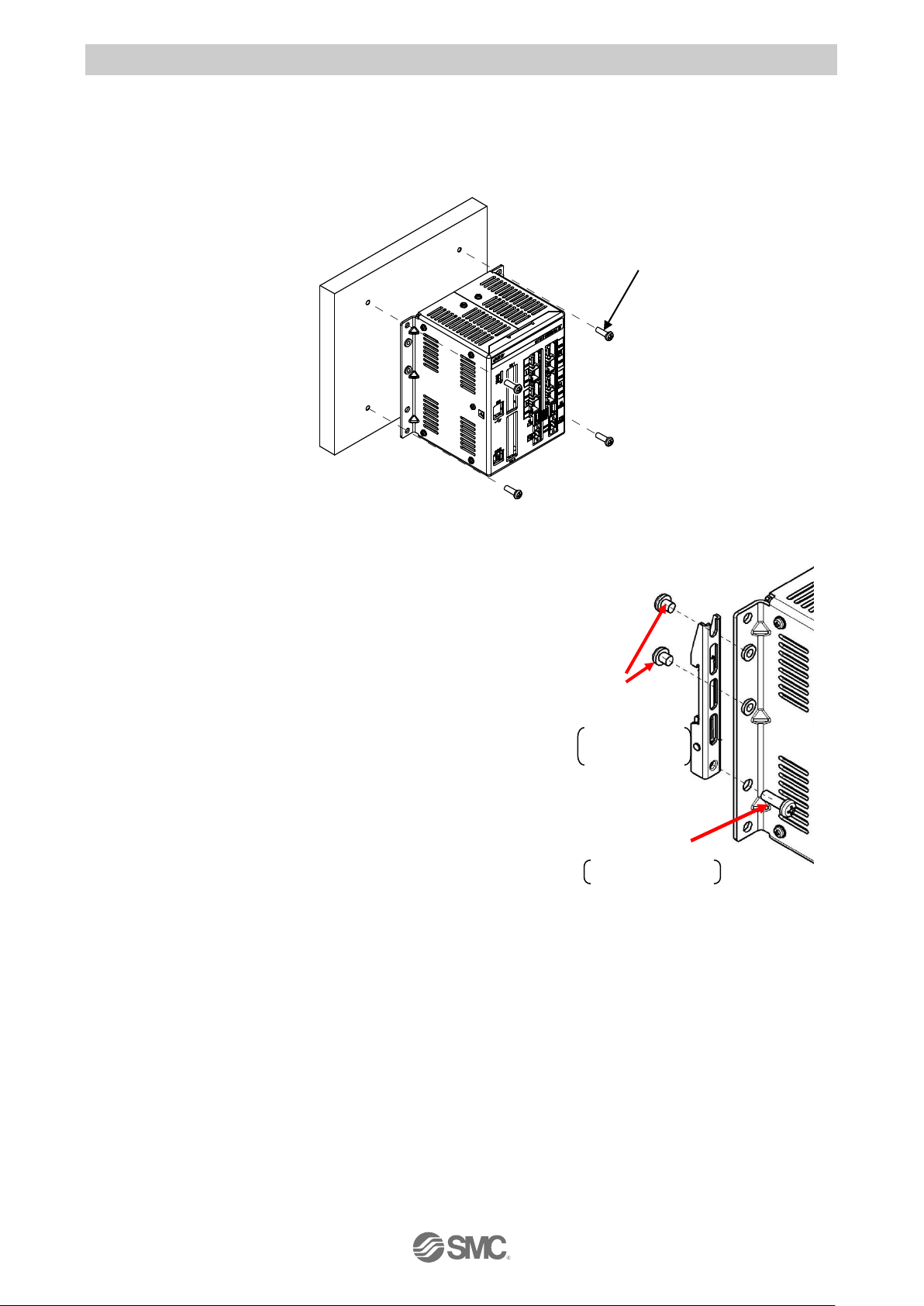

4.4 Mounting

(1) Mounting

There are two ways to mount the controller. (Direct mounting with screws and DIN rail mounting)

Controller mounting methods are shown below.

(a) Direct Mounting with four M5 screws

(b) DIN rail mounting

The figure on the right shows how to mount the DIN rail

mounting brackets.

Secure the DIN rail mounting bracket using the mounting

screws (M5 x 8) 2 places on one side (4 places on both

sides). (Appropriate tightening torque: 3.0Nm)

Secure the DIN rail mounting bracket using the holding

screws (M5 x 14). 1 place on one side (2 places on both

sides). Tighten for approximately 2 threads.

Do not tighten completely.

Mounting screw

M5X8

Included with DIN

rail mounting

bracket

Tightening torque:

3.0 (Nm)

Holdingscrews

M5X14

Included withDIN

rail mounting bracket

Tightening torque: 0.4 to 0.6[Nm]

Mounting screw (M5) 4pcs.

