Page 1

HRX-OM-R039

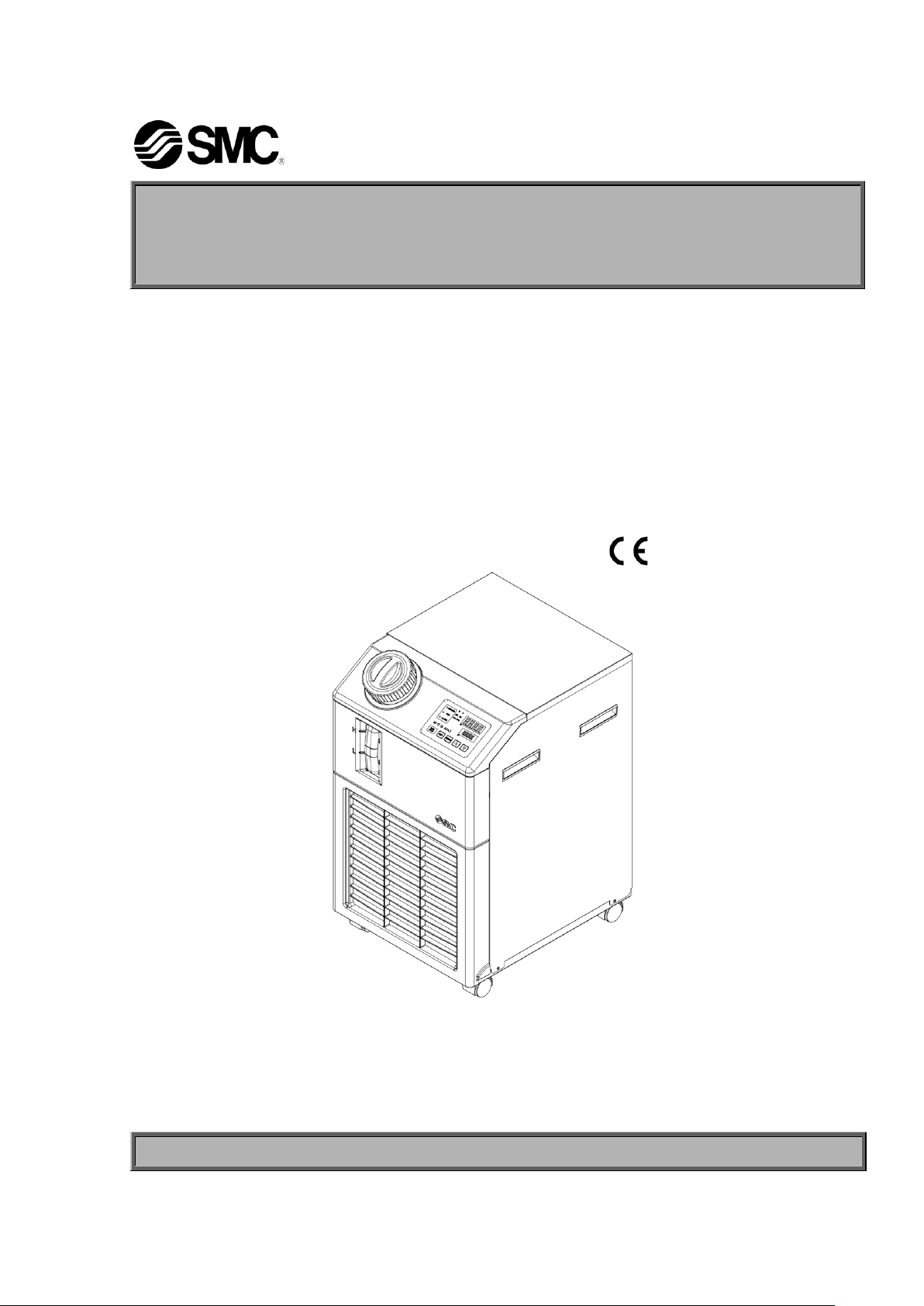

Air-Cooled refrigerated type

HRSE012/018/024 Series

1st edition: Dec. 2013

Rev.E: Feb. 2017

Operation Manual

Installation・Operation

Original Instructions

Thermo chiller

[ HRSE012/018/024-A-23(-T) ]

Keep this manual available whenever necessary

© 2017 SMC CORPORATION All Rights Reserved

Page 2

To the users

Note: This manual is subject to possible change without prior notice.

Thank you for purchasing SMC’s Thermo chiller (hereinafter referred to as the “product”).

For safety and long life of the product, be sure to read this operation manual (hereinafter referred to as the

“manual”) and clearly understand the contents.

Be sure to read and follow all instructions noted with “Warning” or “Caution” in this manual.

This manual is intended to explain the installation and operation of the product. Only people who

understand the basic operation of the product through this manual or who perform installation and

operation of or have basic knowledge about industrial machines are allowed to work on the product.

This manual and other documents attached to the product do not constitute a contract, and will not

affect any existing agreements or commitments.

It is strictly prohibited to copy this manual entirely or partially for the use by a third party without prior

permission from SMC.

Page 3

HRX-OM-R039

Contents

Contents

Chapter 1 Safety Instructions ........................................................... 1-1

1.1 Before using the product ........................................................................................ 1-1

1.2 Reading the Manual ................................................................................................ 1-1

1.3 Hazards .................................................................................................................... 1-2

1.3.1 Level of hazards .................................................................................................................. 1-2

1.3.2 Definition of “Serious injury” and “Minor injury” ................................................................... 1-2

1.3.3 Types of hazard labels ........................................................................................................ 1-3

1.3.4 Locations of Hazard Labels ................................................................................................. 1-4

1.4 Other Labels ............................................................................................................ 1-5

1.4.1 Product Label ...................................................................................................................... 1-5

1.5 Safety Measures ...................................................................................................... 1-5

1.5.1 Safety Instructions for Use .................................................................................................. 1-5

1.5.2 Personal Protective Equipment ........................................................................................... 1-6

1.6 Emergency Measures.............................................................................................. 1-7

1.7 Waste disposal ........................................................................................................ 1-8

1.7.1 Disposal of refrigerant and compressor oil.......................................................................... 1-8

1.7.2 Disposal of product .............................................................................................................. 1-8

1.8 Material Safety Data Sheet (MSDS) ........................................................................ 1-8

Chapter 2 Name and Function of Parts ............................................ 2-1

2.1 Part number of product ........................................................................................... 2-1

2.2 Name and Function of Parts ................................................................................... 2-2

2.3 Function of Parts ..................................................................................................... 2-3

2.4 Operation display panel .......................................................................................... 2-4

Chapter 3 Transport and Setting Up ................................................. 3-1

3.1 Transport.................................................................................................................. 3-1

3.1.1 Transportation using casters ............................................................................................... 3-2

3.2 Installation ............................................................................................................... 3-3

3.2.1 Environment ........................................................................................................................ 3-3

3.2.2 Location (Required ventilation rate and facility water source) ............................................ 3-4

3.2.3 Installation and Maintenance Space ................................................................................... 3-5

3.3 Installation ............................................................................................................... 3-6

3.3.1 Mounting .............................................................................................................................. 3-6

3.3.2 Electrical wiring ................................................................................................................... 3-7

3.3.3 Preparation and wiring of power supply cable .................................................................... 3-8

3.4 PIPING .................................................................................................................... 3-10

3.5 Fill of circulating fluid ........................................................................................... 3-12

Chapter 4 Starting the Product ......................................................... 4-1

4.1 Before Starting ........................................................................................................ 4-1

4.2 Preparation for Start ................................................................................................ 4-2

HRS Series

Page 4

HRX-OM-R039

Contents

4.2.1 Power supply ....................................................................................................................... 4-2

4.2.2 Setting of circulating fluid temperature ................................................................................ 4-2

4.3 Preparation of circulating fluid ............................................................................... 4-3

4.4 Starting and Stopping .............................................................................................. 4-5

4.4.1 Starting the product .............................................................................................................. 4-5

4.4.2 Stopping the product ............................................................................................................ 4-6

4.5 Check items after starting ....................................................................................... 4-7

4.6 Adjustment of Circulating Fluid .............................................................................. 4-7

Chapter 5 Display and setting of various functions ....................... 5-1

5.1 Function.................................................................................................................... 5-1

5.1.1 Key operations ..................................................................................................................... 5-1

5.1.2 Key operations ..................................................................................................................... 5-2

5.1.3 List of parameters ................................................................................................................ 5-4

5.2 Main screen ................................ ................................................................ .............. 5-7

5.2.1 Main screen ......................................................................................................................... 5-7

5.2.2 Display on the main screen ................................................................................................. 5-7

5.3 Alarm display menu ................................................................................................. 5-8

5.3.1 Alarm display menu ............................................................................................................. 5-8

5.3.2 Content of display of alarm display menu ............................................................................ 5-8

5.4 Inspection monitor menu ........................................................................................ 5-9

5.4.1 Inspection monitor menu ..................................................................................................... 5-9

5.4.2 Checking of the Inspection monitor menu ........................................................................... 5-9

5.5 Alarm buzzer sound setting .................................................................................. 5-12

5.5.1 Alarm buzzer sound setting ............................................................................................... 5-12

5.5.2 Alarm buzzer sound setting and checking ........................................................................ 5-12

5.6 Alarm customize function ..................................................................................... 5-13

5.6.1 Alarm customize function................................................................................................... 5-13

5.6.2 Alarm customize function setting and checking ................................................................ 5-13

5.6.3 Setting of temperature alarm monitoring method and alarm generation timing ................ 5-21

5.7 Data reset function ................................................................................................. 5-23

5.7.1 Data reset function ............................................................................................................. 5-23

5.7.2 Method of resetting data reset function ............................................................................. 5-23

5.8 Accumulated time reset function .......................................................................... 5-24

5.8.1 Accumulated time reset function ....................................................................................... 5-24

5.8.2 Method of resetting accumulated time reset function ........................................................ 5-24

5.9 Function to recover from power failure ................................................................ 5-26

5.9.1 Function to recover from power failure .............................................................................. 5-26

5.9.2 Function to recover from power failure setting and checking ........................................... 5-27

Chapter 6 Alarm indication and trouble shooting ........................... 6-1

6.1 Alarm Display ........................................................................................................... 6-1

HRS Series

Page 5

HRX-OM-R039

Contents

6.2 Alarm buzzer stop ................................................................................................... 6-2

6.3 Troubleshooting ...................................................................................................... 6-3

6.4 Other Errors ............................................................................................................. 6-4

Chapter 7 Control, Inspection and Cleaning ................................... 7-1

7.1 Control of Circulating Fluid Quality ....................................................................... 7-1

7.2 Inspection and Cleaning ......................................................................................... 7-2

7.2.1 Daily check .......................................................................................................................... 7-2

7.2.2 Monthly check ..................................................................................................................... 7-3

7.2.3 Inspection every 3 months .................................................................................................. 7-4

7.2.4 Inspection for winter season................................................................................................ 7-4

7.3 Consumables ........................................................................................................... 7-5

7.4 Stop for a Long Time ............................................................................................... 7-5

7.4.1 Discharge of the circulating fluid ......................................................................................... 7-5

Chapter 8 Documents ........................................................................ 8-1

8.1 Specifications List ................................................................................................... 8-1

8.1.1 Product specification ........................................................................................................... 8-1

8.1.2 Refrigerant with GWP reference ......................................................................................... 8-4

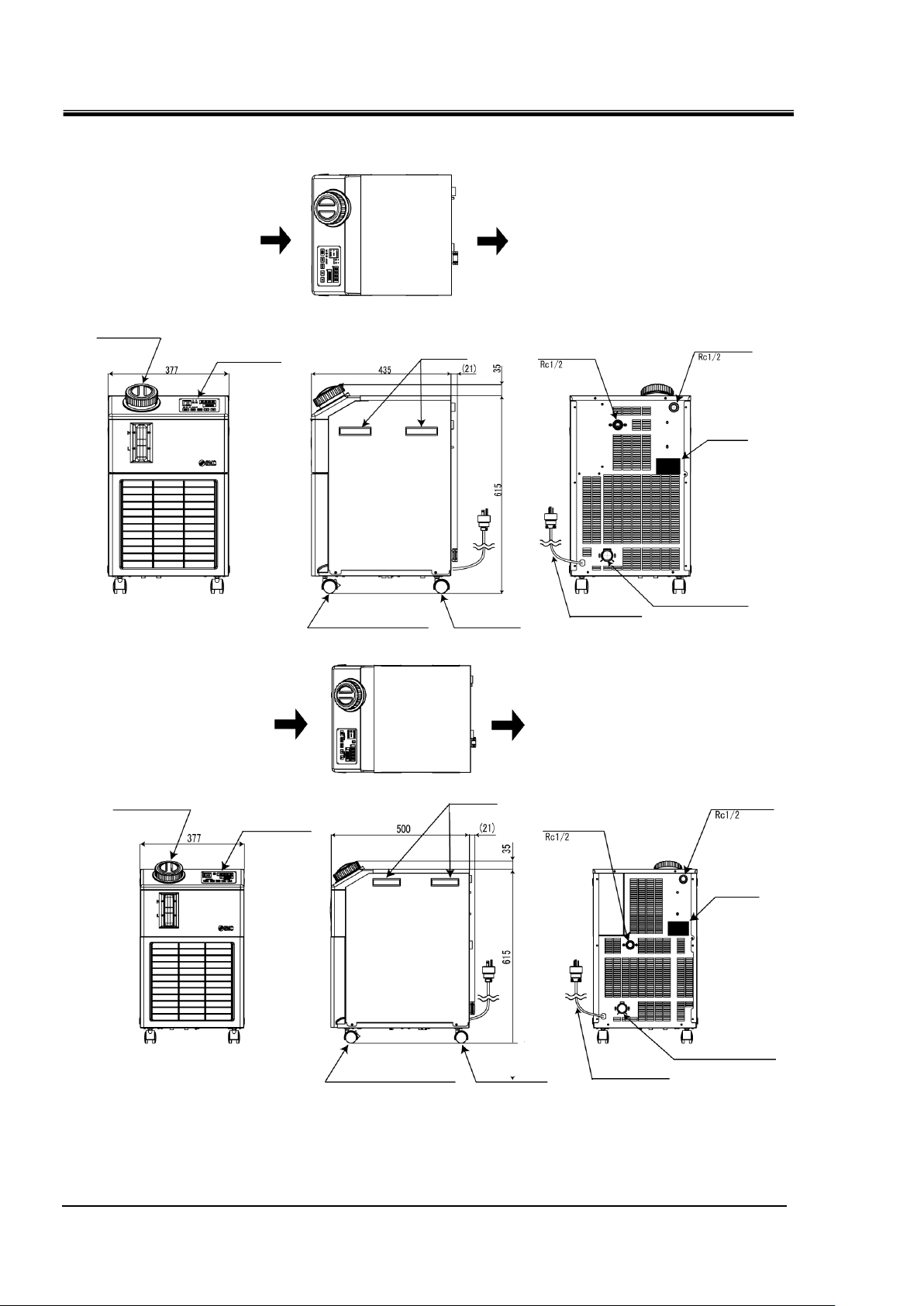

8.2 Outline dimensions ................................ ................................................................. 8-5

