SMC Networks IDH4-10 Series, IDH4-20 Series, IDH6-20 Series, IDHA4-23 Series, IDH6-10 Series Operation Manual

...

IDX-OM-O025E

Initial issue December, 2010

Original Instructions

PRODUCT NAME

PRODUCT NAMEPRODUCT NAME

PRODUCT NAME

THERMODRYER

MODEL

MODELMODEL

MODEL /

/ /

/ Series

IDH4-10 IDH4-20 IDHA4-23

IDH6-10 IDH6-20 IDHA6-23

Please read this manual prior of using the ai

r dryer. Keep the manual readily available for

reference.

© 2010 SMC CORPORATION All Rights Reserved.

Operation Manual

IDX-OM-O025E

Initial issue December, 2010

Dear Customers

Thank you for selecting SMC THERMODRYER.

This opertion manual must be read and understood throughoutly before handling this product. It provides all

essential information for maximizing product operating efficiency, as well as, for safe and longer life span

operation.

For safety operation of SMC THERMODRYER, read thoroughly and follow stated safety instructions, as

well as regulation stated within ISO 4414

*1

& JIS B 8370*2.

*1) IS O 441 4 : P ne um ati c f l ui d po we r – Re co m me n dat i ons fo r t h e app l ic a ti o n o f

pro d uct to tr a n sm i ssi o n a nd c o nt r ol s y ste m s.

*2) JI S B 8 3 70: Pneumatic fluid power – General rules relating to systems

This manual explains about installation and operation of the product. Only those who have thorough

understanding of the fundamental operating procedure or have basic knowledge and skills of handling

industrial product for the installation and operation of the product are qualified to perform installation and

operation.

The contents of the operation manual and the other documents attached to the product cannot become a

part of the contract clause or cannot change and modify existing agreements, promises, and relationship.

Any statements contained in this operation manual cannot be newly guaranteed and modify existing

guarantee certificate.

You are not allowed to copy any part of this operation manual for usage of third person without informing it

to us beforehand.

Note: The contents of this operation manual are subjected to change without prior notice.

To customers

Chapter i. Safety Instructions

i.1 Warning: Before using air dryer

........................................................i-1

i.1.1 Hazards, warnings and Cautions used in this Manual.................................i-1

i.2 Danger classifications/ Position of hazard warning label

........i-2

i.2.1 Danger Classification .................................................................................i-3

i.2.2 Electrical Hazards......................................................................................i-3

i.2.3 Hazards relating to high temperature .........................................................i-3

i.2.4 Hazards relating to rotating motor ..............................................................i-3

i.2.5 Hazards relating to compressed air circuit..................................................i-4

i.2.6 Positions of hazard warning labels .............................................................i-4

i.2.7 Hazards relating to refrigerant....................................................................i-4

i.2.8 Cautions for usage.....................................................................................i-5

i.3 Disposal

.....................................................................................................i-6

i.4

Limited warranty and Disclaimer / Compliance Requirements

.........i-7

Chapter 1. Names and Functions of Parts

1.1 Names and functions of parts

...........................................................1-1

Chapter 2. Transportation and Installation

2.1 Transportation

.........................................................................................2-1

2.2 Installation

................................................................................................2-2

2.2.1 Location....................................................................................................2-2

2.2.2 Anchorage ................................................................................................2-3

2.2.3 Air piping ..................................................................................................2-4

2.2.4 Drain tube.................................................................................................2-4

2.2.5 Electrical wiring.........................................................................................2-5

2.3 Cautions for re-installation

.................................................................2-6

Chapter 3. Operation/ Shutdown

3.1 Check points before operation

..........................................................3-1

3.2 Operation

..................................................................................................3-1

3.3 Functions and operation of temperature controller

..................3-3

3.3.1 Functions of temperature controller...........................................................3-3

3.3.2 Operation of temperature controller...........................................................3-3

3.4 Shutdown

..................................................................................................3-8

3.5 Cautions for re-start

..............................................................................3-8

3.6 Check points before re-start

..............................................................3-8

3.7 Cautions for abnormal stop

...............................................................3-8

3.8 Specifications of operation/ failure signals

..................................3-9

Table of Contents

3.9 Remote control

.......................................................................................3-9

Fig 3.8 Timing chart of signals

................................................................ 3-10

Chapter 4. Checks and Maintenance

4.1 Daily inspection

......................................................................................4-1

4.2 Parts which require regular maintenance

...................................4-1

4.2.1 Maintenance of auto drain.........................................................................4-1

4.2.2 Maintenance of filter .................................................................................4-4

Chapter 5. Troubleshooting

5.1 Troubleshooting

.....................................................................................5-1

Chapter 6. Reference Data

6.1 Specifications

.........................................................................................6-1

6.2 Dimensions

..............................................................................................6-2

6.3 Electrical wiring diagrams

..................................................................6-4

6.4 Air and refrigerant circuits & Function explanation

..................6-5

i Safety Instructions

i - 1

Safety Instructions

Before use, read and comprehend important

cautionary notif ication well on this operattion

manual.

i . 1 Warning: Before Useing THERMODRYER

In t his ch apter , t he st ated cont ents ar e especially a bo ut sa fet y way to us e THERMODR YER f or cu stomer.

