SMC Networks JX73 Series, JX83 Series Installation And Maintenance Manual

Installation & Maintenance Manual

4-axis Step Motor Controller

(Parallel I/O type)

Series JXC73/83

1 Safety Instructions

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

•Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

•Keep this manual in a safe place for future reference.

•These instructions indicate the level of potential hazard by label of

"Caution", "Warning" or "Danger", followed by important safety

information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

CAUTION indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

WARNING indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

J

XC-TFT34

Warning

Warning

The compatibility of the product is the responsibility of the person

who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will

be the responsibility of the person who has determined its compatibility

with the product.

This person should also continuously review all specifications of the

product referring to its latest catalog information, with a view to giving

due consideration to any possibility of equipment failure when

configuring the equipment.

Only personnel with appropriate training should operate

machinery and equipment.

The product may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

must be performed by an operator who is appropriately trained and

experienced.

Do not attempt to service or replace product and

machinery/equipment until safety is confirmed.

1. The inspection and maintenance of machinery/equipment should

only be performed after measures to prevent falling or runaway of

the driven objects have been confirmed.

2. When the product is to be removed, confirm that the above safety

measures are implemented and the power from any appropriate

source is cut, and read and understand the specific product

precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and provide specifications or a contract, if necessary.

If anything is unclear, contact your nearest sales branch.

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com).

1 Safety Instructions (Continued)

Contact SMC beforehand and take special consideration of safety

measures if the product is to be used in any of the following

conditions:

1. Conditions and environments outside of the given specifications, or use

outdoors or in a place exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways,

air navigation, space, shipping, vehicles, military, medical treatment,

combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press

applications, safety equipment or other applications unsuitable for the

standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or

animals requiring special safety analysis.

4. Use in an interlock circuit, which requires the provision of double

interlock for possible failure by using a mechanical protective function,

and periodical checks to confirm proper operation.

Warning

Caution

Connector “CI3 4” must be connected even when axis 3 and 4 are not used.

If not, a “Modbus Error” alarm will be generated.

Use “USB cable (JXC-W1-2)” when communicating with a PC.

