SMC Networks HRL100-A, HRL300-A, HRL200-A Operation Manual

HRX-OM-W069

Thermo-chiller

Air-Cooled refrigerated type

HRL100-A

HRL200-A

HRL300-A

Operation Manual

Communication function

Keep this manual available whenever necessary

© 2019 SMC CORPORATION All Rights Reserved

To Users,

Note: This manual is subject to possible change without prior notice.

Thank you for purchasing SMC’s Thermo chiller (hereinafter referred to as the “product”).

For safety and long life of the product, be sure to read this operation manual (hereinafter referred

to as the “manual”) and clearly understand the contents.

● Be sure to read and follow all instructions noted with “Warning” or “Caution” in this manual.

● This manual is intended to explain the installation and operation of the product. Only people

who understand the basic operation of the product through this manual or who performs

installation and operation of or have basic knowledge about industrial machines are allowed to

work on the product.

●This manual and other documents do not constitute a contract, and will not affect any existing

agreements or commitments.

● It is strictly prohibited to copy this manual entirely or partially for the use by the third party

without prior permission from SMC.

HRX-OM-W069

Contents

Contents

Chapter 1 Read before using ............................................................ 1-1

1.1 Operation mode and operation method ................................................................. 1-1

1.2 Change of operation mode ..................................................................................... 1-3

1.3 Communication port ............................................................................................... 1-4

1.4 Touch panel flow ..................................................................................................... 1-5

Chapter 2 Contact input/output communication /Analog output

communication ...................................................................................... 2-1

2.1 Precautions for communication ............................................................................. 2-1

2.1.1 Precautions wiring communication ...................................................................................... 2-1

2.1.2 Precautions after wiring and before communication ............................................................ 2-2

2.2 Communication specification ................................................................................. 2-2

2.3 Contact input signal ................................................................................................ 2-5

2.3.1 Setting of contact input signal type and form ....................................................................... 2-5

2.3.2 Run/stop・Run・Stop・External switch signal ......................................................................... 2-7

2.3.3 External switch signal ........................................................................................................... 2-8

2.4 Contact output signal ............................................................................................ 2-10

2.4.1 Contact output signal 1 to 3 ...............................................................................................2-10

2.4.2 Contact output signal 4 to 6 ............................................................................................... 2-11

2.5 Analog output signal ............................................................................................. 2-14

Chapter 3 Serial communication ...................................................... 3-1

3.1 Precautions wiring communication ....................................................................... 3-1

3.2 Connected explanation ........................................................................................... 3-1

3.3 Communication specification ................................................................................. 3-2

3.4 MODBUS communication function ........................................................................ 3-3

3.5 Precautions for communication ............................................................................. 3-4

3.5.1 Precautions after wiring and before communication ............................................................ 3-4

3.5.2 Precautions for communicating ............................................................................................ 3-4

3.6 Setting method ........................................................................................................ 3-5

3.7 Communication sequence ...................................................................................... 3-7

3.8 Message configuration ........................................................................................... 3-7

3.8.1 Message frame .................................................................................................................... 3-7

3.9 Function codes ........................................................................................................ 3-9

3.10 Checksum calculation method ............................................................................... 3-9

3.10.1 LRC(ASCII) .......................................................................................................................... 3-9

3.10.2 CRC(RTU) ..........................................................................................................................3-10

3.11 Explanation of function codes ............................................................................. 3-12

3.11.1 Function code:04 Reading multiple registers ....................................................................3-12

3.11.2 Function code:06 Writing registers ....................................................................................3-14

3.11.3 Function code:16 Writing multiple registers ......................................................................3-15

3.12 Negative response ................................................................................................ 3-16

HRL Series

HRX-OM-W069

Contents

3.13 Register Map ................................ ................................................................ .......... 3-18

3.13.1 Circulating fluid discharge temperature ............................................................................. 3-19

3.13.2 Circulating fluid electrical conductivity ............................................................................... 3-19

3.13.3 Circulating fluid discharge pressur .................................................................................... 3-19

3.13.4 Circulating fluid flow rate ................................................................................................... 3-19

3.13.5 Status flag .......................................................................................................................... 3-20

3.13.6 Alarm flag........................................................................................................................... 3-21

3.13.7 Data display ....................................................................................................................... 3-22

3.13.8 Circulating fluid set temperature ........................................................................................ 3-22

3.13.9 Operation instruction ......................................................................................................... 3-23

3.13.10 Data instruction .................................................................................................................. 3-23

Chapter 4 Communication alarm function ...................................... 4-1

4.1 Communication alarm occurs ................................................................................. 4-1

4.2 Communication alarm reset .................................................................................... 4-2

4.3 Setting method ......................................................................................................... 4-2

HRL Series

1-1

Chapter 1 Read before using

Contact input/output communication /

Analog output communication

This product is equipped with a terminal which

runs/stops the product by remote control and a terminal

which can pick up alarm signals. The terminals can be

changed depending on the customer’s application.

Serial

communication

MODBUS standard

protocol

Serial communication (RS-485/RS232C) enables remote

control of run/start of the product, temperature setting,

and details of product condition and alarm condition can

be obtained.

・Displays the current operation mode.

・You can change the operation mode

by pressing it.

