HRX-OM-K003

HRW002-H

HRW008-H

HRW015-H

HRW030-H

HRW002-H1

HRW008-H1

HRW015-H1

HRW030-H1

HRW002-H2

HRW008-H1

HRW015-H2

HRW030-H2

HRW002-HS

HRW008-HS

HRW015-HS

HRW030-HS

HRW002-H1S

HRW008-H1S

HRW015-H1S

HRW030-H1S

HRW002-H2S

HRW008-H1S

HRW015-H2S

HRW030-H2S

1st Edition: July 2006

Rev. G: May 2018

Operation Manual

Original Instructions

THERMO CHILLER

Save This Manual Carefully for Use at Any Time

© 2018 SMC CORPORATION All Rights Reserved

To the Customers

Note: The contents of this manual are subject to change without notice.

Thank you for purchasing our THERMO CHILLER HRW Series (hereinafter called “This system”).

For the long-term, safe use of this system, be sure to read and understand this manual thoroughly before performing

operation of this system.

Warnings and precautions defined in this manual shall be observed.

This manual provides the explanations of the installation and operation of this system. Only those who have

thorough understanding of the fundamental operating procedure or have basic knowledge and skills of handling

industrial equipment for the installation and operation of this system are qualified to perform installation and

operation.

The contents of this manual and related documents supplied with this system shall be neither regarded as a

provision of the contract nor utilized to correct or modify the existing agreements, commitments and relations.

Copying, duplicating or transferring any part of or whole contents of this manual without the prior written consent

of SMC Corporation is strictly prohibited.

The Service Manual is supplied in addition to this manual and provides the explanations of the inspection,

troubleshooting, and in-depth remedies of this system. The Service Manual is intended for service personnel that

completed service training SMC provides. Only those who fall under the above condition are allowed to perform

maintenance and repair of this system with the use of the Service Manual.

HRX-OM-K003

TOC-1

Table of Contents

Table of Contents

Chapter 1 Safety.................................................................................... 1-1

1.1 Before Using this System ....................................................................................... 1-1

1.2 Danger, Warning, and Caution Used in This Manual............................................. 1-2

1.2.1 Hazard Levels ..................................................................................................................... 1-2

1.2.2 Definitions of “Serious injury” and “Minor injury” ................................................................. 1-2

1.2.3 Symbols ............................................................................................................................... 1-3

1.3 Hazard Warning Label ............................................................................................. 1-4

1.3.1 Type of hazard warning label .............................................................................................. 1-4

1.3.2 Location of hazard warning label ........................................................................................ 1-5

1.4 Location of Model Label ......................................................................................... 1-7

1.5 Safety Measures ...................................................................................................... 1-8

1.5.1 Safety Precautions .............................................................................................................. 1-8

1.5.2 Safety Interlock system ....................................................................................................... 1-9

1.5.3 Lockout/Tagout .................................................................................................................. 1-10

1.5.4 Protective equipment ......................................................................................................... 1-12

1.6 Emergency Measures............................................................................................ 1-13

1.6.1 Emergency off [EMO] switch ............................................................................................. 1-13

1.7 Waste Disposal ...................................................................................................... 1-15

1.7.1 Circulating fluid disposal.................................................................................................... 1-15

1.7.2 System disposal ................................................................................................................ 1-15

1.8 Material Safety Data Sheet (MSDS) ...................................................................... 1-15

Chapter 2 Name of Each Section ......................................................... 2-1

2.1 Name of Each Section ............................................................................................. 2-1

Chapter 3 Transporting and Installation .............................................. 3-1

3.1 Transporting ............................................................................................................ 3-1

3.1.1 Transporting with forklift ...................................................................................................... 3-2

3.1.2 Transporting with caster ...................................................................................................... 3-3

3.2 Installation ................................................................................................ ............... 3-3

3.2.1 Installation conditions .......................................................................................................... 3-4

3.2.2 Installation location and maintenance work area ................................................................ 3-5

3.3 Procedure for Installation ....................................................................................... 3-6

3.3.1 Installation ........................................................................................................................... 3-6

3.3.2 Procedure for system securing ........................................................................................... 3-6

3.3.3 Wiring installation ................................................................................................................ 3-7

3.3.4 Procedures for wiring installation ........................................................................................ 3-9

3.3.5 Installation of circulating fluid and facility water piping ...................................................... 3-12

HRW Series

HRX-OM-K003

TOC-2

Table of Contents

Chapter 4 System Startup and Shutdown ............................................. 4-1

4.1 Pre-check .................................................................................................................. 4-1

4.1.1 Installation condition ............................................................................................................ 4-1

4.1.2 Cable connection ................................................................................................................. 4-1

4.1.3 Installation of circulating fluid and facility water piping ........................................................ 4-1

4.1.4 Operating signal from your system ...................................................................................... 4-1

4.1.5 Check emergency off [EMO] switch .................................................................................... 4-1

4.2 Opening of Facility water Valve .............................................................................. 4-1

4.3 Supply of Circulating Fluid ...................................................................................... 4-2

4.3.1 Preparation of circulating fluid ............................................................................................. 4-2

4.3.2 Supply of circulating fluid ..................................................................................................... 4-3

4.4 Requirement for System Startup ............................................................................ 4-4

4.4.1 Turning ON power................................................................................................................ 4-4

4.4.2 Circulating fluid temperature setting .................................................................................... 4-5

4.5 System Startup and Shutdown ............................................................................... 4-5

4.5.1 System startup ..................................................................................................................... 4-5

4.5.2 System shutdown ................................................................................................................ 4-5

Chapter 5 System Operation ................................................................ 5-1

5.1 Operation Display Panel .......................................................................................... 5-1

5.2 Flow Chart of Operation Screen.............................................................................. 5-2

5.3 Operation Screen ..................................................................................................... 5-3

5.3.1 Model Indication screen ....................................................................................................... 5-3

5.3.2 Status screen 1 .................................................................................................................... 5-3

5.3.3 Status screen 2 .................................................................................................................... 5-4

5.3.4 Status screen 3 .................................................................................................................... 5-4

5.3.5 Status screen 4 .................................................................................................................... 5-5

5.3.6 Menu screen ........................................................................................................................ 5-5

5.3.7 Setting screen ...................................................................................................................... 5-6

5.3.8 Mode Selection screen ........................................................................................................ 5-6

5.3.9 Initial Setting screen ............................................................................................................ 5-7

5.3.10 Maintenance screen ............................................................................................................ 5-9

5.3.11 Option screen ...................................................................................................................... 5-9

5.3.12 Alarm Display screen ......................................................................................................... 5-10

5.3.13 Information screen ............................................................................................................. 5-10

5.4 Examples of System Operation ............................................................................ 5-11

5.4.1 Example 1: Circulating fluid set temperature is changed from 25.0°C to 34.1°C. ............. 5-11

5.4.2 Example 2: Communication mode is switched from “DIO REMOTE” to “LOCAL”. ........... 5-13

5.4.3 Example 3: Alarm signal of contact signal is changed from “N/A” to “ALARM1”. .............. 5-14

Chapter 6 Error Message and Troubleshooting ................................. 6-1

HRW Series

HRX-OM-K003

TOC-3

Table of Contents

6.1 Error Message ......................................................................................................... 6-1

6.2 Troubleshooting ................................ ...................................................................... 6-2

Chapter 7 System Maintenance ........................................................... 7-1

7.1 Water Quality Management ..................................................................................... 7-1

7.2 Inspection and Cleaning ......................................................................................... 7-2

