SMC Networks HRR012-W*-20, HRR018-A*-20, HRR018-W*-20, HRR024-W*-20, HRR030-W*-20 Operation Manual

...

HRX-OM-W004-A

Operation Manual

Communication function

Thermo-chiller

Air-Cooled

refrigerated type

HRR012-A

∗

-20-∗

HRR018-A

∗

-20-∗

HRR024-A

∗

-20-∗

HRR030-A

∗

-20-∗

Water-Cooled

refrigerated type

HRR012-W

∗

-20-∗

HRR018-W

∗

-20-∗

HRR024-W

∗

-20-∗

HRR030-W

∗

-20-∗

Keep this manual available whenever necessary

© 2018 SMC CORPORATION All Rights Reserved

To Users,

Thank you for purchasing SMC’s Thermo chiller (hereinafter referred to as the “product”).

For safety and long life of the product, be sure to read this operation manual (hereinafter referred

to as the “manual”) and clearly understand the contents.

● Be sure to read and follow all instructions noted with “Warning” or “Caution” in this manual.

● This manual is intended to explain the installation and operation of the product. Only people

who understand the basic operation of the product through this manual or who performs

installation and operation of or have basic knowledge about industrial machines are allowed to

work on the product.

● This manual and other documents attached to the product do not constitute a contract, and will

not affect any existing agreements or commitments.

● It is strictly prohibited to copy this manual entirely or partially for the use by the third party

without prior permission from SMC.

Note: This manual is subject to possible change without prior notice.

HRX-OM-W004

Contents

HRR Series

Contents

Chapter 1 Read before using ............................................................. 1-1

1.1 Communication mode and operation method ........................................................ 1-1

1.2 Communication port .................................................................................................. 1-3

1.3 Key operations ........................................................................................................... 1-4

1.4 Parameters ................................................................................................................. 1-8

Chapter 2 Contact input/output communication ............................. 2-1

2.1 Precautions for communication ............................................................................... 2-1

2.1.1 Precautions wiring communication ...................................................................................... 2-1

2.1.2 Precautions after wiring and before communication ............................................................ 2-1

2.2 Communication specification ................................................................................... 2-2

2.3 Connection explanation ............................................................................................ 2-2

2.4 Setting and checking ................................................................................................. 2-3

2.4.1 Setting and checking ............................................................................................................ 2-3

2.4.2 Setting and checking ............................................................................................................ 2-4

2.5 Contact input signal ................................................................................................ 2-12

2.5.1 Run/stop・Run・Stop・External switch signal ....................................................................... 2-13

2.5.2 Signal of the external switch .............................................................................................. 2-14

2.6 Contact output signal .............................................................................................. 2-16

Chapter 3 Serial communication ....................................................... 3-1

3.1 Precautions wiring communication ......................................................................... 3-1

3.2 Connected explanation ............................................................................................. 3-1

3.3 Communication specification ................................................................................... 3-2

3.4 MODBUS communication function .......................................................................... 3-3

3.5 Precautions for communication ............................................................................... 3-3

3.5.1 Precautions after wiring and before communication ............................................................ 3-3

3.5.2 Precautions for communicating ............................................................................................ 3-3

3.6 Setting and checking ................................................................................................. 3-4

3.6.1 Setting and checking items .................................................................................................. 3-4

3.6.2 Setting and checking ............................................................................................................ 3-5

3.7 Communication sequence ........................................................................................ 3-7

3.8 Message configuration .............................................................................................. 3-8

3.8.1 Message frame .................................................................................................................... 3-8

3.9 Function codes .......................................................................................................... 3-9

3.10 Checksum calculation method ............................................................................... 3-10

3.10.1 LRC(ASCII) ........................................................................................................................ 3-10

3.10.2 CRC(RTU) .......................................................................................................................... 3-10

3.11 Explanation of function codes ................................................................................ 3-12

3.11.1 Function code:04 Reading multiple registers .................................................................... 3-12

3.11.2 Function code:06 Writing registers .................................................................................... 3-13

3.11.3 Function code:16 Writing multiple registers ...................................................................... 3-14

HRX-OM-W004

Contents

HRR Series

3.11.4 Function code:23 Reading/writing multiple registers ........................................................ 3-15

3.12 Negative response ................................................................................................... 3-16

3.13 Register Map ............................................................................................................ 3-18

3.13.1 Circulating fluid discharge temperature ............................................................................. 3-19

3.13.2 Circulating fluid flow rate ................................................................................................... 3-19

3.13.3 Circulating fluid discharge pressur .................................................................................... 3-19

3.13.4 Electric conductivity of the circulating fluid ........................................................................ 3-19

3.13.5 Status flag .......................................................................................................................... 3-19

3.13.6 Alarm flag........................................................................................................................... 3-20

3.13.7 Data instruction information ............................................................................................... 3-21

3.13.8 Data display ....................................................................................................................... 3-21

3.13.9 Circulating fluid set temperature ........................................................................................ 3-21

3.13.10 Operation Start Command................................................................................................. 3-21

3.13.11 Serial remote instruction .................................................................................................... 3-21

3.13.12 Data instruction .................................................................................................................. 3-22

Chapter 4 Communication alarm function ....................................... 4-1

4.1 Communication alarm occurs .................................................................................. 4-1

4.2 Communication alarm reset ...................................................................................... 4-2

4.3 Setting and checking ................................................................................................. 4-2

4.3.1 Setting and checking items.................................................................................................. 4-2

4.3.2 Setting and checking ........................................................................................................... 4-3

HRX-OM-W004

Chapter 1 Read before using

HRR Series 1.1 Communication mode and operation method

1-1

Chapter 1 Read before using

The communication of this device consists of contact input/output

communication and serial communication.

The serial communication protocol is a MODBUS communication.

Depending on the customer’s specification, communication can be

changed to contact input/output communication or serial

communication.

