SMC Networks HRS100-AX-20-X, HRS150-AX-20-X, HRS100-AX-40-X, HRS150-AX-40-X, HRS100-WX-20-X Operation Manual

...Page 1

HRX-OM-S004

1

st

edition: Jul. 2014

2

nd

edition: Nov. 2014

Operation Manual

Installation・Operation

Original Instructions

Thermo chiller

HRS100-A∗-20-∗

HRS150-A

∗

-20-∗

HRS100-A

∗

-40-∗

HRS150-A

∗

-40-∗

HRS100-W

∗

-20-∗

HRS150-W

∗

-20-∗

HRS100-W

∗

-40-∗

HRS150-W

∗

-40-∗

Keep this manual available whenever necessary

© 2014 SMC CORPORATION All Rights Reserved

Page 2

To the users

Thank you for purchasing SMC’s Thermo chiller (hereinafter referred to as the “product”).

For safety and long life of the product, be sure to read this operation manual (hereinafter referred to as the

“manual”) and clearly understand the contents.

• Be sure to read and follow all instructions noted with “Warning” or “Caution” in this manual.

• This manual is intended to explain the installation and operation of the product. Only people who

understand the basic operation of the product through this manual or who perform installation and

operation of or have basic knowledge about industrial machines are allowed to work on the product.

• This manual and other documents attached to the product do not constitute a contract, and will not

affect any existing agreements or commitments.

• It is strictly prohibited to copy this manual entirely or partially for the use by a third party without prior

permission from SMC.

Note: This manual is subject to possible change without prior notice.

Page 3

HRX-OM-S004

Contents

HRS Series

Contents

Chapter 1 Safety Instructions .......................................................... 1-1

1.1 Before using the product ..........................................................................................1-1

1.2 Reading the Manual ...................................................................................................1-1

1.3 Hazards ....................................................................................................................... 1-2

1.3.1 Level of hazards ................................................................................................................. 1-2

1.3.2 Definition of “Serious injury” and “Minor injury” .................................................................. 1-2

1.4 Product Label .............................................................................................................1-3

1.5 Safety Measures.........................................................................................................1-4

1.5.1 Safety Instructions for Use ................................................................................................. 1-4

1.5.2 Personal protective equipment........................................................................................... 1-4

1.6 Emergency Measures ................................................................................................1-5

1.7 Waste disposal...........................................................................................................1-5

1.7.1 Disposal of refrigerant and compressor oil......................................................................... 1-5

1.7.2 Disposal of product............................................................................................................. 1-5

1.8 Material Safety Data Sheet (MSDS) ..........................................................................1-6

Chapter 2 Name and Function of Parts............................................. 2-1

2.1 Model number of product..........................................................................................2-1

2.2 Name and Function of Parts .....................................................................................2-2

2.2.1 HRS100/150-A∗-20/40 (In case of air cooled type)............................................................ 2-2

2.2.2 HRS100/150-W∗-20/40 (In case of water cooled type)...................................................... 2-3

2.3 Function of Parts........................................................................................................2-4

2.4 Operation display panel ............................................................................................2-5

Chapter 3 Transport and Setting Up ................................................. 3-1

3.1 Transport ....................................................................................................................3-1

3.1.1 Transportation using forklift and hanging ........................................................................... 3-2

3.1.2 Transportation using casters .............................................................................................. 3-3

3.2 Installation .................................................................................................................. 3-4

3.2.1 Environment........................................................................................................................ 3-4

3.2.2 Location .............................................................................................................................. 3-6

3.2.3 Installation and Maintenance Space................................................................................... 3-8

3.3 Installation .................................................................................................................. 3-9

3.3.1 Installation........................................................................................................................... 3-9

3.3.2 Electrical wiring..................................................................................................................3-11

3.3.3 Preparation and wiring of power supply cable.................................................................. 3-13

3.3.4 Contact input/output communicatin wiring........................................................................ 3-18

3.3.5 Wiring of run/stop signal input・Remote signal input ........................................................ 3-19

3.3.6 Wiring of external switch signal input ............................................................................... 3-21

3.3.7 Wiring of contact output signal ......................................................................................... 3-24

3.3.8 RS-485 communication wiring.......................................................................................... 3-25

Page 4

HRX-OM-S004

Contents

HRS Series

3.3.9 RS-232C communication wiring........................................................................................3-26

3.4 Piping........................................................................................................................ 3-27

3.5 Circulating Fluid Supply..........................................................................................3-31

3.5.1 Automatic fluid-fill function ................................................................................................3-31

3.5.2 Fill of fluid without using auto fluid-fill function..................................................................3-33

3.5.3 For option K “Fluid-fill port” ...............................................................................................3-35

Chapter 4 Starting the Product.......................................................... 4-1

4.1 Before Starting........................................................................................................... 4-1

4.2 Preparation for Start ..................................................................................................4-2

4.2.1 Power supply.......................................................................................................................4-2

4.2.2 Option B [Earth leakage breaker]........................................................................................4-2

4.2.3 For HRS100/150-**-40........................................................................................................4-3

4.2.4 Setting of circulating fluid temperature ...............................................................................4-3

4.3 Preparation of circulating fluid.................................................................................4-4

4.4 Operation Start and Stop...........................................................................................4-7

4.4.1 Starting the product............................................................................................................. 4-7

4.4.2 Stopping the product...........................................................................................................4-8

4.5 Check items during startup ......................................................................................4-9

4.6 Adjustment of Circulating Fluid flow rate................................................................ 4-9

Chapter 5 Display and setting of various functions........................ 5-1

5.1 List of function........................................................................................................... 5-1

5.2 Function...................................................................................................................... 5-2

5.2.1 Key operations ....................................................................................................................5-2

5.2.2 List of parameters ...............................................................................................................5-4

5.3 Main Display............................................................................................................... 5-7

5.3.1 Main Display........................................................................................................................ 5-7

5.3.2 Items on the main display ...................................................................................................5-7

5.4 Alarm Menu ................................................................................................................5-8

5.4.1 Alarm menu.........................................................................................................................5-8

5.4.2 Items shown on the alarm menu display ............................................................................5-8

5.5 Check monitor menu .................................................................................................5-9

5.5.1 Check monitor menu...........................................................................................................5-9

5.5.2 Checking with the Inspection monitor menu .......................................................................5-9

5.6 Key-lock.................................................................................................................... 5-13

5.6.1 Key-lock ............................................................................................................................5-13

5.6.2 Key-lock setting / checking ...............................................................................................5-14

5.7 Run timer, stop timer function................................................................................5-15

5.7.1 Run timer and stop timer function ..................................................................................... 5-15

5.7.2 Setting and checking of Run timer and stop timer function ..............................................5-17

5.8 Ready completion (TEMP READY) signal..............................................................5-19

Page 5

HRX-OM-S004

Contents

HRS Series

5.8.1 Ready completion (TEMP READY) signal ....................................................................... 5-19

5.8.2 Ready completion (TEMP READY) signal setting / checking .......................................... 5-20

5.9 Offset function .........................................................................................................5-22

5.9.1 Offset function................................................................................................................... 5-22

5.9.2 Usage example of offset function ..................................................................................... 5-23

5.9.3 Setting/checking of offset function.................................................................................... 5-25

5.10 Operation Restoration after Power Failure............................................................ 5-27

5.10.1 Operation restoration function after power failure ............................................................ 5-27

5.10.2 Setting/checking of the operation restoration function ..................................................... 5-28

5.11 Anti-freezing function..............................................................................................5-29

5.11.1 Anti-freezing function........................................................................................................ 5-29

5.11.2 Setting/checking of anti-freezing function......................................................................... 5-31

5.12 Key Operation Sound Setting .................................................................................5-32

5.12.1 Key operation sound setting ............................................................................................. 5-32

5.12.2 Setting/checking of the button operation sound ............................................................... 5-32

5.13 Temperature unit Change........................................................................................ 5-33

5.13.1 Temperature unit change.................................................................................................. 5-33

5.13.2 Setting/checking of temperature unit change................................................................... 5-33

5.14 Pressure unit Change..............................................................................................5-34

5.14.1 Pressure unit change........................................................................................................ 5-34

5.14.2 Setting/checking of pressure unit change ........................................................................ 5-34

5.15 Data reset function...................................................................................................5-35

5.15.1 Data reset function ........................................................................................................... 5-35

5.15.2 How to operate reset function........................................................................................... 5-35

5.16 Accumulated Operating Time Reset Function ......................................................5-36

5.16.1 Accumulated operating time reset function ...................................................................... 5-36

5.16.2 How to operate accumulated operating time reset function ............................................. 5-36

5.17 Warming up function ...............................................................................................5-40

5.17.1 Warming up function......................................................................................................... 5-40

5.17.2 Setting/checking of warming up function.......................................................................... 5-41

5.18 Anti-snow coverage function..................................................................................5-43

5.18.1 Anti-snow coverage function ............................................................................................ 5-43

5.18.2 Setting/checking of anti-snow coverage function ............................................................. 5-44

5.19 Alarm buzzer sound setting....................................................................................5-45

5.19.1 Alarm buzzer sound setting.............................................................................................. 5-45

5.19.2 Setting/checking of alarm buzzer sound .......................................................................... 5-45

5.20 Alarm customizing function....................................................................................5-46

5.20.1 Alarm customizing function............................................................................................... 5-46

5.20.2 Setting and checking of the alarm customizing function .................................................. 5-50

5.20.3 Setting of temperature alarm monitoring method and alarm generation timing ............... 5-62

Page 6

HRX-OM-S004

Contents

HRS Series

5.21 Communication function.........................................................................................5-69

5.21.1 Communication function ...................................................................................................5-69

5.21.2 Setting/checking of communication function.....................................................................5-69

Chapter 6 Alarm Notification and Troubleshooting......................... 6-1

6.1 Alarm Notification...................................................................................................... 6-1

6.2 Alarm buzzer stop...................................................................................................... 6-3

6.3 Troubleshooting.........................................................................................................6-4

6.3.1 Alarm contents, causes, and troubleshooting..................................................................... 6-4

6.3.2 How to release the thermal relay trip and circuit protector .................................................6-8

6.3.3 How to release the pump thermal trip............................................................................... 6-10

6.4 Other Errors.............................................................................................................. 6-11

Chapter 7 Control, Inspection and Cleaning.................................... 7-1

7.1 Quality Control of Circulating Fluid and Facility Water..........................................7-1

7.2 Inspection and Cleaning ...........................................................................................7-2

7.2.1 Daily check..........................................................................................................................7-2

7.2.2 Monthly check .....................................................................................................................7-3

7.2.3 Inspection every 3 months ..................................................................................................7-4

7.2.4 Inspection every 6 months ..................................................................................................7-6

7.2.5 Inspection during winter season .........................................................................................7-7

7.3 Consumables .............................................................................................................7-7

7.4 Operation Stop for an Extended Period of Time.....................................................7-8

7.4.1 Discharge of the circulating fluid .........................................................................................7-8

7.4.2 Discharge of the facility water (Water-cooled type) ............................................................7-9

Chapter 8 Documents......................................................................... 8-1

8.1 Specifications.............................................................................................................8-1

8.1.1 HRS100/150-A∗-20-∗ ..........................................................................................................8-1

8.1.2 HRS100/150-A∗-40-∗ ..........................................................................................................8-2

8.1.3 HRS100/150-W∗-20-∗ .........................................................................................................8-3

8.1.4 HRS100/150-W∗-40-∗ .........................................................................................................8-4

8.1.5 Communication specification ..............................................................................................8-5

8.2 Outline dimensions....................................................................................................8-6

8.2.1 HRS100/150-A∗-20/40-∗.....................................................................................................8-6

8.2.2 HRS100/150-W∗-20/40-∗....................................................................................................8-7

8.3 Flow diagram.............................................................................................................. 8-8

8.3.1 HRS100/150-A∗-20/40-∗.....................................................................................................8-8

8.3.2 HRS100/150-W∗-20/40-∗....................................................................................................8-9

8.4 Cooling capacity ......................................................................................................8-10

8.4.1 HRS100-A∗-20/40-∗ ..........................................................................................................8-10

8.4.2 HRS150-A∗-20/40-∗ ..........................................................................................................8-10

8.4.3 HRS100-W∗-20/40-∗......................................................................................................... 8-11

Page 7

HRX-OM-S004

Contents

HRS Series

8.4.4 HRS150-W∗-20/40-∗ .........................................................................................................8-11

8.5 Pump capacity..........................................................................................................8-12

8.5.1 HRS100/150-A/W∗-20/40-∗ .............................................................................................. 8-12

8.6 Types of Hazard Labels (HRS∗∗∗-∗∗-40-∗)..............................................................8-13

8.6.1 Positions of danger warning label .................................................................................... 8-14

8.7 Standards..................................................................................................................8-15

8.8 Sample DoC..............................................................................................................8-16

8.9 Daily Check Sheet....................................................................................................8-17

Chapter 9 Product Warranty .............................................................. 9-1

Page 8

HRX-OM-S004

Contents

HRS Series

Page 9

HRX-OM-S004

Chapter 1 Safety Instructions

HRS Series 1.1Before using the product

1-1

Chapter 1 Safety Instructions

1.1 Before using the product

z This chapter is intended to specifically describe the safety related issues

for handling the product. Read this before handling the product.

z The product is a cooling device using circulating fluid. SMC does not take

any responsibility for any problems that may arise from using the product

for other purposes.

z This product is not designed for a clean room. It generates dust from the

internal components such as pump and fan motor.

z The product is operated at high voltage and contains components which

become hot and rotate. If a component needs to be replaced or repaired,

contact a specialized vendor for parts and service.

z All personnel who work with or around the product should read and

understand the safety related information in this manual carefully before

starting work.

z The safety manager is responsible for strictly observing safety standards,

but responsibility in respect to safety standards during daily work resides

with each individual operator and maintainance personnel.

z Do not use the materials that rust or corrode for the circulating fluid

and facility water circuits. Using the materials that tend to rust or

corrode may cause clogs or/and leakages of the circulating fluid and

facility water circuits. In case of using these kind of materials, consider

and carry out some prevention against the rusting or corrosion by the

customer side.

z This manual must be kept available to operators whenever necessary.