(prepared by customer)

Page 30

- 29 -

No.SFOD-OMT0010-B

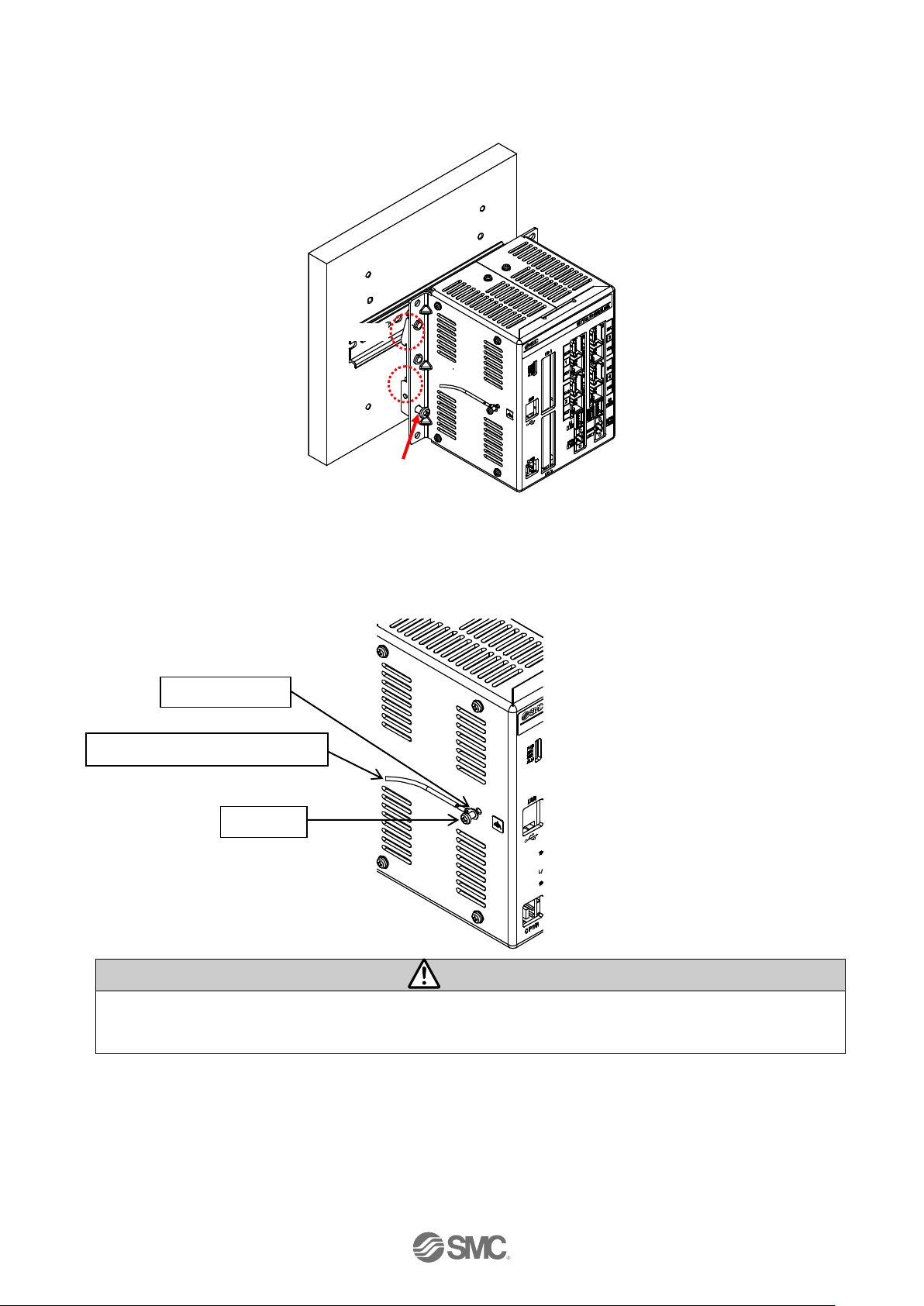

The figure below shows how to mount the controller to the DIN rail. Hook part A on to the DIN

rail. Press part B on to the DIN rail and tighten the holding screws (M5 x 14). (Appropriate

tightening torque: 0.4 to 0.6Nm)

(2) Grounding

Fit the grounding cable with crimped terminal between the M3 screw and shakeproof washer as

shown below and tighten the screw.

Caution

The cable with crimped terminal and shakeproof washer must be prepared by the user.

The controller must be connected to Ground to reduce noise.

Part A

Part B

Holding screw

M5X14

M3 screw

Grounding cable (with crimped terminal)

Shakeproof washer

Page 31

- 30 -

No.SFOD-OMT0010-B

Caution

(1) A dedicated ground connection must be used. Grounding should be to a D-class ground (ground

resistance of 100Ω or less).

(2) The cross sectional area of the grounding cable should be 2mm2 minimum.