7.2.1 Daily inspection ................................................................................................................... 7-2

7.2.2 Quarterly inspection ............................................................................................................ 7-3

7.3 Storage ..................................................................................................................... 7-3

7.3.1 Draining of circulating fluid out of tank ................................................................................ 7-4

7.3.2 Draining of facility water ...................................................................................................... 7-5

7.4 Periodic Replacement Parts ................................................................................... 7-6

Chapter 8 Appendix .............................................................................. 8-1

8.1 Specification ............................................................................................................ 8-1

8.1.1 System specification ............................................................................................................ 8-1

8.1.2 Communication specification............................................................................................... 8-4

8.1.3 Alarm signal selection ......................................................................................................... 8-6

8.2 Outer Dimensions ................................................................................................... 8-7

8.3 Flow Chart ................................................................................................................ 8-8

8.3.1 Part 1 ................................................................................................................................... 8-8

8.3.2 Part 2 ................................................................................................................................... 8-8

8.4 Offset Function ........................................................................................................ 8-9

8.4.1 Example of offset function ................................................................................................. 8-10

8.5 BAND/READY function ......................................................................................... 8-12

8.6 Anchor Bolt Mounting Position ............................................................................ 8-13

8.7 Compliance ............................................................................................................ 8-14

8.8 Thermo Chiller Daily Inspection Sheet ................................................................ 8-15

Product Warranty ............................................................................................................ 8-19

HRW Series

HRX-OM-K003

TOC-4

Table of Contents

HRW Series

1-1

Chapter 1 Safety

Be sure to read and understand the important precautions defined in

this manual thoroughly prior to system use.

1.1 Before Using this System

This "Safety" chapter describes the safety-related items that users should be

aware of upon handling this system.

This system, which is operated under high voltage, is outfitted with the parts

that cause a rise in temperature and rotating parts when it is in action, All

personnel who work with or around this system are required to thoroughly read

and understand the safety-related items in this manual prior to working with or

around this system.

This manual is not intended to be used as a manual for comprehensive safety

and hygiene education. Such a manual should be provided by a safety training

manager.

HRX-OM-K003

Chapter 1 Safety

All personnel who work on or around this system are to have proper training

and education on dangers specific to this system and safety measures against

potential hazards.

A safety manager is responsible for observing safety standards. Operators and

maintainers, however, are to have individual responsibilies for complying with

the safety standard in his/her daily work.

Operators and maintainers must individually take account of safety and assure a

proper working area and working environment.

The relevant personnel must receive proper safety education prior to work

training on this system. Otherwise, personnel may be exposed to hazards. Never

conduct work training without giving proper consideration to safety.

Save this manual at a designated place for reference when necessary.

HRW Series 1.1 Before Using this System

HRX-OM-K003

1-2

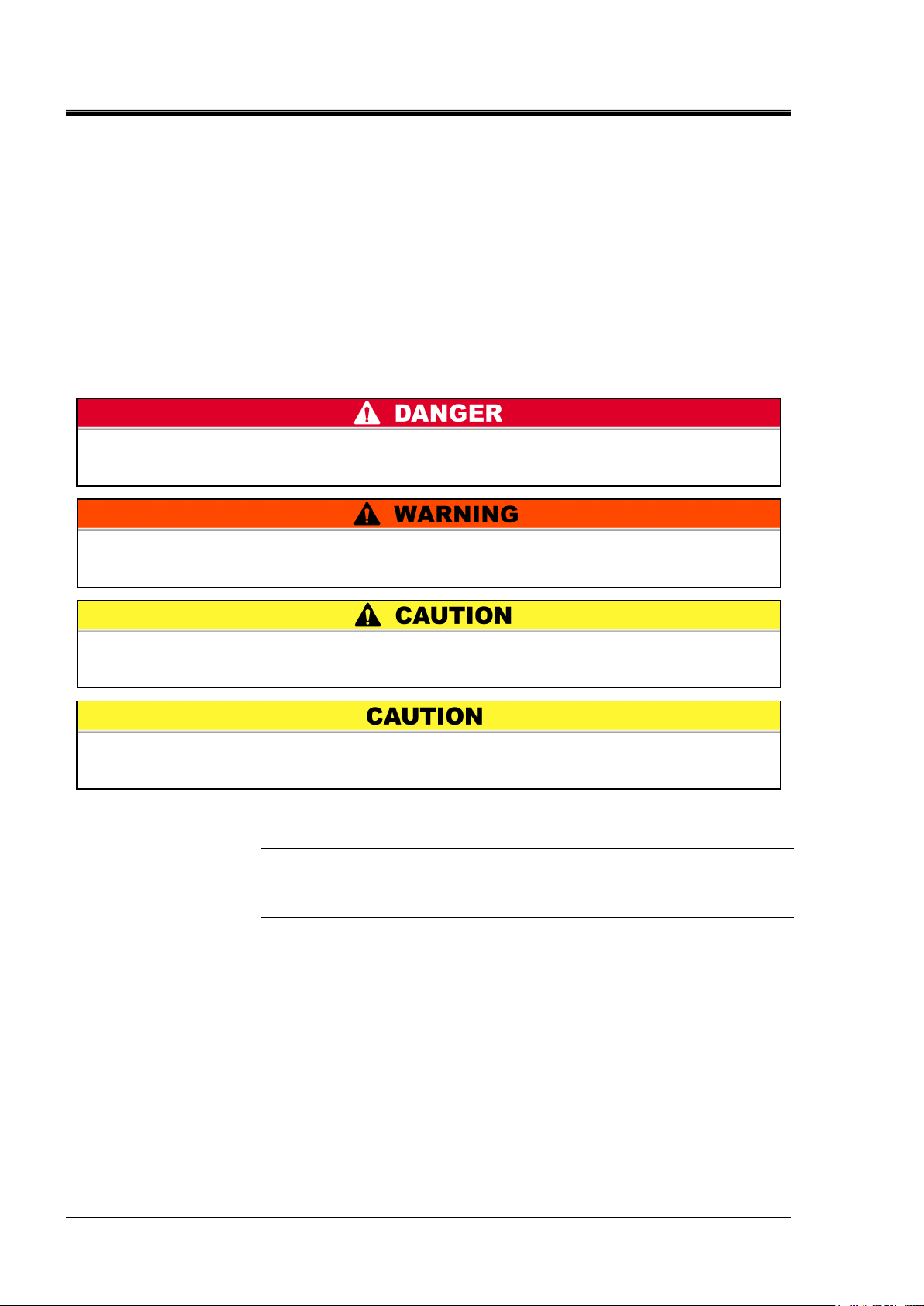

"DANGER" denotes that there is an imminent hazard which will cause serious

personal injury or death during operation.

"WARNING" denotes that there is a hazard which may cause serious personal injury

or death during operation.

"CAUTION" denotes that there is a hazard which may cause minor personal injury

during operation.

"CAUTION" without an exclamation symbol denotes that there is a hazard which

may cause damage or failure of this system, facility, or devices.

Chapter 1 Safety

1.2 Danger, Warning, and Caution Used in This

Manual

1.2.1 Hazard Levels

This system is designed with its first priority being the safety of workers and the

prevention of system damage. This manual classifies the risks into the following

three categories according to the severity and level of the hazard; Danger, Warning,

and Caution. Read the statements carefully, thoroughly understand them before

operating this system.

DANGER, WARNING and CAUTION signs are in order according to hazard

severity (DANGER > WARNING > CAUTION). See below for the details.

