SMC Networks ISA2 Operation Manuals

Wiring

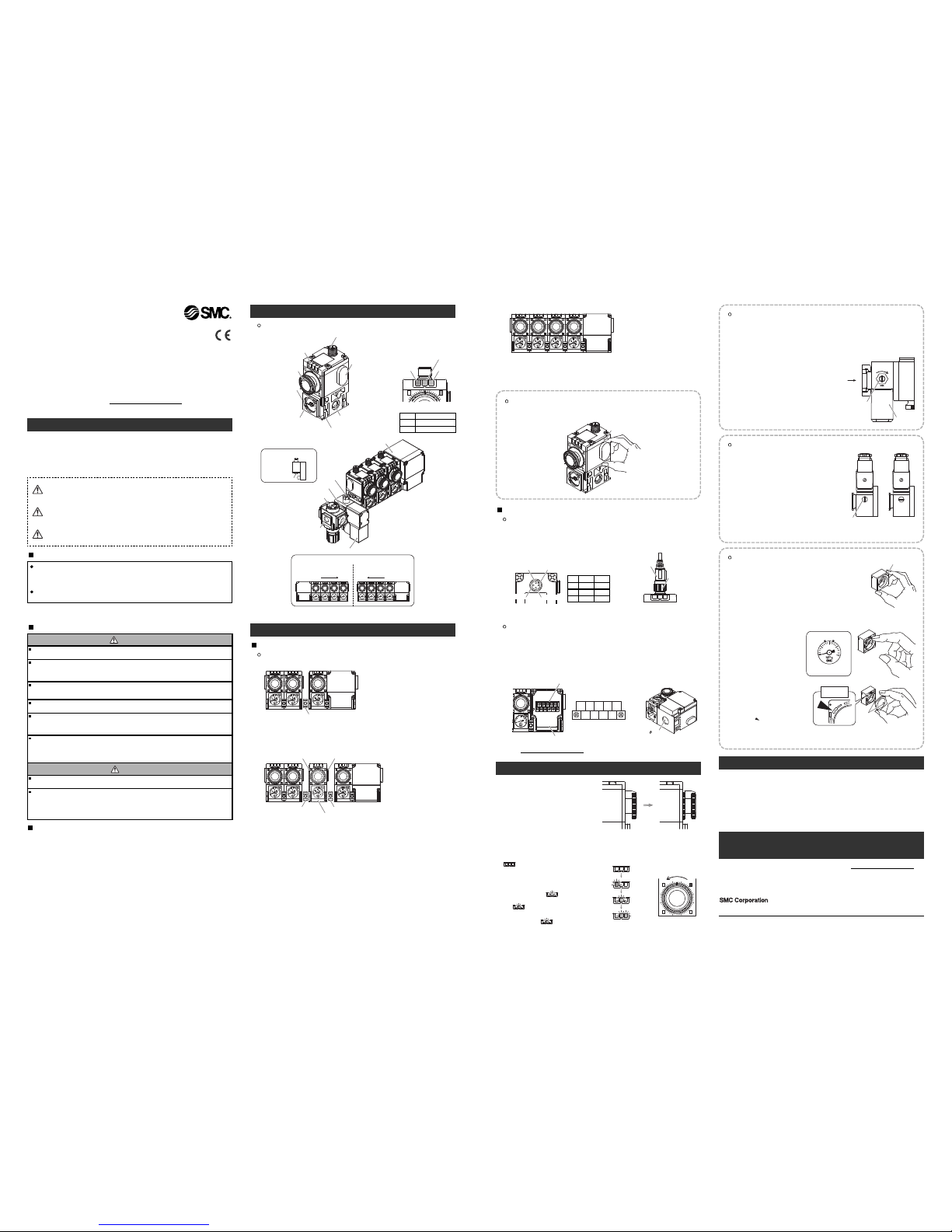

Discrete wiring method

N

ames of individual parts

LED level meter

Setting handle

Connector for connecting lead wire

(See discrete wiring method)

