Page 1

サーモコン

HEC002-A

Air-cooled Thermo-con

Model No.

HEC002-A5*

HEC006-A5*

Keep this manual available at all times.

A_HEC-OM-I009

Rev1.6 Apr.2018

Page 2

Page 3

History

HEC002-A/HEC006-A i

History

Version

Preface

Contents

Chap.1

Chap.2

Chap.3

Chap.4

Chap.5

1.0 1.1

1.1

1.1 1.2

1.2

1.2 1.2

1.2

1.2

1.2

1.3 1.3

1.3

1.4 1.4 1.4

1.4

1.5 1.5 1.5 1.5

1.5

1.6 1.6

Version

Chap.6

Chap.7

Chap.8

Chap.9

Chap.10

1.0 1.1

1.1

1.2

1.2

1.2

1.2

1.3 1.3 1.4 1.5 1.5 1.6

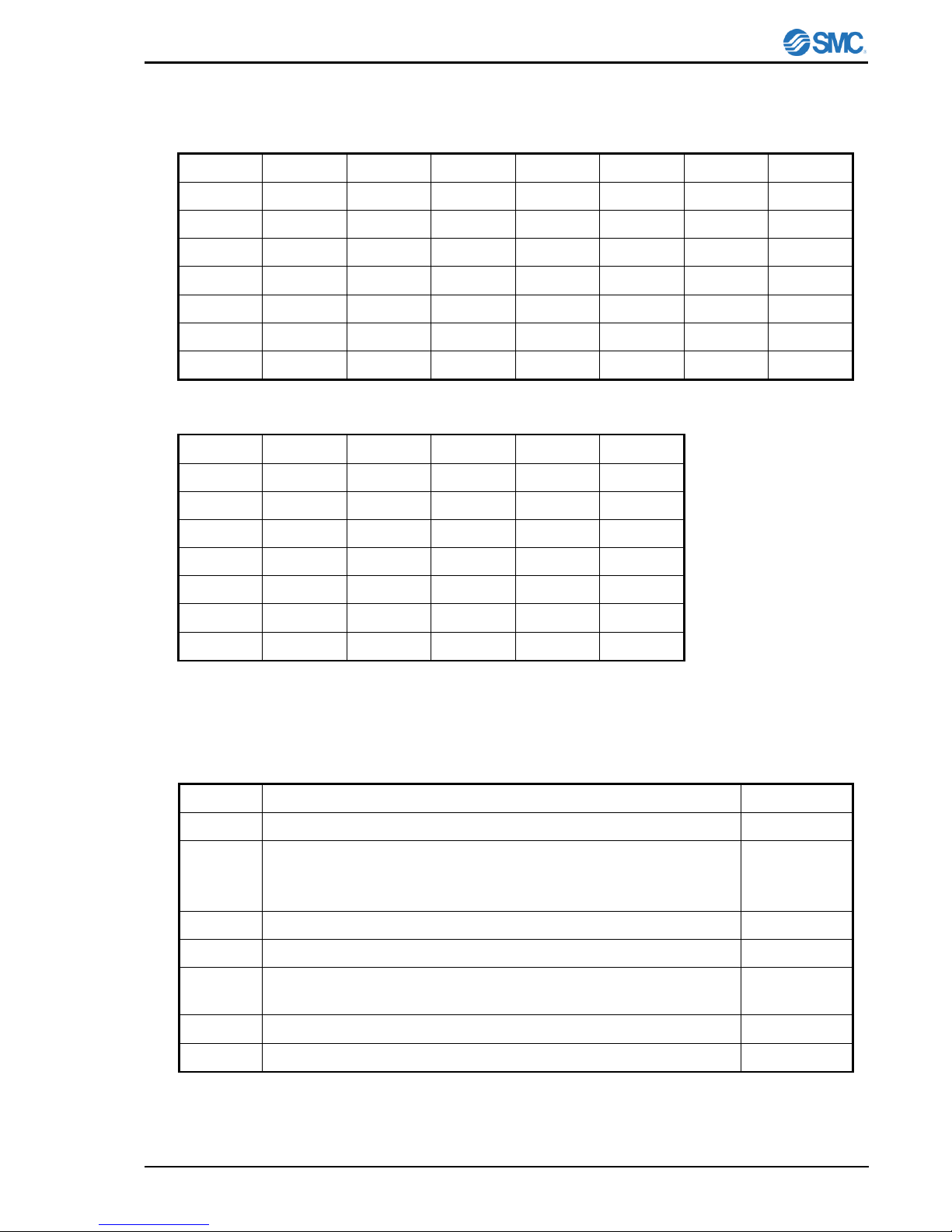

Record of Changes

Version

Contents

Date

1.0

First edition

Sep.2005

1.1

1.2: Change the address of R&D Center.

4.1: Add model option.

6.1: Change Accuracy related to temp(stability)

Jul.26.2006

1.2

Add HEC006-A

May.20.2008

1.3

Add caution of the heavy object. Modify supply circulating fluid and drain

Jun.30.2008

1.4

2.4: Add Disposing of product

5.2.3: Modify opening and closing of reservoir cap.

Nov.5.2014

1.5

Model No. label changed

Jan.29.2016

1.6

Add Warning and Caution label

Apr.20.2018

Page 4

Preface

ii HEC002-A/HEC006-A

Preface

Thank you very much for purchasing SMC Thermo-con. (herein referred to as the “product”).

This manual is describes the operation of the product. Please use this manual for efficient and long use

of this unit. Be sure to read this manual efficiently for your deep understanding of overview and safety of

this unit before installation or carrying out the relevant operations of this unit. Especially, you need to

follow the instructions about ”Danger”, “Warning” and “Caution”.

Packaged items

No.

Item

Qty.

1

Product

1

2

Power supply cable

1

3

Foot (mounting bracket)

2

4

Operation Manual

1

Page 5

Contents

HEC002-A/HEC006-A iii

Contents

Page

No.

1 Introduction ----------------------------------------------------------------------------- 1-1

1.1 Scope and general description of use -------------------------------------------------------------- 1-1

1.2 Operation by external communication -------------------------------------------------------------- 1-1

1.3 Contents of operation manual ------------------------------------------------------------------------ 1-2

2 Safety Instructions ------------------------------------------------------------------- 2-1

2.1 Before using the Thermo-con ------------------------------------------------------------------------- 2-1

2.1.1 Safety training ----------------------------------------------------------------------------------------------------------- 2-1

2.1.2 Identification of “Danger”, “Warning”, “Caution” and “Note” -------------------------------------------------- 2-1

2.2 “Warning” label and “Caution” label ----------------------------------------------------------------- 2-3

2.2.1 The position of attached “Warning” label and “Caution” label ----------------------------------------------- 2-3

2.3 Precautions for running(safety interlock) ----------------------------------------------------------- 2-4

2.3.1 Interlock list -------------------------------------------------------------------------------------------------------------- 2-5

2.4 Disposing of product ----------------------------------------------------------------------------------- 2-6

3 Caution on Installation -------------------------------------------------------------- 3-1

3.1 Environment ----------------------------------------------------------------------------------------------- 3-1

3.2 Installation -------------------------------------------------------------------------------------------------- 3-2

3.3 Mounting ---------------------------------------------------------------------------------------------------- 3-2

3.4 Piping -------------------------------------------------------------------------------------------------------- 3-3

3.5 Handling ---------------------------------------------------------------------------------------------------- 3-3

4 Unit overview --------------------------------------------------------------------------- 4-1

4.1 Method of identifying model --------------------------------------------------------------------------- 4-1

4.2 Manufacturing years method of display ------------------------------------------------------------ 4-1

4.3 Model No. label ------------------------------------------------------------------------------------------- 4-1

4.4 Appearance ------------------------------------------------------------------------------------------------ 4-2

4.5 Outline of operation -------------------------------------------------------------------------------------- 4-3

4.5.1 Electrical diagram ------------------------------------------------------------------------------------------------------ 4-3

