SMC Networks IZN10 Series, IZN10-P Series Operation Manual

Doc. No. IZ※-OML0002-C

OPERATION MANUAL

PRODUCT NAME

:

○ Read this operation manual carefully to

understand before installation and operation.

○ Pay extra attention on the clause concerning the

safety.

○ Keep this operation manual available whenever

necessary.

Ionizer

IZN10 Series MODEL:

- 1 -

INDEX

1. Safety Instructions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3

2. Specifications ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 5

3. How to Order・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 6

4. Mounting

4-1. Precautions for mounting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 7

4-2. How to mount・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 9

4-3. Wiring table・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 15

4-4. Power supply cable wiring diagram・・・・・・・・・・・・・・・・・・・・・・・・・ 16

4-5. Timing chart・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 16

5. Functional Explanations ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 17

6. Outline Dimensions・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 18

7. Maintenance

7-1. Precautions for maintenance・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 19

7-2. How to maintain electrode needle・・・・・・・・・・・・・・・・・・・・・・・・・・ 20

- 2 -

1. Safety instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage. These

instructions indicate the level of potential hazard by labels "Caution," "Warning" and "Danger" to ensure

safety. be to observe ISO4414, JIS B8370 and other safety precautions.

CAUTION Operator error could result in injury or equipment damage.

!

WARNING Operator error could result in serious injury or loss of life.

!

DANGER In extreme conditions, there is a possibility of serious injury or loss of life.

!

1) ISO 4414: Pneumatic fluid power – Recommendation for application of equipment to transmission and

control systems

2) JIS B 8370: Rule for Pneumatic System

!

WARNING

1. The compatibility of equipment is the responsibility of the person who designs the system or

decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility with the

specific system must be based on specifications or analysis and/or tests to meet your specific requirements.

The expected performance and safety assurance will be the responsibility of the person who has determined

the compatibility of the system. This person should continuously review the suitability of all items specified,

referring to the latest catalog information with a view to giving due consideration to any possibility of

equipment failure when configuring a system.

2. Only trained personnel should operate machinery and equipment.

This product generates high voltage, so it can be dangerous if an operator is unfamiliar with it. Assembly,

handling or repair of systems should be performed by trained and experienced operators.

3. Do not service machinery/equipment or attempt to eliminate components until safety is

confirmed.

1) Inspection and maintenance of the machinery and equipment should be performed after confirmation of

safety such as grounding, prevention of electric shock and prevention of other types of injury.

2) When equipment is to be eliminated, confirm the safety process as mentioned above. Cut air pressure

supply and electric power supply that are the energy source for the equipment, and exhaust all residual

compressed air in the system.

3) Before machinery/equipment is re-started, take measures to prevent short circuit etc. with care.

4. Contact SMC if the product is to be used in any of the following conditions.

1) Conditions and environments beyond the given specifications, or if product is used outdoors.

2) Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles, medical

equipment, food and beverages, recreation equipment, emergency stop circuits, clutch and brake

circuits in press applications, or safety equipment.

3) An application which has the possibility of having negative effects on people, property, or animals

requiring special safety analysis.

- 3 -

WARNING

!

1. The ionizer (hereinafter referred to as the “product”) is intended to be used for the general FA devices.

If other applications (especially those indicated in 4 on page 2) are used, contact SMC before use.

2. Use under specified voltage and temperature.

Voltage out of specification may cause malfunction, breakage, electric shock or fire.

3. Use clean compressed air for fluid.

Do not use inflammable or explosive gas for fluid. It may cause fire or explosion. When fluid other than

compressed air is used, contact a SMC service representative.

4. The product doesn’t incorporate explosion-proof construction.

Do not use this product in a place where a dust explosion might be triggered or inflammable or explosive

gas is present. It may cause fire.

!

CAUTION

1. The product has not been washed.

Flush and confirm its purification level before bringing into a clean room.

Selection

Handling

!

CAUTION

1. Do not drop, hit or otherwise apply excessive impact (10 G or more) when handling.

Though the product itself doesn’t break, the inside construction may be broken and cause malfunction.