1.2 Reading the Manual

This manual contains symbols to help identify important actions when

installing, operating or maintaining the product.

Before using the product be sure to read and understand all the

important actions highlighted in this manual.

This sign indicates actions that must be followed.

This sign indicates prohibited actions.

Page 10

HRX-OM-S004

Chapter 1 Safety Instructions

1.3 Hazards HRS Series

1-2

1.3 Hazards

1.3.1 Level of hazards

The instructions given in this manual aim to assure the safe and correct

operation of the product, and to prevent injury of operators or damage to the

product. These instructions are grouped into three categories, Danger,

Warning and Caution, which indicate the level of hazard, damage and also

the degree of emergency. All safety critical information should be carefully

observed at all times.

“DANGER”, “WARNING” and “CAUTION” signs are in order according to

severity (DANGER> WARNING> CAUTION).

1.3.2 Definition of “Serious injury” and “Minor injury”

“Serious injury”

This term describes injuries that result in after effects including loss of

eyesight, burns, electrical shock, fracture, poisoning, etc. and requires

long-term treatment or hospitalization.

“Minor injury”

This term describes injuries that do not need long-term treatment or

hospitalization. (Others excluded from serious injury.)

“WARNING”: Hazard that MAY cause serious personal injury or death during

operation.

“DANGER”: Hazard that WILL cause serious personal injury or death during

operation.

“CAUTION”: Hazard that MAY cause minor personal injury.

“CAUTION without exclamation symbol”: Hazard that MAY cause damage or failure

of the product, facility, devices, ect.

Page 11

HRX-OM-S004

Chapter 1 Safety Instructions

HRS Series 1.4Product Label

1-3

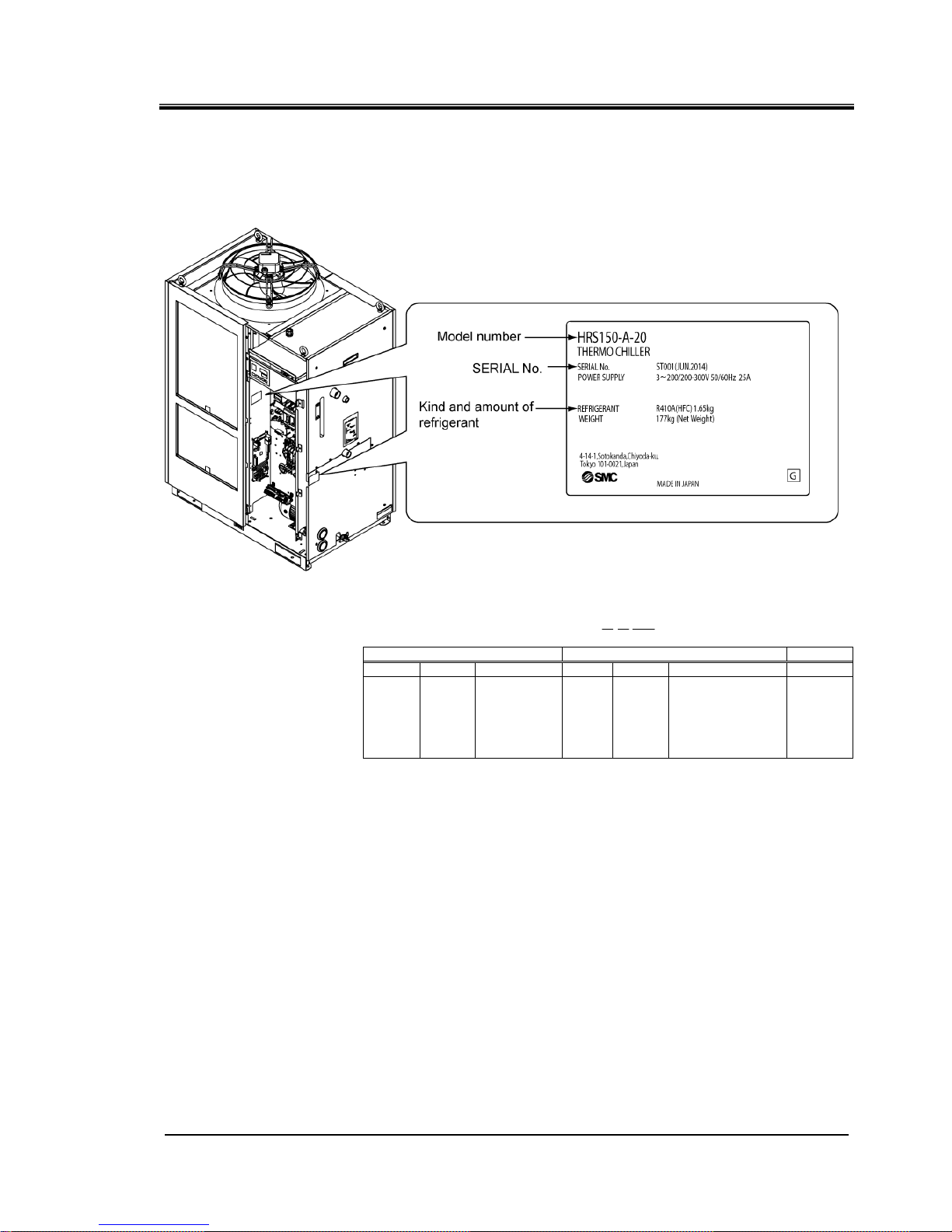

1.4 Product Label

Information about the product, such as Serial No. and Model No. can be

found on the product label. This information is needed when contacting an

SMC sales distributor.

How to see the serial number S O 001 (January 2014)

S O 001

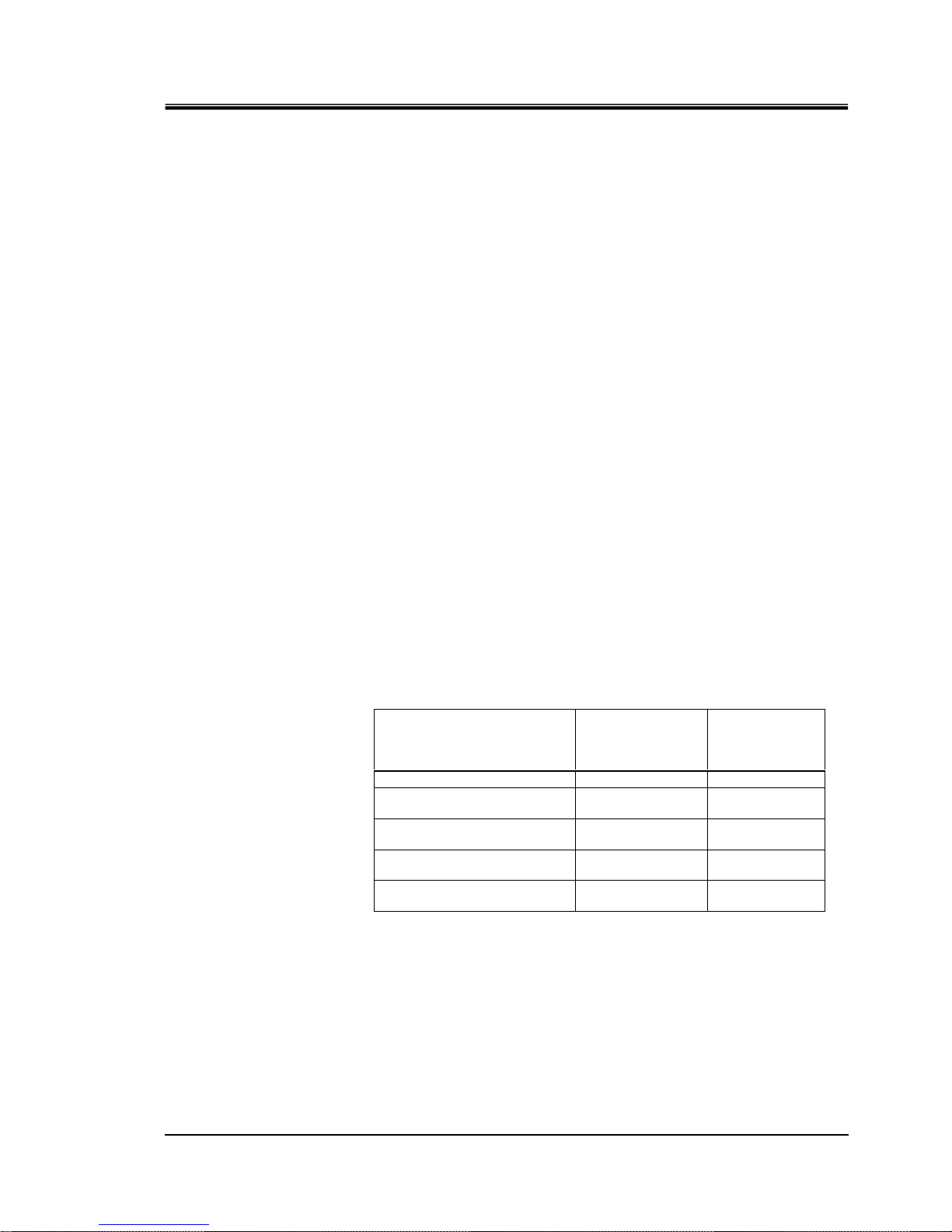

Year Symbol Remarks Month Symbol Remarks Serial no.

2014 S 1 O

2015 T 2 P

2016 U 3 Q

↓ ↓

Repeated

from

A to Z in

alphabetical

order

↓ ↓

Repeated from

O to Z in

alphabetical

order, with O for

January and Z for

December

-

Fig. 1-1 Position of the product label

∗ An example of HRS150-A-20

"3~" stands for "3 interphase".

Page 12

HRX-OM-S004

Chapter 1 Safety Instructions

1.5 Safety Measures HRS Series

1-4

1.5 Safety Measures

1.5.1 Safety Instructions for Use

z Read and understand this manual carefully before using the product.

z Before starting maintenance of the product, be sure to lock out and tag out the

breaker of the user's power supply.

z If operating the product during maintenance, be sure to inform all workers nearby.

z Use only the correct tools and procedure when installing or maintaning the product.

z Use personal protective equipment where specified (“1.5.2Personal protective

equipment”)

z Check all parts and screws are fitted correctly and securely after maintenance.

z Avoid working in a drunken or sick condition, which might cause an accident.

z Do not remove the panels except for the cases permitted in this manual.

z Do not remove the panels during operation.

z Do not handle this product by any means other than specified in this Operation

Manual; this can result in damage to the product or fire.

1.5.2 Personal protective equipment

This manual specifies personal protective equipment for each work.

Transport, Installing and Uninstalling

Handling of circulating fluid

Operation

Always use safety shoes, gloves and head protection when

transporting, installing or uninstalling the product.

Always use safety shoes, gloves, mask, apron and eye protection

when handling the circulating fluid.