[Tips]

Tips are provided when there is information personnel are required to be

aware of for system operation and maintenance. If the task carries useful

information, the relevant tips are given as well.

1.2.2 Definitions of “Serious injury” and “Minor injury”

“Serious injury”

This term describes injuries such as loss of eyesight, wound, burns, frostbite,

electric shock, fracture, and toxication that leave aftereffects, and/or injury

requiring hospitalization and/or prolonged staying in a hospital.

“Minor injury”

This term describes injuries that do not require hospitalization or prolonged staying

in a hospital (injuries other than “serious injuries” described above).

1.2 Danger, Warning, and Caution Used in This Manual HRW Series

1-3

1.2.3 Symbols

This symbol denotes “Don’t” item which you must

not do in operation of this system.

This symbol denotes the “obligation” items which

you must follow in operation of this system.

This symbol warns you of potential electrical shock.

This symbol warns you of potential burns.

This manual provides the following symbols in addition to “Danger”, “Warning”,

and “Caution” to present the warning details in easy-to-understand manner.

Symbol of electrical hazard

Symbol of heat hazard

HRX-OM-K003

Chapter 1 Safety

Symbol of “Don’ts”

Symbol of “Dos”

HRW Series 1.2 Danger, Warning, and Caution Used in This Manual

HRX-OM-K003

1-4

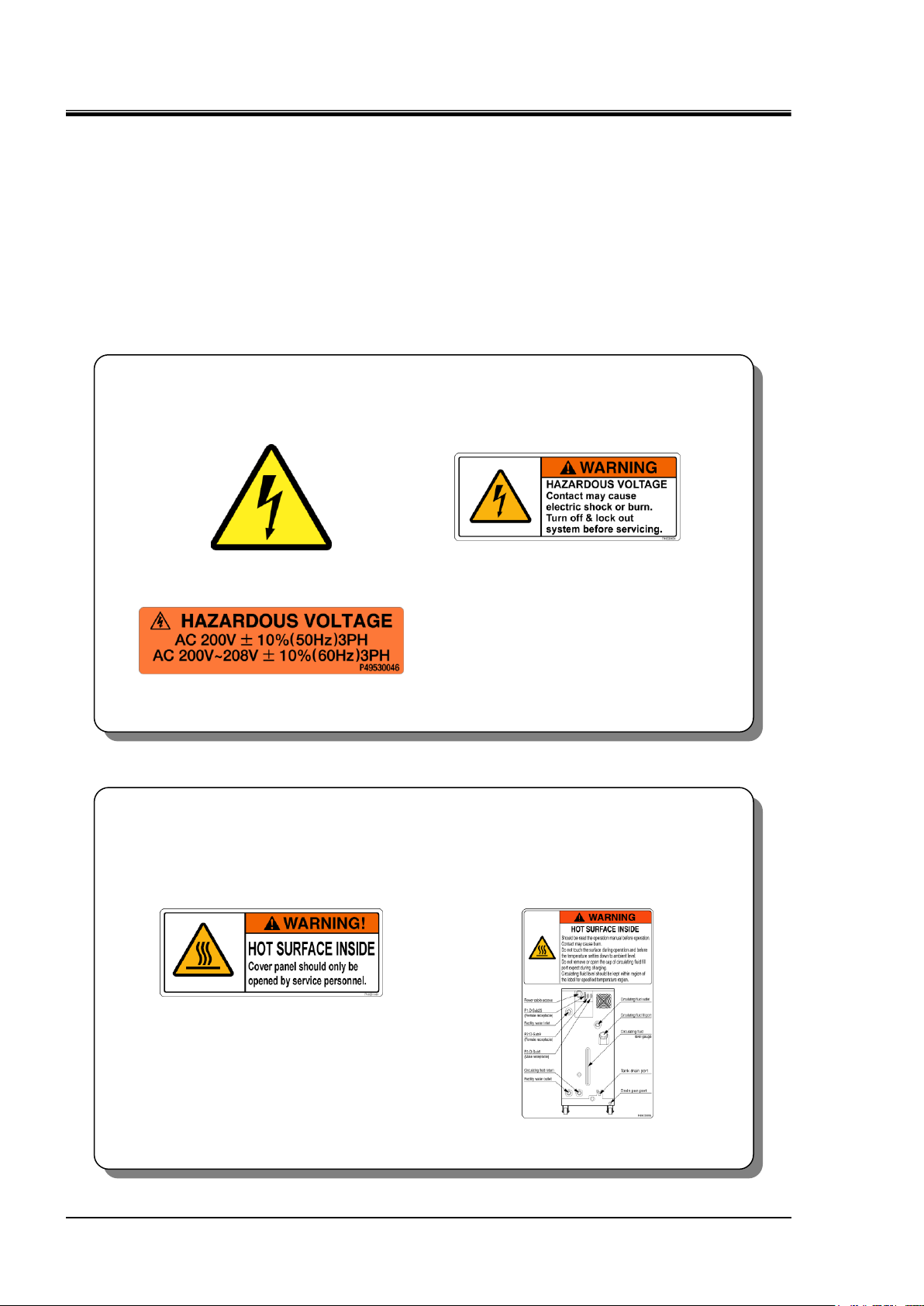

[High voltage hazard]

This warning label is affixed on the part isolated with the cover panel of the system

panel in which high voltage is applied.

Do not remove cover panels that are not designated in this manual.

Figure 1-1 Hazard warning label No.1

Figure 1-2 Hazard warning label No.2

Figure 1-3 Hazard warning label No.3

[Hot surface hazard]

This warning label is affixed on the surface that is at high temperatures carrying

potential burns if touched. Residual heat may cause burns despite the power being

turned OFF. Be sure of the surface reaching room temperature before work.

Figure 1-4 Hazard warning label No.4

Figure 1-5 Hazard warning label No.5

Chapter 1 Safety

1.3 Hazard Warning Label

The hazard warning labels are applied to the sections of this system where

potential hazards are present during system operation and maintenance.

The hazard warning labels are in appropriate sizes and colors to get attention of the

operator. They contain symbols in addition to the descriptions of warnings.

1.3.1 Type of hazard warning label

The hazard warning labels affixed on this system are listed below.