2. When cable is mounted or removed, pinch the modular plug claw with fingers and insert or take out the

plug vertically. If mounted or removed in an inappropriate direction, the mounting part of the modular jack

may be damaged and cause operation failure.

- 4 -

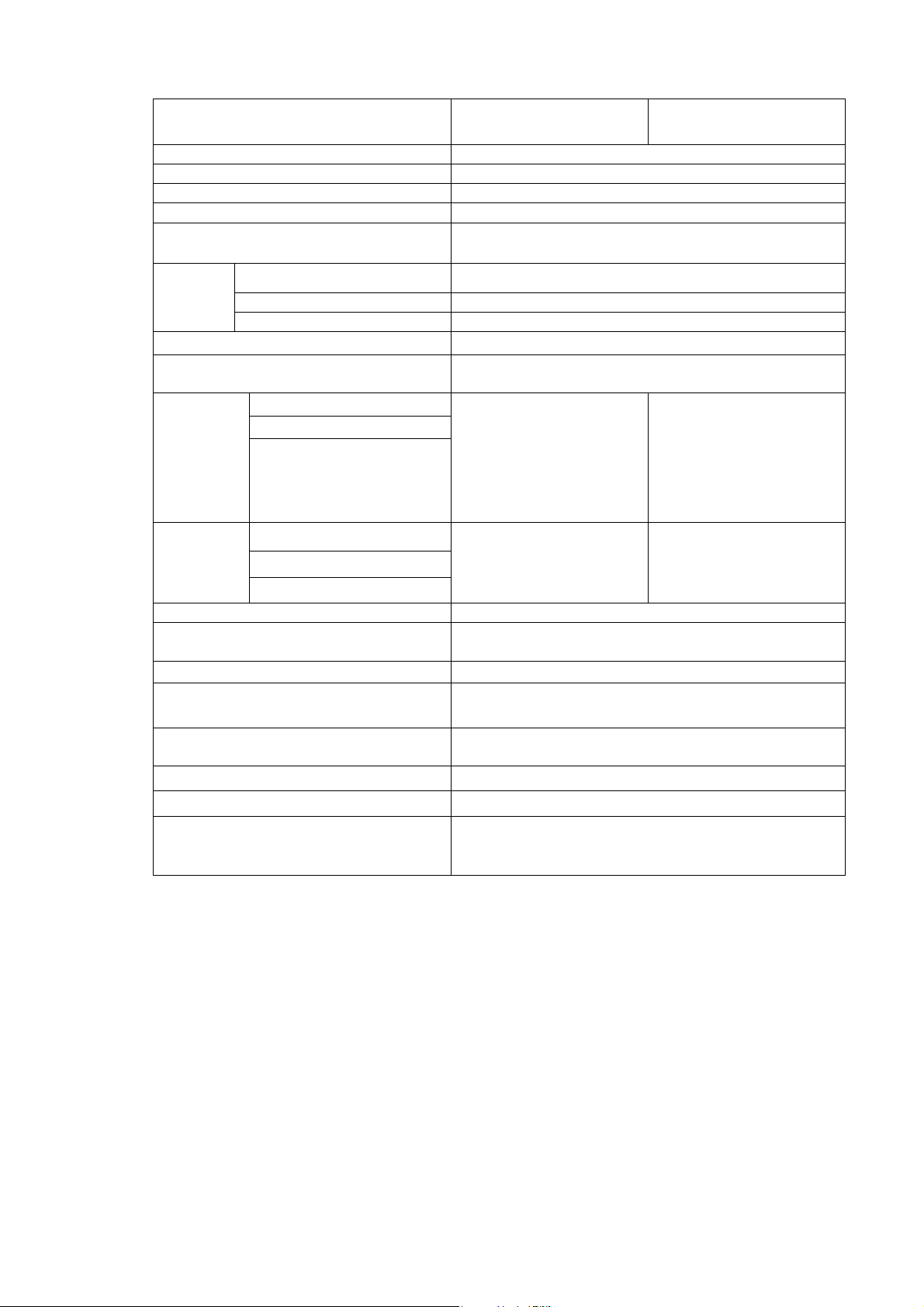

2. Specifications

Model number of ionizer IZN10-□□

(NPN)

Ion generating method Corona discharge type

Voltage applying method High frequency AC type

Discharge output

Ion balance

Ozone generated amount

Air

purge

Note 1)

Note 2)

Note 3)

Fluid

Operating pressure

Note 4)

2500V

±10 V at max.