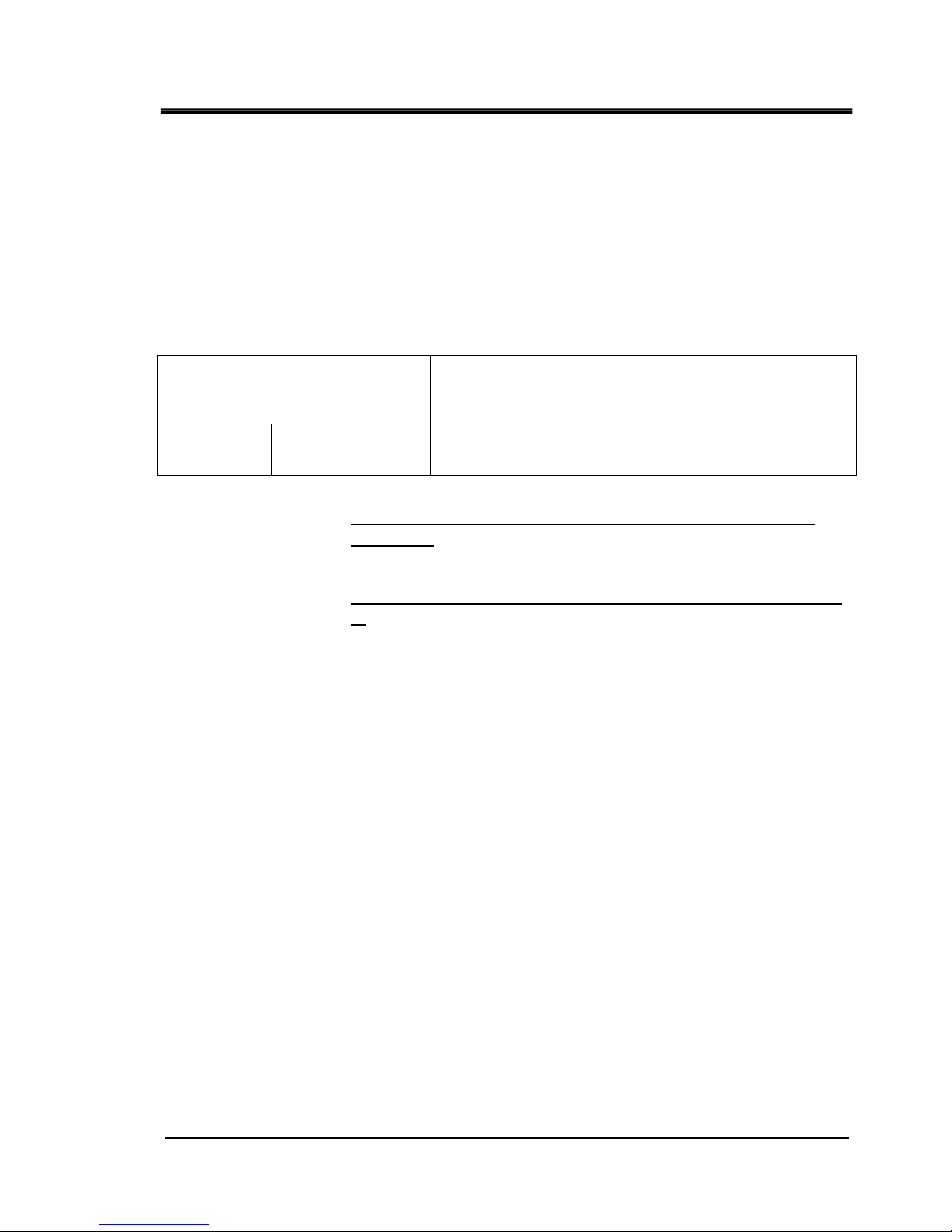

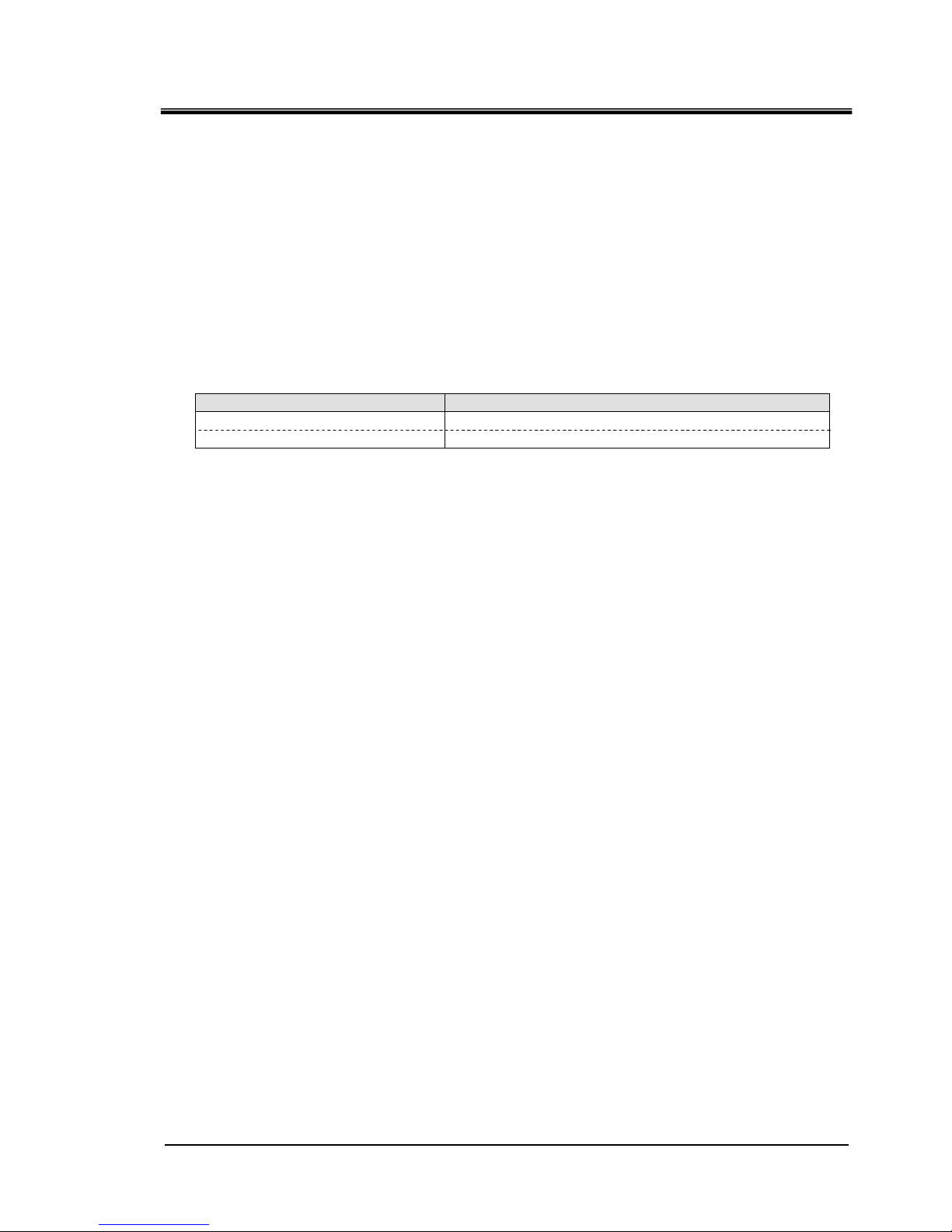

Table 1-1 Communication method

Contact input/output communication.

This product is equipped with a terminal which

runs/stops the product by remote control and a terminal which

can pick up alarm signals. The terminals can be changed

depending on the customer’s application.

Serial

communication

MODBUS standard

protocol

Serial communication (RS-485/RS232C) enables remote

control of run/start of the product, temperature setting, and

details of product condition and alarm condition can be obtained.

●If using contact input/output communication, refer to

chapter 2.

●If using serial communication MODBUS, refer to chapter

3.

1.1 Communication mode and operation method

LOCAL, DIO and SERIAL are available as the communication modes.

Table

1.1-1 explains the communication modes. The default setting is

LOCAL.

The operation method depends on the communication mode. Table

1.1-2 shows how the communication mode and method of operation

are related.

HRX-OM-W004

Chapter 1 Read before using

1.1 Communication mode and operation method

HRR Series

1-2

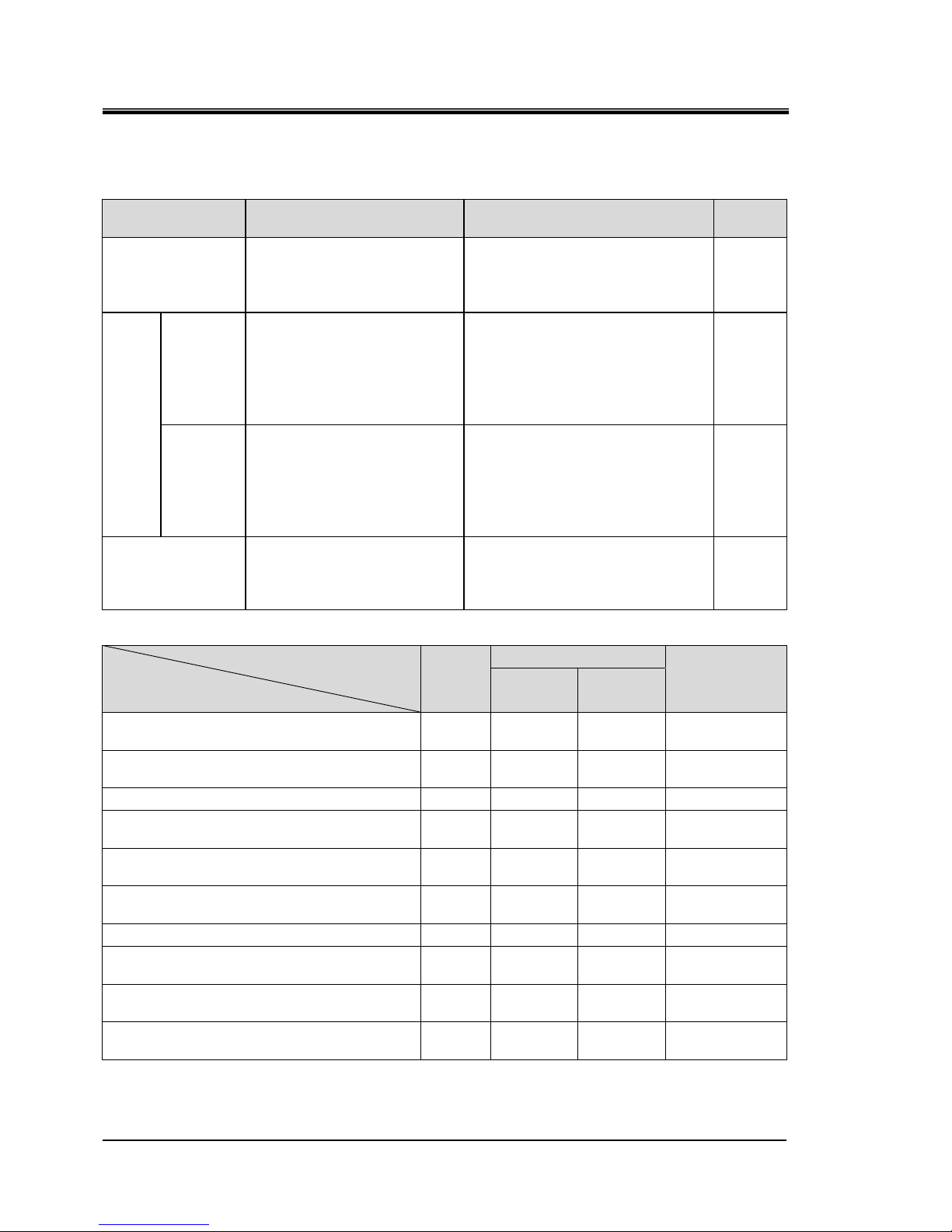

Table 1.1-1 Communication modes.

Communication

mode

Explanation Setting Display

LOCAL

Run / stop and circulating

fluid temperature setting are

possible with the operation

panel.

Select contact input signal

function 1 selection to "OFF"

(initial setting) / "SW".

None

DIO

REMOTE

Run / stop with contact

input,

and set circulating fluid

temperature on the

operation

panel.

Select contact input signal

function 1 selection as

"RN.ST" / "RUN".

RMT

Lamp

Lighting

up

LOCAL

Run / stop with the operation

panel or contact input.

Set the circulating fluid

temperature on the

operation

panel.

When the operation of the

contact input signal function 1

is selected as "MT" in the state

of DIO REMOTE, it becomes

"DIO LOCAL"

RMT

Lamp

Lighting

up

SERIAL

Run / stop and circulating

fluid temperature setting are

possible with the serial

communication

When serial remote instruction is

valid, this mode is switched.

RMT

Lamp

Lighting

up

Table 1.1-2 Communication mode and operation

LOCAL

DIO

SERIAL

DIO

LOCAL

DIO

REMOTE

Run/Stop control with operation

display panel

○ ○ × ○

Circulating fluid discharge temperature

setting control with operation display panel

○ ○ ○ ×

Except above with operation display panel

○ ○ ○ ○

Condition reading with operation

display panel

○ ○ ○ ○

Run/Stop operation by contact input/output

communication

× ○ ○ ×

Condition reading by contact input/output

communication

○ ○ ○ ○

Reading of the external switch

○ ○∗1 ○∗1 ○

Run/Stop operation by serial

communication.

× × × ○

Circulating fluid discharge temperature

setting control by serial communication.

× × × ○

Condition reading by serial

communication.

○ ○ ○ ○

∗1 Only one external switch can be installed.