Labels of high voltage hazard

Labels of hot surface hazard

1.3 Hazard Warning Label HRW Series

1-5

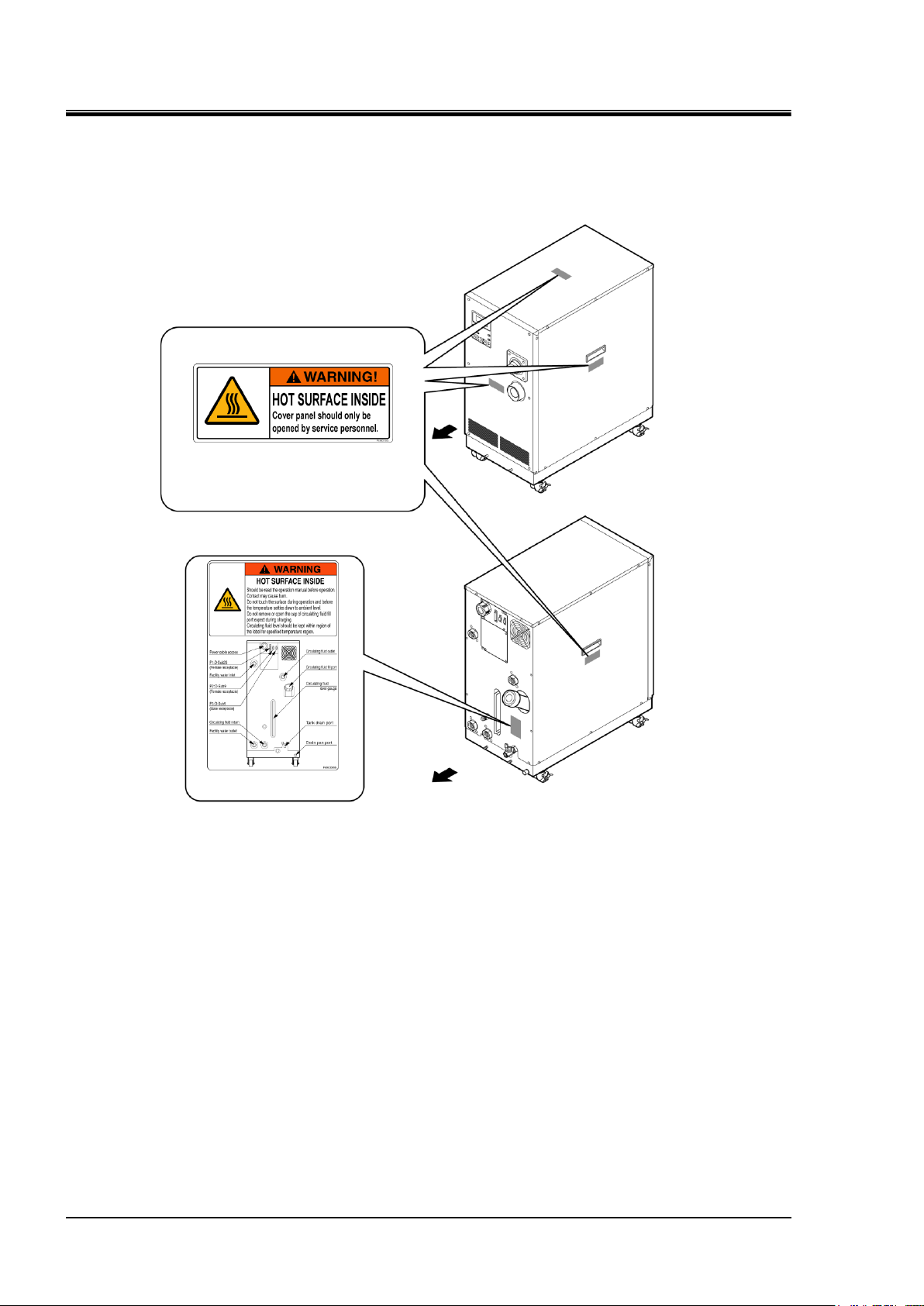

1.3.2 Location of hazard warning label

Figure 1-6 High Voltage Hazard

Confirm the locations of the hazard warning labels.

Read the contents of the hazard warning labels carefully and keep them in

mind.

Do not peel off or deface the hazard warning labels.

Users are NOT allowed to change the locations of the hazard warning

labels. Make sure to affix a new label to exactly the same location of

the replaced label upon replacement of the peeled off or worn out

label.

Hazard warning label No.2

Hazard warning label No.1

Front

Hazard warning label No.3

HRX-OM-K003

Chapter 1 Safety

High voltage hazard

HRW Series 1.3 Hazard Warning Label

HRX-OM-K003

1-6

Figure 1-7 Hot Surface Hazard

Front

Rear

Hazard warning label No.4

Hazard warning label No.5

Chapter 1 Safety

Hot surface hazard

1.3 Hazard Warning Label HRW Series

1-7

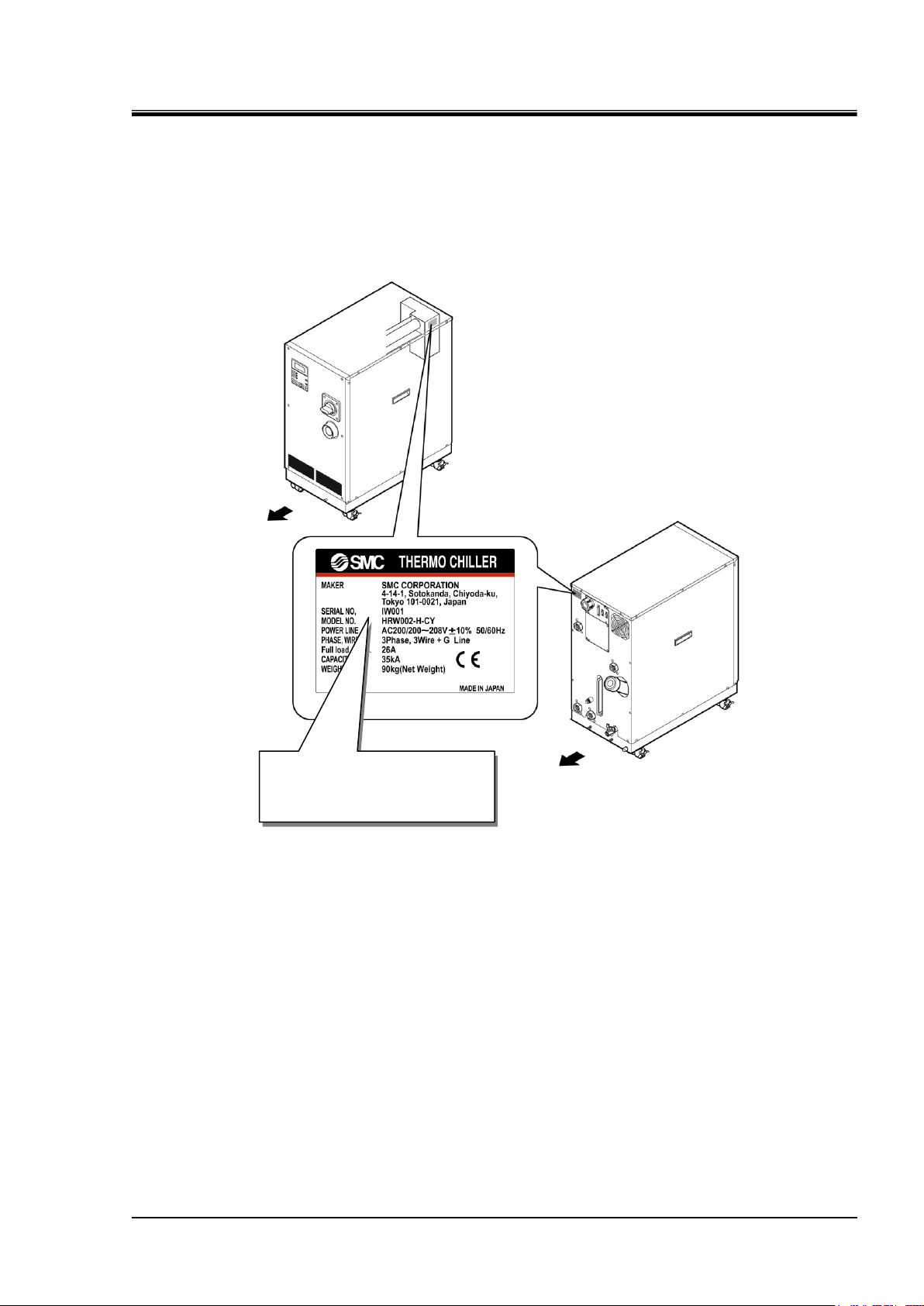

1.4 Location of Model Label

Figure 1-8 Location of Model Label

Label

Front

SERIAL NO.

MODEL NO.