THERMO DRYER is instal l ed on the down st r eam of the com press ed-ai r to remove moi sture and

foreign material

,

regulat e pressure of ai r,a nd contr ol temperatur e of compress ed -ai r. We, m anufactu rer, can not t ake an y

responsibility if you use it f or any other pur pose.

THERMO DRYER wo rks with hi g h vol tage and ha s som e parts that gets hot or rot ates dur ing operati on. Ask sel ler

if yo u need com ponent r eplac em ent and s er vicing.

Not only peop le ha ndle the THERMODRY ER but ev er y peopl e who p er f orm maint enance on or do works related

to i t shou ld read safety instr uct ions on this operation manual befo re han dling .

This oper ati on manual i s n ot a general saf et y manual which is practiced by safety training repr esent atives.

Peo ple who h andle this produ ct or work aroun d it n eed t o tak e trai ni ng to compr eh and i n herent ris ks of it and

mast er measures for saf ety.

It is usua lly responsible for supervisor t o f ol l ow the safet y instructions, but each operat or or m aintemance

repr es en tati ve sho ul d d o dai ly operations on thei r own ha nd.

Op er ators and maintem anc e represent ativ es should take t he safety of working place and work environm ent into

account .

It is necess ary to t hin k of t he safety of workin g pla ce and work environment for ea ch tas k.

Take enough safet y t rai ni ng before th e operation training. It i s v er y dang er ous to do o peration tr ai nin g without

any s af ety training. Op er ati on traini ng mu st be paid attenti on to its safety.

Keep th is operation manual handy for workers relat ed to abov e c on tents to refer t o a nytim e.

i.1.1 Meaning of Signs: Caution, Warning, Danger

These saf ety inst ructions are intended to prevent hazar dous sit uat ion and/or product damage.

These instructi ons indicat e the lev el of potential hazar d by signs “Caution”, “Warning” or

“Dan ger”. Contents wi th these signs state about im portant instructi ons concerning safety. Confirm

where those signs are, and read and com prehend notic es and cautionary not i ces well before

handling.

“Cau tion”, “Warning” or “ Danger” i s the order of

im porta nc e (Danger >Warning> Cauti on). Foll owings

are the m eanin gs of th ose sign s.

Danger

Stat ements with the “Danger” sign explain ab out condi tio ns in which th ere is a

possible result of serious inj ury or lo ss of life if someone h andles wron gly du ring

operation or maintenance and did not follow the procedure to avoid danger.

i Safety Instructions

i - 2

Warning

Stat ements with the “Warnin g” sign exp lain about possibi lities that can resu lt in

serious injury or loss of life if someone handle wron gly du ring operation or

main tenance and did not follow th e procedure to avoid warnig.

Caution

Stat ements with the “Caution” sign explain about possibilities that can result in

injury o r product damage if someone handles wro ngly during operatio n o r

main tenance and did not follow th e procedure to avoid caution.

i .2 Danger Classifications / Position of Danger Warning Label

To protect operat or ’s sef ety , we gr oup danger into some t ypes un iquel y and atta ched l abels i ndicati ng t hose t ypes.

Com firm the co ntent s of t he da nger types an d positi ons of t he label s before oper ati on.

Warning

No one but professionals shoul d operate T HERMO DRYER.

Tran spo rtation, installation, and maintenance invo lve risks. These should be done

by someone who have enough knowledge and experien ce about this p roduct and

incidental devices.

No one but our service personnel or qu alified person should op en the cover panel of

this product.

Warning

Should any problem occur, address it according to statemen ts on this manual.

• Identify problems according to “Ch apter 5 Troublesh ooting.”

• Ask repair an d maintenance.

Warning

The product shou ld not be operated in the event of an y pro blems.

When th e product gets out o f o rder, shutdown it immediatery, and co ntact our

service person or qualified person.

i Safety Instructions

i - 3

i.2.1 Danger Classifications

Specific danger classification of this product is as follows.

Danger of Electricity

Since this product runs at hign voltage, there is the danger of electric shock. So, we display a

symbol with indications,

“Caution”, “Warning” or “Danger,”

on the equipment and this

manual.

Danger of Heat

Since this product becomes hot while driving, there is the danger of burn injury. So, we display a

symbol with indications,

“Caution”, “Warning” or “Danger,”

on the product and this manual.

Danger of Rotor

Since this product has parts that rotate while driving, there is the danger of catching your fingers in

or injury. So, we display a symbol with indications,

“Caution”, “Warning” or “Danger,”

on the

product and this manual.

i.2.2 Danger of Electricity

Inside of this product, there is power-supplying section with high voltage separated by the cover panel. Do not

operate the equipment without the cover panel.

No one but trained qualified person should operate or inspect in the power transmission sections.

Warning

Read with caution and pay attention to the notations on danger warning labels.

Do not remove or rub danger warning labels.