8.3 Flow chart ................................................................................................................ 8-6

8.4 Cooling capacity ...................................................................................................... 8-7

8.4.1 HRSE012-A-10-(T) .............................................................................................................. 8-7

8.4.2 HRSE018-A-10-(T) .............................................................................................................. 8-7

8.4.3 HRSE012-A-20/23-(T) ......................................................................................................... 8-7

8.4.4 HRSE018-A-20/23-(T) ......................................................................................................... 8-8

8.4.5 HRSE024-A-20/23-(T) ......................................................................................................... 8-8

8.5 Pump capacity ......................................................................................................... 8-9

8.5.1 HRSE012/018-A-10 ............................................................................................................. 8-9

8.5.2 HRSE012/018/024-A-20/23 ................................................................................................ 8-9

8.5.3 OPTION-T (HRSE012/018-A-10-T)................................................................................... 8-10

8.5.4 OPTION-T (HRSE012/018/024-A-20/23-T) ...................................................................... 8-10

8.6 Sample DoC. (Power supply “-23”only) ............................................................. 8-11

8.7 Daily Check Sheet ................................................................................................. 8-12

Chapter 9 Product Warranty ........................................................... 9-13

HRS Series

Page 6

HRX-OM-R039

Contents

HRS Series

Page 7

Chapter 1 Safety Instructions

1-1

Before using the product be sure to read and understand all the

important actions highlighted in this manual.

This sign indicates actions that must be followed.

This sign indicates prohibited actions.

Chapter 1 Safety Instructions

1.1 Before using the product

This chapter is intended to specifically describe the safety related issues

for handling the product. Read this before handling the product.

The product is a cooling device using circulating fluid. SMC does not take

any responsibility for any problems that may arise from using the product

for other purposes.

This product is for indoor use only and not to be used outdoors.

This product is not designed for a clean room. It generates dust from the

internal components such as pump and fan motor.

The product is operated at high voltage and contains components which

become hot and rotate. If a component needs to be replaced or repaired,

contact a specialized vendor for parts and service.

HRX-OM-R039

All personnel who work with or around the product should read and

understand the safety related information in this manual carefully before

starting work.

The safety manager is responsible for strictly observing safety standards,

but responsibility in respect to safety standards during daily work resides

with each individual operator and maintainance personnel.

Do not use the materials that rust or corrode for the circulating fluid

and facility water circuits. Using the materials that tend to rust or

corrode may cause clogs or/and leakages of the circulating fluid and

facility water circuits. In case of using these kind of materials, consider and

carry out some prevention against the rusting or corrosion by the customer

side.

This manual must be kept available to operators whenever necessary.

1.2 Reading the Manual

This manual contains symbols to help identify important actions when

installing, operating or maintaining the product.

HRSE Series 1.1 Before using the product

Page 8

HRX-OM-R039

1-2

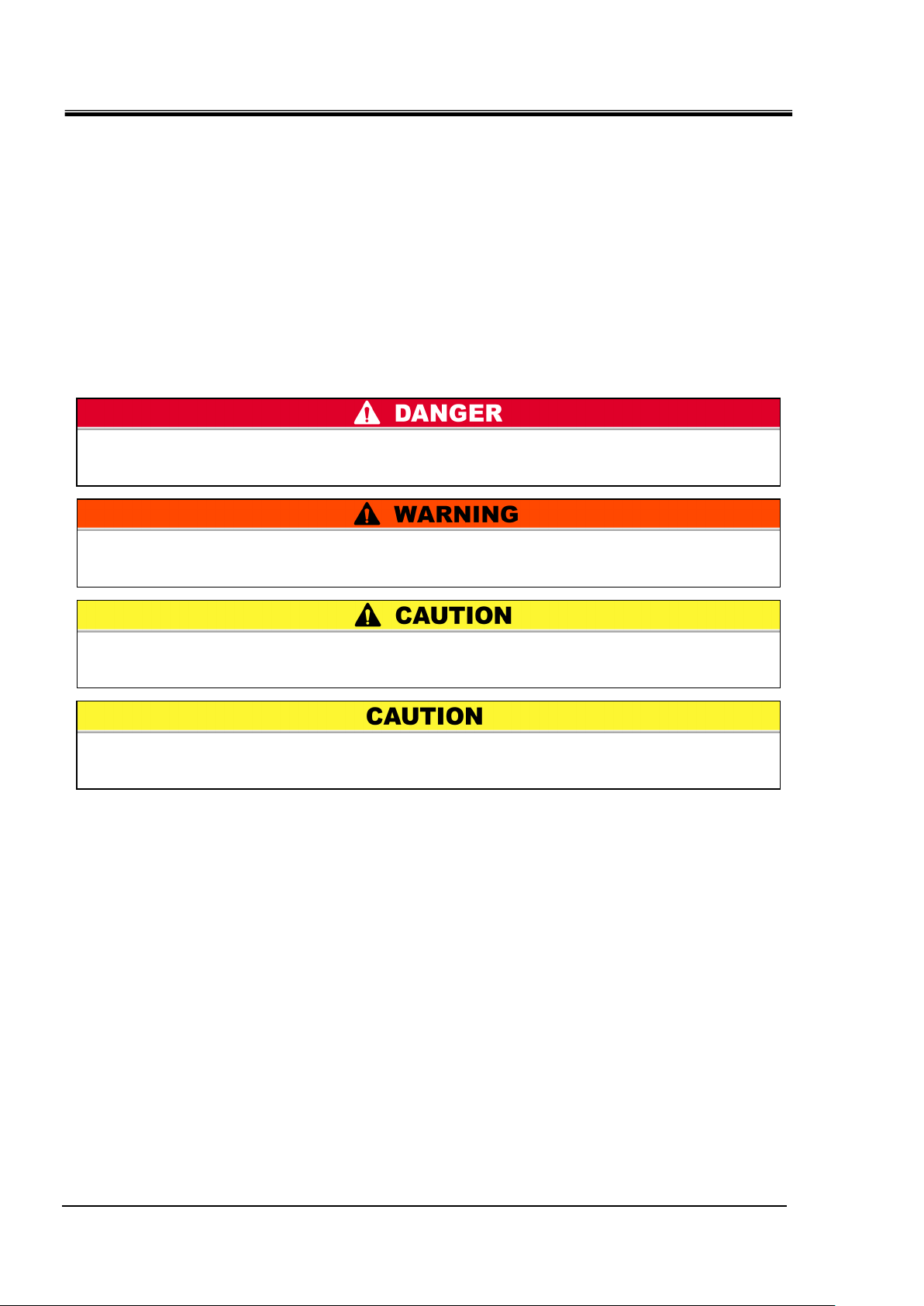

“DANGER”: Hazard that WILL cause serious personal injury or death during

operation.

“WARNING”: Hazard that MAY cause serious personal injury or death during

operation.

“CAUTION”: Hazard that MAY cause minor personal injury.

“CAUTION without exclamation symbol”: Hazard that MAY cause damage or failure

of the product, facility, devices, ect.

Chapter 1 Safety Instructions

1.3 Hazards

1.3.1 Level of hazards

The instructions given in this manual aim to assure the safe and correct

operation of the product, and to prevent injury of operators or damage to the

product. These instructions are grouped into three categories, Danger,

Warning and Caution, which indicate the level of hazard, damage and also

the degree of emergency. All safety critical information should be carefully

observed at all times.

“DANGER”, “WARNING” and “CAUTION” signs are in order according to

severity (DANGER> WARNING> CAUTION).

1.3.2 Definition of “Serious injury” and “Minor injury”

“Serious injury”

This term describes injuries that result in after effects including loss of

eyesight, burns, electrical shock, fracture, poisoning, etc. and requires

long-term treatment or hospitalization.

“Minor injury”

This term describes injuries that do not need long-term treatment or

hospitalization. (Others excluded from serious injury.)

1.3 Hazards HRSE Series

Page 9

1-3

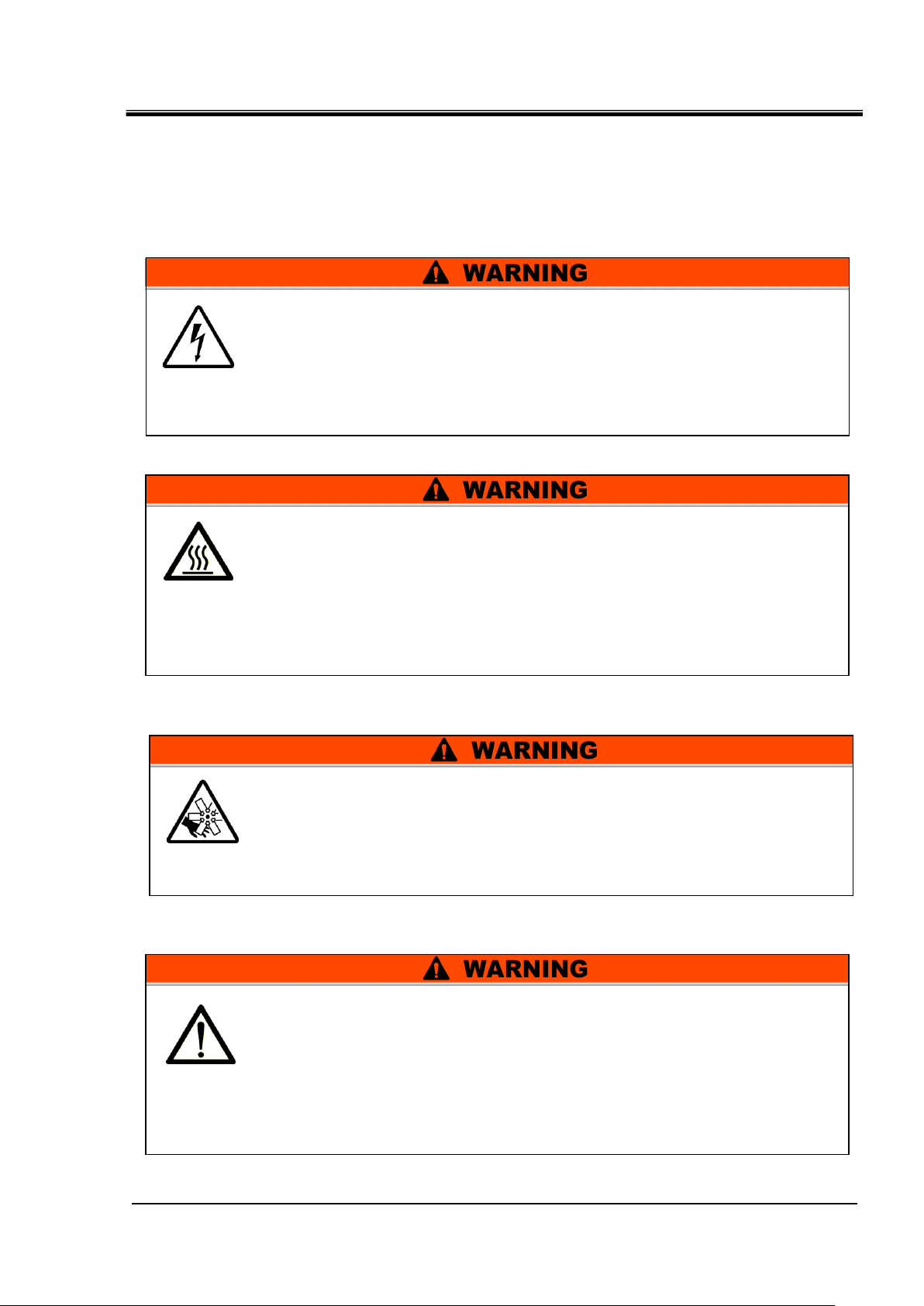

1.3.3 Types of hazard labels

This symbol stands for general danger.

Hazards Inside

Hot Surfaces Inside – See Hot Surface symbol

Rotating Fan Inside – See Rotating Fan symbol (For air-cooled type)

Pressurized Sytem Inside – The product contains pressurised fluid

systems.

DO NOT operate the product without cover panels fitted.

This symbol stands for a possible risk of hot surface and burns.

The product has surfaces that can reach high temperatures during

operation. Even after the power is turned off, there can still be residual

heat in the product.

DO NOT operate the product without cover panels fitted.

DO NOT start working inside the product until the temperature has

decreased sufficiently.

This symbol stands for a possible risk of cutting fingers or hand, or

entanglement by rotating fan (For air-cooled type).

The product contains a cooling fan that rotates during operation of the

product.

The fan can start and stop intermittently and without warning.

DO NOT operate the product without cover panels fitted.

This symbol stands for a possible risk of electric shock.

The product is operated at high voltage and contains uncovered live

terminals inside.

DO NOT operate the product without cover panels fitted.

DO NOT work inside this product unless you have been trained to

do so.

The product has various potential hazards and they are marked with

warning labels. Be sure to read this section before starting any work on the

product.