Rear

Information on your system such as Serial No. and Model No. need to be furnished

when you contact the store you purchased from. Serial No. and model No. are

listed on the label as shown below.

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.4 Location of Model Label

HRX-OM-K003

1-8

Follow the following instructions upon operation of this system.

Failure to follow the instructions can lead to personal injury or

hazardous accidents.

Chapter 1 Safety

1.5 Safety Measures

1.5.1 Safety Precautions

While this system is protected by various safety measures including the safety

interlocks, the following basic safety precautions should be observed to assure

further safe operations.

Read and understand this manual thoroughly before operation of this system.

Before operating the system during maintenance, inform all personnel who are

working in the vicinity of the system to alert them of your action.

Use appropriate tools and follow proper procedures.

See “1.5.4 Protective equipment”to wear protective equipment properly.

Refer to your safety manual for emergency evacuation.

Use assistance to carry object over 20 kg.

Check that all parts and screws are returned to the pre-work conditions at the

end of work.

Do not work when intoxicated or feeling ill. Accidents may occur if

disregarded.

Do not remove a panel unless permitted in this manual.

1.5 Safety Measures HRW Series

1-9

1.5.2 Safety Interlock system

Figure 1-9 Front Panel

Front

Front panel

Breaker handle

Safety Interlock system

The function of the safety interlock system is not only protect personnel by

restricting operation that may cause damage to this system or the facility around it

but also eliminate the danger relating to safety. This system is outfitted with

several interlock functions that are activated when improper operation or hazardous

conditions occur. System operation shall be terminated when a safety interlock is

activated

An alarm message is displayed on the LCD screen when a safety interlock is

activated. See “Chapter 6 Error Message and Troubleshooting” for details on the

alarms and remedies or see section “Troubleshooting” in a separate volume of the

“Service Manual”.

Front panel

System repair may require the removal of the front panel.

The breaker handle operation is available only with the front panel attached.

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.5 Safety Measures

HRX-OM-K003

1-10

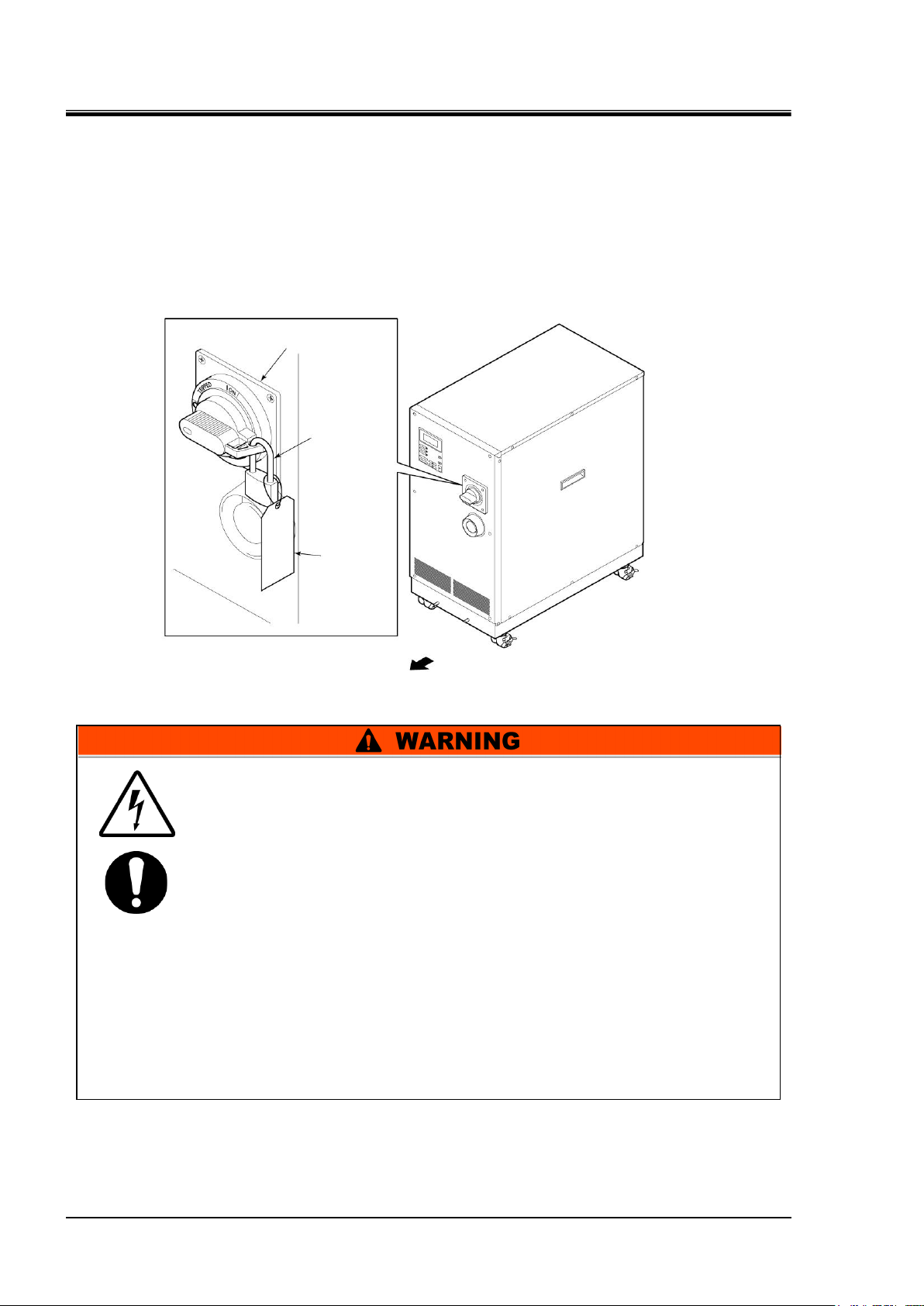

Figure 1-10 Lockout/Tagout

Those who engage in service of this system should build an awareness of

the importance of lockout. Thorough understanding of the procedures

defined in this manual are required for system service.

Lockout is allowed only when the system come to a full stop.

A supervisor should be appointed to direct all personnel if multiple

workers engage in system service.

The supervisor is to perform lockout based on a full understanding of

overall process conditions.

Not only all personnel but new personnel that engage in service of this

system should build an awareness of the importance of lockout and

obtain thorough understanding of the lockout procedure.

Any personnel working in an area with high voltage should be assigned

with padlocks and tags. The key for the padlock is kept under the

responsibility of the supervisor, and lockout release is performed upon

completion of work.

Main breaker

Padlock

Tag

Front

Chapter 1 Safety

1.5.3 Lockout/Tagout

Summary

Lockout in this system disables the main breaker operation to prevent electric

shocks.

Tagout, to be placed on a locked out main breaker, to prevent improper breaker

operation (ON) conducted by other personnel.

See “ Lockout procedure” in the following pages for practical lockout/tagout.