The grounding point should be as near as possible to the controller, to keep the grounding cable

as short as possible.

(3) Mounting location

Design the size of the control panel and the installation so that the temperature surrounding the

controller is 40oC or less. Mount the controller vertically with 50 mm or more space at the top and

bottom of the controller as shown below.

Establish the space more than 100mm between the front of the controller and a door (lid) so that

the connectors are possible to connect and disconnect. Leave enough space between the

controllers so that the operating temperature of the controllers remains within the specification

range. Allow sufficient space for mounting. Avoid mounting the controller near a vibration source,

such as a large electromagnetic contactor or no-fuse breaker on the same panel.

Caution

If the mounting surface for the controller is not flat or is uneven, excessive stress could be

applied to the case, which could cause failure. Mount on a flat surface.

Shared grounding: Not acceptable

Controller

Other

equipment

Dedicated grounding: Good

Controller

Other

equipment

D-class ground

(ground with the

resistance less than

100 ohm)

100 or more

Page 32

- 31 -

No.SFOD-OMT0010-B

5. Power supply connector

5.1 Connector specifications

The power supply connector type included is shown below.

(1) Main control power supply connector: C PWR

Use the power cable for main control, JXC-C1.

Specifications of the cable are as follows.

Item

Specifications

Electric wire size

Stranded wire → AWG20 (0.5mm2)

O.D. of sheath →1.76

Wire sheath colour

+24V:Brown

24-0V: Blue

(2) Motor drive power connector: M PWR

Manufactured by Phoenix Contact (Part number MSTB2,5/2-STF-5,08)

Prepare the electrical wiring according to the following specifications (to be prepared by the user).

Item

Specifications

Applicable wire size

Single, Stranded wire → AWG16(1.25mm2)

The rated temperature of the insulation coating should be

60oC or more.

Stripped wire length

When the wire is inserted into the motir drive power connector, insert only the stripped part of the

wire.

Terminal

Function

Description

+24V

Main control power supply (+)

Power supply (+) for main control.

24-0V

Main control power supply (-)

Power supply (-) for main control.

Terminal

Function

Description

0V

Motor power (-)

Power supply (-) common for M24V terminal, C24V

terminal, EMG terminal and LKRLS terminal

M24V

Motor power (+)

Motor drive power supply (+) for Axis 1 and 2 or

Axix 3 and 4.

+24V

24-0V

0V

M24V

Brown

Blue

7mm

3.4

or less

Page 33

- 32 -

No.SFOD-OMT0010-B

(3) Motor control power supply connector: CI

Manufactured by Phoenix Contact (Part number FK-MC0,5/5-ST-2,5)

Prepare the electrical wiring according to the following specifications (to be prepared by the user).

Item

Specifications

Applicable wire size

Single, Stranded wire → AWG20 (0.5mm2)

The rated temperature of the insulation coating should be

60oC or more.

Stripped wire length

When the wire is inserted into the motor control power supply connector, insert only the stripped

Terminal

Function

Functional explanation

C24V

Motor control power

supply (+)

Power supply side (+) for motor control.

EMG1/EMG3

Stop(+)

Release the stop status (+) of Axis 1 or Axis 3.

(Normal operation by applying 24V.)

EMG2/EMG4

Stop(+)

Release the stop status (+) of Axis 2 or Axis 4.

(Normal operation by applying 24V.)

LKRLS1/LKRLS3

Unlock(+)

Release the lock status (+) of Axis 1 or Axis 3.

LKRLS2/LKRLS4

Unlock(+)

Release the lock status (+) of Axis 2 or Axis 4.

Caution

Do not connect multiple wires into one terminal.

Contact failure or short circuit to adjacent wire may lead to malfunction or fire.

EMG1/EMG3 C24V LKRLS2/LKRLS4 EMG2/EMG4 LKRLS1/LKRLS3

8mm

2.0

or less

Page 34

- 33 -

No.SFOD-OMT0010-B

5.2 Wiring

Connect the main control power supply, motor drive and motor control power supply while referring to

(1) to (3) below, and then insert into the controller C PWR, Cl and M PWR.

(1) Wiring of the power supply connector

Connect the main control power supply 24V and 0V to the main control power supply connector

+24V and 24-0V terminals.

Connect the motor drive and motor control power supply 24V and 0V to the motor drive power

connector M24V and 0V terminals.

Connect the motor drive and motor control power supply 24V to the motor control power supply

connector C24V terminal.

Caution

(1)Do not use a power supply with “inrush current protection” for the motor drive and motor control

power supply. The power supply capacity should be greater than the "Momentary maximum

power consumption” of the actuator specifications.

(2)Connector ‘CI3 4’ must be connected even when Axis 3 and 4 are not used.

If not, a "Modbus Error" alarm will be generated.

(3)The motor power and motor control power supply should be powered at the same time or prior to

the main control power supply.

