Page 1

HRX-OM-K003

HRW002-H

HRW008-H

HRW015-H

HRW030-H

HRW002-H1

HRW008-H1

HRW015-H1

HRW030-H1

HRW002-H2

HRW008-H1

HRW015-H2

HRW030-H2

HRW002-HS

HRW008-HS

HRW015-HS

HRW030-HS

HRW002-H1S

HRW008-H1S

HRW015-H1S

HRW030-H1S

HRW002-H2S

HRW008-H1S

HRW015-H2S

HRW030-H2S

1st Edition: July 2006

Rev. G: May 2018

Operation Manual

Original Instructions

THERMO CHILLER

Save This Manual Carefully for Use at Any Time

© 2018 SMC CORPORATION All Rights Reserved

Page 2

To the Customers

Note: The contents of this manual are subject to change without notice.

Thank you for purchasing our THERMO CHILLER HRW Series (hereinafter called “This system”).

For the long-term, safe use of this system, be sure to read and understand this manual thoroughly before performing

operation of this system.

Warnings and precautions defined in this manual shall be observed.

This manual provides the explanations of the installation and operation of this system. Only those who have

thorough understanding of the fundamental operating procedure or have basic knowledge and skills of handling

industrial equipment for the installation and operation of this system are qualified to perform installation and

operation.

The contents of this manual and related documents supplied with this system shall be neither regarded as a

provision of the contract nor utilized to correct or modify the existing agreements, commitments and relations.

Copying, duplicating or transferring any part of or whole contents of this manual without the prior written consent

of SMC Corporation is strictly prohibited.

The Service Manual is supplied in addition to this manual and provides the explanations of the inspection,

troubleshooting, and in-depth remedies of this system. The Service Manual is intended for service personnel that

completed service training SMC provides. Only those who fall under the above condition are allowed to perform

maintenance and repair of this system with the use of the Service Manual.

Page 3

HRX-OM-K003

TOC-1

Table of Contents

Table of Contents

Chapter 1 Safety.................................................................................... 1-1

1.1 Before Using this System ....................................................................................... 1-1

1.2 Danger, Warning, and Caution Used in This Manual............................................. 1-2

1.2.1 Hazard Levels ..................................................................................................................... 1-2

1.2.2 Definitions of “Serious injury” and “Minor injury” ................................................................. 1-2

1.2.3 Symbols ............................................................................................................................... 1-3

1.3 Hazard Warning Label ............................................................................................. 1-4

1.3.1 Type of hazard warning label .............................................................................................. 1-4

1.3.2 Location of hazard warning label ........................................................................................ 1-5

1.4 Location of Model Label ......................................................................................... 1-7

1.5 Safety Measures ...................................................................................................... 1-8

1.5.1 Safety Precautions .............................................................................................................. 1-8

1.5.2 Safety Interlock system ....................................................................................................... 1-9

1.5.3 Lockout/Tagout .................................................................................................................. 1-10

1.5.4 Protective equipment ......................................................................................................... 1-12

1.6 Emergency Measures............................................................................................ 1-13

1.6.1 Emergency off [EMO] switch ............................................................................................. 1-13

1.7 Waste Disposal ...................................................................................................... 1-15

1.7.1 Circulating fluid disposal.................................................................................................... 1-15

1.7.2 System disposal ................................................................................................................ 1-15

1.8 Material Safety Data Sheet (MSDS) ...................................................................... 1-15

Chapter 2 Name of Each Section ......................................................... 2-1

2.1 Name of Each Section ............................................................................................. 2-1

Chapter 3 Transporting and Installation .............................................. 3-1

3.1 Transporting ............................................................................................................ 3-1

3.1.1 Transporting with forklift ...................................................................................................... 3-2

3.1.2 Transporting with caster ...................................................................................................... 3-3

3.2 Installation ................................................................................................ ............... 3-3

3.2.1 Installation conditions .......................................................................................................... 3-4

3.2.2 Installation location and maintenance work area ................................................................ 3-5

3.3 Procedure for Installation ....................................................................................... 3-6

3.3.1 Installation ........................................................................................................................... 3-6

3.3.2 Procedure for system securing ........................................................................................... 3-6

3.3.3 Wiring installation ................................................................................................................ 3-7

3.3.4 Procedures for wiring installation ........................................................................................ 3-9

3.3.5 Installation of circulating fluid and facility water piping ...................................................... 3-12

HRW Series

Page 4

HRX-OM-K003

TOC-2

Table of Contents

Chapter 4 System Startup and Shutdown ............................................. 4-1

4.1 Pre-check .................................................................................................................. 4-1

4.1.1 Installation condition ............................................................................................................ 4-1

4.1.2 Cable connection ................................................................................................................. 4-1

4.1.3 Installation of circulating fluid and facility water piping ........................................................ 4-1

4.1.4 Operating signal from your system ...................................................................................... 4-1

4.1.5 Check emergency off [EMO] switch .................................................................................... 4-1

4.2 Opening of Facility water Valve .............................................................................. 4-1

4.3 Supply of Circulating Fluid ...................................................................................... 4-2

4.3.1 Preparation of circulating fluid ............................................................................................. 4-2

4.3.2 Supply of circulating fluid ..................................................................................................... 4-3

4.4 Requirement for System Startup ............................................................................ 4-4

4.4.1 Turning ON power................................................................................................................ 4-4

4.4.2 Circulating fluid temperature setting .................................................................................... 4-5

4.5 System Startup and Shutdown ............................................................................... 4-5

4.5.1 System startup ..................................................................................................................... 4-5

4.5.2 System shutdown ................................................................................................................ 4-5

Chapter 5 System Operation ................................................................ 5-1

5.1 Operation Display Panel .......................................................................................... 5-1

5.2 Flow Chart of Operation Screen.............................................................................. 5-2

5.3 Operation Screen ..................................................................................................... 5-3

5.3.1 Model Indication screen ....................................................................................................... 5-3

5.3.2 Status screen 1 .................................................................................................................... 5-3

5.3.3 Status screen 2 .................................................................................................................... 5-4

5.3.4 Status screen 3 .................................................................................................................... 5-4

5.3.5 Status screen 4 .................................................................................................................... 5-5

5.3.6 Menu screen ........................................................................................................................ 5-5

5.3.7 Setting screen ...................................................................................................................... 5-6

5.3.8 Mode Selection screen ........................................................................................................ 5-6

5.3.9 Initial Setting screen ............................................................................................................ 5-7

5.3.10 Maintenance screen ............................................................................................................ 5-9

5.3.11 Option screen ...................................................................................................................... 5-9

5.3.12 Alarm Display screen ......................................................................................................... 5-10

5.3.13 Information screen ............................................................................................................. 5-10

5.4 Examples of System Operation ............................................................................ 5-11

5.4.1 Example 1: Circulating fluid set temperature is changed from 25.0°C to 34.1°C. ............. 5-11

5.4.2 Example 2: Communication mode is switched from “DIO REMOTE” to “LOCAL”. ........... 5-13

5.4.3 Example 3: Alarm signal of contact signal is changed from “N/A” to “ALARM1”. .............. 5-14

Chapter 6 Error Message and Troubleshooting ................................. 6-1

HRW Series

Page 5

HRX-OM-K003

TOC-3

Table of Contents

6.1 Error Message ......................................................................................................... 6-1

6.2 Troubleshooting ................................ ...................................................................... 6-2

Chapter 7 System Maintenance ........................................................... 7-1

7.1 Water Quality Management ..................................................................................... 7-1

7.2 Inspection and Cleaning ......................................................................................... 7-2

7.2.1 Daily inspection ................................................................................................................... 7-2

7.2.2 Quarterly inspection ............................................................................................................ 7-3

7.3 Storage ..................................................................................................................... 7-3

7.3.1 Draining of circulating fluid out of tank ................................................................................ 7-4

7.3.2 Draining of facility water ...................................................................................................... 7-5

7.4 Periodic Replacement Parts ................................................................................... 7-6

Chapter 8 Appendix .............................................................................. 8-1

8.1 Specification ............................................................................................................ 8-1

8.1.1 System specification ............................................................................................................ 8-1

8.1.2 Communication specification............................................................................................... 8-4

8.1.3 Alarm signal selection ......................................................................................................... 8-6

8.2 Outer Dimensions ................................................................................................... 8-7

8.3 Flow Chart ................................................................................................................ 8-8

8.3.1 Part 1 ................................................................................................................................... 8-8

8.3.2 Part 2 ................................................................................................................................... 8-8

8.4 Offset Function ........................................................................................................ 8-9

8.4.1 Example of offset function ................................................................................................. 8-10

8.5 BAND/READY function ......................................................................................... 8-12

8.6 Anchor Bolt Mounting Position ............................................................................ 8-13

8.7 Compliance ............................................................................................................ 8-14

8.8 Thermo Chiller Daily Inspection Sheet ................................................................ 8-15

Product Warranty ............................................................................................................ 8-19

HRW Series

Page 6

HRX-OM-K003

TOC-4

Table of Contents

HRW Series

Page 7

1-1

Chapter 1 Safety

Be sure to read and understand the important precautions defined in

this manual thoroughly prior to system use.

1.1 Before Using this System

This "Safety" chapter describes the safety-related items that users should be

aware of upon handling this system.

This system, which is operated under high voltage, is outfitted with the parts

that cause a rise in temperature and rotating parts when it is in action, All

personnel who work with or around this system are required to thoroughly read

and understand the safety-related items in this manual prior to working with or

around this system.

This manual is not intended to be used as a manual for comprehensive safety

and hygiene education. Such a manual should be provided by a safety training

manager.

HRX-OM-K003

Chapter 1 Safety

All personnel who work on or around this system are to have proper training

and education on dangers specific to this system and safety measures against

potential hazards.

A safety manager is responsible for observing safety standards. Operators and

maintainers, however, are to have individual responsibilies for complying with

the safety standard in his/her daily work.

Operators and maintainers must individually take account of safety and assure a

proper working area and working environment.

The relevant personnel must receive proper safety education prior to work

training on this system. Otherwise, personnel may be exposed to hazards. Never

conduct work training without giving proper consideration to safety.

Save this manual at a designated place for reference when necessary.

