Page 1

IDX-OM-H006-H

Initial issue: January 2004

8th edition : November 2010

Operation Manual

PRODUCT NAME

Refrigerated Air Dryer

MODEL / Series

IDF1E-10

IDF2E-10

IDF3E-10 IDF3E-20

IDF4E-10 IDF4E-20

IDF6E-10 IDF6E-20

IDF8E-10 IDF8E-20

IDF11E-10 IDF11E-20

IDF15E-10 IDF15E-20

Please read this manual prior of using the air dryer. Keep the manual readily available for

reference.

© 2010 SMC CORPORATION All Rights Reserved.

Page 2

To Customers

Thanks for purchasing SMC Refrigerated Air Dryer.

This opertion manual must be read and understood throug houtly before handling. It provides all essential

information for maximizing product operating efficiency, as well as, for safe and longer life span operation.

For safety operation of SMC Refrigerat ed Air Drye r, read thor oughly and foll ow stated safety instructions, as well

as regulation stated within ISO 4414

*1

& JIS B 8370*2.

*1) ISO 4414: Pneumatic fluid power – Recomm endations for the applicatio n of equipment to transmission

and control systems.

*2) JIS B 8370: Pneumatic fluid power – General rules relati ng to systems

This manual explains about installation and operati on of the product. Only those who have thorough

understanding of the fundamental operating procedure or have basic knowledge and skills of handling industrial

product for the installation and operation of the product are qualified to perform installation and opera tion.

The contents of the operation manual and the other docume nts attached to t he product ca nnot become a part of

the contract clause or cannot chang e and modify exist ing agreement s, promises, an d relationship.

Any statements contained in the operation manual canno t be newly guaranteed and modify existing gua rantee

certificate.

You are not allowed to copy any part of this operation manual for usage of third pe rson without i nforming it to u s

beforehand.

Caution: Please understand that the contents of this operation manual are subject to

changed without previous notice.

Page 3

Air Dryer (IDF1E-10~IDF15E-10/20) T able of Contents

Table of Contents - 1

Table of Contents

To Customers

Chapter i Safety Instructions

i - 1 Warning: Before Using Air Dryer..........................................................i - 1

i - 1 - 1 Meanings of signs: Caution, Warning, Danger...............................................i - 1

i - 2 Danger Classifications / Position of Danger warning label......i - 3

i - 2 - 1 Danger Classifications....................................................................................i - 3

i - 2 - 2 Danger of Electricity.......................................................................................i - 4

i - 2 - 3 Danger of high Heat.......................................................................................i - 4

i - 2 - 4 Danger of Rotor..............................................................................................i - 4

i - 2 - 5 Danger of Compressed Air Circuit .................................................................i - 4

i - 2 - 6 Positions of Danger Warning Label................................................................i - 5

i - 2 - 7 Danger of Refrigerant.....................................................................................i - 6

i - 2 - 8 Cautions about Usage....................................................................................i - 7

i - 2 - 9 Other Label.....................................................................................................i - 7

i - 3 Disposal..........................................................................................................i – 8

i - 4 Limited warranty and Disclaimer / Compliance Requirements.........i – 9

Chapter 1 Parts Name and Functions

1 - 1 Parts Names and Functions ................................................................. 1 - 1

Chapter 2 Transport a tion / Installation

2 - 1 Transportation............................................................................................ 2 - 1

2 - 2 Installation.................................................................................................... 2 - 2

2 - 2 - 1 Location........................................................................................................ 2 - 2

2 - 2 - 2 Anchorage.................................................................................................... 2 - 2

2 - 2 - 3 Air piping ...................................................................................................... 2 - 2

2 - 2 - 4 Drain Tube.................................................................................................... 2 - 3

2 - 2 - 5 Electric wiring............................................................................................... 2 - 4

2 - 3 Cautions about reinstallation............................................................... 2 - 5

Chapter 3 Operation / Shutdown

3 - 1 Check points before operation............................................................ 3 - 1

3 - 2 Operation...................................................................................................... 3 - 1

3 - 3 Shutdown...................................................................................................... 3 - 2

3 - 4 Cautions about restart ............................................................................ 3 - 2

3 - 5 Check points before restart.................................................................. 3 - 2

3 - 6 Precautions for long-term non-operation....................................... 3 - 2

Chapter 4 Maintenance

4 - 1 Daily inspection ......................................................................................... 4 - 1

4 - 2 Periodical maintenance.......................................................................... 4 - 1

4 - 2 - 1 Cleaning of ventilation grille (suction grille).................................................. 4 - 1

4 - 2 - 2 Service parts.................................................................................................4 - 1

4 - 2 - 3 Cleaning of Auto Drain Strainer.................................................................... 4 - 1

Chapter 5 Troubleshooting.............................................................................................. 5 - 1

Chapter 6 References

6 - 1 Specifications.............................................................................................6 - 1

6 - 2 Dimensions.................................................................................................. 6 - 2

6 - 3 Electrical Circuit ........................................................................................ 6 - 3

6 - 4 Compressed Air and Refrigerant Circuit / Operation Principles.....6 - 5

Page 4

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

Safety Instructions

Before use, read and comprehend important

cautionary notification well on this operattion

manual.

i – 1 Warning: Before Useing Air Dryer

In this chapter, the stated contents are especially about safety way to use the product. for customer.

An Air Dryer is installed on the downstream of the air compressor to remove moisture. We, manufacturer, cannot

take any responsibility if you use it for any other purpose.

An Air Dryer works with high voltage and has some parts that gets hot or rotates during operation. Ask vendor if you

need component replacement and servicing.

Not only people handle the air dryer but every people who perform maintenance on or do works related to it shou ld

read safety instructions on this operation manual before handling.

This operation manual is not a general safety manual which is practiced b y safety training representatives.

People who handle this product or work around it need to take training to comprehand inherent risks of it and master

measures for safety.

It is usually responsible for super visor to follow the safety instructions, but each operator or maintemance

representative should do daily operatio ns on their own head.

Operators and maintemance representatives should take the safety of working plac e and work environment into

account.

It is necessary to think of the safety of working place and work environment for each task

Take enough safety training before the operation training. It is ver y dangerous to do operation t raining witho ut any

safety training. Operation training must be paid attention to its safet y.

Keep this operation manual handy for workers related to above contents to refer to anytime.

i – 1 – 1 Meaning of Signs: Caution, Warning, Danger

These safety instructions are intended to prevent hazardous situation and/or product damage.

These instructions indicate the level of potential hazard by signs “Caution”, “Warning” or

“Danger”. Contents with these signs st ate about important instructions conce rning safety. Confirm

where those signs are, and read and comprehend notices and cautionary notices well before

handling.

“Caution”, “Warning” or “Danger” is the order of importance (Danger>Warning>Caution). Followings

are the meanings of those signs.

Danger

Statements with the “Danger” sign explain about conditions in which there is a

possible result of serious injury or loss of life if someone handles wrongly during

operation or maintenance and did not follow the procedure to avoid danger.

i - 1

Page 5

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

Warning

Statements with the “Danger” sign explain about possibilities that can result in

serious injury or loss of life if someone handle wrongly during operation or

maintenance and did not follow the procedure to avoid danger.

Caution

Statements with the “Danger” sign explain about possibilities that can result in injury

or product damage if someone handles wrongly during operation or maintenance and

did not follow the procedure to avoid danger.

i - 2

Page 6

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

i – 2 Danger Classifications / Position of Danger Warning Label

To protect operator’s sefety, we group danger into some types uniquely and attached labels indicating those types.

Comfirm the contents of the danger types and positions of the labels before operation.

Warning

No one but professionals should operate an air dryer.

Transportation, installation, and maintenance involve risks. These should be done by

someone who have enough knowledge and experience about this product and incidental

devices.

No one but our service personnel or qualified person should open the cover panel of this

product.

Warning

Should any problem occur, address it according to statements on this manual.