If the sequence of these power supplies is different then a "ModbusErr or" alarm will be generated.

24V

Motor drive and

motor control

power supply

0V

M24V

0V

Open/close lever

Press the open/ close lever with a flat blade

screwdriver and insert the wire into the wire entry.

- Dedicated flat blade screwdriver (recommended)

Phoenix Contact (Part No: SZS0.4×2.0)

Wire entry

24V

0V

Motor drive and

motor control

power supply

C 24V

EMG1/EMG3

LKRLS1/LKRLS3

Motor control power supply connector

EMG2/EMG4

LKRLS2/LKRLS4

M3 screw

Screw type terminal.

Loosen the screws using a flat blade screwdriver.

Insert the wires in the wire inlet.

Tightening torque: 0.5 to 0.6Nm

+24V

24-0V

24V

Main control

power

supply

0V

Page 35

- 34 -

No.SFOD-OMT0010-B

Motor drive and

motor control

power supply

Motor drive and

motor control

power supply

CI1 2

CI3 4

CI3 4

CI1 2

(2) Wiring of the stop switch

A Stop switch must be installed by the user to stop the actuator in abnormal situations. The

actuator stops its operation when the external shutdown switch is activated.

- Stop (Stop switch)

To stop the controller, connect the stop switch (B contact) between the motor drive and motor

control power supply and the EMG terminal of the motor control power supply connector.

- Stop (Stop relay contact)

If there is a separate shutdown circuit for the whole installation or there are multiple controllers

with different power supplies, connect a relay (B contact) between the motor drive and motor

control power supply and the EMG terminal of the motor control power supply connector.

(Circuit example: The Figure below shows the stop status).

Caution

When the EMGx input is turned off (0V) during operation, the corresponding actuator will stop with

maximum deceleration and the servo will be turned off thereafter.

24V

0V

24 VDC

Ry

0V

Emergency

stop

Surge suppressor

The stop is

released

Switch

Ry

U

C 24V

EMG1

LKRLS1

EMG2

LKRLS2

Motor control power supply connector

C 24V

EMG3

LKRLS3

EMG4

LKRLS4

Motor control power supply connector

Stop switch

24V

0V

C 24V

EMG1

LKRLS1

Motor control power supply connector

EMG2

LKRLS2

C 24V

EMG3

LKRLS3

Motor control power supply connector

EMG4

LKRLS4

Page 36

- 35 -

No.SFOD-OMT0010-B

C I□3□

4

Motor drive and

motor control

power supply

CI3 4

CI1 2

Motor power shutdown (relay contact)

If it is necessary to have a circuit to shutdown the motor drive power externally, relay contacts

should be placed between the motor drive and motor control power supply and the M24V of

the motor control power supply connector and the EMG terminal of the motor control power

supply connector. (Circuit example: The Figure below shows the stop status)

Warning

(1) If it is necessary to have a circuit to shutdown the motor power supply, relay contacts should be

placed between the motor drive and motor control power supply and the M24V terminal of the

motor drive power connector and the EMG terminal of the motor control power supply

connector. The actuator may make unexpected movement.

(2) Do not perform a return to origin operation (SETUP input ON) when the motor drive power

(M24V) is disconnected.

The controller cannot recognize the correct origin point if a return to origin instruction is made

with the motor drive power (M24V) disconnected.

(3) When wiring the stop switch, connect the switch such that EMG1 to EMG4 are shut down

together.

24V

0V

C 24V

EMG1

LKRLS1

Motor control power supply connector

EMG2

LKRLS2

C 24V

EMG3

LKRLS3

Motor control power supply connector

EMG4

LKRLS4

Ry

Motor drive power connector

Motor drive power connector

M PWR 1 2

M PWR 3 4

0V

M 24V

0V

M 24V

24 VDC

Ry

0V

Stop

Switch

Surge suppressor

The stop is

released

Switch

Ry

U

Page 37

- 36 -

No.SFOD-OMT0010-B

6. Details of parallel I/O connector

This controller is available with NPN type (JXC73) or PNP type (JXC83) parallel I/O.

6.1 Parallel I/O specifications

■Input specifications

■Output specifications

(NPN) (NPN)

(PNP) (PNP)

6.2 Parallel I/O circuit (NPN, PNP)

(1)Parallel I/O input circuit

No.

Item

Specifications

1

Output circuit

Internal circuit and

Optically isolated

2

Number of outputs

32

3

Max. voltage between

terminals

30 VDC

4

Max. output current

100mA

5

Saturation voltage

-COM+1.8V (Max.)

No.

Item

Specifications

1

Input circuit

Internal circuit and Optically

isolated

2

Number of inputs

16 3 Voltage

24VDC+/-10%

4

Input current at

ON state

5.1mA+/-20% (at 24 VDC)

No.