HRW Series 1.1 Before Using this System

Page 8

HRX-OM-K003

1-2

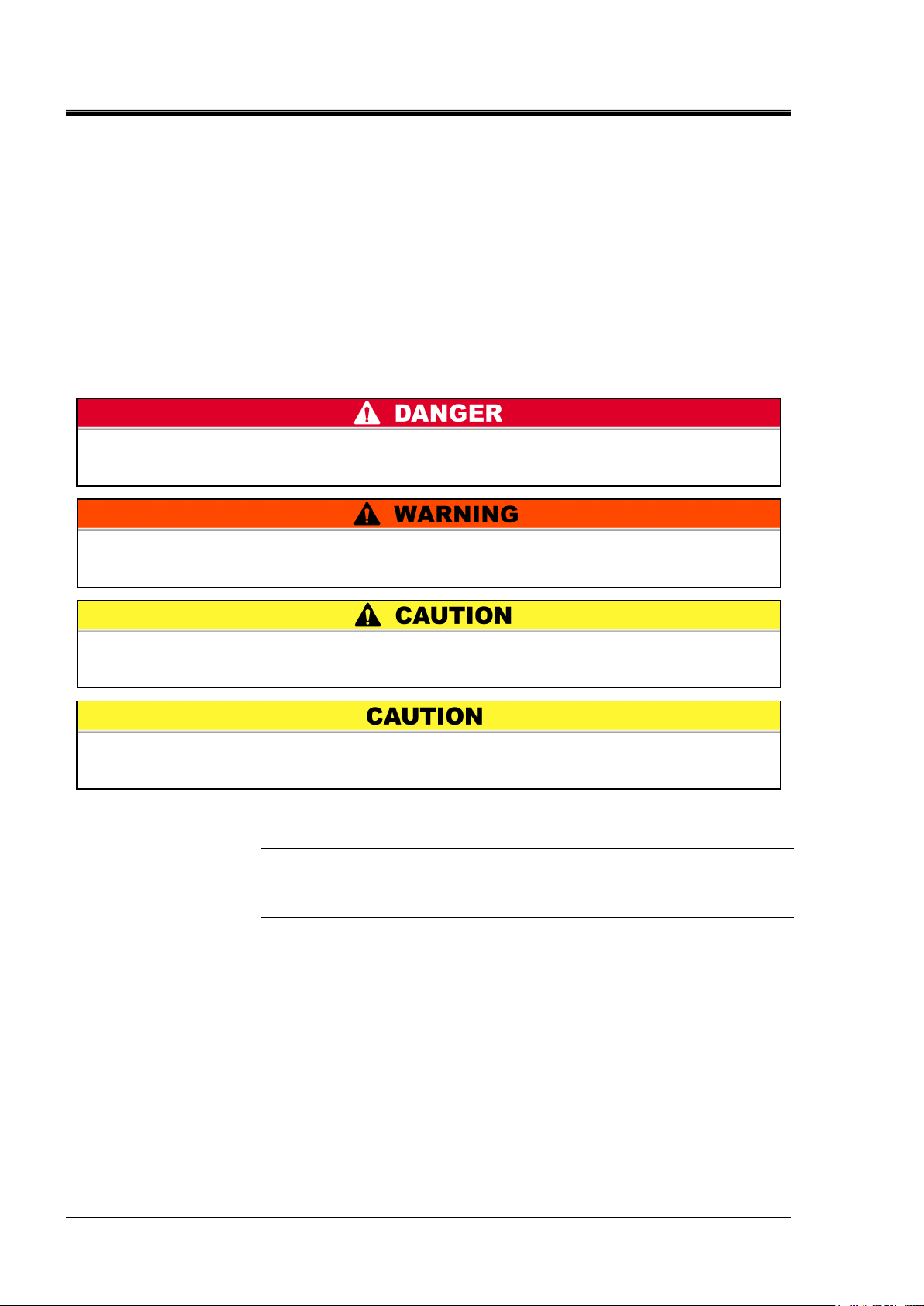

"DANGER" denotes that there is an imminent hazard which will cause serious

personal injury or death during operation.

"WARNING" denotes that there is a hazard which may cause serious personal injury

or death during operation.

"CAUTION" denotes that there is a hazard which may cause minor personal injury

during operation.

"CAUTION" without an exclamation symbol denotes that there is a hazard which

may cause damage or failure of this system, facility, or devices.

Chapter 1 Safety

1.2 Danger, Warning, and Caution Used in This

Manual

1.2.1 Hazard Levels

This system is designed with its first priority being the safety of workers and the

prevention of system damage. This manual classifies the risks into the following

three categories according to the severity and level of the hazard; Danger, Warning,

and Caution. Read the statements carefully, thoroughly understand them before

operating this system.

DANGER, WARNING and CAUTION signs are in order according to hazard

severity (DANGER > WARNING > CAUTION). See below for the details.

[Tips]

Tips are provided when there is information personnel are required to be

aware of for system operation and maintenance. If the task carries useful

information, the relevant tips are given as well.

1.2.2 Definitions of “Serious injury” and “Minor injury”

“Serious injury”

This term describes injuries such as loss of eyesight, wound, burns, frostbite,

electric shock, fracture, and toxication that leave aftereffects, and/or injury

requiring hospitalization and/or prolonged staying in a hospital.

“Minor injury”

This term describes injuries that do not require hospitalization or prolonged staying

in a hospital (injuries other than “serious injuries” described above).

1.2 Danger, Warning, and Caution Used in This Manual HRW Series

Page 9

1-3

1.2.3 Symbols

This symbol denotes “Don’t” item which you must

not do in operation of this system.

This symbol denotes the “obligation” items which

you must follow in operation of this system.

This symbol warns you of potential electrical shock.

This symbol warns you of potential burns.

This manual provides the following symbols in addition to “Danger”, “Warning”,

and “Caution” to present the warning details in easy-to-understand manner.

Symbol of electrical hazard

Symbol of heat hazard

HRX-OM-K003

Chapter 1 Safety

Symbol of “Don’ts”

Symbol of “Dos”

HRW Series 1.2 Danger, Warning, and Caution Used in This Manual

Page 10

HRX-OM-K003

1-4

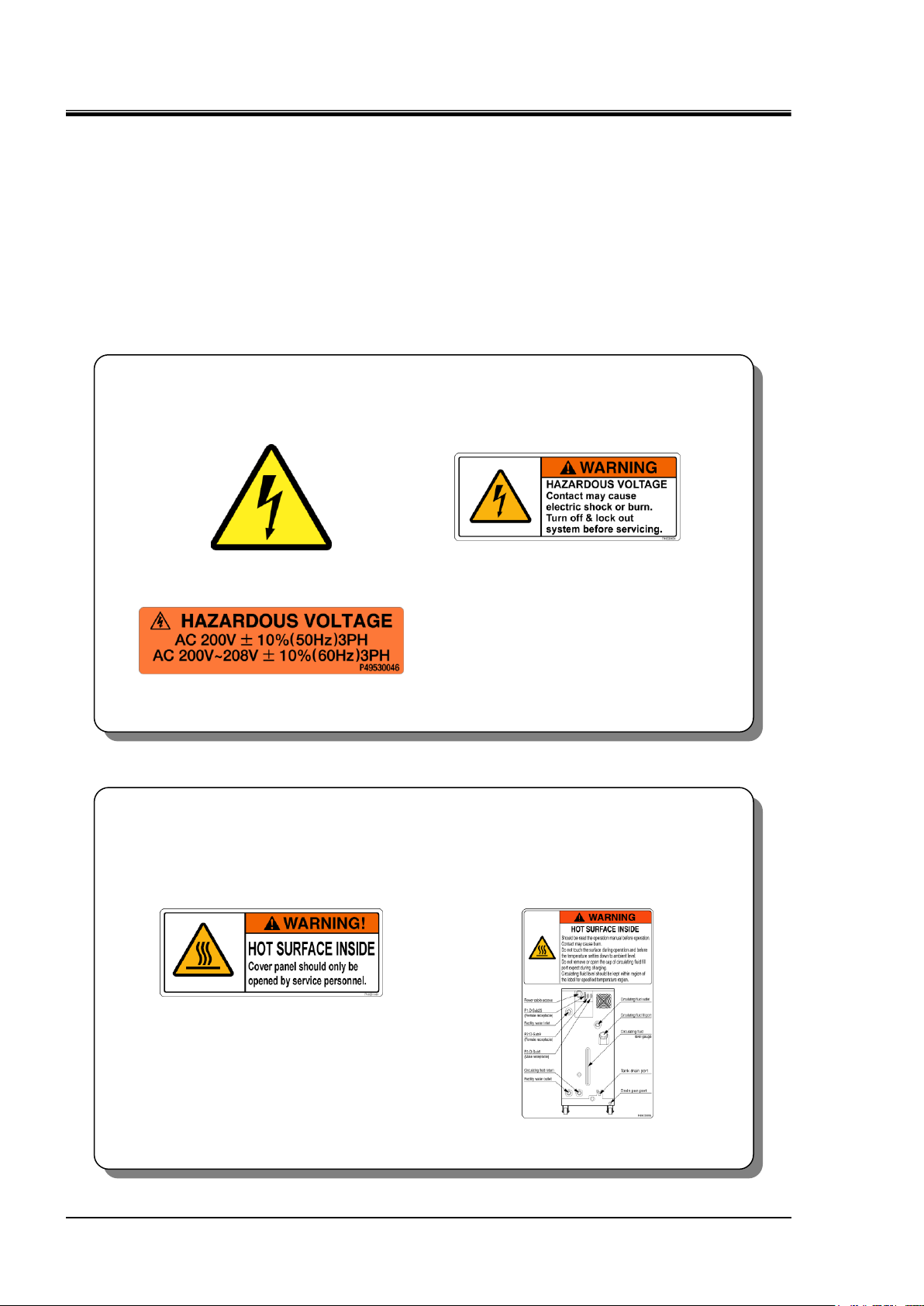

[High voltage hazard]

This warning label is affixed on the part isolated with the cover panel of the system

panel in which high voltage is applied.

Do not remove cover panels that are not designated in this manual.

Figure 1-1 Hazard warning label No.1

Figure 1-2 Hazard warning label No.2

Figure 1-3 Hazard warning label No.3

[Hot surface hazard]

This warning label is affixed on the surface that is at high temperatures carrying

potential burns if touched. Residual heat may cause burns despite the power being

turned OFF. Be sure of the surface reaching room temperature before work.

Figure 1-4 Hazard warning label No.4

Figure 1-5 Hazard warning label No.5

Chapter 1 Safety

1.3 Hazard Warning Label

The hazard warning labels are applied to the sections of this system where

potential hazards are present during system operation and maintenance.

The hazard warning labels are in appropriate sizes and colors to get attention of the

operator. They contain symbols in addition to the descriptions of warnings.

1.3.1 Type of hazard warning label

The hazard warning labels affixed on this system are listed below.

Labels of high voltage hazard

Labels of hot surface hazard

1.3 Hazard Warning Label HRW Series

Page 11

1-5

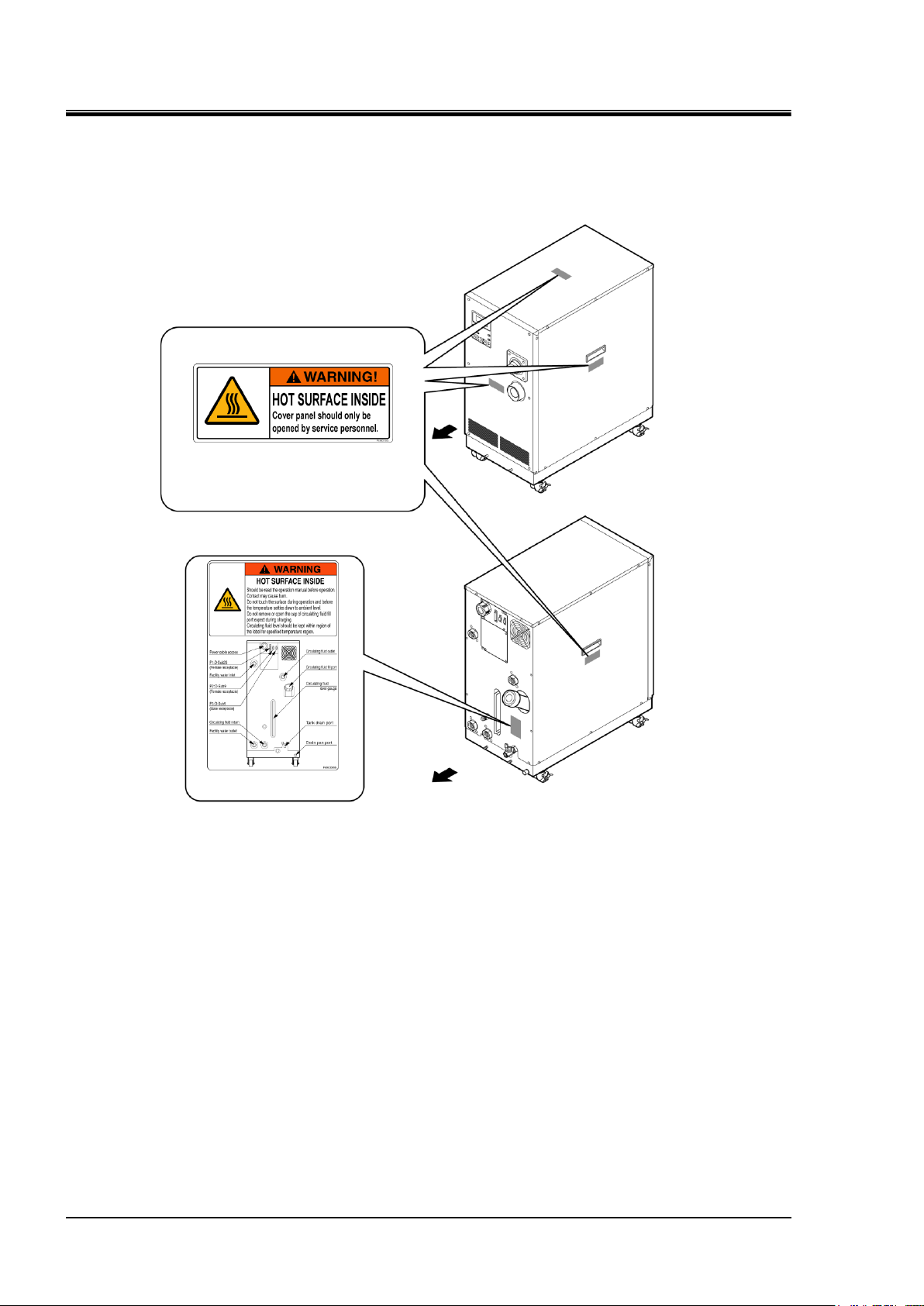

1.3.2 Location of hazard warning label

Figure 1-6 High Voltage Hazard

Confirm the locations of the hazard warning labels.