Follow the instructions below when using the product. Failure to

follow the instructions may cause an accident and injury.

Always use safety shoes and gloves when operating the product.

Page 13

HRX-OM-S004

Chapter 1 Safety Instructions

HRS Series 1.6Emergency Measures

1-5

1.6 Emergency Measures

When emergency conditions such as natural disaster, fire, earthquake and

injury occur, shut off the breaker of the user’s power supply that supplies

power to the product.

1.7 Waste disposal

1.7.1 Disposal of refrigerant and compressor oil

The product uses hydro fluorocarbon type refrigerant (HFC) and

compressor oil. Comply with the laws and regulations in each country for the

disposal of refrigerant and compressor oil. The type and quantity of

refrigerant is described on the 1.4 Product Label.

If these fluids need to be recove

red, read and understand the instructions

below carefully. If there is any unclear point, contact an SMC's sales

distributor.

1.7.2 Disposal of product

The disposal of the product must be handled by a specialized industrial

waste disposal agency in accordance with local laws and regulations.

Only maintenance personnel or qualified people are allowed to open

the cover panels of the product.

Do not mix the compressor oil with domestic waste for disposal. Also,

the disposal of the waste must only be conducted by specific facilities

that are permitted for that purpose.

Even when the power supply switch is turned off, some of the internal

circuits are still energized, unless the user’s power supply is shut off.

Be sure to shut off the breaker of the user’s power supply.

Comply with the laws and regulations in each country for the disposal

of refrigerant and compressor oil.

The release of refrigerant in to the atmosphere is banned by law.

Recover it with specific equipment and dispose of it correctly.

Only people who have sufficient knowledge and experience about the

product and its accessories are allowed to recover the refrigerant and

compressor oil.

Page 14

HRX-OM-S004

Chapter 1 Safety Instructions

1.8 Material Safety Data Sheet (MSDS) HRS Series

1-6

1.8 Material Safety Data Sheet (MSDS)

If the material safety data sheets of chemicals used in this product are

needed, contact an SMC's sales distributor.

Any chemicals used by the user must be accompanied by an MSDS.

Page 15

HRX-OM-S004

Chapter 2 Name and Function of Parts

HRS Series 2.1Model number of product

2-1

Chapter 2 Name and Function of Parts

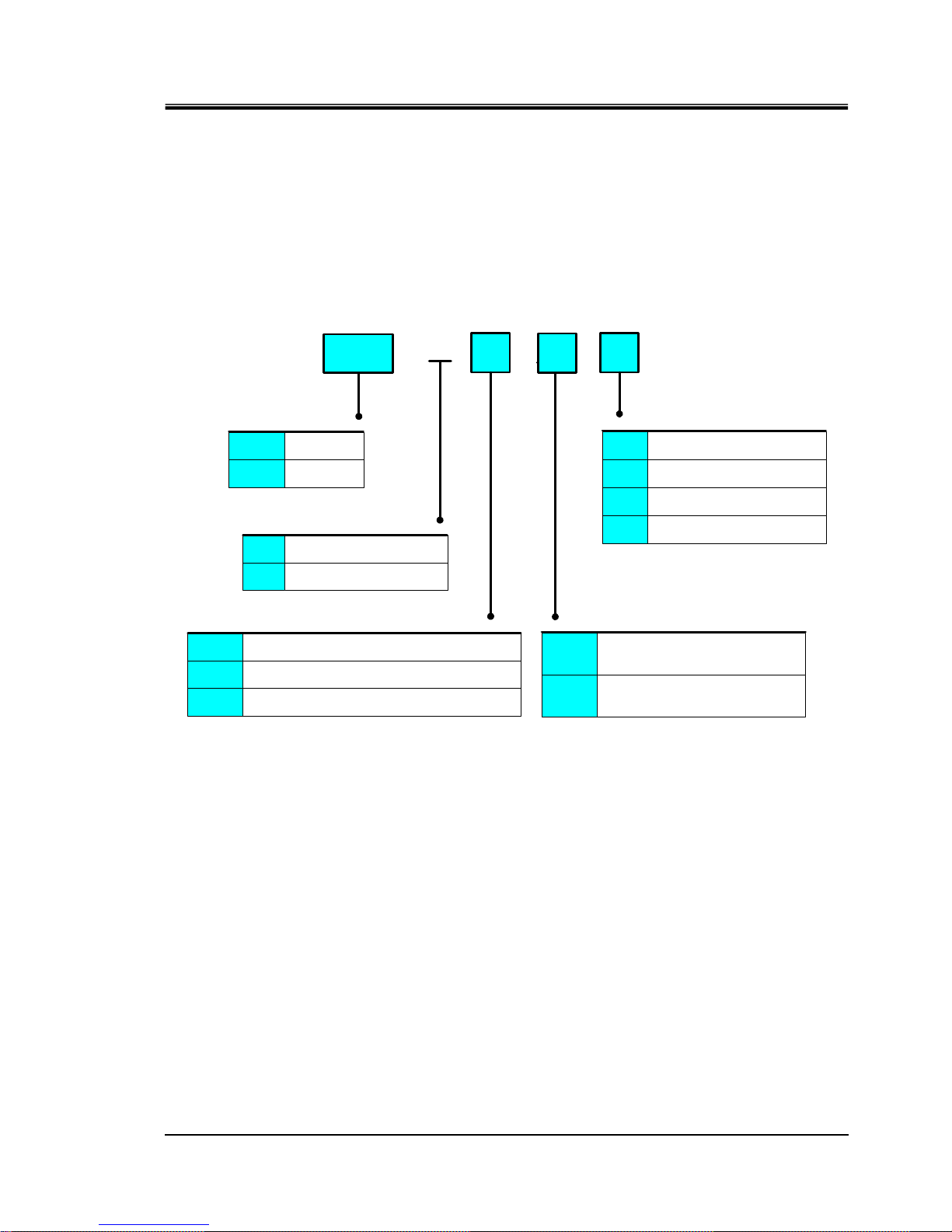

2.1 Model number of product

The product can be ordered with the model number configured as shown

below.

The product needs to be handled in different ways depending on the part

number. Refer to “1.4 Product Label”and check the part number of the

prod

uct.

HRS

①Cooling capacity

②Cooling method

③Piping thread type

④Power supply

- - -

⑤Options

A Air-cooled refrigeration

None

Nill

Nill Rc

F G (Rc-G thread adapter set is included)

N NPT (Rc-NPT thread adapter set is included)

A

20

100 10kW

W Water-cooled refrigeration

150 15kW

Casters・adjuster footsA

20

AC200V/200-230V(50/60Hz)

3phase

Earth leakage breakerB *

40 AC380-415 50/60Hz 3phase

Fluid fill portK

* : In case of power supply '40', this is

standard. (with a handle)

Fig. 2-1 Product model number

Page 16

HRX-OM-S004

Chapter 2 Name and Function of Parts

2.2 Name and Function of Parts HRS Series

2-2

2.2 Name and Function of Parts

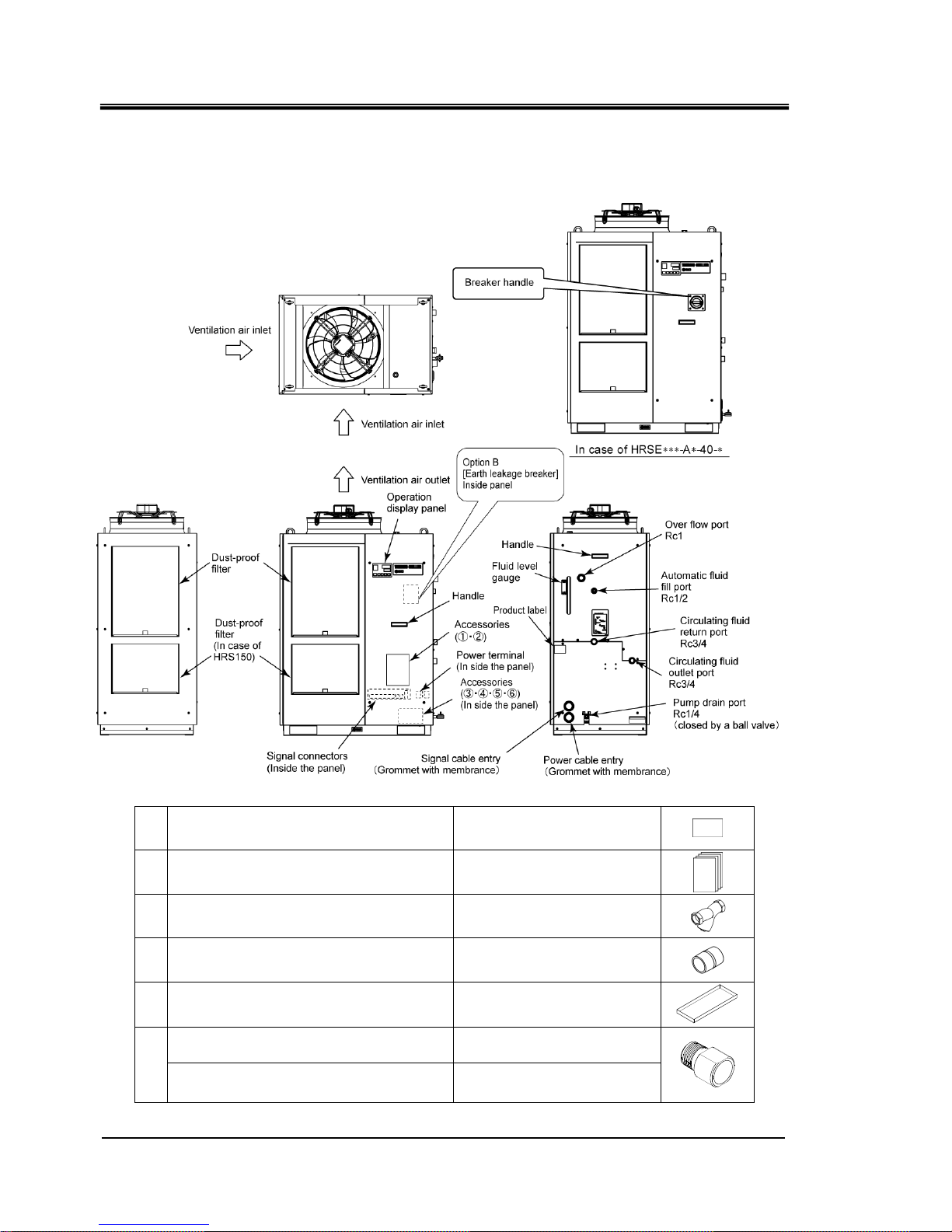

2.2.1 HRS100/150-A∗-20/40 (In case of air cooled type)

Fig. 2-2 Names of the parts (This drawing shows “HRS150-A-20”.)

Table 2-1 Accessory list

①

Alarm code list label

2pcs.

(English 1pc. /Japanese 1pc.)

②

Operation manual

2pcs.

(English 1pc./Japanese 1pc.)

③

Y strainer (40 meshes) 20A

1pc.

④

Barrel nipple 20A

1pc.

⑤

Drain pan for the pump

1pc.

For HRS∗∗∗-AF-∗∗

G thread adapter set (HRS-EP028)

1set

⑥

For HRS∗∗∗-AN-∗∗

NPT thread adapter set (HRS-EP027)

1set

Page 17

HRX-OM-S004

Chapter 2 Name and Function of Parts

HRS Series 2.2Name and Function of Parts

2-3

2.2.2 HRS100/150-W∗-20/40 (In case of water cooled type)

Fig. 2-3 Names of the parts (This drawing shows “HRS150-W-20”.)

Table 2-2 Accessory list

①

Alarm code list label

2pcs.

(English 1pc. /Japanese 1pc.)

②

Operation manual

2 Copies

(English 1 copy/Japanese 1

copy)

③

Y strainer (40 meshes) 20A

1pc.

④

Barrel nipple 20A

1pc.

⑤

Drain pan for the pump

1pc.