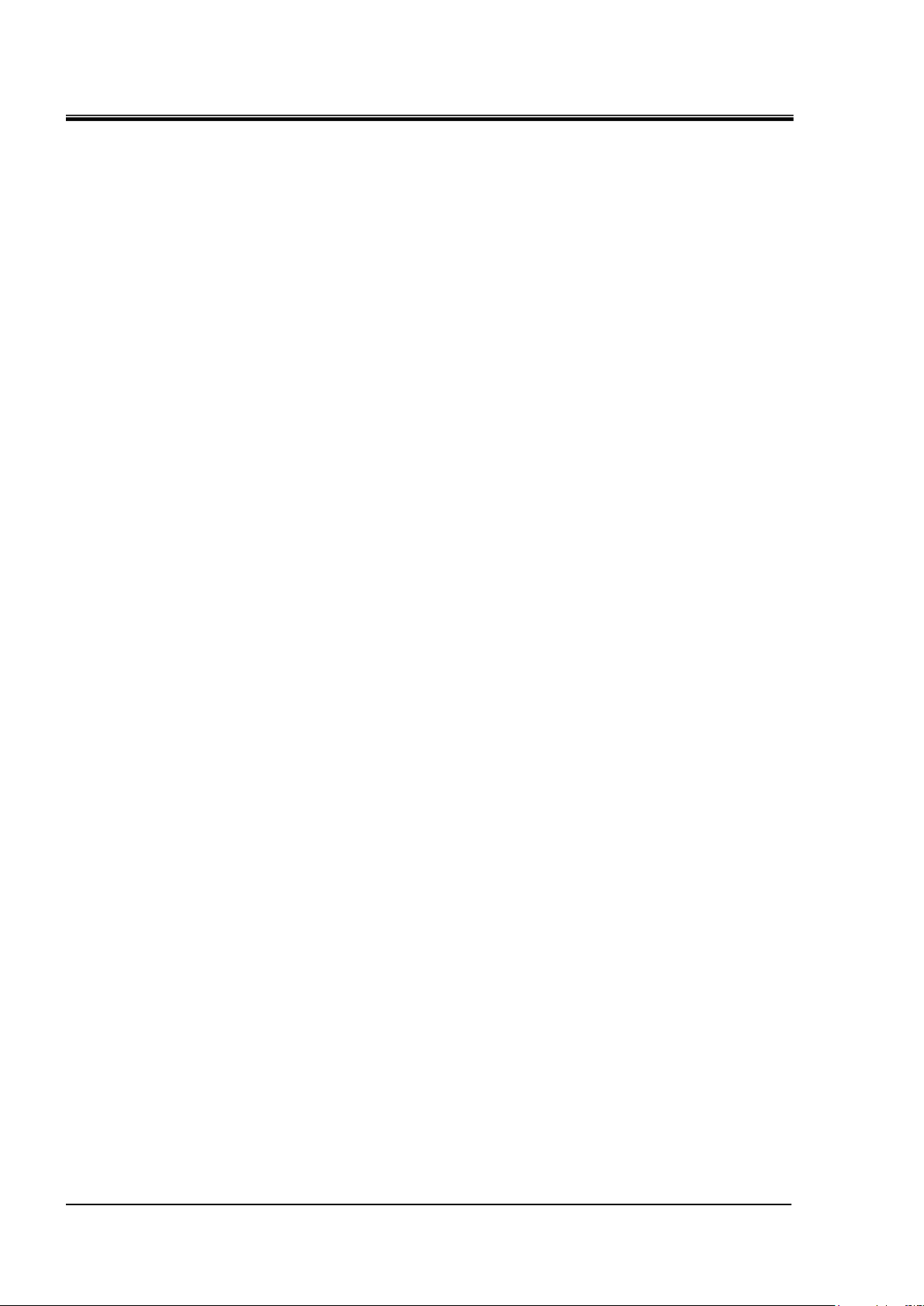

The communication of this device consists of contact input/output

communication and analog output communication and serial

communication.

・ The serial communication protocol is a MODBUS communication.

Depending on the customer’s specification, communication can

be changed to contact input/output communication or serial

communication.

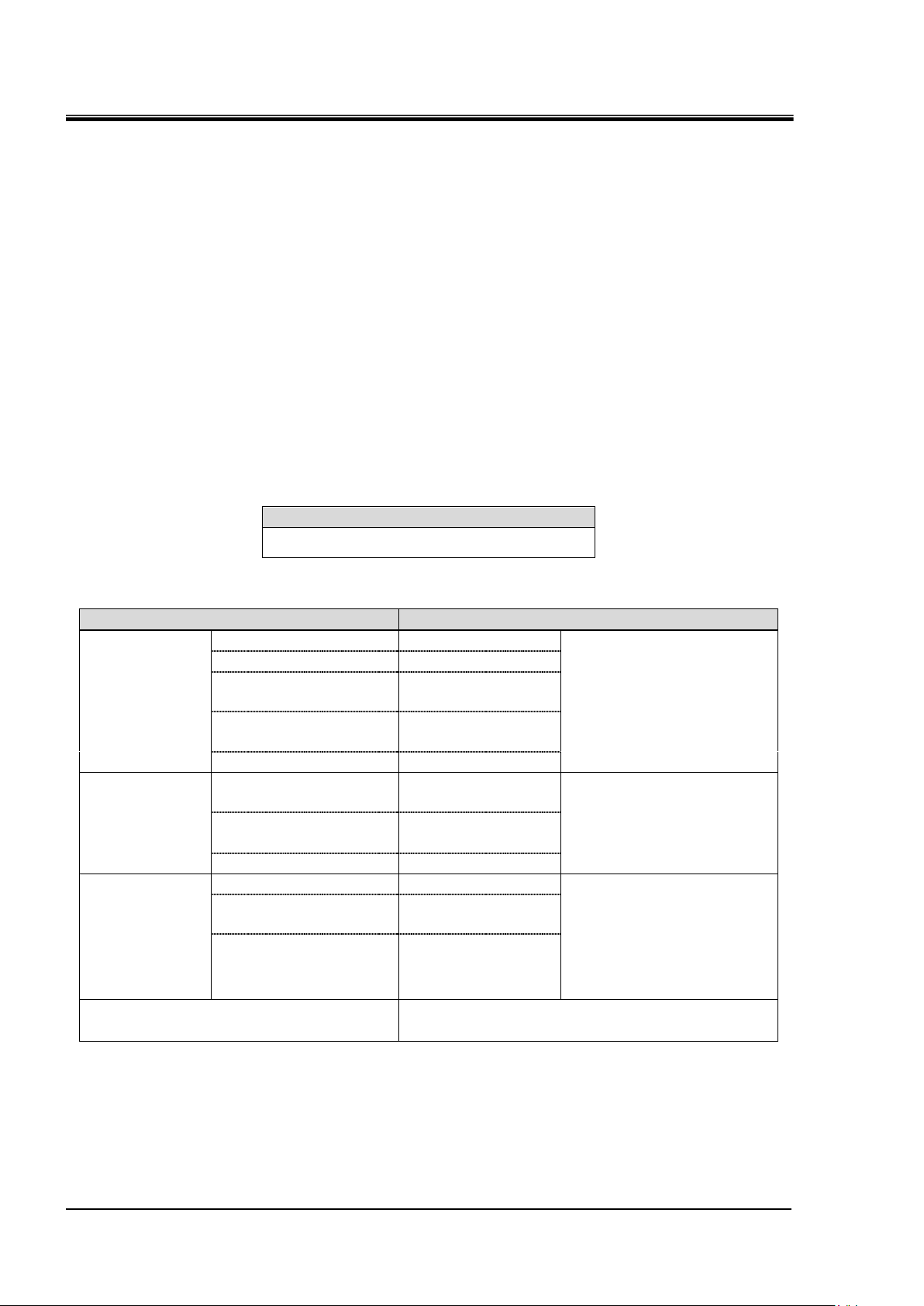

Table 1-1 Communication method

HRX-OM-W069

Chapter 1 Read before using

●If using contact input/output communication, refer to

chapter 2.

●If using serial communication MODBUS, refer to chapter

3.

