SMC Networks ISA3-G series, ISA3-H series, ISA3-F series Operation Manual

No.PS※※-OMR0002-G

PRODUCT NAME

Digital Gap Checker

MODEL / Series / Product Number

ISA3 series

-1-

No.PS※※-OMR0002-G

Table of Contents

1 Before Use

Safety Instructions 2

2 About this product

Features 7

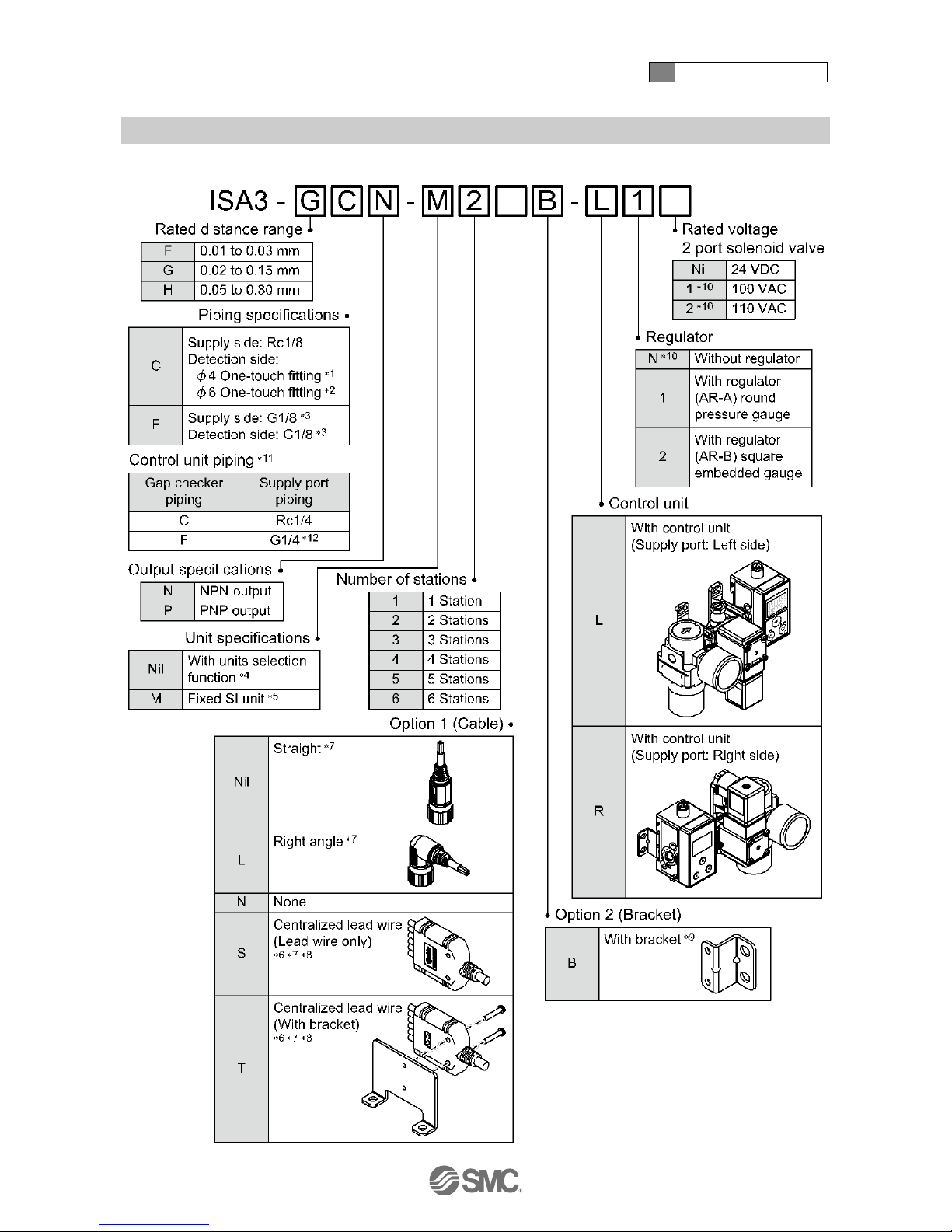

Model Indication and How to Order 8

Summary of Product parts 14

Specification 15

Specifications (ISA3) ··································· 15

Specifications (Regulator) ····························· 16

Specifications (2 port solenoid valve) ··············· 16

Characteristics graph ··································· 17

Dimensions ··············································· 20

3 Installation

Mounting and Installation 26

Piping ······················································ 26

Installation ················································· 29

Wiring ······················································ 34

Part structure ············································· 38

4 How to use

Outline of setting 41

Measurement mode ···································· 42

Switch Point Setting 44

Switch point change mode ···························· 44

Table of default settings ································ 44

Preparation before setting ····························· 45

Setting······················································ 45

Function Setting 46

Function selection mode ······························· 46

Table of default settings ································ 46

Key lock (Security code setting) 58

5 Troubleshooting

Maintenance 59

Troubleshooting 60

Error indication ··········································· 61

Relationship between

Supply Pressure and Display ························· 61

1 Before Use

-2-

No.PS※※-OMR0002-G

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger".

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General requirements)

ISO 10218: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could

result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will

result in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the

person who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when

configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the

product is to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place

exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special

safety analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using

a mechanical protective function, and periodical checks to confirm proper operation.

1 Before Use

-3-

No.PS※※-OMR0002-G

Safety Instructions

Caution

1.The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following "Limited warranty and Disclaimer" and "Compliance

Requirements".

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered,whichever is first.2)

Also, the product may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other

damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers noted in the specified catalog for the particular products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the

vacuum pad or failure due to the deterioration of rubber material are not covered by the

limited warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of

mass destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by

the relevant security laws and regulation of the countries involved in the transaction. Prior

to the shipment of a SMC product to another country, assure that all local rules governing

that export are known and followed.

Caution

SMC products are not intended for use as instruments for legal metrology.

Products that SMC manufactures or sells are not measurement instruments that are qualified by pattern

approval tests relating to the measurement laws of each country.

Therefore, SMC products cannot be used for business or certification ordained by the measurement laws of

each country.

1 Before Use

-4-

No.PS※※-OMR0002-G

■Important

In order to use this product safely, be sure to read and follow the instructions given in "Pressure

switches/Flow switches common precautions" which can be found under "Handling Precautions for

SMC Products" on the SMC website, before use.

■Operator

This operation manual is intended for those who have knowledge of machinery using pneumatic

equipment, and have sufficient knowledge of assembly, operation and maintenance of such

equipment. Only those persons are allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling, operating or providing

maintenance to the product.