Pressure gauge

SUP port

Rc, NPT, G1/8

Detection port

Rc, NPT, G1/8

SUP port

Rc, NPT, G1/8

End plate

03

Red

Green 1

Green 2

Terminal board box (See the concentrated wiring method)

Regulator (AR20 series)

S

pacer (Y200-A)

T

hrottle

2 port solenoid valve (VCA series)

S

UP port

Rc, NPT, G1/4

411 4

Describing stations

Terminal board box is

installed on the right side

Terminal board box is

installed on the left side

Red

Green 1

Above set position

Appropriate set position

G

reen 2

B

elow set position

1. Insert the lead wire connector into the connector key groove.

2. Tighten the connector by hand using the knurl, rotating clockwise.

3. Install the other end of the wires using the correct colours.

1. Mount the conduit in the terminal board box. Refer to the manufacturers

catalogue for the conduit mounting method.

2. Insert the cable through the conduit and install the wires according to the

terminal board layout below.

3. Tighten the conduit. Do not hold down the terminal board box or switch

while tightening the conduit. The tightening torque should be 5 Nm

maximum.

Concentrated wiring method

Setting

Set the detection distance using the LED

level meter and setting handle.

While setting, pull out the setting handle

illustrated right.

Do not release the setting handle, as it

will return to its normal position and the

handle will no longer turn.

Before pulling out Setting handle pulled out

1. Apply a thickness gauge onto the detection nozzle to set the position for

accurate detection.

2. Confirm that supply pressure is applied. If the setting handle is fully closed, the

will turn off.

3. Pull the setting handle and turn in the plus

direction to turn on the LEDs in the

following order.

4. When the Green turns on, the

sensor output turns ON. This completes

the setting.

5. Apply a thickness gauge again and check

that the Green turns on.

Setting of 2-port solenoid valve

Throttle setting for air blasting to prevent water, cutting fluid or other

liquids from entering the nozzle.

Clockwise: Throttle close

Counterclockwise: Throttle open

∗: This setting is not required if the valve of your sensor does not have a throttle.

1. Turn the power of the valve off.

2. Adjust the throttle turning clockwise so that

water, cutting fluid or other liquid does not

splash up from the detection nozzle.

3. Turn the power of the valve on, then turn

the power OFF again. Confirm that water,

cutting fluid or other liquid does not splash

u

p from the detection nozzle.

∗

: Do not rotate more than 5 times from fully closed, as the

orifice will be pulled out.

Throttle

Solenoid

T

urn

clockwise

IN

Manual operation

Slotted locking type (Tool required)

Valve opening: Turn the screw 90°

clockwise using a slotted

screwdriver. The valve

remains open even when

the screwdriver is

removed.

Valve closing: Turn the screw 90°

anticlockwise from a

valve open position to

its original position.

Make sure that the screw is in the

valve closed position during normal operation.

S

etting of limit gauge indicator

1. Cover removal

Hold the edge of the front cover and turn in the

OPEN arrow direction until it stops (15°). Pull the

cover forward to remove it.

2. Installing referential needles

Move the referential

needle using fingertips.

Adjust high and low limits

of pressure by two green

referential needles.

3. Cover mounting

After finishing setting the

referential needles, mount

the cover back to its original

position. Insert the cover pin

into the hole in the case

(mark in enlarged view of

part A) and turn it clockwise

till it stops. (Direction opposite the OPEN arrow direction) Confirm that

the cover is held securely.

NOTE

•If the detection nozzle is exposed to splashes of water or cutting oil, do not

allow backflow from the detection nozzle to the switch body. Install the switch

body at a position higher than the detection nozzle wherever possible.

•The air outlet is provided on the setting dial section of the air catch sensor. Do

not turn off air supply to the switch if water or cutting oil splashes around the

setting dial.

•The switch enclosure conforms to IP66 and the solenoid valve conforms to

IP65. The pressure gauge and the regulator have open constructions. Take

greater protection measures in an environment where water splashes, oil or

spatters from welding may occur.

Air Catch Sensor

Operation Manual

ISA2

Thank you for purchasing an SMC ISA2 Series Air Catch Sensor.