Read the contents of the hazard warning labels carefully and keep them in

mind.

Do not peel off or deface the hazard warning labels.

Users are NOT allowed to change the locations of the hazard warning

labels. Make sure to affix a new label to exactly the same location of

the replaced label upon replacement of the peeled off or worn out

label.

Hazard warning label No.2

Hazard warning label No.1

Front

Hazard warning label No.3

HRX-OM-K003

Chapter 1 Safety

High voltage hazard

HRW Series 1.3 Hazard Warning Label

Page 12

HRX-OM-K003

1-6

Figure 1-7 Hot Surface Hazard

Front

Rear

Hazard warning label No.4

Hazard warning label No.5

Chapter 1 Safety

Hot surface hazard

1.3 Hazard Warning Label HRW Series

Page 13

1-7

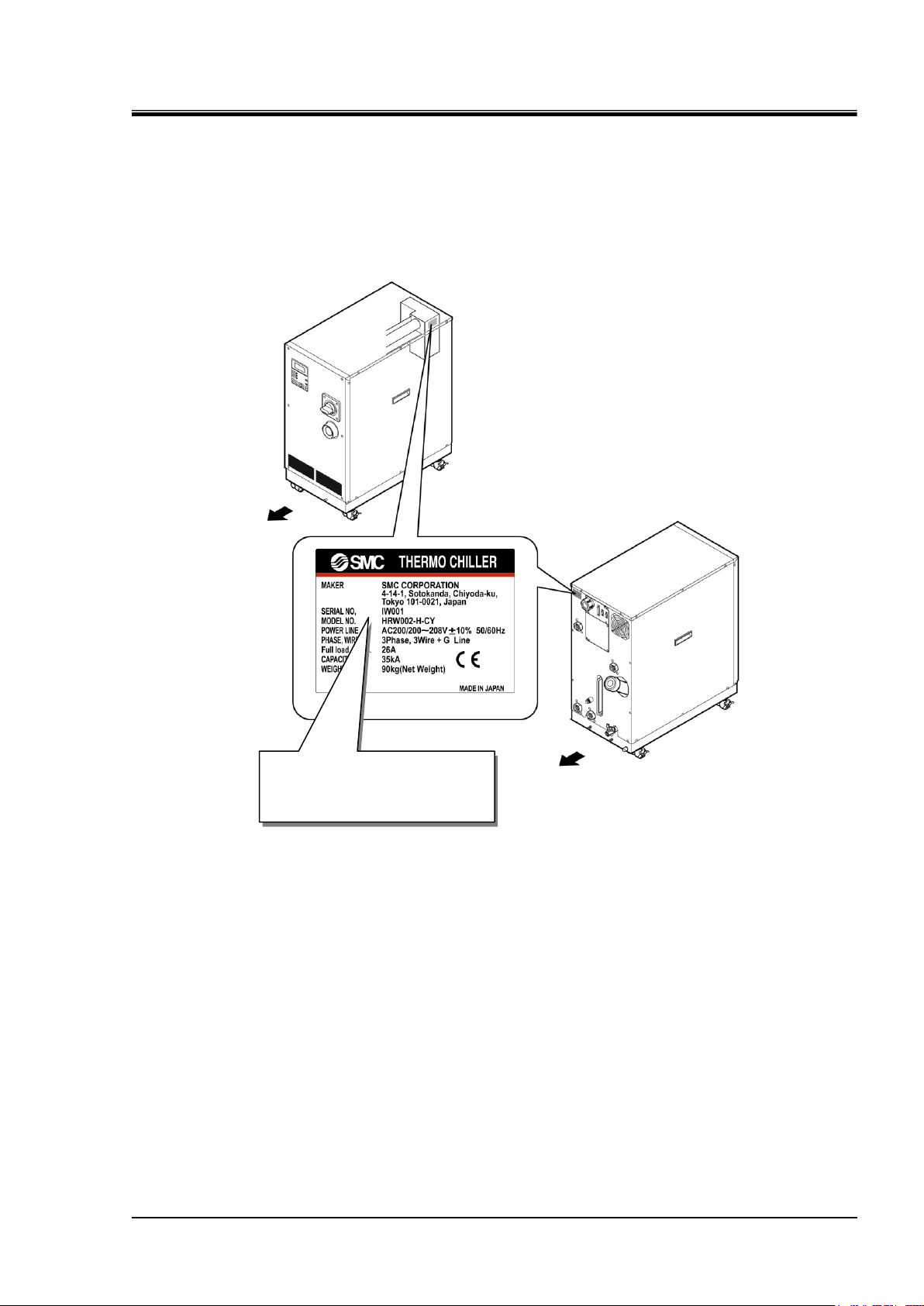

1.4 Location of Model Label

Figure 1-8 Location of Model Label

Label

Front

SERIAL NO.

MODEL NO.

Rear

Information on your system such as Serial No. and Model No. need to be furnished

when you contact the store you purchased from. Serial No. and model No. are

listed on the label as shown below.

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.4 Location of Model Label

Page 14

HRX-OM-K003

1-8

Follow the following instructions upon operation of this system.

Failure to follow the instructions can lead to personal injury or

hazardous accidents.

Chapter 1 Safety

1.5 Safety Measures

1.5.1 Safety Precautions

While this system is protected by various safety measures including the safety

interlocks, the following basic safety precautions should be observed to assure

further safe operations.

Read and understand this manual thoroughly before operation of this system.

Before operating the system during maintenance, inform all personnel who are

working in the vicinity of the system to alert them of your action.

Use appropriate tools and follow proper procedures.

See “1.5.4 Protective equipment”to wear protective equipment properly.

Refer to your safety manual for emergency evacuation.

Use assistance to carry object over 20 kg.

Check that all parts and screws are returned to the pre-work conditions at the

end of work.

Do not work when intoxicated or feeling ill. Accidents may occur if

disregarded.

Do not remove a panel unless permitted in this manual.

1.5 Safety Measures HRW Series

Page 15

1-9

1.5.2 Safety Interlock system

Figure 1-9 Front Panel

Front

Front panel

Breaker handle

Safety Interlock system

The function of the safety interlock system is not only protect personnel by

restricting operation that may cause damage to this system or the facility around it

but also eliminate the danger relating to safety. This system is outfitted with

several interlock functions that are activated when improper operation or hazardous

conditions occur. System operation shall be terminated when a safety interlock is

activated

An alarm message is displayed on the LCD screen when a safety interlock is

activated. See “Chapter 6 Error Message and Troubleshooting” for details on the

alarms and remedies or see section “Troubleshooting” in a separate volume of the

“Service Manual”.

Front panel

System repair may require the removal of the front panel.

The breaker handle operation is available only with the front panel attached.

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.5 Safety Measures

Page 16

HRX-OM-K003

1-10

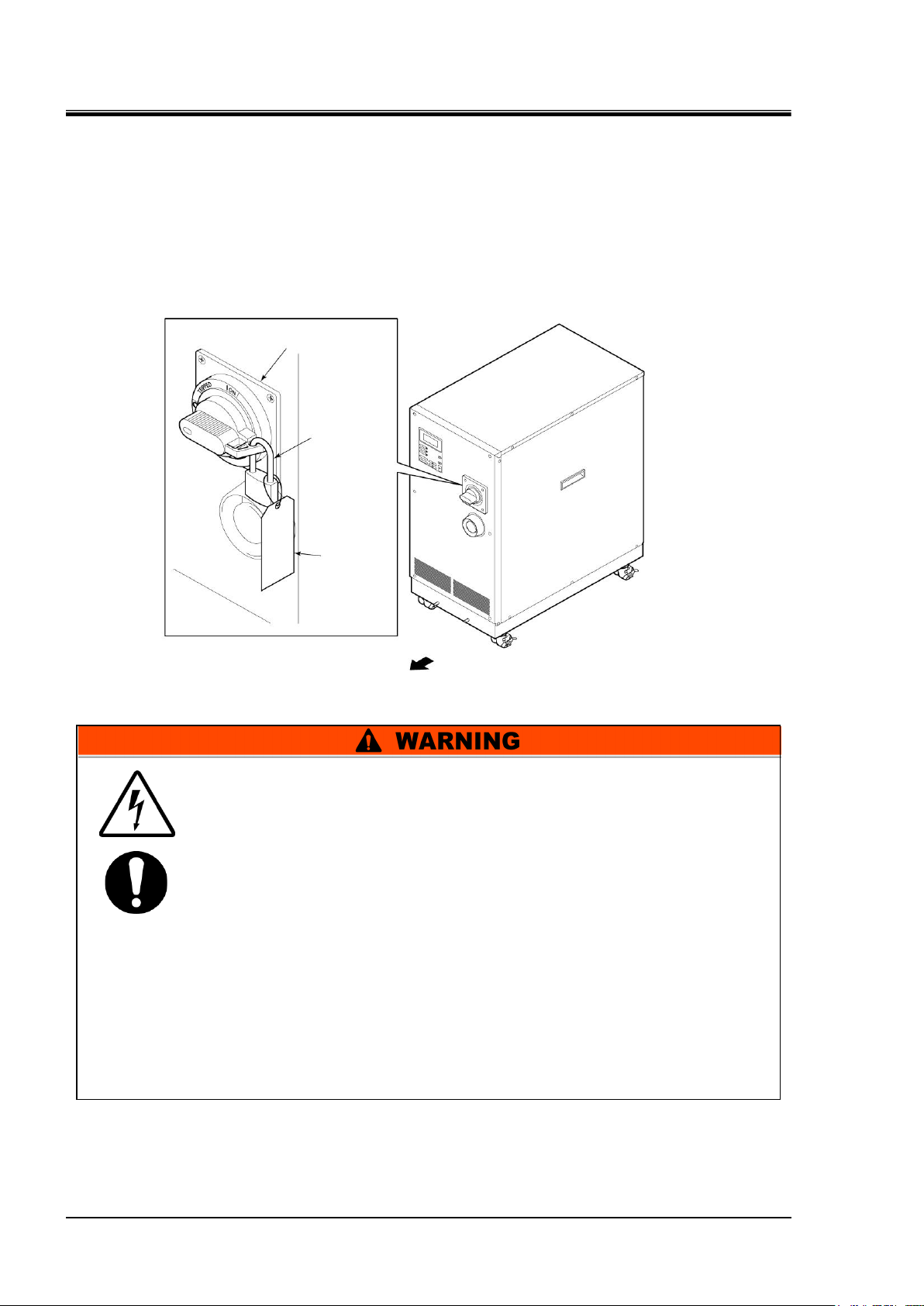

Figure 1-10 Lockout/Tagout

Those who engage in service of this system should build an awareness of

the importance of lockout. Thorough understanding of the procedures

defined in this manual are required for system service.

Lockout is allowed only when the system come to a full stop.

A supervisor should be appointed to direct all personnel if multiple

workers engage in system service.

The supervisor is to perform lockout based on a full understanding of

overall process conditions.

Not only all personnel but new personnel that engage in service of this

system should build an awareness of the importance of lockout and

obtain thorough understanding of the lockout procedure.