For HRS∗∗∗-WF-∗∗

G thread adapter set (HRS-EP030)

1set

⑥

For HRS∗∗∗-WN-∗∗

NPT thread adapter set (HRS-EP029)

1set

Page 18

HRX-OM-S004

Chapter 2 Name and Function of Parts

2.3 Function of Parts HRS Series

2-4

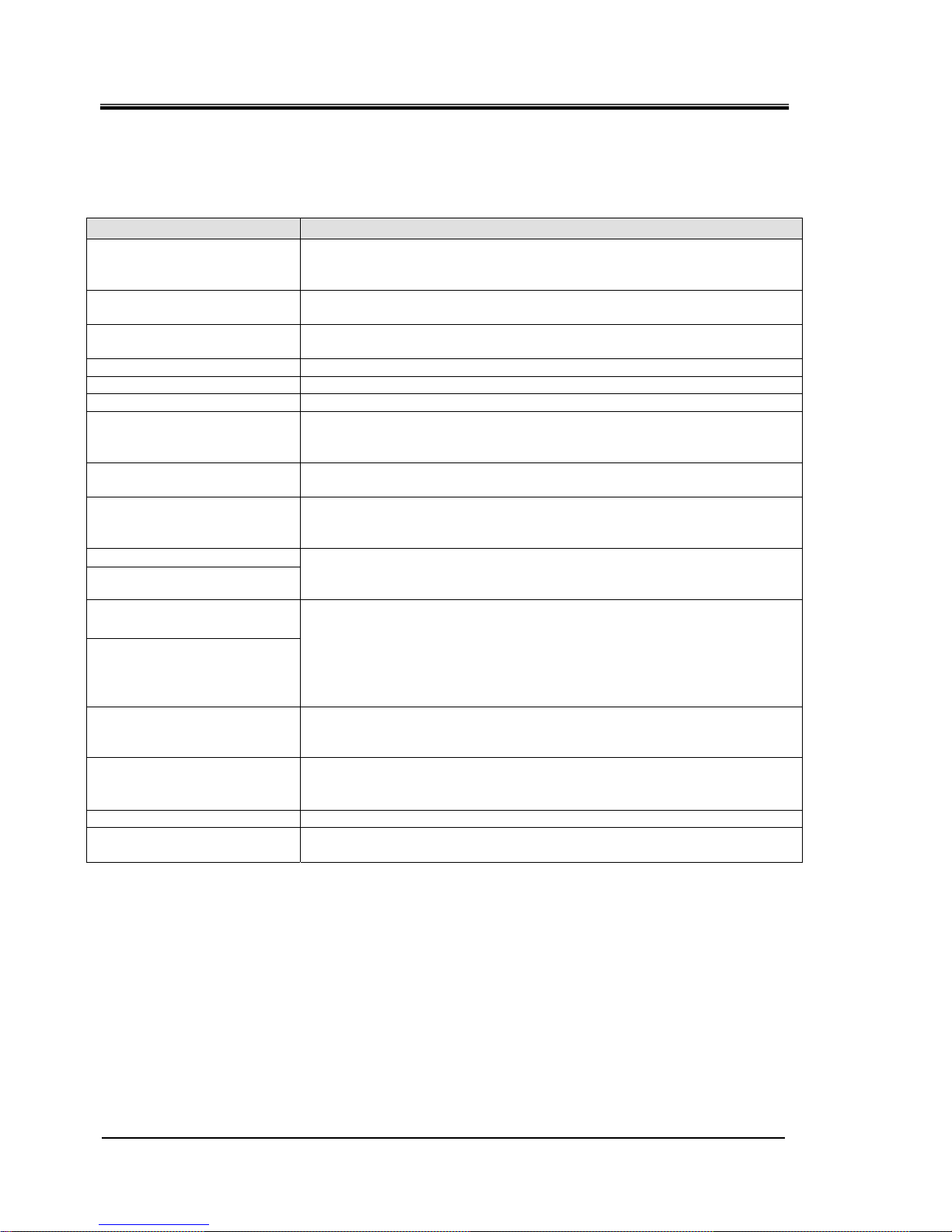

2.3 Function of Parts

The function of parts is as follows.

Table 2-3 Function of parts

Name Function

Operation display panel

Runs and stops the product and performs settings such as the circulating

fluid temperature.

For details, refer to ’’2.4 Operation display panel’’.

Fluid level gauge

Indicates the circulating fluid level of the tank. Confirm the level is between

HIGH and LOW. For details, refer to “3.5Circulating Fluid”.

Product label

Shows the product information such as model number and serial number.

For details, refer to ‘’1.4 Product Label’’.

Circulating fluid outlet port The circulating fluid flows out from the outlet port.

Circulating fluid return port The circulating fluid returns to the return port.

Pump drain port This drain port to drain the circulating fluid out of the tank and the pump.

Automatic fluid fill port

Piping to the automatic fluid filling port enables easy supply of the circulating

fluid through the ball tap in the reservoir.The supply pressure should be

within the range of 0.2 to 0.5MPa.

Overflow port

Be sure to connect piping from this port to sump pit to discharge the exsess

circulating fluid that caused by fluid level rising.

Dust-proof filter

Inserted to prevent that the dust and contamination are clung on the air

cooled condensers directly. Clean the filter periodically. For details, refer to

“7.2.2Monthly check”.

Power cable entry

Power terminal

Insert the power cable to the power cable entry and connect it to the power

terminal. For details, refer to “3.3.2Electrical wiring” and “3.3.3Preparation

and wi

ring of power supply cable”.

Signal cable entry

Signal connecors

Insert the signal cable to the signal cable entry and connect it to the signal

connectors. For details, refer to “3.3.5

Wiring of run/stop signal input・

Remote signal input

”, “3.3.6Wiring of external switch signal input”,

“3.3.7

Wiring of contact output signal”, “3.3.8RS-485 communication

wiring

” , “3.3.9RS-232C communication wiring or the Operation manual

Communication function.

Earth leakage breaker

(When option B [Earth leakage

breaker]I is selected.

Shuts off the power supply to the internal eqipment of the product.

(Parts energized remained in the product)

Refer to “3.3.2Electrical wiring” for the earth leakage breaker.

Earth leakage breaker with

breaker handle

(For HRS∗∗∗-∗∗-40)

Shuts off the power supply to the internal equipment of the product.

(Parts energized remained in the product. )

Refer to “3.3.2Electrical wiring” for the earth leakage breaker.

Facility water inlet port Supply facility water to the inlet port.

Facility water outlet port

Facility water is discharged from the outlet port and returns to the user’s

facility water system.

Page 19

HRX-OM-S004

Chapter 2 Name and Function of Parts

HRS Series 2.4Operation display panel

2-5

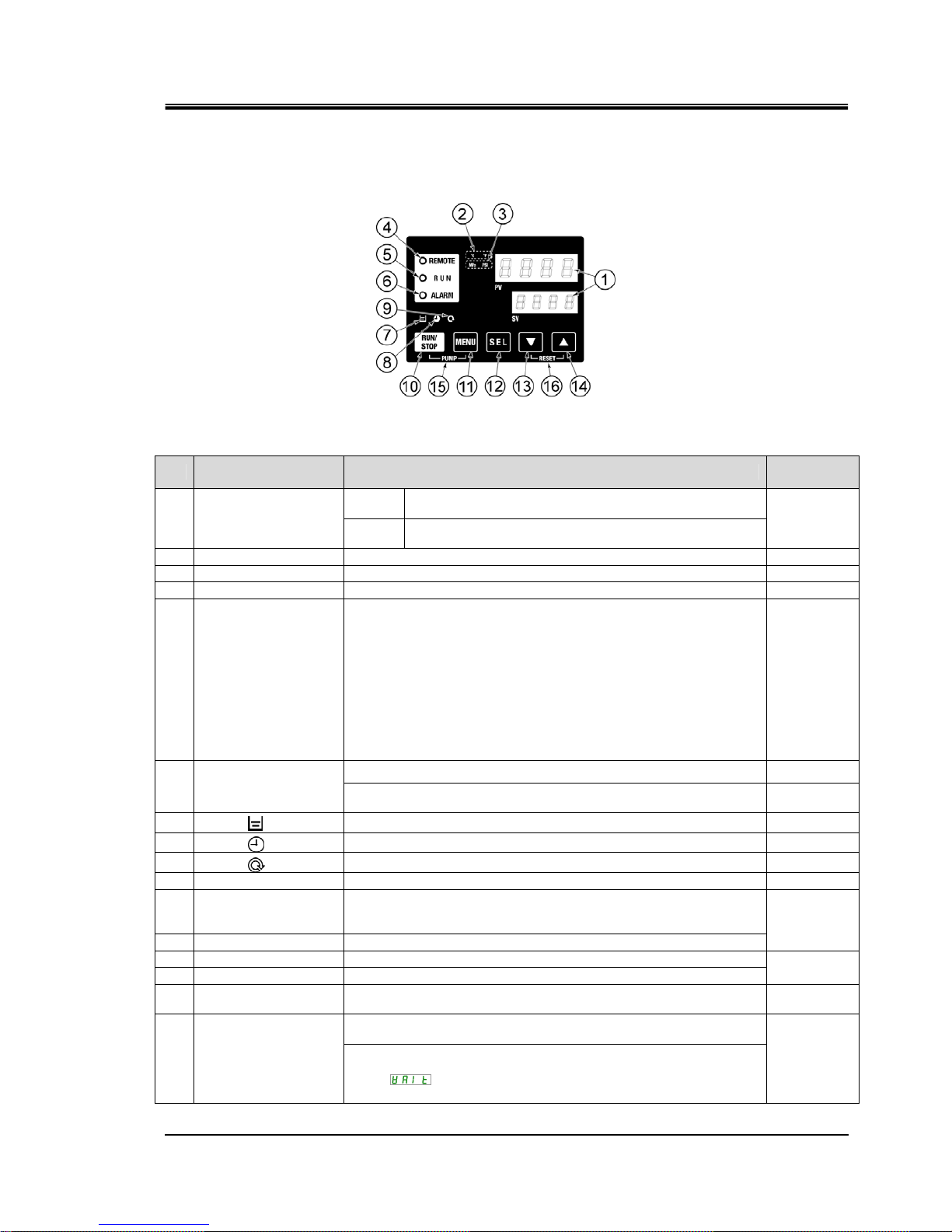

2.4 Operation display panel

The operation panel on the front of the product controls the basic operation

of the product.

Fig. 2-4 Operation display panel

Table 2-4 Operation display panel

No Description Function

Reference

page

PV

Displays the temperature and pressure of the circulating

fluid and alarm codes.

①

Digital display

(7 segment,

4 digits)

SV

Displays the set temperature of the circulating fluid and

the set values of other menus.

5.3

② [ oC oF ] light

Displays the unit of display temperature (

o

C or oF).

5.13

③ [MPa PSI] light

Displays the unit of display pressure (MPa or PSI).

5.14

④ [REMOTE] light

Turns on during remote operation by communication.

5.21

⑤ [RUN] light

・Turns ON when the product is started and in operation. Turns OFF

when the product stops.

・Blinks during stand-by for stop (Interval 0.5 seconds).

・Blinks during independent operation of the pump (Interval 0.3

seconds).

・ Blinks while the anti-freezing function is being set (During

standby: Interval 2 seconds, During operation: Interval 0.3

seconds).

・Blinks during warming up function (During standby: Turns ON

for 0.5 seconds and OFF for 3 seconds, During operation:

Interval 0.3 seconds.)

4.4

Blinks with buzzer when alarm occurs (Interval 0.3 seconds).

5.4

⑥ [ALARM] light

Blinks while AL25 is OFF (Turns ON for 0.5 seconds and OFF

for 3 seconds.)

5.20

⑦

[ ] light

Turns ON when the fluid level lowers below “L” (low) level.

4.3

⑧

[ ] light

Turns ON while the run timer or stop timer function is working.

5.7

⑨

[ ] light

Turns ON when the product is in automatic operation.

5.10

⑩ [RUN/STOP] key

Makes the product start or stop.

4.4

⑪ [MENU] key

Moves from the main menu (display which shows circulating fluid

temperature, pressure and etc.) to the other menus (entry of set

values and monitor screen).

⑫ [SEL] key

Changes the item in menu and enters the set value.

5.2

⑬ [▼] key

Decreases the set value.

⑭ [▲] key

Increases the set value.

-

⑮ [PUMP] key

When the [MENU] and [RUN/STOP] buttons are held down

simultaneously, the pump starts running independently.

4.3

Press the [▼] and [▲] keys simultaneously. This will stop the alarm

buzzer and turn off the [ALARM] light.

⑯ [RESET] key

Keep the [▼] and [▲] keys pressed down simultaneously for 3

seconds to reset AL46 and AL48.(After resetting AL48,

WAIT(

) will be displayed and the product cannot start

running for 40 seconds. Restart 40 seconds later after resetting.