■Specific product precautions

Warning

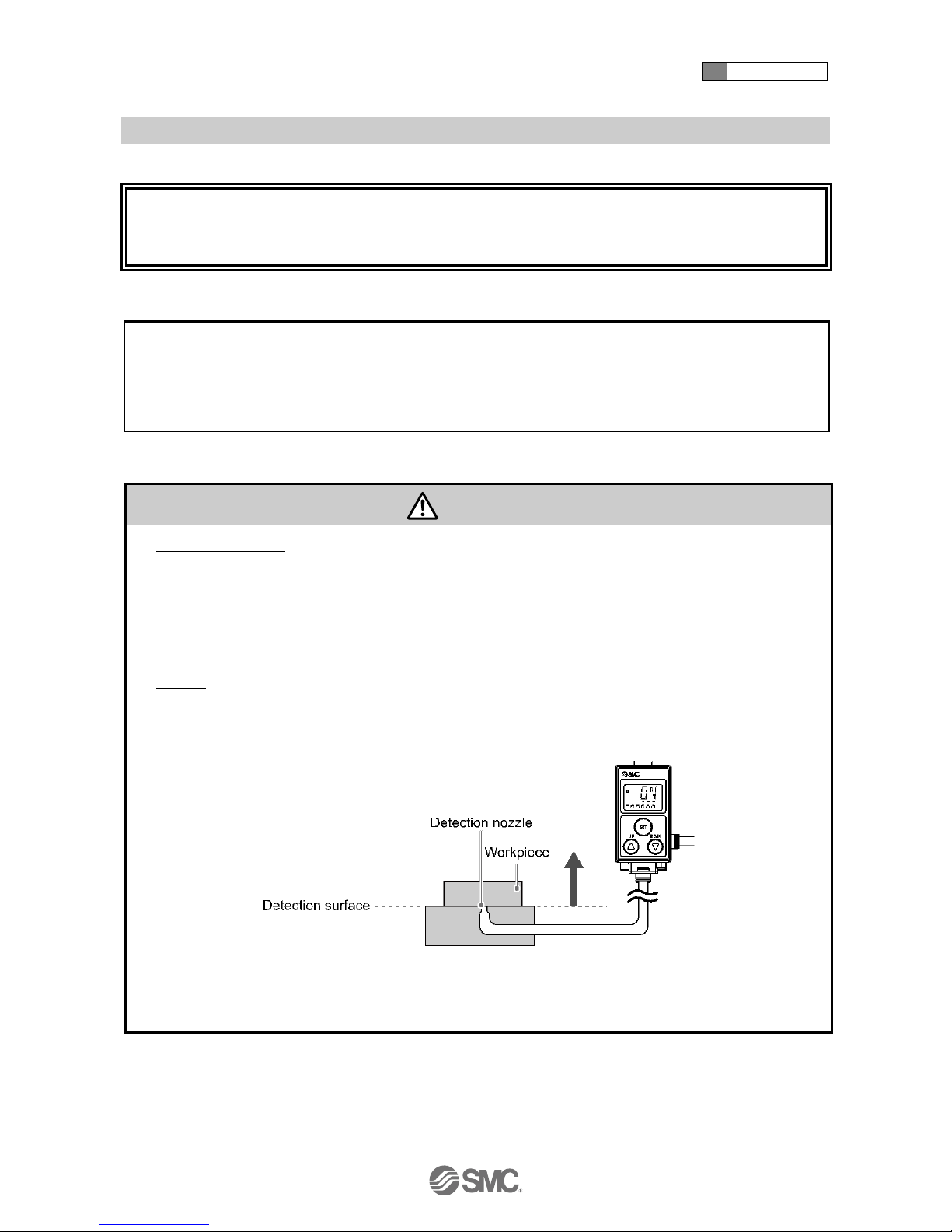

About this product

This product is not designed to be explosion proof.

Do not use a fluid containing chemicals, synthetic oils including organic solvent, salt and

corrosive gases.

Otherwise damage to the product, malfunction and failure can result.

Writing time of input data to product is 1000000 times.

Design

The product should be positioned higher than the detection nozzle.

If the product is positioned lower than the detection nozzle, water or oil may enter the detection port, causing a

malfunction or operational failure.

Do not use multiple detection nozzles with one product.

Correct measurement may not be possible. If multiple nozzles are to be used, please test them on the actual

equipment. It is necessary for the user to verify correct operation.

1 Before Use

-5-

No.PS※※-OMR0002-G

Warning

Mounting/Installation

If the entering of foreign material to the fluid is possible, install the filter (5 m or less) or the

mist separator to the upstream side.

If compressed air containing condensate is used, install the air dryer or the drain catch before

the filter, and perform drainage regularly.

If regular drainage is difficult, the use of a filter with an auto drain is recommended.

Piping

Eliminate any dust left in the piping by air blow before connecting the piping to the product.

Otherwise it can cause damage to the product, malfunction or failure.

Perform function and leakage inspection after piping.

Safety cannot be assured in the case of unexpected malfunction. Disconnect the power supply and stop the fluid

supply if the equipment does not function properly or if there is leakage of fluid.

Do not use equipment or fittings that may leak or obstruct the air flow between the product and

the detection nozzle.

Wiring

The product is CE marked, but not immune to lightning strikes. Take measures against

lightning strikes in the system.

Limit of the cable tensile force is 50 N.

Do not lift or carry the product by holding the cables.

If the lead wire can move, fix it near the body of the product.

Keep wiring as short as possible to prevent interference from electromagnetic noise and surge

voltage.

Do not use a cable longer than 10 m.

Wire the DC (-) line (blue) as close as possible to the power supply.

Operating environment

Do not use the product in an environment where the product is constantly exposed to water or

oil splashes.

Otherwise it can cause failure or malfunction. Take measures such as using a cover.

Do not use in an atmosphere containing oil, corrosive gases, chemicals, sea water, or where

there is direct contact with any of these.

Even exposure for a short period of time, will have adverse effects including damage, failure, malfunction and

hardening of the cable.

Do not use the product in the presence of a magnetic field.

Otherwise malfunction can result.

Do not operate close to a heat source, or in a location exposed to radiant heat.

Otherwise malfunction can result.

When the product is contained in a box for use, provide an exhaust port for constant release

of pressure to atmosphere.

If the pressure in the box is not atmospheric pressure, correct inspection will not be available and malfunction may

result.

1 Before Use

-6-

No.PS※※-OMR0002-G

Warning

Usage

Do not short-circuit the load.

When the load is short circuit, generated excess current lead to cause the damage of the product.

Do not press the setting buttons with a sharp pointed object.

It may damage the setting buttons.

During the any setting, the product will switch the output according to the existing settings

until the changes are complete.

Confirm the output has no adverse effect on machinery and equipment before setting.

Stop the control system before setting if necessary.

Perform settings suitable for the operating conditions.

Incorrect setting can cause operation failure.

For details of each setting, refer to each “Setting” 41 page of this manual.

Do not touch the LCD during operation.

The display can vary due to static electricity.

Maintenance Service

Drain system regularly.

If condensate enters the secondary side, it may cause malfunction of pneumatic equipment.

◆Please read and understand the cautions in the Operation Manuals for

VX2 series (2 port solenoid valve) and AR20 series (Regulator) before

use.