4.5.2 Mechanical system ----------------------------------------------------------------------------------------------------- 4-3

4.6 Functions -------------------------------------------------------------------------------------------------- 4-4

4.6.1 Auto tuning --------------------------------------------------------------------------------------------------------------- 4-4

4.6.2 Offset function----------------------------------------------------------------------------------------------------------- 4-4

4.6.3 Learning control function --------------------------------------------------------------------------------------------- 4-4

4.6.4 External tune control function --------------------------------------------------------------------------------------- 4-4

4.6.5 Temperature sensor fine control function ------------------------------------------------------------------------ 4-4

4.6.6 Setting value memory function -------------------------------------------------------------------------------------- 4-4

Page 6

Contents

iv HEC002-A/HEC006-A

4.6.7 Upper/Lower temperature limit alarm function ------------------------------------------------------------------ 4-7

5 Names and Functions of Components ---------------------------------------- 5-1

5.1 Side view ---------------------------------------------------------------------------------------------------- 5-1

5.1.1 HEC002 ------------------------------------------------------------------------------------------------------------------ 5-1

5.1.2 HEC006 ------------------------------------------------------------------------------------------------------------------ 5-1

5.1.3 Air Filter ------------------------------------------------------------------------------------------------------------------ 5-2

5.2 Top view ----------------------------------------------------------------------------------------------------- 5-2

5.2.1 Operation panel -------------------------------------------------------------------------------------------------------- 5-3

5.2.2 Display -------------------------------------------------------------------------------------------------------------------- 5-3

5.2.3 Reservoir Cap ---------------------------------------------------------------------------------------------------------- 5-4

5.3 Auto tuning function -------------------------------------------------------------------------------------- 5-4

6 Specifications -------------------------------------------------------------------------- 6-1

6.1 Specification table ---------------------------------------------------------------------------------------- 6-1

6.2 Performance chart ---------------------------------------------------------------------------------------- 6-2

1) Cooling capacity ------------------------------------------------------------------------------------------------------------ 6-2

2) Heating capacity ------------------------------------------------------------------------------------------------ ------------ 6-2

3) Pump capacity -------------------------------------------------------------------------------------------------------------- 6-3

7 Preparation for Operation ---------------------------------------------------------- 7-1

7.1 Preparation for circulating fluid ------------------------------------------------------------------------ 7-1

7.2 Power supply ----------------------------------------------------------------------------------------------- 7-2

7.3 Grounding --------------------------------------------------------------------------------------------------- 7-2

7.4 Supply circulating fluid and drain --------------------------------------------------------------------- 7-2

7.5 Check - repair ---------------------------------------------------------------------------------------------- 7-3

7.5.1 Daily check -------------------------------------------------------------------------------------------------------------- 7-3

7.5.2 Check after seismic vibration and impact ------------------------------------------------------------------------ 7-4

7.5.3 Repair and maintenance --------------------------------------------------------------------------------------------- 7-4

8 Operation -------------------------------------------------------------------------------- 8-1

8.1 Condition after power up -------------------------------------------------------------------------------- 8-1

8.2 How to operate -------------------------------------------------------------------------------------------- 8-1

8.3 Setting mode, Level 1 ------------------------------------------------------------------------------------ 8-2

8.3.1 How to enter and return ---------------------------------------------------------------------------------------------- 8-2

8.3.2 Available mode in Level 1 -------------------------------------------------------------------------------------------- 8-2

8.4 Setting mode, Level 2 ------------------------------------------------------------------------------------ 8-3

8.4.1 How to enter and return ---------------------------------------------------------------------------------------------- 8-3

8.4.2 Available mode in Level 2 -------------------------------------------------------------------------------------------- 8-3

Page 7

Contents

HEC002-A/HEC006-A v

8.5 Setting mode, Level 3 ----------------------------------------------------------------------------------- 8-5

8.5.1 How to enter and return ----------------------------------------------------------------------------------------------- 8-5

8.5.2 Available mode in Level 3 -------------------------------------------------------------------------------------------- 8-5

8.6 Detail of setting mode level ---------------------------------------------------------------------------- 8-6

8.6.1 Setting mode, Level 1 ---------------------------------------------------------------- --------------------------------- 8-6

8.6.2 Setting mode, Level 2 ---------------------------------------------------------------- --------------------------------- 8-8

8.6.3 Setting mode, Level 3 ---------------------------------------------------------------- ------------------------------- 8-10

9 Alarm -------------------------------------------------------------------------------------- 9-1

9.1 How to Identify Alarm ----------------------------------------------------------------------------------- 9-1

9.2 Alarm indication ------------------------------------------------------------------------------------------- 9-1

9.3 How to reset alarm --------------------------------------------------------------------------------------- 9-2

9.4 Alarm code list -------------------------------------------------------------------------------------------- 9-2

9.5 Troubleshooting------------------------------------------------------------------------------------------- 9-4

10 Appendix ------------------------------------------------------------------------------ 10-1

10.1 Signal and style of connectors --------------------------------------------------------------------- 10-1

10.2 Calculation of dew point (from psychometric chart) ------------------------------------------ 10-2

10.3 Power supply cable ----------------------------------------------------------------------------------- 10-2

Figure List

Page

No.

Fig. 2-1 The position of attaching “Warning” label and “Caution” label ---------------------------------------------------- 2-3

Fig. 2-2 Detail of “Warning” label and “Caution” label -------------------------------------------------------------------------- 2-3

Fig. 3-1 Installation environment ---------------------------------------------------------------------------------------------------- 3-2

Fig. 3-2 Installation environment (when the back side has been blocked) ------------------------------------------------ 3-2

Fig. 3-3 Mounting ----------------------------------------------------------------------------------------------------------------------- 3-3

Fig. 4-1 Position of Model No. label ------------------------------------------------------------------------------------------------ 4-1

Fig. 4-2 Legend of Model No. label ------------------------------------------------------------------------------------------------- 4-1

Fig. 4-3 Outside drawings of Thermo-con -------------------------------- -------------------------------------------------------- 4-2

Fig. 4-4 Electrical diagram ------------------------------------------------------------------------------------------------------------ 4-3

Fig. 4-5 Circulating fluid circuit ------------------------------------------------------------------------------------------------ ------ 4-3

Fig. 5-1 HEC002-A --------------------------------------------------------------------------------------------------------------------- 5-1

Fig. 5-2 HEC006-A --------------------------------------------------------------------------------------------------------------------- 5-1

Fig. 5-3 Air Filter ------------------------------------------------------------------------------------------------------------------------- 5-2

Fig. 5-4 Top view ------------------------------------------------------------------------------------------------------------------------ 5-2

Fig. 5-5 Operation panel--------------------------------------------------------------------------------------------------------------- 5-3

Fig. 5-6 Display -------------------------------------------------------------------------------------------------------------------------- 5-3

Fig. 5-7 Reservoir Cap ----------------------------------------------------------------------------------------------------------------- 5-4

Fig. 6-1 Cooling capacity -------------------------------------------------------------------------------------------------------------- 6-2

Fig. 6-2 Heating capacity -------------------------------------------------------------------------------------------------------------- 6-2

Fig. 6-3 Pump capacity ---------------------------------------------------------------------------------------------------------------- 6-3

Fig. 9-1 Alarm indication in the event ERR14 arises --------------------------------------------------------------------------- 9-1

Fig. 9-2 Alarm indication in the event ERR14 arises during PB width setting input ------------------------------------- 9-1

Fig. 9-3 Alarm indication in the event temp. upper and lower limit arises ------------------------------------------------- 9-1

Fig. 10-1 Moisture air diagram ----------------------------------------------------------------------------------------------------- 10-2

Page 8

Contents

vi HEC002-A/HEC006-A

Table List

Page

No.