0.03 ppm (0.05 ppm for energy saving charge

elimination nozzle)

Air (clean and dry)

0.05 MPa~0.7 MPa

Connected tube diameter 6 and 1/4 inch

Power supply voltage

Current consumption

Discharge stop signal

Reset signal

Input

signal

External switch signal

Discharge signal

Output

signal

Error signal

Maintenance signal

(When input and output signals are not used)

GND to connection

The voltage to turn on is 0.6V

or less.

Current consumption: 5 mA or

less

Max. load current: 40 mA

Residual voltage: 1 V or less

(with load current of 40 mA)

Max. applied voltage: DC 28

V

24VDC±10%

80 mA

The voltage to turn on is from

Residual voltage: 1 V or less

Effective charge eliminating distance 20~500 mm

Ambient temp.

0~55oC

Fluid temp.

Ambient humidity

35~65% RH(With no condensation)

Body: ABS, Stainless Nozzle: Stainless

Material

Vibration resistance

Impact resistance

Weight

Durable to 50 Hz with amplitude 1 mm for 2 hours in

Electrode needle: Tungsten

each X, Y and Z direction

10 G

120 g

CE (EMC directive: 89/336/EEC, 92/31/EEC、

Applicable standard/directive

93/68/EEC, 2004/108/EC, Low-voltage directive:

73/23/EEC, 93/68/EEC)

Note 1) This is the value when measured by a probe with 1,000 MΩ and5 pF.

Note 2) This specification is applicable when the distance between the charged object and the

ionizer is 100 mm using the power saving static elimination nozzle, and the air purge

pressure is 0.3 MPa.

Note 3) This is the value from which the background is drawn with a distance of 300 mm from the

front face of the nozzle.

Note 4) Charge elimination is not available without air purge. Also, without air purge, internal

ozone concentration will increase and adversely affect the product and peripheral

equipment.

IZN10-□□P

(PNP)

+24V to connection

+19V to the

power supply voltage.

Current consumption: 5 mA

or less

Max. load current: 40 mA

(with load current of 40 mA)