2 About this product

-7-

No.PS※※-OMR0002-G

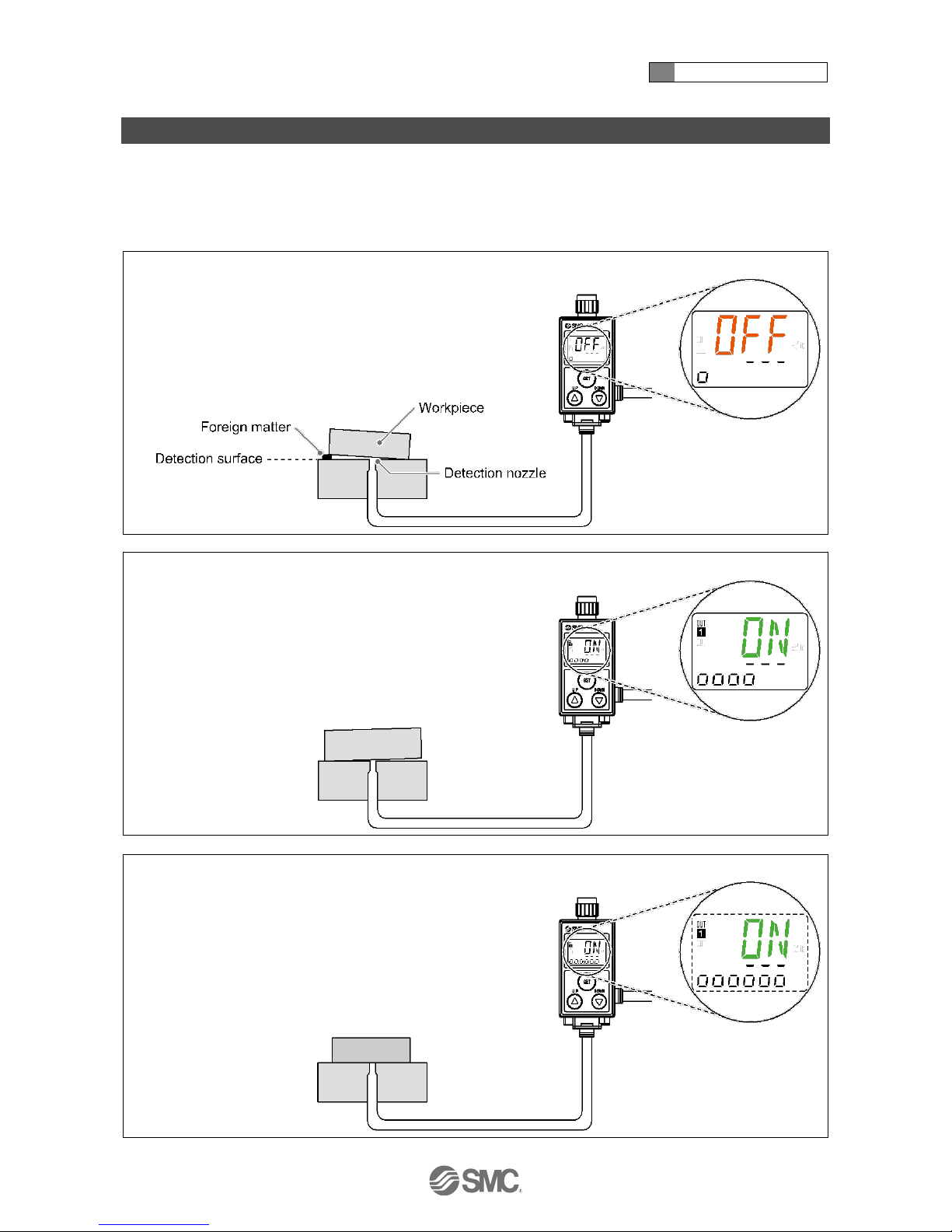

Features

The Gap between the detection surface and the workpiece (0.01 mm to 0.03 mm, 0.02 mm to 0.15 mm,

0.05 mm to 0.30 mm) can be detected.

The Gap condition is indicated on the main screen in Green (ON) or Orange (OFF). : Default setting.

The sub screen indicates the distance between the detection surface and the workpiece using a level meter.

This product is a non-contact switch which will not scratch the workpiece.

(A) The Workpiece is not seated in the correct position due to a foreign object.

(B) Within the acceptable range (Seats correctly).

(C) The Workpiece is more closely in contact than in (B).

2 About this product

-8-

No.PS※※-OMR0002-G

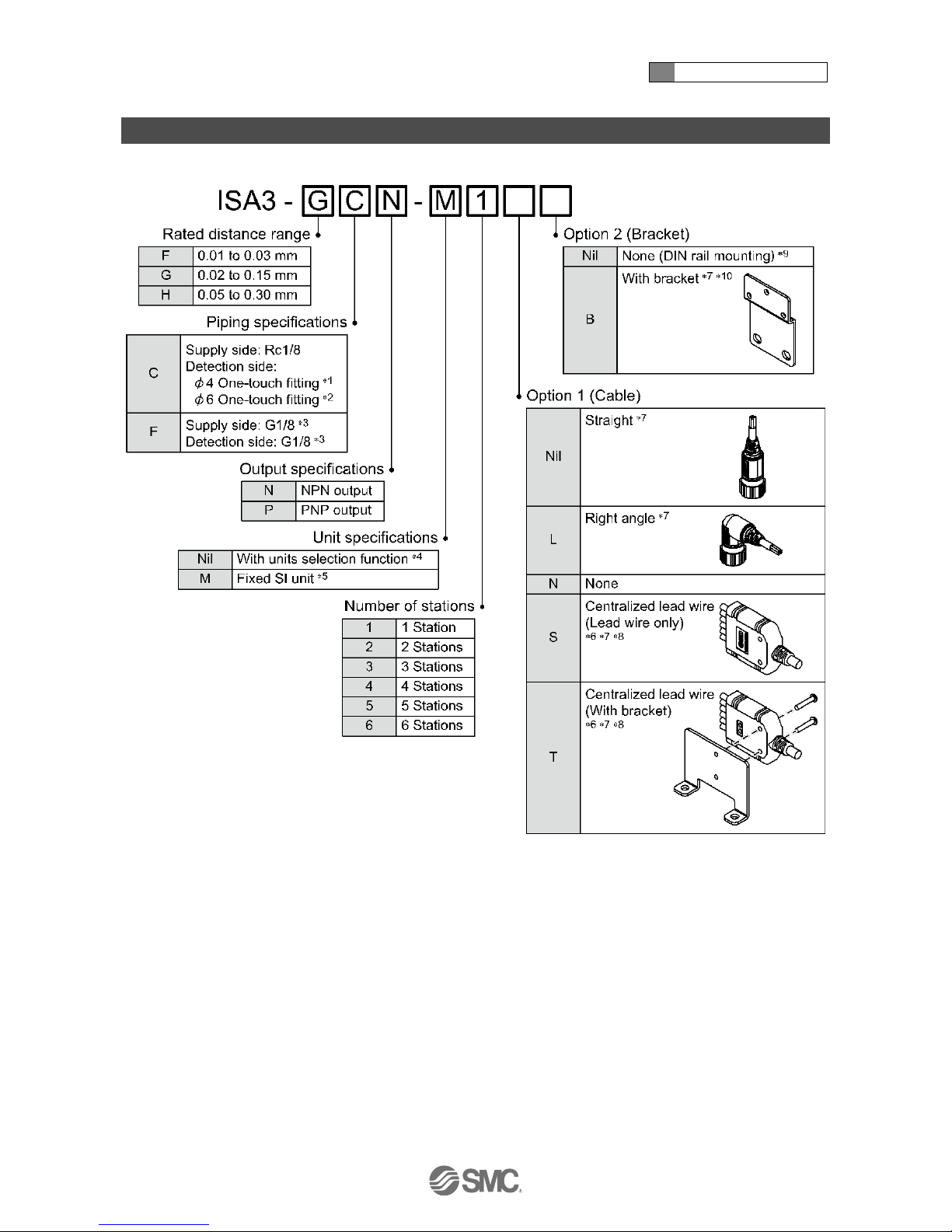

Model Indication and How to Order

○Without control unit

1: To be used for the rated distance range of "F".