Any personnel working in an area with high voltage should be assigned

with padlocks and tags. The key for the padlock is kept under the

responsibility of the supervisor, and lockout release is performed upon

completion of work.

Main breaker

Padlock

Tag

Front

Chapter 1 Safety

1.5.3 Lockout/Tagout

Summary

Lockout in this system disables the main breaker operation to prevent electric

shocks.

Tagout, to be placed on a locked out main breaker, to prevent improper breaker

operation (ON) conducted by other personnel.

See “ Lockout procedure” in the following pages for practical lockout/tagout.

1.5 Safety Measures HRW Series

Page 17

1-11

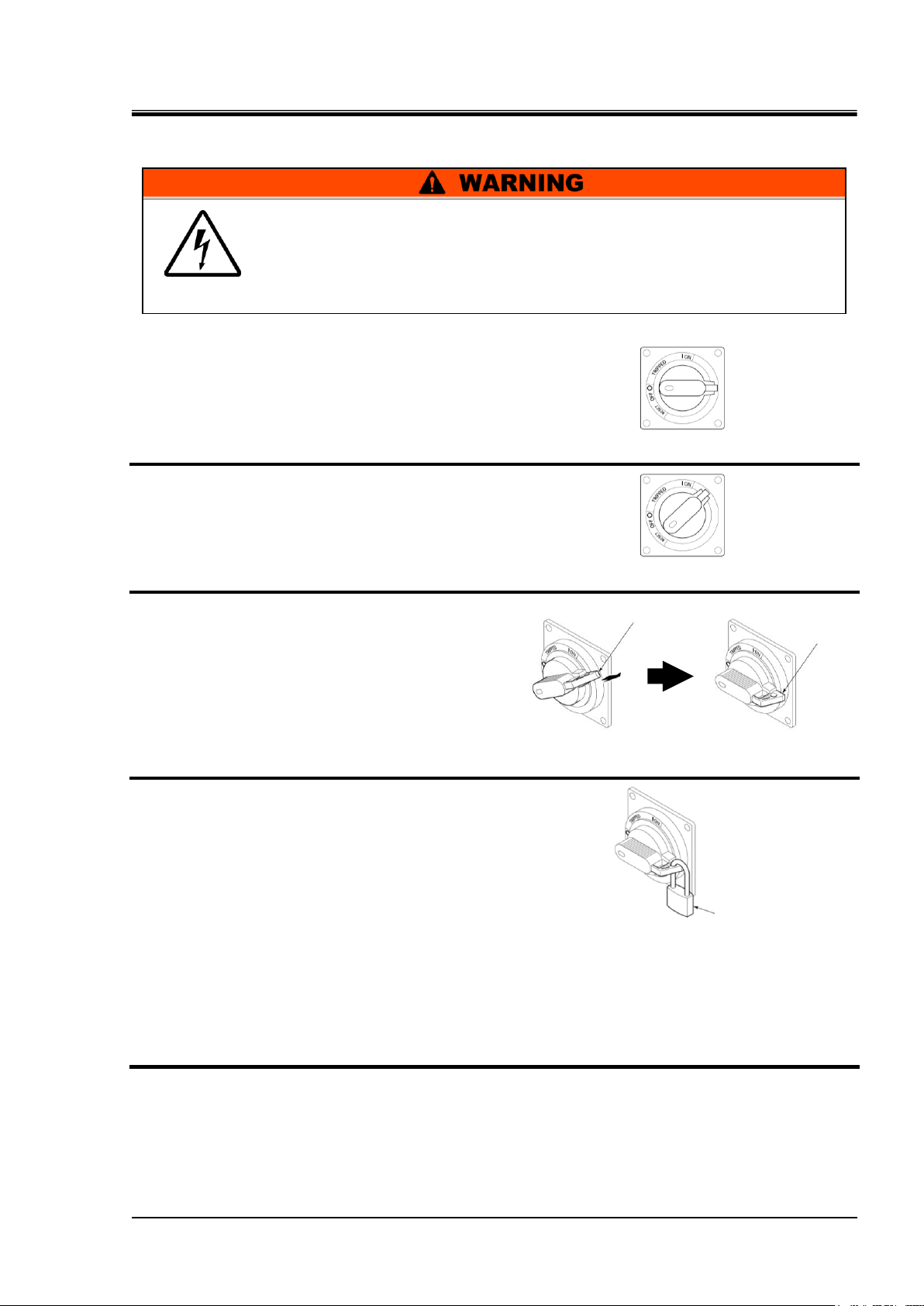

Lockout procedure

Figure 1-11 Breaker Handle at ‘OFF ’

Figure 1-12 Breaker Handle at ‘RESET’

Figure 1-13 Pulling-out of Lock Mounting Part

Figure 1-14 Breaker Lock

Padlock

Lock mounting part

Lock

mounting

part

All service personnel must observe the restrictions applied during

lockout and are required to perform lockout in accordance with this

procedure. No service personnel is allowed to start, energize, or use

the locked out system.

1. Turn the breaker handle to ‘OFF ’.

HRX-OM-K003

Chapter 1 Safety

2. Turn the breaker handle to ‘RESET’.

Hold the breaker handle with hand.

The handle turns back to ‘OFF ’ if released.

3. Pull the lock mounting part out of the

breaker handle, and turn the breaker

handle to ‘OFF ’.

The lock mounting part is to remain pulled

out.

4. Lock the lock mounting part with the

padlock.

Releasing lockout

1. Remove the padlock from the lock mounting part.

2. Turn the breaker handle to ‘RESET’.

The lock mounting part is pulled in.

The handle turns back to ‘OFF ’ if released.

HRW Series 1.5 Safety Measures

Page 18

HRX-OM-K003

1-12

Read and understand the relevant operation manual thoroughly prior

to use of protective equipment.

Chapter 1 Safety

1.5.4 Protective equipment

This manual defines protective equipment according to work type.

Wear proper protective equipment as shown below, according to work type.

For system transportation, installation and removal

Protective footwear Protective gloves Hard hat

For handling circulating fluid

Protective footwear Protective gloves Protective mask

Protective apron Protective goggles

For system operation

Protective footwear Protective gloves

1.5 Safety Measures HRW Series

Page 19

1-13

1.6 Emergency Measures

Figure 1-15 Location of Emergency Off [EMO] Switch

1.6.1 Emergency off [EMO] switch

Press the red emergency off [EMO] switch on the front of the system only if the

need to shut off the power arises due to emergency such as natural disaster, fire,

earthquake or personal injury.

The emergency off [EMO] switch is a large, red mushroom-shaped push button

labeled with ‘EMO’ on it. The system comes to a halt if this button is pressed.

When press the emergency off [EMO] switch, the control power for this system is

shut off to bring the system to a stop. The main breaker of this system, however, is

designed not to trip, which enables the motor circuit to remain partially energized.

“8.1.2 Communication specification” in Chapter 8 Appendix on page 8-4 to view

the circuit diagram and see how the EMO switch is interconnected to the system.

Restart of this system is enabled only when this button is reset manually.

Location of emergency off [EMO] switch

HRX-OM-K003

Chapter 1 Safety

HRW Series 1.6 Emergency Measures

Page 20

HRX-OM-K003

1-14

Figure 1-16 Emergency Off [EMO] Switch

No automatic recovery is applied to the emergency off [EMO] switch.

Always eliminate the cause of activating the EMO before resetting.

Potential serious accidents may occur if disregarded.

When the system is in remote mode, the remote mode is retained

despite the power outage. Thus the system operation is to resume as

the start signal is issued from your system.

Chapter 1 Safety

Reset of emergency off [EMO] switch

1. Before restarting, always make sure that the cause of the emergency off condition (The

reason why the EMO switch was activated) has been eliminated from the power supplies,

the system and peripheral equipment.

2. With the cause completely eliminated,

turn the emergency off [EMO] switch

clockwise to reset.

The EMO button returns to its original position.

3. The screen then changes from the “Model Indication screen” to “Status screen 1” as power

is being restored to the system.

1.6 Emergency Measures HRW Series

Page 21

1-15

1.7 Waste Disposal

Disposal of the fluid and system must be in accordance with

regulations and rules of local authorities.

1.7.1 Circulating fluid disposal

As to the disposal of a circulating fluid (ethylene glycol solution, fluorinated fluid),

consign the specialized industrial waste disposal agency with the contents detailed.

1.7.2 System disposal

As to the disposal of this system, consign the specialized industrial waste disposal

agency in accordance with local laws and regulations.

HRX-OM-K003

Chapter 1 Safety

1.8 Material Safety Data Sheet (MSDS)

Material Safety Data Sheet (MSDS) is supplied separately. Contact the system

supplier if you need the MSDS regarding chemicals used in this system.

For each chemical you purchased, the relevant MSDS is to be obtained under your

responsibility. Keep the MSDS along with this manual in the condition that allows

all personnel to check the contents anytime to gain the understanding of potential

hazards.

HRW Series 1.7 Waste Disposal

Page 22

HRX-OM-K003

1-16

Chapter 1 Safety

1.8 Material Safety Data Sheet (MSDS) HRW Series

Page 23

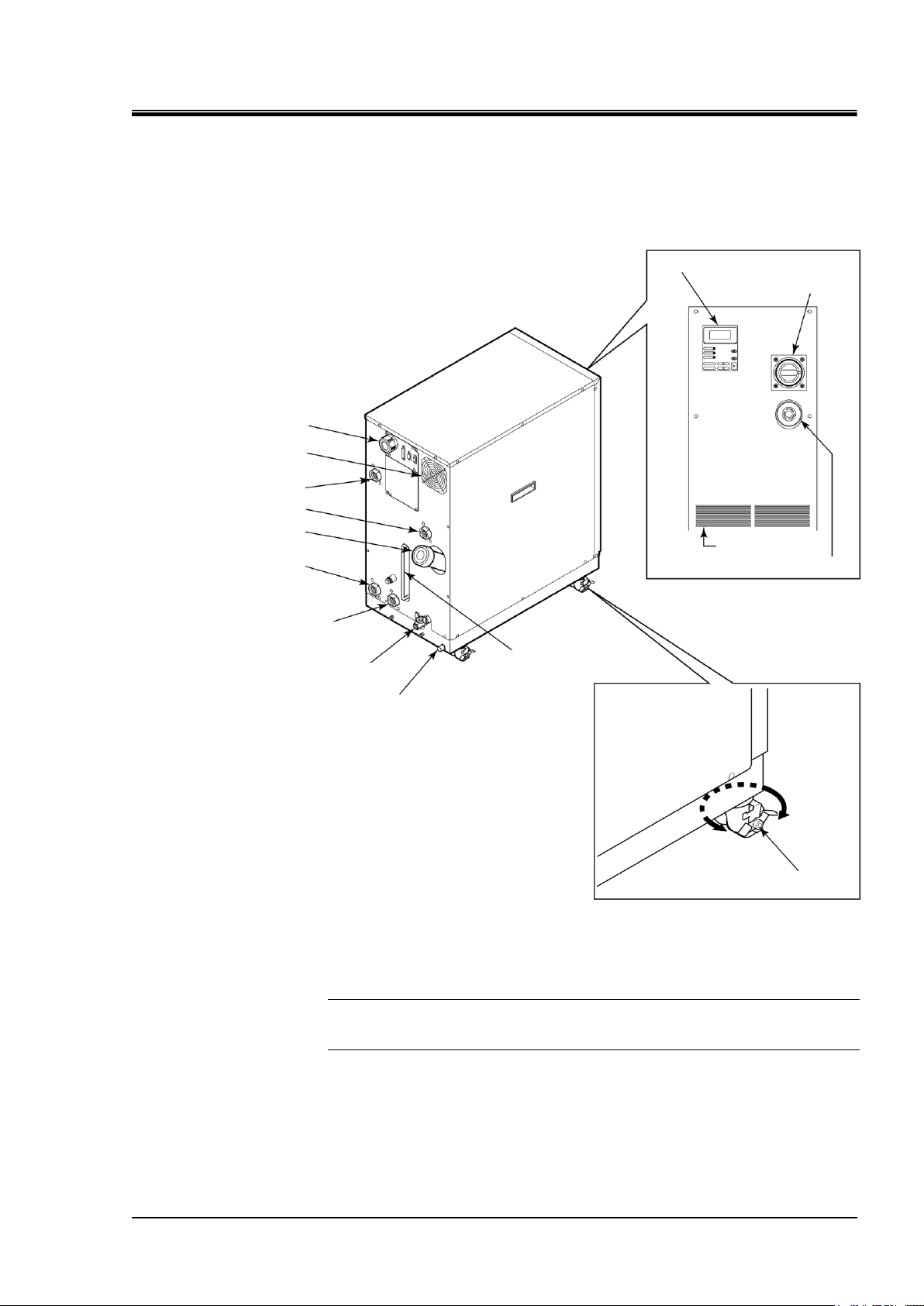

Chapter 2 Name of Each Section

2-1

Caster w/ brake

Rotates 360°.