1.5 Safety Measures HRW Series

1-11

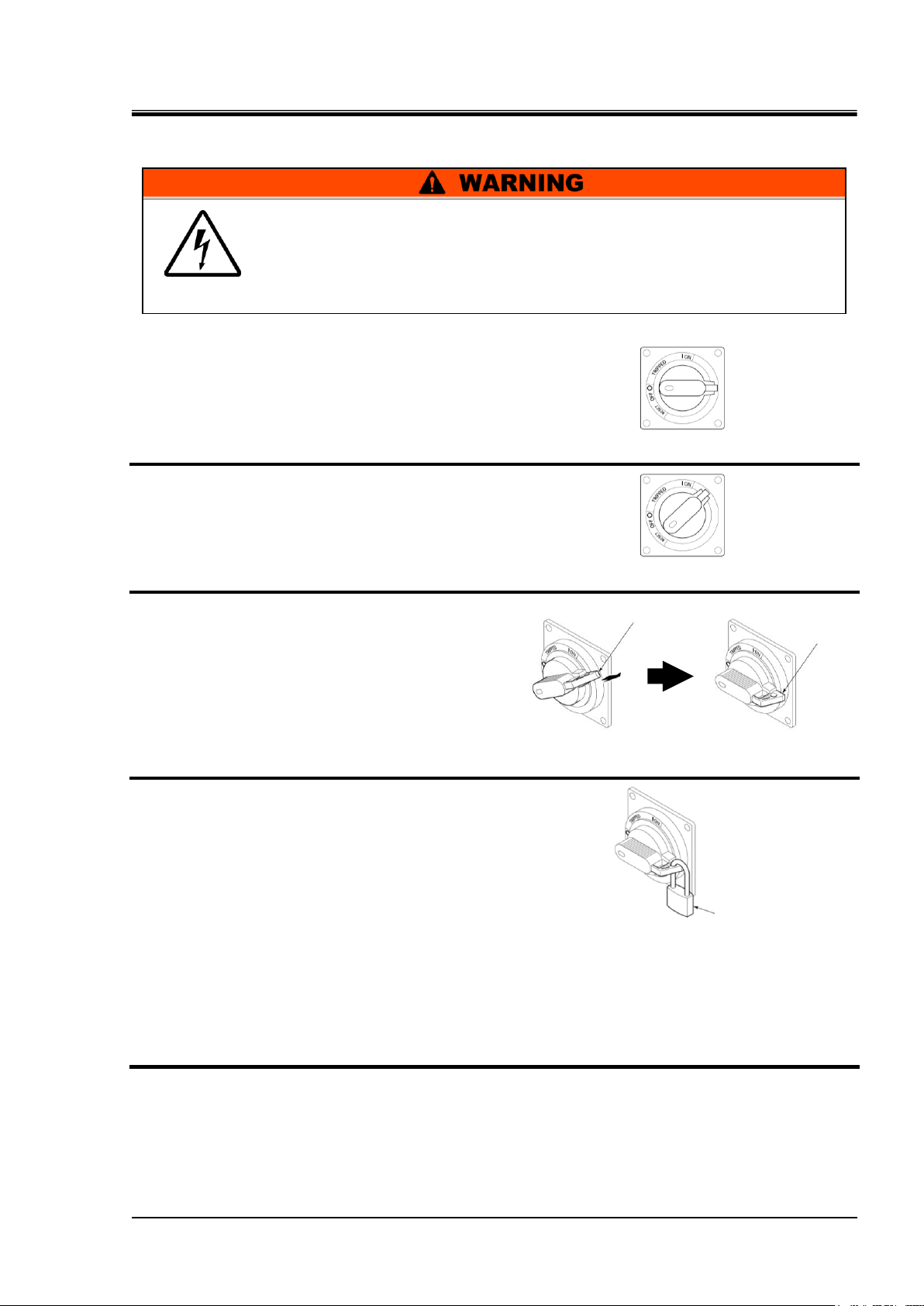

Lockout procedure

Figure 1-11 Breaker Handle at ‘OFF ’

Figure 1-12 Breaker Handle at ‘RESET’

Figure 1-13 Pulling-out of Lock Mounting Part

Figure 1-14 Breaker Lock

Padlock

Lock mounting part

Lock

mounting

part

All service personnel must observe the restrictions applied during

lockout and are required to perform lockout in accordance with this

procedure. No service personnel is allowed to start, energize, or use

the locked out system.

1. Turn the breaker handle to ‘OFF ’.

HRX-OM-K003

Chapter 1 Safety

2. Turn the breaker handle to ‘RESET’.

Hold the breaker handle with hand.

The handle turns back to ‘OFF ’ if released.

3. Pull the lock mounting part out of the

breaker handle, and turn the breaker

handle to ‘OFF ’.

The lock mounting part is to remain pulled

out.

4. Lock the lock mounting part with the

padlock.

Releasing lockout

1. Remove the padlock from the lock mounting part.

2. Turn the breaker handle to ‘RESET’.

The lock mounting part is pulled in.

The handle turns back to ‘OFF ’ if released.

HRW Series 1.5 Safety Measures

HRX-OM-K003

1-12

Read and understand the relevant operation manual thoroughly prior

to use of protective equipment.

Chapter 1 Safety

1.5.4 Protective equipment

This manual defines protective equipment according to work type.

Wear proper protective equipment as shown below, according to work type.

For system transportation, installation and removal

Protective footwear Protective gloves Hard hat

For handling circulating fluid

Protective footwear Protective gloves Protective mask

Protective apron Protective goggles

For system operation

Protective footwear Protective gloves

1.5 Safety Measures HRW Series

1-13

1.6 Emergency Measures

Figure 1-15 Location of Emergency Off [EMO] Switch

1.6.1 Emergency off [EMO] switch

Press the red emergency off [EMO] switch on the front of the system only if the

need to shut off the power arises due to emergency such as natural disaster, fire,

earthquake or personal injury.

The emergency off [EMO] switch is a large, red mushroom-shaped push button

labeled with ‘EMO’ on it. The system comes to a halt if this button is pressed.

When press the emergency off [EMO] switch, the control power for this system is

shut off to bring the system to a stop. The main breaker of this system, however, is

designed not to trip, which enables the motor circuit to remain partially energized.

“8.1.2 Communication specification” in Chapter 8 Appendix on page 8-4 to view

the circuit diagram and see how the EMO switch is interconnected to the system.

Restart of this system is enabled only when this button is reset manually.