2: To be used for the rated distance range of "G" or "H".

3: ISO1179-1

4: The new Measurement Law prohibits the use of pressure switch with the units selection function in Japan.

5: Fixed unit: kPa

6: Cannot be selected for 1 station.

7: At the factory, the options are not attached to the product, but packed together with it for shipment.

8: Refer to 8 (page 10).

9: DIN rail must be ordered separately.

10: About the number of brackets.

1 station: 1 piece is packed

More than 2 stations: 2 pieces is packed

2 About this product

-9-

No.PS※※-OMR0002-G

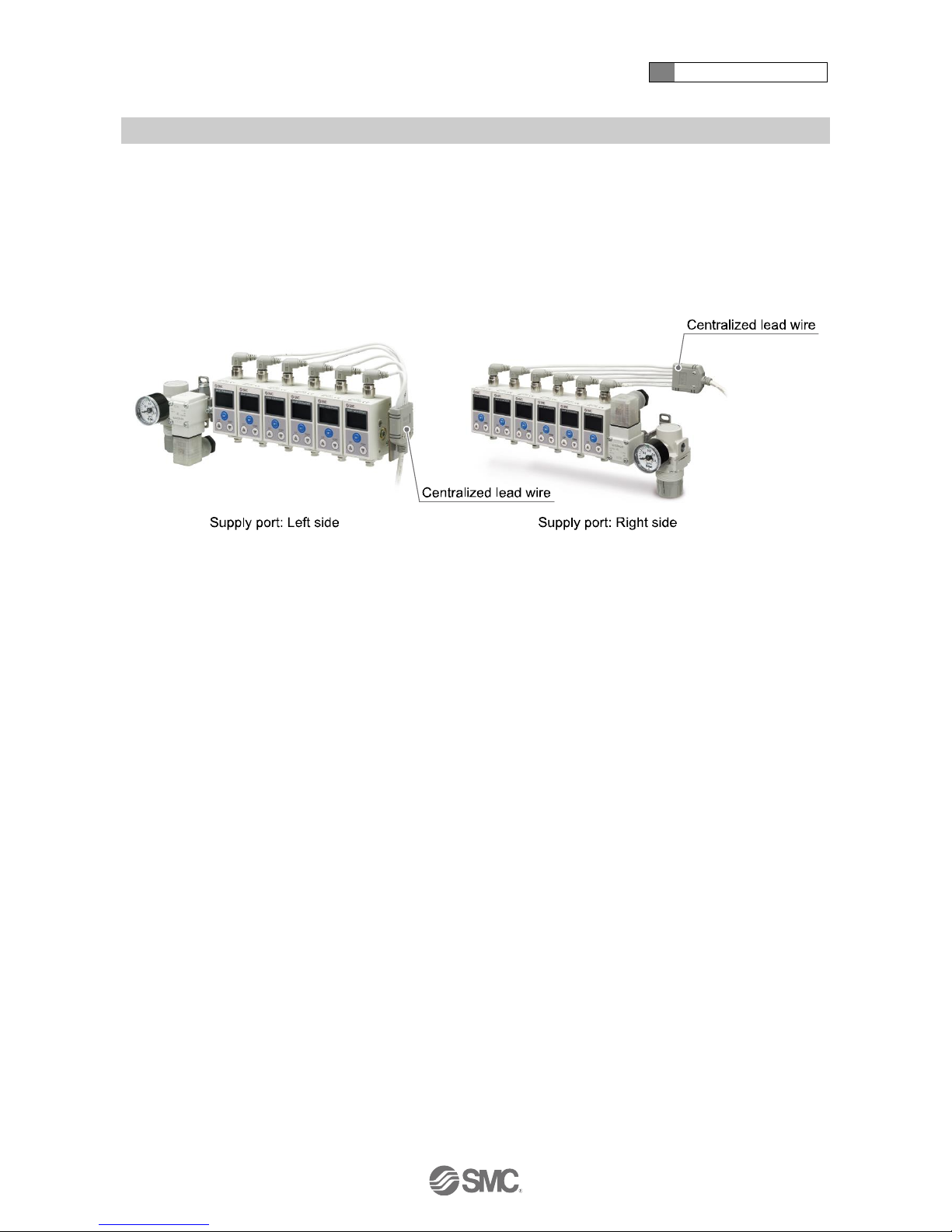

○With control unit

2 About this product

-10-

No.PS※※-OMR0002-G

1: To be used for the rated distance range of "F".

2: To be used for the rated distance range of "G" or "H".

3: ISO1179-1

4: The new Measurement Law prohibits the use of pressure switch with the units selection function in Japan.

5: Fixed unit: kPa

6: Cannot be selected for 1 station.

7: At the factory, the options are not attached to the product, but packed together with it for shipment.

8: The electrical entry of centralized lead wire for M12 connector is on the right side.

If the supply port on the right side is used, arrange the centralized lead wire so that it does not interfere with the control unit.

9: The bracket for control unit will be assembled before shipment.

10: Made to order

11: When the control unit is mounted, the piping specifications of the supply port will be changed due to piping specification of the gap

checker.