Operation display panel

Emergency off [EMO] switch

Main breaker

Ventilating hole

(intake side)

Power cable access

Ventilating fan (exhaust side)

Circulating fill port

Facility water inlet

Circulating fluid supply

Circulating fluid level gauge

Circulating fluid return

Tank drain port

Drain pan port

Facility water outlet

Chapter 2 Name of Each Section

2.1 Name of Each Section

HRX-OM-K003

[Tips]

Figure 2-1 Name of Each Section

HRW Series 2.1 Name of Each Section

The casters have built-in brakes. The disengagement of the brakes is

required when transporting the system.

Page 24

HRX-OM-K003

2-2

Chapter 2 Name of Each Section

2.1 Name of Each Section HRW Series

Page 25

HRX-OM-K003

3-1

Proper procedure must be followed when using this system.

Exercise caution to assure personnel safety during the installation,

operation, maintenance, and inspection of the system.

Only personnel, who have adequate knowledge and experiences with

not only this system but associated equipment are allowed to perform

transport, installation, and maintenance involving potential hazardous

task.

For transporting with the forklift, be sure to insert the fork into a

designated position, referring to “3.1.1 Transporting with forklift” on

page 3-2.

Do not set this system on its side during transportation.

Drain the remaining fluid out of the pipe as much as possible.

The remaining fluid may spill if disregarded.

Exercise caution not to damage the panel and piping with the forklift

when transporting the system.

Chapter 3 Transporting and Installation

Chapter 3 Transporting and Installation

3.1 Transporting

This system is heavy, which poses potential danger at transportation.

When transporting this system, the following safety precautions should be

observed to prevent system damage and breakdown.

HRW Series 3.1 Transporting

Page 26

HRX-OM-K003

3-2

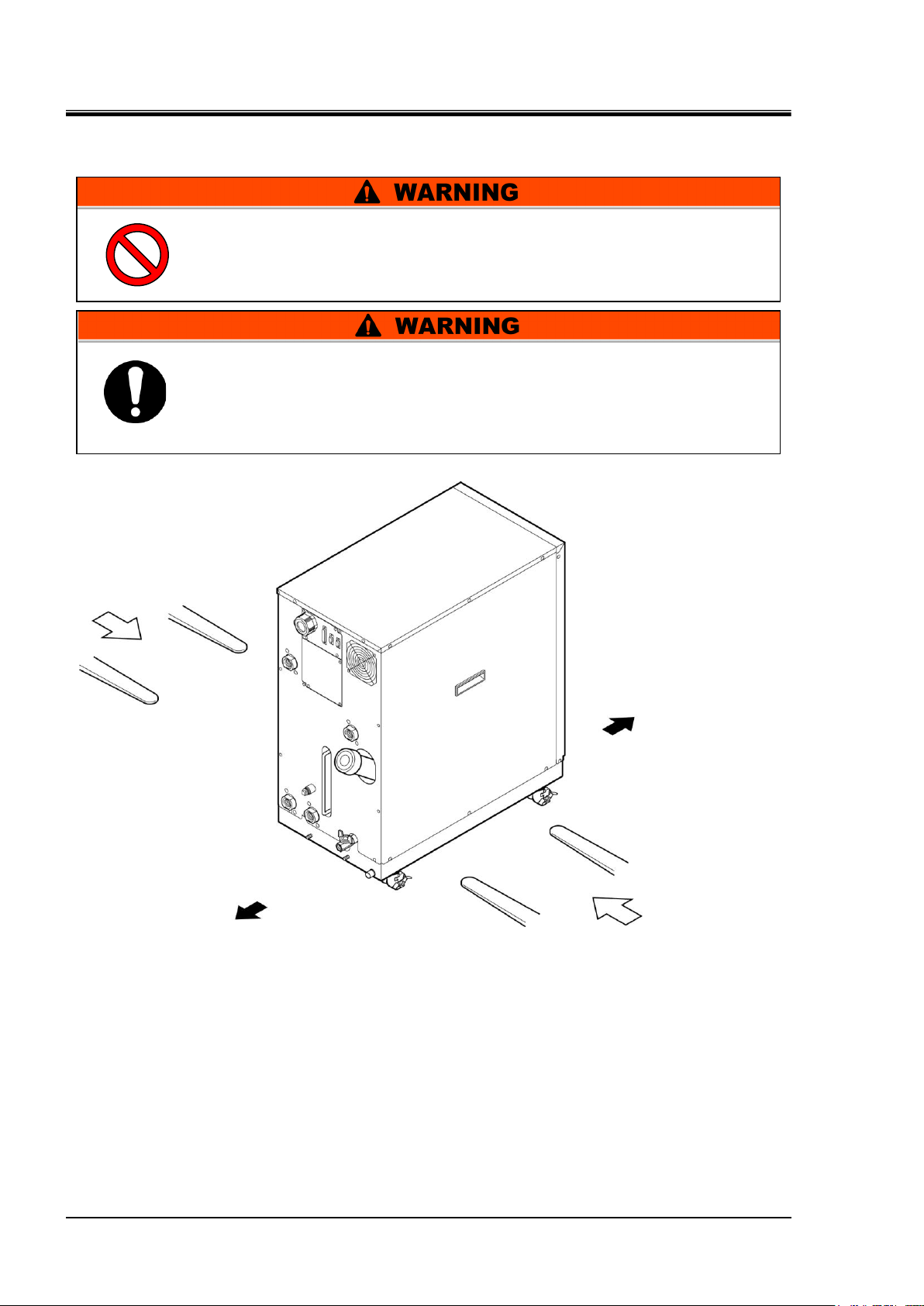

Figure 3-1 Transport with Forklift

This system is heavy, and requires a forklift to safely move it.

Forklift insertion positions are on either left or right side of this system.

Always insert the forks all the way through. Be careful not to hit the

casters.

Do not set this system on its side for transportation. Potential damage to

this system carrying danger of personnel injury if disregarded.

Do not insert the fork from the back as well as front.

Rear

Front

Forklift insertion side

Forklift insertion side

Chapter 3 Transporting and Installation

3.1.1 Transporting with forklift

3.1 Transporting HRW Series

Page 27

3-3

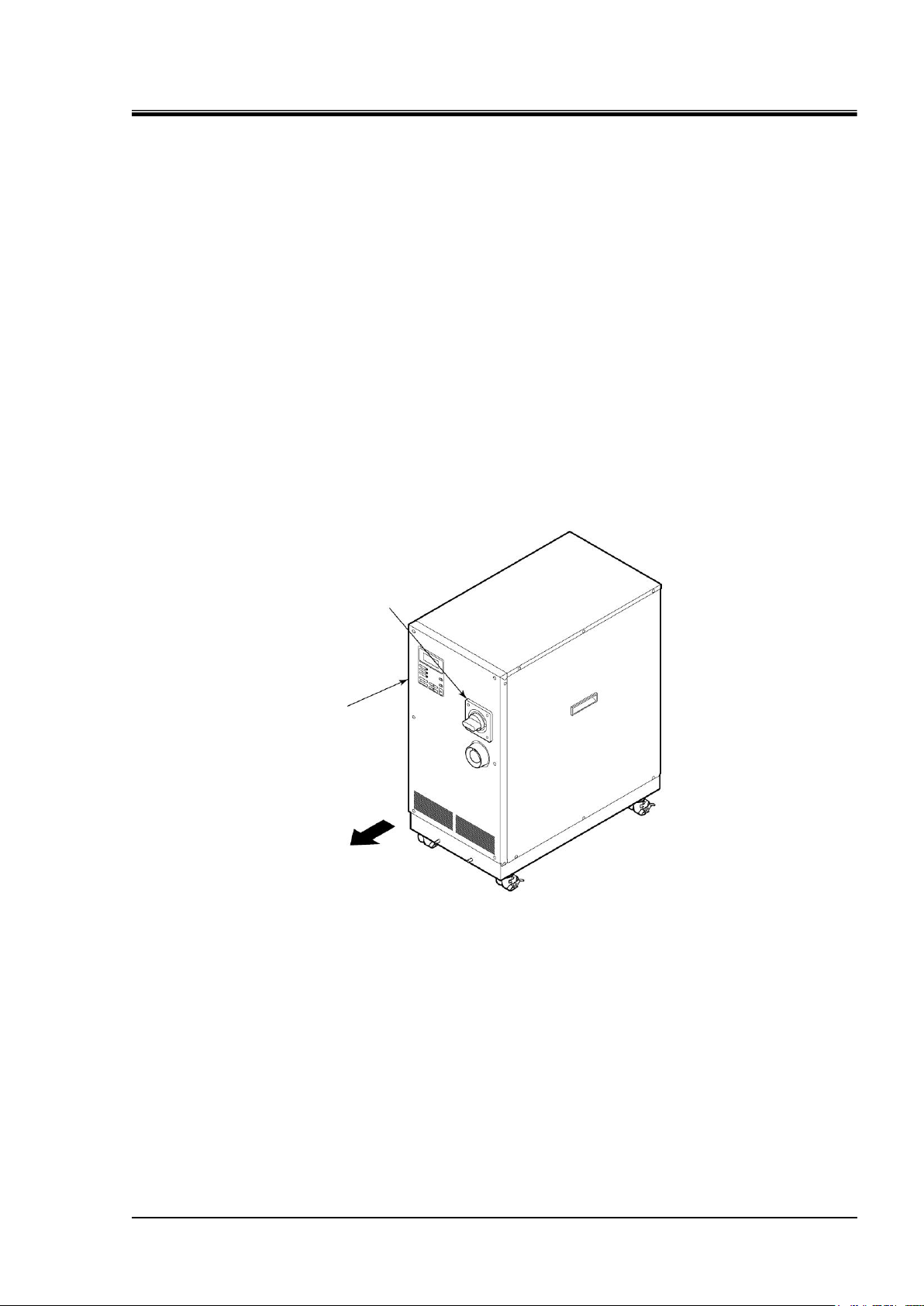

3.1.2 Transporting with caster

This system is heavy, which requires assistance for this work.

Exercise caution and look out for sloped surfaces such as ramps, etc.

Do not grab piping on the back of this system or panel handles when

transporting with the casters.

Potential damage to piping and panels may occur if disregarded.

System installation should be kept from areas with the potential of

flammable gas leak. Ignition may occur if leaked gas is collected

around the system.

This system is NOT designed for outside use.

Potential electric shock, fire and system damage may occur if exposed

to rain, water and dust.

This system is to be installed on a level floor that can withstand the

weight of this system. Potential water leak and personal injury due to

system tipping over may occur if disregarded.

3.2 Installation

HRX-OM-K003

Chapter 3 Transporting and Installation

HRW Series 3.2 Installation

Page 28

HRX-OM-K003

3-4

Chapter 3 Transporting and Installation

3.2.1 Installation conditions

System installation is not allowed outside or in the conditions described below.

Potential system malfunction and damage may occur if disregarded.

Clean room specifications are not applied to this system. The pump and ventilating

fan installed in this system generate particles.

