SMC Networks HRS200 Series, HRS200-A*-46-*S Series Information

INFORMATION

Thermo-chiller

Standard Type

Air-cooled 460 V Type

How to Order

HRS 200 A

Cooling capacity

200

20.5 kW

Nil

F

N

NPT (With Rc-NPT conversion fitting)

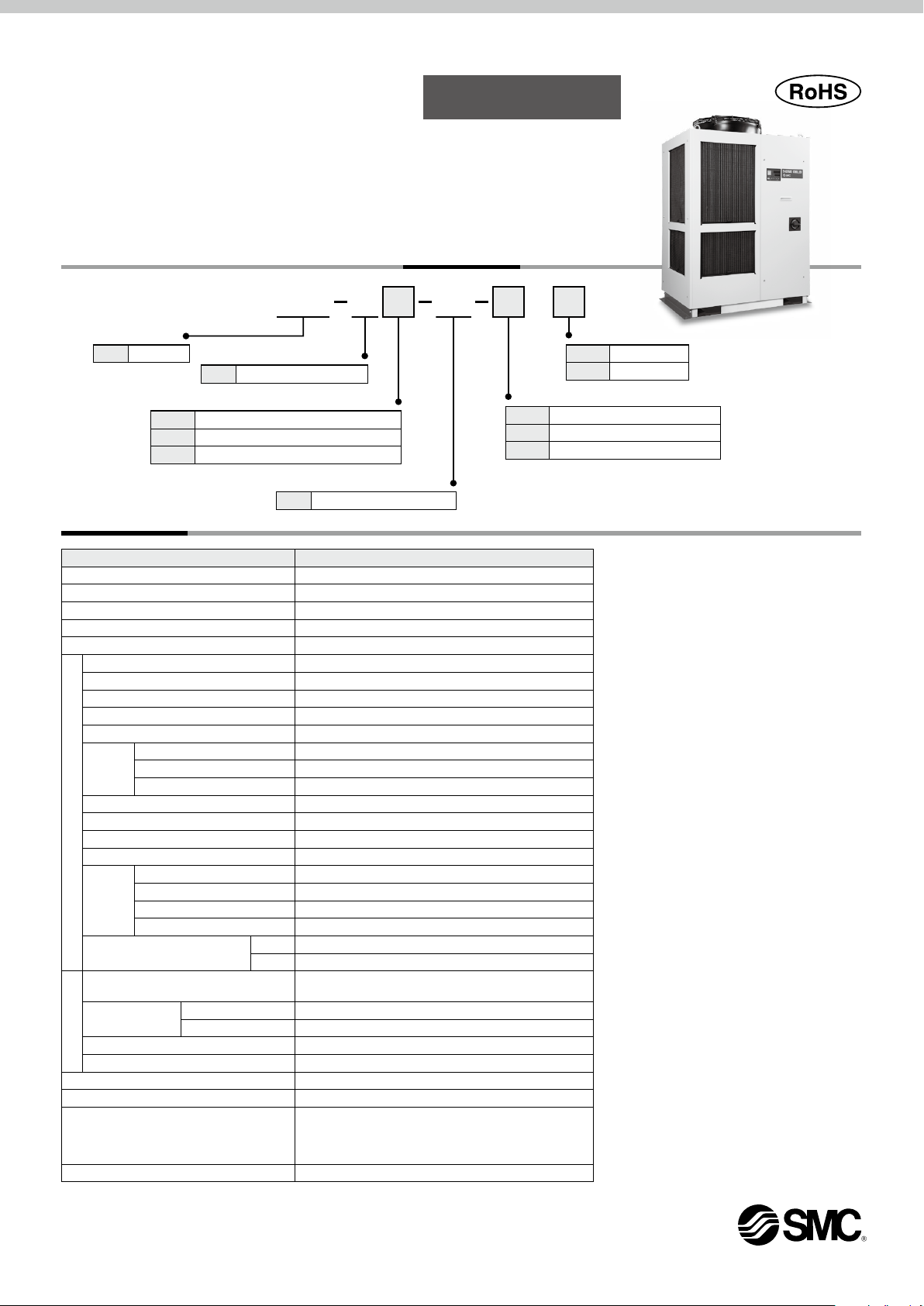

Specifications

Model

Cooling method Air-cooled refrigeration

Refrigerant R410A (HFC)

Refrigerant charge kg 1.65

Control method PID control

Ambient temperature/Altitude

Circulating fluid

Set temperature range

Cooling capacity

Heating capacity

Temperature stability

Pump

capacity

Minimum operating flow rate

Tank capacity L 25

Circulating fluid outlet, circulating fluid return port

Tank drain port Rc3/4 (Symbol F: G3/4, Symbol N: NPT3/4)

Circulating fluid system

Automatic

fluid fill

system

(Standard)

Fluid contact material

Power supply

Applicable earth leakage

breaker (Standard)

Rated operating current

Electrical system

Rated power consumption

Noise level (Front 1 m/Height 1 m)

Waterproof specification IPX4

Accessories

Weight (dry state) kg 214

1, 2

*

1

*

3, 7

*

4

*

5

*

Rated flow (Outlet) L/min 45 (0.45 MPa)

Maximum flow rate L/min 130

Maximum pump head m 50

Supply side pressure range

Supply side fluid temperature

Automatic fluid fill port Rc1/2 (Symbol F: G1/2, Symbol N: NPT1/2)