• Identify problems according to “Chapter 5 Troubleshooting. ”

• Ask repair and maintenance.

Warning

The product should not be operated in the event of any problems.

When the product gets out of order, shutdown it immediatery, and contact our service

person or qualified person.

i-2-1 Danger Classifications

Specific danger classification of this product is as follows.

Danger of Electricity

Since this product runs at hign voltage, there is the danger of electric shock. So, we display a

symbol with indications,

“Caution”, “Warning” or “Danger,” on the product and this manual.

Danger of Heat

Since this product becomes hot while driving, there is the danger of burn injury. So, we display a

symbol with indications,

“Caution”, “Warning” or “Danger,” on the product and this manual.

Danger of Rotor

Since this product has parts that rotate while driving, there is the danger of catching your fingers in

or injury. So, we display a symbol with indications,

“Caution”, “Warning” or “Danger,” on the

product and this manual.

i - 3

Page 7

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

i – 2 – 2 Danger of Electricity

Inside of this product, there is power-supplying section with high voltage separated by the

cover panel. Do not operate the product without the cover panel.

No one but trained qualified person should operate or inspect in the power transmission

sections.

Warning

Read with caution and pay attention to the notations on danger warning labels.

Do not remove or rub danger warning labels.

Confirm the positions of danger warning labels.

i – 2 – 3 Danger of High Heat

Warning

Since this product has parts that become hot during operation, there is the danger of burn

injury resulting from contact with them. What is more, there is also the danger of burn injury due to

remaining heat after the power supply is cut. Therefore, wait until the t emperature of hot parts become

50

o

C and below.

i – 2 – 4 Danger of Rotor

Warning

Since this product has parts that rotate during operation, there is the danger of burn injury

resulting from contact with them. Though sometimes those parts can temporarily stop the rotation,

they will rotate again, and so do not work with them while driving.

i – 2 – 5 Danger of Compressed Air Circuit

Warning

Before replacing or cleaning parts, be sure to bleed compressed air remain inside of the

product untill the gauge indicates “0”. If you do not do this air-bleeding,

there would be the

great danger of unexpected accident, such as shooting out of parts when they are being unscrewed.

i - 4

Page 8

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

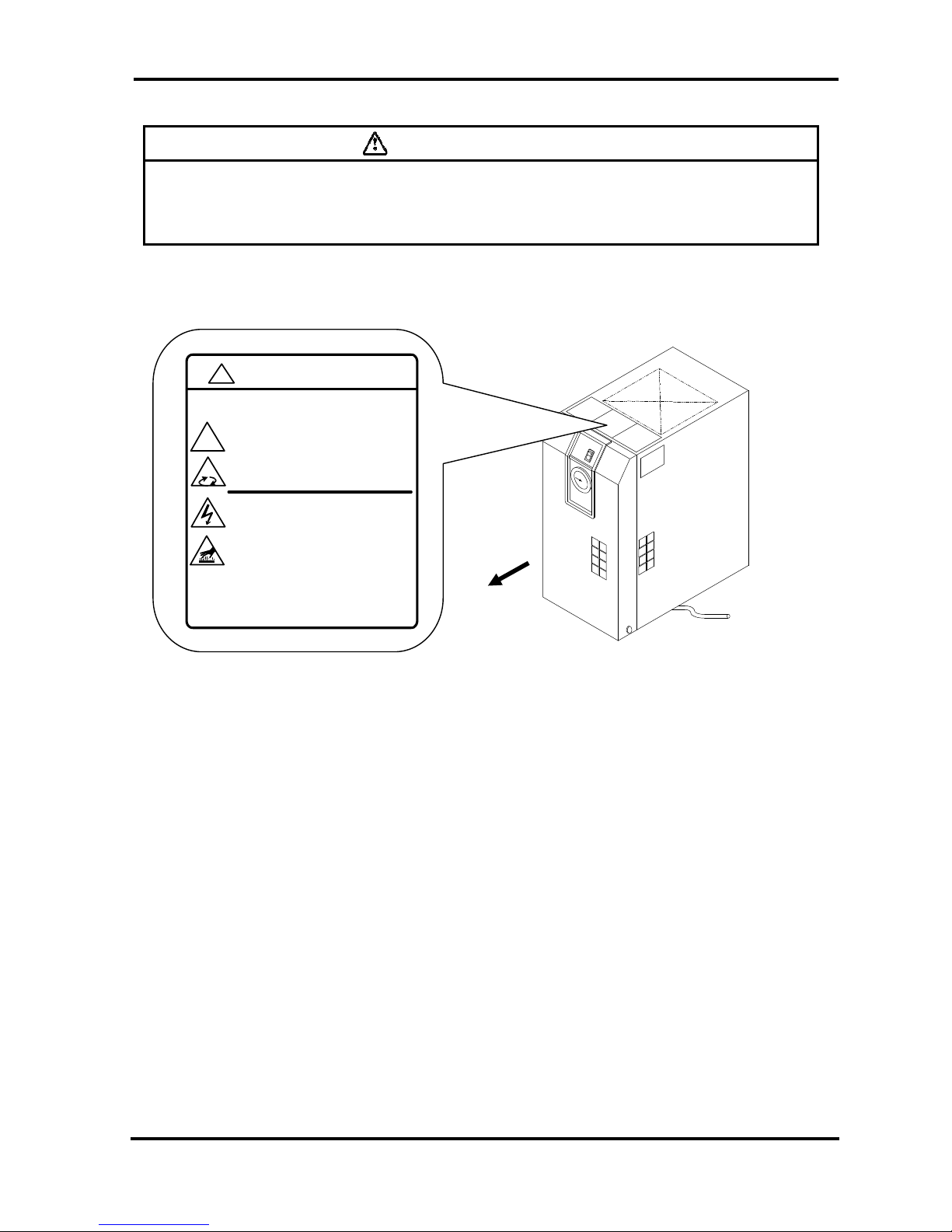

i – 2 – 6 Positions of Danger Warning Label

Warning

Read with caution and pay attention to the notations of danger warning labels.

Do not remove or rub danger warning labels.

Confirm the positions of danger warning labels.

Front

WARNING 警告

!

1 Remove panels for maintenance onl y.

2 Never insert anything into prod uct to ensu re

safety.

3 Cut power prior to maintenance to p revent

electric shock.

4 Settle product to room temp.before main tenance toprevent burn or frostbite.

5 Ensure zero air pr essure before replacing parts.

1 点検以外はパネルを取り外さないこと。

2 回転物があるので指、棒状の物を差し

込まないこと。

3 感電の恐れがあるので、点検の前には電源を

切ること。

4 火傷の恐れがあるので、点検の前には装置を

常温にすること。

5 部品交換の前には必ず、空気圧力を"0"に

すること。

!