2 Product configuration

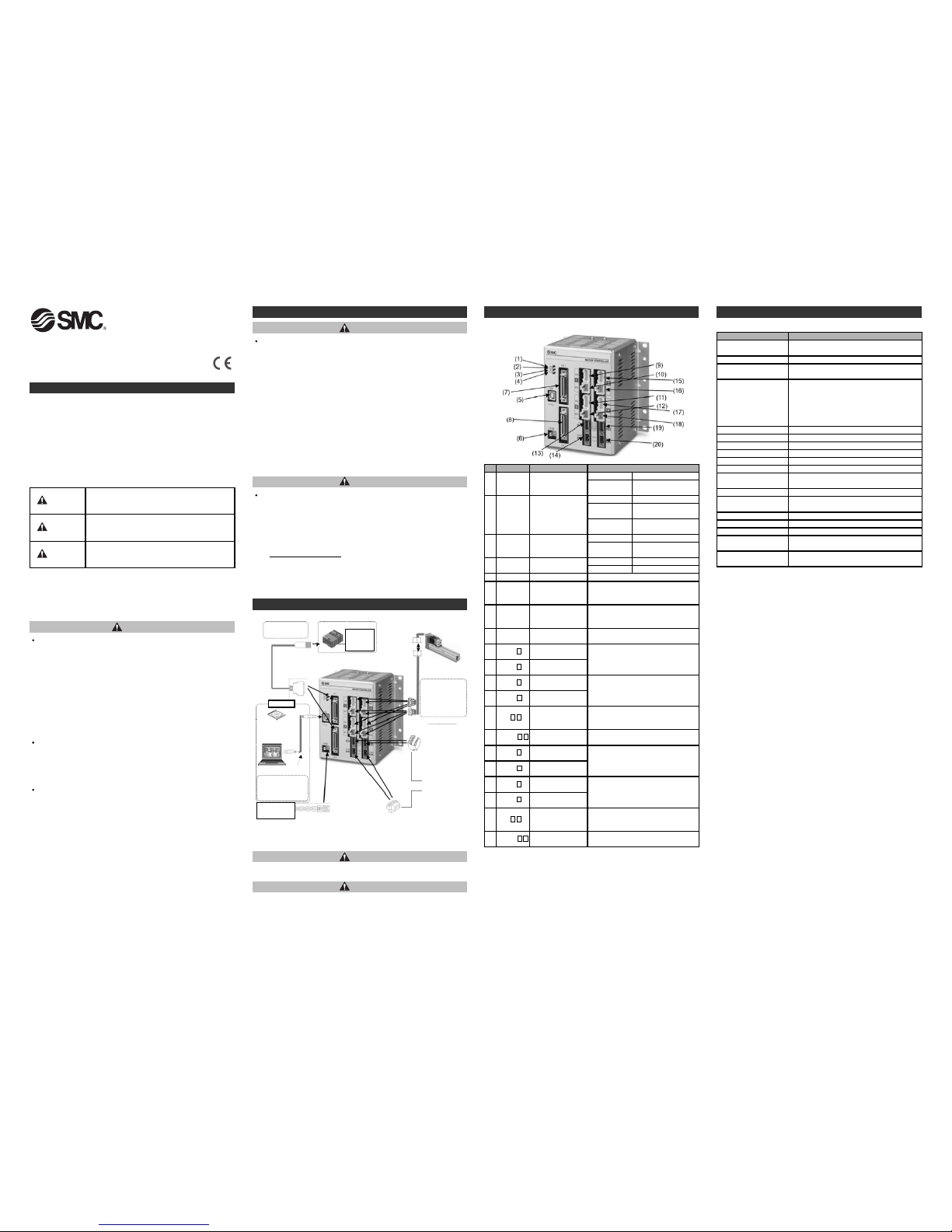

3 Parts Description

PLC

PC

•Controller

•Electric actuator

Note2)

Note2)

Note1)

To

ENC

To

MOT

To CI

To M

PWR

Input/output

signal power

supply

24VDC

Note2)

Note2)

To C

PWR

To

I/O

•Controller setting

software

Product No.: JXC-W1-1

•USB cable

Product No.: JXC-W1-

2

•Power cable for main control

Cable length: 1.5m (Accessory)

Product No.: JXC-C1

•Motor control power

supply connector

(Accessory)

<Applicable wire size>

AWG20 (0.5mm

2

)

•Motor drive power connector

(Accessory)

<Applicable wire size>

AWG16 (1.25mm2)

Motor control and

motor drive power

supply 24 VDC

Note 1) Connected actuators should be ordered separately.

Note 2) PLC, PC and 24VDC power supply should be prepared by the user.

Note) The connector is included.

No.D

isplayDescription

D

etails

1 P

WR

Power supply LED

(green)

OFF Power supply OFF

Green LED is

O

N

Power supply ON

3 USB

U

SB LED

(green)

O

FF

U

SB not connected

Green LED is

O

N

USB connected

4 ALM

Alarm LED

(

red)

OFF No alarm

5 USB Serial communication Connect to a PC using a USB cable.

6 C

PWR

Main control power

s

upply connector

(2 pin)

N

ote)

C

onnect to the PLC using an I/O cable.

7 I/O 1

Parallel I/O connector

(40 pins)

Connect to the PLC using an I/O cable.

8 I/O 2

Parallel I/O connector

(40 pins)

Display the status of the EtherNet/IP

communication.

9 ENC 1

Encoder connector

(16 pins)

Axis 1: Connect the actuator cable.

10 MOT 1

Motor power

connector (6 pins)

Axis 2: Connect the actuator cable.

11 ENC 2

Encoder connector

(16 pins)

Motor control power supply(+), Axis 1

stop(+), Axis 1 unlock(+), Axis 2 stop(+),

Axis 2 unlock(+)

12 MOT 2

Motor power

connector (6 pins)

Axis 1, Axis 2 Motor drive power(+),

common(

-

)

13 CI 1 2

Motor control power

supply connector

N

ote)

14 M PWR 1 2

Motor drive power

connector

Note)

15 ENC 3

Encoder connector

(16 pins)

16 MOT 3

Motor power

connector (6 pins)

17 ENC 4

Encoder connector

(16 pins)

Axis 4: Connect the actuator cable.

18 MOT 4

Motor power

connector (6 pins)

Axis 3: Connect the actuator cable.