Table 2-1 Division of DANGER, WARNING, CAUTION, and NOTE ------------------------------------------------------- 2-2

Table 2-2 Meaning of a symbol ----------------------------------------------------------------------------------------------------- 2-2

Table 2-3 Safety interlock list(Part 1) ---------------------------------------------------------------------------------------------- 2-5

Table 2-4 Safety interlock list(Part 2) ---------------------------------------------------------------------------------------------- 2-5

Table 6-1 Specifications -------------------------------------------------------------------------------------------------------------- 6-1

Table 8-1 Available mode in Level 1 ----------------------------------------------------------------------------------------------- 8-2

Table 8-2 Available mode in Level 2 ----------------------------------------------------------------------------------------------- 8-4

Table 8-3 Available mode in Level 3 ----------------------------------------------------------------------------------------------- 8-5

Table 9-1 Alarm information --------------------------------------------------------------------------------------------------------- 9-1

Table 9-2 Reset of alarm ------------------------------------------------------------------------------------------------------------- 9-2

Table 9-3 Alarm code list ------------------------------------------------------------------------------------------------------------- 9-2

Table 9-4 Troubleshooting ----------------------------------------------------------------------------------------------------------- 9-4

Table 10-1 Signal and style of connectors --------------------------------------------------------------------------------------- 10-1

Table 10-2 Power Supply Cable --------------------------------------------------------------------------------------------------- 10-2

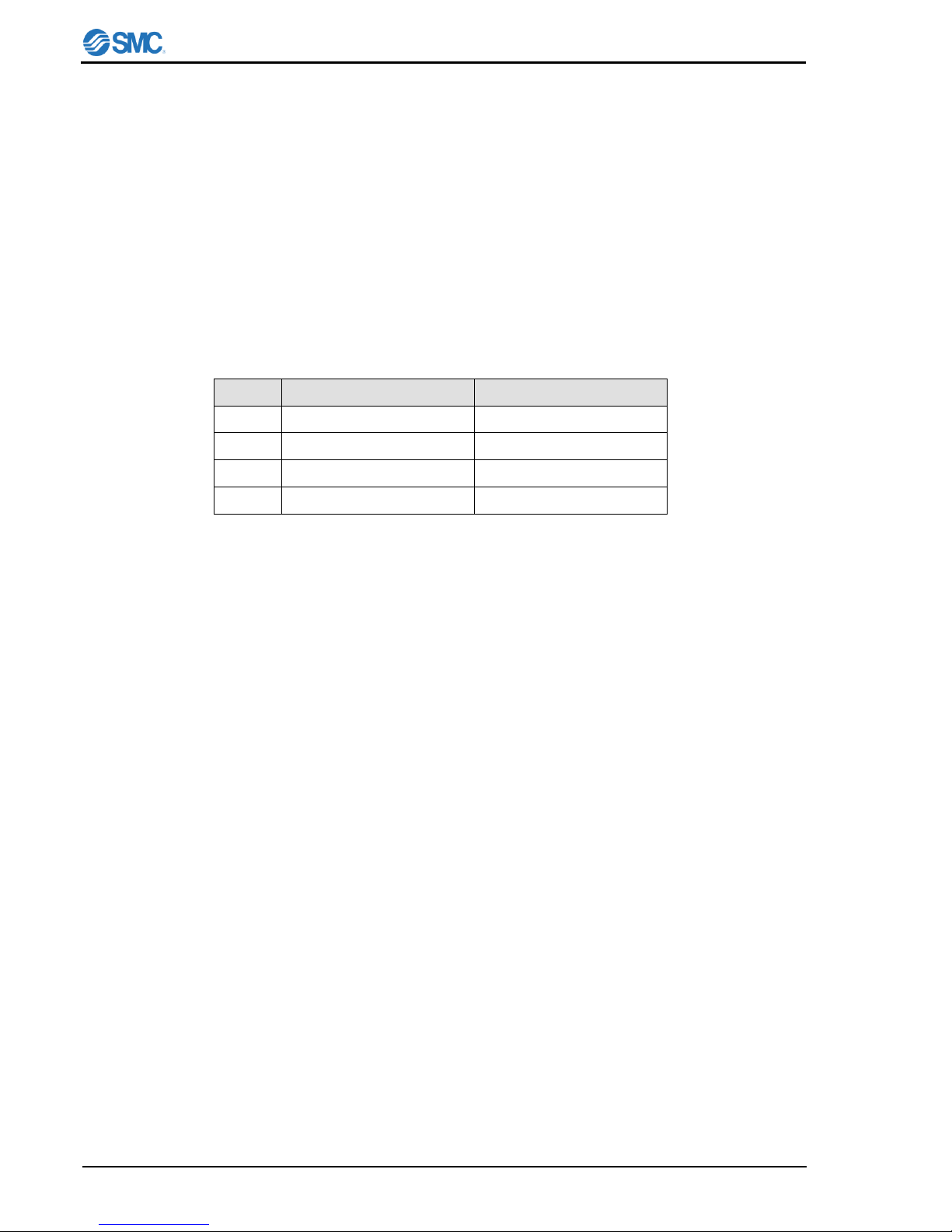

Abbreviations

Abbreviation (The order of ABC) Meaning

AC Alternating Current

AT Auto Tuning

Chap. Chapter

DC Direct Current

EMI Electro Magnetic Interference

EPDM Ethylene Propylene Diene Monomer

ERR Error

IEC International Electrotechnical Commission

LCD Liquid Crystal Display

PE (Electricity) Protective Earth

PE (Material) Polyethylene

PID Proportional, Integral, Differentiate

PPS Polyphenylene Sulfide

PV Process Value

RET Return

RXD Received Data

SEL Select

SER (No.) Serial (No.)

SG Signal Ground

SUS Special Use Stainless steel

SV Setting Value

Temp. Temperature

TXD Transmitted Data

WRN Warning

Page 9

Introduction

HEC002-A/HEC006-A 1-1

1 Introduction

The definition and construction of operation manual are described below.

1.1 Scope and general description of use

The operation manual applies to operation method of SMC-brand Thermo-con HEC002-A and HEC006A. Thermo-con is air-to-liquid heat exchanger to be used to control the temperature (e.g. detectors in an

X-Ray system). It aims easier understanding of operational and Installation information of the Thermocon. Before any operation and Installation of this unit, be sure to read this operation manual carefully

and understand the contents well.

This unit is Class 1 equipment with regard to the type of protection for electric shock.

1.2 Operation by external communication

It complies with communication standard RS-232C and RS-485. RS-232C can have a cable with length

up to 15m. RS-485 can have a cable with length up to 500m.

The content which can be communicated is as follows.

1) Setting and reading of target temperature

2) Reading of the value detected by temperature sensor

3) Reading of warning status

4) Setting and reading of off-set value

For operation by communication, it is necessary to order “Communication Specifications”.

<Contact>

If you have any questions or are unclear about any of the content of this manual, please contact the

following department.

SMC Corporation R&D Center

Product Development Division-6

Address: 4-2-2, KINUNODAI, TSUKUBAMIRAI-SHI, IBARAKI-KEN 300-2493, JAPAN

Phone:+81-297-52-6666

Fax:+81-297-20-5007

E-mail:kaihatsu_6_g3@smcjpn.co.jp

Page 10

Introduction

HEC002-A/HEC006-A

1-2

1.3 Contents of operation manual

1) Chap. 1 Introduction

The definition and use of operation manual are described.