Confirm the positions of danger warning labels.

i.2.3 Danger of High Heat

Warning

Since this product has parts that become hot during operation,

there is the danger of burn

injury resulting from contact with them. What is more, there is also the danger of burn injury due to

remaining heat after the power supply is cut. Therefore, wait until the temperature of hot parts become

50

o

C

and below.

i.2.4 Danger of Rotor

Warning

Since this product has parts that rotate during operation,

there is the danger of burn injury

resulting from contact with them. Though sometimes those parts can temporarily stop the rotation,

they will rotate again, and so do not work with them while running mode.

i Safety Instructions

i - 4

i.2.5 Danger of Compressed Air Circuit

Warning

Before replacing or cleaning parts, be sure to bleed compressed air remain inside of the

product untill the gauge indicates “0”. If you do not do this air-bleeding,

there would be the

great danger of unexpected accident, such as shooting out of parts when they are being unscrewed.

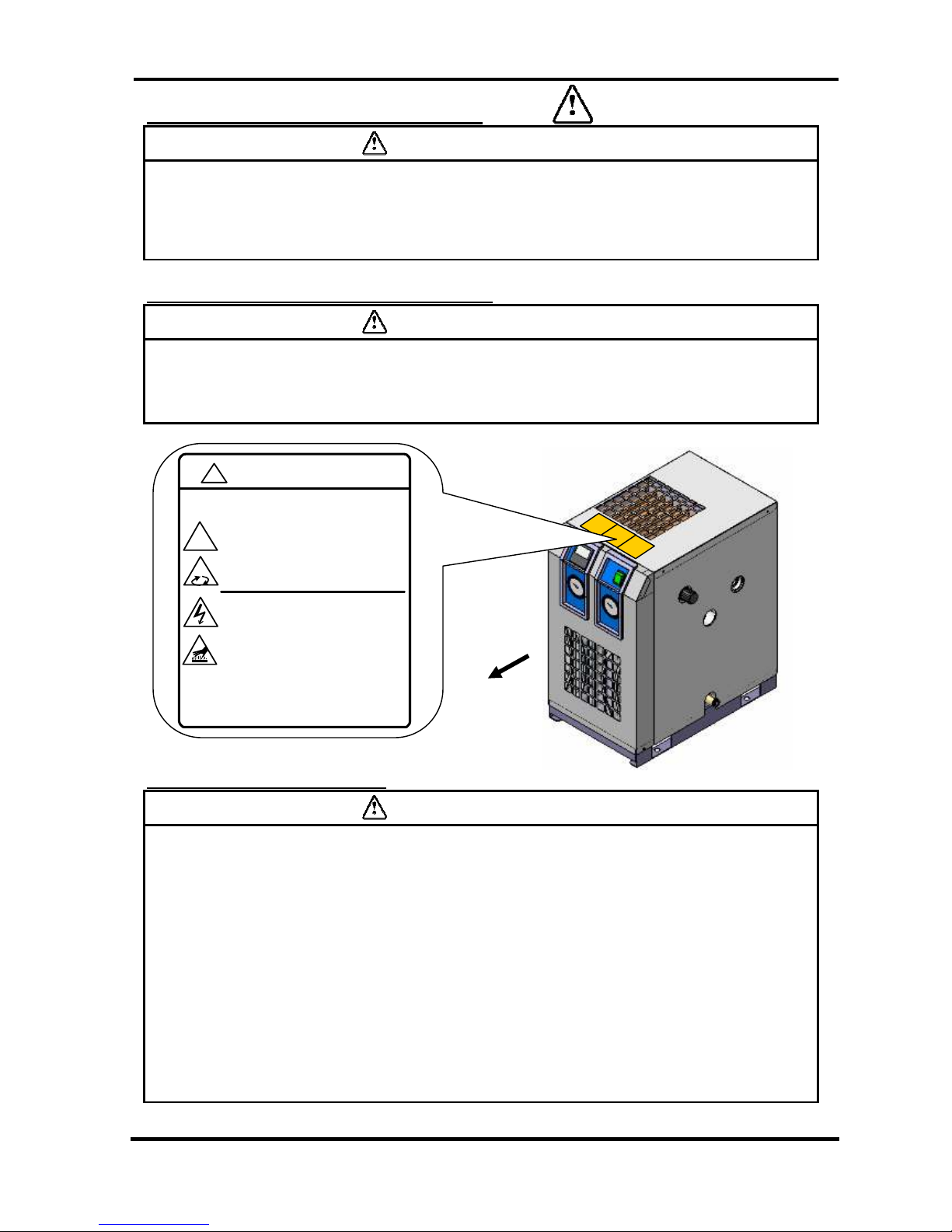

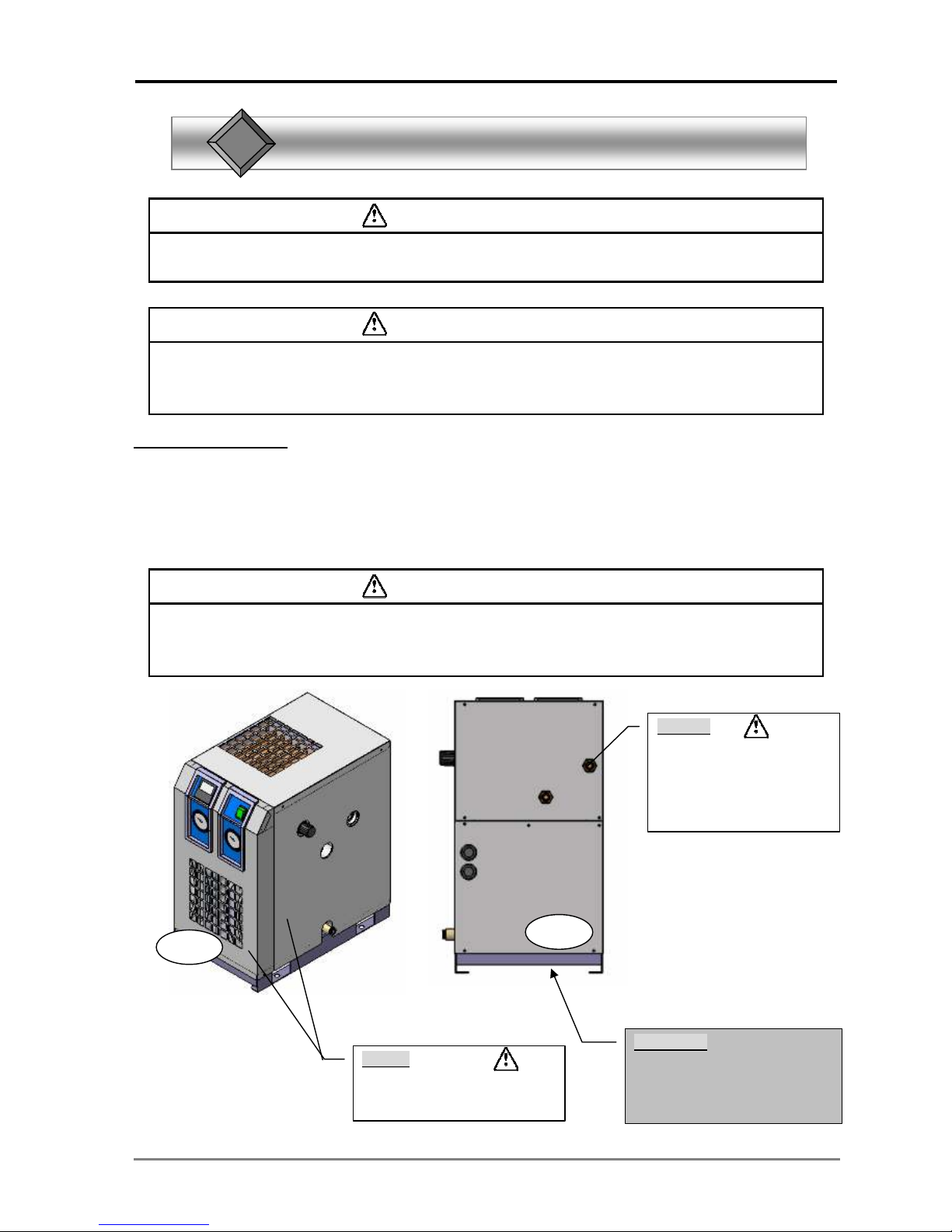

i.2.6 Positions of Danger Warning Label

Warning

Read with caution and pay attention to the notations of the danger warning labels.

Do not remove or rub the danger warning labels.

Confirm the positions of the danger warning labels.

i.2.7 Danger of Refrigerant

Caution

This product uses Fluorocarbon (HFC) as a refrigerant.

This product is specified by “Class 1 Fluorocarbon Collection and Destruction Law in