Item

Specifications

1

Output circuit

Internal circuit and

Optically isolated

2

Number of outputs

32

3

Max. voltage between

terminals

30 VDC

4

Max. output current

100mA

5

Saturation voltage

+COM-1.8V (Max.)

No.

Item

Specifications

1

Input circuit

Internal circuit and Optically

isolated

2

Number of inputs

16 3 Voltage

24VDC+/-10%

4

Input current at

ON state

5.1mA+/-20% (at 24 VDC)

NPN type

(a)

+COM1, +COM2

(b)

IN0 to IN10, SETUP, HOLD,

DRIVE, RESET, SVON

Inside the controller

(a)

(b)

External

I/O 1

I/O 2

Unused

PNP type

(a)

-COM1, -COM2

(b)

IN0 to IN10, SETUP, HOLD,

DRIVE, RESET, SVON

Inside the controller

External

I/O 1

I/O 2

Unused

(a)

(b)

4.7 kΩ

2.2 kΩ

4.7 kΩ

2.2 kΩ

Page 38

- 37 -

No.SFOD-OMT0010-B

(2)Parallel I/O output circuit

-NPN type

-PNP type

I/O 1

I/O 2

(a)

+COM3, +COM4

(b)

BUSY1 to BUSY4, AREA1 to

AREA4, INP1 to INP4, ALARM1

to ALARM4

(c)

-COM3, -COM4

(a)

+COM1, +COM2

(b)

OUT0 to OUT8, BUSY, AREA,

SETON, INP, SVRE, ESTOP,

ALARM

(c)

-COM1, -COM2

I/O 1

(a)

+COM1, +COM2

(b)

OUT0 to OUT8, BUSY, AREA,

SETON, INP, SVRE, ESTOP,

ALARM

(c)

-COM1, -COM2

I/O 2

(a)

+COM3, +COM4

(b)

BUSY1 to BUSY4, AREA1 to

AREA4, INP1 to INP4,

ALARM1 to ALARM4

(c)

-COM3, -COM4

External

Inside the controller

10KΩ

20KΩ

(a)

(b)

(c)

External

Inside the controller

10KΩ

4.7KΩ

(a)

(b)

(c)

Page 39

- 38 -

No.SFOD-OMT0010-B

6.3 Parallel I/O signals

Pin No.

Insulator colour

Dot mark

Dot colour

Pin No.

Insulator colour

Dot mark

Dot colour

1

Orange

■

Black

11

Orange

■■■

Black

21

Orange

■

Red

31

Orange

■■■

Red

2

Grey

■

Black

12

Grey

■■■

Black

22

Grey

■

Red

32

Grey

■■■

Red

3

White

■

Black

13

White

■■■

Black

23

White

■

Red

33

White

■■■

Red

4

Yellow

■

Black

14

Yellow

■■■

Black

24

Yellow

■

Red

34

Yellow

■■■

Red

5

Pink

■

Black

15

Pink

■■■

Black

25

Pink

■

Red

35

Pink

■■■

Red

6

Orange

■■

Black

16

Orange

■■■■

Black

26

Orange

■■

Red

36

Orange

■■■■

Red

7

Grey

■■

Black

17

Grey

■■■■

Black

27

Grey

■■

Red

37

Grey

■■■■

Red

8

White

■■

Black

18

White

■■■■

Black

28

White

■■

Red

38

White

■■■■

Red

9

Yellow

■■

Black

19

Yellow

■■■■

Black

29

Yellow

■■

Red

39

Yellow

■■■■

Red

10

Pink

■■

Black

20

Pink

■■■■

Black

30

Pink

■■

Red

40

Pink

■■■■

Red

Signals are different for I/O1 and I/O2. Refer to the table below for details.

Page 40

- 39 -

No.SFOD-OMT0010-B

(1) I/O1

-Input side

Pin No.

Signal

name

Description

1

+COM1

Connect the 24 VDC power supply to the input/ output signals

For IN0 to IN10, SETUP, HOLD, DRIVE, RESET, SVON

For OUT0 to OUT8, BUSY, AREA, SETON, INP, SVRE, ESTOP, ALARM

21

+COM2

2

IN0

Step data instruction Bit No.(Standard: When 512 is used)

Step data instruction Bit No. (Input is instructed in the combination of IN0 to

IN8.)

Ex. (Assign step data No.3)

IN8

IN7

IN6

IN5

IN4

IN3

IN2

IN1

IN0

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON 0 0 0 0 0 0 0 1

1

22

IN1 3 IN2

23

IN3 4 IN4

24

IN5 5 IN6

25

IN7 6 IN8

26

IN9

Step data instruction extended mode bit No (Extended: 2048 is used)

7

IN10

27

SETUP

Command to Return to Origin

Actuators return to origin based on the order of setting for return to origin.

When SVRE output is ON, the SETUP operation (return to origin) will be

performed. During the SETUP operation, BUSY will be turned ON and after

completion of the SETUP operation, SETON and INP will be turned ON.