Location that is exposed to water, water vapor, salt water, and oil

Location that is exposed to dust

Location that is exposed to corrosive gas, organic solvent, chemical solution,

and flammable gas (this system is not flame-proof)

Location where ambient temperature is out of the following range:

In transportation -40 to 70°C (with no water or circulating fluid in piping)

In storage 0 to 50°C (with no water or circulating fluid in piping)

In operation 10 to 35°C

Location where ambient humidity is out of the following range or where

condensation forms:

In transportation and storage 15 to 85%

In operation 30 to 70%

Location that is exposed to direct sun light or radiant heat

Location that is near heat sources and poor in ventilation

Location that is subjected to abrupt changes in temperature

Location that is subjected to intense electromagnetic noise (intense electric field,

intense magnetic field, or surges)

Location that is subjected to static electricity, or condition that discharges static

electricity to the system

Location that is subjected to strong high frequencies

Location that is subjected to potential lightning damage

Location with altitudes of 1000m or higher (except for system storage and

transport)

Location that is affected by strong vibrations or impacts

Condition that applies external force or weight causing the system deformation

Condition with no adequate space for maintenance as required

3.2 Installation HRW Series

Page 29

Chapter 3 Transporting and Installation

3-5

Front

Daily inspection area

Operation area

Front

3.2.2 Installation location and maintenance work area

This system does not have ventilating hole on the both right and left sides. Although this can be

installed directly contacting to walls or devices, installation with maintenance space is

recommended. (See “Figure 3-2”)

HRX-OM-K003

Figure 3-2 Recommended Installation Location

To save space, this system can be installed to allow access only in front and back for daily operation

and inspection. For maintenance and repair work, additional access space is required for the left and

right side of the system. We recommend a separate repair area, without taking space from

installation site, to accommodate the needed extra space.

Figure 3-3 Installation Location

HRW Series 3.2 Installation

Page 30

HRX-OM-K003

3-6

Anti-seismic bracket is an optional part, which is required for the installation of this

system (HRZ-TK002).

Preparation of anchor bolts suitable for floor material is your responsibility. Prepare

M12-anchor bolts (4 pcs.) for installation. See “8.6 Anchor Bolt Mounting Position” on

page 8-13 for mounting of the anchor bolt.

Figure 3-4 Anti-seismic Bracket Attachment

Drain pan port is assigned to the bottom on the back of this system. Exercise

caution not to damage the dain pan port when attaching the anti-seismic bracket.

Anti-seismic bracket (optional)

HRZ-TK002

M8 nut (2 pcs.)

(Accessory for anti-seismic bracket)

Caster w/ brake

Front

Brake

lever

M12 anchor bolt

Chapter 3 Transporting and Installation

3.3 Procedure for Installation

3.3.1 Installation

System installation should be on a vibration-free stable level plane.

See “Appendix 8.2 Outer Dimensions” in Chapter 8 on page 8-7 for the

dimensions of this system.

3.3.2 Procedure for system securing

1. Transfer this system to the installation site.

2. Lock the brakes on casters.

3. Using a13-mm open end wrench, attach the anti-seismic brackets to the front and back.

3.3 Procedure for Installation HRW Series

Page 31

3-7

3.3.3 Wiring installation

Item

Type

Power

cable

Size (recommended)

10AWG4-conductor

Crimp contact

(recommended)

Breaker

R5.5-8

Earth bar

R5.5-8

Torque

(recommended)

Breaker

12.5N•m (1.84 ft-lbf)

Earth bar

12.5N•m (9.22 ft-lbf)

Main breaker (This System)

30A

Connector

Type (for your system)

Contact signal (P1 connector)

D-Sub 25-pin (male)

Serial RS-485 (P2 connector)

D-Sub 9-pin (male)

Only designated personnel are allowed to install wiring.

Be sure to turn OFF the power prior to wiring to assure safety.

Do not do any wiring when the system is energized.

The system wiring requires not only a thorough connection with the

designated cable but also securing to prevent loose connection. Poor

connection and securing may cause electric shock, heat sports, fire or

communication errors.

Be sure to supply the power to this system according to specifications.

Supply pure AC power. Potential malfunction may occur if a rectified AC

with voltage rise (dv/dt)

at zero crossing exceeds 40V /200µ sec.

Always establish a connection to a ground for safety.

Be sure that no ground connection is made to

a water pipe, gas pipe and lighting rod.

V

dV

dt

dt

= Voltage ratio

on zero-cross point

dV

t

Voltage rise %

Time

Voltage

Power cable

The power cables are to be prepared under your responsibility, referring to the

following table.

HRX-OM-K003

Chapter 3 Transporting and Installation

Table 3-1 Power Cable and Main Breaker (This System)

Communication connector

The communication connectors are to be prepared under your responsibility,

referring to the following table.

Table 3-2 Communication Connector

HRW Series 3.3 Procedure for Installation

Page 32

HRX-OM-K003

3-8

This product is equipped with the breaker which has different

operating characteristics depending on each model. For the

customer’s equipment (primary side), use the breaker whose

operating time is equal to or longer than the breaker of this product. If

the breaker with shorter operating time is connected, the customer’s

equipment could be cut off du eto the inrush current of the motor of

this product.

100 135 200 300 400 500 600 700 1000 1500 2000 3000 4000 5000 7000 10000

4h

2h

1h

30min

20min

14min

10min

6min

4min

2min

1min

30s

20s

10s

5s

2s

1s

0.5s

0.2s

0.1s

0.05s

0.02s

0.01s

MAX

MIN

Current (% to the capacity of the main breaker of this product)

Operating Time

Figure 3-5 Breaker operating characteristics curve

Chapter 3 Transporting and Installation

Selection of the breaker for the customer’s equipment (primary side)

HRW002-H HRW008-H HRW015-H HRW030-H

HRW002-H1 HRW008-H1 HR W015-H1 HRW030-H1

HRW002-H2 HRW008-H2 HRW015-H2 HRW030-H2

HRW002-HS HRW008-HS HRW015-HS HRW030-HS

HRW002-H1S HRW008-H1S HRW015-H1S HRW030-H1S

HRW002-H2S HRW008-H2S HRW015-H2S HRW030-H2S

3.3 Procedure for Installation HRW Series

Page 33

HRX-OM-K003

3-9

M

F

Be sure to turn OFF the factory side (primary side) power before

connection to this system.

Use the assigned procedure to peform lockout/tagout (Page 1-10).

Figure 3-6 Main Breaker OFF and Removal of Front Panel/Breaker Cover

Front

Front panel

Screw

Screw

OFF

Breaker cover

Breaker

Main breaker OFF

Chapter 3 Transporting and Installation

3.3.4 Procedures for wiring installation

1. Turn OFF the power breaker on customer side (primary side), and then use the assigned

procedures to peform lockout/tagout.

[Tips]

Connection of the power cable with this system must be established first.

Do not connect the cable with the factory side at this point.

2. Turn OFF the main breaker of this system.

3. Undo the screws (2 pcs.) to remove the front panel.

Be sure to use a Phillips screwdriver.

4. Undo the screws (2 pcs.) to remove the breaker cover.

Be sure to use a Phillips screwdriver.

[Tips]

Make sure the breaker is at the ‘OFF’ position.

Otherwise, the removal of the front panel is not possible.

HRW Series 3.3 Procedure for Installation

Page 34

HRX-OM-K003

3-10

Figure 3-7 Power Cable Insertion and Communication Cable Connection

Correct phase rotation is required when attach the power cable to the

breaker terminal.

Do not drop a screw or washer in the electrical unit when attaching the

breaker cover and terminal.

Do not leave it in the unit if dropped in. Potential failure may occur if

the power is turned ON without removing it.

Cap

Power cable

Contact signal cable

Serial RS-485 communication cable

P1 (D-sub 25P female)

P2 (D-sub 9P female)

P3 (D-sub 9P male)

Not used.

(Only for maintenance)

Chapter 3 Transporting and Installation

5. Loosen the cap and insert the power cable from the power cable access.

6. Connect the communication cables with P1 and P2.

[Tips]

See “Table 3-1 Power Cable and Main Breaker (This System)” on page 3-7

for the recommended cable size and crimp contact.

3.3 Procedure for Installation HRW Series

Page 35

Chapter 3 Transporting and Installation

3-11

Figure 3-8 Connection of Power Cable and Grounding Terminal

Earth bar

Main

breaker

Grounding

terminal

Power cable

7. Connect the power cables to the breaker terminal.

Be sure to use a Phillips screwdriver. See Table 3-1 on page 3-7 for recommended torque.

8. Connect the grounding terminal (M8) of

the power cable to the earth bar.

Be sure to use a 13-mm open end wrench.

Recommended torque: 12.5 N•m (9.22 ft-lbf)

HRX-OM-K003

[Tips]

See “Table 3-1 Power Cable and Main Breaker (This System)” on page 3-7

for torque value.

9. Attach the breaker cover to the breaker.

10. Attach the front panel.

11. Connect the power cable to the power breaker on customer side (primary side).

HRW Series 3.3 Procedure for Installation

Page 36

HRX-OM-K003

3-12

Pipe

Diameter

Recommended torque

(Material: SS* vs SS)

Facility water inlet

Rc3/4

28 to 30N•m

(20.7 to 22.1ft-lbf)

Facility water outlet

Rc3/4

28 to 30N•m

(20.7 to 22.1ft-lbf)

Circulating fluid supply

Rc3/4

28 to 30N•m

(20.7 to 22.1ft-lbf)

Circulating fluid return

Rc3/4

28 to 30N•m

(20.7 to 22.1ft-lbf)

Tank drain port

Rc3/8 (with valve)

Piping not necessary

Drain pan port

Rc3/8

Piping not necessary

Choose proper external piping with consideration for pressure,

temperature and compatibility with the circulating fluid. Potential pipe

rupture during operation may occur if disregarded.

Always insulate external circulating piping. Potential insufficient cooling

performance due to heat absorption from the pipe surface and potential

insufficient heating performance caused by thermal radiation if

disregarded.

Use clean pipes and pipe fittings, free of particles, oil and moisture.

Apply air blow to the parts before using. The presence of particles, oil or

moisture in the circulating fluid circuit causes system failure attributed to

insufficient cooling or froths in the circulating fluid in the tank.

Install circulating fluid piping not to exceed 10m high. The maximum

amount of circulating fluid in piping, including your system, should

remain under 2.5L if 7m or higher circulating fluid piping is installed (for

HRW-H, -HS). An alarm may be raised, or potential fluid leak from the

tank may occur at system stop if disregarded.

Be sure to choose a circulating fluid pipe capable of letting the fluid flow

at rated flow rate or better. See “Pump performance” defined in

“Appendix 8.1.1 System specification” for the flow rate rating.

Have a drip pan available incase of a fluid leak.

Make sure of the locations of ports for the circulating fluid supply, return,

facility water inlet, outlet and their corresponding connections are

correct.

Install valves in circulating fluid piping for flow rate adjustment and

maintenance. As the value of flow rate displayed on the screen will be

less than proper value when flow rate is excessive, flow rate adjustment

should be started with the valves shut. See “Circulating fluid flow rate

display range” defined in “Appendix 8.1.1 System specification” for the

flow rate display range.

Secure the piping connector section with a pipe wrench, and provide

proper tightening to the pipe.

Avoid physical shock when securing and tightening the connectors.

Potential breakage and fluid leak may occur if disregarded.

Chapter 3 Transporting and Installation

3.3.5 Installation of circulating fluid and facility water piping

Pipe diameter

3.3 Procedure for Installation HRW Series

Table 3-3 Pipe Diameter

*: SS Stainless steel

Page 37

3-13

Procedure for piping installation

No.

Name

Size

Material

1

Valve

Rc3/4

Stainless steel

2

Y-strainer (100m)

Rc3/4

Stainless steel

3

Valve

Rc3/4

Stainless steel

4

Y-strainer (5m)

Rc3/4

Stainless steel

Figure 3-10 Recommended Piping Installation

Pipe coupling section

Figure 3-9 Pipe Tightening

System on the

customer side

Circulating fluid supply

Circulating fluid return

Facility water inlet

Facility water outlet

Secure the pipe coupling section with a pipe wrench, and provide proper tightening

to the pipe.