Overflow por t

Rated current

Sensitivity of leak current

Cooling method

A

Air-cooled refrigeration

Pipe thread type

Rc

G (With Rc-G conversion fitting)

46

3-phase 460 VAC (60 Hz)

1, 7

*

5

*

°C

°C

kW 20.5

kW 5.3

°C ±1

6

*

L/min 25

MPa 0.2 to 0.5

°C

Metal

Resin PTFE, PU, FKM, EPDM, PVC, NBR, POM, PE, NR

A 30

mA 30

A 14.2

5

*

kW(kVA)

5

*

dB(A) 75

Temperature: –5 to 45, Altitude: less than 3000 m

Tap water, 15% Ethylene glycol aqueous solution, Deionized water

Stainless steel, Copper (Heat exchanger brazing), Brass, Bronze

Allowable voltage range ±10% (No continuous voltage fluctuation)

Operation Manual (for installation/operation) 1 pc. (English),

Y-strainer (40 meshes) 25A, Barrel nipple 25A,

Anchor bolt fixing brackets 2 pcs. (including 6 M8 bolts)

Power supply

Rc1 (Symbol F: G1, Symbol N: NPT1)

Rc1 (Symbol F: G1, Symbol N: NPT1)

3-phase 460 VAC (60 Hz)

Alarm code list sticker 1 pc. (English),

46

HRS200-Am-46-mS

5 to 35

5 to 35

9.1 (11.4)

S

Option 1

Nil None

A With caster adjuster-foot

1

*

K

*1 This is a manual fluid fill port that is different from the automatic

fluid fill port. Fluid can be supplied manually into the tank without

removing the side panel. (Fluid can be supplied manually for

models without option K if the side panel is removed.)

(Pending for UL Standards)

Option 2

Nil None

W SI unit only

With fluid fill port

*1 When the ambient temperature or circulating fluid

temperature is 10°C or below, refer to "Operation at

low ambient temperature or low circulating fluid temperature" (page 14).

*2 Use fluid in condition below as the circulating fluid.

Tap water: Standard of The Japan Refrigeration And

Air Conditioning Industry Association (JRA GL-02-

1994)

15% ethylene glycol aqueous solution: Diluted with

clean water, without any additives such as antiseptics.

Deionized water: Electric conductivity 1 μS/cm or

higher (Electric resistivity 1 MΩ·cm or lower)

*3 q Ambient temperature: 32°C, w Circulating fluid:

Tap water, e Circulating fluid temperature: 20°C, r

Circulating fluid flow rate: Rated flow, t Power supply: 460 VAC

*4 q Ambient temperature: 32°C, w Circulating fluid:

Tap water, e Circulating fluid flow rate: Rated flow,

r Power supply: 460 VAC

*5 q Ambient temperature: 32°C, w Circulating fluid:

Tap water, e Circulating fluid temperature: 20°C, r

Load: Same as the cooling capacity, t Circulating

fluid flow rate: Rated flow, y Power supply: 460 VAC,

u Piping length: Shortest

*6 Fluid flow rate to maintain the cooling capacity. If the

actual flow rate is lower than this, install a bypass

piping.

*7 If the product is used at altitude of 1000 m or higher,

refer to “Operating Environment/Storage Environment” (page 13) Item 13 “* For altitude of 1000 m or

higher.”

*8 The anchor bolt fixing brackets (including 6 M8 bolts)

are used for fixing to wooden skids when packaging

the thermo-chiller. No anchor bolt is included.

8

*

HRS200 Series

18-E700

617

1020 (Dimension of anchor bolt fixing bracket)

2

715

556

851

1114

428

421

278

110

108

Overflow port Rc1

Fluid level indicator

Power cable entry (Hole 40)

(Grommet with membrane)

Tank drain port Rc3/4

(Valve stopper)

485

574

382

305

270

104

65

Handle

Circulating fluid outlet Rc1

Facility water outlet Rc1

Facility water inlet Rc1

Circulating fluid return port

Rc1

(850) (Thermo-chiller dimension)

700

1100 (Dimension of anchor bolt fixing bracket)

756 136

12 x ø12

670

43

752

50

(1035) (Thermo-chiller dimension)