8

HOLD

Pause of operation

All axes in operation are paused.

If HOLD input is ON during operation, the speed decreases at maximum

deceleration of the basic parameter until the actuator stops. The remaining

stroke will be on hold as long as HOLD is ON and when HOLD is turned OFF,

the actuator restarts to travel the remaining stroke.

Caution

(1) Do not command SETUP or DRIVE while the HOLD input is ON.

The actuator may make unexpected movements.

(2) While HOLD input is ON, do not move the actuator position.

Changing the residual travel distance may cause inconsistency with

the target position.

(3) HOLD input is invalid during return to origin operation.

28

DRIVE

Operation instruction

Read the step data from IN0 to IN8 while the DRIVE signal is ON and start

operation.

The number of ongoing steps is output to the OUT terminal when the DRIVE

signal is ON.

Binary code

Page 41

- 40 -

No.SFOD-OMT0010-B

Pin No.

Signal

name

Description

9

RESET

Alarm reset and interruption of operation

When RESET is turned ON during operation, the speed decreases at

maximum deceleration of the basic parameter until the actuator stops.

INP and OUT0 to OUT10 are OFF. (However, if the actuator is stopped

within the in-position range, the INP will be turned ON).

An Alarm is reset when the RESET signal is turned ON if an alarm has

been generated. (Some alarms cannot be reset by the RESET

command).

Caution

(1) Do not command SETUP or DRIVE while the RESET input is ON.

The actuator may make unexpected movements.

(2) If the RESET input is ON during a return to origin operation, return

to origin may not be available when the RESET input is turned OFF.

In this case, turn on the servo, and then turn on the SETUP input.

29

SVON

Servo ON instruction

When SVON is ON, the servo motor for all axes will be turned ON.

Note1)

When SVON is OFF, the servo motor will be turned OFF.

Note 1) When power is supplied, it may take up to 20 seconds from Servo ON to SVRE ON,

depending on the actuator position or conditions.

Page 42

- 41 -

No.SFOD-OMT0010-B

-Output side

Pin No.

Signal

name

Description

10

OUT0

Output the number of ongoing step data.

When the operation is started and the DRIVE input is turned ON, a Bit No. corresponding

to the number of the active step data will be output from these terminals. These output

signals will be updated when the DRIVE input is turned ON.

Caution

(1) When RESET is turned ON, these terminals are turned OFF.

(2) During an alarm, these terminals output the alarm group.

30

OUT1

11

OUT2

31

OUT3

12

OUT4

32

OUT5

13

OUT6

33

OUT7

14

OUT8

34

BUSY

(OUT9)

The Busy signal turns on until the completion of operation time (theoretically value) of all

actuators, and also during the movement of one or more actuators. (OR of BUSY1 to

BUSY4.)However, when the positioning operation of pushing operation is inhibited and the

movement stops, the Busy signal keeps turning ON exceptionally until operation is

released. (Not OR of BUSY1 to BUSY4.)

The Bit No is output during step data in extended mode.

Note

3)

15

AREA

(OUT10)

The Area signal turns on when all actuators are within the area output range. (AND of

AREA1 to AREA4)

The Bit No is output during step data in extended mode.

Note

3)

35

SETON

Return to origin completion signal.

SETON turns on when all axes have completed the return to origin operation.

16

INP

Positioning complete signal

INP turns on according to the conditions below.(AND of INP1 to INP4)

Movement

mode

Details

Positioning

operation

When the actuator moves to within this range from the target position after the

positioning completion time (theoretical value), the INP output will turn ON.

Pushing

operation

When the Pushing force becomes more than the set "Trigger level" value in the

profile parameter and the actuator stopped within the pushing area, the INP output

will turn ON.

36

SVRE

The Servo ON signal turns on when the servo motor is ON.

Note1)

17

ESTOP

ESTOP turns OFF when EMG signal stops

Note2).

37

ALARM

ALARM turns OFF when an alarm is generated to one or more actuator. (Reverse of OR

of ALARM1 to ALARM4)

Note

2)

18

-COM1

Connects the power supply 0V to the input/output signals

For OUT0 to OUT7

19

-COM1

38

-COM1

20

-COM2

Connects the power supply 0V to the input/output signals

For OUT8, BUSY, AREA, SETON, INP, SVRE, ESTOP, and ALARM

39

-COM2

40

-COM2

Note 1) When power is supplied, it may take up to 20 seconds from Servo ON to SVRE ON, depending

on the actuator position or conditions.

Note 2) Negative logic signal.

Note 3) For BUSY and AREA signals, use BUSY1 to BUSY4 and AREA1 to AREA4 for I/O2 (optional).

Page 43

- 42 -

No.SFOD-OMT0010-B

(2) I/O2

-Input side

Pin No.