19 CI 3 4

Motor control power

supply connector

Note)

Motor control power supply(+), Axis 3

stop(+), Axis 3 unlock(+), Axis 4 stop(+),

Axis 4 unlock(+)

20 M PWR 3 4

Motor drive power

connector

Note)

Axis 3, Axis 4 Motor drive power(+),

common(

-

)

Red LED is ON Alarm condition

2 R

UN

Operating LED

(

green)

O

FF

S

top

G

reen LED is

ON

O

peration by parallel I/O

Green LED is

flashing

Operation by USB

communication

Detail of the controller parts.

•I/O cable

Product No: JXC-C2-∗

To

USB

4 Product Specifications

Basic specifications

I

tem

S

pecifications

N

umber of axes per

c

ontroller

Max. 4-axis

C

ontrolled motor

S

tep motor (servo 24 VDC)

Controlled encoder

I

ncremental phase A/B

(Encoder resolution 800 pulse/rotation)

P

ower supply specification

N

ote1)

M

ain control power supply

Power supply voltage: 24VDC+/

-

10%

M

ax. current consumption: 300 mA

Motor drive and motor control power supply

P

ower supply voltage: 24VDC+/

-

1

0%

Max. current consumption: Depends on connected

a

ctuator.

Note2)

Serial communication

USB2.0 (Full Speed 12Mbps)

M

emory

F

lash ROM and EEPROM

Parallel input 16 inputs (Optically isolated)

P

arallel output

3

2 outputs (Optically isolated)

L

ock control

W

ith forced lock-release terminal

N

ote3)

Cable length

I/O cable: 5 m maximum

A

ctuator cable: 20 m maximum

C

ooling method

N

atural air cooling

Operating temperature

range

0

to 40

o

C

(No freezing)

O

perating humidity range90% RH or less (No condensation)

Storage temperature range-10 to 60oC (No freezing)

S

torage humidity range90% RH or less (No condensation)

I

nsulation resistance

Between the external terminals and case

50MΩ (500 VDC)

W

eight

1050 g (Direct mounting)

1

100 g (DIN rail mounting)

L

ED indicator

P

WR (green), RUN (green), USB (green), ALM (red)

Note 1) Do not use a power supply with "inrush current protection" for the motor

drive power and motor control power supply.

N

ote 2) Power consumption depends on the actuator connected. Refer to the

a

ctuator specifications for further details.

Note 3) Applicable to non-magnetizing lock.

Options

•Controller set up kit

Contents

-Controller Setting Kit

-USB cable

Product No.: JXC-W1

[

]

Main control

power supply

24VDC

•Actuator cable

Part No:

LE-CP-*-

*

(Robotic type cable)

LE-CP-*-*-S

(Standard cable)

Note1)

(2) Grounding

Fit the grounding cable with

crimped terminal between

the M3 screw and

shakeproof washer as

shown below and tighten

the screw.

J

XC-TFT34

Refer to the operation manual on SMC website

(URL http://www.smcworld.com).

6 Power supply connector

The figure below shows how

to mount the controller to the

DIN rail. Hook part A on to the

DIN rail. Press part B on to the

DIN rail and tighten the locking

screws (M5 x 14).

(Appropriate tightening torque:

0.4 to 0.6 Nm)

Locking screw M5 x 14

Part B

Part A

Shakeproof washer

M3 screw

Grounding cable

(with crimped terminal)

Caution

The cable with crimped terminal and shakeproof washer must be

prepared by the user.

The controller must be connected to Ground to reduce noise.

Refer to the operation manual on SMC website

(URL http://www.smcworld.com

).

Caution

Connector specifications

The power supply connector included is shown below.

(1) Main control power supply connector: C PWR

(2) Motor drive power connector: M PWR

Specifications of the cable are as follows.

Use the power cable for main control, JXC-C1.

T

erminalFunction

D

escription

+24V

M

ain control

power supply(+)

P

ower supply(+) for main

control.

24-0V

M

ain control

power supply(

-

)

P

ower supply(

-

)

for main

control.

B

rown

+24V

24-0V

B

lue

T

erminalFunction

D

escription

0V M

otor power(

-

)

Power supply(-) common for

M

24V terminal, C24V terminal,

EMG terminal and LKRLS

t

erminal

M24V Motor power(+)

Motor drive power supply(+) for

A

xis 1 and 2 or Axix 3 and 4.