Location of emergency off [EMO] switch

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.6 Emergency Measures

HRX-OM-K003

1-14

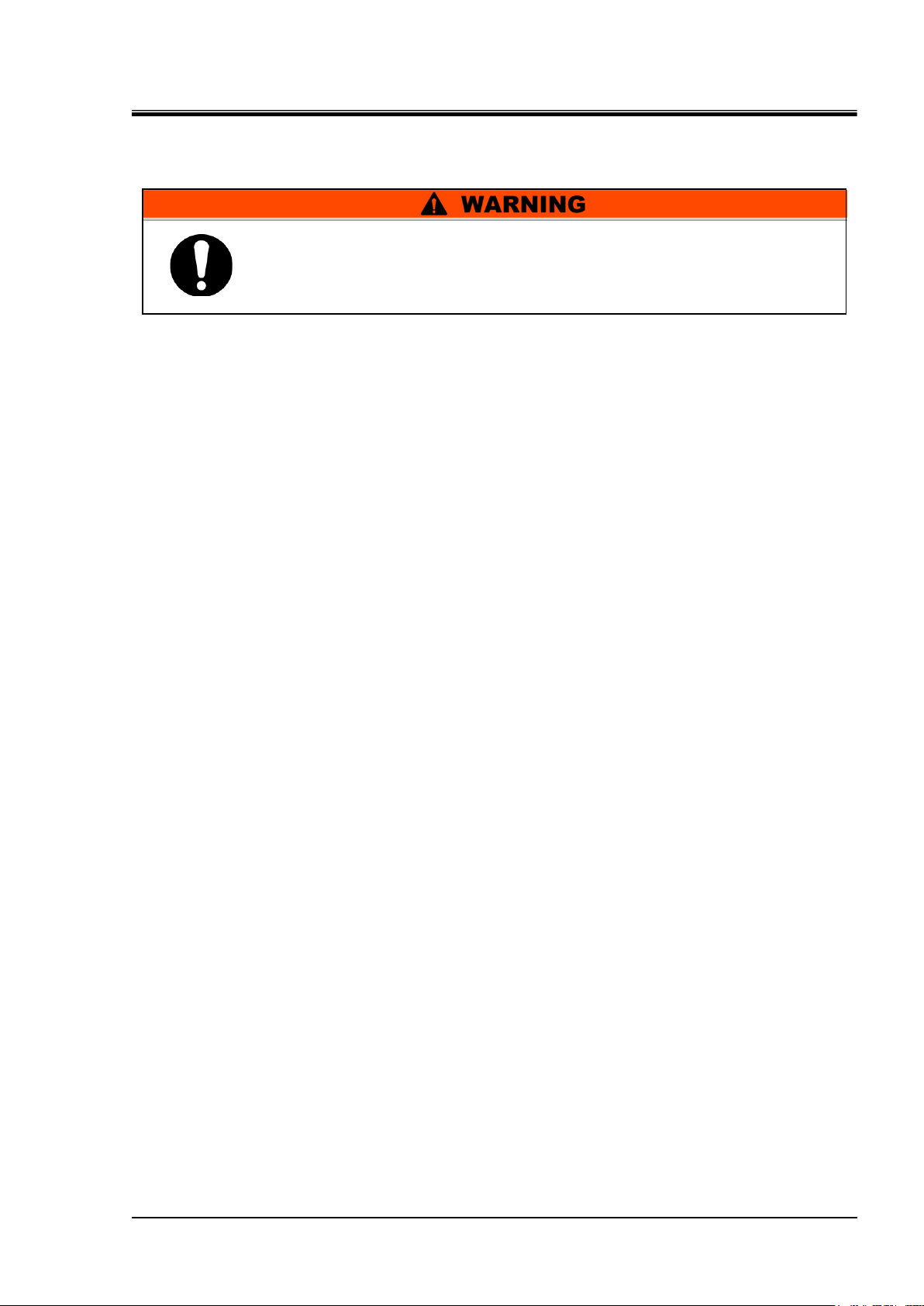

Figure 1-16 Emergency Off [EMO] Switch

No automatic recovery is applied to the emergency off [EMO] switch.

Always eliminate the cause of activating the EMO before resetting.

Potential serious accidents may occur if disregarded.

When the system is in remote mode, the remote mode is retained

despite the power outage. Thus the system operation is to resume as

the start signal is issued from your system.

Chapter 1 Safety

Reset of emergency off [EMO] switch

1. Before restarting, always make sure that the cause of the emergency off condition (The

reason why the EMO switch was activated) has been eliminated from the power supplies,

the system and peripheral equipment.

2. With the cause completely eliminated,

turn the emergency off [EMO] switch

clockwise to reset.

The EMO button returns to its original position.

3. The screen then changes from the “Model Indication screen” to “Status screen 1” as power

is being restored to the system.

1.6 Emergency Measures HRW Series

1-15

1.7 Waste Disposal

Disposal of the fluid and system must be in accordance with

regulations and rules of local authorities.

1.7.1 Circulating fluid disposal

As to the disposal of a circulating fluid (ethylene glycol solution, fluorinated fluid),

consign the specialized industrial waste disposal agency with the contents detailed.

1.7.2 System disposal

As to the disposal of this system, consign the specialized industrial waste disposal

agency in accordance with local laws and regulations.

HRX-OM-K003

Chapter 1 Safety

1.8 Material Safety Data Sheet (MSDS)

Material Safety Data Sheet (MSDS) is supplied separately. Contact the system

supplier if you need the MSDS regarding chemicals used in this system.

For each chemical you purchased, the relevant MSDS is to be obtained under your

responsibility. Keep the MSDS along with this manual in the condition that allows

all personnel to check the contents anytime to gain the understanding of potential

hazards.

HRW Series 1.7 Waste Disposal

HRX-OM-K003

1-16

Chapter 1 Safety

1.8 Material Safety Data Sheet (MSDS) HRW Series

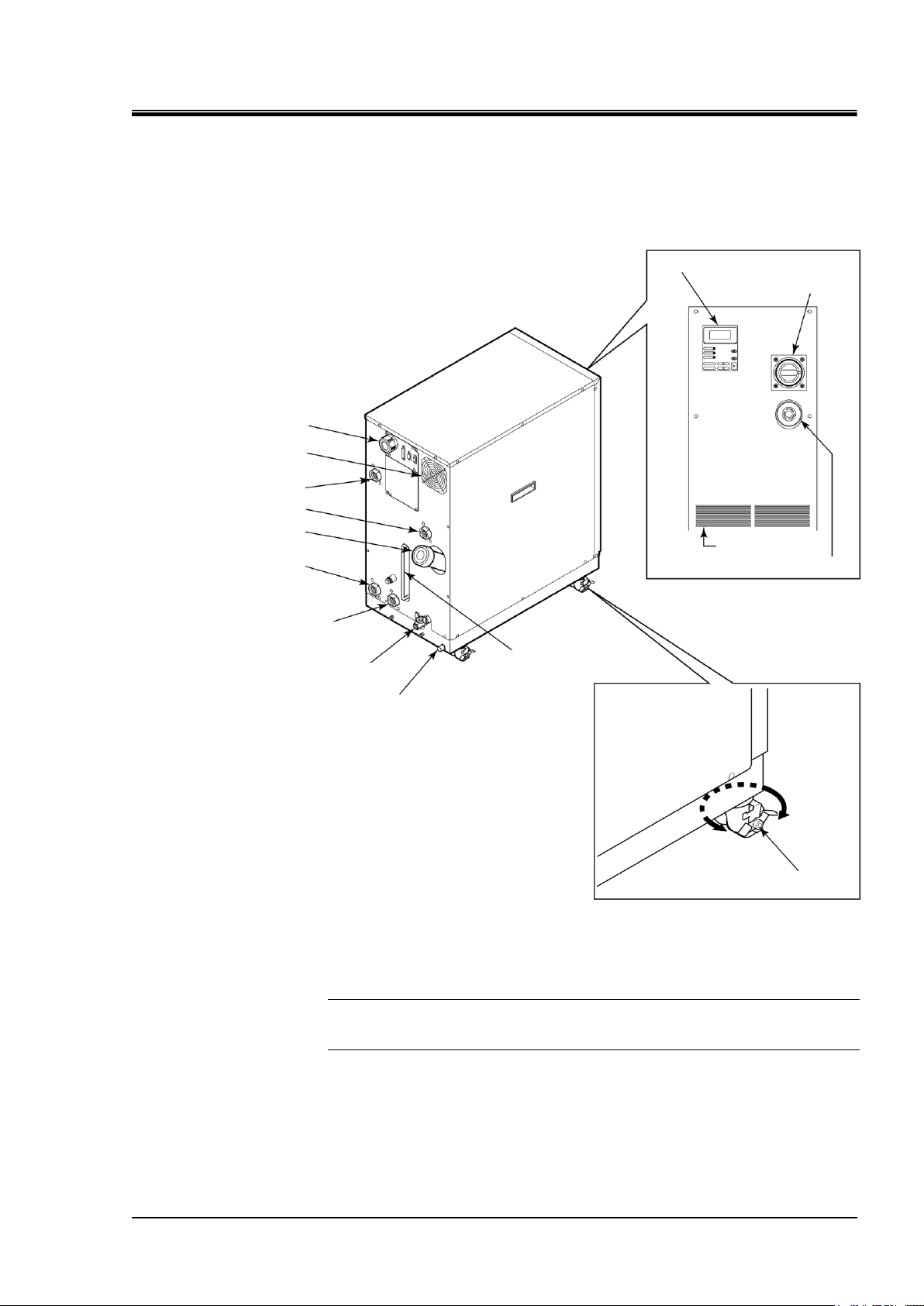

Chapter 2 Name of Each Section

2-1

Caster w/ brake

Rotates 360°.