1064

19

76

View B-B

HRS200 Series

Standard Type

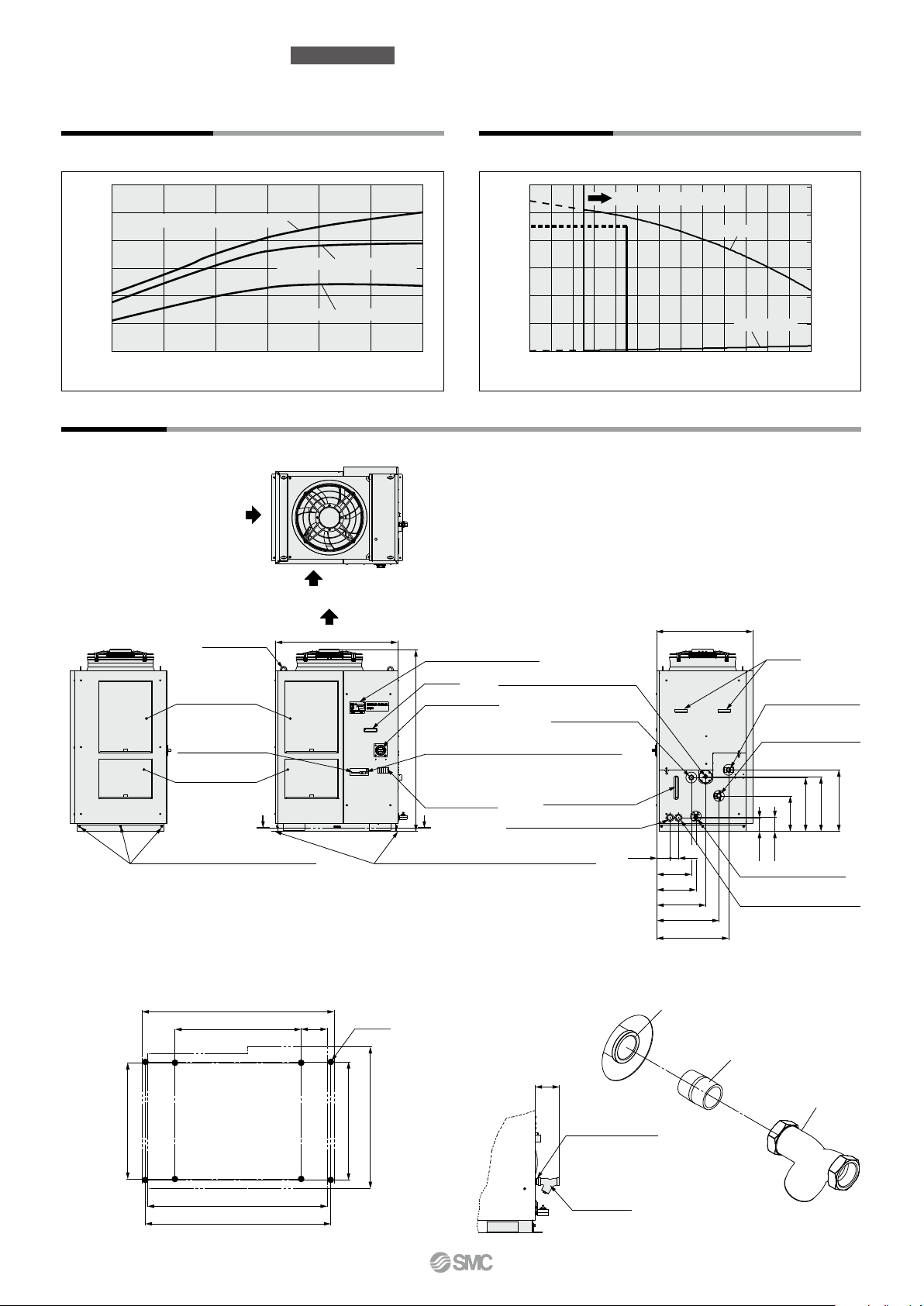

Cooling Capacity Pump Capacity

HRS200-Am-46-mS HRS200-Am-46-mS

30

25

Ambient temperature 32°C

20

15

Ambient temperature 40°C

10

Cooling capacity [kW]

5

0

5 10 15 20 25 30 35

Circulating fluid temperature [°C]