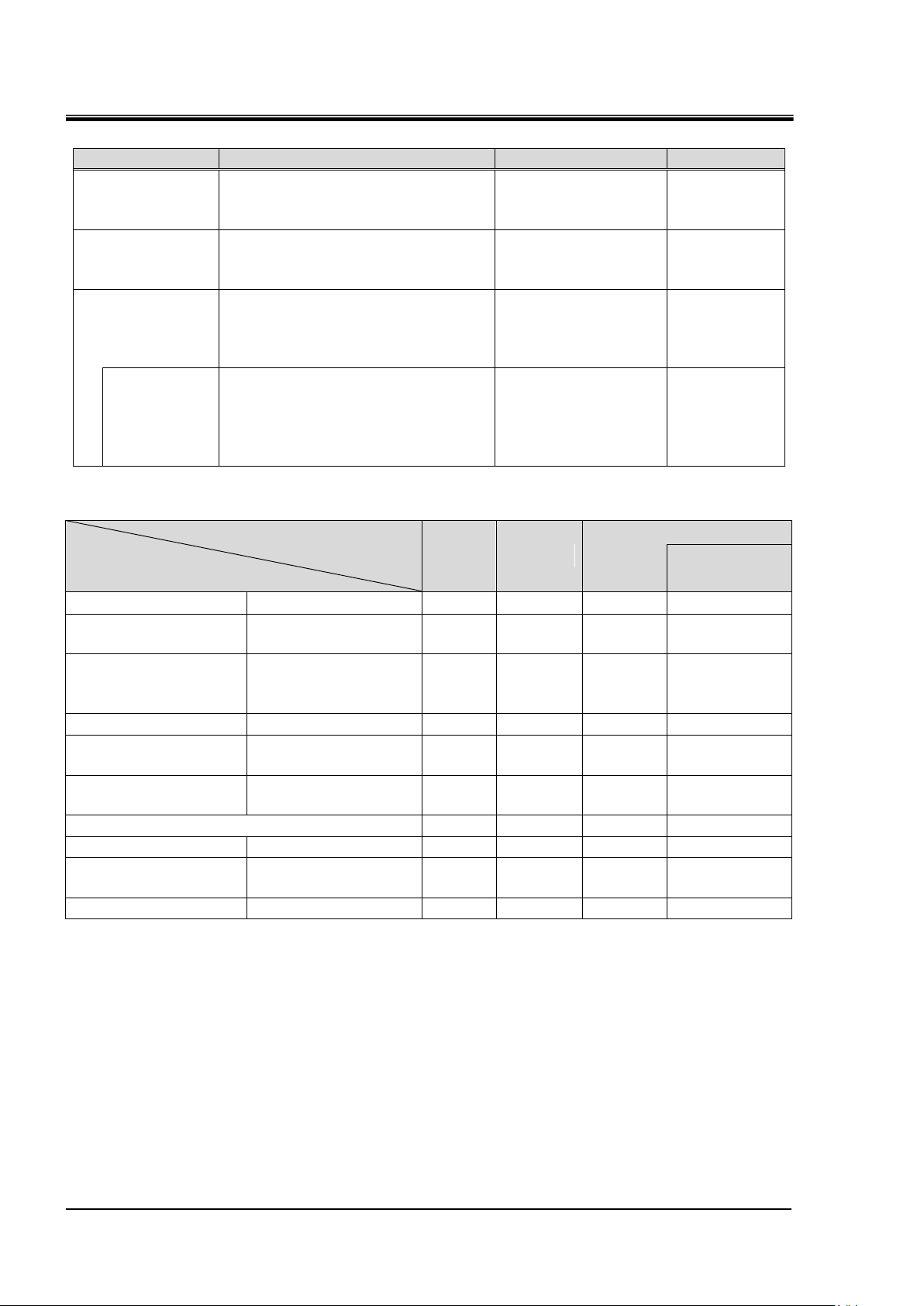

1.1 Operation mode and operation method

LOCAL, DIO and SERIAL are available as the operation modes. Table

1.1-1 explains the operation modes. The default setting is LOCAL.

The operation method depends on the operation mode. Table 1.1-2

shows how the operation mode and method of operation are related.

Operation mode display and setting

HRL Series 1.1 Operation mode and operation method

HRX-OM-W069

1-2

Operation ode

Explanation

Contents

Display

LOCAL

Run / stop and circulating

fluid temperature setting are

possible with the touch panel.

Set the operation

mode to "LOCAL".

To display

the "LOCAL"

DIO

Run / stop by contact input.

Circulating fluid temperature

setting is done at the touch panel.

Set the operation

mode to "DIO".

To display

the "DIO"

SERIAL

Run / stop and circulating

fluid temperature setting are

possible with the serial

communication(RS-232C,RS-485)

Set the operation

mode to "SERIAL".

To display

the "SERIAL"

DIO

Run/Stop

Run / stop by contact input.

Set circulating fluid temperature

by serial communication.

Set to "SERIAL"

mode and set "DIO

Run / Stop" in

"Serial Setting" to

"ON" (enabled).

To display

the "SERIAL

(DIO Run)".

Operation mode

Operation

LOCAL

DIO

SERIAL

DIO

Run/Stop

Touch panel

Run/Stop

○ × ×

×

Touch panel

Circulating fluid

temperature setting

○ ○ ×

×

Touch panel

Settings other than

circulating fluid

temperature setting

○ ○ ○

○

Touch panel

Condition reading

○ ○ ○

○

Contact input/output

communication

Run/Stop

× ○ ×

○

Contact input/output

communication

Condition reading

○

○1 ○ ○1

Reading of the external switch

○ ○ ○

○

Serial communication

Run/Stop

× × ○

×

Serial communication

Circulating fluid

temperature setting

× × ○

○

Serial communication

Condition reading

○ ○ ○

○

Chapter 1 Read before using

Table 1.1-1 Operation modes.