Japan.”

It is strictly forbitten to emit Fluorocarbon to the atmosphere. Before you repair this

product, you should collect the refrigerant with “Refrigerant collector.” Then, ask a

destruction agency to dispose of collected refrigerant. No one but someone have enough

knowledge and experience about the equipment and incidental device should do the

collection of the refrigerant.

No one but service person or qualified person should remove the cover panel of the

product.

The quantity and the sort of the Fluorocarbon are mentioned on the specification label.

Front

WARNING 警告

警告警告

警告

!

1 Remove panels for maintenance only.

2 Never inser t anythin g into product t o ensure

safety.

3 Cut power prior to maintenance to prevent

electric s hock.

4 Settle produ ct to room temp.before main tenance topr event burn or frostb ite.

5 Ensure zer o air pressure before r eplacing parts.

1111 点 検以外

点検以外点検 以外

点検以外 ははははハハハパ゚゚゚ネル

ネルネル

ネルをををを取取取取りりりり外外外外さな いこと

さないこ とさないこ と

さないこ と。。。。

2222 回 転物

回転物回転物

回転物 がある ので

があるのでがあるので

があるので 指指指指、、、、棒状

棒状棒状

棒状のののの物物物物をををを 差差差差しししし

込

込 込

込 まない こと

まないこ とまないこ と

まないこ と。。。。

3333 感 電

感電感電

感電のののの恐恐恐恐れ があるの で

れがあ るのでれがあ るので

れがあ るので、、、、点 検

点検点検

点検のののの前前前前には

にはには

には電 源

電源電源

電源をををを

切切切切るこ と

ることること

ること 。。。。

4444 火 傷

火傷火傷

火傷のののの恐恐恐恐れ があるの で

れがあ るのでれがあ るので

れがあ るので、、、、点 検

点検点検

点検のののの前前前前には

にはには

には装 置

装置装置

装置をををを

常 温

常温常温

常温に するこ と

にするこ とにするこ と

にするこ と。。。。

5555 部 品交換

部品交換部品 交換

部品交換 のののの前前前前には

にはには

には必必必必ずずずず、、、、空 気圧力

空気圧力空気 圧力

空気圧力 をををを""""0000""""にににに

す ること

することす ること

すること 。。。。

!