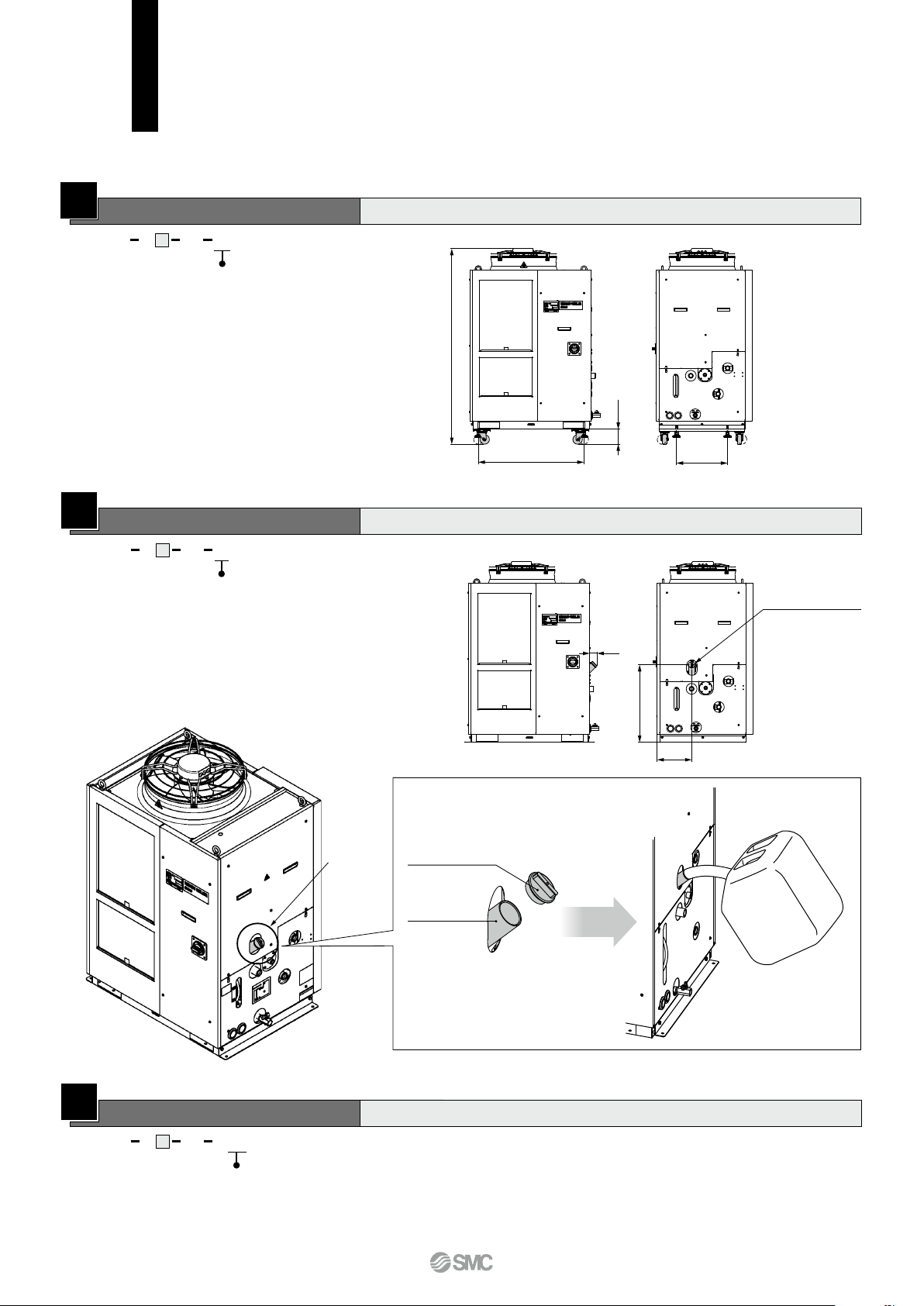

Dimensions

HRS200-A-46-S (Air-cooled 460 V type)

Ventilation air inlet

Anchor bolt fixing position

M8 bolt (Accessory)

3 pcs. attached on the opposite side

Ventilation air outlet

Eye bolt M12

(4 places)

Dustproof filter

Contact input/output

communication connector

Dustproof filter

Ambient temperature 45°C

Ventilation air inlet

A A

670

954

138

Anchor bolt fixing bracket (Accessory)

For details about the fixing position, refer to

“Anchor bolt fixing position” shown below.

8 x ø1

0.6

0.5

0.45

0.4

0.3

0.2

0.1

Circulating fluid pressure [MPa]

0

0 2010

Operation display panel

Handle

Breaker handle

Serial communication (RS-485/RS-232C) connector

1420

D-sub female receptacle

Power terminal

Automatic fluid fill port Rc1/2

Overflow port Rc1

Fluid level indicator

Signal cable entry (Hole 40)

(Grommet with membrane)

Accessory: Y-strainer mounting view

Usable flow rate range

Outlet

Return port

45

403050

60 70 80 90

100 110 120 130

Circulating fluid flow rate [L/min]

752

270

305

382

65

485

560

Tank drain port Rc3/4

(Valve stopper)

Power cable entry (Hole 40)

(Grommet with membrane)

105

Circulating fluid return port Rc1

60

50

40

30

20

Pump head [m]

10

0

Handle

Circulating fluid outlet

Rc1

Circulating fluid return port

Rc1

480

428

421

278

110

107

(954) (Thermo-chiller dimension)

1

984

View A-A

Barrel nipple 25A

130

627

(752) (Thermo-chiller dimension)

Barrel nipple (25A)

(Accessory)

Y-strainer

(Accessory)