Warning related to electricity

HRX-OM-R039

Chapter 1 Safety Instructions

Warning related to high temperatures

Warning related to rotating objects

Warning related to other general dangers

HRSE Series 1.3 Hazards

Page 10

HRX-OM-R039

1-4

Rear

Front

Chapter 1 Safety Instructions

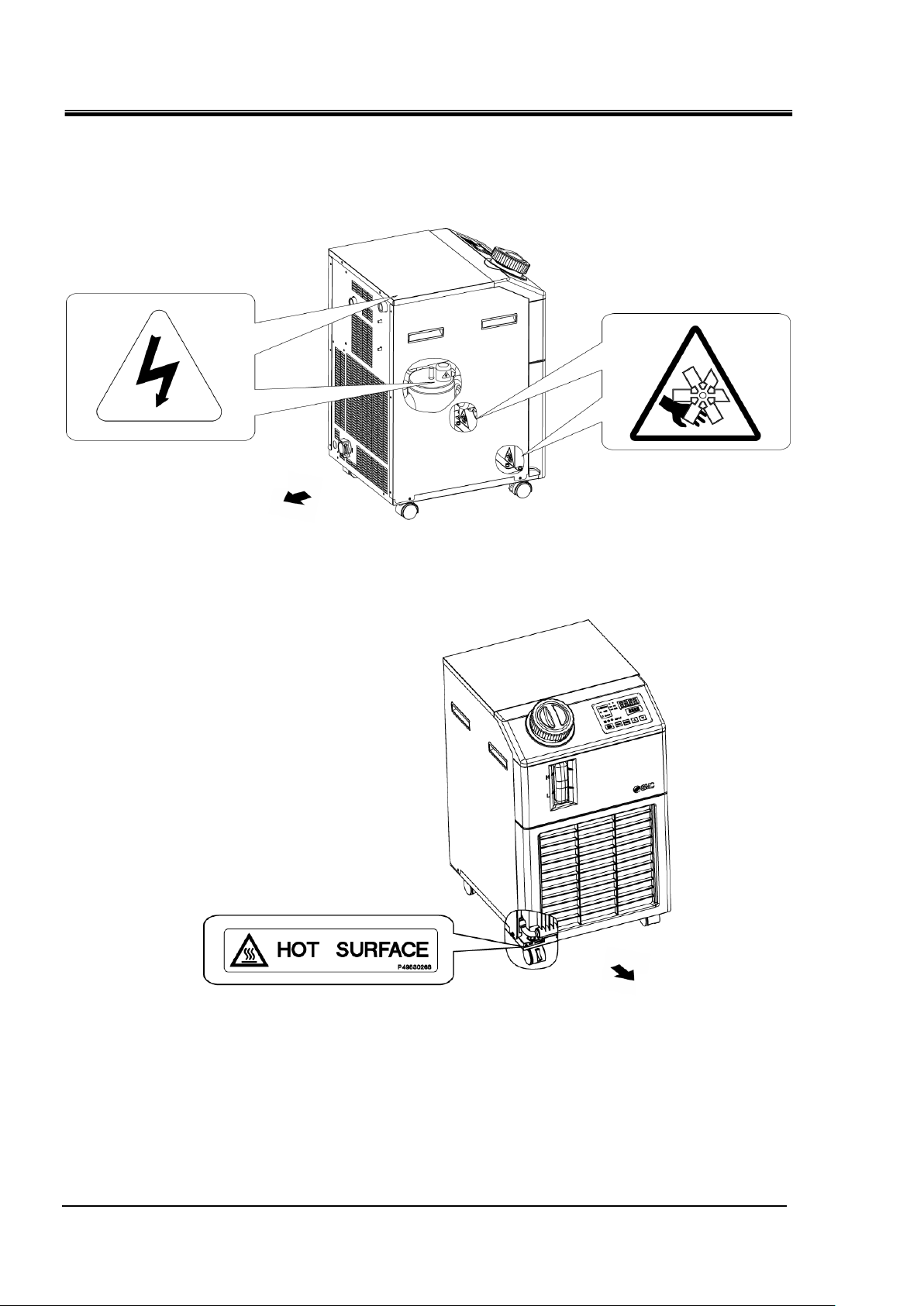

1.3.4 Locations of Hazard Labels

There are various warning labels on the product to show the potential

hazards.

Fig. 1.3-1 Warning label position

Fig. 1.3-2 Warning label position

1.3 Hazards HRSE Series

Page 11

1-5

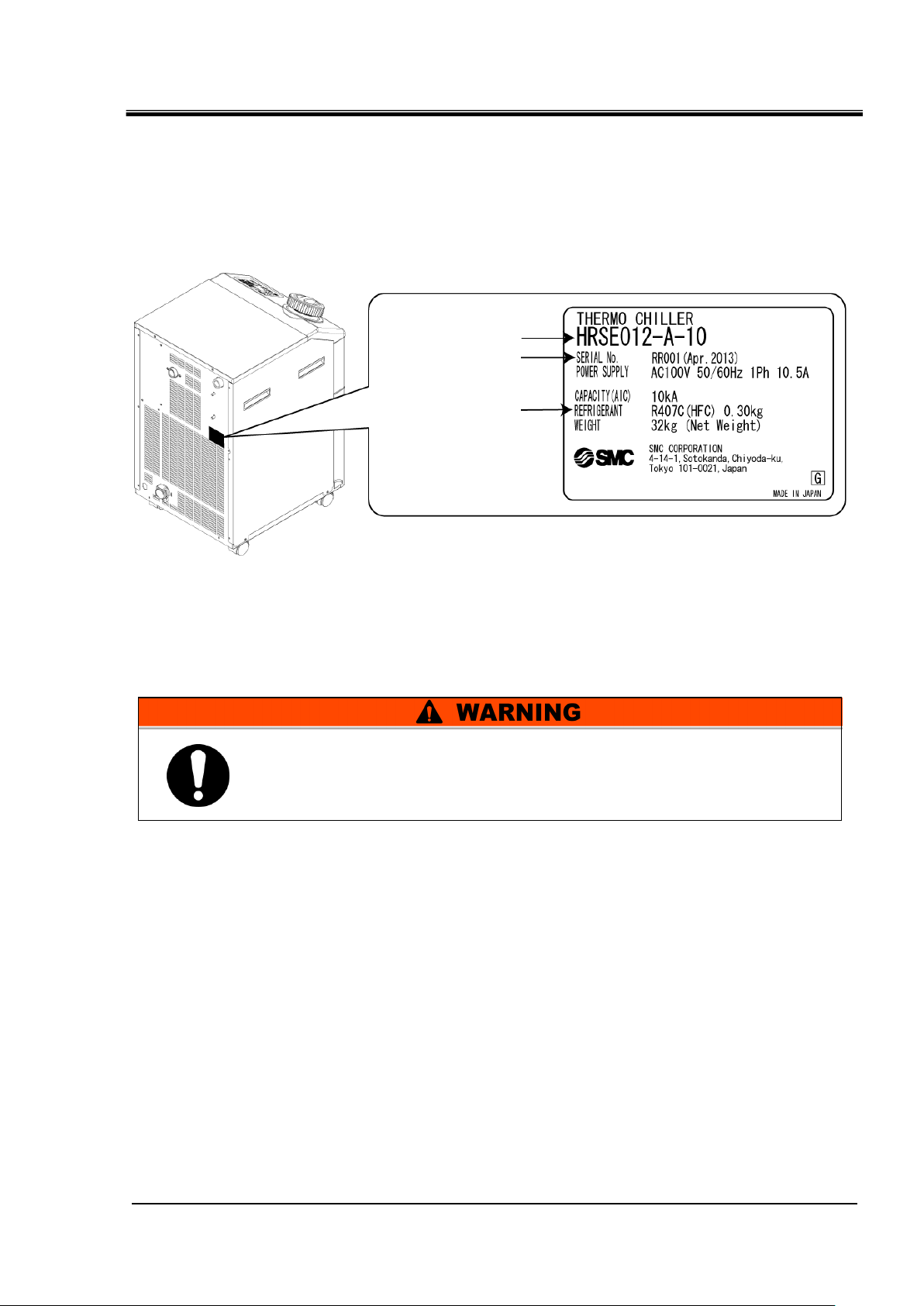

1.4 Other Labels

Follow the instructions below when using the product. Failure to

follow the instructions may cause an accident and injury.

(It is an example of model "HRSE012-A-10".)

Model Number

Serial Number

(SERIAL No.)

The type and quantity

of refrigerant

(REFRIGERANT)

1.4.1 Product Label

Information about the product, such as Serial No. and Model No. can be

found on the model label. This information is needed when contacting an

SMC sales distributor.

HRX-OM-R039

Chapter 1 Safety Instructions

Fig. 1.4-1 Position of product label

1.5 Safety Measures

1.5.1 Safety Instructions for Use

Read and understand this manual carefully before using the product.

Before starting maintenance of the product, be sure to lock out and tag out the

breaker of the user's power supply.

If operating the product during maintenance, be sure to inform all workers nearby.

Use only the correct tools and procedure when installing or maintaning the product.

Use personal protective equipment where specified (“1.5.2 Personal Protective

Equipment”)

Check all parts and screws are fitted correctly and securely after maintenance.

Avoid working in a drunken or sick condition, which might cause an accident.

Do not remove the panels except for the cases permitted in this manual.

Do not remove the panels during operation.

HRSE Series 1.4 Other Labels

Page 12

HRX-OM-R039

1-6

Always use safety shoes, gloves and head protection when

transporting, installing or uninstalling the product.

Always use safety shoes, gloves, mask, apron and eye protection

when handling the circulating fluid.

Always use safety shoes and gloves when operating the product.

Chapter 1 Safety Instructions

1.5.2 Personal Protective Equipment

This manual specifies personal protective equipment for each work.

Transport, Installing and Uninstalling

Handling of circulating fluid

Operation

1.5 Safety Measures HRSE Series

Page 13

1-7

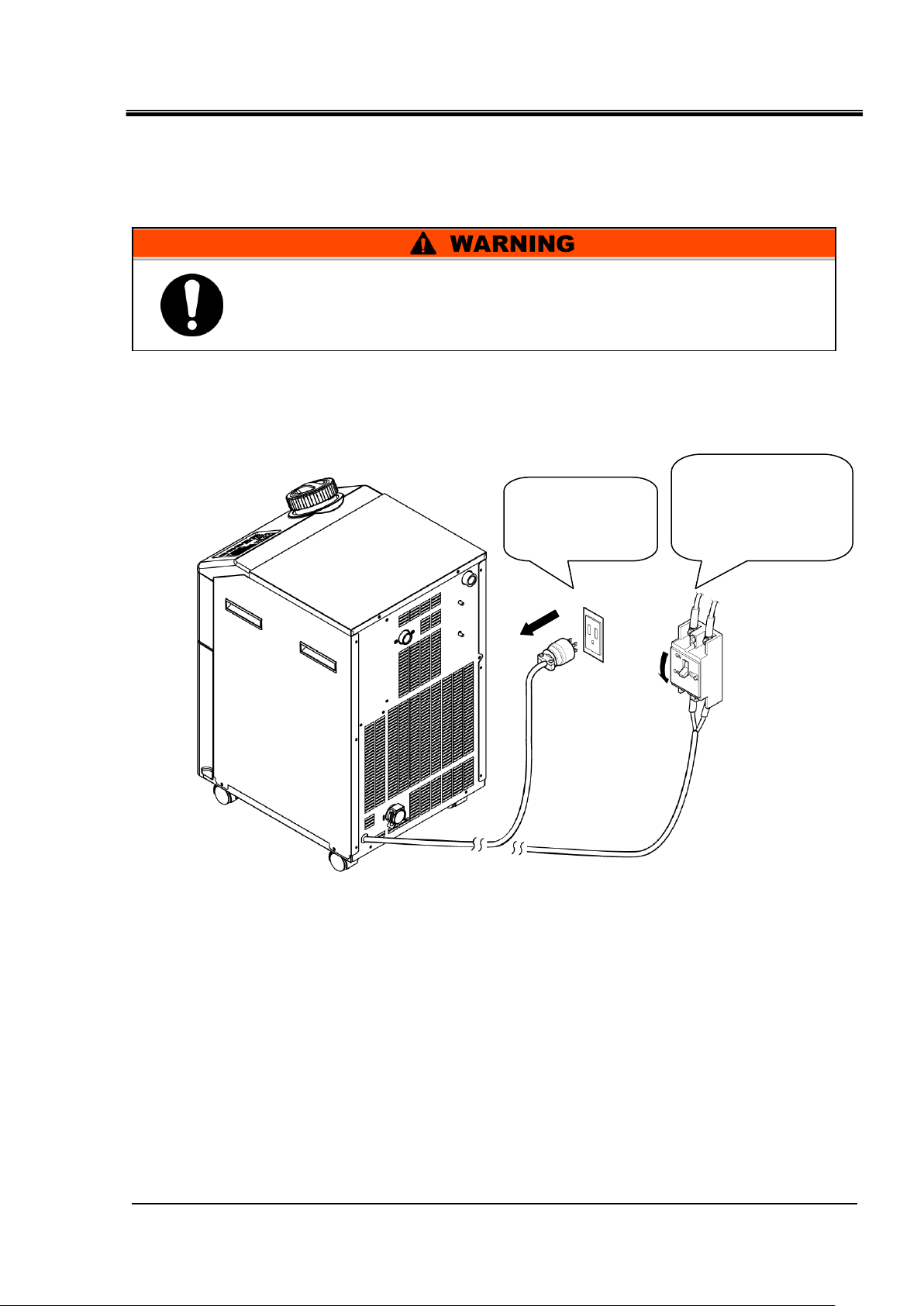

1.6 Emergency Measures

When the protective device (i.e. fuse) inside the product operates, this thermo

chiller stops operation without disconnecting the power supply. Some parts

of the thermo chiller are still being energized. Power supply to the thermo

chiller MUST be disconnected from the user's equipment.

Disconnect the

plug from an

outlet.

Turn OFF the

breaker of the power

supply source

(power supply of the

user's equipment).

In the event of natural disaster, emergency such as fire, earthquake, injury,

etc., disconnect the power supply to this product.

1. Disconnect power supply to the product.

HRX-OM-R039

Chapter 1 Safety Instructions

Fig. 1.6-1 Shut off of facility power supply 元電源の遮断 電源供給の

Fig. 1.6-2 Disconnect power supply

HRSE Series 1.6 Emergency Measures

Page 14

HRX-OM-R039

1-8

Comply with the laws and regulations in each country for the

disposal of refrigerant and compressor oil.

The release of refrigerant in to the atmosphere is banned by law.