6.3

Page 20

HRX-OM-S004

Chapter 2 Name and Function of Parts

2.4 Operation display panel HRS Series

2-6

Page 21

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.1Transport

3-1

Chapter 3 Transport and Setting Up

3.1 Transport

The product is heavy and has potential danger at transport. Also, to prevent

damage and breakage of the product, be sure to follow the instructions for

shown below for transport.

When moving the product by a folklift, insert the fork into the right

psitions referring to 3.1.1

Moving by forklift and slinging should be done by persons who have

the licenses.

z Be sure to use all the four eye bolts when sling the product.

z The slant angle of each rope should be 60 degrees oe less.

When the product is carried by using folklift, make sure that the folk

dose not damage the cover panels and piping port.

Never lay the product on its side.

The compressor oil will leak in to the refrigerant piping, which may

cause early failure of the compressor.

Drain the residual fluid from the piping as much as possible to prevent

any spillage.

z Only persons who have sufficient knowledge and experience about

the product and system are allowed to transport and set up the

product.

z Especially pay attention to personal safety.

Page 22

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.1 Transport HRS Series

3-2

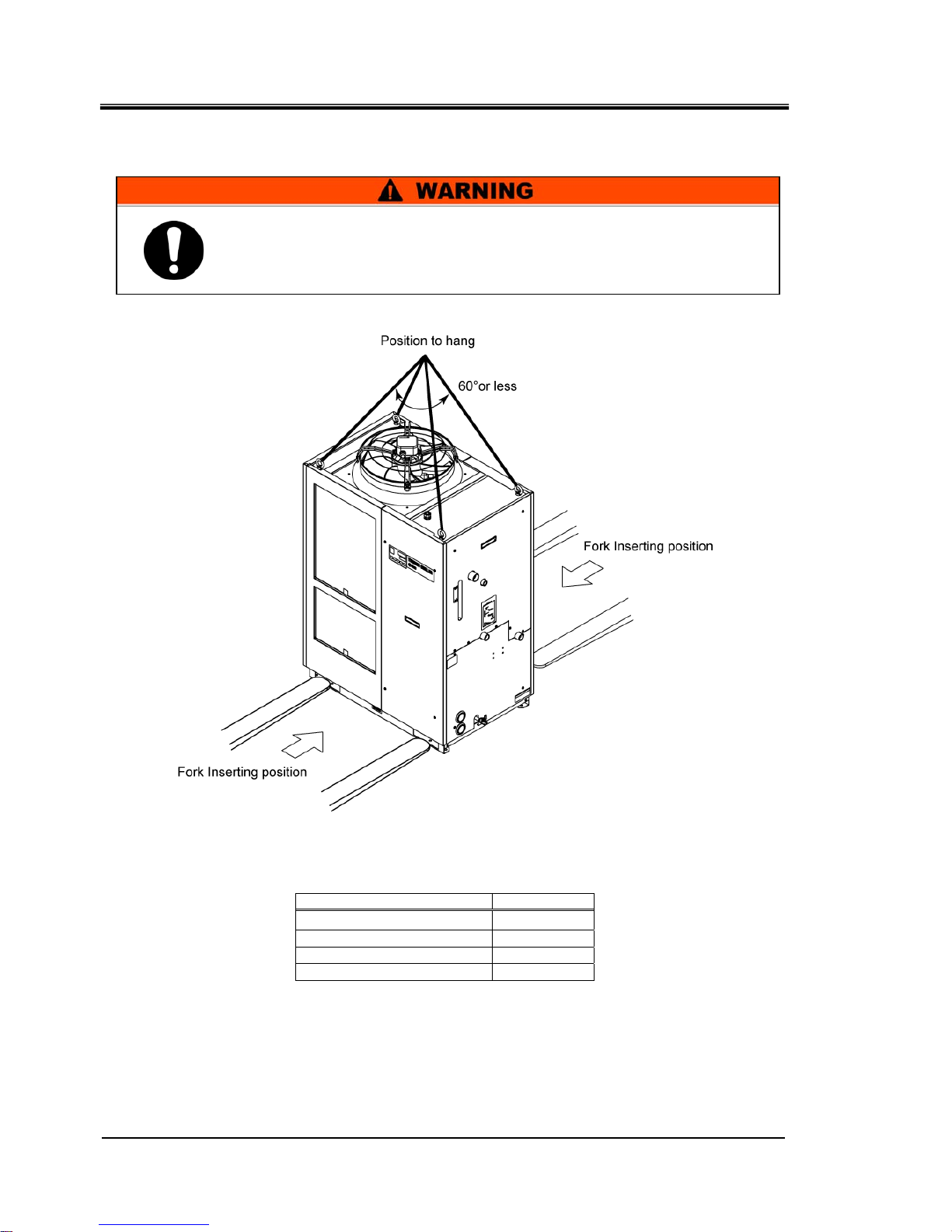

3.1.1 Transportation using forklift and hanging

Fig 3-1 Fork inserting and hanging position (This drawing is [HRS150-A-20].)

Table 3-1 Weight of the product

Model Weight kg

HRS100-A∗-20/40

Approx. 171

HRS150-A∗-20/40

Approx. 177

HRS100-W∗-20/40

Approx. 151

HRS150-W∗-20/40

Approx. 154

The product are heavy object. (Refer to Table 3-1 Weight of the

product) Moving by forklift and slinging should be done by persons

who have the licenses.

Page 23

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.1Transport

3-3

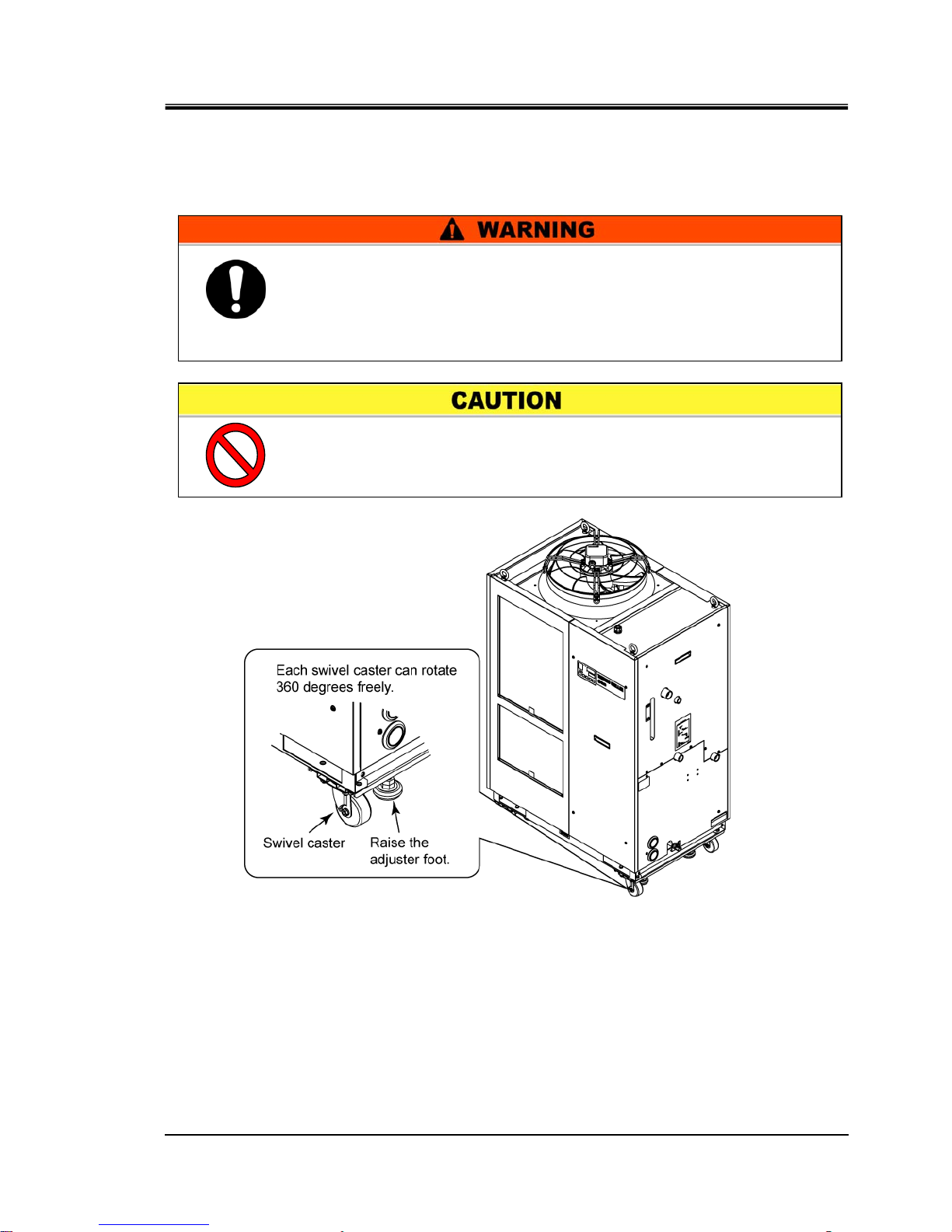

3.1.2 Transportation using casters

<In case of purchasing the optional accessories, “Caster Adjuster-foot kit”

(HRS-KS001

/KS002) separately and after fastening it to the product.>

Fig. 3-2 Transportation using casters (This drawing is [HRS150-A-20].)

Raise the adjuster feet and push the corners of the product when

moving the product using the casters.

Do not hold the piping connections or handles of the panels when

movin

g by

casters, or it may cause damage to the product.

z This is a heavy object. (Refer to Table 3-1 Weight of the product).

z Moving the product by casters should be done by 2 persons or

more.

z Do not impact on the casters by bump. It will damage of the

casters and the base of the Thermo chiller.

Page 24

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.2 Installation HRS Series

3-4

3.2 Installation

3.2.1 Environment

The product must not be operated, installed, stored or transported in the

following conditions. Potential malfunction or damage to the product may

occur if these instructions are disregarded.

The product is not designed for clean room. The pump and ventilating fan

inside the product generate particles.

z Location that is exposed to steam, salt water or oil.

z Location that is exposed to dust or powder material.

z Location that is exposed to corrosive gas, organic solvent, chemical

solution, or flammable gas (the product is not explosion-proof)

z Location where the ambient temperature is out of the following range:

During transportation or storage: -15 to 50°C (No water or circulating fluid

in the piping.)

During operation: -5 to 45°C

z Location where condensation forms on the inside electrical parts.

z Location that is exposed to direct sunlight or heat radiation.

z Location that is near heat sources and poor in ventilation.

z Location that is subjected to abrupt changes in temperature.

z Location that is subjected to strong electromagnetic noise (intense electric

field, intense magnetic field, or surges).

z Keep the product uplight on a rigid and flat floor which can resist

the weight of the product, and take measures to prevent the

product from tipping over. Improper installation may cause water

leakage, tipping, damage of the product or injure the operator.

z Keep the ambient temperature of the product between -5 to 45

o

C.

Operation out of this ambient temperature range may cause a

malfunction of the product. Operating the product in an

environment temperature of 45

o

C may reduce the heat

discharging efficiency of the heat exchanger and the safety device

may function, resulting in the product operation stoppage.

z The installer/end user is responsible for carrying

out a acoustic noise risk assessment on the equipment after

installation and taking appropriate measures as required.

Do not set up the product in places possibly exposed to leakage of

flammable gas. Should any flammable gas stay around the product,

the product may cause a fire.

Page 25

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.2Installation

3-5

z Location that is subjected to static electricity, or conditions where static

electricity can discharge to the product.

z Location that is subjected to strong high frequencies raditation

(microwaves).

z Location that is subjected to potential lightening srtike.

z Location where the product is affected by strong vibrations or impacts.

z Condition that applies external force or weight causing the product to be

damaged.

z Location without adequate space for maintenance as required.

z Location that is exposed to splash of the water that is higher than IPX4.

z Refer to the below for product installation or operation in an environment

temperature of 10

o

C or less.

z Location at altitude of 3000m or higher (except during product storage and

transport). Refer to the below for details.