Y-strainer

(40 mesh) 25A

Partially enlarged view A

Thermo-chiller

Standard Type

HRS200 Series

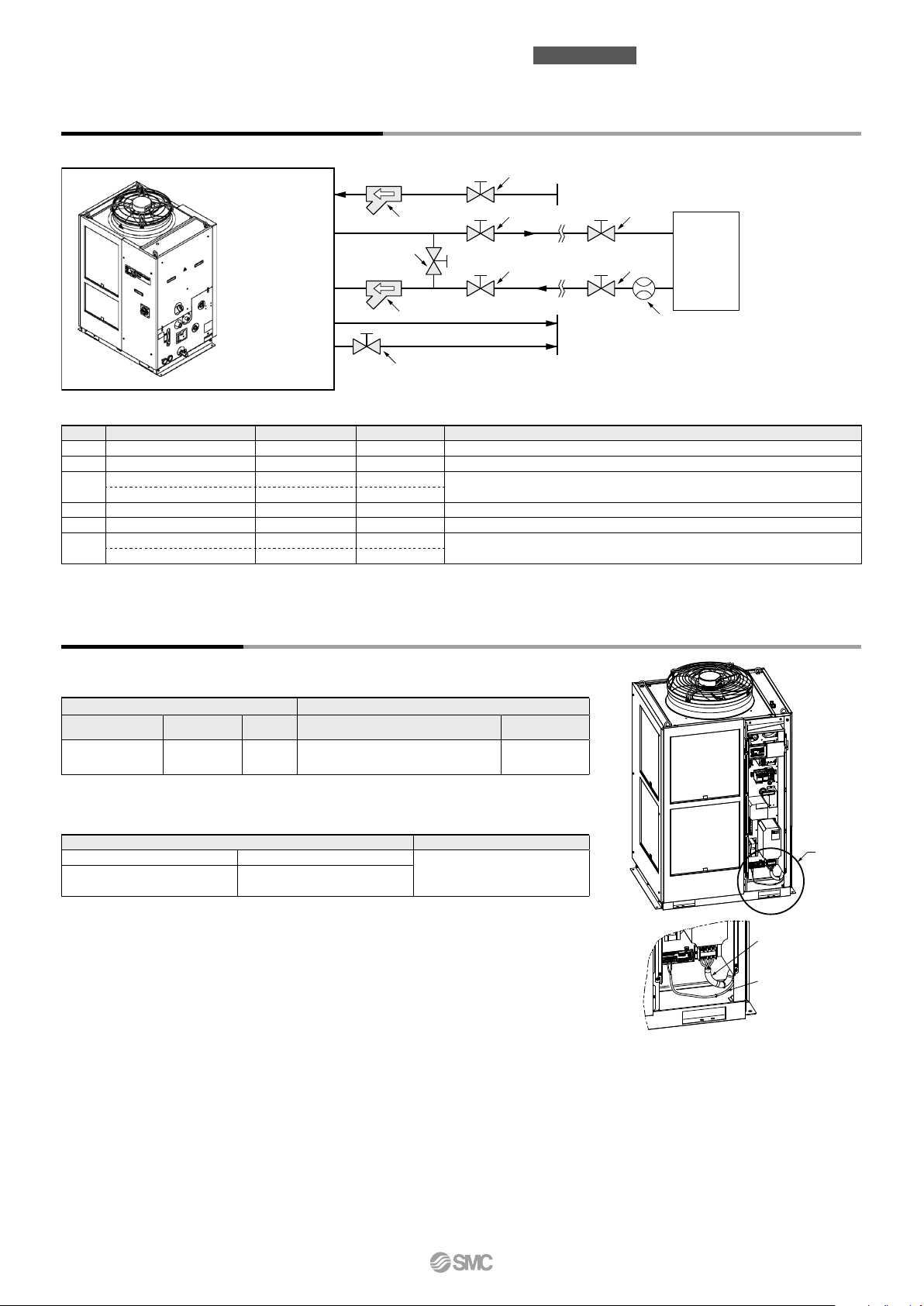

Recommended External Piping Flow

External piping circuit is recommended as shown below.

Thermo-chiller

automatic fluid

fill port

Circulating fluid

outlet

6

1

Circulating fluid

return port

Overflow port

3

Tank drain port

5

* Ensure that the overflow port is connected to the wastewater collection pit in order to avoid damage to the tank of the thermo-chiller.

1

Fluid supply

2 2

2 2

To wastewater collection pit

User’s

equipment

4

No. Description Size

1 Valve Rc1/2 — —

2 Valve Rc1 — —

3

4 Flow meter — — Prepare a flow meter with an appropriate flow range.

Valve (Part of thermo-chiller)

5

6

*1 The filter shown above cannot be directly connected to the thermo-chiller. Install it in the user’s piping system.

Y-strainer Rc1 #40 Accessory

Filter Rc1 20 μm HRS-PF005

Rc3/4 — —

Y-strainer Rc1/2 #40 —

Filter Rc1/2 20 μm —

Recommended part no.

*

Note

Install either the strainer or filter. If foreign matter with a size of 20 μm or more are likely to enter, install

1

the particle filter. For the recommended filter, refer to the optional accessory HRS-PF005 (page 9).

Install either the strainer or filter. If foreign matter with a size of 20 μm or more

are likely to enter, select and prepare a particle filter.

Cable Specifications

Power supply and signal cable should be prepared by user.

Power Cable Specifications

Rated value for thermo-chiller Power cable examples

Power supply

3-phase 460 VAC

(60 Hz)

An example of the cable specifications is when two kinds of vinyl insulated wires with a continuous allowable operating temperature

*

of 70°C at 600 V, are used at an ambient temperature of 30°C. Select the proper size of cable according to an actual condition.

Applicable breaker

rated current

30 A M5

Terminal block

thread size

Cable size

4 cores x 5.5 mm2 (4 cores x AWG10)

(Including grounding cable)

Signal Cable Specifications

Terminal block screw diameter Recommended crimped terminal

Terminal specifications Cable specifications

M3

Y-shape crimped terminal

1.25Y-3

0.75 mm

Crimped terminal on

the thermo-chiller side

2

(AWG18)