Table 1.1-2 Operation mode and operation

1 Only one external switch can be connected

1.1 Operation mode and operation method

HRL Series

1-3

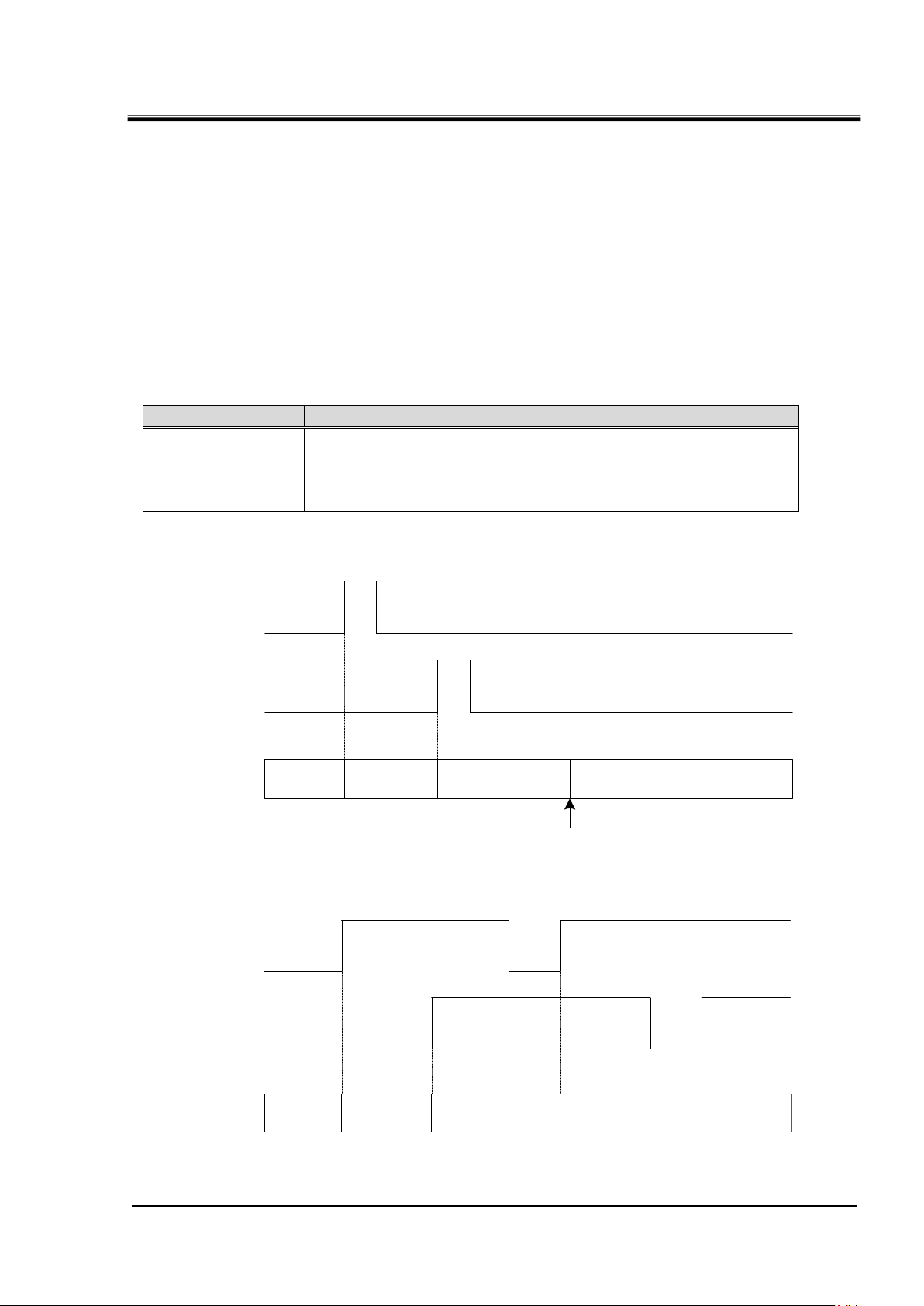

Operation mode

Operation mode change method

LOCAL

None1

DIO

Input the mode request signal (OFF to ON) to contact input 3.

SERIAL

The mode request flag is turned from OFF to ON by serial

communication.2

LOCAL DIO SERIAL LOCAL

Contact input 3

Mode request signal

Serial communication

Mode request flag

Select the LOCAL in the touch panel

Operation

mode

LOCAL DIO SERIAL DIO SERIAL

Contact input 3

Mode request signal

Serial communication

Mode request flag

Operation

mode

HRX-OM-W069

Chapter 1 Read before using

1.2 Change of operation mode

There are the following methods to change the operation mode.

・ Change by touch panel

・ Change by mode request

■About mode request

The mode request, is the ability to change the operation mode by the

contact input or serial communication.

When switching from OFF to ON for both contact input and serial

communication, the mode request becomes effective and the

operation mode changes.

Table 1.2-1 Operation mode change by mode request

1 Change to LOCAL mode is possible only from touch panel operation.

2 When "DIO Run / Stop" is set in advance by the touch panel, run / stop is performed by the contact

input signal.

Fig. 1-1 Communication port

Fig.1-2 Mode switching by the mode request (ON state mixed)

HRL Series 1.2 Change of operation mode

HRX-OM-W069

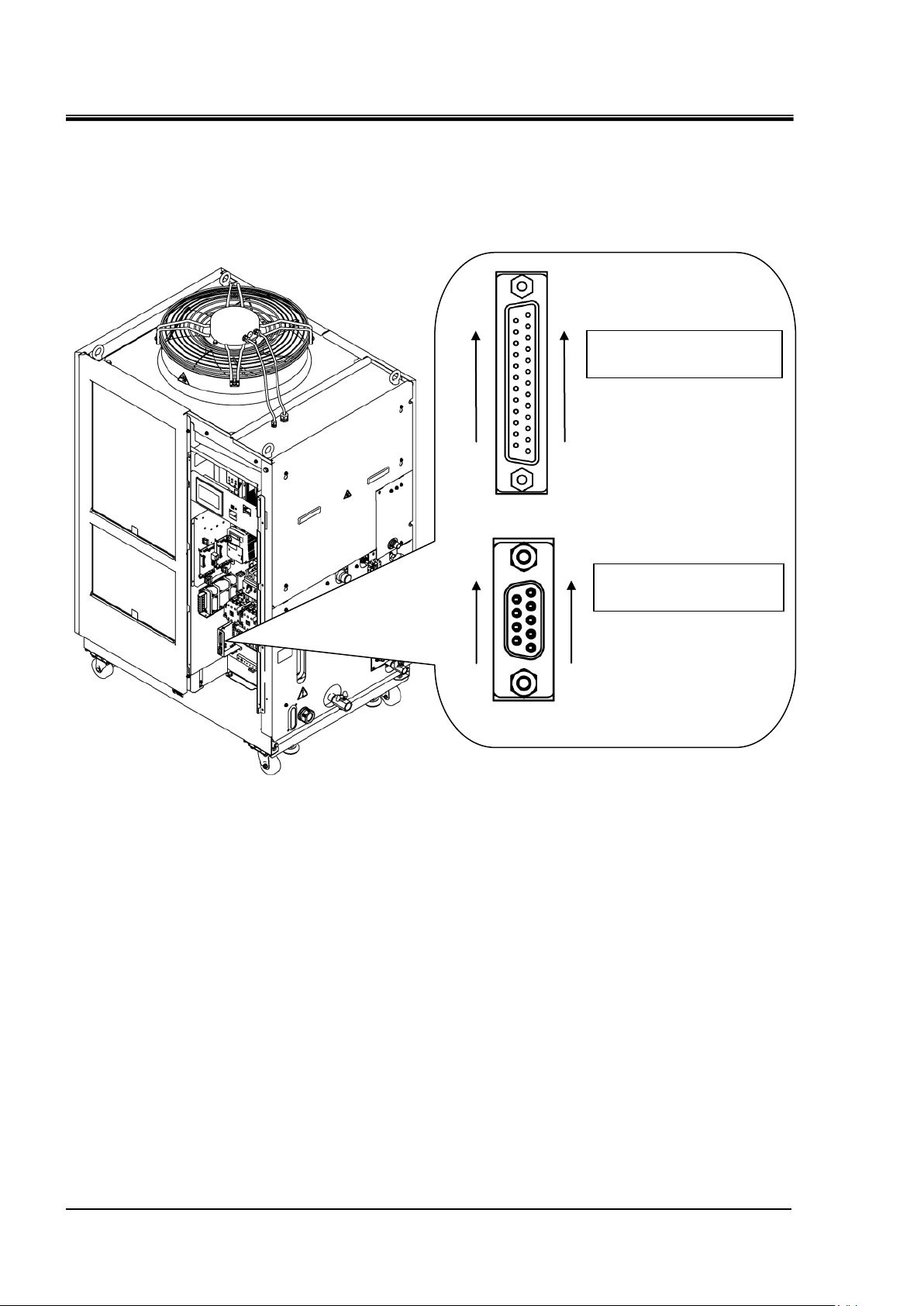

1-4

Contact input / output

signal connector

D sub 25 female pin

(socket) type

Serial communication

connector

D sub 9 female pin

(socket) type

13

1

25

14

5

1

9

6

Chapter 1 Read before using

1.3 Communication port

The communication port In the lower left of the electrical component

box is used for communication.