i Safety Instructions

i - 5

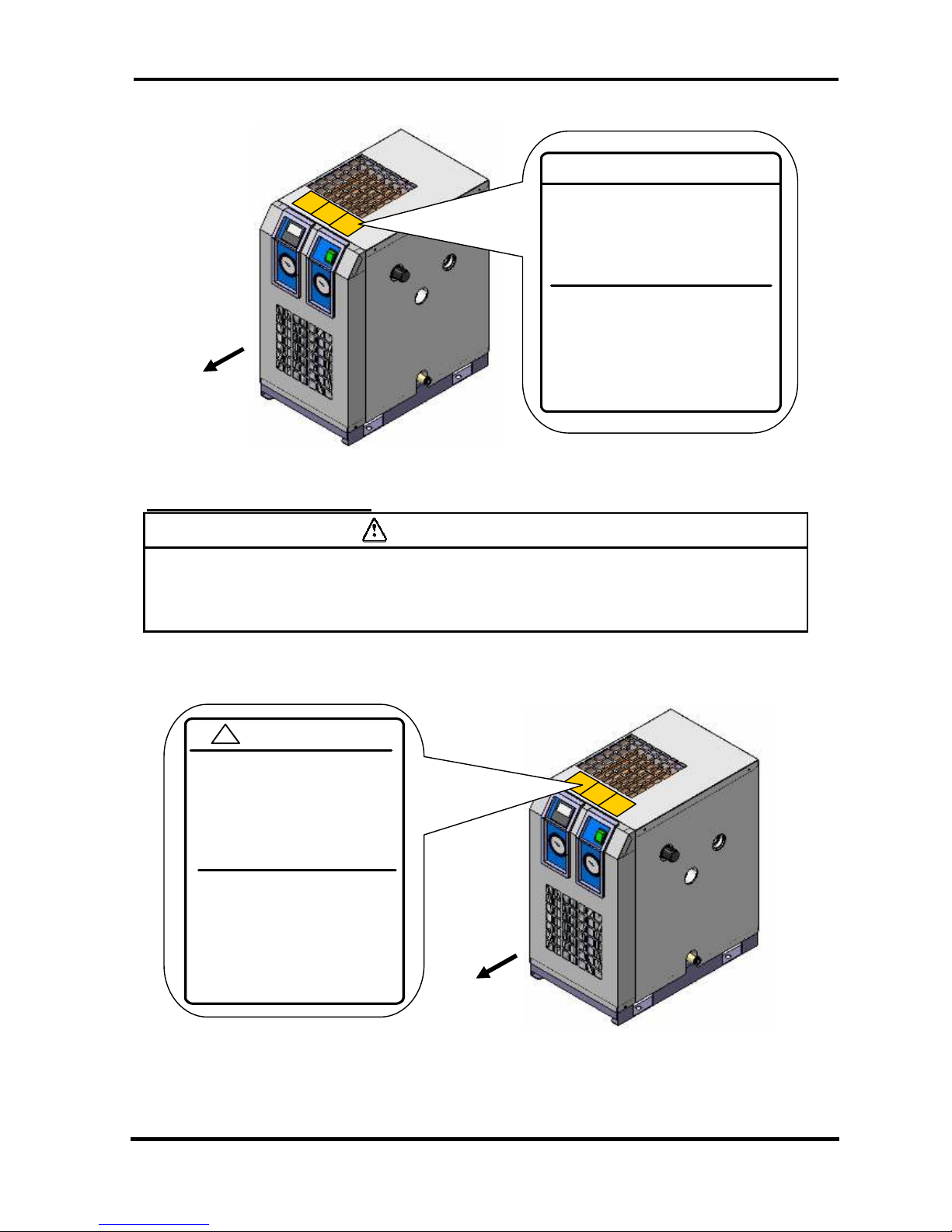

Front

i.2.8 Cautions about Usage

Warning

Read with caution and pay attention to the notations on the danger warning labels.

Do not remove or rub the danger warning labels.

Cimfirm the positions of the danger warning labels.

Front

Fluorocar bon Collection and Destructi on Law in Japan

フロン

フロンフロン

フロン回収破壊法第一 種特定 製品

回収破壊法第一種特定製品回収破壊法第一種特定製品

回収破壊法第一種特定製品

This product uses

Fluorocarbon (HFC) as a refrigerant.

1 It is stric tly forbidden to emit Fluorocarbon

to th e atmosph ere.

2 When dis posing this product, Fluorocarbon

must be collected in an approp riate manner.

3 The kin d of Fluorocarbon and the amount used

in this product is prited on the name label.