Shielded cable

R5.5-5

A

Power cable

Signal cable

2

t

r

y

u

i

o

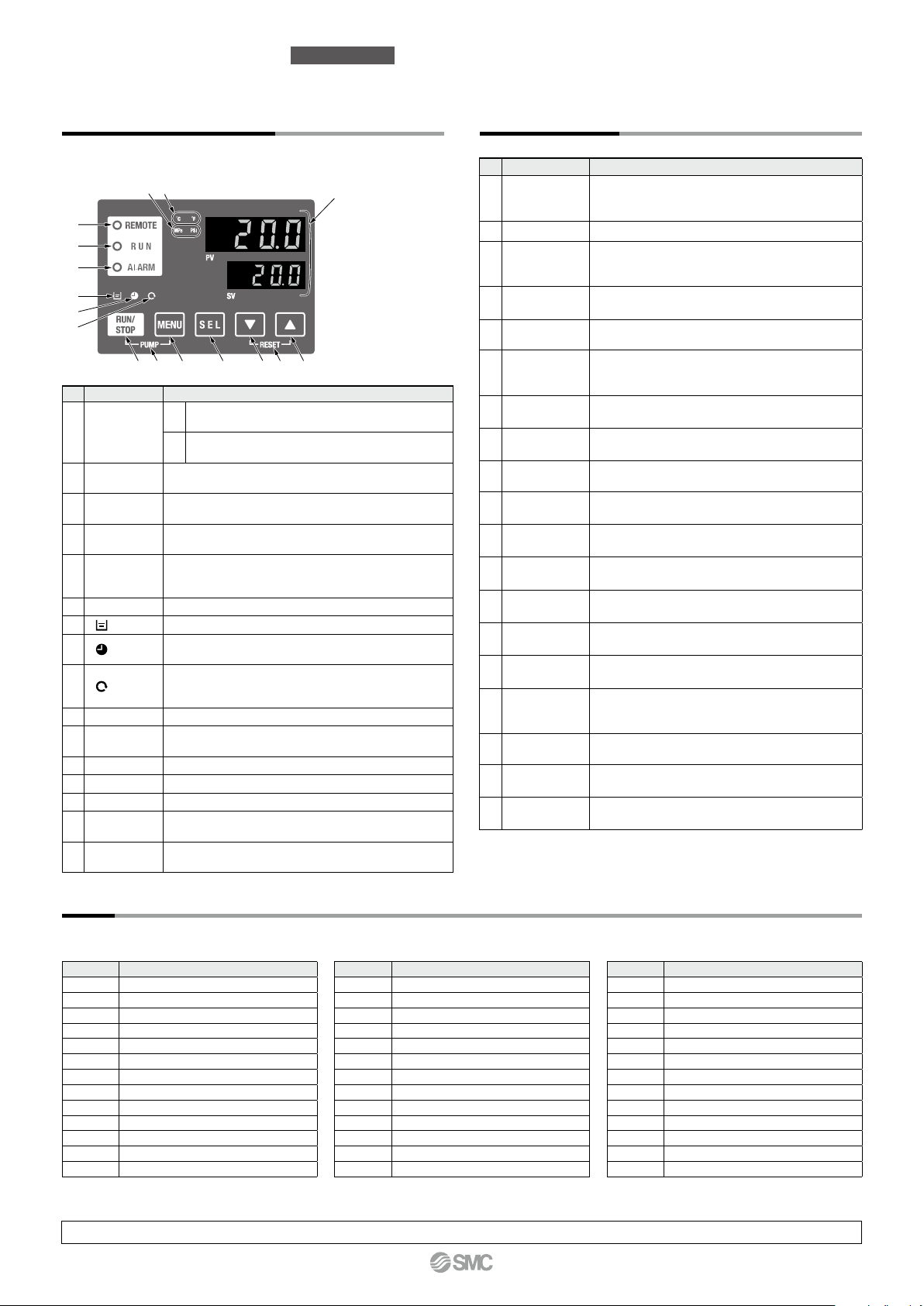

HRS200 Series

Standard Type

Operation Display Panel

The basic operation of this unit is controlled through the

operation display panel on the front of the product.

we

!0 !1 !2 !3 !4!5 !6

No.

Description Function

Displays the circulating fluid current discharge temperature

lamp

lamp

lamp

lamp

PV

and pressure and alarm codes and other menu items (codes).

Displays the circulating fluid discharge temperature

SV

and the set values of other menus.

Equipped with a unit conversion function. Displays the

unit of displayed temperature (default setting: °C).

Equipped with a unit conversion function. Displays the

unit of displayed pressure (default setting: MPa).

Enables remote operation (start and stop) by

communication. Lights up during remote operation.

Lights up when the product is started, and goes off when

it is stopped. Flashes during stand-by for stop or antifreezing function, or independent operation of the pump.

Flashes with buzzer when alarm occurs.

Lights up when the surface of the fluid level indicator falls below the L level.

Equipped with a timer for start and stop. Lights up

when this function is operated.

Equipped with a power failure auto-restart function, which

restarts the product automatically after stopped due to a

power failure. Lights up when this function is operated.

Makes the product start or stop.

Shifts the main menu (display screen of circulating fluid discharge temperature

and pressure) and other menus (for monitoring and entry of set values).

Press the [MENU] and [RUN/STOP] keys simultaneously. The pump starts

running independently to make the product ready for start-up (release the air).

Press the [] and [] keys simultaneously. The alarm

buzzer is stopped and the [ALARM] lamp is reset.

Digital display

(7-segment,

q

4 digits)

[°C] [°F] lamp

w

[MPa] [PSI]

e

lamp

[REMOTE]

r

lamp

[RUN]

t

[ALARM] lamp

y

[ ]

u

[ ]

i

[ ]

o

[RUN/STOP] key

!0

[MENU] key

!1

[SEL] key Changes the item in menu and enters the set value.

!2

[] key Decreases the set value.

!3

[] key Increases the set value.

!4

[PUMP] key

!5

[RESET] key

!6

q

List of Function

No.

Function Outline

Displays the current and set temperature of the

1 Main display

2

Alarm display menu

Inspection

3

monitor menu

4 Key-lock

Timer for operation

5

start/stop

Signal for the

6

completion of

preparation

7

Offset function

Reset after

8

power failure

Key click

9

sound setting

Changing

10

temp. unit

Changing

11

pressure unit

12 Data reset

Accumulation

13

time reset

Anti-freezing

14

function

Warming-up

15

function

Anti-snow

16

coverage

function

Alarm buzzer

17

sound setting

Alarm

18

customizing

19

Communication

circulating fluid, discharge pressure of the circulating

fluid. Changes the circulating fluid set temperature.