Signal name

Description

1

+COM3

Connects the power supply 24 V to the input/output signals

For BUSY1 to BUSY4, AREA1 to AREA4, INP1 to INP4, and ALARM1 to

ALARM4.

21

+COM4

2

N.C.

Unused

22 3 23 4 24 5 25 6 26 7 27 8 28 9 29

-Output side

Pin No.

Signal name

Description

10

BUSY1

Busy signal for Axis x

When the actuator starts to operate, the BUSY signal will be turned

ON until the completion of operation time (theoretically value). After

the completion of operation time if the actuator has stopped, the

BUSY signal will be turned off.

30

BUSY2

11

BUSY3

31

BUSY4

12

AREA1

Area signal for Axis 1

32

AREA2

Area signal for Axis 2

13

AREA3

Area signal for Axis 3

33

AREA4

Area signal for Axis 4

14

INP1

Positioning complete signal for Axis 1

34

INP2

Positioning complete signal for Axis 2

15

INP3

Positioning complete signal for Axis 3

35

INP4

Positioning complete signal for Axis 4

16

ALARM1

Alarm signal for Axis 1

Note1)

36

ALARM2

Alarm signal for Axis 2

Note1)

17

ALARM3

Alarm signal for Axis 3

Note1)

37

ALARM4

Alarm signal for Axis 4

Note1)

18

-COM3

Connect the power supply 0V to the input/output signals

For BUSY1 to BUSY4, AREA1 to AREA4.

19

-COM3

38

-COM3

20

-COM4

Connect the power supply 0V to the input/output signals

For INP1 to INP4, ALARM1 to ALARM4.

39

-COM4

40

-COM4

Note 1) Negative logic signal.

Page 44

- 43 -

No.SFOD-OMT0010-B

The table below shows the changes in the output signal with respect to the state of the controller.

BUSY

INP

SVRE

Lock

SETON

OUT0 to 8

Controller powered down [SVOFF] with no

motion

OFF

OFF

OFF

Lock

OFF

OFF

Controller powered down [SVON] with no

motion

OFF

OFF

Note1)

ON

Unlock

OFF

OFF

During Return to origin

ON

OFF

ON

Unlock

OFF

OFF

The actuator is at the origin, on completion of

[SETUP]

OFF

ON

Note1)

ON

Unlock

ON

OFF

During movement by positioning/pushing

operation

ON

OFF

ON

Unlock

ON

ON

Note2)

The actuator is paused by [HOLD]

OFF

OFF

Note4)

ON

Unlock

ON

ON

Note2)

On completion of the positioning operation.

OFF

ON

ON

Unlock

ON

ON

Note2)

Stopped due to pushing a workload in

pushing operation.

OFF

ON

ON

Unlock

ON

ON

Note2)

Stopped due to no detection of a workload in

pushing operation.

OFF

OFF

ON

Unlock

ON

ON

Note2)

Servo is OFF after return to origin.

OFF

OFF

OFF

Lock

ON

ON

Note3)

EMG signal stop from the CI connector after

the actuator is at the origin.

OFF

OFF

OFF

Lock

ON

ON

Note3)

Note1) The output turns on when the actuator is within the range defined in the basic parameter setup.

Note 2) The output is updated due to the transition of (OFF→ON) of the DRIVE input signal.

Note 3) Retain the previous state.

Note 4) The output turns on when the actuator is "In position" according to the step data.

Output

Status

Page 45

- 44 -

No.SFOD-OMT0010-B

6.4 Parallel I/O Wiring Example

The Wiring depends on the parallel input/output type of the controller (NPN or PNP).

(1) NPN type

Caution

Prepare a separate power supply for the main control, motor drive and motor control and input/ output

signal.

I/O 1

OUT0

10

OUT1

30

OUT2

11

OUT3

31

OUT4

12

OUT5

32

OUT6

13

OUT7

33

OUT8

14

BUSY

(OUT9)

34

AREA

(OUT10)

15

SETON

35

INP

16

SVRE

36

ESTOP

17

ALARM

37

-COM1

18

-COM1

19

-COM1

38

-COM2

20

-COM2

39

-COM2

40

+COM1

1

+COM2

21

IN0

2

IN1

22

IN2

3

IN3

23

IN4

4

IN5

24

IN6

5

IN7

25

IN8

6

IN9

26

IN10

7

SETUP

27

HOLD

8

DRIVE

28

RESET

9

SVON

29

24 VDC

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Load

Page 46

- 45 -

No.SFOD-OMT0010-B

Caution

+COM1, +COM2 and +COM3, +COM4 are not connected inside the controller. When I/O2 is used,

connect +COM1, +COM2 and +COM3, +COM4 to the 24V side of the common input/ output signal 24

VDC power supply.

Caution

-COM1, -COM2, -COM3, -COM4 are not connected inside the controller. Connect the corresponding

common -COM of the 0V side of the input/ output signal 24 VDC power supply.