i - 5

Page 9

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

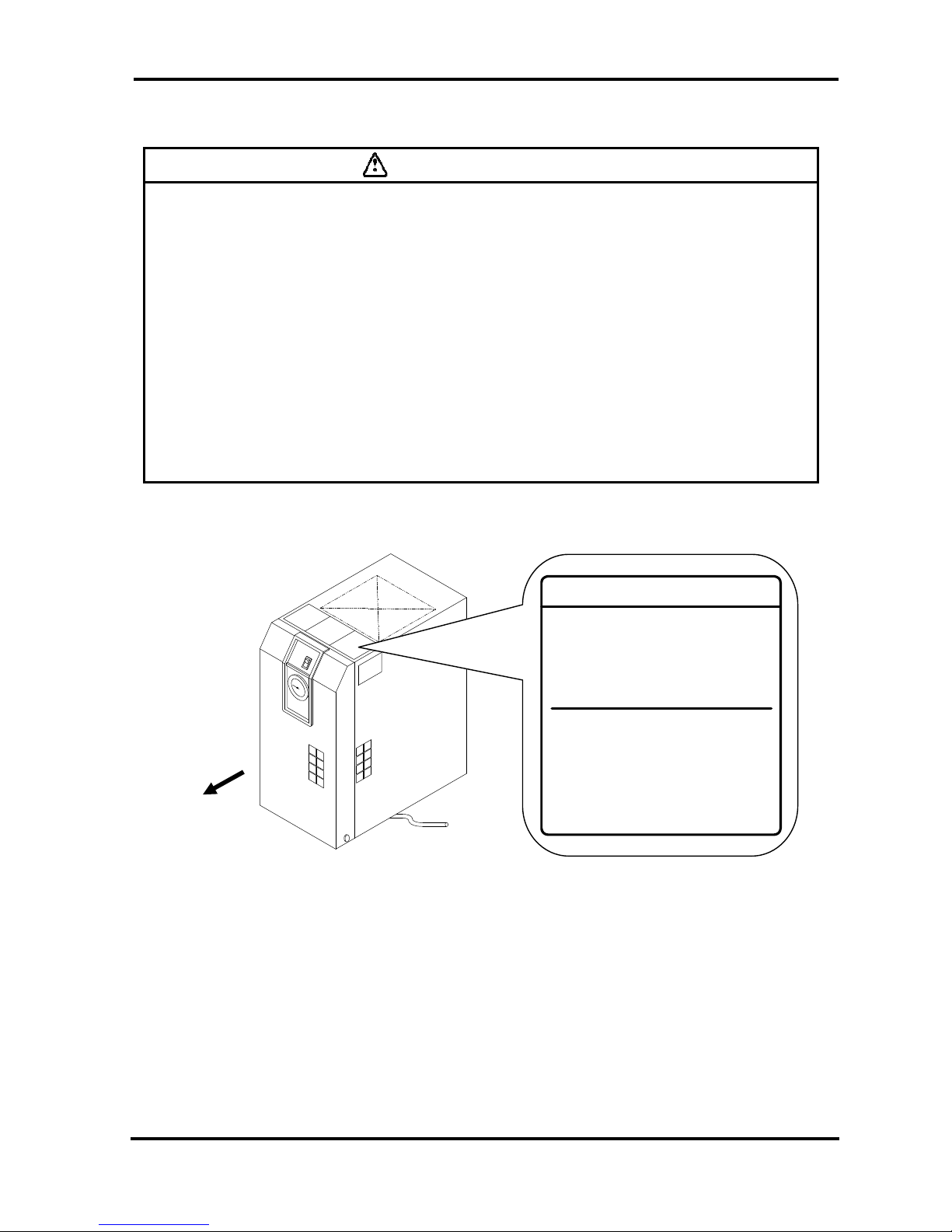

i – 2 – 7 Danger of Refrigerant

Caution

This product uses Fluorocarbon (HFC) as a refrigerant.

This product is specified by “Class 1 Fluorocarbon Collection and Destruction Law in

Japan.”

It is strictly forbitten to emit Fluorocarbon to the atmosphere. Before you repair this

product, you should collect the refrigerant with “Refrigerant collector.” Then, ask a

destruction agency to dispose of collected refrigerant. No one but someone have enough

knowledge and experience about the product and incidental device should do the collec tion

of the refrigerant.

No one but service person or qualified person should remove the cover panel of the

product.

The quantity and the sort of the Fluorocarbon are mentioned on the specification label that

are explained on Page i – 8.

Fluorocarbon Collection and Destruction Law in Japan

フロン回収破壊法第一種特定製品

This product uses

Fluorocarbon (HFC) as a refrigerant.

1 It is strictly forbidden to emit Fluorocarbon

to the atmosphere.

2 When disposing this product, Fluorocarbon

must be collected in an appropriate manner.

3 The kind of Fluorocarbon and the amount used

in this product is prited on the name label.

この製品には冷媒として、

フロン類(HFC)が使われています。

1 フロン類をみだりに大気中に放出することは

禁じられています。

2 この製品を廃棄する場合には、フロン類の回収が

必要です。

3 フロン類の種類及び数量は、型式銘板に記載

されています。

Front

i - 6

Page 10

Air Dryer (IDF1E-10~IDF15E-10/20) i Safety Instructions

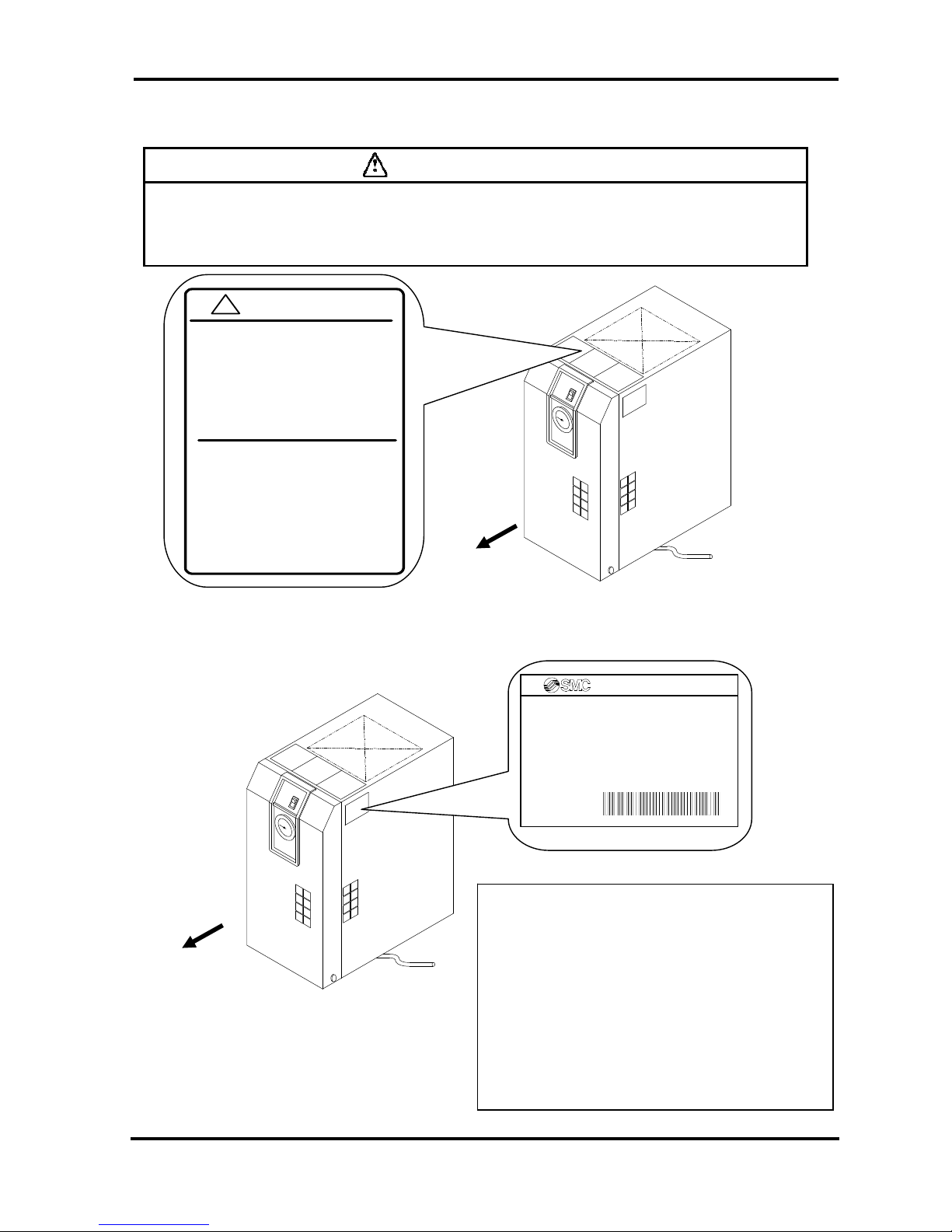

i – 2 – 8 Cautions about Usage

Warning

Read with caution and pay attention to the notations on danger warning labels.

Do not remove or rub danger warning labels.