Fig.1-3 shows the location of the communication port.

Fig.1-3 Communication port

1.3 Communication port

HRL Series

1-5

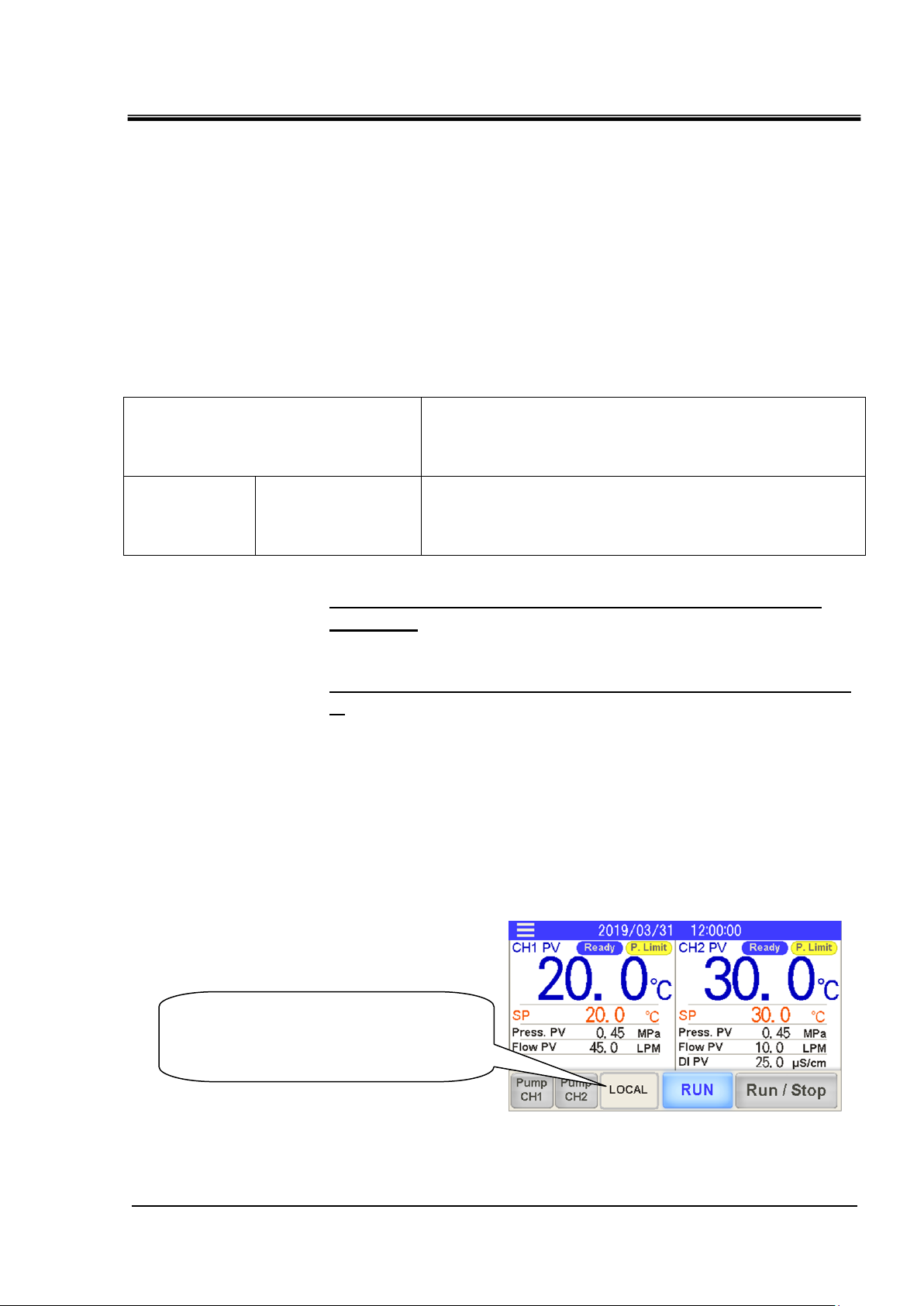

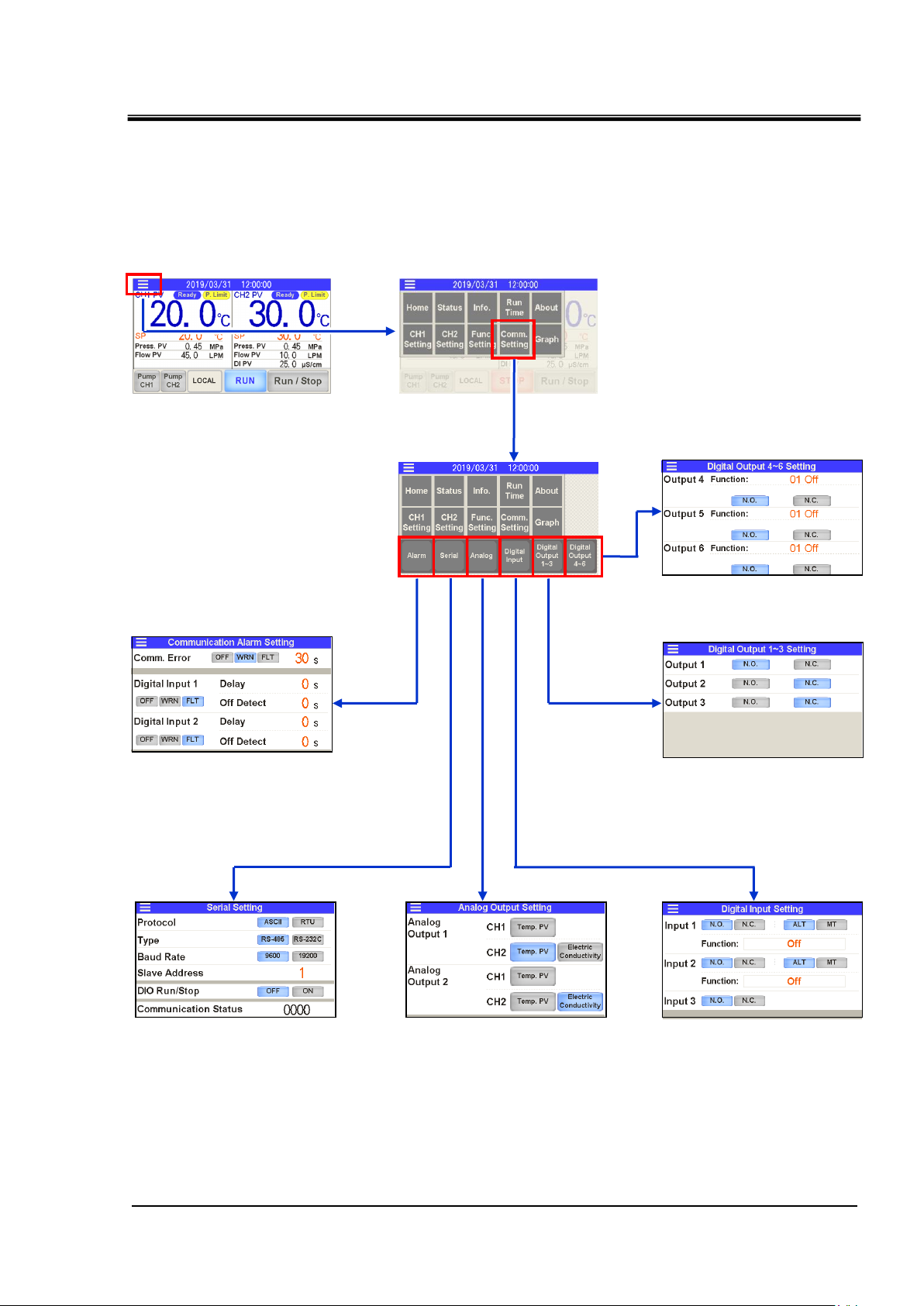

1.4 Touch panel flow

Menu

1. Communication error (AL34)

Detection of contact input signal

Setting for alarm (AL30 and AL31)

3. Analog output setting

4. Setting for contact

input signal 1 to 3

2. Serial communication setting

5. Setting for contact

output signal 1 to 3

6. Setting for contact

output signal 4 to 6

Various screens

Press the [Comm. Setting] on the menu, make the communication

settings from the various setting screens.

Fig.1-4 Communication setting touch panel flow

HRX-OM-W069

Chapter 1 Read before using

HRL Series 1.4 Touch panel flow

HRX-OM-W069

1-6

Chapter 1 Read before using

1.4 Touch panel flow

HRL Series

Chapter 2 Contact input/output communication /Analog output communication

2-1

Signal content

Contact input 1

Contact input 2

Contact input 3 Mode request signal only (momentary)

Contact output 1

・Output operation status (RUN / STOP) signal *1

・Selectable contact type (normally open / normally closed)

Contact output 2

・Output the operation stop "FLT" alarm signal *1

・Selectable contact type (normally open / normally closed)

Contact output 3

・Output the continued operation "WRN" alarm signal *1

・Selectable contact type (normally open / normally closed)

Contact output 4

Contact output 5

Contact output 6

Analog output 1

Analog output 2

Signal

Contact input

3pcs.

・Operation / stop signal, Allowed input an external switch signal

・Selectable signal configuration (Alternate/Momentary)

・Selectable contact type (normally open / normally closed)

Contact output

6 pcs.

・Selectable signal content(Refer to “2.4 Contact output signal)

・Selectable contact type (normally open / normally closed)

Analog output

2pcs.

Selectable from the following 3 points

・CH1 Circulating fluid discharge temperature

・CH2 Circulating fluid discharge temperature

・CH2 Circulating fluid electric conductivity

Chapter 2 Contact input/output

communication /Analog

output communication

The device is equipped with a terminal which runs/stops the product. It is also

equipped with a terminal which picks up operation signals, alarm signals and setting

condition.

The device starts contact input/output communication according to the setting of the

operation display panel. Contact input/output communication can be customized by