Recover it with specific equipment and dispose of it correctly.

Only people who have sufficient knowledge and experience about

the product and its accessories are allowed to recover the

refrigerant and compressor oil.

Only maintenance personnel or qualified people are allowed to

open the cover panels of the product.

Do not mix the compressor oil with domestic waste for disposal.

Also, the disposal of the waste must only be conducted by specific

facilities that are permitted for that purpose.

Chapter 1 Safety Instructions

1.7 Waste disposal

1.7.1 Disposal of refrigerant and compressor oil

The product uses hydrofluorocarbon type refrigerant (HFC) and compressor

oil. Comply with the laws and regulations in each country for the disposal of

refrigerant and compressor oil. The type and quantity of refrigerant is

described on the 1.4.1 Product Label.

If these fluids need to be recovered, read and understand the instructions

below carefully. If there is any unclear point, contact an SMC's sales

distributor.

1.7.2 Disposal of product

The disposal of the product must be handled by a specialized industrial

waste disposal agency in accordance with local laws and regulations.

1.8 Material Safety Data Sheet (MSDS)

If the material safety data sheets of chemicals used in this product are

needed, contact an SMC's sales distributor.

Any chemicals used by the user must be accompanied by an MSDS.

1.7 Waste disposal HRSE Series

Page 15

HRX-OM-R039

2-1

10A012HRSE

A Air-cooled refrigerator type

1) Cooling capacity

2) Cooling method

3) Power supply

- -

012 1000W/1200W (50/60Hz)

024 1900W/2200W (50/60Hz) *1

20 1-phase AC200V (50/60Hz)

*1 3)Power supply:-10(100V Type)can not be chosen.

-

4) Option

None

Nil

High-pressure pump

mounted

T

10 1-phase AC100V (50/60Hz)

018 1400W/1600W (50/60Hz)

23 1-phase AC230V (50/60Hz) CE

Chapter 2 Name and Function of Parts

Chapter 2 Name and Function of Parts

2.1 Part number of product

The product can be ordered with the part number configured as shown

below.

Refer to “1.4.1 Product Label” and check the part number of the product.

Fig. 2.1-1 Part number of product

HRSE Series 2.1 Part number of product

Page 16

HRX-OM-R039

2-2

Operation

display panel

Lid for tank

Circulating fluid

return port

Circulating fluid

outlet

Model no.

label

Drain port

(with O-ring seal plug)

Ventilation air inlet

Ventilation air outlet

Caster with stopper

Caster

Power supply

Cable (3m)*

Handle

Operation

display panel

Lid for tank

Circulating fluid

outlet

Model no.

label

Drain port

(with O-ring seal plug)

Caster with stopper

Caster

Power supply

Cable (3m)*

Handle

Ventilation air inlet

Ventilation air outlet

Circulating fluid

return port

Chapter 2 Name and Function of Parts

2.2 Name and Function of Parts

Fig. 2.2-1 Names of each part

2.2 Name and Function of Parts HRSE Series

Fig. 2.2-2 Names of each part

* Power supply cable terminal

- 100V power supply specification: Cable is provided with a plug with ground terminal (JIS C8303 Plug for

the receptacle with dipole grounding electrodes).

- 200/230V power supply specification: The end part of all three lead wires are untreated (bare cut).

Page 17

2-3

1

Operation Manual

2pcs.

(Jpn: 1pc., Eng:1pc.)

2

Fitting (for drain port)*

1pc.

Name

Function

Operation display panel

Runs and stops the product and performs settings such as the circulating

fluid temperature.

For details, refer to section ’’2.4 Operation display panel’’.

Power supply cable

For power supply of 100 V specifications, connect the plug to the outlet of

100 VAC (50/60 Hz).

For power supply of 200 V specifications, connect the plug to the breaker

(recommended size: 15 A) of the user's equipment.

Model label

Shows the part number of the product.

For details, refer to section ‘’1.4.1 Product Label’’.

Circulating fluid outlet port

The circulating fluid flows out from the outlet port.

Circulating fluid return port

The circulating fluid returns to the return port.

Drain port

This drain port to drain the circulating fluid out of the tank.

(The plug is connected to standard pump type at the time of shipment. The

ball valve is installed in the high pump head type.)

Facility water inlet

(For water-cooled type)

A facility water inlet to which the facility water is fed through piping.

The pressure of facility water should be in a range of 0.3 to 0.5MPa.

Table 2-1 Accessories list

2.3 Function of Parts

The function of parts is as follows.

Table 2-2 Function of parts

HRX-OM-R039

Chapter 2 Name and Function of Parts

HRSE Series 2.3 Function of Parts

Page 18

HRX-OM-R039

2-4

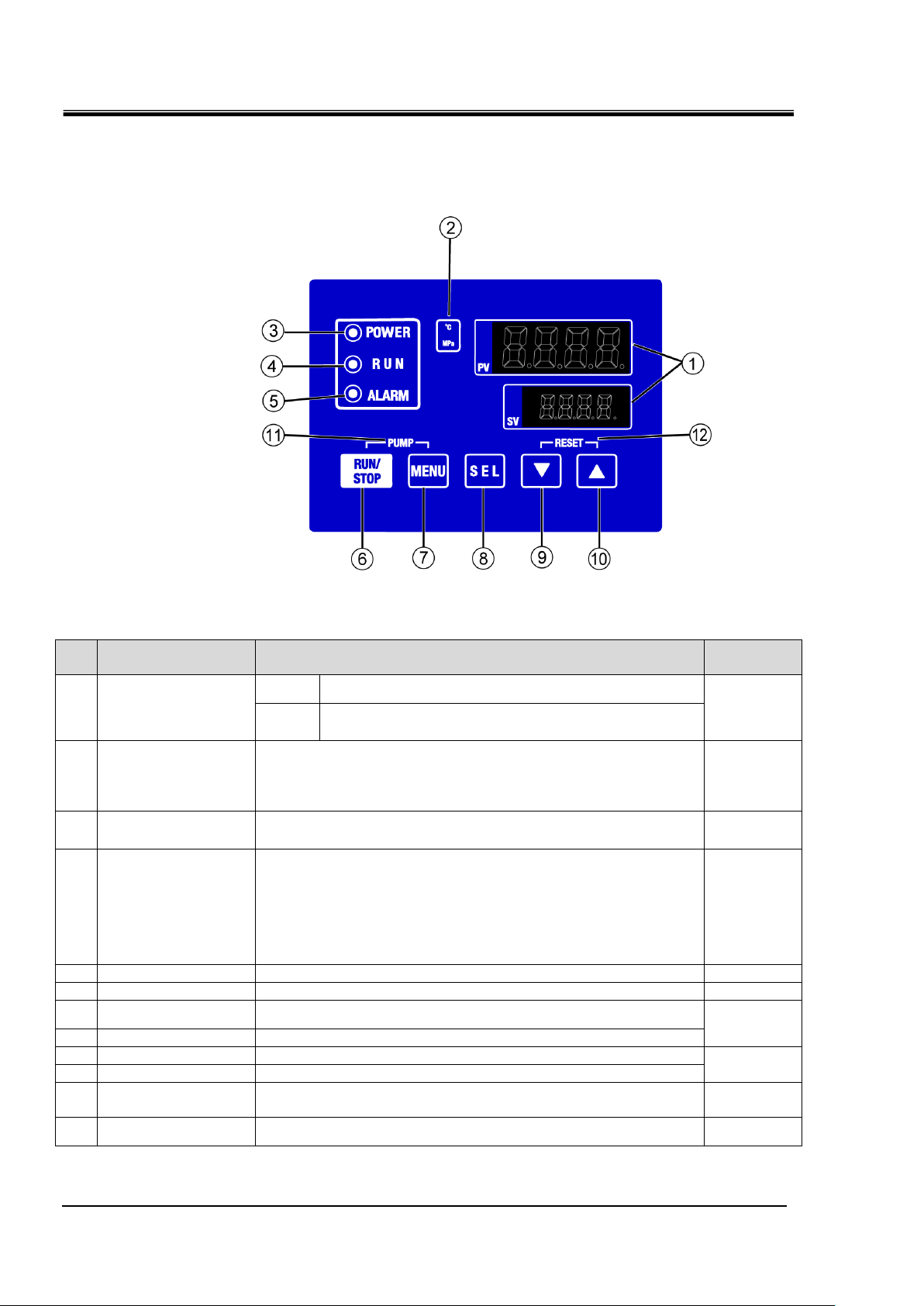

No

Description

Function

Reference

page

1

Digital display

(7 segment,

4 digits)

PV

Displays the temperature and pressure of the circulating

fluid and alarm codes.

5.2

SV

Displays the set temperature of the circulating fluid and

the set values of other menus.

2

[oC ] [MPa]lamp

[oC] light is turned on when temperature is displayed on the digital

display.

[MPa] light is turned on when pressure is displayed on the digital

display.

-

3

[POWER] lamp

Turns ON when power is being supplied.

-

4

[RUN] lamp

・Lights up when the product is started and in operation. Goes off

when the product is stopped.

・Flashes during stand-by for stop (Interval 0.5 seconds).

・Flashes during independent operation of the pump (Interval

0.3 seconds).

・Flashes during anti-freezing function (At standby: Interval 2

seconds, At operation: Interval 0.3 seconds).

4.4

5

[ALARM] lamp

Flashes with buzzer when alarm occurs (Interval 0.3 seconds).

5.3

6

[RUN/STOP] key

Makes the product start or stop.

4.4

7

[MENU] key

Shifts the main menu (display screen of temperature) the other

menu (entry of set values and monitor screen).

5.1

8

[SEL] key

Changes the item in menu and enters the set value.

9

[▼] key

Decreases the set value.

-

10

[▲] key

Increases the set value.

11

[PUMP] key

When the [MENU] and [RUN/STOP] keys are held down

simultaneously, the pump starts running independently.

4.3

12

[RESET] key

Keep the [▼] and [▲] keys pressed down simultaneously. This will

stop the alarm buzzer and reset the [ALARM] lamp.

6.3

Chapter 2 Name and Function of Parts

2.4 Operation display panel

The operation panel on the front of the product controls the basic operation

of the product.

Fig. 2.4-1 Operation display panel

Table 2-3 Operation display panel

2.4 Operation display panel HRSE Series

Page 19

HRX-OM-R039

3-1

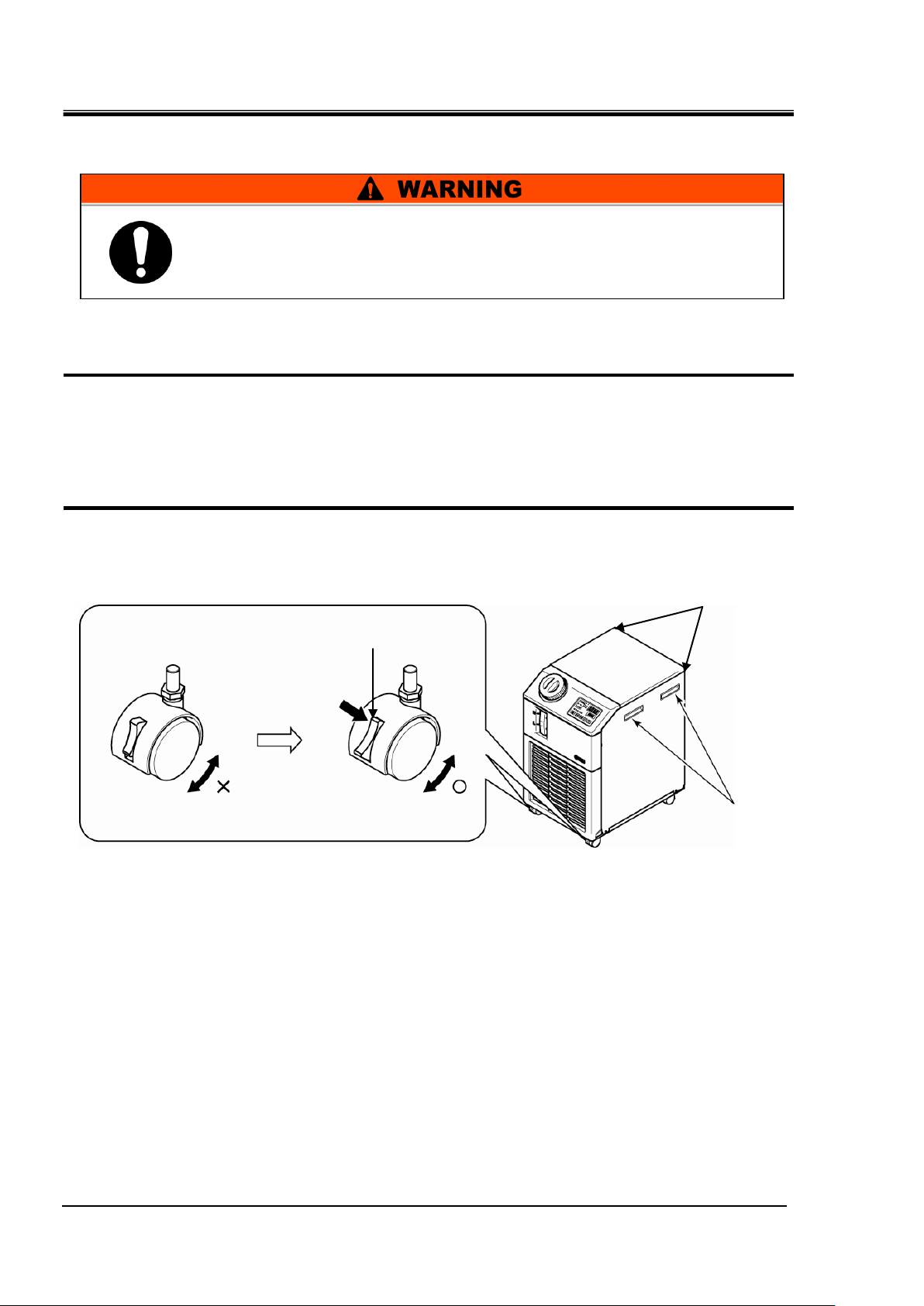

Only persons who have sufficient knowledge and experience

about the product and system are allowed to transport and set up

the product.

Especially pay attention to personal safety.

Never lay the product on its side.