Recommended piping installation

HRX-OM-K003

Chapter 3 Transporting and Installation

Table 3-4 Recommended Pipe

HRW Series 3.3 Procedure for Installation

Page 38

HRX-OM-K003

3-14

Chapter 3 Transporting and Installation

3.3 Procedure for Installation HRW Series

Page 39

HRX-OM-K003

4-1

Only personnel, who have adequate knowledge of and experiences

with not only this system but associated equipment, are allowed to

implement system startup and shutdown.

Check that the facility water complies with not only the water quality

standard defined in section 7.1 “Water Quality Management” on page

7-1 but the requirements provided in “8.1.1 System specification” in

Chapter 8 Appendix on page 8-1.

Chapter 4 System Startup and Shutdown

Chapter 4 System Startup and Shutdown

4.1 Pre-check

Check the following items prior to starting up the system.

4.1.1 Installation condition

Make sure that the system is installed in a horizontal position.

No heavy object is placed on this system. This system should not be applied

with an undue force such as caused by piping installation.

Re-check the items defined in “3.2 Installation” on page 3-3.

4.1.2 Cable connection

Make sure proper connection of the power cable, ground, and communication

cables.

4.1.3 Installation of circulating fluid and facility water piping

Make sure that circulating fluid and facility water piping are installed properly.

4.1.4 Operating signal from your system

Make sure that no remote signal is being issued from your system. System startup

takes effect upon power-ON if this system receives a remote signal and it is in

remote mode.

4.1.5 Check emergency off [EMO] switch

Make sure of the location of the emergency off [EMO] switch before operating the

system. See section 1.6.1 “Emergency off [EMO] switch” in Chapter 1 “Safety”

for details.

4.2 Opening of Facility water Valve

Open the facility water valve for water supply.

HRW Series 4.1 Pre-check

Page 40

HRX-OM-K003

4-2

Rear

Circulating fluids to use vary with system models.

See section 8.1.1 “System specification” in Chapter 8 for the

designated circulating fluid for a specific model.

High concentration EG in the circulating fluid may cause circulating pump overload,

which triggers “Pump Breaker Trip FLT”.

Potential cooling error may occur if the circulating fluid varies in concentration.

Make sure of no oil, moisture, and other foreign materials contaminate the

circulating fluid. Potential cooling error or system failure, due to contaminant

freezes internally, may occur if disregarded.

Attention should be taken on water quality. Ensure water quality is within specified

range, and other foreign materials contaminate the circulating fluid. Potential

cooling error or system failure, due to contaminant freezes internally, may occur if

disregarded.

Circulating fluid fill port

Circulating fluid level gauge

Circulating fluid

specified level

Chapter 4 System Startup and Shutdown

4.3 Supply of Circulating Fluid

Figure 4-1 Circulating Fluid Fill Port and Circulating Fluid Level Gauge

4.3.1 Preparation of circulating fluid

When the circulating fluid is an ethylene glycol aqueous solution

Always check the concentration of the circulating fluid.

Normal concentration: 55 to 60%

When the circulating fluid is a fluorinated fluid

When the circulating fluid is water

4.3 Supply of Circulating Fluid HRW Series

Page 41

4-3

4.3.2 Supply of circulating fluid

When supplying the circulating fluid, make sure that the fluid inside

this system has dropped to room temperature for the prevention of

burns.

Circulating fluid must be supplied to be in the range between “HIGH”

and “LOW”. Potential overflow of hot circulating fluid may occur due

to excessive volume.

Total fluid volume use to fill up the system including initial priming

should not exceed combined volume of Sub Tank and Main Tank.

If level is below the “LOW” mark, this system will trigger an alarm.

Be sure to tighten the cap until it clicks after circulating fluid supply.

Potential circulating fluid vaporization may occur if disregarded.

Remove the circulating fluid fill cap, and fill the circulating fluid until it reaches its

specified level.

The circulating fluid specified level is a range between “HIGH” and “LOW” in

Figure 4-1.

Be sure to tighten the cap until it clicks after fluid supply.

If the circulating fluid is supplied over the specified level, follow the procedure

provided in section 7.3.1 “Draining of circulating fluid out of tank” on page 7-4 to

drain excess fluid until it reaches the specified level.

[Tips]

Level between “HIGH” and “LOW” represent liquid level in normal running

condition. Immediately as you start filling up the chiller, the internal

transferring pump start pumping fluid from the Sub Tank into the Main Tank.

Thus the fluid level in the level gauge will start to drop.

During initial priming of the external piping, addition fluid is needed. See

section 8.1.1 “System specification” on page 8-1 for Sub Tank and Main Tank

capacity.

HRX-OM-K003

Chapter 4 System Startup and Shutdown

HRW Series 4.3 Supply of Circulating Fluid

Page 42

HRX-OM-K003

4-4

Figure 4-2 Main Breaker at ‘ON’

Press the emergency off [EMO] switch immediately upon ocurrence of

abnormal conditions. Be sure to turn OFF the main breaker afterwards.

Front

ON

Model Indication screen

Status screen 1

Chapter 4 System Startup and Shutdown

4.4 Requirement for System Startup

4.4.1 Turning ON power

1. Make sure that the main breaker for this system is OFF, and release lockout/tagout of the

power breaker on customer side (primary side). Then, turn ON the power.

2. Turn ON the main breaker of this system.

The “Model Indication screen” are displayed in sequence on the LCD screen. The screen will change to the

“Status screen 1” in approx. 20 seconds, and the system is ready to run.

4.4 Requirement for System Startup HRW Series

Page 43

Chapter 4 System Startup and Shutdown

4-5

Internal equipment may remain at elevated in temperature immediately

after system shutdown. Potential burns may happen if your skin

comes in contact with these surfaces. Further work is allowed only

when the system reaches room temperature.

Emergency off [EMO] switch and main breaker (OFF) should not be

used for system shutdown unless it is an emergency.

4.4.2 Circulating fluid temperature setting

From the “Setting screen” on the LCD screen, set the circulating fluid at any

temperature. See section 5.4 “Examples of System Operation” in “Chapter 5

System Operation” on page 5-11 for operating procedure.

[Tips]

See section 8.1.1 “System specification” in “Chapter 8 Appendix” on page 8-1

for the setting range of circulating fluid temperature.

4.5 System Startup and Shutdown

4.5.1 System startup

Press the [START/STOP] key on the operation display panel.

The ‘RUN’ lamp on the operation display panel comes on, and system operation is initiated

4.5.2 System shutdown

Press the [START/STOP] key on the operation display panel.

HRX-OM-K003

‘RUN’ lamp on the operation display panel goes out, and the system comes to a halt accordingly.

HRW Series 4.5 System Startup and Shutdown

Page 44

HRX-OM-K003

4-6

Chapter 4 System Startup and Shutdown

4.5 System Startup and Shutdown HRW Series

Page 45

5-1

Chapter 5 System Operation

Be sure to use your fingers only to operate the Operation Display Panel.

Using sharp object will damage the panel.

Operation Display Panel

[RESET] key

Used to stop an alarm

buzzer and initialize the

alarm.

“REMOTE” lamp

This comes on when the

system is in remote mode.

“RUN” lamp

This comes on when the

equipment is running.

[START/STOP] key

Used to start and stop the operation.

[SEL] key

Used to select the

screen.

[ENT] key

Used to determine a set value.

[▲][▼] key

Used to move the cursor and change set

values.

“LCD screen”

“ALARM” lamp

This comes on when an

alarm is raised.

[ ]key

Used to move the cursor

when setting data.

5.1 Operation Display Panel

Use the operation display panel located in front of the system for the basic

operations.

HRX-OM-K003

Chapter 5 System Operation

Figure 5-1 Operation Display Panel

HRW Series 5.1 Operation Display Panel

Page 46

HRX-OM-K003

5-2

Screen

Descriptions

Reference

Model Indication screen

Displays the model and revision No. of this system.

Page 5-3

Status screen 1, 2, 3, 4

Displays the operating condition of this system.

Page 5-3

Page 5-5

Menu screen 1, 2

Allows setting screen selection.

Page 5-5

Setting screen

Allows the setting of TEMP SP value.

Page 5-6

Mode Selection screen

Allows communication mode selelction.

Page 5-6

Initial Setting screen 1, 2, 3, 4, 5

Allows the setting of set values.

Page 5-7

Maintenance screen 1, 2

Not used during system operation.

Not allowed to use unless otherwise specified.

Page 5-9

Option screen

Allows the setting of option.

Page 5-9

Alarm Display screen

The alarm message is displayed in the event of an error in

this system.

Not displayed if no error.

Page 5-10

Information screen

Displayed upon system power-ON.

Disables system operation when displayed.

Page 5-10

Chapter 5 System Operation

5.2 Flow Chart of Operation Screen

Figure 5-2 Flow Chart of

Operation Screen

[Tips]

With the press of the [SEL] key, the screen is switched to the “Menu screen 1”

regardless of the screen status.

Table 5-1 Descriptions of Operation Screens

5.2 Flow Chart of Operation Screen HRW Series

Page 47

Chapter 5 System Operation

5-3

No.

Item

Descriptions

1

-

System model 2 -

System revision No.

No.

Item

Descriptions

1

TEMP PV

Discharge temperature of the circulating fluid

(A value derived according to the offset*1 if applied)

2

FLOW PV

Flow rate of the circulating fluid

3

PRESS

Discharge pressure of the circulating fluid

4

F. TEMP PV

Facility water inlet temperature

1

2

1 2 3

4

5.3 Operation Screen

5.3.1 Model Indication screen

Figure 5-3 Model Indication Screen

The “Model Indication screen” is displayed upon power-ON of this system.

This screen remains ON for approx. 20 seconds and is automatically switched to the “Status screen 1”.

The “Alarm Display screen” is displayed if error occurs in this system.

Table 5-2 Model Indication Screen

HRX-OM-K003

5.3.2 Status screen 1

Figure 5-4 Status Screen 1

Table 5-3 Status Screen 1

[Tips]

See “Appendix 8.4 Offset Function” in Chapter 8 on page 8-9 for details on

offset (*1).

HRW Series 5.3 Operation Screen

Page 48

HRX-OM-K003

5-4

No.

Item

Descriptions

1

TEMP PV

Discharge temperature of the circulating fluid

(A value derived according to the offset*1 if applied)

2

TEMP SP

Set circulating fluid temperature

3

OFFSET

Set offset

4

OFFSET

The current offset mode

No.

Item

Descriptions

1

TEMP PV

Discharge temperature of the circulating fluid

2

TEMP SP

Set circulating fluid temperature

3

<<TEMP READY>>

Displays the BAND/READY [Displayed when set value

conditions are satisfied]*1

4

TEMP BAND

Set value of BAND range*1

1

2

3 4 1 2 3

4

Chapter 5 System Operation

5.3.3 Status screen 2

[Tips]

See “Appendix 8.4 Offset Function” in Chapter 8 on page 8-9 on offset

features (*1).

5.3.4 Status screen 3

Figure 5-5 Status Screen 2

Table 5-4 Status Screen 2

Figure 5-6 Status Screen 3

Table 5-5 Status Screen 3

[Tips]

See “Appendix 8.5 BAND/READ” in Chapter 8 on page 8-12 on offset

features (*1).

5.3 Operation Screen HRW Series

Page 49

5-5

5.3.5 Status screen 4

No.

Item

Descriptions

1

FLOW PV*1

Discharge flow rate of the circulating fluid

2

FLOW SP*1

Set Discharge flow rate

No.

Item

Descriptions

1

SETTING

Swicthes to the “Setting screen” with the press of the [ENT] key.

2

REMOTE/LOCAL

Swicthes to the “Mode Selection screen” with the press of the

[ENT] key.

3

INITIAL SET

Swicthes to the “Initial Setting screen 1” with the press of the

[ENT] key.

4

MAINTENANCE

Swicthes to the “Maintenance screen 1” with the press of the

[ENT] key.

5

OPTION

Swicthes to the “Option screen” with the press of the [ENT] key.

1 2 3

4 5 1

2

HRX-OM-K003

Chapter 5 System Operation

*Status screen 4 is only indicated on HRW-HS

(pump inverter type).