Indicates alarm number when an alarm occurs.

Product temperature, pressure and accumulated

operating time can be checked as daily inspection.

Use these for daily inspection.

Keys can be locked so that set values cannot be

changed by operator error.

Timer is used to set the operation start/stop.

A signal is output when the circulating fluid

temperature reaches the set temperature, when

using contact input/output and serial communication.

Use this function when there is a temperature offset between the

discharge temperature of the thermo-chiller and user’s equipment.

Start operation automatically after the power supply

is turned on.

Operation panel key sound can be set on/off.

Temperature unit can be changed.

Centigrade (°C) ⇔ Fahrenheit (°F)

Pressure unit can be changed.

MPa ⇔ PSI

Functions can be reset to the default settings

(settings when shipped from the factory).

Reset function when the pump, the fan or the compressor

is replaced. Reset the accumulated time here.

Circulating fluid is protected from freezing during winter

or at night. Set beforehand if there is a risk of freezing.

When circulating fluid temperature rising time at starting

needs shortening during winter or at night, set beforehand.

If there will be a possibility of the snow coverage

due to the change of the installation environment

(season, weather), set beforehand.

Alarm sound can be set to on/off.

Operation during alarm condition and threshold

values can be changed depending on the alarm type.

This function is used for contact input/output or

serial communication.

Alarm

This unit has 39 types of alarms as standard, and displays each of them by its alarm code on the PV screen with the [ALARM] lamp ([LOW LEVEL] lamp) lit

up on the operation display panel. The alarm can be read out through communication.

Code Alarm message

AL01 Low level in tank

AL02 High circulating fluid discharge temp.

AL03 Circulating fluid discharge temp. rise

AL04 Circulating fluid discharge temp. drop

AL05 High circulating fluid return temp.

AL08 Circulating fluid discharge pressure rise

AL09 Circulating fluid discharge pressure drop

AL10 High compressor intake temp.

AL11 Low compressor intake temp.

AL12 Low super heat temp.

AL13 High compressor discharge pressure

AL15

Refrigeration circuit pressure (high pressure side) drop

AL16

Refrigeration circuit pressure (low pressure side) rise

For details, refer to the Operation Manual. Please download it via our website, https://www.smcworld.com