この

このこの

この 製品

製品製品

製品には

にはには

には冷媒

冷媒冷媒

冷媒と して

としてとして

として 、、、、

フロ ン

フロンフロン

フロン 類類類類(H FC )

(HF C)(H FC )

(HF C) がががが使使使使われ ています

われてい ますわれてい ます

われてい ます。。。。

1111 フ ロン

フロンフロン

フロン 類類類類をみ だりに

をみだりにをみだりに

をみだりに 大気 中

大気中大気中

大気中 にににに放出

放出放出

放出す ることは

すること はすること は

すること は

禁

禁 禁

禁 じら れてい ます

じられて いますじられて います

じられて います 。。。。

2222 この

このこの

この製 品

製品製品

製品をををを廃棄

廃棄廃棄

廃棄す る

するする

する場合

場合場合

場合には

にはには

には、、、、フ ロン

フロンフロン

フロン 類類類類のののの回収

回収回収

回収がががが

必 要

必 要 必 要

必 要です

ですです

です。。。。

3333 フ ロン

フロンフロン

フロン 類類類類のののの種類 及

種類及種類及

種類及 びびびび数 量

数量数量

数量はははは、、、、型式 銘板

型式銘板型式 銘板

型式銘板 にににに記載

記載記載

記載

さ れてい ます

さ れてい ます さ れてい ます

さ れてい ます。。。。

CAU TION

CAU TIONCAU TION

CAU TION 注 意

注 意注 意

注 意

!

1 R ead ma nual be fore op erati on.

2 E nsur e van tilati on an d ma inten ance

space.

3 K eep wat er aw ay fr om the pr odu ct.

4 S ecur e In / Out conne ctor w ith spa nn er

durin g pi ping.

5 W ait 3 min utes b efore restart.

6 E nsur e Ru nning Cond ition / Evaporating

Temp . in gr ee n z one.

1111 ごごごご 使 用 前

使 用 前使 用 前

使 用 前 にににに 必必必必 ずずずず 取 扱 説 明書

取 扱 説 明 書取 扱説 明 書

取 扱 説 明 書をををを 読読読読 ん で く だ さ い

ん でく だ さ いん でく だ さ い

ん でく だ さ い 。。。。

2222 通 風

通 風通風

通 風 、、、、 メ ン テ ナ ン ス ス ペ ース

メン テナ ン ス ス ペ ースメン テナ ン ス ス ペ ース

メン テナ ン ス ス ペ ース をををを 確 保

確 保確保

確 保 し て

し てし て

し て

く だ さ い

く だ さ い く だ さ い

く だ さ い 。。。。

3333 雨雨雨雨 やややや 水 滴

水 滴水滴

水 滴 が か から な い よう に して くださ い

が か か ら な い よう に して くだ さいが か か ら な い よう に して くだ さい

が か か ら な い よう に して くだ さい 。。。。

4444 I N / O U T

I N / O U T IN / OU T

I N / O U T ポー ト

ポ ー トポ ー ト

ポ ー ト をををを ス パ ナ

ス パ ナス パ ナ

ス パ ナ でででで 固 定

固 定固定

固 定 し て

し てし て

し て

配 管

配 管 配 管

配 管 して く だ さ い

して くださ いしてく だ さ い

して くださ い 。。。。

5555 再 起 動

再 起 動再 起動

再 起 動 はははは 運 転 停止

運 転 停 止運 転 停 止

運 転 停 止 3333 分 後

分 後分後

分 後 にににに 行行行行 っ て く だ さ い

っ て くだ さいっ て くだ さい

っ て くだ さい 。。。。

6666 R UN N IN G C O N D ITIO N

R U NN IN G C O N D ITIO N R U NN IN G C O N D ITIO N

R U NN IN G C O N D ITIO N ・・・・ 蒸 発 温 度計

蒸 発 温 度 計蒸 発温 度 計

蒸 発 温 度 計はははは

グリ ー ン

グ リー ング リー ン

グ リー ン帯帯帯帯 でででで 使 用

使 用使用

使 用 し て く だ さい

して くださ いして くだ さ い

して くださ い 。。。。

i Safety Instructions

i – 6

i . 3 Disposal

When you dispose of the product, you shoud collect the refrigerant and the

refrigerat oil enclosed in the refrigerant

circuit.

Caution

Dispose of the refrigerant and refrigerant oil according to the bylaw or regulation of

local government.

Do not dispose of refrigerant oil together with domestic garbage. And do not burn it in

unauthorized incinerators.

No one but

someone have enough knowledge and experience about the product and

incidental devices should do the collection of the refrigerant oil.

No one but service person or qualified person shoud remove the cover panel of the

product.

If there are something not clear, please contact our service office.

i Safety Instructions

i – 7

i . 4 Limited warranty and Disclaimer / Compliance Requirements

The product used subject to the following “Limited warranty and Disclaimer“ and “Compliance Requirements.

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is delivered.

Also, the product may have specified durability, running distance or replacement parts. Please consult

your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage incurred

due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted in

the specified catalog for the particular products.

Compliance Requirements

1. The use of SMC products with production product for the manufacture of weapons of mass destruction

(WMD) or other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are govemed by the relevant

security laws and regulation of the countries involved in the transaction. Prior to the shipment of a SMC

product of a SMC product to another country, assure that all local rules goveming that export are known

and followed.

Caution

The Product is provided use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contact if necessary.

If anything is unclear, contact your nearest sales branch.