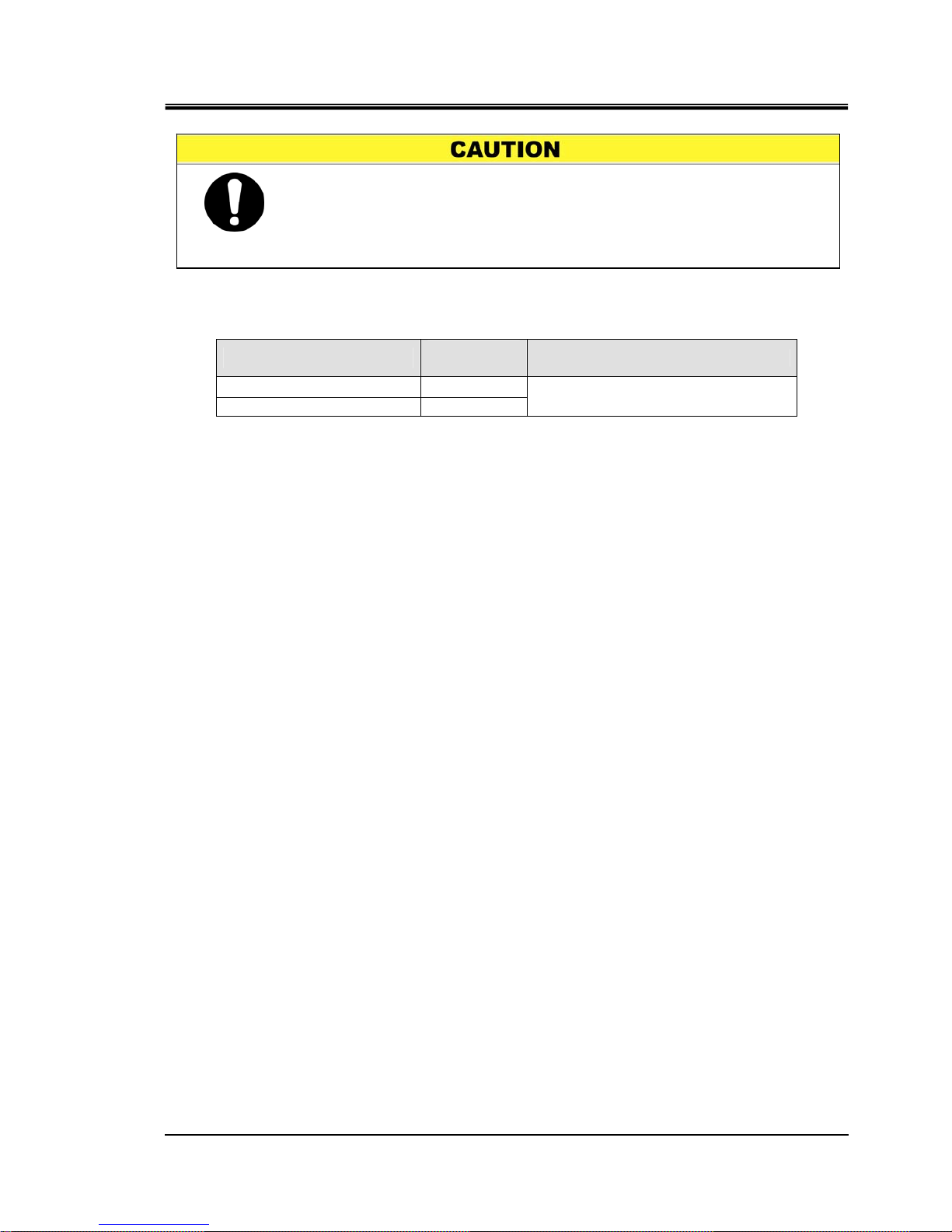

Thermo-chiller installation in high altitude of 1000 meters or more

Because of lower air density, the heat radiation efficiencies of the devices in the product will be

lower in the location at altitude of 1000m or higher. For this reason, the maximum ambient

temperature for the thermo-chiller operation and the cooling capacity will be reduced.

For product installation at a place of high altitude of 1000 meters or more, select a thermo-chiller

of the applicable capacity referring to the table below.

1. Max. ambient temp.: Use the product in lower ambient temperature than

the described value at each altitude.

2. Cooling capacity correction coefficient: Coefficient to calculate the

cooling capacity at each altitude

For the product operation at an altitude of 1800 meters,

“the cooling capacity at an altitude of 1800 meters” =

“the cooling capacity at an altitude of 1000 meter” x 0.8.

Installation/Operation in an ambient temperature of 10 oC or less

Use ethylene glycol solution at a concentration of 15 % for the circulating

fluid.

Altitude [m]

1. Max. ambient

temp. [

o

C]

2. Cooling

capacity

correction

coefficient

Less than 1000m 45 1.00

1000 m or more - Less than

1500 m

42 0.85

1500m or more - Less than

2000m

38 0.80

2000m or more - Less than

2500m

35 0.75

2500m or more - Less than

3000m

32 0.70

Page 26

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.2 Installation HRS Series

3-6

3.2.2 Location

Installation of multiple products

Keep sufficient space between products so that the air vented from one product will not be taken

in by other products.

Installation at indoor site

1 In case of facility having a large installation area (that can vent the air naturally)

Make an air outlet on a wall at a high level and air inlet on a wall at a low level, to allow for

adequate airflow.

2 In case of facility having a small installation area (that can not vent the air naturally)

Make a forced air exhaust vent on a wall at a high level and an air inlet on a wall at a low level.

3 Using duct to exhaust the air

In case the indoor site cannot accept the exhausted air from the product or/and is air

conditioned, ventilate by installing a duct on the outlet ventilation of the product. Do not fasten

the duct on the outlet ventilation of the product directly. Have the space at least the dust’s

diameter apart. Use a fan for the duct that considered the ventilation resistance of the duct.

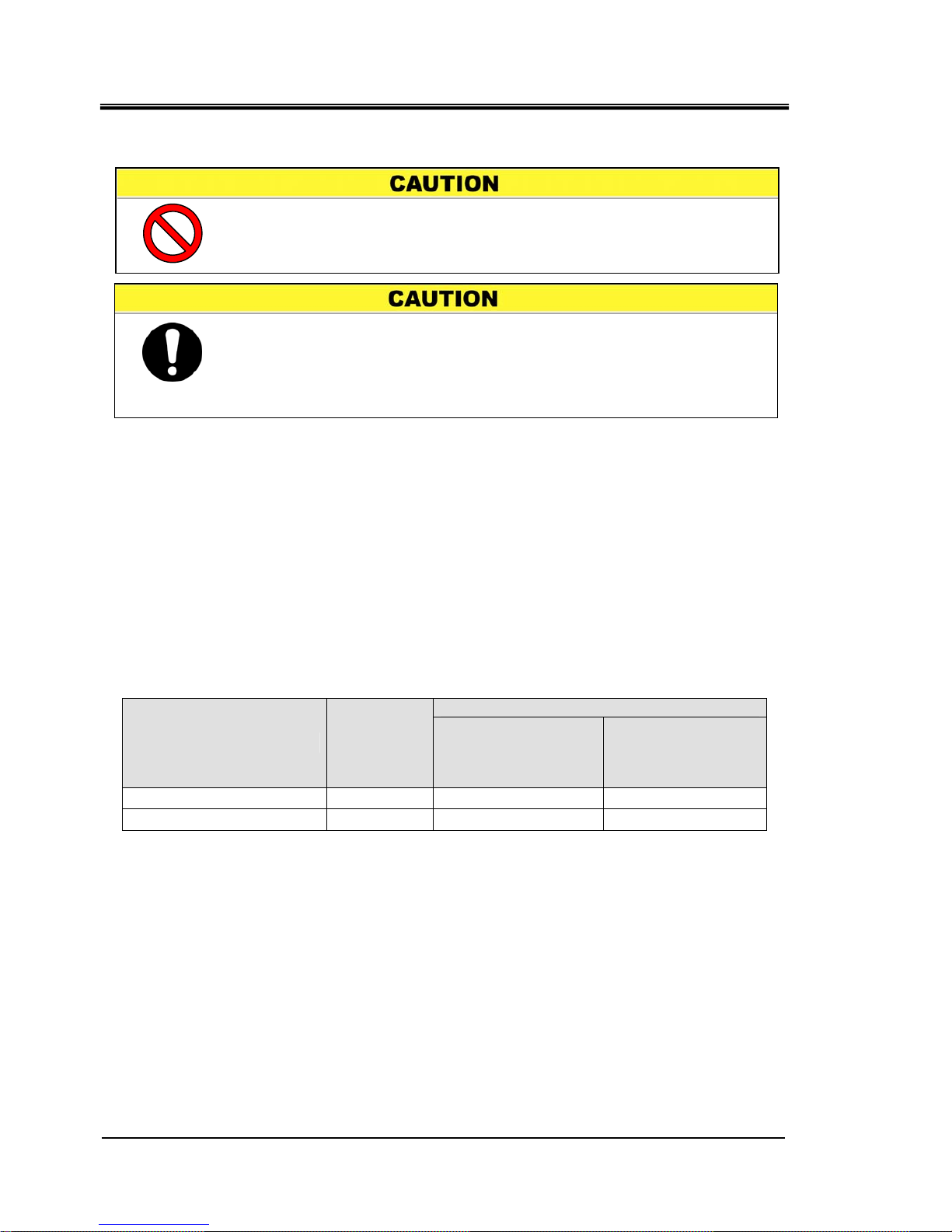

Table 3-2 Amount of radiation and required ventilation

Required ventilation amount m3/min

Model

Heat

radiation kW

Differential temp. of

3 oC between inside

and outside of

installation area

Differential temp. of

6 oC between inside

and outside of

installation area

HRS100-A∗-20/40-∗

Approx.18 305 155

HRS150-A∗-20/40-∗

Approx.26

440 220

Do not install in a location which can be subjected to any of the

conditions in 3.2.1 Environment.

The air cooled product radiates heat from the air vent of the cooling fan.

If the product is operated with insufficient air ventilation the internal

temperature can exceed 45

oC∗

, which can cause an affect the

performance and life of the product. To prevent this ensure that

suitable ventilation is available (see below).

Page 27

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.2Installation

3-7

Required facility water system

Table 3-3 Heat radiation

Model

Heat

radiation kW

Facility water specifications

HRS100-W∗-20/40-∗

Approx. 19

HRS150-W∗-20/40-∗

Approx. 28

Refer to [8.1 Specifications].

Installation at indoor site

The product’s splash-proof specification is IPX4.

Installation environment specification

Sound noise: HRS100-A-20/40, HRS150-A-20: 70dB (A)

HRS100/150-W-20/40

: 70dB (A)

HRS150-A-40: 72dB (A)

∗Front 1m, height 1m, rated condition

The water cooled product radiates heat to the facility water.

It is necessary to supply the facility water. Please prepare the facility

water system that satisfies the heat radiation and the facility water

specifications below.

Page 28

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.2 Installation HRS Series

3-8

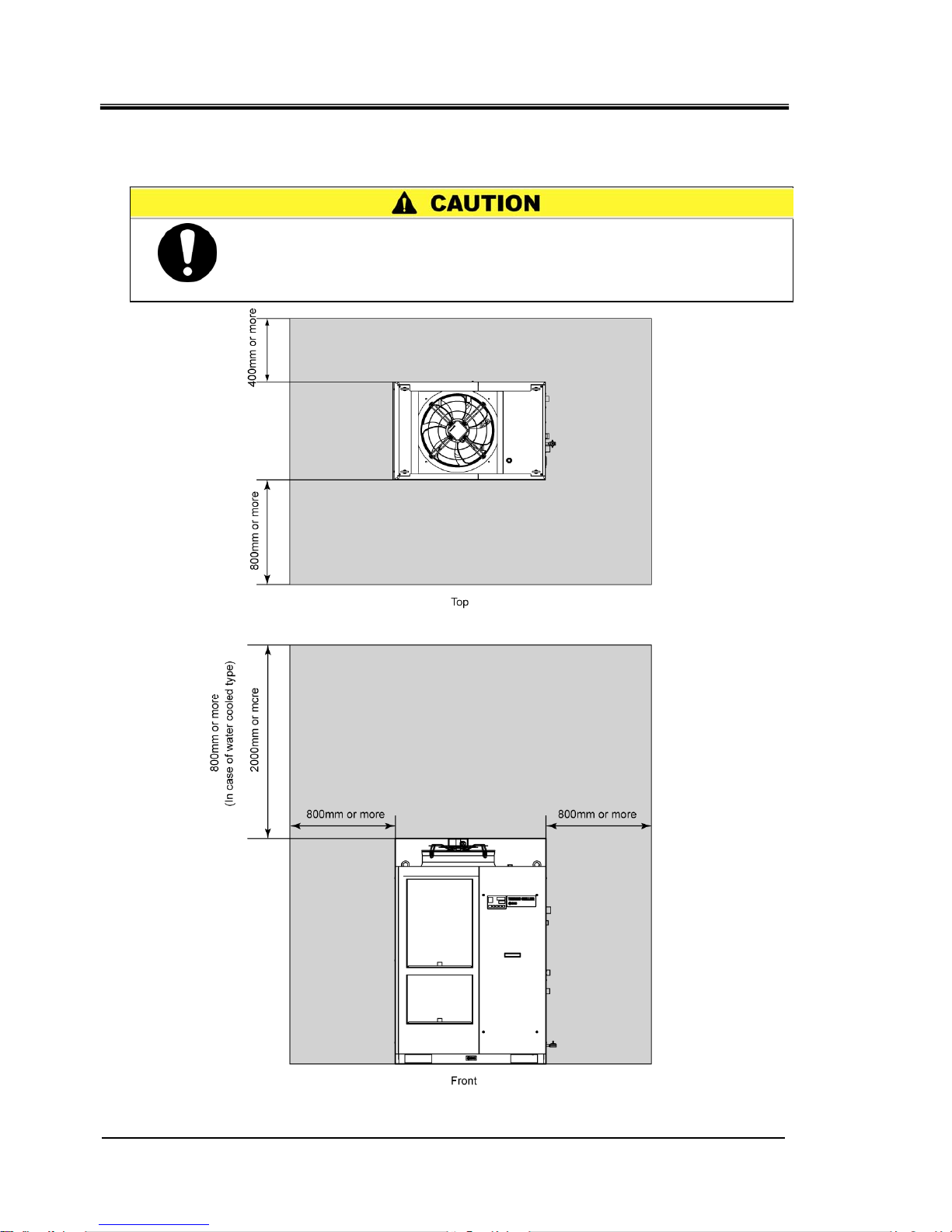

3.2.3 Installation and Maintenance Space

It is recommended to keep the space around the product shown in Fig. 3-3.