I/O 2

BUSY1

10

BUSY2

30

BUSY3

11

BUSY4

31

AREA1

12

AREA2

32

AREA3

13

AREA4

33

INP1

14

INP2

34

INP3

15

INP4

35

ALARM1

16

ALARM2

36

ALARM3

17

ALARM4

37

-COM3

18

-COM3

19

-COM3

38

-COM4

20

-COM4

39

-COM4

40

+COM3

1

+COM4

21

N.C.

Note 1)

2

N.C.

Note 1)

22

N.C.

Note 1)

3

N.C.

Note 1)

23

N.C.

Note 1)

4

N.C.

Note 1)

24

N.C.

Note 1)

5

N.C.

Note 1)

25

N.C.

Note 1)

6

N.C.

Note 1)

26

N.C.

Note 1)

7

N.C.

Note 1)

27

N.C.

Note 1)

8

N.C.

Note 1)

28

N.C.

Note 1)

9

N.C.

Note 1)

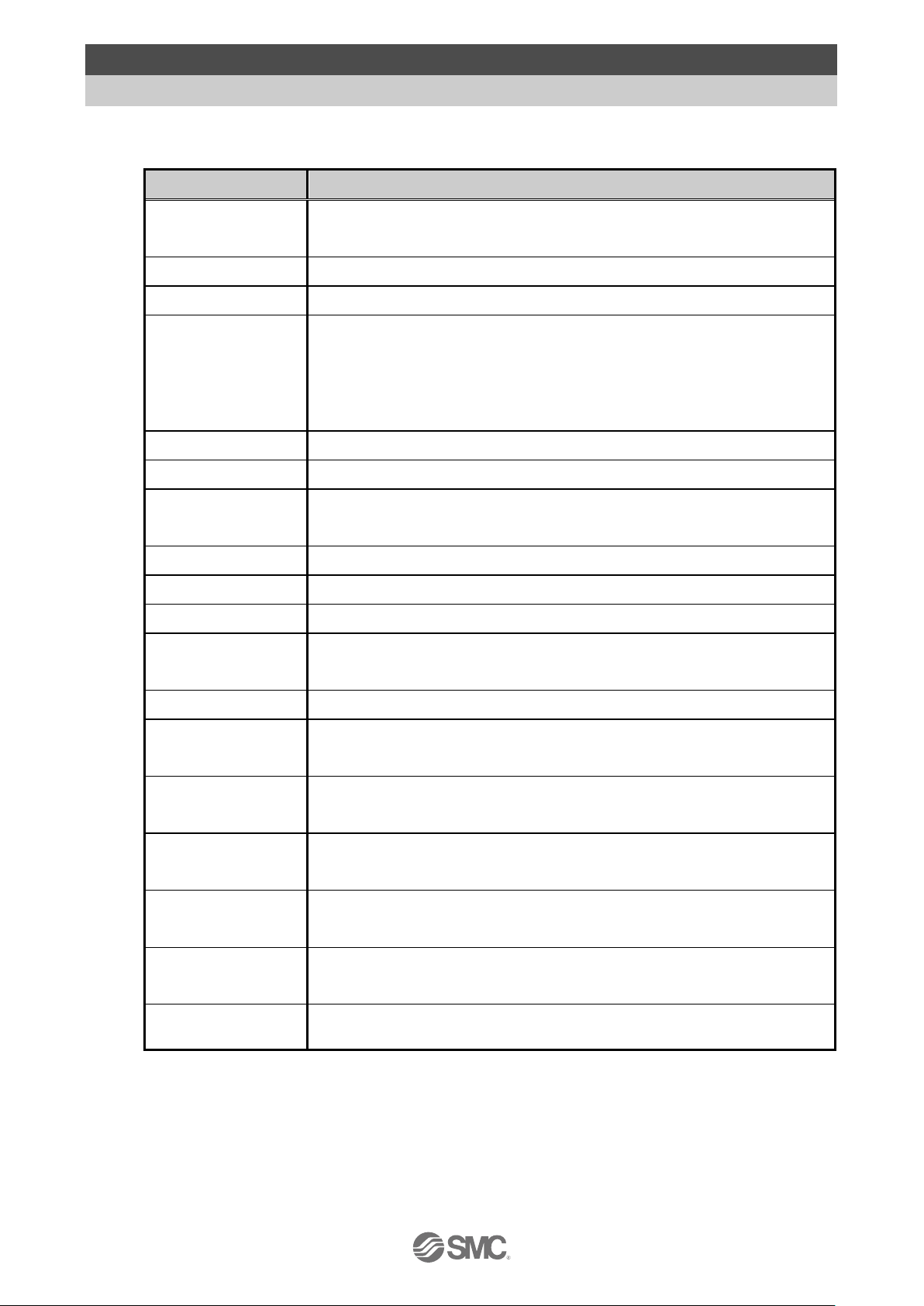

29