1. Names and Functions of Parts

1-1

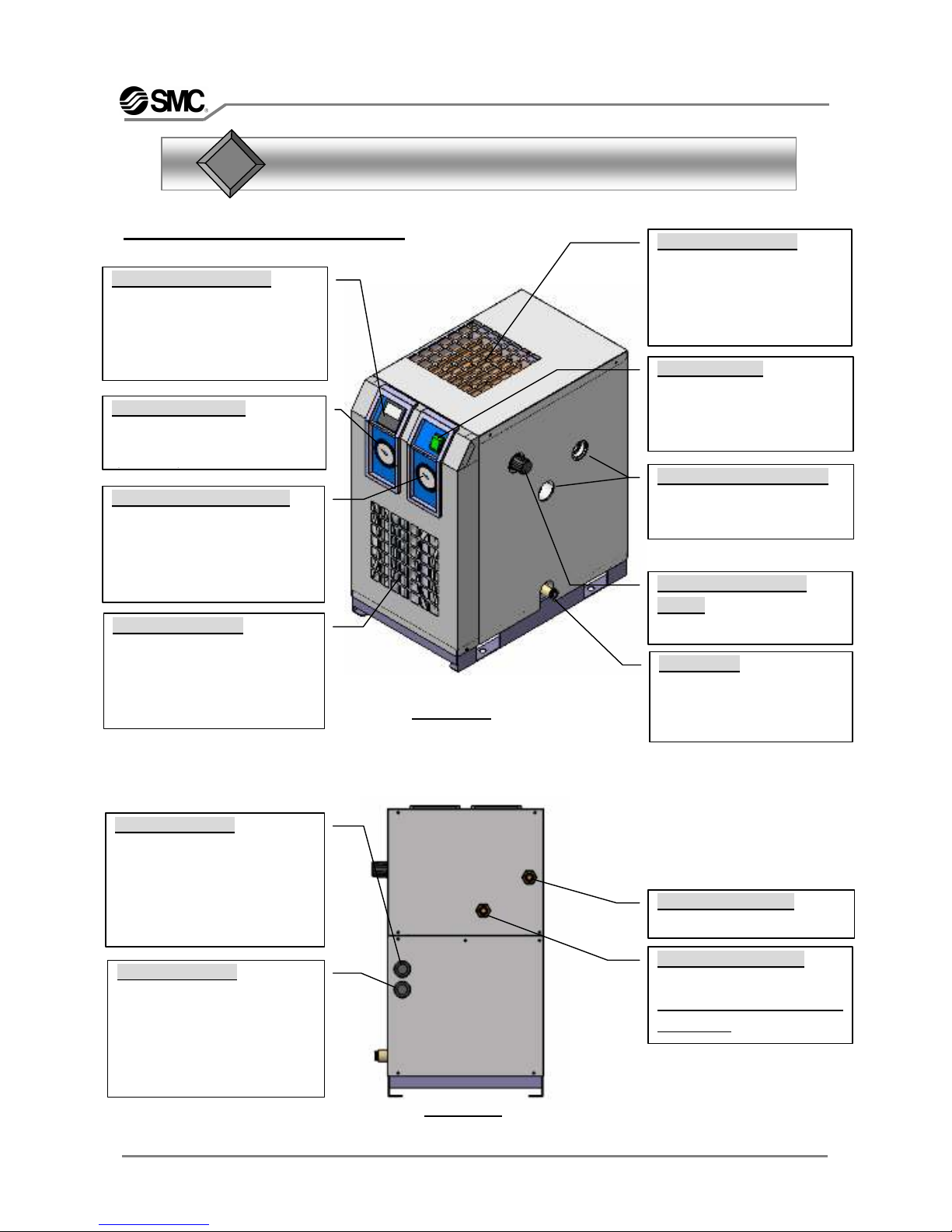

1.1 Names and Functions of Parts

Names and Functions of Parts

1111

Pressure adjustment

handle

To set outlet air pressure.

Air pressure gauge

Displays the dryer outlet air

pressure.

Evaporation thermometer

Displays the evaporation

temperature of the refrigerant.

While running, it is normal if it

displays within the green zone.

ON/OFF switch

Operation start/ stop control

switch. Green light is lit

during operation.

Temperature controller

For setting and display of the

dryer outlet air temperature.

* For details, please refer to

Section 1.2

Filter inspection window

The state of the filter can be

checked.

Drain outlet

Discharges drainage.

Please connect with tube

of external diameter 10mm.

Ventilation air inlet

Inlet for cooling air for

condenser, with built-in dust

filter. Please ensure that

ventilation is not obstructed.

Ventilation air outlet

Outlet for cooling air for

condenser. Please ensure

that ventilation is not

obstructed by any object etc.

Main body

Back view

Air inlet connection

This is the air supply inlet.

Air outlet connection

This is the air outlet.

* Please insulate piping

after

this device.

Signal cord entry

Cable entry for operation and

failure signals. Wire of max

outer diameter 17mm can be

plugged in.

(Panel hole diameter Ø22mm)

Power cord entry

Cable entry for power supply

and earth wire. Wire of max

outer diameter 17mm can be

plugged in.