changing the settings. The contact input / output signals and analog output signals

that this product is equipped with are shown in Table 2-1.

Table 2-1 Contact input / output signal and analog output signal

HRX-OM-W069

1 Signal the contents of the contact output 1 to 3 is a fixed value.

It is not possible to change the content of the signal.

2.1 Precautions for communication

2.1.1 Precautions wiring communication

○Communication wiring

A communication cable that connects the product and customer

system is not included with the product. Please prepare according to

“3.2 Connected explanation”.In order to avoid malfunction, do not

connect to any place other than those shown in “3.2 Connected

explanation”.

HRL Series 2.1 Precautions for communication

HRX-OM-W069

2-2

Connector specification (this product side)

Dsub 25 pin female (socket) type

Item

Specification

Contact

input

signal1,2,3

Insulation system

Photo coupler

・Run/Stop signal

・External switch signal

・Operation mode request

signal

(Contact input 3 fixed)

Rated input voltage

DC24V

Operating voltage

range

DC21.6V to 26.4V

Rated input

current

5mA TYP

Input impedance

4.7kΩ

Contact output

signal

1,2,3,4,5,6

Rated load voltage

AC48V or less /

DC30V or less

・Signal of operating status

・Alarm signal

・TEMP READY signal

etc 2

Maximum load

current

AC/DC

800mA or less 1

Minimum load current

DC5V 10mA

Analog output

signal 1,2

Output voltage range

0V to +10V

・CH1 Circulating fluid

discharge temperature

・CH2 Circulating fluid

discharge temperature

・CH2 Circulating fluid

electric conductivity

Maximum output

current

10mA

Maximum accuracy

±1.0%F.S. or less

DC24V output voltage

DC24V±10% 200mA MAX 1

(It can not be used for inductive load.)

Chapter 2 Contact input/output communication /Analog output communication

○Power supply

To use the power of the product, the total load current must be 200mA

or less.

2.1.2 Precautions after wiring and before communication

○Check or set the Operation mode by the touch panel.

・Operation mode shall be DIO.

You can read also in the other mode, but you can not run / stop if it

is not DIO mode.

2.2 Communication specification

Table 2.2-1 Contact input/output communication connector

Table 2.2-2 Contact input/output/ analog output communication specification

1 : The total load current must be 800 mA or less. To use the power of the device, the total load current

must be 200 mA or less.

2 : Refer to “2.4.2 Contact output signal 4 to 6”.