Operation display panel

Emergency off [EMO] switch

Main breaker

Ventilating hole

(intake side)

Power cable access

Ventilating fan (exhaust side)

Circulating fill port

Facility water inlet

Circulating fluid supply

Circulating fluid level gauge

Circulating fluid return

Tank drain port

Drain pan port

Facility water outlet

Chapter 2 Name of Each Section

2.1 Name of Each Section

HRX-OM-K003

[Tips]

Figure 2-1 Name of Each Section

HRW Series 2.1 Name of Each Section

The casters have built-in brakes. The disengagement of the brakes is

required when transporting the system.

HRX-OM-K003

2-2

Chapter 2 Name of Each Section

2.1 Name of Each Section HRW Series

HRX-OM-K003

3-1

Proper procedure must be followed when using this system.

Exercise caution to assure personnel safety during the installation,

operation, maintenance, and inspection of the system.

Only personnel, who have adequate knowledge and experiences with

not only this system but associated equipment are allowed to perform

transport, installation, and maintenance involving potential hazardous

task.

For transporting with the forklift, be sure to insert the fork into a

designated position, referring to “3.1.1 Transporting with forklift” on

page 3-2.

Do not set this system on its side during transportation.

Drain the remaining fluid out of the pipe as much as possible.

The remaining fluid may spill if disregarded.

Exercise caution not to damage the panel and piping with the forklift

when transporting the system.

Chapter 3 Transporting and Installation

Chapter 3 Transporting and Installation

3.1 Transporting

This system is heavy, which poses potential danger at transportation.

When transporting this system, the following safety precautions should be

observed to prevent system damage and breakdown.

HRW Series 3.1 Transporting

HRX-OM-K003

3-2

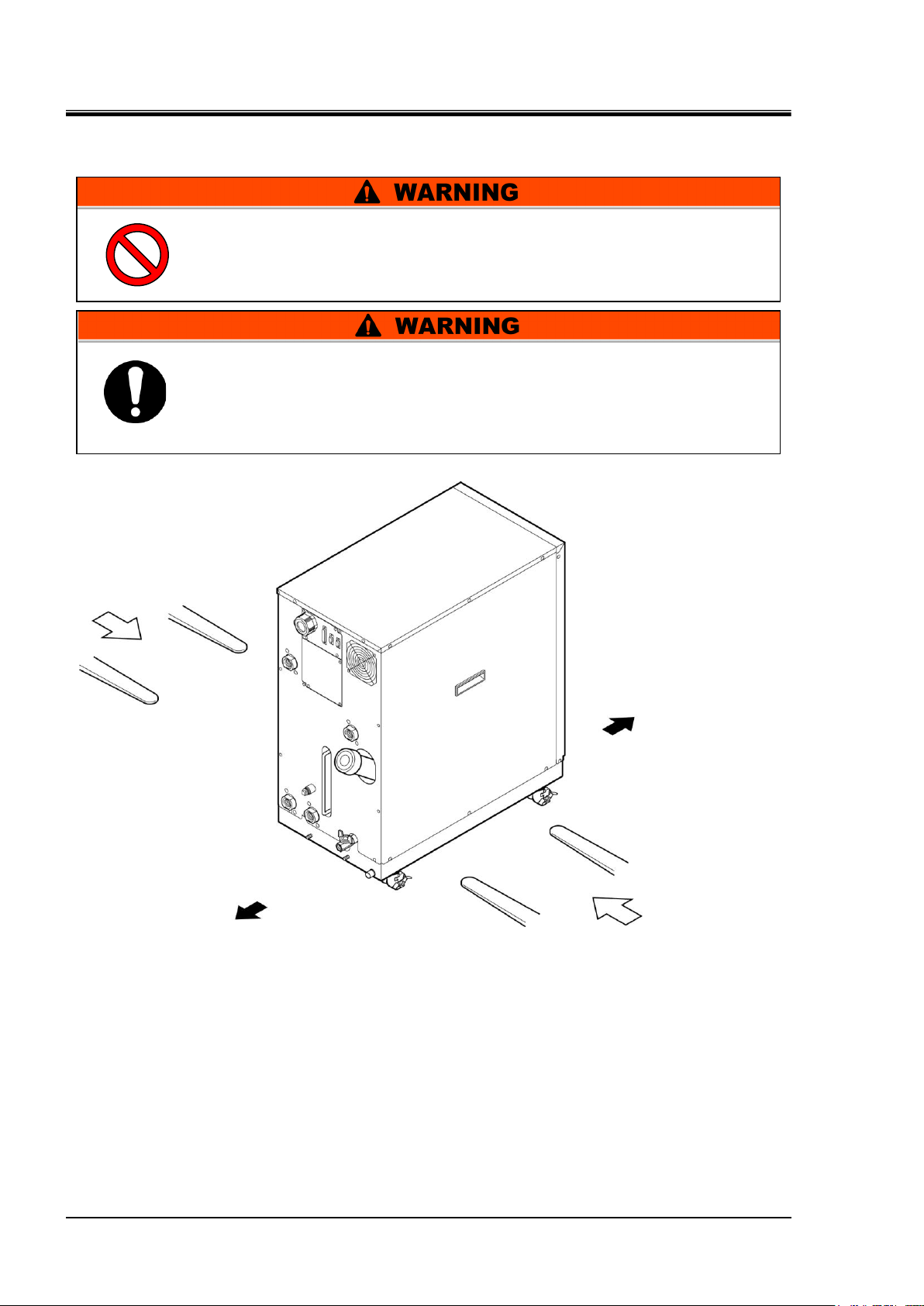

Figure 3-1 Transport with Forklift

This system is heavy, and requires a forklift to safely move it.

Forklift insertion positions are on either left or right side of this system.

Always insert the forks all the way through. Be careful not to hit the

casters.

Do not set this system on its side for transportation. Potential damage to

this system carrying danger of personnel injury if disregarded.

Do not insert the fork from the back as well as front.

Rear

Front

Forklift insertion side

Forklift insertion side

Chapter 3 Transporting and Installation

3.1.1 Transporting with forklift

3.1 Transporting HRW Series

3-3

3.1.2 Transporting with caster

This system is heavy, which requires assistance for this work.

Exercise caution and look out for sloped surfaces such as ramps, etc.

Do not grab piping on the back of this system or panel handles when

transporting with the casters.

Potential damage to piping and panels may occur if disregarded.

System installation should be kept from areas with the potential of

flammable gas leak. Ignition may occur if leaked gas is collected

around the system.

This system is NOT designed for outside use.

Potential electric shock, fire and system damage may occur if exposed

to rain, water and dust.

This system is to be installed on a level floor that can withstand the

weight of this system. Potential water leak and personal injury due to

system tipping over may occur if disregarded.

3.2 Installation

HRX-OM-K003

Chapter 3 Transporting and Installation

HRW Series 3.2 Installation

Loading...

Loading...