- 5 -

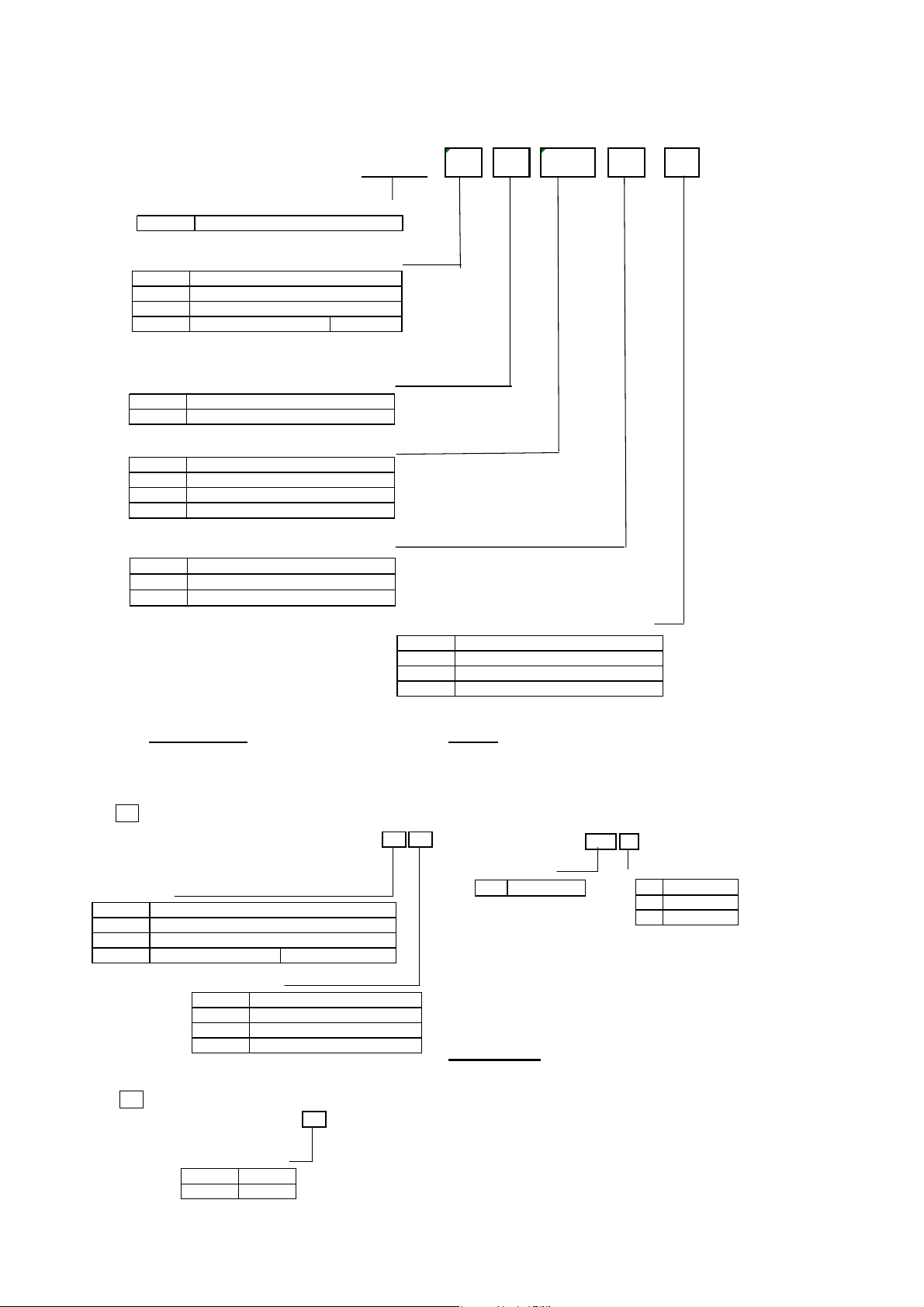

3. How to Order

A

d

Series name

IZN10 High frequency AC nozzle type

IZN10 - 01 P 06 Z - B1

Nozzle shape

NIL

Energy saving charge elimination nozzle

01

02

11 Piping female Note 1) Rc1/8

Output specification

NIL NPN

PPNP

Piping diameter

06 f6: metric

07 f6.35

16 f6: metric (elbow)

17 f6.35

Power s upply cable

NIL 3m

Z 10m

N Not provided

Type

Large flow nozzle

1/4"): inch

(

1/4"): inch (elbow)

(

Bracket

NIL Not provided

B1 L-bracket

B2 Swing brac ket

B3 DIN rail mounting bracket

Service parts Option

Electrode needle assembly Manifold mounting parts set

IZN10-NT Hexagon socket head bolts, s pacer and hexagon nuts are included.

・

B

Body Assembly

・IZN10 - A002 - 01 06

Noz z le shape

NIL

01

02

11 Piping female Note 1) Rc1/8

Energy s aving charge elim ination noz zle

Piping diamete r

B

Cartridge As sembly ・

・IZN10 - A003 - P

Output specification

NIL NPN

PPNP

Type

Large flow nozz le

06 f6: metric

07 f6.35(1/4"): inch

16 f6: metric (elbow)

17 f6.35(1/4"): inch (elbow)

The ionizer and L-bracket or DIN rail mounting need to be ordered separately.

Manifold mounting parts

IZN10 - ES 2

・

Mounting pitch

ES 17mm

Electrode needle cleaning kit/IZS30-M2

Number of manifol

2 2 stations

3 3 stations

4 4 stations

ccessories

Power supply cable

IZN10-CP(3m) ・IZN110-CPZ(10m)

Bracket

L-bracket/IZN10-B1

・

Swing brac ket/IZN10-B2

・

DIN rail mounting bracket/IZN10-B3

・

- 6 -

Loading...

Loading...