2) Chap. 2 Safety Instructions

Safety instruction, caution note, danger and warning, warning label and caution label and safety

interlock used in this unit are described.

3) Chap.3 Caution on Installation

The precautions for setting up and mounting this unit are described.

4) Chap. 4 Unit Overview

Describes the outlook of this unit and operation overview.

5) Chap. 5 Names and Functions of Components

The description and function of the parts in this unit are mentioned.

6) Chap. 6 Specifications

The specifications of this unit are described.

7) Chap. 7 Preparation for Operation

The precautions for operation of this unit are described by each part.

8) Chap. 8 Operation

The method for operation of this unit is explained.

9) Chap. 9 Alarm

The alarms, which arise in this unit, are explained.

10) Chap. 10 Appendix

The signal of connectors and the method for calculating dew points are described.

Page 11

Safety Instructions

HEC002-A/HEC006-A 2-1

2 Safety Instructions

2.1 Before using the Thermo-con

This chapter is dedicated for your safety during interaction with the product.

The product is operated at high voltage.

Therefore, not only those who operate the unit, but those who are in charge of service and who work

nearby the product should read carefully and thoroughly understand descriptions related to safety in this

manual before starting the work.

2.1.1 Safety training

This manual is not a general manual for safety and hygiene education that safety and hygiene tutors are

supposed to conduct.

Anyone working with or near the product should be fully trained in recognition of the danger inherent to

the product and the related safety countermeasures.

A manager is responsible for strict compliance to the safety standard in whole system, but individual

person in charge of operation and maintenance should take responsibility for the daily work and should

consider the safety of the working location and environment.

Operators and maintenance personnel responsible should ensure the safety of workshops and their

environment before starting work.

Training concerning the product should take place after the sufficient training on safety. The training

must not be carried without consideration to safety.

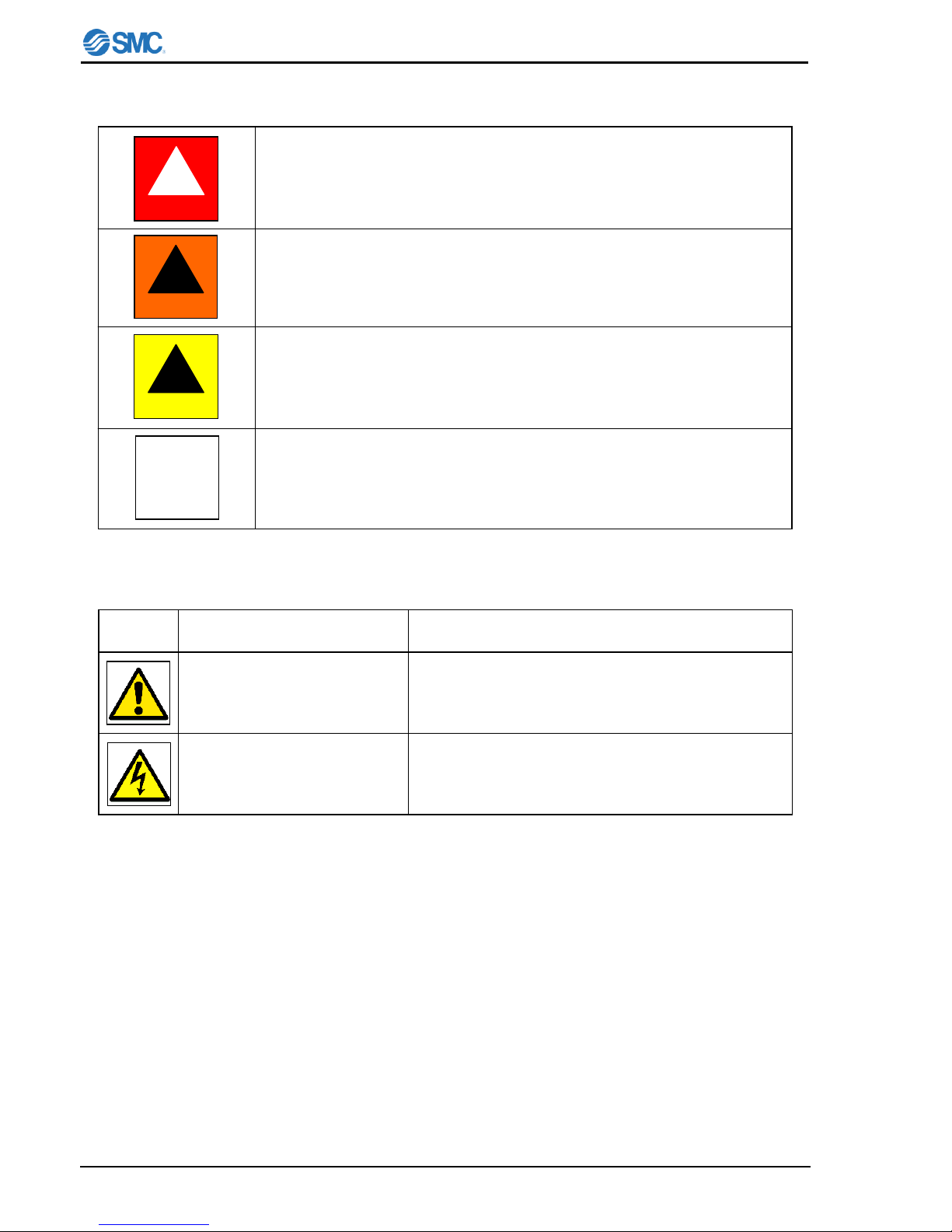

2.1.2 Identification of “Danger”, “Warning”, “Caution” and “Note”

The notifications given in this operation manual aim to assure the safe and correct operation of the

product to prevent injury of operators or damage to the product. The notifications are grouped into four

categories, “Danger”, “Warning”, “Caution”, and “Note”, which indicate the severity of the hazard and

damage and also the degree of emergency. All notifications contain critical matter on safety, so they

shall be carefully observed.

DANGER, WARNING, CAUTION and NOTE signs are in order according to severity (DANGER>

WARNING> CAUTION> NOTE).

Page 12

Safety Instructions

HEC002-A/HEC006-A

2-2

Table2-1 Division of DANGER, WARNING, CAUTION, and NOTE

Table2-2 Meaning of symbols

These paragraphs highlight hazards that would cause serious or even

fatal injuries to workers if handled improperly or important instructions

are ignored.

These paragraphs highlights hazards that might cause serious injuries to

workers if the appropriate procedure is not carried out or warnings are

ignored.

These paragraphs highlights hazards that might cause serious injuries to

workers or might damage the unit, installed devices or products if the

appropriate procedure is not carried out or cautions are ignored.

These paragraphs highlight knowledge which is recommended to be

known to avoid mistakes that likely to happen during operation. Also

anything that might damage the unit or performance of product for

checking is described.

IEC/ISO standard

Attention, consult accompanying

documents

Meaning

Caution, risk of electric shock

Symbol

IEC 348

ISO 3864, No. B.3.6

!

DANGER

!

WARNING

!

CAUTION

NOTE

Page 13

Safety Instructions

HEC002-A/HEC006-A 2-3

2.2 “Warning” label and “Caution” label

This product is provided with “Warning” labels and “Caution” labels to inform the operator of hazards

related to the product. Check the contents and position of all labels before starting the work.

The product shall be handled only by trained personnel only.

Transportation, installation and maintenance including dangerous work

shall be done by persons who have full knowledge and experience on

the product and the system. Cover panels of the product shall be

opened only by qualified service technicians or qualified personnel.