2.2 Communication specification

HRL Series

Chapter 2 Contact input/output communication /Analog output communication

2-3

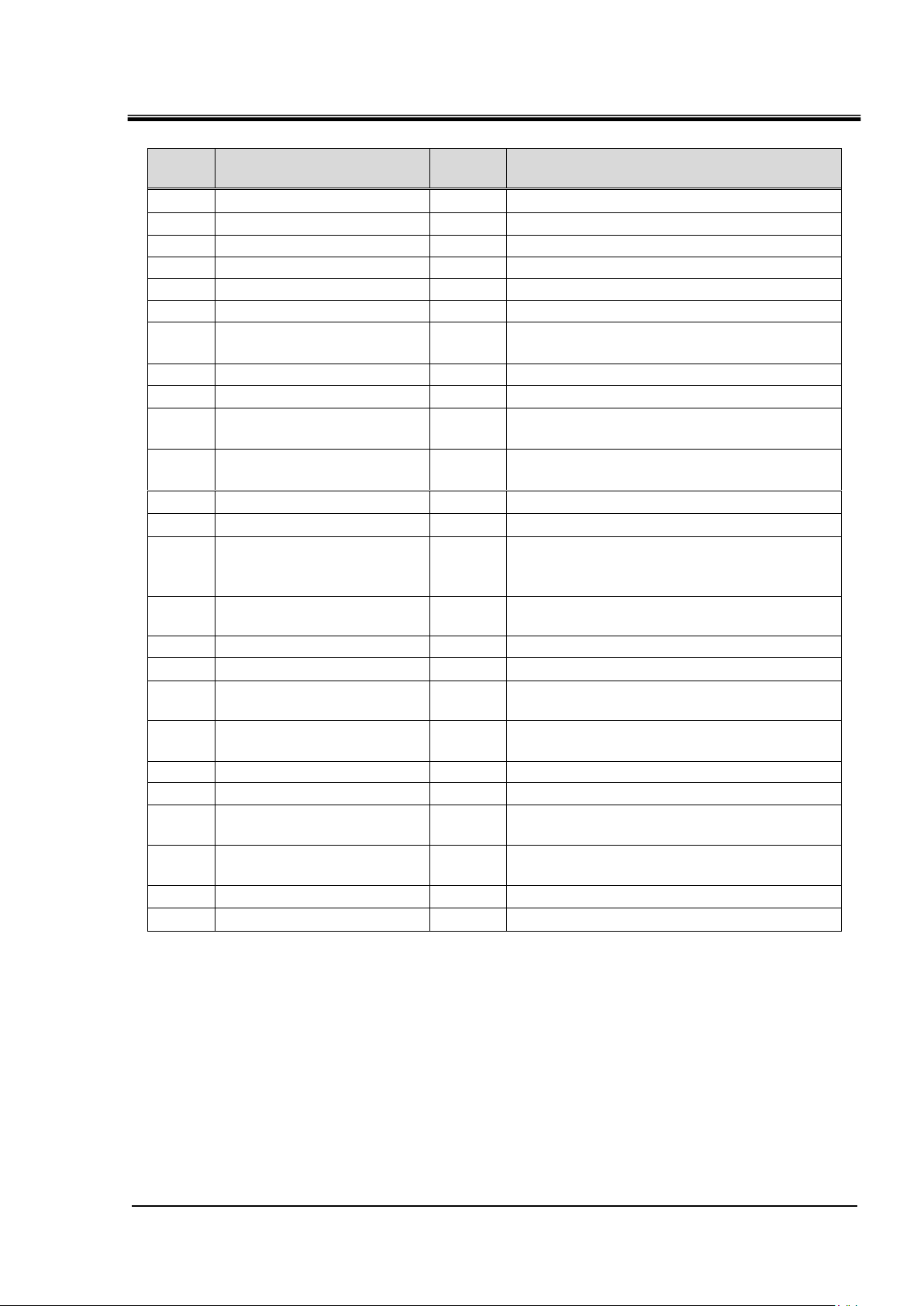

PIN

No.

Item

Division

Contents

1

DC24V output

Output

-

2

DC24V input

Input

-

3

Contact input signal 1

Input

Run/Stop 1

4

Contact input signal 3

Input

Operation mode request signal (fix )2

5

Contact output signal 6

Output

OFF1

6

Contact output signal 1

Output

Run status signal [N.O type](fix)2

7

Contact output signal 3

Output

Operation continuation[WRN]alarm

status signal [N.C. type ](fix)2

8

Contact output signal 5

Output

OFF1

9

None

-

Can not connect

10

Analog output signal 2

Output

CH2 Circulating fluid electric

conductivity signal 1

11

Analog output signal 1

Output

CH2 Circulating fluid discharge

temperature signal 1

12

None

-

Can not connect

13

None

-

Can not connect

14

24 COM output

(Common of contact input

signal)

Output

-

15

Common of contact

output signal 1, 2, 3, 4, 5

Output

-

16

Contact input signal 2

Input

External switch signal 1

17

None

-

Can not connect

18

Common of contact

output signal 6

Output

-

19

Contact output signal 2

Output

Operation stop [FLT] alarm status signal

[N.C. type ](fix)2

20

Contact output signal 4

Output

OFF*1

21

None

-

Can not connect

22

Common of contact

output signal 2

Output

CH2 Circulating fluid electric

conductivity GND

23

Common of contact

output signal 1

Output

CH2 Circulating fluid discharge

temperature GND

24

None

-

Can not connect

25

None

-

Can not connect

Table 2.2-3 Contact input/output communicatin /Analog output pin number

HRX-OM-W069

1 : It is possible to change the setting.

2 : You can not change the setting(“N.O type / N.C. type” can be changed).