0

V

M

24V

I

tem

S

pecifications

W

ire size

Stranded wire → AWG20 (0.5mm2)

O

.D. of sheath →ø1.76

W

ire sheath colour

+

24V: Brown

24-0V: Blue

Prepare the electrical wiring according to the following specifications

(to be prepared by the user).

When the wire is inserted into the motor drive power connector, insert

only the stripped part of the wire.

Manufactured by Phoenix Contact

(Part number MSTB2,5/2-STF-5,08)

Item Specifications

A

pplicable wire size

Single, Stranded wire → AWG16 (1.25mm2)

T

he rated temperature of the insulation coating

should be 60

o

C or more.

Stripped wire length

7mm

ø3.4 or less

(3) Motor control power supply connector: CI

Prepare the electrical wiring according to the following specifications

(to be prepared by the user).

Manufactured by Phoenix Contact

(Part number FK-MC0,5/5-ST-2,5)

Item Specifications

Applicable wire size

Single, Stranded wire → AWG20 (0.5mm2)

The rated temperature of the insulation coating

should be 60

o

C or more.

Stripped wire length

8mm

ø2.0 or less

EMG1/EMG3

EMG2/EMG4

LKRLS2/LKRLS4

C24V

LKRLS1/LKRLS3

Terminal Function Description

C24V

Motor control

power supply(+)

Power supply side(+) for motor

control.

EMG1/

EMG3

Stop(+)

Release the stop status(+) of

Axis 1 or Axis 3.

(Normal operation by applying

24V.)

EMG2/

EMG4

Stop(+)

Release the stop status(+) of

Axis 2 or Axis 4.

(Normal operation by applying

24V.)

LKRLS1/

LKRLS3

Unlock(+)

Release the lock status(+) of

Axis 1 or Axis 3.

LKRLS2/

LKRLS4

Unlock(+)

Release the lock status(+) of

Axis 2 or Axis 4.

Do not connect multiple wires into one terminal.

Contact failure or short circuit to adjacent wire may lead to malfunction or

fire.

URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2016 SMC Corporation All Rights Reserved

11 Contacts

AUSTRIA (43) 2262 62280-0

NETHERLANDS

(31) 20 531 8888

BELGIUM (32) 3 355 1464

NORWAY

(47) 67 12 90 20

CZECH REP. (420) 541 424 611

POLAND

(48) 22 211 9600

DENMARK (45) 7025 2900

PORTUGAL

(351) 21 471 1880

FINLAND (358) 207 513513

SLOVAKIA

(421) 2 444 56725

FRANCE (33) 1 6476 1000

SLOVENIA

(386) 73 885 412

GERMANY (49) 6103 4020

SPAIN

(34) 945 184 100

GREECE (30) 210 271 7265

SWEDEN (46) 8 603 1200 HUNGARY (36) 23 511 390

SWITZERLAND (41) 52 396 3131 IRELAND (353) 1 403 9000

UNITED KINGDOM

(44) 1908 563888

ITALY (39) 02 92711

BULGARIA (359) 2 974 4492

ESTONIA (372) 651 0370

ROMANIA

(40) 21 320 5111

LATVIA

(371) 781 77 00

LITHUANIA

(370) 5 264 8126

7

How to order

8 Outline with Dimensions (mm)

9

Maintenance

10 Troubleshooting

Refer to the operation manual on the SMC website

(URL http://www.smcworld.com).

(b) DIN rail mounting

The figure on the right shows

how to mount the DIN rail

mounting brackets.

Secure the DIN rail mounting

bracket using 4 mounting

screws (M5 x 8 mm) 2 on

each side. (Appropriate

tightening torque: 3.0 Nm)

Secure the DIN rail mounting

bracket using 2 locking

screws (M5 x 14 mm), 1 on

each side. Tighten for

approximately 2 threads.

Do not tighten completely.

5

Mounting

(1) Mounting

There are two ways to mount the controller.

(Direct mounting and DIN rail mounting)

Controller mounting methods are shown below.

(a) Direct Mounting with four M5 screws

Mounting screw (M5) 4pcs.

(prepared by user)

Mounting screw M5 x 8

Included with DIN rail

mounting bracket

T

ightening torque: 3.0 (Nm)

Locking screw M5 x 14

Included with DIN rail

mounting bracket

Tightening torque: 0.4 to 0.6 (Nm)

[]

[]

When the wire is inserted into the motor control power supply connector,

insert only the stripped.

Loading...

Loading...