Cimfirm the positions of danger warning labels.

i – 2 – 9 Other Label

Comfirm the model, contents of specifications on the label.

Front

S

p

ecification Label

Contents

MODEL: Model

VOL TAGE: Power supply voltage (frequency)

RUNNING CURRENT: Running current

REFRIGERANT: Type of refrigerant (amount)

WEIGHT:Weight MAX.PRESS: Maximum

operating pressure

SERIAL No.: Serial No.

MANUFACTURI NG DATE: Manufacturing Date

MADE IN: Country of manufacture

AIR DRYER

MODEL

VOLTAGE

RUNNING CURRENT

REFRIGERANT

WEIGHT MAX.PRESS.

SERIAL No.

MAKER

MADE IN

CAUTION 注意

!

1 Read man ual b efore operation.

2 Ensure van tilation and maintenance

space.

3 Keep water aw ay from the p r oduct.

4 Secur e In / O ut c onn ector w ith spa n ne r

during piping.

5 Wait 3 minutes before restart.

6 Ensure Running Condition / Evaporating

Temp . in g r een z one .

1 ご使用前に必ず取扱説明書を読んでください。

2 通風、メンテナンススペースを確保して

ください 。

3 雨や水滴がかからないようにしてください。

4 IN/OU Tポー トをスパ ナで 固定し て

配管 して くださ い。

5 再起動は運転停止3分後に行ってください。

6 RUNNING CONDITION・蒸発温度計は

グリーン帯で使用してください。

Front

i - 7

Page 11

Air Dryer(IDF1E-10~IDF15E-10/20) i Safety Instructions

i – 3 Disposal

When you dispose of the product, you shoud collect the refrigerant and the refrigerat oil enclosed in the ref ri ge r ant

circuit.

Caution

A sort of Fluorocarbon (HFC) is used for this product as refrigerant.

This product is specified by “Class1 Fluorocarbon Collection Destruction Law

in Japan.”

It is strictly forbitten by the law to emit the refrigerant to the atmosphere. Before

you repair this product, you should collect the refrigirant with “Refriger ant

collector.” Then, ask a destruction agenc y to dis pos e of collected refrigerant.

No one but someone have enough knowledge and experience about the product

and incidental devices should do the collection of the refrigerant.

No one but service person or qualified perso n shoud remove the cover panel of

the product.

The quantity and the sort of the Fluor ocarbon are printed on the specification

label.

Caution

Dispose of the refrigerant and refrigerant oil accordin g to the bylaw or regulation

of local government.

Do not dispose of refrigerant oil together with domestic garbage. And do not

burn it in unauthorized incinerators.

No one but someone have enough knowledge and experience about the product

and incidental devices should do the collection of the refrigerant oil.

No one but service person or qualified perso n shoud remove the cover panel of

the product.

If there are something not clear, please contact our service office.

i – 8

Page 12

Air Dryer(IDF1E-10~IDF15E-10/20) i Safety Instructions

i – 4 Limited warranty and Disclaimer / Compliance Requirements

The product used subject to the following “Limited warranty and Disclaimer“ and “Compliance Requirements.

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the produc t is delivered.

Also, the product may have specified durability , running distance or replacement parts. Please consult

your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other da mage incurred

due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and disclaimers noted in

the specified catalog for the particular products.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of mass

destruction (WMD) or other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are govemed by the relevant

security laws and regulation of the countries involved in the transaction. Prior to the shipment of a SMC

product of a SMC product to another country, assure that all local rules goveming that export are known

and followed.

Caution

The Product is provided use in manufacturing industries.

The product herein described is bas ic ally provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contact if necessary.

If anything is unclear, contact your nearest sales branch.

i – 9

Page 13

Air Dryer (IDF1E-10~IDF15E-10/20) 1 Name and Functions Parts

1

Parts Name and Functions

1-1 Parts Name and Functions

y IDF1E ~ 3E

Front

Switch with Lamp

(ON/OFF Switch)

The lamp is continuously ON

during normal operation. Use it

for ON/OFF operations.

Evaporation thermometer

(EV APORATING TEMP)

Indicates the temperature of

refrigerant of low-pressure

side.

During normal driving, it

indicates in the green zone.

Top Ventilation Grille

(Outlet)

Hot air will be exhausted from

condenser by fan. No obstacles

shall be allowed to place on top

of it or even close the grille.

Inspection Grille

From this grille, confirm the

discharge of drain.

Panel Lock

Another one is on the left side.

No Front Panel

Drain Tube

Discharges drain.

It is covered with insulator, which

should not be removed.

Auto Drain

1 - 1

Page 14

Air Dryer (IDF1E-10~IDF15E-10/20) 1 Name and Functions Parts

y IDF1E ~ 3E-10 (100V AC specification)

Panel Lock

Another one is on the right side

Air outlet(OUT)

Port size:Rc3/8

Air inlet (IN)

Port size: Rc3/8

Rear Ventilation Grille (Inlet)

Breathe in cooling air from this

grille. Do not bung up with wall

and so on.

Earth Screw

Connect the earth to this screw

Power Cord

Insert the plug to a 100V AC only

outlet.

Front

y IDF3E-20 (200V AC specification)

Membrane Grommet

Power cord outlet

Front

Electrical Terminal Cover

(Width 6.5mm and below)

Applied Pressure Terminal: 1.25-3

Terminal Connecting Screw: M3

Customer Connection Side

Y ou ca n see the terminal block when

you remove this cover. Connect the

power cable through the membrane

grommet.

L

N

PE

( )

1 - 2

Page 15

Air Dryer (IDF1E-10~IDF15E-10/20) 1 Name and Functions Parts

y IDF4E ~ 15E

Front

Switch with Lamp

(ON/OFF Switch)

The lamp is continuously ON

during normal operation. Use

it for ON/OFF operations.

Evaporation

Thermometer

(EV APORATING TEMP)

Indicates the temperature of

refrigerant of low-pressure

side.

During normal driving, it

indicates in the green zone.

Right Side Ventilation

Grille (Outlet)

Waste heat will be exhausted

as hot air by the fan motor. Do

not block with wall and so on.

Inspection Grille

Confirm the discharge of drain

from this grille once a day.

Panel Lock

Another one is on the left side

Discharge drain.

Drain Tube

View with Front Panel removed

Do not remove the insulation on

the auto drain.

Auto Drain

1 - 3

Page 16

Air Dryer (IDF1E-10~IDF15E-10/20) 1 Name and Functions Parts

y IDF4E ~ 15E-10(100V AC specification)

y IDF4E ~ 15E-20 (200V AC specification)

Fixing Screw for Front Panel

Another one is on the right side.

Air Outlet (OUT)

Air Inlet (IN)

Left Side Ventilation

Grille (Inlet)

Breathe in cooling air

from this grill. Do not

bung up with wall and so

on.

Screw for the Earth

Connect the earth to this

screw

Power Cord

Insert the plug to an

outlet for exclusive use of

100V AC.

Front

Rear Panel

Y ou ca n see the terminal block when

you remove this cover. Connect the

power cable through the membrane

grommet.

Membrane Grommet

Power cord outlet

(Width 6.5mm and below)

Applied Pressure Terminal: 1.25-3

Terminal Connecting Screw: M3

Customer Connection Side

L

N

PE

( )

Front

1 - 4

Page 17

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

Transportation / Installation

2

Warning

Use the product in the right way. During Installation, operation, maintenance, and check,

you should be careful in keeping the safety of human body.

Caution

Transportation, installation, and maintenance including dangerous work must be done by

a personnel who has enough knowledge and experience about the product and the

sysytem.

2-1

Transportation

When you transport the product, you should follow these instructions below.

• You should uplift the product from the base surface with careful attention to prevent falling sideways and drop.

• Do not bring the product lying sideways. If you lay it sideways, it will be broken.

• Do not hang up the product.

• Do not transport the product with any part such as an air filter mounted on the fittings at the air inlet or outlet port

of the product. If it is unavoidable to transport the product with such a part mounted, support the mounted part

with a bracket to prevent the product from being affected by vibration during transportation.