Read all warning and caution labels carefully and keep them in mind. Do

not peel off or rub alert warning and caution labels.

Confirm locations of alert warning and caution labels.

This product cannot be used for the device related to food.

If abnormal conditions, such as abnormal noise or smoke, or water

leakage appeared, take the following actions:

Shut down power.

Stop water radiating water supply

Contact an authorised SMC dealer for repair

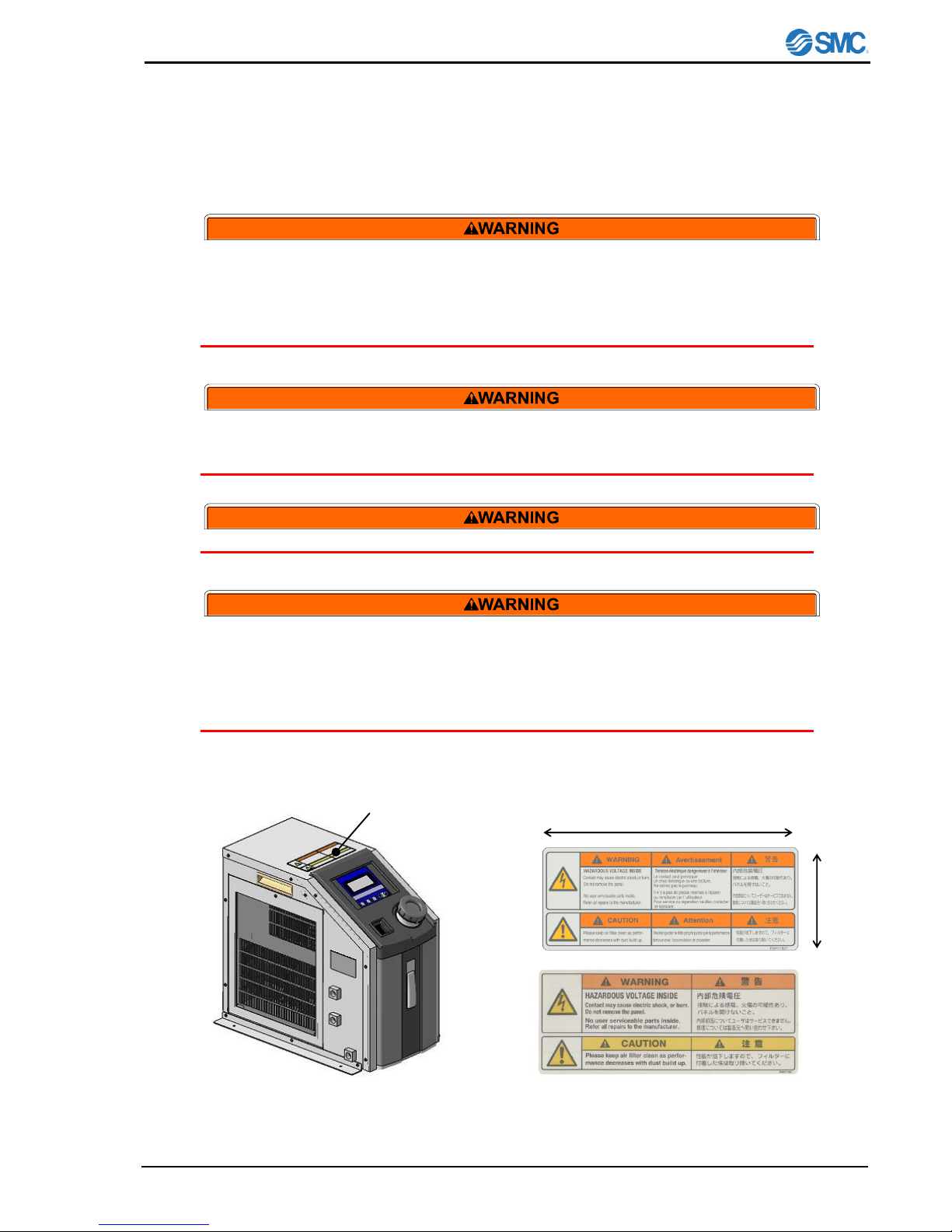

2.2.1 The position of attached “Warning” label and “Caution” label

Fig. 2-1 The position of attaching “Warning”

label and “Caution” label

“Caution” label and “Warning” label

60mm

150mm

Fig.2-2 Detail of “Warning” and “Caution” label

for HEC002-A

for HEC006-A

Page 14

Safety Instructions

HEC002-A/HEC006-A

2-4

2.3 Precautions for running (safety interlock)

This is a function to protect personnel, to restrict operation, that may cause damage to the product or

facility, and to remove dangers related to safety.

This unit has several interlock functions, which activate when dangerous operation or condition occurs to

stop operation and make it safe.

See “2.3.1 Interlock list” for contained function.

During operation or maintenance of the product, do not disable the

interlock function of any device. Otherwise unexpected personnel injury

or damage to the product may occur.

When turning on/off the power observe the procedure. Otherwise

unexpected malfunction or danger may occur.

When maintaining, cleaning or in case of emergency, turn off the power

source.

After identifying a problem be sure to check the cause and take

necessary countermeasures before turning on the power.

When the power supply is restarted after turned off once, keep time

interval at least 1sec. The restart of supply within that interval may break

the unit.

Please do not use the device which generates the electromagnetic

radiation such as cellular phones beside the unit. There is a possibility

that the unit mis-operates.