Fig. 3-3 Installation space (This drawing is [HRS150-A-20].)

Have an enough space for the ventilation for the product. Otherwise it

may cause a lack of cooling capacity or/and stoppage of the product.

Have an enough space for maintenance.

Page 29

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-9

3.3 Installation

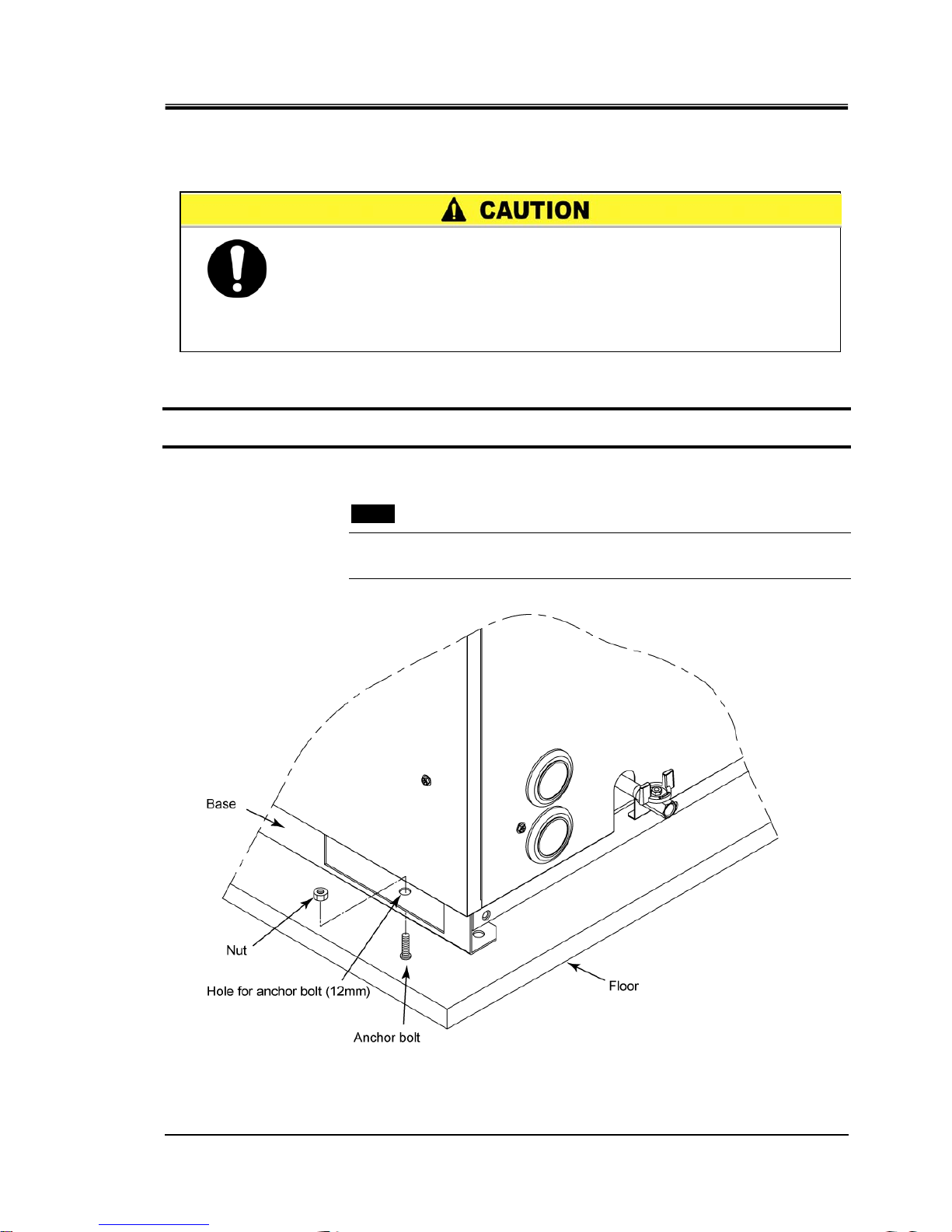

3.3.1 Installation

How to mount the product

1. Insert the product to the anchor bolts that were previously driven on the level floor.

2. Fasten the nuts to the anchor bolts.

3. Make sure that there is no looseness on all the anchor bolts and nuts.

[Tips]

SMC Foundations bolt set [IDF-AB500] (SUS M10x50mm) is applicable.

Please order separately.

Fig. 3-4 Installation procedures

Install the product on the horizontal floor.

Prepare the M10 anchor bolts that are appropriate to the material of

the floor that the product will be installed. Drive the anchor bolts at

least at two places of the left and right side of the product (four places

in total). Refer to the “8.2 Outline dimensions” for the dimensions for

the position of the anchor bolts.

Page 30

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-10

〈In case of purchasing option A or [Caster Adjuster-foot kit]

(HRS-KS002/KS003)〉

Refer to the Operation manual for the separately sold accessory for the further details of the swivel

caster and the adjuster foot set.

Fig. 3-5 Installation by adjuster foot

In case of using [Caster Adjuster-foot kit], be sure to use the adjuster

foot to install on the floor. The adjuster foot is not earthquake-proof.

Make an earthquake-resistant measure by the customer side.

Page 31

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-11

3.3.2 Electrical wiring

Do not modify the intenal electrical wiring of the product. Incorrect

wiring may cause electrical shock or fire. Also, modifing the internal

wiring will void the product’s warranty.

NEVER connect the ground to water line, gas pipe or lightening

z The installation of electrical equipment and wiring work should be

performed only by personnel with sufficient knowledge and

experience.

z Be sure to shut off the user’s power supply. Wiring with the

product energized is strictly prohibited.

z The wiring must be conducted using cables complying with “Table

3-4” and firmly and secured to the product to prevent the external

force of cables being applied to the terminals. Incomplete wiring or

improper securing of wiring may cause electrical shock, excessive

heat and fire.

z Ensure a stable power supply with no voltage surges.

z Ensure that an Earth Leakage Breaker is used in the power supply

of the product. See “Table 3-4”.

z Use a power supply suitable for the specifications of the product.

Be sure to connect the ground connection.

z Ensure that a lock out facility is availble on the power supply.

z Each product must have its own separate Earth Leakage Breaker.

Otherwise there can be a risk of electric shock or fire.

z Ensure that no harmonics are superimposed at power supply.

(Do not use inverter etc.)

z Supply a steady power supply which is not affected by surges or

distortion. In particular, if the voltage rate of increase (dv/dt) at

zero crossing exceeds 40V/200μsec, it may cause malfunction.

V

dV

dt

dt

= V

oon

dV

t

Voltage rise %

Time

Voltag

e

Page 32

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-12

Power supply specifications, power supply cable and earth leakage breaker

Prepare the power supply shown in the following table. For the connection

between the product and power supply, use the power supply cable and

earth leakage breaker shown below. An earth leakage breaker must be

mounted to a position where the breaker is easily accessible and close to

the thermo-chiller.

Table 3-4 Power supply cable and Earth Leakage Breaker(Recommended)

Earth leakage

breaker *1

Model

Power

supply

voltage

Term i nal

block

screw

diameter

Recomm

ended

crimp

terminal

Cable qty. x

size*2

Rated

current

[A]

Sensitivity

of leak

current

[mA]

HRS100-A∗-20-∗

HRS100-W∗-20-∗

R5.5-5

4 cores x AWG10

(4 cores x 5.5mm2)

*including ground

30

HRS150-A∗-20-∗

HRS150-W∗-20-∗

200/

200-230VAC

50/60Hz

3phase

R8-5

4 cores x AWG8

(4 cores x 8mm2)

*including ground

40

HRS100-A∗-40-∗

HRS100-W∗-40-∗

HRS150-A∗-40-∗

HRS150-W∗-40-∗

380-415VAC

50/60Hz

3phase

M5

R5.5-5

4 cores x AWG10

(4 cores x 5.5mm2)

*including ground

20

30

*1: A specified earth leakage breaker is installed for option B [Earth leakage breaker] of each model.

If the product is not option B [Earth leakage breaker], please prepare an earth leakage breaker by

the user’s side.

A specified earth leakage breaker and handle are installed for HRS∗∗∗-∗∗-40-∗.

*2: Cable specifications are the examples when using the product at a continuous allowable operating

temperature of 70

o

C, with an operating voltage of 600 V and two kinds of plastic insulated wires at

an ambient temperature of 30

o

C. Please select the proper size of cables according to an actual

condition.

Page 33

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-13

3.3.3 Preparation and wiring of power supply cable

Be sure to lock out and tag out the breaker of the facility power supply

(customer power supply facility) before wiring.

z The electrical facilities should be installed and wired in accordance

with local laws and regulations of each country and by a person

who has knowledge and experience.

z Check the power supply. Operation with voltages, capacities and

frequencies other than the specified values can cause fire and

electrical shock.

z Wire with an applicable cable size and terminal. Forcibly mounting

with an unsuitable size cable ma

y

result in heat generation or fire.

Be sure to connect the power supply cable from the product side first,

and then connect the breaker of the facility power supply (the user’s

machine power supply).

When the panel is removed or mounted, be sure to wear protective

shoes and gloves to prevent injury with the edge of the panel.

Page 34

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-14

In case of option B [Earth leakage breaker],HRS∗∗∗-∗∗-40-∗

A breaker that has the operating characteristic below is installed. Please use a

breaker that has the same or longer operating time as/than this for the user’s side

(primary side). If it is a shorter operating time, there is a possibility of accidental

breaker trip due to the internal motors’ inrush currents of this product.

100 125 200 300 400 500

600

700 1000 1500 2000 3000 4000

5000

6000

7000

10000

0.02s

0.01s

0.05s

0.1s

0.2s

0.5s

1s

2s

5s

10s

20s

30s

1min

2min

4min

6min

10min

14min

20min

30min

1h

2h

4h

Min.

Operating time

Current (% for breaker capacity)

Max.

For HRS100-A/W-20/40, HRS150-A/W-40

4h

2h

1h

30min

20min

14min

10min

6min

4min

2min

1min

30s

20s

10s

5s

2s

1s

0.5s

0.2s

0.1s

0.05s

0.02s

0.01s

100 125 200 300 400 500 600700 1000 1500 2000 3000 4000

Current (% for breaker capacity)

Operating time

Min.

Max.

For HRS150-A/W-20

Page 35

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-15

Preparation for operation

1. Remove four screws to remove the front panel for the electrical unit.

Fig. 3-6 Remove the front panel for the electrical unit (This drawing shows air cooled type.)

Fig. 3-7 Remove the front panel for the electrical unit (This drawing shows water cooled type.)

Page 36

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-16

2. Hold the handle and put up the front panel of the electrical unit, and remove it.

Fig. 3-8 Remove the front panel of the electrical unit (This drawing shows air cooled type.)