12: ISO16030

2 About this product

-11-

No.PS※※-OMR0002-G

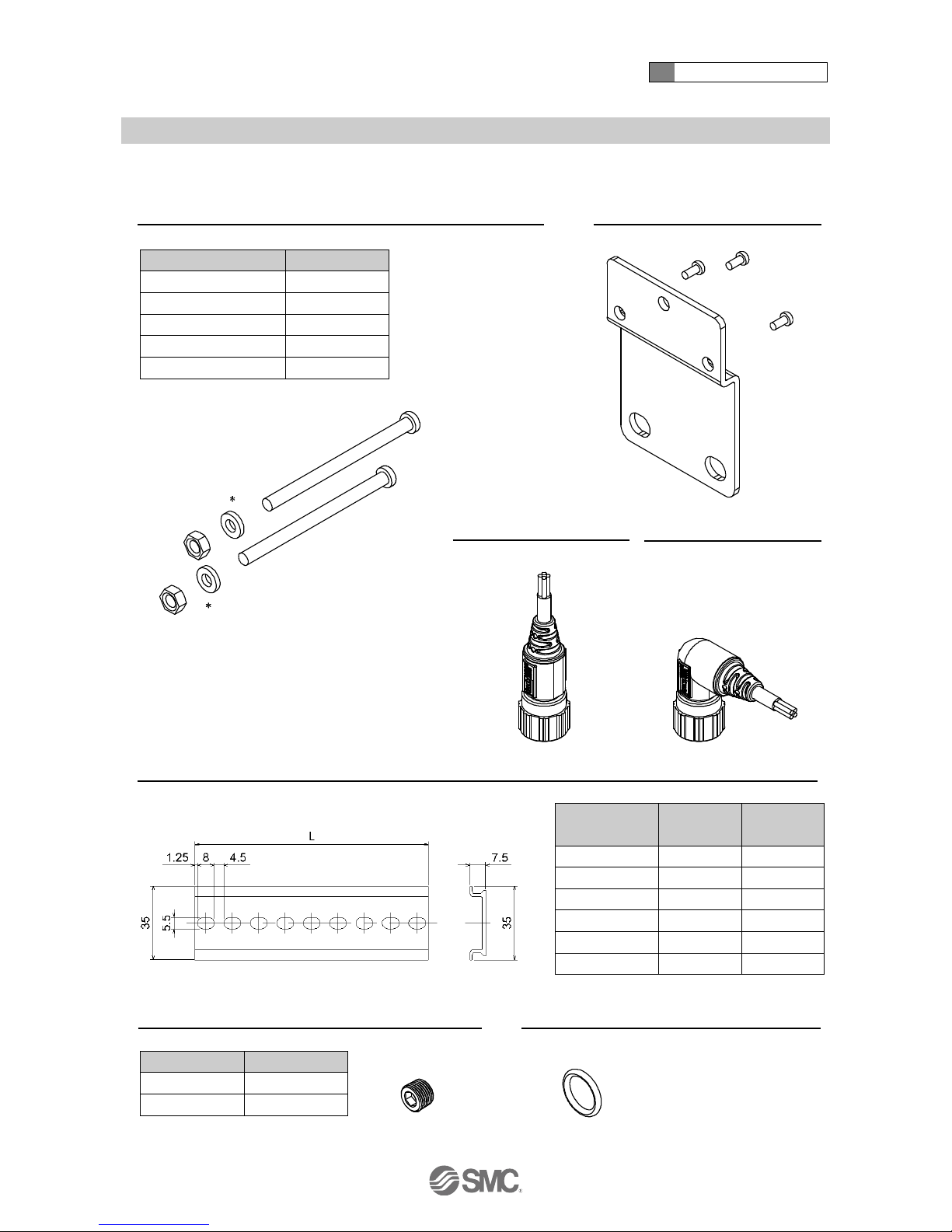

○Option/Part number

Joint screws

(2 screws, 2 spacers

, 2 nuts)

ISA-16-

Bracket (when control unit not fitted)

(Nominal size:3 x 8, 3 screws)

ISA-14

Number of stations

Part number

2

ISA-16-2

3

ISA-16-3

4

ISA-16-4

5

ISA-16-5

6

ISA-16-6

: Spacers are included for 4 and 6 stations.

With connector cable

ZS-31-B

With connector cable

ZS-31-C

DIN rail

ISA-5-

Part number

L

Number of

stations

ISA-5-1

73.0

1

ISA-5-2

135.5

2

ISA-5-3

173.0

3

ISA-5-4

210.5

4

ISA-5-5

248.0

5

ISA-5-6

285.5

6

Threaded plug with seal

ISA-12-

Seal for extra station

ISA-15

Piping type

Part number

Rc1/8

ISA-12-A

G1/8

ISA-12-C

: This is applicable in both

piping specification C and F.

2 About this product

-12-

No.PS※※-OMR0002-G

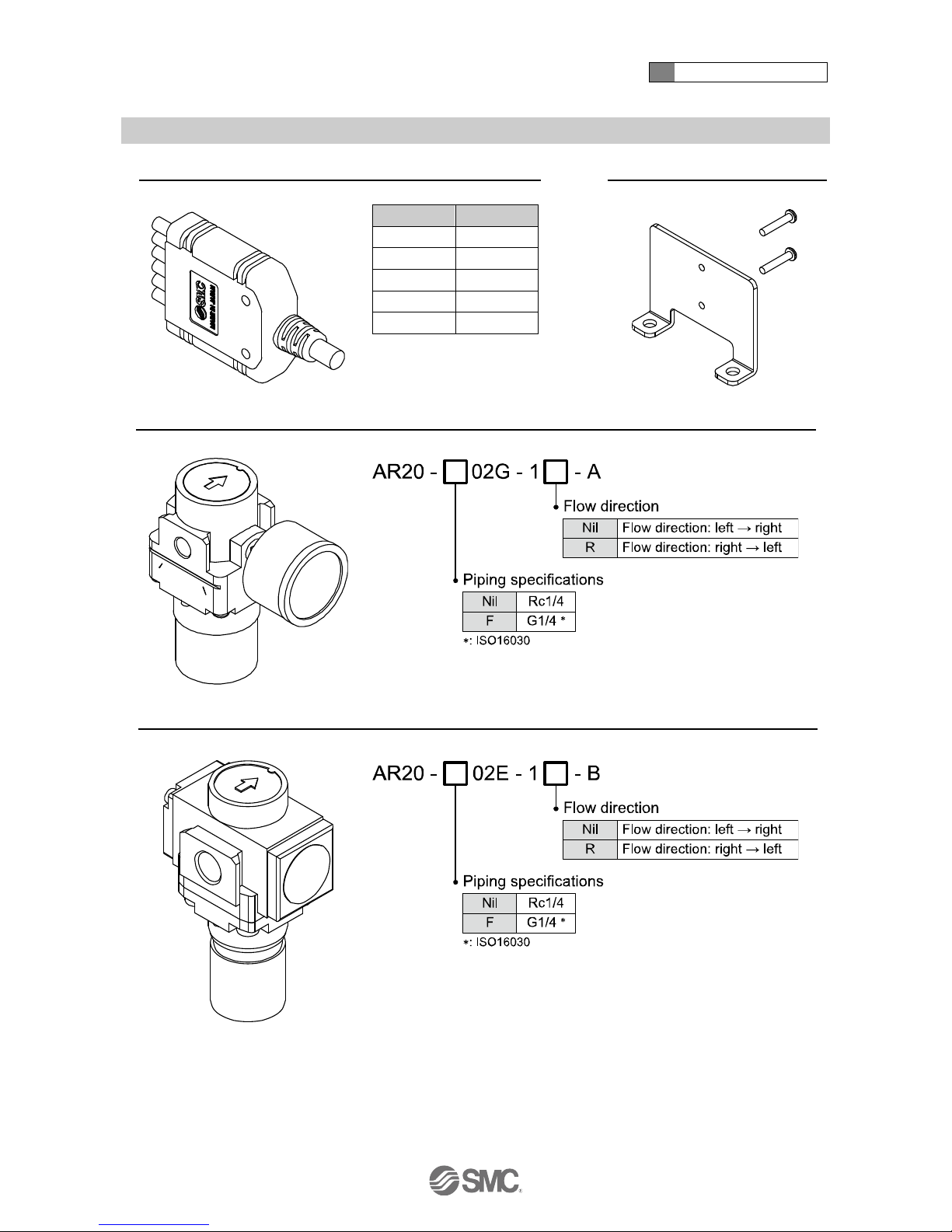

Centralized lead wire

ISA-19-

Bracket for centralized lead wire

ISA-20

Stations

Model

2

ISA-19-2

3

ISA-19-3

4

ISA-19-4

5

ISA-19-5

6

ISA-19-6

Regulator (Round pressure gauge)

AR20-02G-1-A

Regulator (Square embedded gauge)