HRX-OM-W004

Chapter 1 Read before using

HRR Series 1.2 Communication port

1-3

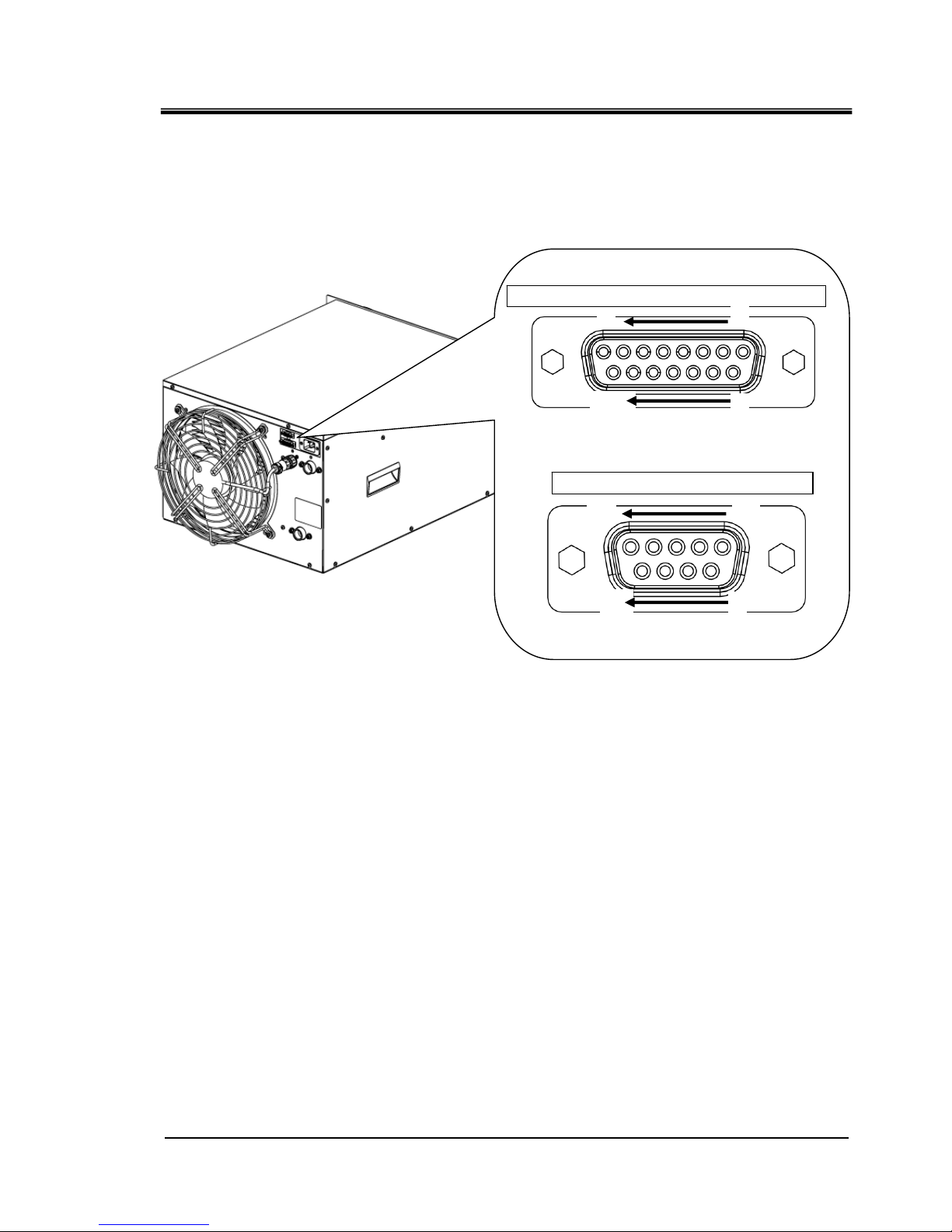

1.2 Communication port

The communication port at the back of the product is used for communication.

Fig 1.2-1 shows the location of the communication port.

Fig 1.2-1 Communication port

Dsub 15 pin female (socket) type

Dsub 9 pin female (socket) type

Connector for contact input / output signal

Serial communication connector

8

1

15

9

5

1

9

6

HRX-OM-W004

Chapter 1 Read before using

1.3 Key operations

HRR Series

1-4

1.3 Key operations

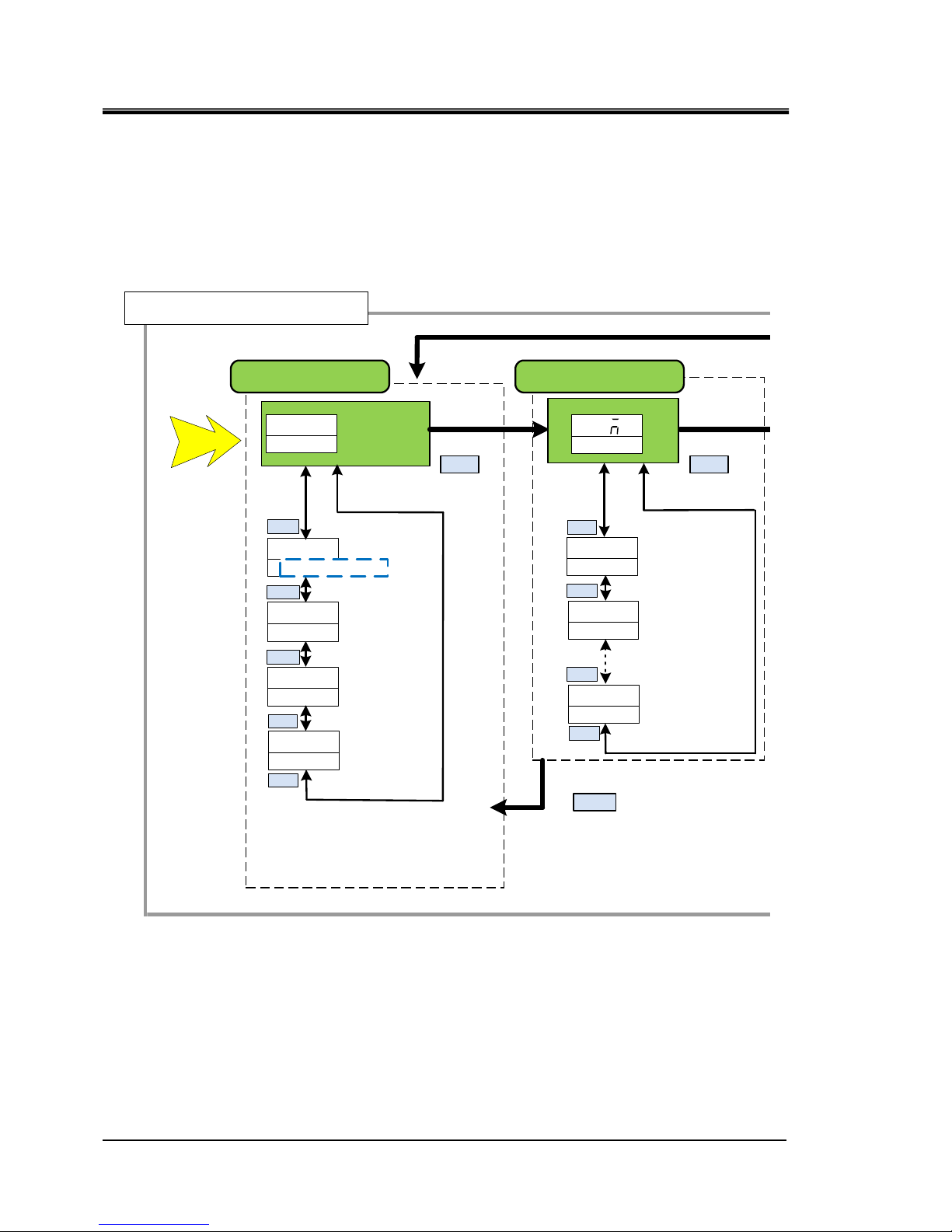

Fig 1.3-1‘’Key operation(1/4)’’ and

Fig1.3-4 ‘’Key operation(4/4)’’ show the operation of keys of the

thermo-chiller. This manual explains the “Communication setting menu”.

Fig 1.3-1 Key operation (1/4)

MENU

Main menu

Power supply ON

Allarm number

(Allarm number

maximum)

Alarm display menu

Allarm number

AL01

Allarm number

(Alarm number minimum)

AL02

ALXX

MENU

AL

XXALM

Basic setting mode

00

circulating fluid return

temp

014

Circulating fluid

outlet pressure

123

DIPV

Electric

conductivity∗

(μS/cm)

PRESS

79

Circulating fluid

flow rate

FLOW

RET ⇔ TEMP

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

200

200

Circulating fluid

outlet temperature

Circulating fluid set

temperature

∗ Option D【Electric conductivity control function】 only

RESET

Displays only when the alam is generated.