Page 15

Safety Instructions

HEC002-A/HEC006-A 2-5

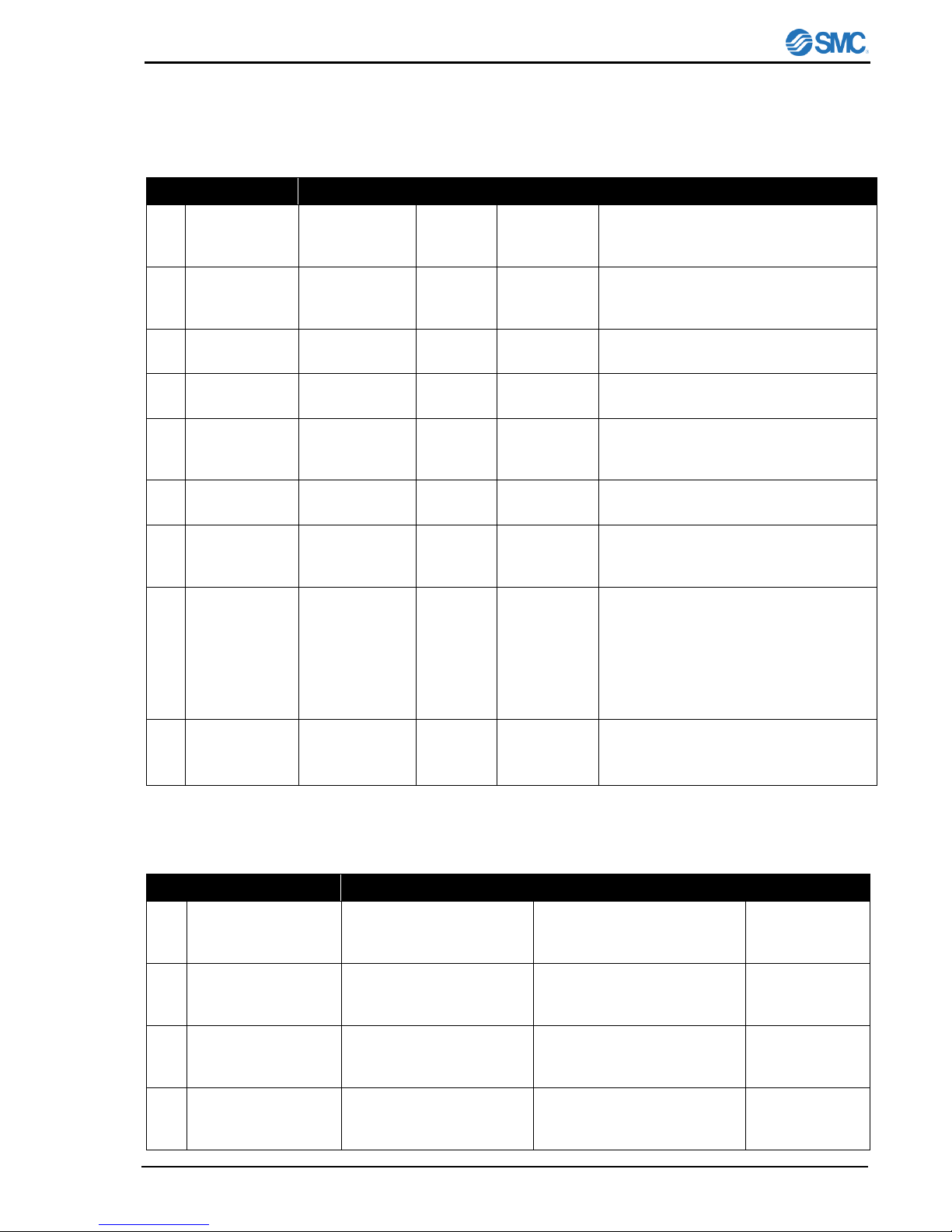

2.3.1 Interlock list

Table2-3 Safety interlock list (Part 1)

No.

Description

Part

Quantity

Location

Cause

1

Overheat in

Heat

Exchanger

Thermostat

1

Heat

Exchanger

Detects abnormal heat in heat

exchanger.

2

Switching

power supply

failure

Thermostat

2

Power supply

Detects abnormal current, voltage or

heat.

3

Overheat in

Heat Sink

Thermostat

1

Heat sink

Detects overheat in Heat Sink.

4

Low circulating

fluid level

Level sensor

1

Reservoir

Detects lowering of circulating fluid level

in reservoir.

5

Detection of

breakage of

temp. sensor

Controller

internal circuit

-

Detects breakage and short circuit of

temp. sensor and cables.

6

Excessive

temp. increase

Controller

internal circuit

-

Detects temp. input value not less than

70 C.

7

Excessive

temp.

decrease

Controller

internal circuit

-

Detects temp. input value not more than

0 C.

8

Abnormal

output

(Overload)

Controller

internal circuit

-

Works when temp. change is smaller

than over load detection temp.(selected

between 0.1 to 9.9 C) even if 100%

output continues during overload

detection time (selected between 0 to

99min.) When 0 is set, the alarm doesn’t

arise.

9

Low flow rate

(Option)

Flow sensor

-

Detects lowering of flow rate at

0.7±0.3L/min or less.

Table2-4 Safety interlock list (Part 2)

No.

Description

Condition of unit

Indication

How to reset

1

Overheat in Heat

Exchanger

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR14)

Restart power

supply

2

Switching power

supply failure

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR11)

Restart power

supply

3

Overheat in Heat

Sink

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR14)

Restart power

supply

4

Low circulating fluid

level

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR20)

Restart power

supply

Page 16

Safety Instructions

HEC002-A/HEC006-A

2-6

5

Detection of

breakage of temp.

sensor

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR17)

Restart power

supply

6

Excessive temp.

increase

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display.

(ERR12)

Restart power

supply

7

Excessive temp.

decrease

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display

(ERR13)

Restart power

supply

8

Abnormal output

(Overload)

The unit continues to

operate.

Error indication on display

(ERR15)

Restart power

supply

9

Low flow rate

(Option)

Shuts off power supply to

the Heat exchanger, Pump

and Fan.

Error indication on display

(ERR16)

Restart power

supply

2.4 Disposing of product

Contact an industrial waste disposal company for disposal of the product.

To minimize the risk, drain the fluid from the product when it is scrapped. If the fluid is left inside, an

accident and damage can result during transportation.

Page 17

Caution on Installation

HEC002-A/HEC006-A 3-1

3 Caution on Installation

Pay special attention to the safety of all personnel when installing and

transporting the product.

The product is heavy, be careful when installing or moving the product.

Only trained personnel can perform work such as installation,

transportation and maintenance of the product.

3.1 Environment

The product shall be installed in an environment that meets the following requirements.

1) Where the product is not exposed to water, oil or any chemical spills.

2) Where the product is installed horizontally in a stable position .

3) Where the product is installed without interfere the suction and discharge port.

4) Where the product is not exposed to corrosive or flammable gas. (The unit is not explosion proof.)

5) Where the ambient temperature range is between 10 to 35C and the relative humidity range is

between 35 to 80%. No dew condensation is allowed on the unit. Information about due

condensation is shown on “10.2 Calculation of Dew Point”.

6) Where the product is not exposed to noise sources (such as discharging equipment, large relay and

thyristor).

7) Where the there is enough space between power supply cable and communication cable of the

product and power cables of other equipments.

8) Where the product is not exposed to strong electrical or magnetic emissions.

9) Where the power supply and ground connections can be made correctly.

10) Where the product is not exposed to materials such as silicone, which may generate harmful gas.

11) Where the product is not outdoors or in a place with the direct sunshine or heat radiation.

12) Where the product is at an altitude of more than 1000 meters.

Page 18

Caution on Installation

HEC002-A/HEC006-A

3-2

3.2 Installation

If the air inlet of Thermo-con and the outlet opening is not enough, the cooling capacity decreases

due to the rise of the ambient temperature, decrease of the radiating air flow. Install Thermo-con

following condition. Moreover, when the exhaust duct is necessary, prepare it by customer.

3.3 Mounting

The product should be mounted as follows.

1) Use the foot attached to the product for mounting.

2) Then tighten M4 screws (bolts) or equivalent into 4 holes sized to 5mm on the parts marked with

arrow for mounting.

Fig. 3-1 Installation environment

Air IN

Air OUT

Air IN

Air OUT

Fig. 3-2 Installation environment (when the back side

has been blocked)

HEC002:100mm or more

HEC006:500mm or more

HEC002:200mm or more

HEC006:500mm or more

Page 19

Caution on Installation

HEC002-A/HEC006-A 3-3

Fig3-3 Mounting

Be sure to correctly tighten all screws the required torque.

3.4 Piping

1) Ensure the flow rate of the circulating fluid is as high as possible to maintain the temperature

stability. Therefore, the length of the external piping should be minimized and internal diameter

should be as large as possible. Piping must have sufficient strength for the maximum discharge

pressure of the circulating circuit.

2) Likewise, if a tube is bent or multiple elbow fittings are used, the piping resistance will increase and

the flow rate will decrease. If the flow rate falls, the temperature stability will decrease.

3) If installing a tank externally, only a sealed tank should be used. Do not use an open tank.

Ensure that the INLET and OUTLET for circulating fluid is connected

correctly. If any valves are used ensure that they do not restrict the flow,

otherwise low flow my cause an alarm.

3.5 Handling

Transport Thermo-con with both handles.

240(HEC002)

270(HEC006)

300(HEC002)

280(HEC006)

Page 20

Caution on Installation

HEC002-A/HEC006-A

3-4

Page 21

Unit Overview

HEC002-A/HEC006-A 4-1

4 Unit Overview

4.1 Method of identifying model

4.2 Manufacturing years method of display

SERIAL No. M o -0001

4.3 Model No. label

A model No. label is attached to the unit in the position shown below.