AR20-02E-1-B

2 About this product

-13-

No.PS※※-OMR0002-G

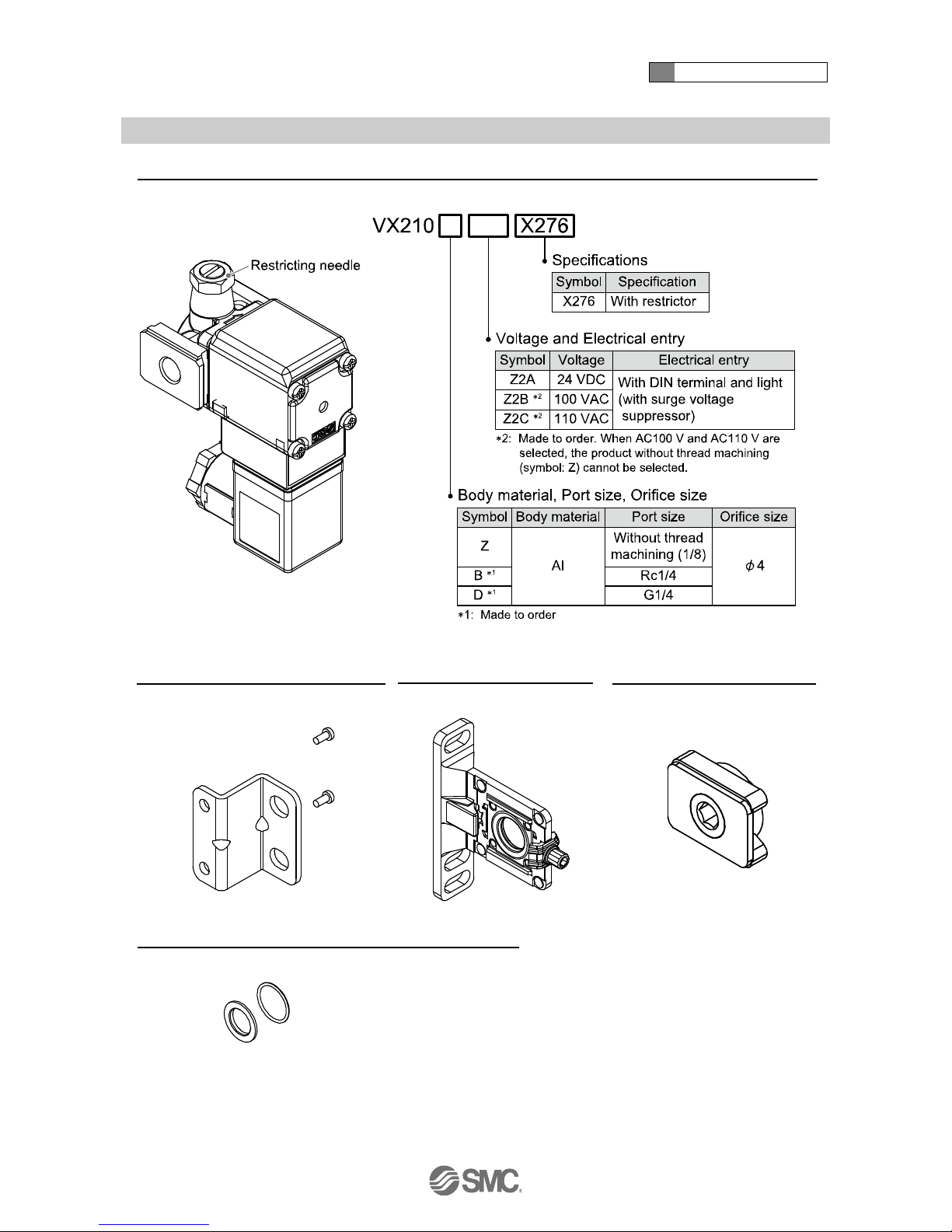

2 port solenoid valve

VX210X276

Bracket (when control unit fitted)

(Nominal size:3 x 8, 2 screws)

ISA-17

Spacer with bracket

Y200T-A

Modular adapter

E210-U01

Spacer

ISA-18

With O-ring

: When a 2 port solenoid valve is connected to the right.

2 About this product

-14-

No.PS※※-OMR0002-G

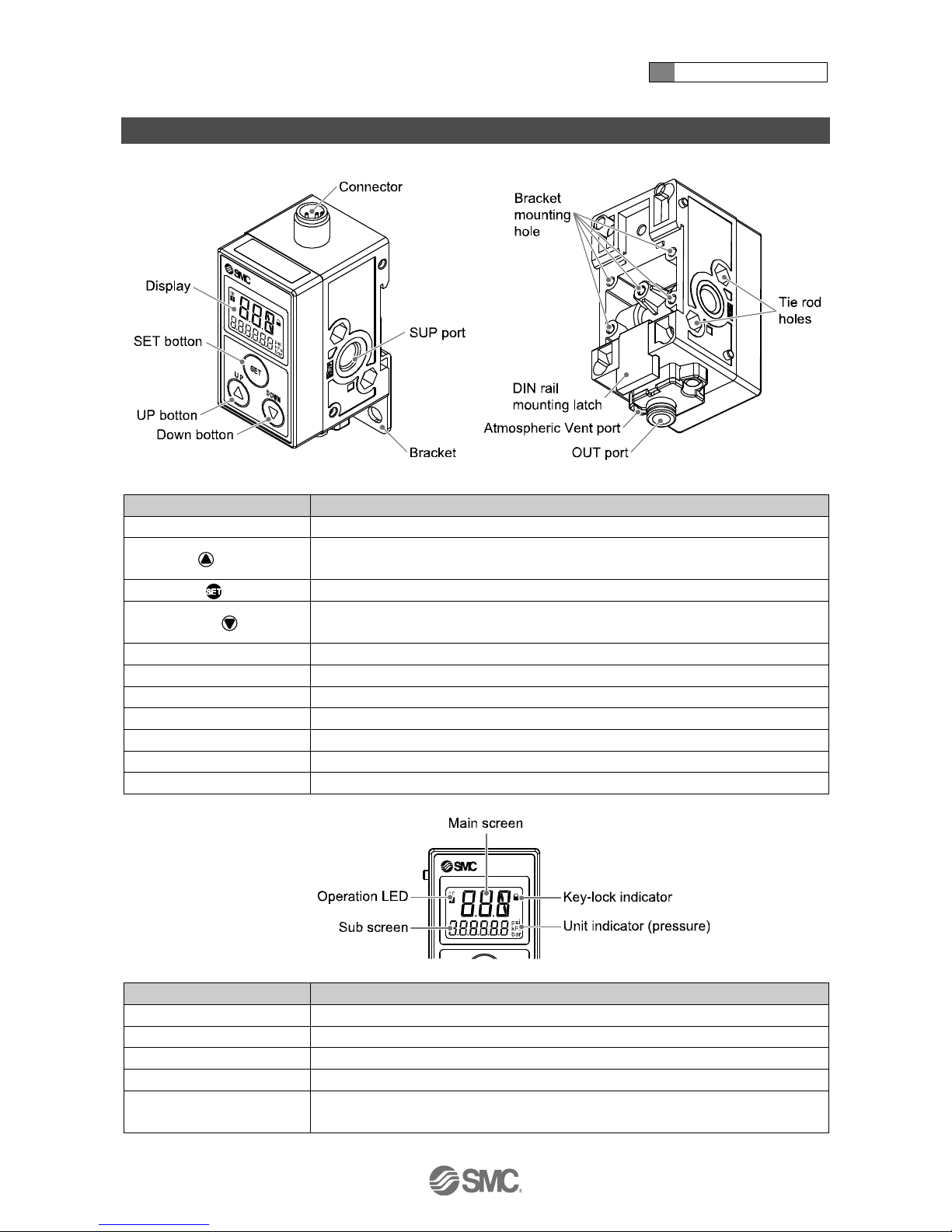

Summary of Product parts

Element

Description

Display

See below

UP button ( button)

Selects the mode and the display shown on the sub screen, or increases the switch

point.