HRX-OM-W004

Chapter 1 Read before using

HRR Series 1.3 Key operations

1-5

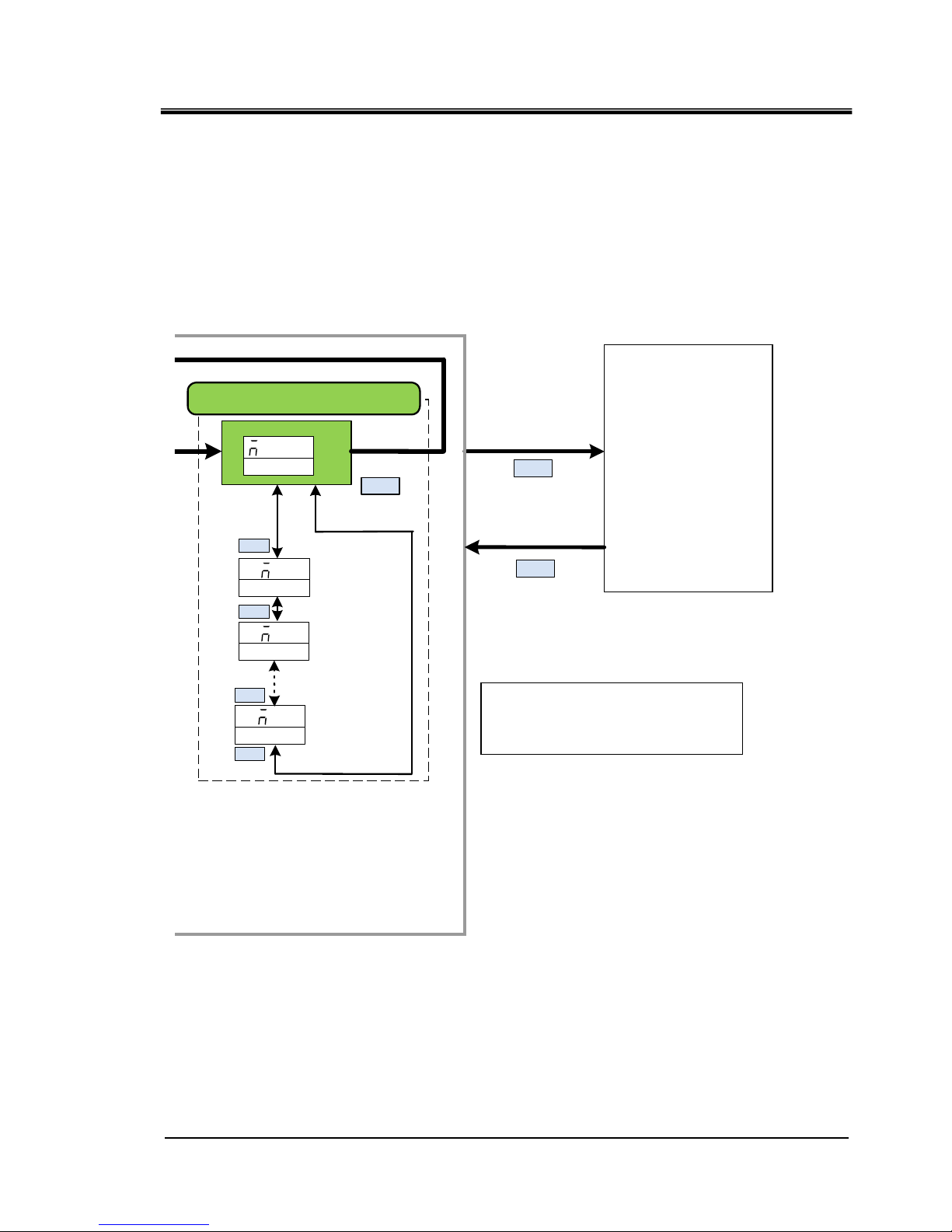

Fig 1.3-2 Key operation (2/4)

MENU

Maintenance

notification number

(Maintenance number

maximum)

Maintenance notification menu

Maintenance

notification

number

T01

Maintenance

notification number

(Notification number

Minimum)

TNN

▲/▼

▲/▼

▲/▼

▲/▼

ANT

MENU

T02

Advanced

setting

mode

To switch to 「Advanced setting

mode」 press and hold 「MENU」

key for 5 seconds

MENU

MENU

Press and hold

for approximately

5 second.

Displays only when the maintenance notice is generated.

HRX-OM-W004

Chapter 1 Read before using

1.3 Key operations

HRR Series

1-6

Fig 1.3-3 Key operation (3/4)