Fig.4-1 Position of Model No. label Fig.4-2 Legend of Model No. label

HEC002 – A 5 B - *

Cooling capacity

002

230W

006

600W

Radiating method

A

Air-cooled

Power supply

5

AC100-240V

Serial communication

A

RS-485

B

RS-232C

Option

Nil

With no option

-F

With flow switch

-N

NPT fitting

Mfg. month

o

Jan.

U

Jul. P Feb.

V

Aug.

Q

Mar.

W

Sep.

R

Apr.

X

Oct. S May

y

Nov.

T

Jun.

Z

Dec.

Mfg. year

L

2007

M

2008

N

2009

Serial No.

0001

0002

------

Model No.

label

Page 22

Unit Overview

HEC002-A/HEC006-A

4-2

4.4 Appearance

The appearance and the outline dimensions are as shown below.

HEC002-A

HEC006-A

Fig.4-3 Outside drawings of Thermo-con

240

270

300

390

210

270

300

280

370

240

278

455

390

382

281

436

393

385

Page 23

Unit Overview

HEC002-A/HEC006-A 4-3

4.5 Outline of operation

The unit is operated as explained below.

4.5.1 Electrical diagram

The unit is equipped with electrical circuits as shown below.

Fig.4-4 Electrical diagram

4.5.2 Mechanical system

The unit is equipped with circulating fluid as shown below.

Fig.4-5 Circulating fluid circuit

Reservoir

DC pump

Temp. sensor

Circulating

fluid IN

Circulating

fluid OUT

DC fan

DC fan

Filter

Thermo-module

Heat sink

Heat exchange plate

Membrane

key sheet

LCD

display

Temp. sensor

Thermo-module

DC pump

DC fan

CPU board

Switching

power supply

for CPU board

DC12V

Switching

power supply

for main

DC24V/48V

R

Thermostat

Level switch

RS-485/RS-232C

AC100

to 240V

Power switch

(Circuit protector)

Controller

Power supply

board

DC5V, DC12V

DC24V

External sensor

Alarm output

Chassis

Page 24

Unit Overview

HEC002-A/HEC006-A

4-4

4.6 Functions

4.6.1 Auto tuning

This function sets the values necessary for the control system such as PID (proportional band, integral

time, derivative time and ratio of cooling/ heating gain) automatically.

4.6.2 Offset function

This function controls the temperature slide by an offset value from set point temperature. The range of

offset is -9.99 to 9.99 C. When the circulating fluid is carried to the target object, a certain deviation

occurs between the temperature before the object and the setting temperature of the product due to the

influence of ambient temperature on the piping. In this case, if the deviation is input as the offset value,

the temperature of circulating fluid just before the object can match with setting value.

Internal sensor value for alarm does not include the offset value.

4.6.3 Learning control function

This function lets the product measure the temperature of circulating fluid flowing before temperature

target object by an external temperature sensor and adjusts the offset function automatically to the set

value at a certain sampling interval. The external temperature sensor needs to be prepared separately

by the customer.

4.6.4 External tune control function

This function makes the temperature of circulating fluid consistent to the external (ambient) temperature

all the times. This function lets the product measure the temperature from a temperature sensor

mounted in the customer preferred location, then it adjusts the temperature of the fluid automatically to

the temperature detected by the sensor. The separate temperature sensor needs to be prepared

separately by the customer.

4.6.5 Temperature sensor fine control function

This is a function to finely control the measurement temperature of the control sensor within the range of

-9.99 to 9.99 C separate from offset function. Control sensor can be corrected by inputting difference

(calibration value) between temperature of standard and that of control sensor.

Internal sensor value for alarm includes the fine control value.

Internal sensor value for alarm = Internal sensor value – Fine control value

4.6.6 Setting value memory function

(Function that backs up with EEPROM)

This function backs up all the manually set values to nonvolatile memory (EEPROM). Even if the power

is turned off the set values are saved and will be restored at power on.

4.6.7 Upper/ Lower Temperature Limit Alarm Function

This function raises an alarm when temperature of the circulating fluid is out of allowable upper and

lower range. When the alarm is raised, WRN is indicated on LCD. If circulating fluid temperature returns

to within allowable upper/ lower range, this alarm is automatically canceled. The allowable upper and

lower range of temperature can be set between 0.1 and 10 C.

Page 25

Names and Functions of Components

HEC002-A/HEC006-A 5-1

5 Names and Functions of Components

The parts included into the unit have description and function individually.

5.1 Side view

5.1.1 HEC002

Fig.5-1 HEC002-A

5.1.2 HEC006

Fig.5-2 HEC006-A

Communication

connector

Alarm

connector

EXT. Sensor

connector

Power supply connector

Handle

Circulating fluid

OUT

Communication

connector

Alarm

connector

EXT. Sensor

connector

Power supply connector

Handle

Air filter

Circulating fluid

IN

Circulating fluid

OUT

Handle

Drain Rc1/4

Level

gauge

Air filter

Circulating fluid

IN

Handle

Drain Rc1/4

Level

gauge

Page 26

Names and Functions of Components

HEC002-A/HEC006-A

5-2

5.1.3 Air Filter

Fig.5-3 Air Filter

Please keep air filter clean as performance decreases with dust build up.

We will recommend the removal of dust once every three months.

Please remove dust with the cleaner, do not use water to clean.

5.2 Top view

The parts attached to the top of Thermo-con have description and function individually as shown below.

Fig.5-4 Top view

Operation panel and

Display

Reservoir Cap

Air Filter

The Thermo-con adopts air-cooled heat

exchanger not to allow dust to enter easily

inside. However, should the dust be allowed

and attached on the filter, the filter may

become unable to function properly. To prevent

this, the filter should be taken out by removal of

circled screws and cleaned periodically.

Power switch

Page 27

Names and Functions of Components

HEC002-A/HEC006-A 5-3

5.2.1 Operation panel

Fig.5-5 Operation panel

5.2.2 Display

Fig.5-6Display

E R R 1 1 W R N

P

V < 3 1 .

6

C #

1 S

V

3 0 .

0 C

M O D

E N o r m a

l

SEL key

Used to change

setting mode.

AT key

Used to start and

stop auto tuning.

Up and Down Key

Used to change set

value in each setting

mode.

RET key

Used to fix set value or

return to present temp.

status indication.

2nd, 3rd line

Current

temp.[PV]]and target

temp.[SV] during

normal operation.

When the alarm

arises, the error is

indicated instead and

during setting mode

selection, the

selected setting mode

is indicated.

1st line

Indicates No. corresponding

to the alarm which arises

and [WRN] comes to light

up when temp. upper or

lower limit warning occurs.

4th line

Indicates control operation

mode during normal

operation and set values

during setting mode

selection.

Page 28

Names and Functions of Components

HEC002-A/HEC006-A

5-4

5.2.3 Reservoir Cap

Fig.5-7 Reservoir Cap

5.3 Auto tuning function

If controlled temp. fluctuates constantly after reaching the

target temp., perform auto tuning. Controller calculates

optimum control PID and set automatically. Auto tuning

may require time depending on conditions.

1) Select "2" in control operation choices

2) Pressing [AT] key to light "AT" indicator and start auto

tuning.

3) Pressing [AT] key stops auto tuning. (“AT” indicator

turns off)

4) ”AT" indicator turns off when auto tuning completes. If

not completed after 20min. [ERR19] (AT abnormal)

occurs.

5) If auto tuning is no successful, reset to default value, or

input the optimum value.

Reservoir Cap

Removed to supply circulating

fluid before operation. Replace

cap before starting operation.

Counter-clockwise to open

Clockwise to close.