The compressor oil will leak in to the refrigerant piping, which may

cause early failure of the compressor.

Drain the residual fluid from the piping as much as possible to

prevent any spillage.

Chapter 3 Transport and Setting Up

Chapter 3 Transport and Setting Up

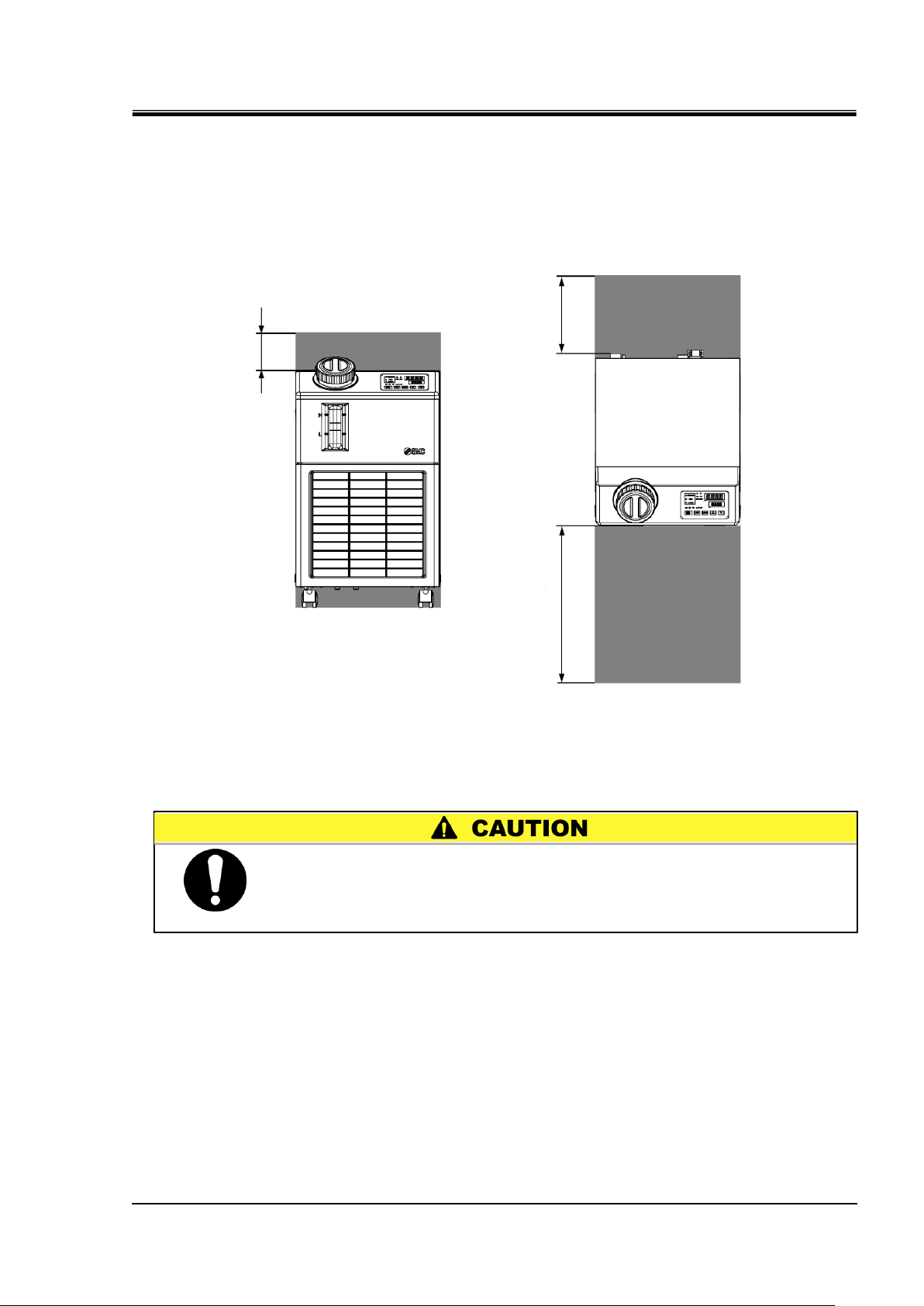

3.1 Transport

The product is heavy and has potential danger at transport. Also, to prevent

damage and breakage of the product, be sure to follow these instructions for

transport.

HRSE Series 3.1 Transport

Page 20

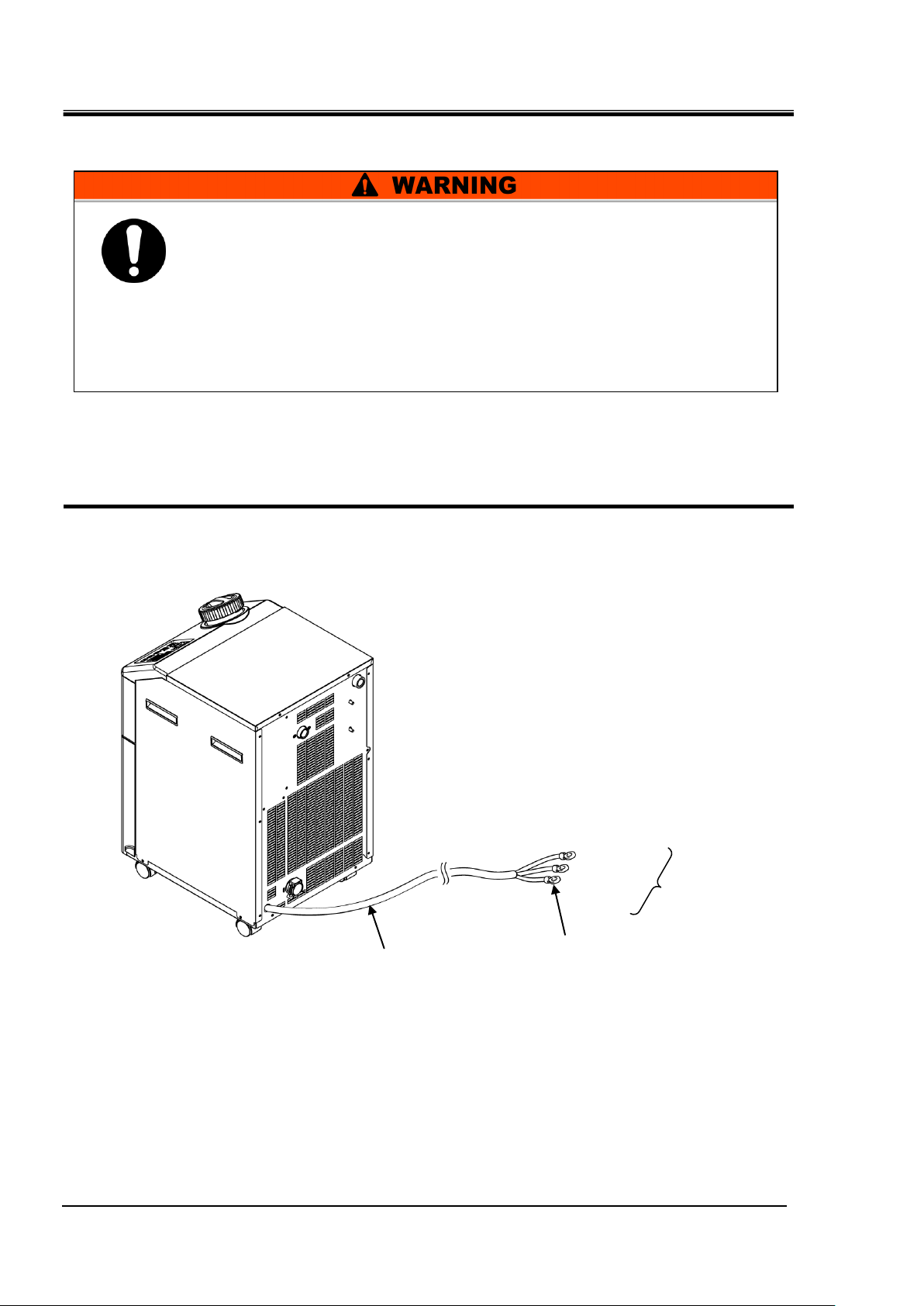

HRX-OM-R039

3-2

Handle

Unlocking

Press

Corners

This product is heavy.

Care should be taken when the product is transported on a slope.

Chapter 3 Transport and Setting Up

3.1.1 Transportation using casters

1. Release the lock levers of the front casters.

2. Push the handles on the right/left panel or the corner of the product to move the product

to the destination.

Do not hold the product by the cap to move it. This will apply excess force to the piping of

internal parts which may lead to malfunctions such as fluid leakage.

3. To push the front or rear panel, push it by the corner. Pushing by the center of the panel

may deform the shape.Care should be taken.

Fig. 3.1-1 Transportation using casters

3.1 Transport HRSE Series

Page 21

3-3

3.2 Installation

Keep the product horizontal to a rigid and flat floor which can

resist the weight of the product, and take measures to prevent the

product from tipping over. Improper installation may cause water

leakage, tipping, damage of the product or injure the operator.

Keep the ambient temperature of the product between 5 to 35oC.

Operation below 5oC may cause the compressor failure, and

operation above 35oC may cause the product to overheat and shut

down.

Power supply 200V : The operating ambient temperature is 5 to

40oC.

Do not set up the product in places possibly exposed to leakage of

flammable gas. Should any flammable gas stay around the

product, the product may cause a fire.

Do not use the product outdoors. If the product subjected to rain

or water splash it may cause electrical shock, fire or failure.

HRX-OM-R039

Chapter 3 Transport and Setting Up

3.2.1 Environment

The product must not be operated, installed, stored or transported in the

following conditions. Potential malfunction or damage to the product may

occur if these instructions are disregarded.

The product does not conform to any Clean room specifications. The pump

and ventilating fan inside the product generate particles.

Location that is outside.

Location that is exposed to water, water vapour, steam, salt water or oil.

Location that is exposed to dust or powder material.

Location that is exposed to corrosive gas, organic solvent, chemical

solution, or flammable gas (the product is not flame-proof)

Location where the ambient temperature is out of the following range:

In transportation and In storage 0 to 50°C

(with no water or circulating fluid in piping)

In operation *Power supply 100V : 5 to 35°C

*Power supply 200/230V : 5 to 40°C

Location where the ambient humidity is out of the following range or where

condensation occurs:

In transportation and storage 15 to 85%

In operation 30 to 70%

Location that is exposed to direct sunlight or heat radiation.

Location that is near heat sources and poor in ventilation.

Location that is subjected to abrupt changes in temperature.

Location that is subjected to strong electromagnetic noise (intense electric

HRSE Series 3.2 Installation

field, intense magnetic field, or surges).

Location that is subjected to static electricity, or conditions where static

electricity can discharge to the product.

Page 22

HRX-OM-R039

3-4

Model

Heat

Radiated

kW

Required ventilation amount m3/min

Differential temp. of 3 oC

between inside and

outside of installation area

Differential temp. of 6 oC

between inside and

outside of installation area

HRSE012-A-

Approx. 2

40

20

HRSE018-A-

Approx. 4

70

40

HRSE024-A-20/23

Approx. 5

90

50

Do not install in a location which can be subjected to any of the

conditions in 3.2.1 Environment.

The product radiates heat from the air vent of the cooling fan.

If the product is operated with insufficient air ventilation the internal

temperature can exceed 35oC, which can cause an overload or affect

the performance and life of the product. To prevent this ensure that

suitable ventilation is available (see below).

Power supply 200/230V : 40°C

Chapter 3 Transport and Setting Up

Location that is subjected to strong high frequencies raditation

(microwaves).

Location that is subjected to potential lightning srtike.

Location at altitude of 1000m or higher (except during product storage and

transport).

Location where the product is affected by strong vibrations or impacts.

Condition that applies external force or weight causing the product to be

damaged.

Location without adequate space for maintenance as required.

3.2.2 Location (Required ventilation rate and facility water source)

Installation of multiple products

Keep sufficient space between products so that the air vented from one product will not be taken

in by other products.

Installation Area Ventilation

① Facility having a large installation area (that can vent the air naturally)

Make an air vent on a wall at a high level and another air vent on a wall at a low level, to

allow for adequate airflow.

② Facility having a small installation area (that can not vent the air naturally)

Make a forced air exhaust vent on a wall at a high level and an air vent on a wall at a low

level.

Table 3-1 Amount of radiation and required ventilation

3.2 Installation HRSE Series

Page 23

3-5

3.2.3 Installation and Maintenance Space

300mm or more

500mm or more

100mm or more

The temperature of the outlet of for the ventilation of the thermo-chiller

and the panel surface may become approx. 50oC or higher. When

placing the thermo-chiller, ensure the thermo-chiller does not affect

surrounding environment.

It is recommended to keep the space around the product shown in Fig.3.2-1

For maintenance, move the thermo-chiller into a space where maintenance

work is possible.