EASY mode

resetKey cl ick sound

Electric conductivity

set valve hysteresis*1

Unuse

d

ON

ON

WAKE

250

DISP

50

DIHYS

OFF

EXTMD

PUMPF

00

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

Key-lock

OFF

▲/▼

Circulating fluid temp time

outside monitoring range

5

WRM

▲/▼

SET

MENU

MENU

KEY ⇒ LOCK

EASY ⇒ MODE

KEY ⇒ CLICK

Offset mode

OFF

▲/▼

OFSET ⇒ MODE

00

▲/▼

OFSET ⇒ TEMP

▲/▼

EXT ⇔ OFSET

TEMP ⇒ OUT ⇒ OVER

DI filter maintenance

time*1

Dustproof filter

maintenance time

*Air-coold type only

5000

FILTT

5000

FUNUP

▲/▼

▲/▼

▲/▼

DI ⇔ TIME

050

5

WRN

HIPRS

HIPRS

HITEM

40

LOFL

5

LOTEM

450

DIHI

ON

ON

OFF

400

Detection time of circulating

fluid discharg e pressure

rise alarm

Changing of the flow

rate decrease alarm

Setting of low flow

rate alarm

Detection time of low

flow rate alarm

Setting of electric

conductivity increase

alarm*1

Switching circulating fluid

temperature drop alarm

Switching circulating fluid

temperature drop alarm

Unused

Unused

Setting of circulating fluid

discharge pressure

rise alarm

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

FLT

Changing of circulating fluid

discharge pressure

rise alarm

▲/▼

ALST

MENU

▲/▼

MENU

HIPRS ⇒ ALARM

TEMP ⇒ OUTHI ⇒ OUTP

TEMP ⇒ OUTLO ⇒OUTP

AMB ⇒ TEMP ⇒ ALARM

AMB ⇒ HITEMP

Alarm setting menu

FLTR ⇔ TIME

Lower limit of circulati ng

fluid temperature

monitoring function

Circulating fluid temp

monitoring start time

PUMPP

600

WRM

50

▲/▼

▲/▼

TEMP ⇒ OUT ⇒ TYPE

TEMP ⇒ OUT ⇒ START

HIPRS ⇒ TIME

LOFL ⇒ ALARM

LOFL ⇒ TIME

OFF

Switching circulating fluid

temperature range rising

alarm

▲/▼

TEMP ⇒ OUTLO ⇒ ALARM

Alarm buzzer sound

ON

ALARM ⇒ BUZZ

▲/▼

Unused

Pressure of lower

pressure refrigerant

circuit

Pressure of higher

pressu reref rigerant

circuit

000

000

▲/▼

▲/▼

ON

MENU

MENU

REF ⇔ PRSHI

REF ⇔ PRSLO

212

▲/▼

REF ⇔ TEMP

Ambient temperature

*Air-cooled type only

212

AMB ⇔ TEMP

▲/▼

▲/▼

Advance setting mode

0

0

WRN

Contact input signal 2

Delay timer

Contact input signal 2

OFF Detection timer

▲/▼

▲/▼

▲/▼

INP2 ⇒ DELAY

INP2 ⇒ OVER

COMM ⇒ ALARM

Changing of

communication error

monitoring alaarm

OFF

▲/▼

MANT ⇒ ALARM

Changing of

maintenance alarm

Monitor menu

Standard setting menu

Offset temperature

Electric conductivit y set

valve* 1

PUMPF

350

▲/▼

Unuse

d

FLT

Changing of contact

input signal 2 detection

alarm

INP2 ⇒ ALARM

▲/▼

Switching circulating fluid

temperature range rising

alarm

OFF

PUMPF

▲/▼

TEMP ⇒ OUTHI ⇒ ALARM

0

0

INP2

INP2

Contact input signal

1Delay timer of reading

Contact input signal 1

OFF Detection timer

▲/▼

▲/▼

INP1 ⇒ DELAY

FLT

Changing of contact

input signal 1 signal

detection

INP1 ⇒ ALARM

▲/▼

EXT ⇔ CTRL

EXT ⇒ HITMP ⇒ LIMIT

Upper limit of circul ating

fluid temperature

monitoring function

400

▲/▼

TEMP ⇒ OUT ⇒ HITMP

Unused

10

WAKE

Unuse

d

100

▲/▼

EXT ⇒ LOTMP ⇒ LIMIT

EXT ⇔ TIME

▲/▼

Temperature of the

compressor inlet

Basic

setting

mode

10

READY ⇒ HBEND

TEMP READYband

width Upper Limit

▲/▼

-10

▲/▼

READY ⇒ LBRND

TEMP READY Band

width Lower Limit

180

▲/▼

READY ⇒ TIME

TTEMP READY

stabilization time

600

▲/▼

READY ⇒ START

TTEMP READY alarm

monitoring start time

5

▲/▼

TEMP ⇒ OVER

TTEMP READY

Time when it goes away

▲/▼

▲/▼

TEMP READY alarm

OFF

PUMPF

TEMP ⇒ READY ⇒ ALARM

TEMP READY alarm output

added

ON

PUMPF

TEMP ⇒ READY ⇒ OUTP

▲/▼

100

Unused

▲/▼

AMB ⇒ LOTEMP

ARN

Switch leakage alarm

WATER ⇒ LEAK ⇒ ALARM

▲/▼

▲/▼

INP1 ⇒ OVER

30

▲/▼

COMM ⇒ TIME

The monitoring time of

communication error

0

PUMP ⇒ TIME

Time when only pump

rus when alarm is generated

▲/▼

400

PUMP ⇒ TEMP

Temp when only pump

rus when alarm is generated

▲/▼

CTRL

dDI

▲/▼

Electric conductivity

control methhod* 1

DI ⇒ CTRL

Circulating fluid temperature

range increases, the monitoring

method of lowering alarm

RNST

WRM

TEMP ⇒ OUT ⇒ ALARM

▲/▼

HRX-OM-W004

Chapter 1 Read before using

HRR Series 1.3 Key operations

1-7

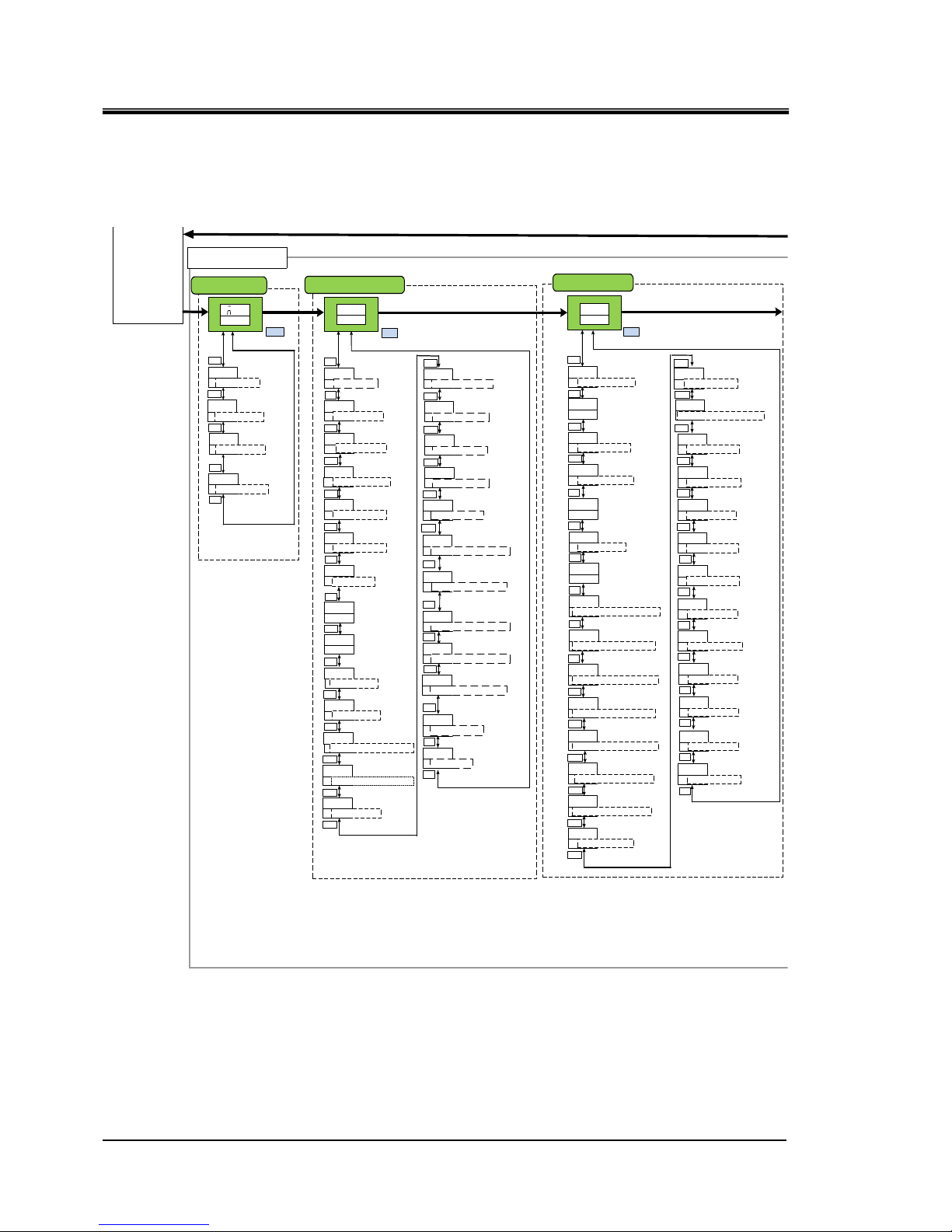

Fig 1.3-4 Key operation (4/4)

ASC

485

OFF

PROT

TYPE

TERM

1

192

SPEED

T01

DIN1

ALT

INP1

Serialprotocol

Communication

specifications

Slave address

Communication speed

RS-485terminal

Digital input signal 1

Selective Maintenance

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

MENU

OFF

INP2

ALT

INP2

A

INP2

A

OUT1

Digital input

signal 2

operation

Digital output signal 1

operation

Digital input signal 2

function selection

Digital input signal 2 type

▲/▼

▲/▼

▲/▼

▲/▼

A

INP1

Contact inputsignal 1

operation

▲/▼

DIN2 ⇔ SEL

DOUT1 ⇒ TYPE

SLV ⇔ ADDR

NO

MODE

Setting date reset

RST

MENU

MENU

ALL ⇔ RESET

Communication setting menu Reset menu

R T

OUT2

OUT2

AL01

OUT2

AL

OUT3

B

OUT3

AL01

OUT3

Digital output 2

selected alarm

Digital output signal 3

selected alarm

Digital output signal 2

function selection

Digital output signal 2

operation

Digital output signal 3

function selection

Digital output signal 3

operation

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

DOUT2 ⇔ SEL

DOUT2 ⇔ TYPE

DOUT3 ⇔ SEL

DOUT3 ⇔ TYPE

▲/▼

0

Operation time

Pump operation time

Accumulated operation time

of the dust-proof filter

Accumulated operation

time of the DI filter ∗1

DIT

0

RUNT

0

PUMPT

0

COMPT

0

FLTRT

▲/▼

▲/▼

▲/▼

▲/▼

▲/▼

Compressor

operation time

0

FANT

▲/▼

Fan operation time

*Air-cooled type only

INFO

MENU

Information moniter menu

00

PGVER

Program version

▲/▼

0000

PGNO

Program number

▲/▼

▲/▼

MENU

Digital input

signal 1 type

OUT1

RUN

Digital output signal 1

function selection

▲/▼

DOUT1 ⇒ SEL

OUT1

AL01

Digital output signal 1

selected alarm

DIN1 ⇒ SW ⇒ TYPE

DIN1 ⇒ CON ⇒ TYPE

DIN2 ⇒ SW ⇒ TYPE

DIN2 ⇒ CON ⇒ TYPE

DOUT1 ⇒ ALARM ⇒ CODE

A

▲/▼

DOUT2 ⇒ ALARM ⇒ CODE

OUT1

T01

Digital output 2

selected maintenance

DOUT2 ⇒ MANT ⇒ CODE

OUT1

T01

Digital output 3

selected maintenan ce

DOUT3 ⇒ MANT ⇒ CODE

DOUT3 ⇒ ALARM ⇒ CODE

▲/▼

▲/▼

DOUTI⇒ MANT ⇒ CODE

aAL h

nnn

Alarm history menu

MENU

AL17

Alarm

(The latest)

▲/▼

OFF

DINI

▲/▼

Digital input signal 1

function selection

hRR

018-R

Model

▲/▼

20-

DMTU

Power Options

▲/▼

Example

AL10

Alarm

▲/▼

ALNN

Alarm

(The oldest)

▲/▼

*1:With electric conductivity

control function only

0

Number of times of

momentary power failure

POWF

▲/▼

NO

NO

PROT

Reset of dust-proof

filter operation time

DI filter

Reset usage time

▲/▼

▲/▼

FLTRT ⇒ RESET

DIT ⇒ RESET

▲/▼

NO

PROT

Reset of pump

operation time

▲/▼

PUMPT ⇒ RESET

NO

PROT

Reset of compressor

operation time

▲/▼

COMPT ⇒ RESET

NO

PROT

Reset of fan

operation time

▲/▼

FANT ⇒ RESET

OFF

Forced DI solenoid

valve

open

DI ⇒ VALVE

0000

instantaneous power failure

occurrence count

DIT

▲/▼

▲/▼

▲/▼

CO

MENU

STD

WS001

standard product/

special numbers

▲/▼

SELIAL.NO

*2

By pressing the ENT key on each alarm history screen,

accumulated operating time and the number of

historcases at the time of occurrence are displayed.