Please read this manual carefully before operating the product and make sure you

understand its capabilities and limitations.

Please keep this manual handy for future reference.

To obtain more detailed information about operating this product, please

refer to the SMC website (URL http:// www.smcwor ld.com

) or co ntact SMC

directl y.

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety and must

be followed in addition to International standards (ISO/IEC) and other safety

r

egulations.

CAUTION indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

m

oderate injury.

Operator

This operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenance of such equipment. Only those persons are

allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

Caution:

Warning:

Danger:

WARNING indicates a hazard with a medium level of

risk which, if not avoided, could result in death or

serious injury.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

Safety Instructions

Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

T

his product is not designed to be explosion proof.

D

o not use the product in a place where static electricity is a problem.

Otherwise it can cause failure or malfunction of the system.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system

•Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during maintenance:

•Turn off the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance work

Otherwise an injury can result.

After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid.

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply.

Do not apply fluid under leaking conditions.

Safety cannot be assured in the case of unexpected malfunction.

Do not touch the terminals and connectors while the power is on.

Otherwise electric shock, malfunction or damage to the product can result.

D

o not operate the product outside of the specifications.

D

o not use for flammable or harmful fluids.

F

ire, malfunction, or damage to the product can result.

Verify the specifications before use.

Warning

Caution

Summary of Product parts

Mounting and Installation

1: Brown

2: NC

4: Black

3: Blue

K

nurled part

Lead wire with

c

onnector

OUT1OUT2OUT3OUT4OUT

5

OUT

6DC(

-

)

NC

DC

(+)

Terminal board

Conduit mounting area

39

3

6

9

0

0

0.1 0.3

0.4

0.2

Conduit port ( 21)

1

2

DC(+)

NC

3

DC(-)

Brown

-

Blue

4

OUT

Black

V

alve closed

(Vertical slit)

V

alve opened

(Horizontal slit)

Manual lock

Maintenance

Refer to the product catalogue or SMC website

(URL http://www.smcworld.com

) for more information about wiring.

OPEN arrow

0

0

.1

0.2

0

.3

0.4

High limit: 0.24 MPa

Low limit: 0.16 MPa

Example

A

Pin

E

nlarged view

of part A

Red

Green 1

Green 2

Turn in the plus direction

3 0

69

Bracket (ISA-3-A)Existing bracket

Expansion switches

Convex

Concave

1. Set the expansion packing (ISA-7-B) in the concave of the SUP port for

expansion switches.

2. Mount the convex of the expansion switch onto the existing switch.

3. Mount the two brackets (ISA-3-A) in their positions.

∗: Fasten the screws temporarily.

4. Make sure that an expansion packing is set in the concave of the

existing switch SUP port.

5. Fit the convex of the existing switch onto the concave of the added

switch.

6. Mount the existing bracket.

∗: Fasten the screws temporarily.

2. Assembly

1

. Tighten the fasteners to a torque of 1.2 Nm.

2. Install the air pipes and confirm that there is no air leakage.

3. Tightening

1. Disassembly

Existing bracket

1. Loosen the screws to remove two brackets, one each from the front and

back surfaces.

2. Split the switch slowly so as not to disengage the O-ring of the SUP port.

H

ow to remove the end plate

The end plate can be removed by levering under the slot for removal, and

pulling the end plate.

Slot for removal

Mounting

Manifold expansion

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2011-2015 SMC Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

How to reset the product after a power cut or forcible de-energizing

The setting of the product will be retained as it was before a power cut or

de-energizing.

The output condition is also basically recovered to that before a power cut or

de-energizing, but may change depending on the operating environment.

Therefore, check the safety of the whole installation before operating the product. If

the installation is using accurate control, wait until the product has warmed up

(approximately 10 minutes).

Specifications

Outline with Dimensions (in mm)

Refer to the product catalogue or SMC website (URL http://www.smcworld.com) for

more information about the product specifications and outline dimensions.

PS※※-OMN0005-E

Manual lock

Manual lock part

Loading...

Loading...