SET button ( button)

Press this button to change the mode and to fix the settings.

DOWN button ( button)

Selects the mode and the display shown on the sub screen, or decreases the switch

point.

Connector

Electrical connection.

SUP port (Supply port)

Port to supply pressure.

Bracket mounting hole

Used to attach the bracket to the product.

Tie rod holes

Used to connect additional products.

OUT port (Detection port)

Port to be connected to the detection nozzle.

Atmospheric vent port

Port to vent exhaust air to the atmosphere.

DIN rail mounting latch

Used to mount the product on a DIN rail.

Display

Element

Description

Main screen

ON/OFF, display value and error code are displayed. (2 colour display)

Operation LED

Indicates the switch output status. Turns ON (orange) when the switch output is ON.

Sub screen

Level meter, display value, switch point, pressure etc. are displayed.

Key-lock indicator

Turns ON when keys are locked.

Unit indicator (pressure)

When pressure is displayed on the sub screen, indicates the pressure unit currently

selected.

2 About this product

-15-

No.PS※※-OMR0002-G

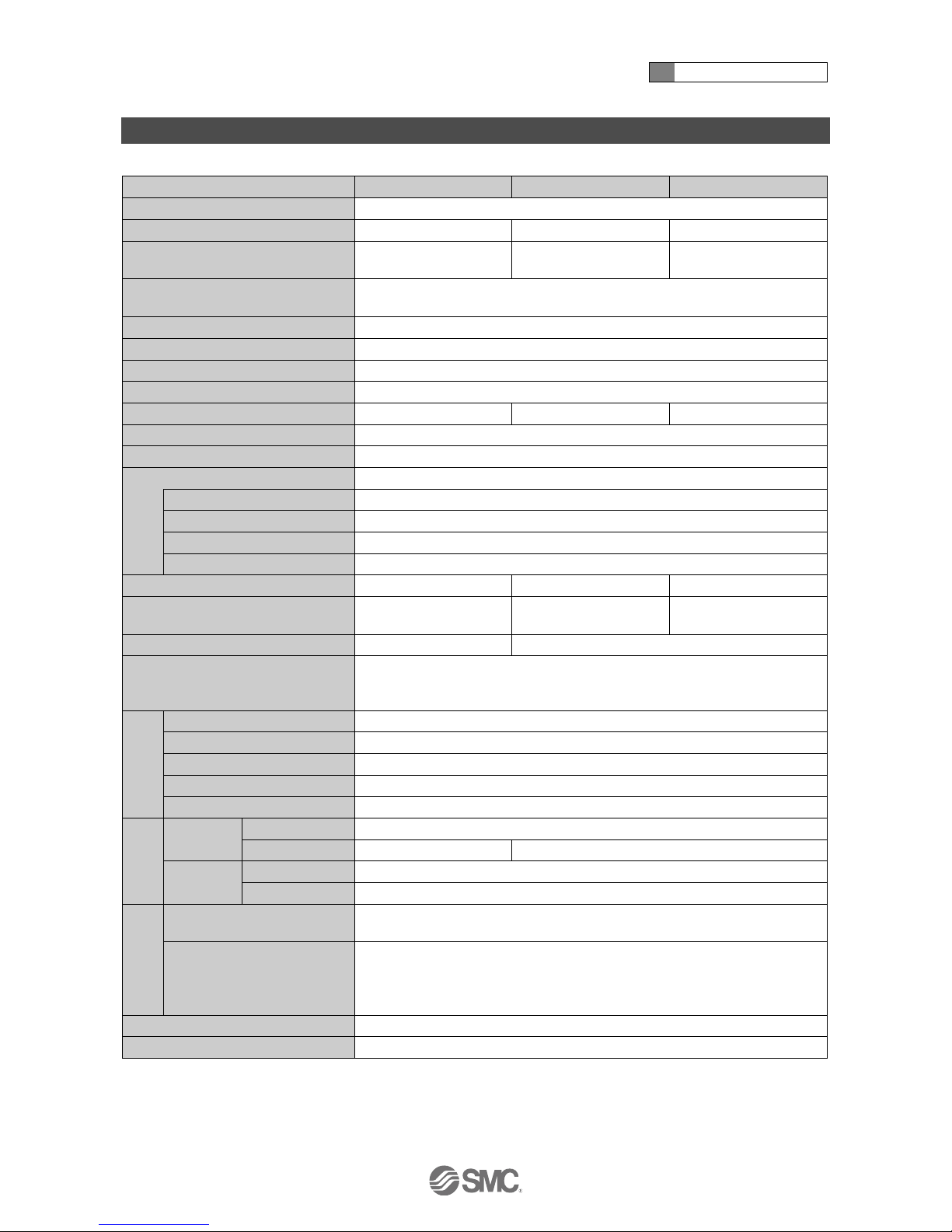

Specification

■Specifications (ISA3)

Model

ISA3-F

ISA3-G

ISA3-H

Applicable fluid

Dry air (Filtered through a 5 μm filter)

Rated distance range

0.01 to 0.03 mm

0.02 to 0.15 mm

0.05 to 0.30 mm

Displayable/Settable range

(Distance reference)

1

0 to 60

2

10 to 300

2

30 to 500

2

Minimum display resolution

(Distance reference)

1

1

Rated pressure range

100 to 200 kPa

Displayable range (Pressure value)

3

-20 to 220 kPa

Withstand pressure

600 kPa

Detection nozzle

1.5

4

Current flow

5 L/min or less

12 L/min or less

22 L/min or less

Power supply voltage

24 VDC 10%, Ripple(p-p) 10% or less (with power supply polarity protection)

Current consumption

25 mA or less

Switch output

1 output (NPN or PNP)

Max. load current

10 mA

Max. applied voltage

26.4 V

Residual voltage

1 V or less (at 10 mA)

Short circuit protection

Provided

Repeatability

0.005 mm or less

0.010 mm or less

0.020 mm or less

Temperature characteristics

(Reference: 25 oC)

0.010 mm or less

0.015 mm or less

0.030 mm or less

Hysteresis

0 to variable (Default: 3)

0 to variable (Default: 20)

Display

2-screen display LCD

Main screen: 3-digit, 7-segment 2-colour (Orange/Green)

Sub screen: 6-digit, 7-segment 1-colour (White)

Environment

Enclosure

IP67 equivalent

Operating temp. range

Operation: 0 to 50 oC, Stored: -20 to 70 oC (No condensation or freezing)

Operating humidity range

Operation/Stored: 35 to 85% RH (No condensation)

Withstand voltage

1000 VAC or more (in 50/60 Hz) for 1 minute between terminals and housing

Insulation resistance

2 MΩ or more at 500 VDC, between terminals and housing

Piping

spec.