AL10

123

NO2

MENU

ENT

Accumulated operating time at alarm accurrence is displayed

Alarm log number

COMM ⇒ STUS

HRX-OM-W004

Chapter 1 Read before using

1.4 Parameters

HRR Series

1-8

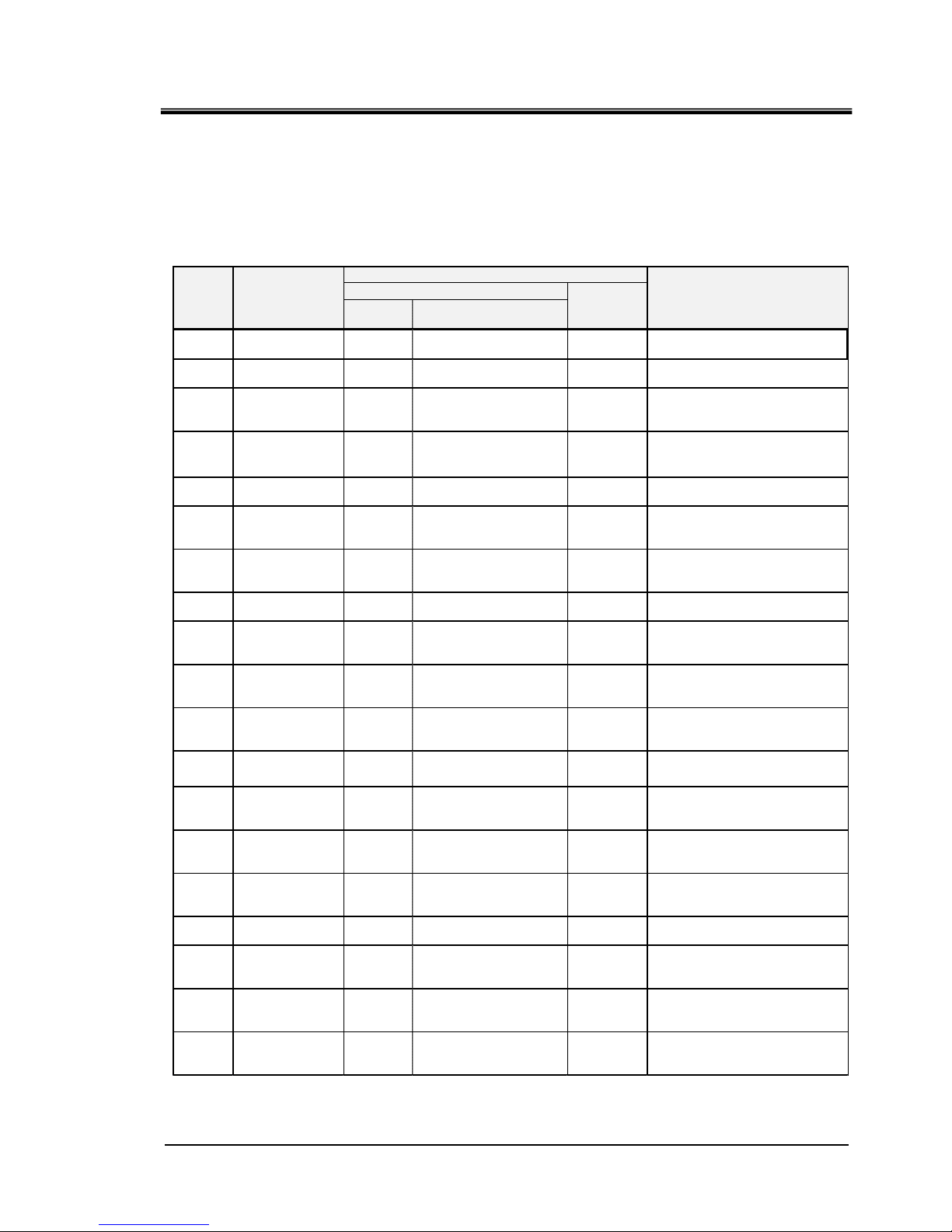

1.4 Parameters

Table 1.4-1 ‘’Communication setting menu Parameters’’ explains the

parameters of the 「communication setting menu」.

Table 1.4-1 Communication setting menu Parameters

∗1 Selectable from OFF/RUN/RMT/EXT.C/RDY/T.OUT/FLT/WRN/MENT/ALM/SW1/SW2/A.SEL/M.SEL

Initial value Select/setting range

TOP

screen

-

COMM

-

MEN U -

No.1

screen

Serial protocol

ASC AS C/ RTU PR OT

No.2

screen

Communic ation specification

485 485/232C TYPE

No.3

screen

RS-485 terminal unit

OFF OFF/ON TERM

No.4

screen

Slave address

11

~

32 SLV ⇒ ADDR

No.5

screen

Communic ation speed

(

bps

)

19.2 9.6/19.2 SPEED

No.6

screen

Contact input signal 1 function OFF OFF/RN.ST/RUN/SW D.IN1 ⇒ SEL

No.7

screen

Contact input signal 1 type ALT ALT/MT D.IN 1 ⇒ SW ⇒ TYPE

No.8

screen

Contact input signal 1 operation A A/B D.IN1 ⇒ CON ⇒ TYPE

No.9

screen

Contact input signal 2 function OFF OFF/STOP/SW D.IN2 ⇒ SEL

No.10

screen

Contact input signal 2 type ALT ALT/MT D.IN 2 ⇒ SW ⇒ TYPE

No.11

screen

Contact input signal 2 operation A A/B D.IN2 ⇒ CON ⇒ TYPE

No.12

screen

Contact output signal 1 function RUN

∗

1D.OUT1

⇒

SEL

No.13

screen

Contact output signal 1 operation A A/B D.OUT1 ⇒ TYPE

No.14

screen

Contact output signal 1

alarm

AL.01 AL.01~AL .32 D .OU T1 ⇒ ALARM ⇒ CODE

No.15

screen

Contact output signal 1 maintenance MT.01 MT.01~MT. 05 D.O UT1⇒ MANT ⇒ CODE

No.16

screen

Contact output signal 2 function RMT

∗

1D.OUT2

⇒

SEL

No.17

screen

Contact output signal 2 operation A A/B D.OUT2 ⇒ TYPE

No.18

scree

Contact output signal 2

alarm

AL.01 AL.01~AL .32 D .OU T2 ⇒ ALARM ⇒ CODE

No.19

screen

Contact output signal 2 maintenance MT.01 MT.01~MT.05 D.OUT2 ⇒ MANT ⇒ CODE

No.20

screen

Contact output signal 3 function ALM

∗

1D.OUT3

⇒

SEL

No.21

screen

Contact output signal 3 operation B A/B D.OUT3 ⇒ TYPE

No.22

screen

Contact output signal 3

alarm

AL.01 AL.01~AL .32 D .OU T3 ⇒ ALARM ⇒ CODE

No.23

screen

Contact output signal 3 maintenance MT.01 MT.01~MT.05 D.OUT3 ⇒ MANT ⇒ CODE

3.5.2

2.4.2

ScreenNo. Item

Display unit

Reference

page

Upper stage(White

)

Lower stage

(

Green

)

HRX-OM-W004

Chapter 2 Contact input/output communication

HRR Series 2.1 Precautions for communication

2-1

Chapter 2 Contact input/output

communication

The device is equipped with a terminal which runs/stops the product. It is also

equipped with a terminal which picks up operation signals, alarm signals and

setting condition.

The device starts contact input/output communication according to the setting

of the operation display panel. Contact input/output communication can be

customized by changing the settings. Table 2-1 ‘’Customizable content’’

shows the contents which can be changed by the operation display panel.

Table 2-1 Customizable content

Signal Can be changed

Contact input signal (2pcs.) Signal configuration (Alternate/Momentary)

Contact output signal (3pcs.) Type of signal, signal operation (N.O type / N.C type)

2.1 Precautions for communication

2.1.1 Precautions wiring communication

○Communication wiring

A communication cable that connects the product and customer system is not

included with the product. Please prepare a cable, referring to 2.3

“Connection explanation“. In order to avoid malfunction, do not connect to

any place other than those shown in 2.3 “Connection explanation“.

○Power supply

To use the power of the product, the total load current must be 500mA or

less.

2.1.2 Precautions after wiring and before communication

○Check or set the communication mode by the operation display panel.

・Communication mode shall be DIO.

Other modes can perform reading, but only DIO mode can perform writing.

HRX-OM-W004

Chapter 2 Contact input/output communication

2.2 Communication specification HRR Series

2-2

2.2 Communication specification

Table 2.2-1 DIO Communication specification

Item Specification

Connector type(for this product) Dsub 15P type female connector

Contact input

signal

Insulation system

Photo coupler

Rated input voltage

DC24V

Used input voltage

DC 21.6 to 26.4V

Rated input current

5mA TYP

Input signal

4.7kΩ

Contact output

signal

Rated load voltage

AC48V or less/DC30V or less

Maximum load current

AC/DC 500mA (Resistance load)

Minimum load current DC5V 10mA

DC24V output voltage

DC24V±10% 500mA MAX

(It can not be used for inductive load.)

2.3 Connection explanation

This part explains the port of the contact input/output communication. A

communication cable that connects the product and customer system is not

included with the product.

Table 2.3-1 Contact input/output pin number

PIN

no

Application Division Default setting

Setting

available

1 DC 24V output Output

2 DC 24V output Output

3 DC 24V output Output

4 Contact input signal 1 Input None

○

5 Common of contact output signal 1 Output

6 Common of contact output signal 2 Output

7 Common of contact output signal 3 Output

8 None -

9 24 COM output Output

10 24 COM output Output

11 Common of contact input signal Output

12 Contact input signal 2 Input None

○

13 Contact output signal 1 Output

Run status signal

(N.O. type)

○

14 Contact output signal 2 Output Remote signal (N.O. type)

○

15 Contact output signal 3 Output Alarm signal (N.C. type)

○

HRX-OM-W004

Chapter 2 Contact input/output communication

HRR Series 2.4 Setting and checking

2-3

2.4 Setting and checking

2.4.1 Setting and checking

The table below explains the setting items of the contact input/output signal

and the initial values.

Table 2.4-1 List of set communication items

*1:Selectable from OFF/RUN/RMT/EXT.C/RDY/T.OUT/FLT/WRN/MENT/ALM/SW1/SW2/

A.SEL/M.SEL

Initial

va lu e

Select/setting range

TOP

screen

-

COMM

-

MEN U

Com m un icati on s etting m enu

TOP screen

No.6

screen

Contact input

signal 1 function

OFF OFF/RN .ST/R UN /SW

D.IN1

⇒

SEL

Setting function of contact input

signal 1.

No.7

screen

Contact input

signal 1 type

AL T AL T/MT

D.IN1

⇒

SW

⇒

TYPE

Setting input type of contact

input signal 1.

No.8

screen

Contact input

signal 1

operation

AA/B

D.IN1

⇒

CON

⇒

TYPE

Setting input operation of

contact input signal 1.

No.9

screen

Contact input

signal 2 function

OFF OFF/STOP/SW

D.IN2

⇒

SEL

Setting function of contact input

signal 2.

No.10

screen

Contact input

signal 2 type

AL T AL T/MT

D.IN2

⇒

SW

⇒

TYPE

Setting input type of contact

input signal 2.

No.11

screen

Contact input

signal 2

operation

AA/B

D.IN2

⇒

CON

⇒

TYPE

Setting input operation of

contact input signal 2.

No.12

screen

Contact output

signal 1 function

RUN

※

1

D.OUT1

⇒

SEL

Setting function of contact input

signal 1.

No.13

screen

Contact output

signal 1

operation

AA/B

D.OUT1

⇒

TYPE

Setting output operation of

contact output signal 1.

No.14

screen

Contact output

signal 1alarm

AL .0 1 AL .0 1~AL .3 2

D.OUT1

⇒

ALARM

⇒

CODE

Setting selected alarm of

contact output signal 1.