Figure 5-7 Status Screen 4

Table 5-6 Status Screen 4

[Tips]

When using accessory [by-pass piping set] flow becomes total of flow on

customer side and flow on by-pass (*1).

5.3.6 Menu screen

Figure 5-8 Menu Screen

Table 5-7 Menu Screen

HRW Series 5.3 Operation Screen

Page 50

HRX-OM-K003

5-6

No.

Item

Setting range

1

TEMP SP

20.0 to 90.0°C

2

FLOW SP

10 to 40LPM(2.6 to 10.6GPM)

FLOW SP is only indicated on HRW-HS and Setting is available*2.

No.

Item

Setting

1

MODE

LOCAL

System start/stop and TEMP SP value setting are available only from the

operation display panel.

DIO REMOTE

System start/stop is allowed only through contact signal. TEMP SP value

setting is available only from the operation display panel.

SER REMOTE

System start/stop and TEMP SP value setting are available only through

serial RS-485 communication.

1 1 2

Chapter 5 System Operation

5.3.7 Setting screen

Figure 5-9 Setting Screen

This screen enables the setting of TEMP SP value.

Not available if the communication mode is in “SER REMOTE”

Table 5-8 Setting Screen

[Tips]

See “Mode Selection screen” in Chapter 5 on page 5-6 for details on “SER

REMOTE” (*1).

See “Appendix 8.1.1 System specification” in Chapter 8 on page 8-1 for

setting range. (*2).

5.3.8 Mode Selection screen

*1

.

Figure 5-10 Mode Selection Screen

This screen enables the selection of the communication mode. The procedures for system start/stop and TEMP SP

value setting may vary with the communication mode.

Other operations and settings are available only from the operation display panel.

Table 5-9 Mode Selection Screen

5.3 Operation Screen HRW Series

Page 51

5-7

5.3.9 Initial Setting screen

1 2 3 4 5 6 7 8 9

10

11

12

13

Figure 5-11 Initial Setting Screen

HRX-OM-K003

Chapter 5 System Operation

HRW Series 5.3 Operation Screen

Page 52

HRX-OM-K003

5-8

No.

Item

Setting range

Descriptions

1

TEMP BAND

1.0 to 5.0°C *1

Allows the selection of the band width for TEMP SP.

2

READY TIME

10 to 480sec*1

Allows the setting of the time from TEMP PV value

reaching BAND range to TEMP READY is displayed

and put out.

3

OFFSET

-20.0 to 20.0°C *2

Calibrates variations in temperature between this

system and your system.

(See “Appendix 8.4 Offset Function” in Chapter 8 on

page 8-9 for details.)

4

OFFSET

OFF, MODE1, MODE2,

MODE3

5

HIGH TEMP

20 to 93°C

Issues an alarm of “Reservoir High Temp WRN” if the

circulating fluid exceeds the set temperature.

6

LOW FLOW

HRW002-H, H*S:

0, 2~16LPM

0, 0.5~4.2GPM

HRW008-H, -H*S

HRW015-H, -H*S

HRW030-H, -H*S:

0, 8~50LPM

0, 2.1~13.2GPM

Issues an alarm of “Return Low Flow WRN” if the

circulating fluid does not reach the set flow rate.

Lift this alarm if the selection is “0”.

7

FLOW UNIT

LPM, GPM

Allows the selection of the unit of flow rate.

8

PRESS UNIT

MPa, PSI

Allows the selection of the unit of pressure.

9

SLAVE

ADRS.

1 to 16CH

Allows the selection of the slave address for serial

RS-485 communication.

10

OUT

N/A

ALARM1 to 23

Allows the selection of alarm signals for contact

signal. (See Appendix 8.1.3 Alarm signal selection”

on page 8-6 for details.)

11

E_OUT

TEMP READY,

AUTO PURGE*1

Allows the selection of EVENTOutput.

(See Appendix 8.1.2 Communication specification”

on page 8-4 for details.)

12

F.LOW TEMP

5 to 10°C

Issues an alarm of “F.Water Low Temp WRN” if the

facility water falls below the set temperature.

13

F.HIGH

TEMP

35 to 50°C

Issues an alarm of “F.Water High Temp WRN” if the

circulating fluid exceeds the set temperature.

Chapter 5 System Operation

This screen enables the setting of set values.

Table 5-10 Initial Setting Screen

[Tips]

Valid during option setting with “5.3.11 Option screen“ on page 5-9.

See “Appendix 8.5 BAND/READ” in Chapter 8 on page 8-12 on

BAND/READY function (*1).

TEMP SP+OFFSET value (*2) should be in the TEMP SP setting range

defined in “Table 5-8 Setting Screen” on page 5-6.

5.3 Operation Screen HRW Series

Page 53

5-9

5.3.10 Maintenance screen

No.

Item

Setting

1

VALVE

OPEN

The facility water solenoid valve is opened forcefully.

CLOSE

The facility water solenoid valve is closed forcefully.

No.

Item

Setting

1

CUSTOM DIO

ON / OFF

Allows the selection of Valid / invalid.

(See “Communication specifications” for details.)

2

TEMP READY

ON / OFF

Allows the selection of valid / invalid of BAND / READY function.

This becomes valid after turning off the power, then supply the power

again.

1

1

2

Table 5-11 Maintenance Screen

HRX-OM-K003

Chapter 5 System Operation

Figure 5-12 Maintenance Screen

[Tips]

Available only if a solenoid value (optional) is provided.

5.3.11 Option screen

Figure 5-13 Option Screen

Table 5-12 Option Screen

HRW Series 5.3 Operation Screen

Page 54

HRX-OM-K003

5-10

No.

Item

Setting

1

Initialize Mode

Displayed upon system power-ON.

Disables system operation when displayed.

1

Chapter 5 System Operation

5.3.12 Alarm Display screen

Figure 5-14 Alarm Display Screen

In the event of an error in this system, the current screen is switched to the Alarm Display screen to display the

relevant alarm code. And message.

The Alarm Display screen is displayed only if an error is raised.

See section 6.2 “Troubleshooting” in “Chapter 6 Error Message and Troubleshooting” for alarm numbers and

messages.

5.3.13 Information screen

Figure 5-15 Information screen

The above “Information screen” may be displayed in response to system startup and shutdown.

Table 5-13 Information screen

5.3 Operation Screen HRW Series

Page 55

HRX-OM-K003

5-11

Chapter 5 System Operation

5.4 Examples of System Operation

5.4.1 Example 1: Circulating fluid set temperature is changed from

25.0°C to 34.1°C.

Figure 5-16 Change of Set Temperature from 25.0°C to 34.1°C

1. Press the [SEL] key to display the “Menu

screen 1”.

2. With the use of the arrow keys ([▲], [▼]),

move the cursor to “1. SETTING” and

press the [ENT] key.

The “Setting screen” is displayed.

3. Press the [ENT] key.

Figure 5-17 Menu Screen 1

Figure 5-18 Setting Screen

The cursor is now appear on the current value for

TEMP SP, which enables change of the

temperature set value.

Figure 5-19 Setting Screen: Cursor Display

HRW Series 5.4 Examples of System Operation

Page 56

HRX-OM-K003

5-12

Figure 5-20 Setting Screen: Change of Set Value

Chapter 5 System Operation

4. Use the arrow keys ([▲], [▼], [ ]) to

change the temperature to 34.1°C.

[▲] key: Used to add one value on which the cursor is placed.

[▼] key: Used to subtract one value on which the cursor is

placed.

[ ] key: Used to move the cursor to the right.

[Tips]

To cancel a selection, press the [SEL] key, not [ENT] key. With the press of

the [SEL] key, the cancellation takes effect and the screen is switched to the

“Menu screen 1”.

5. Press the [ENT] key with a new set

temperature (34.1°C) entered.

The cursor goes out, and the setting takes effect.

Figure 5-21 Setting Screen: Setting Confirmation

6. Press the [SEL] key to display the “Menu screen 1”.

5.4 Examples of System Operation HRW Series

Page 57

HRX-OM-K003

5-13

Chapter 5 System Operation

5.4.2 Example 2: Communication mode is switched from “DIO

REMOTE” to “LOCAL”.

Figure 5-22 Switching of Communication Mode from “DIO REMOTE” to “LOCAL”

1. Press the [SEL] key to display the “Menu

screen 1”.

2. With the use of the arrow keys ([▲], [▼]),

move the cursor to “2. REMOTE/LOCAL”

and press the [ENT] key.

The “Mode Selection screen” is displayed.

The name of the current mode flashes.

3. Use the arrow keys ([▲], [▼]) to select

“LOCAL”.

Figure 5-23 Menu Screen 1

Figure 5-24 Mode Selection Screen: DIO REMOTE

Figure 5-25 Mode Selection Screen: LOCAL

4. Press the [ENT] key.

The mode name stop flashing, and the selection

takes effect.

Figure 5-26 Mode Selection Screen: Setting Confirmation

[Tips]

To cancel a selection, press the [SEL] key, not [ENT] key. With the press of

the [SEL] key, the cancellation takes effect and the screen is switched to the

“Menu screen 1”.

5. Press the [SEL] key to display the “Menu screen 1”.

HRW Series 5.4 Examples of System Operation

Page 58

HRX-OM-K003

5-14

Chapter 5 System Operation

5.4.3 Example 3: Alarm signal of contact signal is changed from

“N/A” to “ALARM1”.

Figure 5-27 Change of Alarm Signal of Contact signal from “N/A” to “ALARM1”

1. Press the [SEL] key to display the “Menu

screen 1”.

2. With the use of the arrow keys ([▲], [▼]),

move the cursor to “3. INITIAL SET” and

press the [ENT] key.

The “Initial Setting screen 1” is displayed.

3. Use the arrow keys ([▲], [▼]) to display

the “Initial Setting screen 3”, which

prompts “OUT” to flash.

Figure 5-28 Menu Screen 1

Figure 5-29 Initial Setting Screen 1

The name of the current mode flashes.

Figure 5-30 Initial Setting Screen 3: OUT

4. Press the [ENT] key.

Only the current mode flashes.

Figure 5-31 Initial Setting Screen 3: N/A

5.4 Examples of System Operation HRW Series

Page 59

5-15

5. Use the arrow keys ([▲], [▼]) to select

“ALARM1”.

6. Press the [ENT] key.

“OUT” flashes again, and the selection takes

effect.

[Tips]

To cancel a selection, press the [SEL] key, not [ENT] key. With the press of

the [SEL] key, the cancellation takes effect and the screen is switched to the

“Menu screen 1”.

HRX-OM-K003

Chapter 5 System Operation

Figure 5-32 Initial Setting Screen 3: ALARM1

Figure 5-33 Initial Setting Screen 3:

Setting Confirmation (OUT)

7. Press the [SEL] key to display the “Menu screen 1”.

HRW Series 5.4 Examples of System Operation

Page 60

HRX-OM-K003

5-16

Chapter 5 System Operation

5.4 Examples of System Operation HRW Series

Page 61

Chapter 6 Error Message and Troubleshooting

6-1

LCD screen

“ALARM” lamp is

ON.

Alarm Display screen (Alarm No. and alarm message)

Front

Chapter 6 Error Message and

Troubleshooting

6.1 Error Message

The following are to be performed in the event of an error in this system.

The “ALARM” lamp comes on.

Alarm buzzer comes on.

The “Alarm Display screen” is displayed on the LCD screen.

Error signal is issued through external communication.

(See section 8.1.2 “Communication specification” in Chapter 8 on page 8-4

Appendix for details.)

This system is brought to a stop forcefully according to error types.

HRX-OM-K003

HRW Series 6.1 Error Message

Figure 6-1 Error Occurrence

Page 62

HRX-OM-K003

6-2

Code

Error message

System

condition

Cause

Remedies

01

Water Leak

Detect FLT

Stop

The fluid is pooled at the base

of this system.

Check for fluid leak.

02

Incorrect Phase

Error FLT

Stop

The power phase rotation is

wrong.

Check that a proper connection

is established between the

power cable and main breaker

of this system.

05

Reservoir Low

Level FLT

Stop

An insufficient amount of the