HRL Series 2.2 Communication specification

HRX-OM-W069

2-4

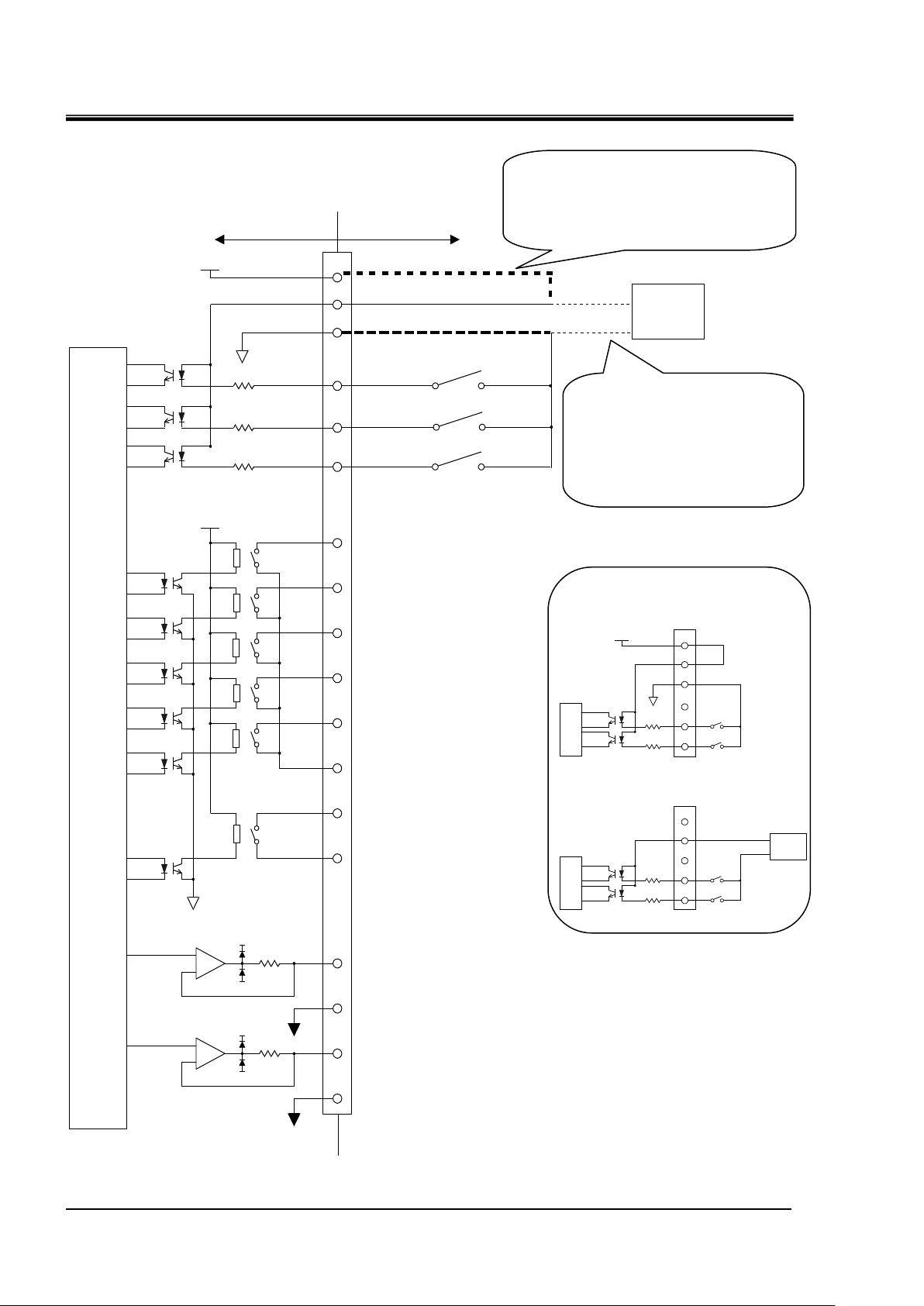

Power supply usage example

Analog output 1 : CH2 Circulating fluid discharge temperature

This product side Customer system side

DC24V

+

-

-15V

100Ω

ANALOG COM

24COM

Contact output 1 : Operation status

1

24COM

DC +24V(output)

4.7kΩ

4.7kΩ

4.7kΩ

+15V

+

-

-15V

100Ω

+15V

ANALOG COM

Internal

circuit

14

3

16

4

6

19

7

20

8

15

5

18

11

23

10

22

Contact output 2 : "FLT"

Contact output 3 : "WRN"

Contact output 4 : OFF

Contact output 5 : OFF

(Momentary)

Run/Stop

Operation mode request

[Warning when an alarm occurs OFF]

[Fault when an alarm occurs OFF]

[Operation ON]

Contact output 6 : OFF

2

DC24V

DC +24V(input)

EXT DC24V

EXT 24COM

Power

supply

Analog output 2 : CH2 Circulating fluid electric conductivity

External switch

24COM(output)

Contact output 1-5 common

Contact output 6 common

Analog output1common

Analog output 2 common

When using this product's power supply,

connect pin 1 to pin 2 and the COM side

of each contact input signal to pin 14.

When using a customer's power

supply, connect the 24V DC +

side to pin 2 and the COM side

of each contact input signal to

the customer's power COM.

DC24V

1

14

3

2

1

14

3

2

Power

supply

DC24V

24COM

4

3

4

This product power supply

usage example

Customer power supply usage example

Chapter 2 Contact input/output communication /Analog output communication

2.2 Communication specification

Fig.2-1 Circuit diagram

HRL Series

Chapter 2 Contact input/output communication /Analog output communication

2-5

Setting of contact input signal form

(1)

(2)

(3)

2.3 Contact input signal

There are 3 contact input signals. Two of them can be customized by

the customer.

2.3.1 Setting of contact input signal type and form

The type of contact input signal can be set from the “1.4 Touch panel flow” (Refer

to "4. Contact input signal form" screen).

Following items can be set for contact input signal 1 and 2:

・ Contact type––selects [ N.O. ] (A contact) or [N.C] (B contact)

・ Signal form–––selects [ALT] (alternate) or [MT] (momentary)

・ Signal type–––selects “OFF” (disabled), “external switch” (external switch

signal) or “run/stop” (run/stop) signal., Run (run) signal, Stop

(stop)signal

HRX-OM-W069

HRL Series 2.3 Contact input signal

HRX-OM-W069

2-6

No.

Indication

Item

Setting and selection

(1)

Input 1

Contact input

signal 1

Contact

type

1

A contact (normally open)

B contact

(normally closed)

Signal

form

1

Alternate

Momentary

Signal

type

[Off]

Disabled

[External Switch]

External switch signal

[Run/Stop] 1

Run/stop signal

[Run] 2

Run signal

(2)

Input 2

Contact input

signal 2

Contact

type

1

A contact (normally open)

B contact

(normally closed)

Signal

form

1

Alternate

Momentary

Signal

type

[Off]

Disabled

[External Switch] 1

External switch signal

[Run/Stop]

Run/stop signal

[Stop] 2

Stop signal

(3)

Input 3

Contact input

signal 3 3

Contact

type

1

A contact (normally open)

B contact

(normally closed)

Chapter 2 Contact input/output communication /Analog output communication

Table 2.3-1 Setting of contact input signal form

1 : By default.

2 : This setting assigns “run” signal to “contact input 1” and “stop” signal to “contact input 2”.

3 : The signal form of contact input 3 is “momentary”.

2.3 Contact input signal

HRL Series

2-7

OFF

ON

Run

Stop

Product condition

Run/stop signal

(Alternate)

O

FF

ON

Run

Stop

Product condition

Run/stop signal

(Momentary)

O

FF

ON

Run

Stop

Product condition

Run signal

O

FF

ON

Stop signal

②

①

③

Chapter 2 Contact input/output communication /Analog output communication

2.3.2 Run/stop・Run・Stop・External switch signal

1) Run/stop signal (Signal type: Alternate)

The product keeps operating while the input signal from the customer is ON.

2) Run/stop signal (Signal type: Momentary)

The state changes when the input signal from the customer goes ON. This signal

operates while the product is stopped, and stops while the product is being operated.

3) Run signal (Signal type: Alternate) /Stop signal (Signal type:Alternate)

Digital input signal 1 is for Run signal(Signal type:Alternate), digital input signal 2 is

for stop signal(Signal type: Alternate). Stop signal becomes valid when both signals are

turned ON.

(1) The product starts operation when the contact input signal 1 is turned ON.

(2) The product stops operation when the contact input signal 2 is turned ON.

(3) The product starts operation because the contact input signal 1 is turned ON

although the contact input signal 2 is OFF.

HRX-OM-W069

HRL Series 2.3 Contact input signal

Loading...

Loading...