Piping

option C

Supply port

Rc1/8

Detection port

4 One-touch fitting

6 One-touch fitting

Piping

option F

Supply port

G1/8 (ISO1179-1)

Detection port

G1/8 (ISO1179-1)

Cable

Lead wire with connector

M12 lead wire with 4 pin connector, 4 cores, 4, 5 m

Conductor O.D.: 0.72 mm, Insulator O.D.: 1.14 mm

Centralized lead wire

M12 lead wire with 4 pin connector part, 4 cores, 4, Insulator O.D.: 1.14 mm

Centralized lead wire part, 2 to 3 stations: 5 cores, 4, 5 m

4 to 6 stations: 8 cores, 6, 5 m

Conductor O.D.: 0.50 mm, Insulator O.D.: 1.00 mm (2 to 6 stations common)

Weight

113 g (Cable not included, One-touch fitting)

Standard

CE, RoHS compliant

1: Refer to the Characteristics Curve on page 19 for the relationship between the display value and the detected distance.

2: For ISA3-F type, the range is up to 57, with a hysteresis of 3.

For ISA3-G type, the range is up to 280, with a hysteresis of 20.

For ISA3-H type, the range is up to 480, with a hysteresis of 20.

3: The Pressure value will be indicated on the sub screen.

4: Refer to page 27 for details of the detection nozzle.

2 About this product

-16-

No.PS※※-OMR0002-G

■Specifications (Regulator)

Refer to the standard regulator catalogue for detailed specifications.

■Specifications (2 port solenoid valve)

Refer to "Option/Part number" (page 13) or the catalogue of the standard 2 port solenoid valve for the

detailed specifications of models other than X276.

2 About this product

-17-

No.PS※※-OMR0002-G

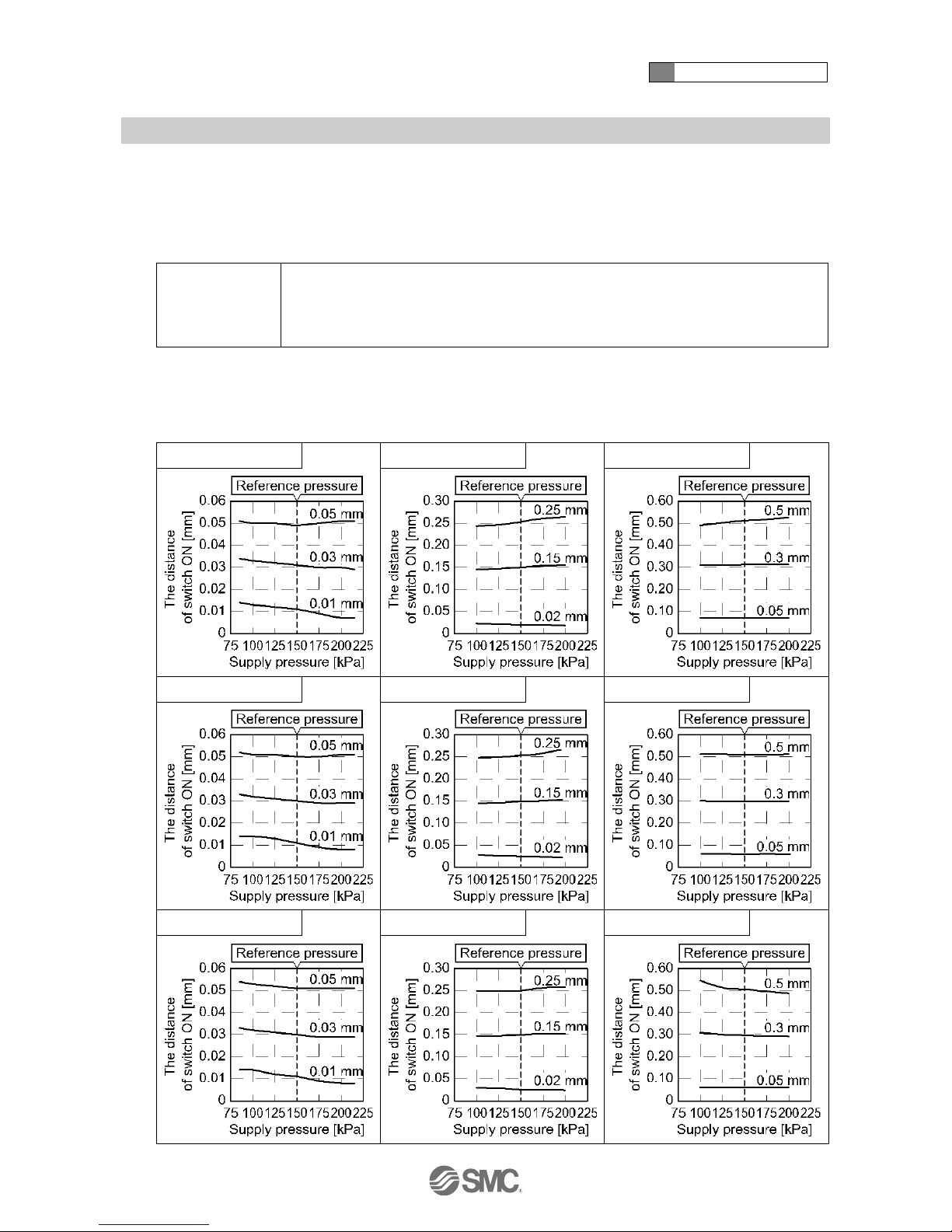

■Characteristics graph

○Supply pressure dependence characteristics

The detection distance for turning ON the output depends on the supply pressure.

The graphs below show the variation of the distance for the product to turn ON, for 3 types of gap, by

changing the supply pressure (50 kPa) when the product is set to turn ON at 150 kPa supply pressure.

Test conditions

Detection nozzle: ø1.5

Piping: F type: ø4 x ø2.5 tube

G, H type: ø6 x ø4 tube

Reference pressure: 150 kPa

: Use within the rated pressure range (100 kPa to 200 kPa).

It will be impossible to measure the gap when the operating pressure is less than 80 kPa or more than 220 kPa. And the output

will be OFF.

ISA3-F

ISA3-G

ISA3-H

Piping length: 1 m

Piping length: 1 m

Piping length: 1 m

Piping length: 3 m

Piping length: 3 m

Piping length: 3 m

Piping length: 5 m

Piping length: 5 m

Piping length: 5 m

2 About this product

-18-

No.PS※※-OMR0002-G

○Response time

Response time is the elapsed time between the pressure supply and the turning ON of the switch output.

The Response time varies depending on the piping length from the OUT port to the detection nozzle, and

the seating condition of the workpiece.

The graphs below show the response time when the workpiece is approached at 90% distance and 0%

distance (close contact). (: The switch point is 100% distance)

(Example: When the switch point is set to 0.1 mm, the response time when the workpiece is at 0.09 mm

and 0.00 mm are measured).

Test conditions

Detection nozzle: ø1.5

Piping: F type: ø4 x ø2.5 tube

G, H type: ø6 x ø4 tube

Supply pressure: 200 kPa

ISA3-F

ISA3-G

ISA3-H

Piping length: 1m

Piping length: 1m

Piping length: 1m

Piping length: 3 m

Piping length: 3 m

Piping length: 3 m

Piping length: 5 m

Piping length: 5 m

Piping length: 5 m

Loading...

Loading...