No.15

screen

Contact output

signal 1

maintenance

MT. 01 MT. 01~MT. 05

D.OUT1

⇒

MANT

⇒

CODE

Setting selected maintenance of

contact output signal 1.

No.16

screen

Contact output

signal 2 function

RMT

※

1

D.OUT2

⇒

SEL

Setting function of contact output

signal 2.

No.17

screen

Contact output

signal 2

operation

AA/B

D.OUT2

⇒

TYPE

Setting output operation of

contact output signal 2.

No.18

screen

Contact output

signal 2 alarm

AL .0 1 AL .0 1~AL .3 2

D.OUT2

⇒

ALARM

⇒

CODE

Setting selected alarm of

contact output signal 2.

No.19

screen

Contact output

signal 2

maintenance

MT. 01 MT. 01~MT. 05

D.OUT2

⇒

MANT

⇒

CODE

Setting selected maintenance of

contact output signal 2.

No.20

screen

Contact output

signal 3 function

AL M

※

1

D.OUT3

⇒

SEL

Setting function of contact output

signal 3.

No.21

screen

Contact output

signal 3

operation

BA/B

D.OUT3

⇒

TYPE

Setting output operation of

contact output signal 3.

No.22

screen

Contact output

signal 3 alarm

AL .0 1 AL .0 1~AL .3 2

D.OUT3

⇒

ALARM

⇒

CODE

Setting selected alarm of

contact output signal 3.

No.23

screen

Contact output

signal 3

maintenance

MT. 01 MT. 01~MT. 05

D.OUT3

⇒

MANT

⇒

CODE

Setting selected maintenance of

contact output signal 3.

Display

No.

Item

Display unit

Contents

Upper stage(White

)

Lower

stage

(

Green

)