Warning

Those instructions above must be followed because the product is so heavy that it carries

a great risk to transport.

IDF4~11E are 20kg or more. They must be transported by more than one person, a forklift

and so on.

IDF15E is 46kg or more. They must be transported by forklift.

2 - 1

Page 18

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

2-2 Installation

2-2-1 Location

The product should not be used or stored in the circumstances as follows. Those

circumstances will cause not only malfunction but also failures.

• Environment where the product is exposed to

rainwater, moisture vapor, salty water, oil and

so on.

• Locations where dust or particles are.

• Locations where inflammable or explosiv e gas

are.

• Locations where corrosive gas, solvent,

combustible gas are.

• Locations that receive direct sunlight or where

radiant heat is generated.

• Locations where ambient temperature is

beyond following range:

On-stream: 2 ~ 40

o

C

Storage: 0 ~ 50

o

C (when there is no drain

water inside of the piping)

• Locations where temperature changes rapidly.

• Locations where strong electromagnetic no ise

is generated (locations where electromagnetic

field, strong magnetic field, surge is generated)

• Circumstances where static electricity is

produced or discharged through the body of the

product.

• Locations where strong high frequency wave is

generated.

• Locations where danger of thunder is apparent.

• Locations by loading on vehicles, marine

vessels, and so on.

• Locations whose altitude is higher than 2,000

meters.

• Circumstances where strong vibration or impact

are transmitted.

• Circumstances where too much force and

weight are put on the body of the product that

causes it to deform.

• Circumstances where enough spaces cannot

be taken to do maintenance (in the plant where

the product is operated).

Spaces needed for maintenance

Front : 600 mm

Rear : 600 mm

Top : 600 mm

Right : 600 mm

Left : 600 mm

• Locations the ventilation grille of the product

can be blocked.

• Place where rejection style air of air

compressor or other driers (hot wind) is inhaled.

2-2-2 Anchorage

• The air dryer should be installed on a vibration-free, stable, horizontal flat surface.

• Refer to “Chapter6 6-2 Dimensions” for the dimensions.

• IDF4E~15E should be bolted by anchor bolts to prevent falling. We recommend the anchor bolt sets that

we are selling separately as accessories.

2-2-3 Air piping

• Connection to the inlet and outlet of compressed air should be made removable by using union and so on.

• Pressing the hexagonal fitting with screw wrench and so on, connect the air piping fittings to the body.

• When mounting any part such as an air filter on the fitting at the compressed air inlet or outlet port, support the

part to prevent excessive force from being applied to the product.

• Be careful not to let the vibration of the air compressor transmit.

• If the temperature of compressed air on the inlet side is higher than 50

o

C, place an aftercooler after the air

compressor. Or, make the temperature of the place where the air compressor is installed lower than 50

o

C.

2 - 2

Page 19

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

• Flash the piping sufficiently in order to avoid any foreign substances such as dust, sealing tape, liquid gasket, etc.

when piping before piping connection.Foreign substances in the piping can caus e cooling failure or drainage

failure.

• Use pipes and fittings that have enough endurance against the operating pressure and temperature. And

connect it firmly to prevent air leakage.

• Provide bypass piping to make it possible to do maintenance without stopping the air compressor.

We recommend the bypass piping sets that

we are selling separately as accessories.

The bypass piping sets

2-2-4 Drain Tube

• A polyurethane tube of 10mm external diameter is attached to the drain tube. The outlet end of the tube is

released to atmosphere. And let drain flow through the tube into a scupper and so on.

• Using the pressure of the compressed air, drain will be discharged periodically. Fix the outlet end of the tube so

as not to swing during discharge.

• Prevent the drain tube from riser piping.

• Prevent the drain tube from being folded or flatted. Since the drain tube is coming from the bottom of the body,

be careful to avoid the body from stomping over the tube during installation.

Warning

During drain work, follow the procedure that you define to keep the safety of worker (ex. Put on

protective glass, apron, and gloves).

In case that oil gets mixed in the wasted water that is discharged from the auto drain, the waste liquid treatment

is necessary. Handle it following the bylaw or regulation of local government.

2 - 3

Page 20

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

2 – 2 – 5 Electric Wiring

Warning

No one but qualified person should do the wiring work.

・ Before wiring, you must cut the power off for safety. Do not work under any

energized conditions.

・ Supply power from a stable place, which is free from the effect of surge.

・ Ensure that a Ground Fault Circuit Interrupter(GFCI) with appropriate capacity for

earth leakage and load is used in the power supply of the product to prevent

electrical shock and burnout of the compressor motor. See “6-1 List of

specifications” for details.

・ Supply power for the product should meet the specifications.

The product should be grounded for safety.

・ Do not connect the earth to a water pipe, a gas pipe, or a lightening rod.

・ Do not plug too many leads into a single socket. That causes exothermic heat or

fire.

・ Do not convert the wiring to use.

・ In European countries, a circuit breaker that meets the IEC standard should be used

for the supply power.

There are two methods depends on model (specified power).

IDIDF1E-10 ~ 15E-10 (100V specified)

• Insert the power plug into an outlet of 100V AC.

Install a Ground Fault Circuit Interrupter(GFCI) to the power supply (sensitivity of leak current

30mA and rated current 10A).

(Prepare by yourself)

• Do not extend the power cable using power strip and so on. That causes decrease of the voltage and the product

cannot be operated.

F3E-20 ~ 15E-20 (200Vspecified)

• Remove the terminal block cover or the rear cover in the rear of the product, and connect the power (200V AC)

to the terminal block.

•

Install a Ground Fault Circuit Interrupter(GFCI) to the power supply (sensitivity of leak current

30mA and rated current 10A).

(Prepare by yourself)

Specification of power cable

Prepare following power cable.

Power cable: 1.25mm

2

(16AWG), Three-cores (including the earth), External diameter: about 8 ~ 12mm

Additional length of about 0.1m is needed to wire inside of the product.

Length of the power cable

The length of the power cable should extend less than 30m from the product.

Connecting to the power supply

Connect the power cable and the earth to the terminal block. M3 screw is used for the connection part. Make sure

to use round crimped terminal.

Applicable crimped terminal: 1.25-3 (Width: 6.5mm and below)

Wiring procedure

• Remove the terminal block cover or the rear panel.

• Insert the cor d through the membrane grommet and connec t it to the terminal block (refer to the label on the

terminal block). M3 screw tightening torque: 0.6~1Nm

During wiring work, do not touch other sections except terminal block.

• Attach the cover or the rear panel as it were.

2 - 4

Page 21

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

2-3

2 - 5

Page 22

Air Dryer (IDF1E-10~IDF15E-10/20)

2 Transportation / Installation

2 - 6

Cautions about Reinstallation

Caution

No one but someone who has enough knowledge about the product and

incidental devices should reinstall in another place. And following instructions

must be executed.

If you move the product and reinstall it into another place after some operations (including trial running),

instructions that are not only following ones but also all of those in the chapter 2 should be followed.

0BDisassembly of the power cable

Cut off the power source when you disassemble the power cable.

1BDisassembly of the air piping

• Remove the seal tape completely after detaching the piping. Remained tape will cause imperfect cooling

and failure by entering into the body of the product.

Residual compressed air pressure release procedure

• Even while the dryer is removed, only when compressed air is needed, open the bypass piping valve.

• Close the compressed air inlet and outlet valve.

• Unscrew the front panel fixing screw (in 2 points) and remove the front panel with upholding it a little.

• Open the residual pressure release cock of auto drain tube, and release compressed air pressure l eft inside o f

the product. Refer to the figure at right.

Warning

No one but qualified personnel should do the electric wiring.

Cut off the power supply for safety before the wiring. Do not work under energized

condition.

Warning

No one but qualified personnel should do the air piping.

Separate the compressor from the product for safety before removing the piping.