(Panel hole diameter Ø22mm)

1. Names and Functions of Parts

1-2

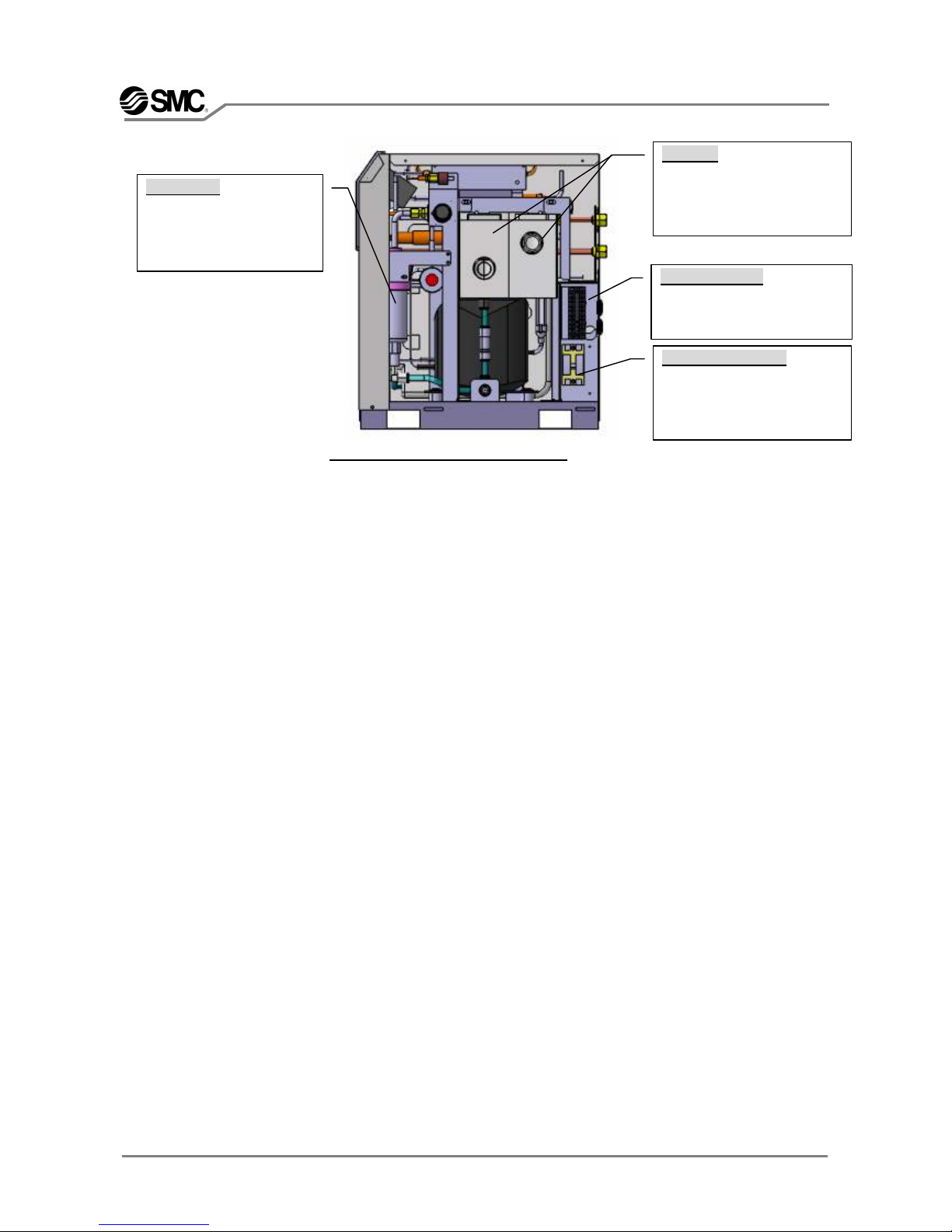

Side view (with panel removed)

Auto drain

Covered with insulation.

Please do not remove the

insulation while operation.

Air filter

Covered with insulation.

Please do not remove the

insulation while operation.

Circuit Interrupter

Set at OFF when shipped.

Please let to ON when

before operation starts.

Terminal block

Terminal for power supply &

signals see 2.2.4.

2 Transportation / Installation

2 Transportation / Installation2 Transportation / Installation

2 Transportation / Installation

2 - 1

Warning

・・・・Use the product in the right way. During Installation, operation, maintenance, and check,

you should be careful in keeping the safety of human body.

Caution

・・・・Transportation, installation, and maintenance including dangerous work must be done by a

personnel who has enough knowledge and experience about the equipment and the

sysytem.

2.1 Transportation

When transporting the dryer, always follow the instructions below.

・When lifting the dryer, lift carefully by the base to prevent dropping or tipping over.

・Do not lift by the panels, fittings or piping.

・Never lay this equipment on its side to move it. Pushing it over onto its side will damage the dryer.

Warning

・・・・Those instructions above must be followed because the equipment is so heavy that it

carries a great risk to transport.

・・・・The dryer must be transported by more than one person, or using a forklift.

Transportation and Installation

2222

Fittings

Do not hold the fittings or

piping when moving the

dry

er, as this can damage

the internal piping.

Base plate

The dryer must be lifted by two

or more people

holding the

base at the front and back.

Front

Back

Panels

Do not hold the panels when

moving the dryer.

Loading...

Loading...