Fig. 3.2-1 Installation space

HRX-OM-R039

Chapter 3 Transport and Setting Up

HRSE Series 3.2 Installation

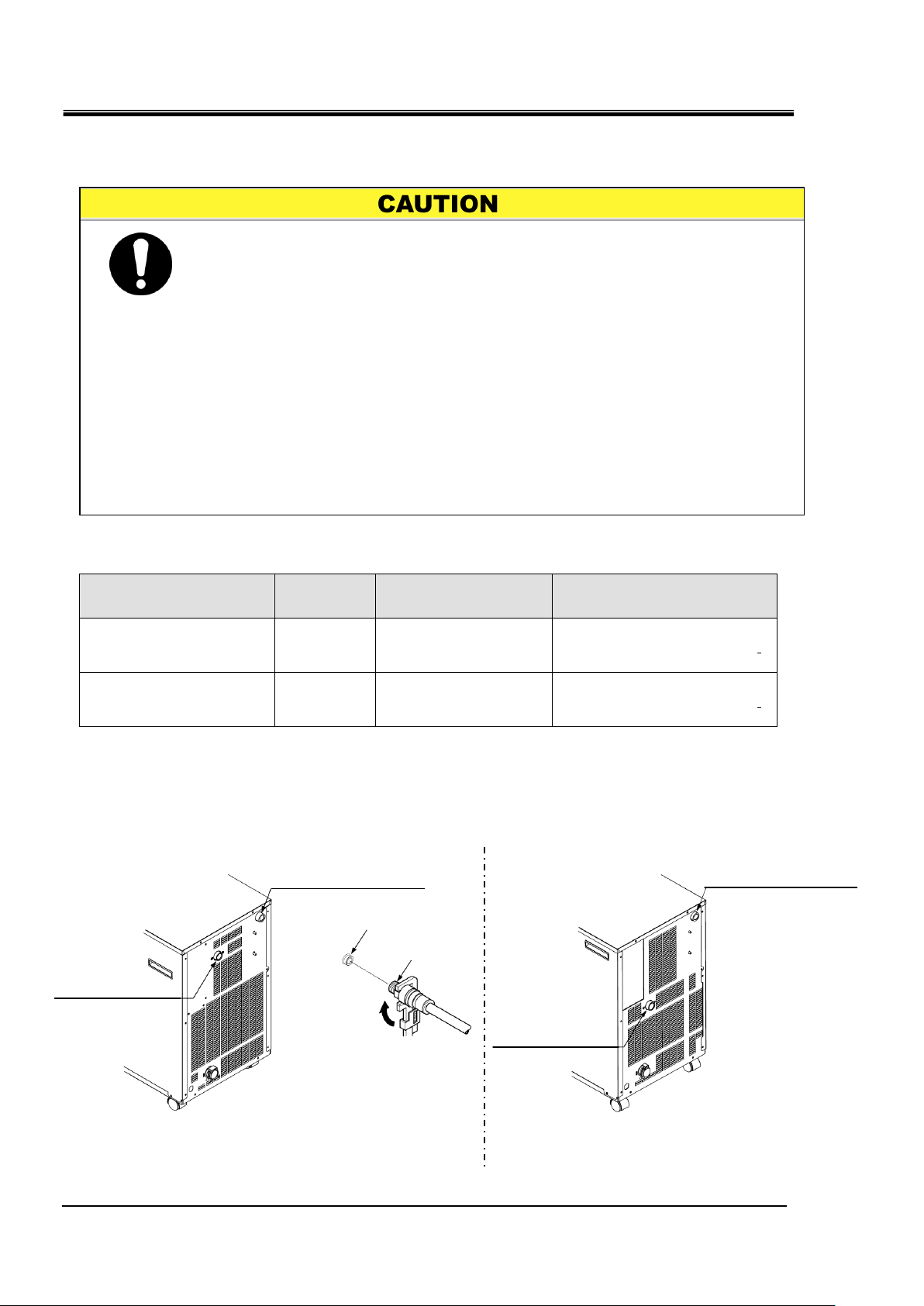

Page 24

HRX-OM-R039

3-6

Item

Part number

Anti-seismic brackets

HRS-TK003

Lock

For option T [High head pump]

Chapter 3 Transport and Setting Up

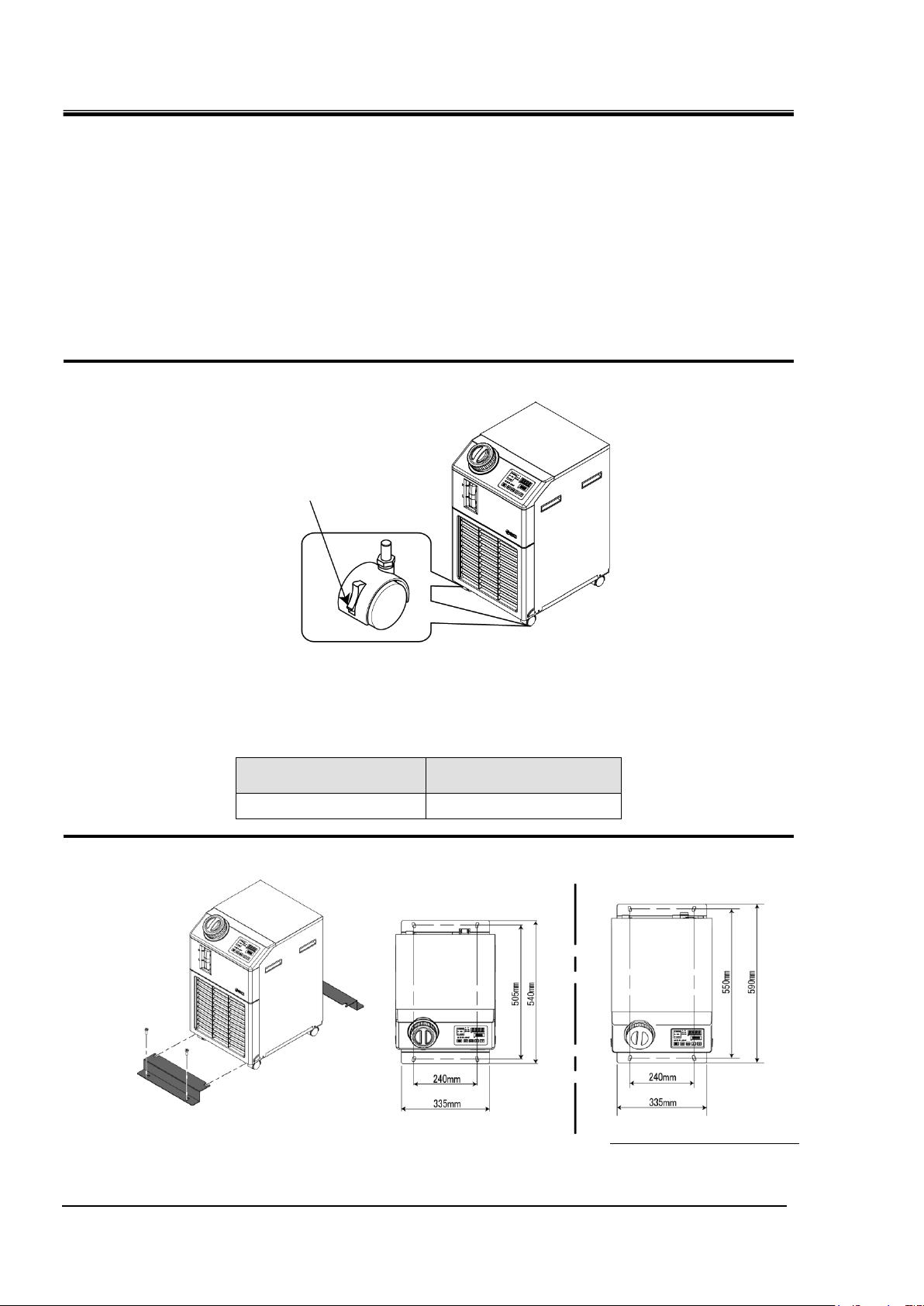

3.3 Installation

3.3.1 Mounting

Mount the product on a flat and stable floor with no vibrations.

Refer to’’8.2 Outline dimensions" for dimensional information of the

product.

How to mount the product

1. Move the product to the installation area.

2. After moving, lock the front casters again.

Fig. 3.3-1 Installation procedures

<Fixture>

Follow the procedure below when fixing the thermo-chiller to the floor or the mounting frame.

1. Prepare the fixing bracket shown below (Not included in the package).

2. Use M8 foundation bolts to fix the product within the dimensions below.

Fig. 3.3-2 Anti-seismic brackets installing

4 (four) M8 foundation bolts should be prepared by the customer.

3.3 Installation HRSE Series

Page 25

3-7

Model

Power

supply

voltage

Power supply cable spec

Recommended earth

leakage breaker

Spec.

Size

Rated

current

Terminal

configuration

(to be onnected

to the user's

equipment)

Rated

voltage

Rated

current

Sensitivity

of leak

current

HRSE012-A-10

1-phase

100V AC

(50/60Hz)

3 cores x

14AWG

(3 cores x

2.0mm2)

(including

ground)

15A

Plug with ground

terminal

(JIS C8303 Plug

for the eceptacle

for 15A and 125 V

with dipole

grounding

electrodes)

Shared

with 100

V and

200 V

15A

15mA

or

30mA

HRSE012-A-10-T

HRSE018-A-10

HRSE018-A-10-T

HRSE012-A-20/23

1-phase

200V AC

(50/60Hz)

-23 Only

1-phase

230V AC

(50/60Hz)

3 cores x

14AWG

(3 cores x

2.0mm2)

(including

ground)

15A

Lead wire end not

treated

(Bare cut)

(L: White,

N: Black,

E: Green)

Shared

with 100

V, 200

V and

230V

15A

30mA

HRSE012-A-20/23-T

HRSE018-A-20/23

HRSE018-A-20/23-T

HRSE024-A-20/23

HRSE024-A-20/23-T

Only qualified persons are allowed to wire the product.

Be sure to shut off the user’s power supply. Wiring with the

product energized is strictly prohibitted.

The wiring must be secured to the product to prevent the external

force of cables being applied to the terminals. Incomplete wiring or

improper securing of wiring may cause electrical shock, excessive

heat and fire.

Ensure a stable power supply with no voltage surges.

Ensure that an Earth Leakage Breaker is used in the power supply

of the product. See “Table 3-2”.

Use a power supply suitable for the specifications of the product.

Be sure to connect the ground connection.

Ensure that a lock out facility is availble on the power supply.

Each product must have its own separate Earth Leakage Breaker.

Otherwise there can be a risk of electric shock or fire.

Do not modify the intenal electrical wiring of the product. Incorrect

wiring may cause electrical shock or fire. Also, modifing the

internal wiring will void the product’s warranty.

Do not connect the ground to water line, gas pipe or lightening

conductor.

3.3.2 Electrical wiring

HRX-OM-R039

Chapter 3 Transport and Setting Up

Power supply cable and Earth Leakage Breaker

Prepare the power supply shown in the following table. For the connection

between the product and power supply, use the power supply cable and

Table 3-2 Power supply cable and Earth Leakage Breaker (Recommended)

HRSE Series 3.3 Installation

earth leakage breaker shown below.

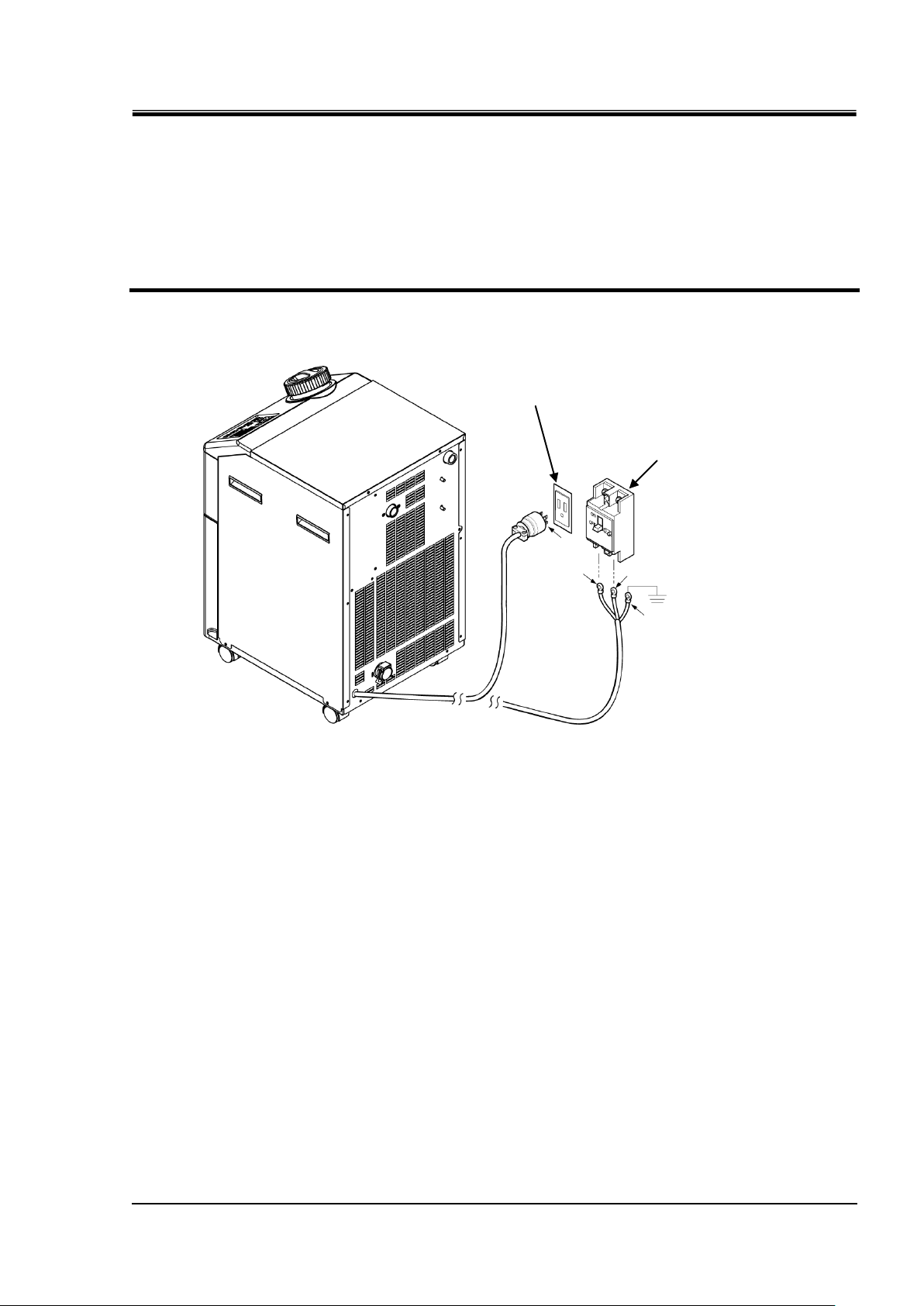

Page 26

HRX-OM-R039

3-8

Cable

The electrical facilities should be installed and wired in

accordance with local laws and regulations of each country and by

a person who has knowledge and experience.

Check the power supply. Operation with voltages, capacities and

frequencies other than the specified values can cause fire and

electrical shock.

Wire with an applicable cable size and terminal. Forcibly mounting

with an unsuitable size cable may result in heat generation or fire

Crimped terminal

(Prepared by customer)

L (White)

Earth leakage

breaker

(Secondary side)

N (Black)

E (Green)

Chapter 3 Transport and Setting Up

3.3.3 Preparation and wiring of power supply cable

Preparation 【For power supply : 200/230V 】

1. Strip the sheath from the cable of the product.

2. Connect the other end of the cable to a terminal (e.g. crimped terminal) that is compatible to the

secondary side of the earth leakage breaker of the user's equipment.