Do not remove any piping when there is remaining compressed air pressure inside

of it.

Case Assembly

The ramainder depressure cock.

※

It opens when turning in the

drection og the arrow of figure.

Page 23

Air Dryer (IDF1E-10~IDF15E-10/20) 3 Operation / Shutdown

3

Operation / Shutdown

Caution

No one but someone who has enough knowledge and experience about the product and

incidental devices should operate or shut down the product.

3-1 Check points before operation

Before a trial running, check following points.

• Installed Condition

By visual inspection check that the product is installed horizontally.

The product make sure the product is fixed enough with anchor bolts.

Do not place heavy obstacles on the product and add unreasonable loading by piping and so on.

• Wiring Connections

Power cord, and the earth should be connected firmly.

• Drain Tube

Drain tube should be connected correctly.

• Air Piping

Make sure the piping for compressed air is connected correctly. Those valves of IN / Out side of the product and

of the bypass piping should be completely fasten.

3-2 Operation

Start operation according to the procedure below.

• Turn on the breaker of the main power supply. Then, turn on the illuminated switch.

• The lamp will light u p. Few minutes later, the cooling fan will rotate and hot air will be exha usted from the

ventilation grille.

Place of the ventilation grille: IDF1E ~ 3E: Top Ventilation Grille

IDF4E ~ 15E: Right Side Ventilation Grille

• Open the IN / Out side valve slowly. Make sure the bypass valve is completely closed. Confirm there is no air

leakage.

• Depending on the condition of compressed air or ambient temperatur e, the cooli ng fan so metimes alt ernates

between rotation and stop at the beginning. Then, the refrigerator will go into continuous run and the pointer of

the evaporation thermometer will indicate in the green zone. If the pointer of the evaporation thermometer

indicates higher than the green zone, refer to “Chapter5 Troubleshooting.”

• After a while from the start of flowing the compressed air, drain will be discharged from the drain tube

automatically.

• Keep the condition of continuous run to use.

3 - 1

Page 24

Air Dryer (IDF1E-10~IDF15E-10/20) 3 Operation / Shutdown

Caution

Avoid frequent On/Off operation, which can cause troubles.

The auto drain used for the product has a structre that closes the valve with air pressure hig her

than 0.15MPa. Therefore, until the pressure increase, air will be emitted form the drain outlet at

the begining of opening the IN side valve. Keep in mind that sometime the pressure cannot

increase enough with air compressor that has low dischage flow rate.

3-3 Shutdown

• Turn off the illuminated switch.

• The lamp will go out and then, the operation will be stopped. Depending on the condition of operation, hot air

continues to be emitted from the ventilation grille by the cooling fan for a while after turning off the switch,

which is not an abnormality but a process for safety shutdown.

3-4 Cautions about restart

• One must wait for at least 3 minutes before restarting air dryer after it has been shut down. Failure to do this

may cause safety devices to trip due to over load.

3-5 Check points before restart

Check following points before you start operation. If any abnormalities occur, immediately stop the operation. Turn off the

illuminated switch of the product and then the breaker to the power supply.

• There is no leakage of compressed air.

• Compressed air pressure, temperature, flow rate, and ambient temperature meet the specifications.

• Drain is being discharged from the drain tube.

• The pointer of evaporation thermometer is indicating in the green zone.

• There are no abnormal sound, vibration, or smelling.

3-6 Precautions for long-term non-operation

• If the product will not be operated for more than 24 hours, for example at the weekend, turn off the ILS (switch

with lamp) or power supply, for energy saving and safety. It is also recommended to r elease the pressure

inside the compressed air piping and this air dryer.

3 - 2

Page 25

Air Dryer (IDF1E-10~IDF15E-10/20)

4 Maintenance

4

MAINTENANCE

4-1 Daily Inspection

Check following points during usual operations. If you find some problems, immediately stop the ope ration and

refer to “Chapter 5 Troubleshooting” as soon as possible.

• There is no air leakage

• The running lamp is lighting during operation

• Drain is being discharged from drain tube

• The pointer of the evaporation thermometer indicates in the green zone when it is running with

pressurized air supply.

• The pointer of the evaporated thermometer indicates about 3~10

o

C lower than that of ambient

temperature when the product is suspended with no pressurized air supply.

• There is no abnormal sound or vibration coming up from the product.

• There are no abnormal smell or smoke coming up from the product.

4-2 Periodical Maintenance

4-2-1 Cleaning of ventilation grille (suction grille)

Clean dust and other foreign particles from the ventilation area with vacuum cleaner or air blow nozzle once a

month.

Danger

During air blowing, put on protective glass and mask to prevent dusts from coming into throat or eyes.

4-2-2 Service parts

It is recommended to replace the following parts regularly. The interval shown in this operation manual

depend on the operating conditions (ambient temperature, installation environment, etc.), so that they

are for reference .

• Table 1. List of parts to be replaced regularly

Description Recommended replacement interval

Pressure switch One Million times.

Fan motor 20,000 hours

Magnetic Contactor, Magnetic Switch (Note) One Million times.

*Note)If it is mounted by option ”T” (With terminal block for power supply , run , alarm signal and remote

operation) or special order.

4-2-3 Cleaning of Auto Drain Strainer

Remove the dust deposited in the auto drain strainer every month. Use neutral detergent for cleaning. If they are

too dirty, replace them and shorten the period of maintenance from next time.

• Auto Drain Strainer order part number

Part No. Name Quantity Applicable Model

IDF-S0001

Auto Drain Strainer

1 IDF1E, IDF2E, IDF3E, IDF4E

IDF-S0002

Auto Drain Strainer

1 IDF6E, IDF8E, IDF11E,IDF15E

4 - 1

Page 26

Air Dryer (IDF1E-10~IDF15E-10/20)

4 Maintenance

・ Maintenance of the air dryer should only be carried out by someone with sufficient knowledge and

experience of air dryers and related equipment.

・ Before carrying out maintenance, the important warnings in this manual must be thoroughly read and

understood.

Warnin

g

・ When replacing or cleaning parts of the air drye r, be sure to remove the compressed air pressure inside

the air dryer to “0”. Never remove the case assembly when the air dryer is operated or air pressure

remains inside. It is extremely dangerous if compressed air pressure remains inside the air dryer, as

parts may come flying off at speed when loosened, or other u nexpected accidents.

・ This product has parts that become hot during operation and a po wer supply with high voltage applie d.

There is a risk of burns due to heat or electrification by high voltage. Even when operation is shut down

after switching off the air dryer’s illuminated light, there are also charging lines. When working on the

charged sections, be sure to switch off the earth leaka ge breaker installed before starting work.

・ As some parts of the air dryer will remain hot, there is a risk of burns due to residual heat after the

power is switched off. So do not carry out replacement work until the temperature of these parts has

fallen to 50℃ or less. Wait for about 10 to 15 minutes as a guide.

・ When carrying out maintenance work on the auto drain strainer and auto drain, there is a risk of

touching the drain fluid during work. Please follow the safety procedure for operators specified by

customer.(Example: carry out work wearing safety glasses, apron and gloves to prevent discharged

fluid from touching the human body.)

・ Use neutral detergent solution to clean parts such as the auto drain strainer and auto drain. Never

use solvent such as thinner.

・ When removing the outer casing panel or case assembly of the auto drain, wear gloves to prevent

injuries.

Danger

How to clean and replace the auto drain/strainer.

Please execute work through the following procedure when an auto drain and auto drain

strainer are washed and you exchange it .

・Turn off the illuminated ON/OFF switch.

・Disconnect the earth leakage breaker at the power supply or unplug the powe r plug from the socket.

・ Fully close the IN/OUT valves. Only open the bypass when comp ressed air is required during work.

・ Only the point that is necessary for work please remove a decoration panel.

4 - 2

Page 27

Air Dryer (IDF1E-10~IDF15E-10/20)

4 Maintenance

SO

Drain tube

Open

Drain t ube

rerease bush

Close

Lock button

Residual

pressure

rerease cock

【IDF1E~11E】

・ Open the residual pressure release cock at

the drain tube connection port to release air

and drain fluid left in the product.