3

Code Alarm message

AL17

Refrigeration circuit pressure (low pressure side) drop

AL18 Compressor running failure

AL19 Communication error

AL20 Memory error

AL21 DC line fuse cut

AL22

Circulating fluid discharge temp. sensor failure

AL23

Circulating fluid return temp. sensor failure

AL24 Compressor intake temp. sensor failure

AL25

Circulating fluid discharge pressure sensor failure

AL26

Compressor discharge pressure sensor failure

AL27

Compressor intake pressure sensor failure

AL28 Pump maintenance

AL29 Fan maintenance

Code Alarm message

AL30 Compressor maintenance

AL31 Contact input 1 signal detection

AL32 Contact input 2 signal detection

AL37

Compressor discharge temp. sensor failure

AL38 Compressor discharge temp. rise

AL40 Dustproof filter maintenance

AL41 Power stoppage

AL42 Compressor waiting

AL43 Fan failure

AL45 Compressor over current

AL47 Pump over current

AL50 Incorrect phase error

AL51 Phase board over current

Communication Functions

To the thermo-chiller

User’s equipment side

To the thermo-chiller User’s equipment side

To the thermo-chiller User’s equipment side

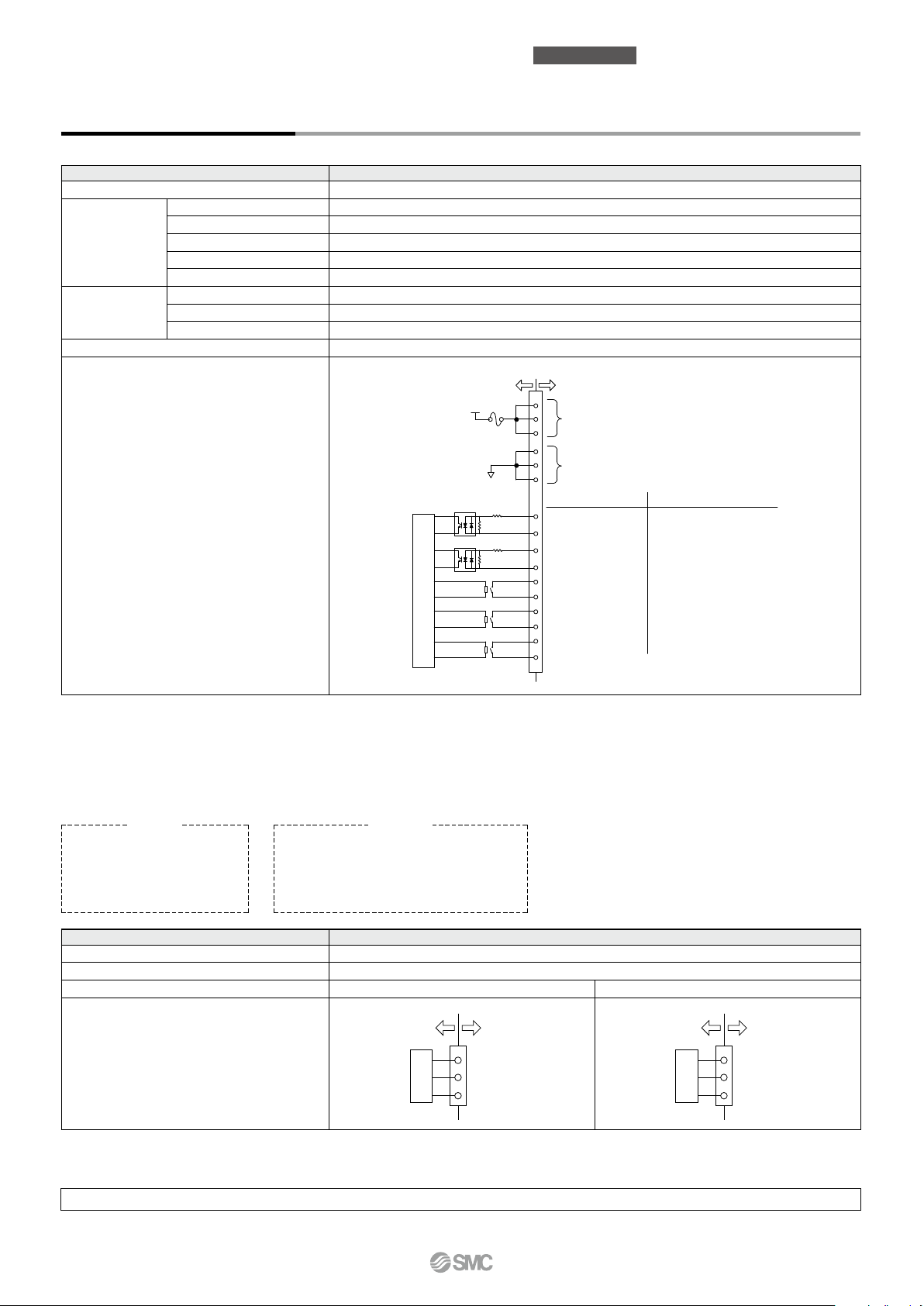

Contact Input/Output

Item Specifications

Connector type M3 terminal block

Insulation method Photocoupler

Rated input voltage 24 VDC

Input signal

Contact output

signal

Operating voltage range 21.6 to 26.4 VDC

Rated input current 5 mA TYP

Input impedance 4.7 kW

Rated load voltage 48 VAC or less/30 VDC or less

Maximum load current 500 mA AC/DC (Resistance load)

Minimum load current 5 VDC 10 mA

Output voltage 24 VDC ±10% 500 mA MAX (No inductive load)

Thermo-chiller

Standard Type

HRS200 Series

7

6

24 VDC output

(500 mA MAX)

5

15

14

24 VCOM output

13

Signal description

12

Contact input signal 2

4

11

Contact input signal 1

3

10

Contact output signal 3

2

9

Contact output signal 2

1

8

Contact output signal 1

0

2

∗

Default setting

Run/stop signal input

Alarm status signal output

Remote status signal output

Operation status signal output

1

∗

—

Circuit diagram

24 VCOM

Internal circuit

24 VDC

1 kΩ

1 kΩ

4.7 kΩ

4.7 kΩ

*1 The pin numbers and output signals can be set by user. For details, refer to the Operation Manual for communication.

*2 When using with optional accessories, depending on the accessory, the allowable current of 24 VDC devices will be reduced. Refer to the operation

manual of the optional accessories for details.

Serial Communication

The serial communication (RS-485/RS-232C) enables the following items to be written and read out.

For details, refer to the Operation Manual for communication.

Writing

Run/Stop

Circulating fluid temperature

setting (SV)

Circulating fluid present temperature

Circulating fluid discharge pressure

Status information

Alarm occurrence information

Readout

Item Specifications

Connector type D-sub 9-pin, Female connector (Mounting screw: M2.6 x 0.45)

Protocol Modicon Modbus compliant/Simple communication protocol

Standards EIA standard RS-485 EIA standard RS-232C

Circuit diagram

* The terminal resistance of RS-485 (120 W) can be switched by the operation display panel. For details, refer to the Operation Manual for communication.

Do not connect other than in the way shown above, as it can result in failure.

Please download the Operation Manual via our website, https://www.smcworld.com

circuit

Internal

1

SD+

5

SG

9

SD−

circuit

Internal

2

RD

3

SD

5

SG

4

HRS200 Series

Option

[K: With fluid fill port]

Thread size: G1 1/2

(With cap)

56

609

271

Options

Option symbol

A

With Caster Adjuster-foot

HRS200 A 46 AS

With caster adjuster-foot

Unfixed casters and adjuster feet stops are mounted

* Options have to be selected when

ordering the thermo-chiller.

It is not possible to add them after

purchasing the unit.

1538

118

Option symbol

K

With Fluid Fill Port

HRS200 A 46 KS

With fluid fill port

When the automatic fluid fill in port is not used, water can be

supplied manually without removing the panel.

Fluid fill port

Cap

830

401

Option

[K: With fluid fill port]

Thread size: G1 1/2

56

609

271

(With cap)

Fluid fill port

Option symbol

W

SI Unit Only

HRS200 A 46 SW

SI unit only

The circulating fluid temperature and pressure are displayed in SI units [MPa/°C] only.

If this option is not selected, a product with a unit selection function will be provided by default.

* No change in external dimensions

5

Loading...

Loading...