Fig. 3.3-3 Power supply cable

3.3 Installation HRSE Series

Page 27

HRX-OM-R039

3-9

L

N E Earth

Earth leakage

breaker

E

Grounded socket

Chapter 3 Transport and Setting Up

Connecting [For power supply : 100V, 200V and 230V]

1. Connect the plug or crimped terminal to the outlet with ground or to the secondary side

of the electrical leakage breaker and to the grounding.

2. Plug the power supply cable in to the power cable connector on the product.

Fig. 3.3-4 Wiring of power supply

HRSE Series 3.3 Installation

Page 28

HRX-OM-R039

3-10

Name

Port size*1

Recommended

tightening torque

Recommended proof

pressure for piping

Circulating fluid supply

Rc1/2

28 to 30N・m

0.3MPa more

(For option T [High head pump] :

0.4MPa more)

Circulating fluid return

Rc1/2

28 to 30N・m

0.3MPa more

(For option T [High head pump] :

0.4MPa more)

Connect piping firmly. Incorrect piping might cause leakage of

supplied or drained leakage and wet surrounding area and facility.

Pay attention not to allow dust and foreign materials to enter into

water circuit etc. during connection of piping.

Hold the piping port firmly with specific wrench when tightening.

The piping should be selected with due consideraton of pressure and

temperature. Otherwise, the piping can burst in service.

Do not use the materials that rust or corrode for the circulating fluid

circuits. Using the materials that tend to rust or corrode may cause

clogs or/and leakages of the circulating fluid circuits. In case of

using these kind of materials, consider and carry out some

prevention against the rusting or corrosion by the customer side.

Do not generate a rapid change of pressure by water hammer etc.

The product and external piping might be damaged.

Circulating fluid return port

Rc1/2

Circulating fluid outlet

Rc1/2

Piping port

Circulating fluid return port

Rc1/2

Circulating fluid outlet

Rc1/2

Chapter 3 Transport and Setting Up

3.4 PIPING

Piping port size

Table 3-3 Piping port size

How to connect piping

Tighten the piping to circulating fluid outlet / return port and facility water outlet / inlet.

3.4 PIPING HRSE Series

Fig. 3.4-1 Tightening of piping

Page 29

3-11

Recommended piping circuit

No.

Name

Size

1

Valve

Rc1/2

2

Y-shaped strainer or filter

Rc1/2 (#40) Rc1/2 (500μm)

3

Flow meter

0 to 30 L/min

4

Others (Pipe, hose, etc.)

I.Dφ15more

Circulating fluid

Return

Circulating fluid

Outlet

Load device

Fig. 3.4-2 Recommended piping circuit

HRX-OM-R039

Chapter 3 Transport and Setting Up

HRSE Series 3.4 PIPING

Page 30

HRX-OM-R039

3-12

Item

No

Remarks

Ethylene glycol aqueous solution 60%

HRZ-BR001

Please dilute to 15% with tap

water and use it.

Densitometer

HRZ-BR002

-

Tank lid

Circulating fluid fill

Liquid level

Check the drain port is plugged or closed by the valve to prevent the

supplied circulating fluid from draining out.

Supply the circulating fluid up to the “H” mark on the tank.

If the liquid level in the tank becomes lower than the "L" level or the

circulating fluid flow becomes 4L/min or less, the thermo chiller stops

operation.

Chapter 3 Transport and Setting Up

3.5 Fill of circulating fluid

Turn the tank lid anticlockwise to open. Supply the circulating fluid up to the

“H” mark on the fluid level indicator. Use tap water which satisfies the water

quality standard shown inTable 7-1, or a 15% aqueous solution of ethylene

glycol.

Fig. 3.5-1 Circulating fluid fill

15% aqueous solution of ethylene glycol

When a 15% aqueous solution of ethylene glycol is used, prepare the ethylene glycol aqueous

solution separately.

To control the concentration of the ethylene glycol aqueous solution, a concentration meter is available

separately from SMC.

3.5 Fill of circulating fluid HRSE Series

Page 31

Chapter 4 Starting the Product

4-1

Only people who have sufficient knowledge and experience about the

product and its accessories are allowed to start and stop the product.

Chapter 4 Starting the Product

4.1 Before Starting

Check the following items before starting the product.

Installation conditions

Check the product is installed horizontally.

Check that there are no heavy objects on the product, and the external

piping is not applying excessive force to the product.

Connection of cables

Check the power cables are correctly connected.

Circulating fluid

HRX-OM-R039

Check proper connection of piping at inlet and outlet.

Fluid level indicator (for tank)

Ensure that the fluid level is on “H”.

HRSE Series 4.1 Before Starting

Page 32

HRX-OM-R039

4-2

Press

L

N E Earth

Earth leakage

breaker

E

Grounded socket

Chapter 4 Starting the Product

4.2 Preparation for Start

4.2.1 Power supply

Turn ON the electrical leakage breaker of the user's equipment, and supply

power to the thermo chiller.

* For 100 V power supply specification, connect the plug to the outlet with

grounding (JIS C8303 Plug for the receptacle for 15A and 125 V with dipole

grounding electrodes).

When the product is switched on, the operation panel displays the following

conditions.

The initial screen (HELLO screen) is displayed for 8 seconds on the operation

display panel. Then, the display changes to the main screen which displays

the circulating fluid outlet temperature.

The set value of circulating fluid temperature is displayed as SV on the panel.

The present value of circulating fluid temperature is displayed as PV on the

panel.

Fig. 4.2-1 Power supply

4.2.2 Setting of circulating fluid temperature

4.2 Preparation for Start HRSE Series

Press the [▼] and [▲] buttons on the operational panel to change the SV to

required value.

Fig. 4.2-2 Setting of circulating fluid temperature

Page 33

HRX-OM-R039

4-3

If leakage occurs due to faulty piping including an opened fitting of eternal piping,

stop manual operation of the pump and fix the leak.

Flash

Press together

Chapter 4 Starting the Product

4.3 Preparation of circulating fluid

When the circulating fluid tank is filled the user’s machine and piping remains

empty. In that condition, the circulating fluid flows out to the user’s machine

and piping and the tank level decreases and may require a refill. In that case,

refill the circulating fluid in the following procedure.

1. Press the [PUMP] key on the operation display panel (press the [RUN/STOP] key and

[MENU] key simultaneously).

The pump operates independently while the [PUMP] key is pressed. The [RUN] lamp

(green) flashes while the pump is operating independently, and the circulating fluid in

the tank is supplied to the customer’s device and piping. This can be done to check for

leakage, and to discharge air from the piping.

When the fluid level in the tank drops below the "L" level, stop the operation of the

pump itself, and add some circulating fluid into the tank. Repeat the same sequence

after adding the fluid until the fluid level in the tank stops decreasing. When the liquid

level in the tank stops decreasing, it means that the circulating fluid is filled completely

in the piping of the user's facility.

Fig. 4.3-1 Manual operation of the pump

HRSE Series 4.3 Preparation of circulating fluid

Page 34

HRX-OM-R039

4-4

Confirm that the drain port is closed with a plug or a valve to avoid

discharging the circulating fluid that is added to the tank from the

drain port.

Supply the circulating fluid up to the “H” mark on the tank.

Tank lid

Filling of Circulating Fluid

Liquid

Chapter 4 Starting the Product

2. Open the tank lid and supply the circulating fluid up to the “H” mark on the tank.

Fig. 4.3-2 Filling of Circulating Fluid

4.3 Preparation of circulating fluid HRSE Series

Page 35

4-5

4.4 Starting and Stopping

Press

When an alarm occurs Refer to “Chapter 6 Alarm indication and trouble

shooting’’

Allow at least five minutes before restarting the product.

ON

4.4.1 Starting the product

Before starting, check the items specified in “4.1 Before Starting”

If any alarm lamp remains on, refer to Chapter 6 Alarm indication and

trouble shooting”

1. Press the [RUN/STOP] key on the operation panel.

The [RUN] lamp lights up (in green) and the product starts running. The circulating

discharge temperature (PV) is controlled to the set temperature (SV).

HRX-OM-R039

Chapter 4 Starting the Product

Fig. 4.4-1 Starting the product

HRSE Series 4.4 Starting and Stopping

Page 36

HRX-OM-R039

4-6

Except in case of emergency, do not turn off the power supply switch

until the product has stopped completely. Doing so could cause

failure.

Be sure to shut off the breaker of the facility power supply (the user’s

machine power supply) before wiring.

Also, drain the circulating fluid, etc. from the product in accordance

with and put into storage properly

(Referring to "7.4.1 Discharge of the circulating fluid".)

Flash

OFF

Press

Chapter 4 Starting the Product

4.4.2 Stopping the product

1. Press the [RUN/STOP] button on the operation panel.

The [RUN] lamp on the operation panel flashes green at 1 second intervals, and

continues operation to prepare to stop. After approx. 15 seconds, the [RUN] lamp goes

off and the product stops.

Fig. 4.4-2 Stopping the product

2. Turn OFF the electrical leakage breaker of the user's equipment, and disconnect the

power supply to the thermo chiller.

4.4 Starting and Stopping HRSE Series

Page 37

4-7

4.5 Check items after starting

When an Alarm is seen, press the [STOP] button and then turn off the

power supply switch to stop the product, and turn off the breaker of

the user’s power supply to isolate the product.

Check the following items after starting the product.

There is no leakage from piping.

There is no drain of circulating fluid from the drain port.

The tank level is within the specified range.

4.6 Adjustment of Circulating Fluid

Flow adjustment

HRX-OM-R039

Chapter 4 Starting the Product

If the flow rate is less than 5L/min it will not be able to achieve the specified

cooling capacity. The adjustment of flow rate should be performed using a

manual bypass valve and monitoring the pressure or flow rate in the

customer’s device, referring to the recommended piping flow shown in

Figure 3.4-2, until they reach the required value.

When the flow rate of the circulating fluid becomes 4L/min. or lower, a

protective device of the thermo chiller operates to stop it's operation.

("AL07" alarm will be generated.)

Please reconsider the piping of the equipment that the product is

connected to, or consider using the "Bypass piping set; HRS-BP001"

that is available as an option.

HRSE Series 4.5 Check items after starting

Page 38

HRX-OM-R039

4-8

Chapter 4 Starting the Product

4.6 Adjustment of Circulating Fluid HRSE Series

Page 39

Chapter 5 Display and setting of various functions

5-1

NO

Function

Outline

Reference

page

1

Main display

Displays the current temperature of the circulating fluid, discharge pressure of

the circulating fluidhange the circulating fluid temperature.

5.2

2

Alarm display

menu

Indicates alarm number when an alarm occurs.

5.3

3

Inspection

monitor menu

Product temperature, pressure and accumulated operating time can be

checked as daily inspection. Use these for daily inspection.

5.4

4

Setting of alarm

buzzer

Alarm sound can be set to on/off.

5.5

5

Alarm

customizing

Operation during alarm condition and threshold values can be changed

depending on the alarm type.

5.6

6

Data reset

Functions can be reset to the default settings (settings when shipped from the

factory).

5.7

7

Accumulation

time reset

Reset function when the pump, the fan, or the compressor is replaced.

Accumulated time is reset.

5.8

8

Reset after

power failure

Start operation automatically after the power supply is turned on.

5.9

Read and understand this manual carefully before changing the

settings.

Chapter 5 Display and setting of

various functions

5.1 Function

5.1.1 Key operations

HRX-OM-R039

The product can have the displays and settings shown in table 5-1.

Table 5-1 List of function

HRSE Series 5.1 Function

Page 40

HRX-OM-R039

5-2

PV

SV

Unused

SEL

Main display

Unused

Check monitor menu

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Setting menu

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Alarm

(The latest)

Alarm

Alarm display menu

Alarm

(The oldest)

PV

SV

PV

SV

PV

SV

MENU

MENU

Press the

2sec.

PV

SV

PV

SV

PV

SV

PV

SV

Power supply ON

PV

SV

PV

SV

Unused

PV

SV

PV

SV

PV

SV

SEL

SEL

SEL

SEL

SEL

MENU MENU

MENU MENU

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

PV

SV

PV

SV

PV

SV

SEL

SEL

SEL

Circulating

fluid outlet

temperature

Circulating

fluid set

temperature

Note) It changes only when the

alarm is generated.

Circulating

fluid outlet

temperature

Temperature

of the

compressor

inlet.

Unused

Pressure of

higher

pressure

refrigerant

circuit

Pressure of

lower

pressure

refrigerant

circuit

Unused

Accumulated

operation

time of the

pump

Accumulated

operation

time of the

fun motor

Accumulated

operation

time of the

compressor

Accumulated

operation

time

Press the

2sec.

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Recover

from power

failure

Unused

Unused

Unused

Unused

Data reset

Pump

accumulated

operating

time reset

Fan motor

accumulated

operating

time reset

Compressor

accumulated

operating

time reset

Unused

Unused

Unused

Unused

Unused

Press the

2sec.