(Leave the drain tube connected and hold it

with hand so that it does not get twisted.)

・ Because drain may be given by air

pressure left in a product like a careful.

・ Remove the drain tube.

Pull out the tube while pushing up the drain

tube release bush.

Pull it do wn

slowly.

Mark

Lock button

Turn to 45

゜

(right or left)

・ Hold the case assembly lightly and pull down

the lock button with thumb. Then, turn the

case assembly to the left (or right) to 45°to

align the marks.

・ Release your thumb from the lock button and

slowly pull down the case assembly

(vertically) to remove it.

・ Remove the auto drain strainer and clean it. T ake ca re

not to cut your hand with the sharp edges of the

strainer.

Drain separator

body

Auto drain

strainer

“O”ring

Case a ssembly

CAUTION

Check that air

pres sure is zero

befor e servicing.

・ Pour solution of neutral detergent into the case

assembly and shake it well to clean.

・ Check the case O-ring for damage such as scratches,

twisting or foreign particles attached to it. Then, a pply

grease thinly and fit it in the groove in the case

assembly.

・ Fit the auto drain strainer to the case assembly and fit

it into the drain separator body. Turn it untill the lock

button clicks.

・ Try to turn the case assembly lightly and check that it

does not turn. If it turns, start with fitting the case

assembly to the body again.

・ Close the residual pressure release cock and mount

the drain tube and front panel as they were.

・ When reapplying compressed air to the air dryer, first

open the valve on the inlet side slowly. Check for

compressed air leak and if everything is all right, open

the valve on the outlet side.

・ If the auto drain strainer or case assembly is

damaged or very dirty, replace it with a new one.

4 - 3

Page 28

Air Dryer (IDF1E-10~IDF15E-10/20)

4 Maintenance

【IDF15E】

Lock button

Mark

Drain tube

Open

Close

Residual pressure

release cock

Drain tube

release bush

Lock button

T o remove the case assembly , turn it to

45

°until the lock button and mark a

Then, pull it down slowly .

lign.

・ O

pen the residual pressure release cock at the drain

tube connection port to release air and drain fluid left

in the product.

(Leave the drain tube connected and hold it with hand

so that it does not get twisted.)

S

O

Auto drain strainer

"O"ring

Lock button

Case assembly

Residual pressure

release cock

Release bush

・ Remove the tube while pushing the release bush.

・ Hold the case assembly lightly and pull down the lock button

with thumb.Then, turn the case assembly to the left (or right)

to 45°to align the marks,Release your thumb from the lock

button and slowly pull down the case assembly (vertically)

to remove it.

・ Remove the auto drain strainer and clean it. Take care not

to cut your hand with the sharp edges of the strainer.

・ Pour solution of neutral detergent into the case assembly

and shake it well to clean.

・ Check the case O-ring for damage such as scratches,

twisting or foreign particles attached to it. Then, apply

grease thinly and fit it in the groove in the case assembly.

・ Fit the auto drain strainer to the case assembly and fit it into

the drain separator body. Turn it untill the lock button clicks.

Try to turn the case assembly lightly and check that it does

not turn. If it turns, start with fitting the case assembly to the

body again.

・ Close the residual pressure release cock and mount the

drain tube and front panel as they were.

・ If the auto drain strainer or case assembly is damaged or

very dirty, replace it with a new one.

4 - 4

Page 29

Air Dryer (IDF1E-10~IDF15E-10/20) 5 Troubleshooting

Troubleshooting

5

Should any problem occur, inspect the following table, and if the problem cannot be solved, shut off the power supply and

then contact one of our sales offices for further instructions.

Problem Probable Causes Remedy

Power cord or plug is in loosening state

or completely pulling out.

Perform proper connection on the power cord and plug. Air dryer does not

operate and running

lamp does not light on,

even switch is ON.

Circuit breaker is OFF .

Confirm whether the proper capacity of the circuit

breaker is used.

It is not possible to restart the air dryer within 3

minutes after shutdown. Wait for 3 minutes before

restarting.

Resume the operation after resetting the circuit

breaker to ON. If the circuit breaker still trips to OFF,

failure of electrical insulation may have occurred.

Remove the power supply and contact one of our

agents for further instructions.

Installation place is poorly

ventilated. Ambient temperature

is too high.

Improve the ventilation system to lower the ambient

temperature.

The ventilation grilles are

obstructed by wall or clogged

with dust.

Install the air dryer more than 40cm away from the

wall.

Clean the ventilation grilles once a month.

Temperature of the compressed

air is too high.

Improve the ventilation system around air

compressor or make ambient temperature around air

compressor low to lower the temperature of

discharge from compressor.

Reduce the temperature of the compressed air by

installing an additional after-cooler after air dryer.

Running lamp

extinguishes and

compressor stops

during operation but

resumes normal

operation

illuminating the

lamp after a

period of time.

Supply voltage is not in the

following range:

100VAC: 90V ~ 110V/90V ~

121V (50/60Hz)

200VAC: 180V ~ 220V/180V ~

242V (50/60Hz)

Set the voltage to a proper value by installing a

transformer or review the electrical wiring.

Installation place is poorly

ventilated. Ambient temperature

is too high.

Improve the ventilation system to lower the ambient

temperature.

The ventilation grilles are

obstructed by wall or clogged

with dust.

Install the air dryer more than 40cm away from the

wall.

Clean the ventilation grilles once a month.

Evaporation

thermometer indicates

higher than green zone.

Temperature of the compressed

air is too high.

Improve the ventilation system around air

compressor or make ambient temperature around air

compressor low to lower the temperature of

discharge from compressor.

Reduce the temperature of the compressed air by

installing an additional after-cooler after air dryer.

Bypass valve of air dryer is not

fully closed.

Close the valve completely.

Drain is not discharged from auto

drain properly.

Check if the drain pipe has been raisen up or bent.

Check auto drain.

Check auto drain strainer.

Moisture occurs

downstream of the

compressed air

lines.

Confluence of piping with another

unit without air dryer.

Install air dryer on the line that does not have it.

Separate two lines not to converge.

Large pressure drop IN / OUT valve on the air dryer

side is not fully opened.

Open IN/OUT valve thoroughly.

5 - 1

Page 30

Air Dryer (IDF1E-10~IDF15E-10/20) 6 References

References

6

6-1

Specifications

Model

Specification

IDF1E IDF2E IDF3E IDF4E IDF6E IDF8E IDF11E IDF15E

50Hz 0.1 0.2 0.32 0.52 0.75 1.22 1.65 2.8 Air Flow Rate

m

3

/min (ANR)(Note 1)

60Hz 0.12 0.235 0.37 0.57 0.82 1.32 1.82 3.1

Operating Pressure 0.7MPa

Inlet Air Temperature 35oC

Ambient Temperature 32oC

Rated Condition

Pressurized Dew Point 10oC

Working Fluid Compressed Air

Inlet Air Temperature 5 ~ 50oC

Inlet Air Pressure 0.15 ~ 1.0MPa

Operating

Range

Ambient Temperature 2 ~ 40oC(Relative Humidity of 85% or less)

100VAC(50/60Hz)

Single phase AC100/100 , 110V[Voltage fluctuations±10%]

Power source

200VAC(50/60Hz)

Single phase AC200/200 , 220V

[Voltage fluctuations±10%]

100VAC(50/60Hz) 1 8 / 1 6 1 8 / 1 6 1 8 / 1 6 1 9 / 1 8 1 9 / 1 8 2 2 / 2 2 2 8 / 2 6 2 7 / 2 6 Starting current