HRX-OM-W004

Chapter 2 Contact input/output communication

2.4 Setting and checking HRR Series

2-4

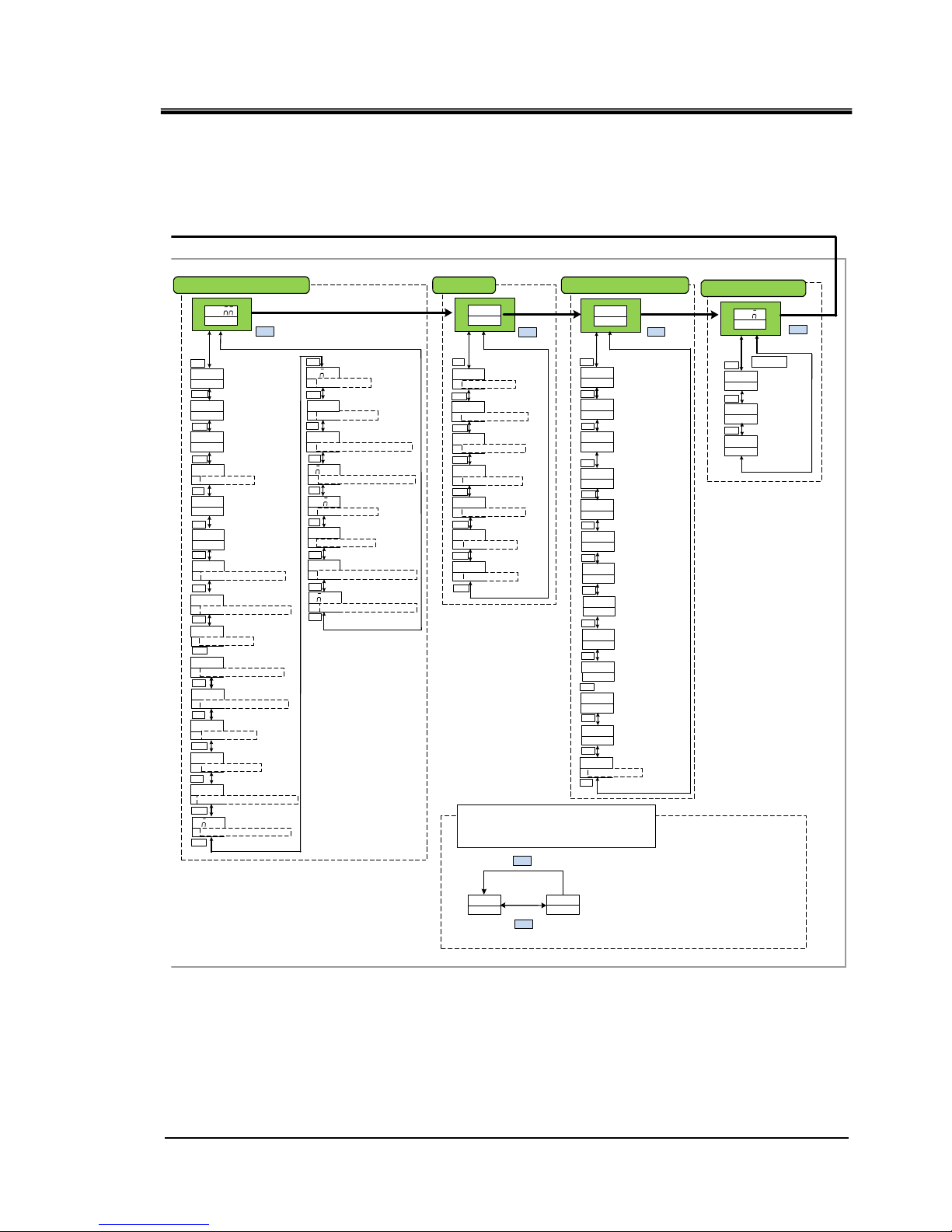

2.4.2 Setting and checking

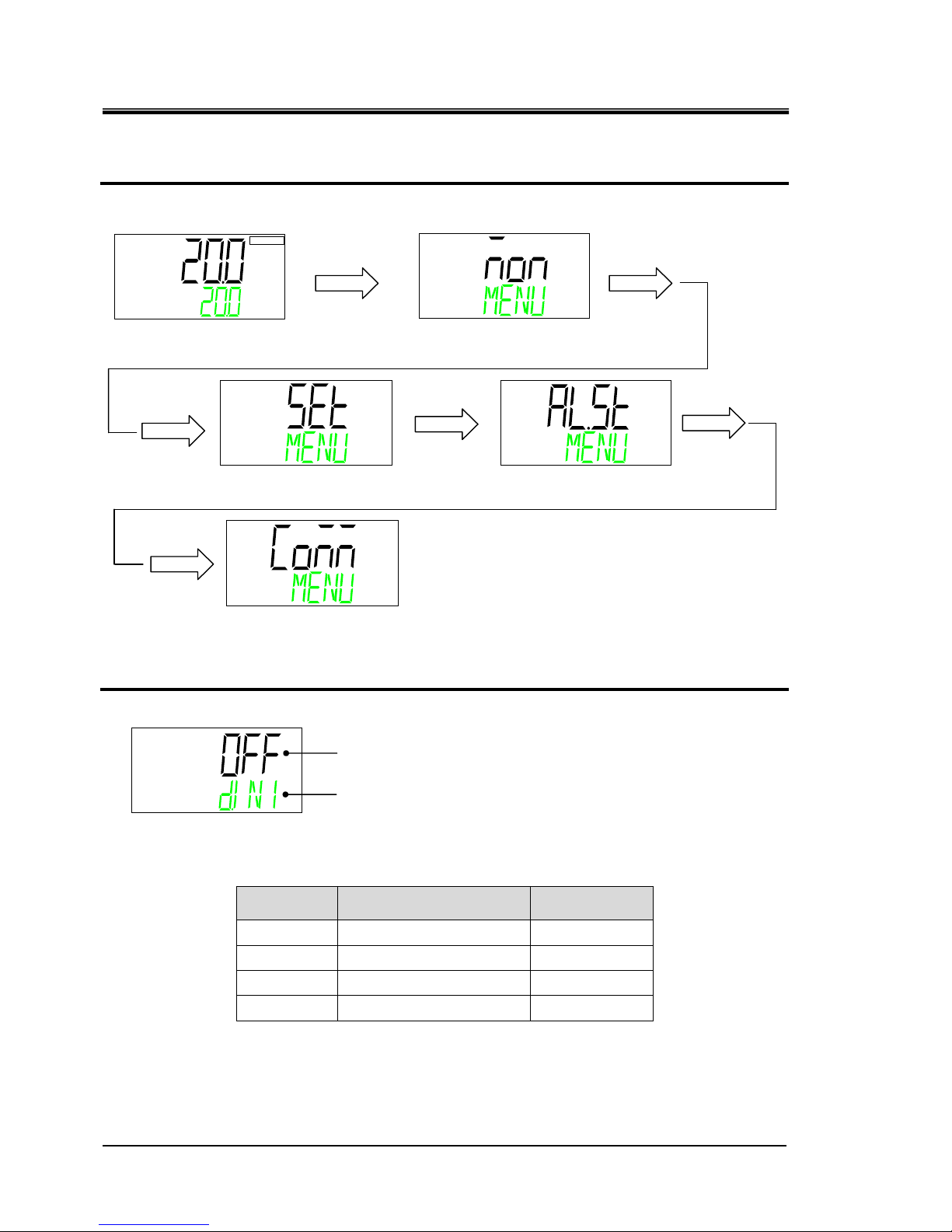

Communication setting menu TOP screen

1. Displays communication setting menu.

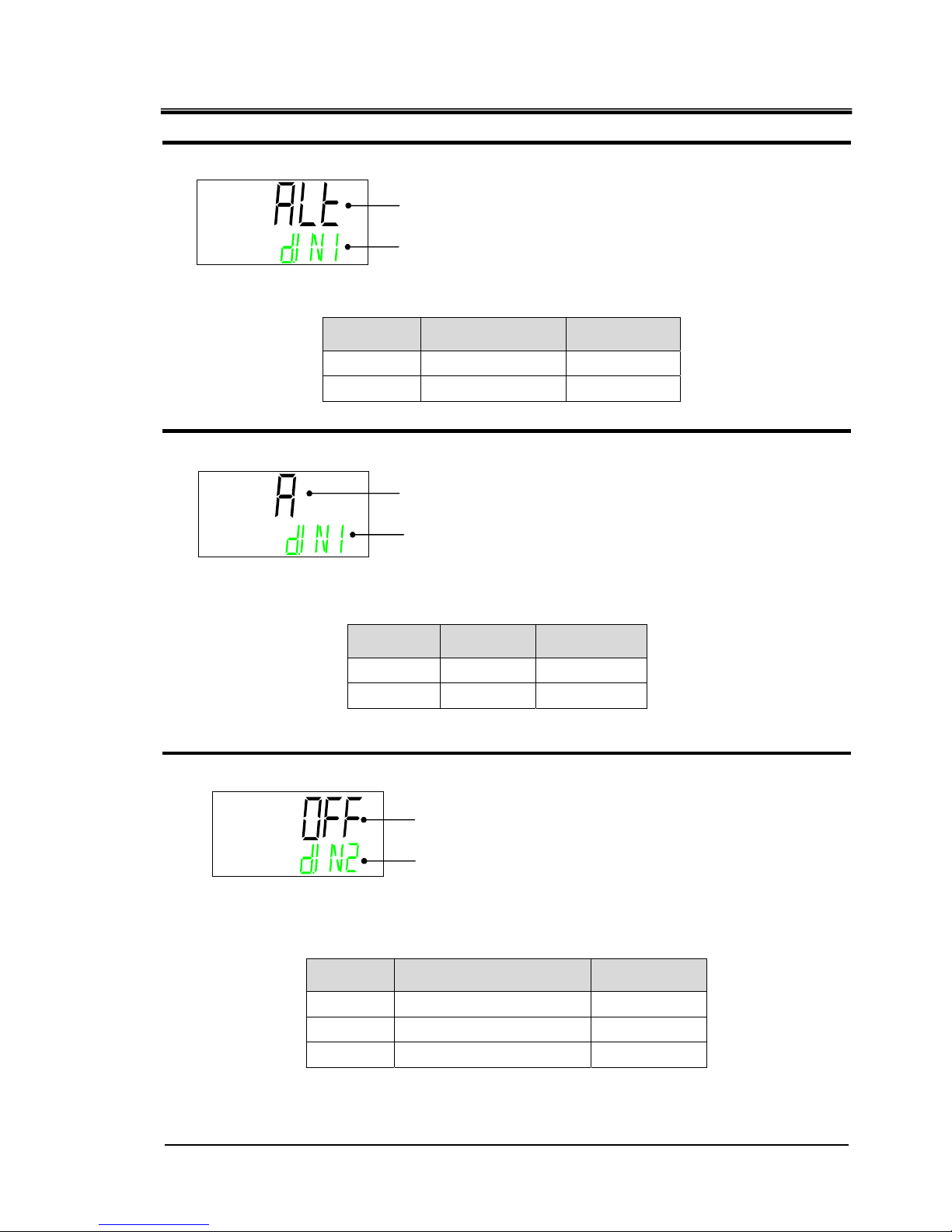

Contact input signal 1 function

2. Press the [▼] key. Displays screen for setting the function of the Contact input signal 1

Displays the function for the Contact input signal 1.

Set value Contents

Initial value

OFF

No input signal

○

RNST

Run / stop signal is input

―

RUN

Run signal is input

―

SW

External switch signal input

―

℃

Main menu

TOP

screen

[MENU] key

Press and hold

(5 seconds)

Monitor Menu

TOP

screen

[MENU]

key

Standard setting menu

TOP

screen

[MENU]

key

Alarm setting menu

TOP

screen

Communication setting menu

TOP

screen

[MENU]

key

[MENU]

key

[MENU]

key

Contact input signal 1 function

DIN1 ⇒ SEL(Alternately displayed)

HRX-OM-W004

Chapter 2 Contact input/output communication

HRR Series 2.4 Setting and checking

2-5

Contact input signal 1 type

3. Press the [▼] key. Displays screen for setting the type of Contact input signal 1.

Displays the type of Contact input signal 1.

Contact input signal 1

operation

4. Press the [▼] key. Displays screen for setting the operation of the Contact input signal 1.

Select the Contact input signal 1 operation.

Contact input signal 2 Select function

5. Press the [▼] key. Displays screen for setting the function of the Contact input signal 2.

Displays the function of the Contact input signal 2.

Set value Contents

Initial value

OFF

No input signal

○

STOP

Stop signal input

―

SW

External switch signal input

―

Set value Contents

Initial value

ALT

Alternate signal

○

mT

Momentary signal

―

Set value Contents

Initial value

A

N.O. type

○

B

N.C. type

―

Contact input signal 1 type

DIN1 ⇒ SW ⇒ TYPE(Alternately displayed)

Contact input signal 1 operation

DIN1 ⇒ CON ⇒ TYPE(Alternately displayed)

Contact input signal 2 function

DIN2 ⇒ SEL(Alternately displayed)

HRX-OM-W004

Chapter 2 Contact input/output communication

2.4 Setting and checking HRR Series

2-6

Contact input signal 2 type

6. Press the [▼] key. Displays screen for setting the type of Contact input signal 2.

Displays the type of Contact input signal 2.

Set value Contents

Initial value

ALT

Alternate signal

○

mT

Momentary signal

―

Contact input signal 2 operation

7. Press the [▼] key. Displays screen for setting the operation of the Contact input signal 2.

Select the Contact input signal 2 operation.

Set value Contents

Initial value

A

N.O. type

○

B

N.C. type

―

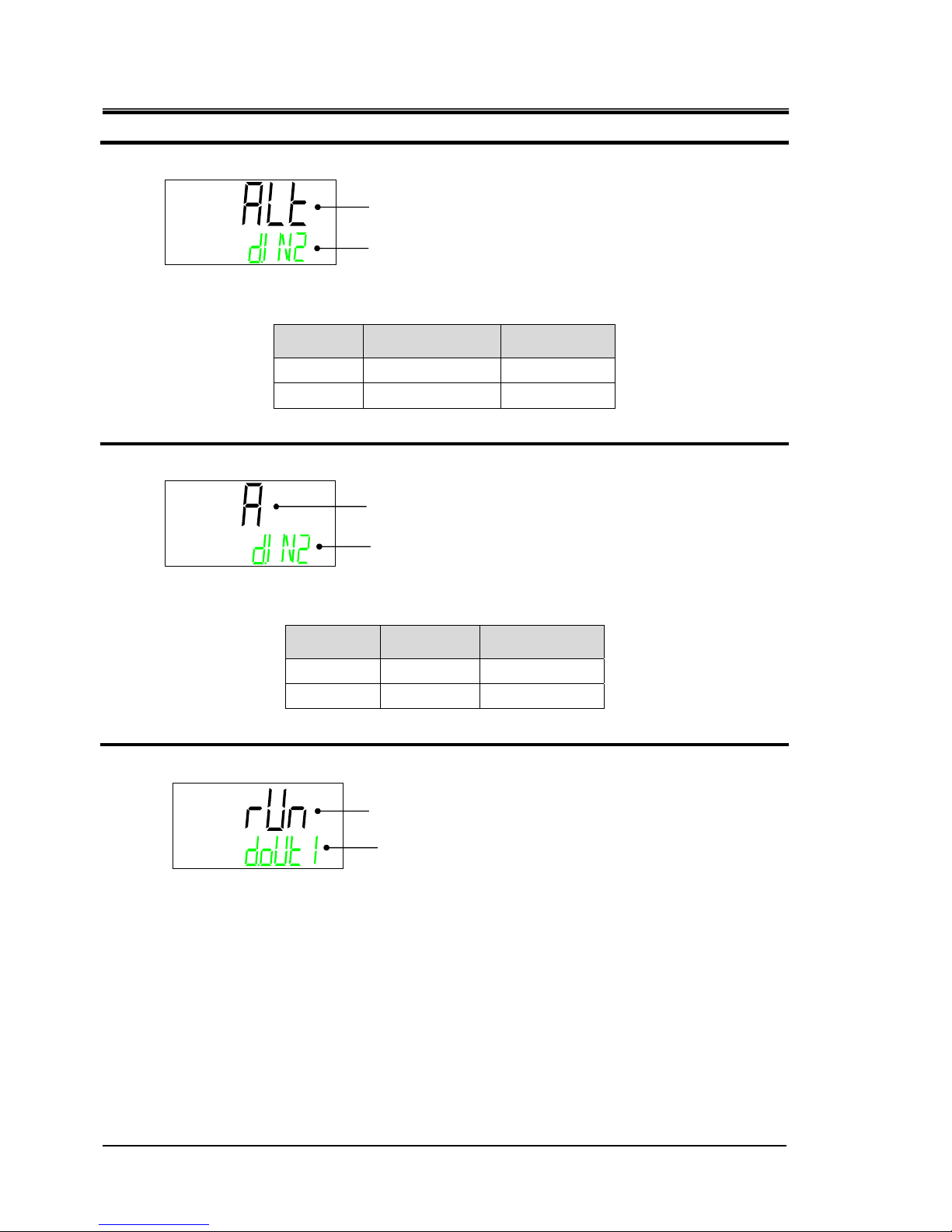

Contact output signal 1 function

8. Press the [▼] key. Displays setting screen for function of contact output signal 1 .

Displays the function of the Contact output signal 1.

Contact input signal 2 type

DIN2 ⇒ SW ⇒ TYPE(Alternately displayed)

Contact input signal 2 operation

DIN2 ⇒ CON ⇒ TYPE(Alternately displayed)

Contact output signal 1 function

DOUT1 ⇒ SEL(Alternately displayed)

Loading...

Loading...