Chapter 5 Display and setting of various functions

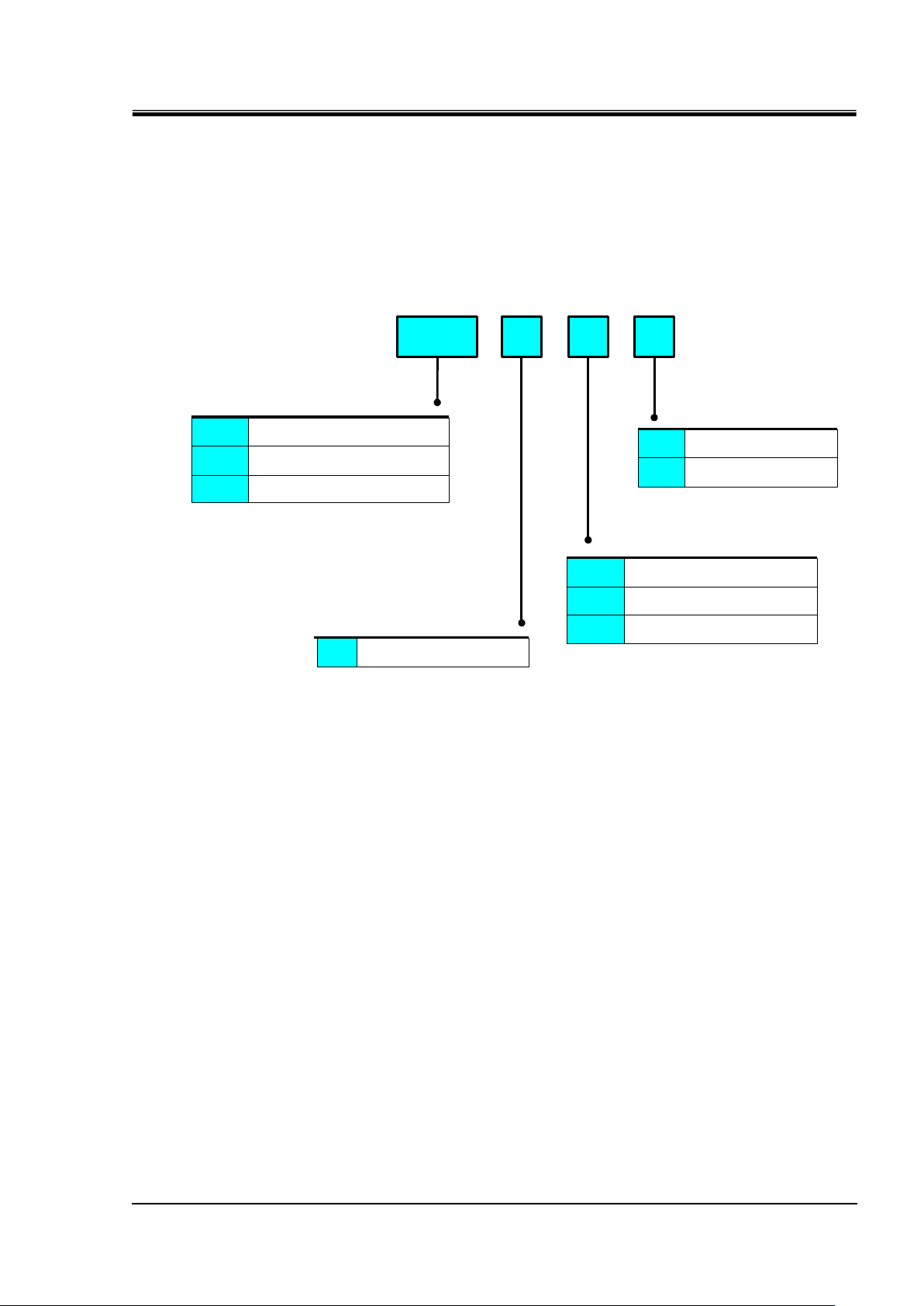

5.1.2 Key operations

Fig. 5.1-1 “Key operation (1/2)” and

Fig. 5.1-2 “Key operation (2/2)” show the operation of keys of the

thermo-chiller.

5.1 Function HRSE Series

Fig. 5.1-1 Key operation (1/2)

Page 41

HRX-OM-R039

5-3

Alarm setting menu

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Unused

Communication

setting menu

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Unused

Unused

Unused

PV

SV

PV

SV

SV

Unused

Unused

PV

SV

PV

SV

Unused

Unused

Unused

Unused

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Unused

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

MENU MENU

MENU

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

PV

Unused

Unused

PV

SV

SEL

PV

SV

SEL

PV

SV

SEL

SEL

Unused

Alarm

buzzer

sound

Unused

Changing of

circulating fluid

discharge

temperature rise

Detection

temperature for

circulating fluid

discharge

temperature rise

Changing of

circulating fluid

discharge

temperature drop

Detection

temperature for

circulating fluid

discharge

temperature drop

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Unused

Temperature

alarm

Monitoring

method

Monitoring

start timer

Range over

Detection timer

Press the

2sec.

Unused

MENU

Press the

2sec.

Chapter 5 Display and setting of various functions

HRSE Series 5.1 Function

Fig. 5.1-2 Key operation (2/2)

Page 42

HRX-OM-R039

5-4

Display

Item

Initial value

(Default setting)

Reference

page

Category

Temperature

Circulating fluid temperature

(TEMP PV)

5.2

Main display

Circulating fluid set temperature (TEMP

SV)

20 oC

Unused

-

Unused

X X

Alarm no. 5.3

Alarm

display

menu

Circulating fluid outlet temperature

5.4

Check

monitor

menu

Unused

Temperature of the compressor inlet.

Unused

Pressure of higher pressure refrigerant

circuit

Pressure of lower pressure refrigerant

circuit

Unused

Accumulated operation time of the pump

Accumulated operation time of the fun

motor

Accumulated operation time of the

compressor

Accumulated operation time

Unused

-

-

Setting

menu

Unused

- Unused

- Unused

-

Unused

-

Unused

- Unused

- Unused

- Recover from power failure

OFF

5.9

Unused

-

-

Unused

- Unused

- Pressure unit

- Data reset

NO

5.7

Pump accumulated operating time reset

NO

5.8

Fun motor accumulated operating time

reset

NO

Compressor accumulated operating

time reset

NO

Unused

-

-

Unused

-

Unused

-

Unused

-

Unused

-

Chapter 5 Display and setting of various functions

5.1.3 List of parameters

Table 5.1-2“List of parameter (1/3)” and Table 5.1-4“List of parameter (3/3)”

show the parameters of the thermo-chiller.

Table 5.1-2 List of parameter (1/3)

5.1 Function HRSE Series

Page 43

HRX-OM-R039

5-5

Display

Item

Initial value

(Default setting)

Reference

page

Category

Alarm buzzer sound

ON

5.5

Alarm setting

menu

Unused

-

5.6

Changing of circulating fluid discharge

temperature rise

A.RUN

Detection temperature for circulating

fluid discharge temperature rise

35 oC

Changing of circulating fluid discharge

temperature drop

A.RUN

Detection temperature for circulating

fluid discharge temperature drop

1 oC

Unused

-

-

Unused

- Unused

- Unused

- Unused

- Unused

- Unused

- Unused

-

Unused

-

Unused

- Unused

- Unused

- Unused

- Unused

-

Temperature alarm

Monitoring method

0

5.6

Monitoring start timer

----

Range over

Detection timer

5

Unused

-

-

-

Unused

- Unused

- Unused

-

Unused

-

Unused

- Unused

- Unused

- Unused

- Unused

- Unused

- Unused

- Unused

- Unused

-

Unused

- Unused

-

Unused

-

Unused

- Unused

- Unused

- Unused

-

Chapter 5 Display and setting of various functions

Table 5.1-3 List of parameter (2/3)

HRSE Series 5.1 Function

Page 44

HRX-OM-R039

5-6

Display

Item

Initial value

(Default setting)

Reference

page

Category

Unused

-

-

-

Unused

-

Unused

-

Unused

-

Unused

-

Unused

-

Unused

-

Unused

-

Unused

-

Unused

-

Chapter 5 Display and setting of various functions

Table 5.1-4 List of parameter (3/3)

5.1 Function HRSE Series

Page 45

Chapter 5 Display and setting of various functions

5-7

PV

SV

PV

SV

PV

SV

Current discharge temperature

Set Temperature

5.2 Main screen

5.2.1 Main screen

Displays the current temperature and the set temperature of the circulating

fluid. The set temperature can be changed on this screen.

5.2.2 Display on the main screen

The display on the main screen is as follows.

Current discharge temperature of circulating fluid Display

1. Connect the plug of the power supply cable to an outlet to supply power.

Current temperature and set temperature are displayed on the digital display.

Alarm display screen (See 5.3) appears when an alarm is generated.

Circulating fluid temperature Set

HRX-OM-R039

2. Change the set temperature by pressing the [▼][▲] key.

After changing the set temperature, set it by pressing the [SEL] key.

The set value flashes while it is being changed.

If [SEL] key is not pressed, the value is reset after 3 sec.

Circulating fluid discharge pressure Diaplay

3. Press the [SEL] key.

"P1" is displayed, but this feature is not available on this product.

Electric resistivity Display

4. Press the [SEL] key.

"dl" is displayed, but this feature is not available on this product.

HRSE Series 5.2 Main screen

Page 46

HRX-OM-R039

5-8

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Alarm code

Alarm history

[SEL]

[MENU]

Alarm

release

Chapter 5 Display and setting of various functions

5.3 Alarm display menu

5.3.1 Alarm display menu

The alarm display screen appears when an alarm is generated.

The alarm display menu cannot be accessed when no alarm has been

generated.

Refer to “Chapter 6 Alarm indication and trouble shooting” for the content

of alarms.

5.3.2 Content of display of alarm display menu

The alarm display screen appears when an alarm is gernerated.

When multiple alarms are generated, the latest alarm is displayed on the

screen.

Each time the [SEL] key is pressed, the alarms are displayed in order,

starting from the latest one.

The main screen is displayed when the alarm is reset.

The main screen is displayed when [MENU] key is pressed while an alarm is

output.

The alarm display screen is displayed if [MENU] key is pressed again.

5.3 Alarm display menu HRSE Series

Page 47

Chapter 5 Display and setting of various functions

5-9

Display

Item

Contents

Circulating fluid outlet temperature

Displays the temperature of the circulating fluid outlet.

This temperature does not take offset into

consideration.

Circulating fluid return

port temperature

Displays the temperature of the circulating fluid return.

Temperature of the inlet of the

compressor

Displays the temperature of the inlet of the compressor.

Circulating fluid outlet pressure

Displays the circulating fluid outlet pressure at the

outlet.

Pressure of higher pressure

refrigerant circuit

Displays the pressure of higher pressure side of the

refrigerant circuit.

Pressure of lower pressure

refrigerant circuit

Displays the pressure of lower pressure side of the

refrigerant circuit.

Electric resistivity

Displays the electric resistivity.

Accumulated operation time of the

pump

Displays the accumulated operation time of the pump.

Accumulated operation time of the

fun motor

Displays the accumulated operation time of the fan

motor. (For air-cooled type)

Accumulated operation time of the

compressor

Displays the accumulated operation time of the

compressor.

Accumulated operation time

Displays the accumulated operation time.

PV

SV

PV

SV

PV

SV

[MENU]

Press and

5.4 Inspection monitor menu

5.4.1 Inspection monitor menu

As a part of the daily inspection, the temperature, pressure and accumulated

operating time can be checked.

Please use this for confirmation of your daily inspection.

5.4.2 Checking of the Inspection monitor menu

The table below explains the check items of the inspection monitor menu.

Table 5.4-1 List of check items of Inspection monitor menu

HRX-OM-R039

Check of the circulating fluid outlet temperature

1. Press and hold the [MENU] key for approx. 2 sec.

The temperature of the circulating fluid outlet 「 」is displayed on the digital display.

Displays the temperature of the circulating fluid at the outlet from which the fluid is fed to

the customer’s device.

2. Press the [SEL] key once.

"t2" is displayed, but this feature is not available on this product.

HRSE Series 5.4 Inspection monitor menu

Page 48

HRX-OM-R039

5-10

PV

SV

PV

SV

PV

SV

PV

SV

PV

SV

Chapter 5 Display and setting of various functions

Check of the temperature of the inlet of the compressor.

3. Press the [SEL] key once.

The temperature of the refrigerant circuit compressor inlet is displayed on the digital

display.

Displays the temperature of the compressor inlet.

4. Press the [SEL] key once.

"P1" is displayed, but this feature is not available on this product.

Check of the pressure of the higher pressure side of the refrigerant circuit

5. Press the [SEL] key once.

The pressure of higher pressure refrigerant circuit is displayed on the digital display.

Displays the pressure of the higher pressure side of the refrigerant circuit.

Check of the pressure of the lower pressure side of the refrigerant circuit

6. Press the [SEL] key once.

The pressure of lower pressure refrigerant circuit is displayed on the digital display.

Displays the pressure of the lower pressure side of the refrigerant circuit.

Displayed only when the compressor is operating.

7. Press the [SEL] key once.

"d1" is displayed, but this feature is not available on this product.

5.4 Inspection monitor menu HRSE Series

Page 49

5-11

Check of the accumulated operation time of the pump

PV

SV

Cumulative time

Indicated value

0h to 999h

to

1,000h to 99,999h

to

100,000h

Return to

PV

SV

PV

SV

PV

SV

8. Press the [SEL] key once.

The accumulated operation time of the pump is displayed on the digital display.

Displays the accumulated operation time of the pump. Refer to the table below for the display.

AL28 Pump maintenance alarm is generated when the accumulated operation time of the

pump reaches 20,000 hours ( ) or more. For details, refer to Chapter 6 Alarm

indication and trouble shooting.

Check of the accumulated operation time of the fan motor

HRX-OM-R039

Chapter 5 Display and setting of various functions

Table 5.4-2 List of time display

9. Press the [SEL] key once.

The accumulated operation time of the fun motor is displayed on the digital display.

Displays the accumulated operation time of the fan motor. Refer to Table 5.4-2 for the display.

AL29 Fan motor maintenance alarm is generated when the accumulated operation time of

the fan motor reaches 20,000 hours ( ) or more. For details, refer to Chapter 6

Alarm indication and trouble shooting.

Check of the accumulated operation time of the compressor

10. Press the [SEL] key once.

The accumulated operation time of the compressor is displayed on the digital display.

Displays the accumulated operation time of the compressor. Refer to Table 5.4-2 for the

display.

AL30 Compressor maintenance alarm is generated when the accumulated operation time

of the compressor reaches 50,000 hours ( ) or more. For details, refer to

Chapter 6 Alarm indication and trouble shooting.

Check of the accumulated operation time

11. Press the [SEL] key once.

The accumulated operation time is displayed on the digital display.

Displays the accumulated operation time. Refer to Table 5.4-2 for the display.

HRSE Series 5.4 Inspection monitor menu

Page 50

HRX-OM-R039

5-12

Display

Item

Contents

Initial value

(Default setting)

Alarm buzzer sound

Sets alarm buzzer sound.

ON

PV

SV

PV

SV

PV

SV

PV

SV

Set value

Explanation

Initial value

(Default setting)

No alarm buzzer sound

Alarm buzzer sound

✓