(Note 2) A

200VAC(50/60Hz) 8 / 8 7 / 8 9/ 8 11 / 1 0 2 1 / 2 0 23 / 2 2

100VAC(50/60Hz) 2. 4 / 2 . 5 2 . 4 / 2 . 5 2 . 4 / 2 . 5 2 . 4 / 2 . 5 2 . 4 / 2 . 5 3 . 0 / 3 . 1 5 . 7 / 5 . 7 4 . 3 / 4 . 6Operating urrent

(Note 2) A

200VAC(50/60Hz) 1 . 2 / 1 . 3 1 . 2 / 1 . 3 1 . 2 / 1 . 3 1 . 5 / 1 . 5 3 . 4 / 3 . 0 3 . 4 / 3 . 1

Power

consumption

(Note 2) W

100VAC,200VAC

(50/60Hz)

180/202 180/202 180/202 180/202 180/202 208/236 385/440 480/480

100VAC 10A

Electrical Specification

Circuit Breaker

(Note 3)

200VAC 5A

Condenser Plate fin tube type with forced air cooling

Refrigerant R134a (HFC) (GWP:1300)

Refrigerant Charge(AC100V/200V) g

70±5 115 ±5 150 ±5 180 ±5 200 ±5 250 ±5 260 ±5 350 ±10

Drain Connection Rc3/8 Rc1/2 Rc3/4 Rc1

Drain Connection 10mm

Coating Color

Panel: Urbanwhite 1

Base: Urbangray 2

Weight kg 16 17 18 22 23 27 28 46

Applicable Compressor(Standard) kW 0.75 1.5 2.2 3.7 5.5 7.5 11 15

Note1: The data for l/min (ANR) is referring to the conditions of 20°C, 1atm . pressure & relative humidity of

65%.

Note 2: The value is that of under specified condition.

Note 3: Install cicuit breaker that comes with sensivity of

≤30mA.

6 - 1

Page 31

Air Dryer (IDF1E-10~IDF15E-10/20) 6 References

6-2 External Dimentions

IDF1E / IDF2E / IDF3E

B

N

M

Q

C

Ventilation

Ventilation

Powercord(Length:1.9m)

[AC100Vspecification]

[AC200Vspecification]

AirOutlet

PortSize

AirInlet

PortSize

PowerSupplyEntry(φ17)

DraftAirInlet

TerminalBlock

OnlyIDF3E‑20

J

H

GF

DE

[AC200Vspecification]

Length:0.82m)

Evaporation

Switch

Thermometer

WithLamp

DrainTube

(O.D.10

P

KL

A

CheckWindow

Drain

CheckWindow

Drain

measure:mm

Model Port size A B C D E F G H J K L M N P Q

IDF1E

Rc3/8 69 101 270 32 21 330

IDF2E

Rc3/8 51 232 138 24 327

IDF3E

Rc3/8 473 67 304 33 73 31 36 154 21 330

226 410

413

125

240 15

--38150

IDF4E / IDF6E / IDF8E / IDF11E

MN

C

Q

B

4‑φ13

Draft

AirOutlet

CheckWindow

Drain

CheckWindow

Drain

Length:0.82m)

Ventilation

Evaporation

Thermometer

Switch

Ventilation

DrainTube

(O.D.10,

WithLamp

P

L K

A

[AC100V specification]

PowerCord(Length:1.9m)

Airinlrt

AirOutlet

PortSize

PortSize

[AC200V specification]

TerminalBlock

H

J

DE

GF

[AC200V specification]

PowerSupplyEntry(φ17)

Model Port size A B C D E F G H J K L M N P Q

IDF4E

Rc1/2 453 13

IDF6E

Rc3/4 455

IDF8E

Rc3/4

IDF11E Rc3/4

284

15

240 80

275

300

80 230 32 1531 42

283

355

270

485

498

568

6 - 2

Page 32

Air Dryer (IDF1E-10~IDF15E-10/20) 6 References

IDF15E

K

M

P

L

A

C

B

Q

FG

DNE

H

Evaporation

Thermometer

Ventilation

Ventilation

DrainTube

WithLamp

Switch

(O.D.10

Length:0.82m)

4‑φ13

AirOutlet

Draft

AirOutlet

AirInlet

AirOutlet

Draft

TerminalBlock

[AC200Vspecification]

PortSize

PortSize

PowerSupplyEntry(φ17)

[AC200Vspecification]

Powercord(Length:1.9m)

[AC100Vspecification]

J

measur

e

:mm

Model Port size

ABCDEFGH J K LMNPQ

IDF15E

Rc1 300 603 578 41 54 396 87 258 43 15 270 101 380 314 16

6-3 Electrical Circuit

y IDF1E〜3E

OLR

CM Compressor Motor

FM

Fan Motor

SYMBOL

DESCRIPTION

C01

Capacitor For Running Compressor Motor

ILS

Capacitor For Starting Compressor MotorC02

Capacitor For Running FAN Motor

C11

Terminal Block

TB

Pressure Switch

PRS

PTC

Overload Relay

PTC Starter

Switch with Lamp

PC

Power Supply Code

Resister

R

Starting Relay

RY

TM

Terminal Block

AC100/100,110V

(50/60Hz)

AC200/200,220V

(

50/60Hz

)

※1

※2

※1

※2

PC

L

N

※2

※1

TB

P

CM

FM

ILS

OLR

PRS

PTC

PE

y ID F4E〜8E

AC200/200,220V

(50/60Hz)

L

N

PE

※2

※

1

TB

C11 for 200V

ILS

※

1

※2

OLR

PRS

CM

PTC

AC100/100,110

V

(50/60Hz)

※1

※2

PC

P

CM

FM

6 - 3

Page 33

Air Dryer (IDF1E-10~IDF15E-10/20) 6 References

y IDF11E-10

ILS

OLR

PRS

PC

PTC

C01

A

C100/100,110

V

(50/60Hz)

P

CM

FM

y IDF11E-20

C11

AC200/200,220

V

ILS

OLR

PRS

TB

PTC

L

N

PE

P

CM

FM

・ IDF15E-10・IDF15E-20

CM

ILS

OLR

PR

S

C02

TB

P

FM

RY

C11

RY

CM

ILS

OLR

C01

PR

S

C02

PC

P

FM

RY

RY

R

TM

6 - 4

Page 34

Air Dryer (IDF1E-10~IDF15E-10/20) 6 References

6-4 Compressed Air and Refrigerant Circu it / Operation Principles

y IDF1E

Compressed Air Circuit

Humid hot air entering air dryer is cooled in

the cooler. At this time, the condensed

moisture is separated from the air by the

drain separator and automatically

discharged.The dried clean air is heated by

the reheater untill it gets about the same

temperature as that of ambient air. It is then

discharged from air dryer outlet.

Refrigerant Circuit

The Fluorocarbon charged in the

refrigerant circuit is compressed by the

compressor and cooled by the condenser

to become liquid. Then, going through the

capillary tube, it is decreased the pressure

to reach a low temperature. Passing

through the cooler part, it

draws heat from

compressed air and intensely boils. Finally

it is inhaled into the compressor again. The

capacity control valve opens to prevent

dew drops from freezing when

compressed air is cooled enough.

y IDF2E,IDF3E

Compressed Air Inlet

Coole

r

Capillary Tube

Pressure Switch

Fan Moto

r

Evaporation Thernarete

r

Condenso

r

Compressor

Capacity Control

Valve

Dorain Outlet

Dorain Separator

Compressed Air Outle t

y IDF4E,IDF6E,IDF8E,IDF11E,IDF15E

Compressed Air Inlet

Coole

r

Capillary Tube

Pressure Switch

Fan Motor

Evaporation Th ernareter

Condenso

r

Compressor

Capacity Control

Valve

Dorain Outlet

Dorain Separator

Compressed Air Outle

t

Reheter

Compressed Air Inlet

Capillar

y

Tub

e

Pressure Switch

Fan Moto

r

p

Thermorete

r

Condenso

r

Compressor

Capacity Control

Valve

Dorain Outlet

Dorain Separato

r

ompressed Air Outlet

Heat Exchange r

6 - 5

Loading...

Loading...