Fig. 3-9 Remove the front panel of the electrical unit (This drawing shows water cooled type.)

Page 37

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-17

3. Connect the power supply and the ground cable as shown in the figure below.

Fig. 3-10 Wiring of power supply cable

∗ Connect over current protection to the user’s side (primary side) to avoid hazard.

Page 38

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-18

3.3.4 Contact input/output communicatin wiring

The product has a contact input/output communication function as shown

below. Connect cables referring to the applicable chapter for each function.

(For details of the functions, refer to Operation Manual Communication

Function.)

z Run/stop input・Remote signal input (Refer to 3.3.5 Wiring of

run/sto

p signal input・Remote signal input.)

z External switch signal input (Refer to 3.3.6 Wiring of external

swit

ch signal input.)

z Output of contact output signal (Refer to 3.3.7 Wiring of contact

output sig

nal.)

Use the signal cable described below for wiring of each function.

Signal cable

Use the cable and terminals as follows below for wiring of each function.

Table 3-5 Signal cable

Terminal specification

Terminal block

screw diameter

Recommended

crimp terminal

Cable specification

M3

1.25Y-3

0.75 mm

2

(AWG18)

Shielded cable

Be sure to lock out and tag out the breaker of the facility power supply

(customer power supply facility) before wiring.

Use the cable and terminal that are specified.

The capacity of the output contact of the product is limited. If the capacity is not

large enough, install a relay, etc. (to allow for larger capacity). Also, ensure that the

input current of the relay is small enough in relation to the contact capacity of the

product.

Page 39

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-19

3.3.5 Wiring of run/stop signal input・Remote signal input

Run/Stop signal input and remote signal input enable the product to

operate/stop or switched DIO REMOTE and DIO LOCAL remotely by

applying a contact signal input. This chapter illustrates examples of wiring.

Select DIO mode as the communication mode to activate the run/stop signal

input and remote signal input after wiring referring to Operation Manual

Communication Function.

[Tips]

This product has two input signals. These can be customized depending on

the customer’s application.

Table 3-6 Power supply, contact specifications

Name Terminal NO. Specification

5, 6, 7 (24VDC)

Power supply output

13,14, 15 (24V COM)

DC 24V ±10% 500mA MAX

∗

1

3 (Contact input signal 1)

Contact input signal 1

11 (Common of contact input signal 1)

-Run/stop signal

input

-External switch

signal input

∗

2

4 (Contact input signal 2)

Contact input signal 2

12 (Common of contact input signal 2)

-Run/stop signal

input

-Remote signal

input

-External switch

signal input

∗

2

Switch the

input on the

operation

display panel.

Refer to the

Operation

manual

communication

function for

details.

*1: To use the power of the device, the total load current must be 500mA or less.

If the load is 500mA or more, the internal fuse will be cut to protect the product and the alarm [AL21 DC

line fuse cut] will be generated. Refer to Chapter 6 for handling of alarms.

*2: Refer to 3.3.6 Wiring of external switch signal input.

1. Prepare the switch (power supply voltage: 24VDC, contact capacity: 35mA or more,

minimum load current: 5mA), and a signal cable (See “Table 3-5 Signal cable”).

Page 40

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-20

2. Connect the signal cable and switch to the terminal as follows. (This wiring is an

example.)

Fig. 3-11 Wiring of Run/stop signal input・Remote signal input (Example)

Terminal No. 5

Terminal No.13

Terminal No.11

Terminal No. 3

Page 41

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-21

3.3.6 Wiring of external switch signal input

This product can be monitored by sampling the signal of the external switch

prepared by the customer.

Table 3-7 Power supply, contact specifications

Name Terminal NO. Specification

5, 6, 7 (24VDC)

Power supply output

13,14, 15 (24V COM)

24VDC ±10% 500mA MAX

∗

1

3 (Contact input signal 1)

Contact input signal 1

11 (Common of contact output signal 1)

4 (Contact input signal 2)

Contact input signal 2

12 (Common of contact output signal 2)

NPN open collector output

PNP open collector output

(Refer to the operation manual

communication function.)

*1:To use the power of the device, the total load current must be 500mA or less.

If the load is 500mA or more, the internal fuse will be cut to protect the product and the alarm [AL21 DC

line fuse cut] will be generated. Refer to Chapter 6 for handling of alarms.

One external switch can be connected to contact input signal 1 and one to

contact input signal 2. (Two in total) The external switch cannot be

connected to the contact input signal 1 depending on the communication

mode.

Table3-9 External switches used in the examples .

Table 3-8 Sets external switch

Communication mode ∗1

Contact input signal 1 Contact input signal 2

Local mode

✓ ✓

MODBUS

✓ ✓

Simple

communication

protocol 1

✓ ✓

SERIAL mode

Simple

communication

protocol 2

x

✓

DIO mode

x

✓

∗1:Refer to the Operation Manual Communications Function for more details of each mode.

Local mode: Mode allowing the product to be operated by the operation panel. (Default setting)

SERIAL mode: Mode allowing the product to be operated by serial communication.

DIO mode: Mode allowing the product to be operated by the contact input/output communication.

Example of connection

As an example of connection of an external switch, the connecting method is

shown below using the SMC flow switch (NPN, PNP).

This chapter illustrates examples of wiring

Table3-9 External switches used in the examples

Discription Manufacturer Part NO. Out put type

Current

consumption

PF3W721□-□□-A□(-M)

NPN open collector

output

50mA or less

Flow switch SMC

PF3W721□-□□-B□(-M) PNP open collector output 50mA or less

Be sure to turn OFF the breaker of the facility power supply (the user’s

machine power supply) before wiring.

Page 42

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-22

Flow switch

3

6

5

11

Terminal No.

14

Blue(DC COM)

Brown(DC 24V)

Black

(Output1)

11

6

13

3

14

Terminal No.

Terminal No.

Terminal No.

Terminal No.

Blue(DC COM)

Brown(DC 24V)

Black

(Output1)

Terminal No.

Terminal No.

Terminal No.

Terminal No.

Terminal No.

Flow switch

1. Prepare the flow switch described in the table purchasing separately.

2. Depending on the external switch output type, connect the wire the switch to the

terminals for contact input signal as shown below. (This is an example of wiring. Refer

to the Operation Manual Communication Function for further details.)

Fig. 3-12 Wiring of the external switch (NPN open collector output) (example)

Fig. 3-13 Wiring of the external switch (PNP open collector output) (example)

Flow switch

Brown (DC 24V)

Blue(DC COM)

Black(Output1)

Flow switch

Brown (DC 24V)

Blue(DC COM)

Black(Output1)

Page 43

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-23

Setting items

Table 3-10 shows the setting items of the external switch. For details, refer

to 5.21 Communication function.

Table 3-10 Setting list of the external switch

Display Item

Initial value

(Default setting)

Example

∗

Reference

page

Category

Communication mode LOC LOC

Contact input signal 1 RUN SW_A

Contact input signal 1 type ALT ALT

Contact input signal 1

delay timer (time delay) of

reading

0 0

Contact input signal 1 OFF

detection timer

0 2

Contact input signal 2 OFF OFF

Contact input signal 2 type ALT Contact input signal 2

delay timer (time delay) of

reading

0 -

Contact input/output

communication

Contact input signal 2 OFF

detection timer

0 -

5.21

Comm

unication

setting menu

∗ Example: Connect flow switch A to contact input signal 1 in local mode.

Page 44

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-24

3.3.7 Wiring of contact output signal

Contact output signals are the signals that output the status of this product.

Contact specification of each signal output is shown below

The specifications of the contact for each signal output are shown below.

Table 3-11 Signal output contact spec. at the time of shipment

Contact output

Signal explanation

(Default setting)

Operation

During operation:

Contact closed

During operation stop:

Contact open

Contact output signal 1

(Terminal no.0,8)

Operation status signal

output

A

With power supply

cutoff:

Contact open

During remote operation: Contact closed

During non-remote

operation:

Contact open

Contact output signal 2

(Terminal no.1,9)

Remote status signal

output

A

With power supply

cutoff:

Contact open

While alarm being

generated:

Contact open

While alarm not being

generated:

Contact closed

Contact output signal 3

(Terminal no.2,10)

Alarm status signal

output

B

With power supply shut

off:

Contact open

[Tips]

This product has three output signals which can be customized depending on

the customer’s application

Signals below can be output. Refer to the Communications Operation Manual

for more details.

・Ready completion (TEMP READY) signal output

・Operation stop alarm signal output

・Operation continuation alarm signal output

・Selected alarm status signal output

・Operation start timer setting status signal output

・Operation stop timer setting status signal output

・Recovery from power failure setting status signal output

・Anti-freezing setting status signal output

・Contact input signal detecting output

・Warming up function setting status output

・Anti-snow coverage function setting status output

Be sure to turn OFF the breaker of the facility power supply (the user's

machine power supply) before wiring.

Page 45

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.3Installation

3-25

3.3.8 RS-485 communication wiring

Serial communication RS-485, operation start/stop, setting and reading of

circulating fluid temperature, and reading of alarm condition can be done by

remote control.

Refer to the Operation Manual Communication Function for more details.

Wiring of interface communication cable

z Connecting to PC

RS-485 cannot be directly connected to a normal PC. Use a RS-232C/RS485 converter which is

available on the market.

Be sure to follow the wiring procedure shown below for connecting multiple thermo-chillers.

z

Configuration of connection

One thermo-chiller for one host computer, or multiple thermo-chillers for one host computer.

(31 thermo-chillers can be connected at maximum.)

1

SD+

5

SG

9

SD-

SD+

SD- SG

Terminal

resistance

Master This product

(first slave)

1

SD+

5

SG

9

SD-

This product

(second slave)

1

SD+

5

SG

9

SD-

This product

(31

st

slaves)

Terminal

resistance120Ω

Fig. 3-14 Connection of RS-485

[Tips]

Both ends of the communication connection (the end nodes) need to be

connected to the host computer.

With or without the terminating resistor (120Ω) of this product can be set by

the operation display panel. Refer to “5.21 Communication function”.

Be sure to turn OFF the breaker of the facility power supply (the user's

machine power supply) before wiring.

Page 46

HRX-OM-S004

Chapter 3 Transport and Setting Up

3.3 Installation HRS Series

3-26

3.3.9 RS-232C communication wiring

Serial communication RS-232C, operation start/stop, setting and reading of

circulating fluid temperature, and reading of alarm condition can be

performed by remote control.

Refer to the Communications Operation Manual for more details.

Wiring of communication cable

Be sure to wire as shown in the figure below.

z

Configuration

One thermo-chiller for one master.

2

3

5

RD

SD

SG

2

3

5

RD

SD

SG

Master This product

Fig. 3-15 Connection of RS-232C

Be sure to turn OFF the breaker of the facility power supply (the user's

machine power supply) before wiring.

Page 47

HRX-OM-S004

Chapter 3 Transport and Setting Up

HRS Series 3.4Piping

3-27

z Connect piping firmly. Incorrect piping might cause leakage of

supplied or drained fluid and wet surrounding area and facility.

z Use caution not to allow dust and foreign matter to enter the water

circuit, etc. during connection of piping.

z Securely connect the piping at the piping port with specific wrench

when tightening.

z Incorrect piping can burst in service.

z Use non-corrosive material for fluid contact parts of circulating

fluid and/or facility water. Using the materials that tend to rust or

corrode may cause clogging or/and leakages of the circulating

fluid and facility water circuits. In case of using these kinds of

materials, consider and carry out some prevention against the

rusting or corrosion by the customer side.

z Do not generate a rapid change of pressure by water hammer, etc.

Internal parts of the product and/or the piping may be damaged.

z

Facility water temperature of the facility water outlet port might

rise up to approx.60deg.C.

3.4 Piping

Piping port size

Table 3-12 Piping port size

Name Port size

∗1

Recommended

tightening torque

Recommended piping

specification

Circulating fluid outlet port Rc3/4

28 to 30N・m

1.0MPa and more

Circulating fluid return

port

Rc3/4

28 to 30N・m

1.0MPa and more

Facility water inlet port*1 Rc3/4

28 to 30N・m

Facility water outlet port*1 Rc3/4

28 to 30N・m

1.0MPa and more.

(Supply puressure : 0.3 to

0.5MPa)

Automatic fluid fill port Rc1/2

20 to 25N・m

1.0MPa and more

(Automatic fluid -fill pressure :

0.2 to 0.5MPa)

Overflow port Rc1

36 to 38N・m

ID25mm and more

Length 5m and less

Pump drain port Rc1/4

8 to 12N・m

---