Gasket (Included)

Between the reservoir cap and reservoir

for sealing.

Under a circumstance where a tank

get negative pressure, remove the

gasket after confirming that the

circulating fluid will not flow back when

it the product stopped.

C o n t r o l

O p e r a t i o n

M O D E < 2 : A

T

AT

Page 29

Specifications

HEC002-A/HEC006-A 6-1

6 Specifications

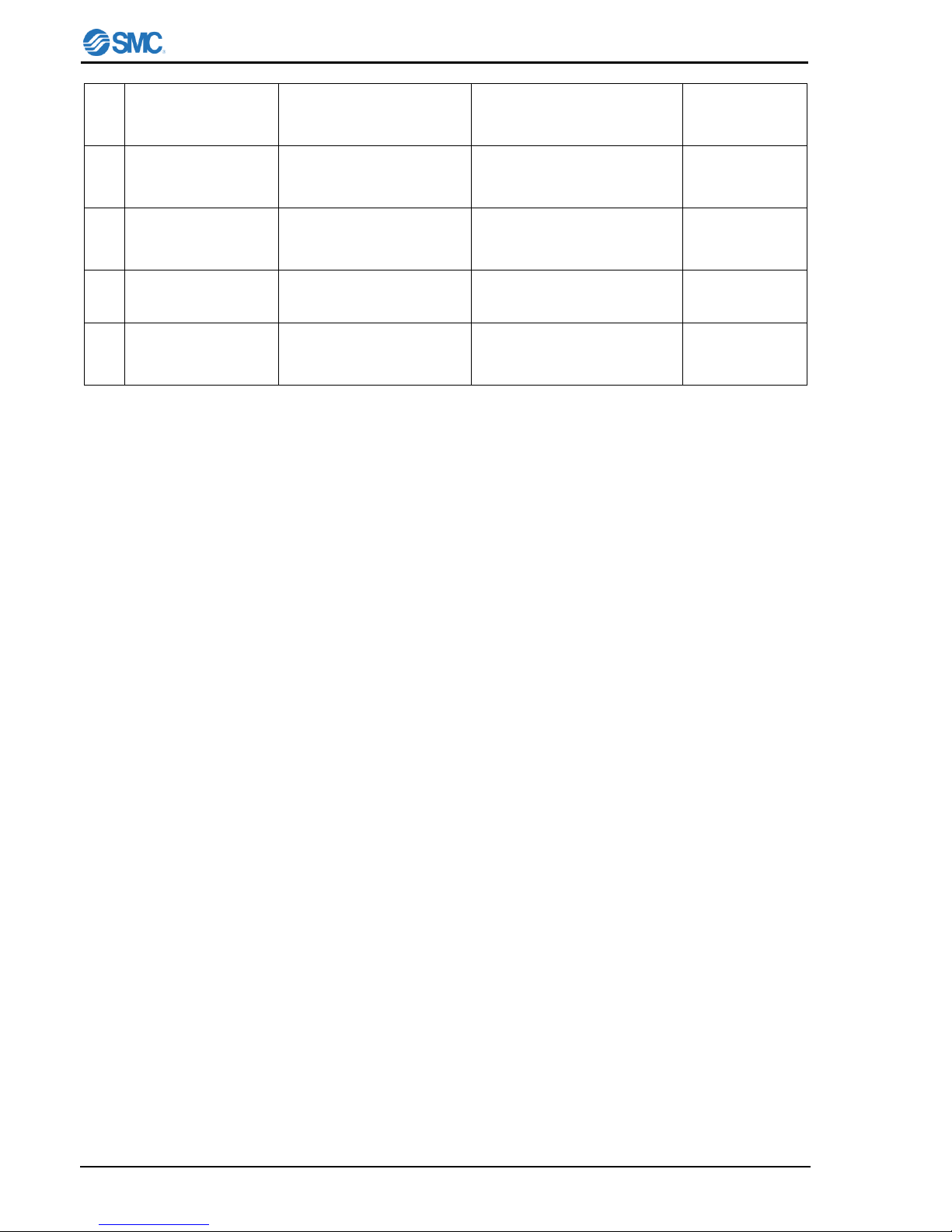

6.1 Specification table

The specifications of the Thermo-con is as shown below.

6-1 Specifications

Item

Spec.

Model No.

HEC002-A

HEC006-A

Operation temp. range

10.0 to 60.0 C (No dew condensation)

Indication temp. range

-9.9 - 80.0 C

Ambient environment

Temp. :10 to 35 C

Humidity : 35 to 80%RH

Environment : No corrosive gas, solvent such as thinner and flammable gas

Storage environment

Temp. :-40 to 70 C (No dew condensation and icing)

Humidity : 5 to 95%RH

Environment : No corrosive gas, solvent such as thinner and flammable gas

Accuracy related to temp.

Indication accuracy: +/- 0.2 C.

Stability: +/- 0.01 to 0.03 C (Circulating fluid OUT is directly connected with IN)

Cooling capacity

(Water)

Approx.230W

(Set temperature25C and ambient

temperature 25C)

Approx.600W

(Set temperature25C and ambient

temperature 20C)

Circulating fluid

Circulating fluid : Water

Reservoir capacity : Approx.1.2L

Pump

Max. pressure: 0.09MPa

Max. pressure: 0.1MPa

Wetted materials

SUS303, SUS304, EPDM, Ceramic, PPS glass 30%, Carbon

Polyethylene, Polyurethane

Piping port size

Circulating fluid IN/OUT : Rc1/4

Circulating fluid drain : Rc1/4

Circulating fluid IN/OUT : Rc3/8

Circulating fluid drain : Rc1/4

Power supply voltage

Single phase AC100-240V, 50/60Hz

Current consumption

8A(100V) to 3A(240V)

10A(100V) to 4A(240V)

Inrush current

50A or less

Over current protection

15A circuit protector

Insulation resistance

50M or more (DC500V, with surge absorber removed)

Acoustic noise

55dBA

65dBA

Cooling method

Air cooled

Main functions

Auto tuning, Off set, Temperature sensor fine control, Temp. upper and lower

limit alarm, Output shut off alarm, Serial communication (RS-232C)

Input operation and

indications

Membrane key sheet

LCD display panel (with back light)

Temp. sensor

Resistance thermometer sensor (Pt100, 3-wire, class A, 2mA)

(both internal sensor and external sensor)

Painting color

Urban white

Mass (at dry)

Approx.17.5kg (with feet)

Approx.27.5kg (with feet)

IP class

IP20 (IEC60529)

Page 30

Specifications

HEC002-A/HEC006-A

6-2

6.2 Performance chart

Value on performance chart is not guaranteed value but representative value. The value used for

consideration should not be the very limit for the safety.

1) Cooling capacity

Fig. 6-1 Cooling capacity

2) Heating capacity

Fig. 6-2 Heating capacity

3) Pump capacity

The pressure on Y axis stands for discharge pressure of circulating fluid from Thermo-con.

0

200

400

600

800

1000

1200

1400

10 15 20 25 30 35 40 45 50

Fluid temperature degC

Cooling capacity W

Fluid: water

Ambient 30C

Ambient 20C

Ambient 15C

200

400

600

800

1000

1200

1400

1600

1800

2000

10 15 20 25 30 35 40 45 50

Fluid temperature degC

Heating capacity W

Fluid: water

Ambient 30C

Ambient 20C

Ambient 15C

0

100

200

300

400

500

10 15 20 25 30 35 40 45 50

Circulating fluid temperature degC

Cooling capacity W

Fluid: water

Ambient 15C

Ambient 25C

Ambient 35C

0

100

200

300

400

500

600

700

800

900

1000

10 15 20 25 30 35 40 45 50

Circulating fluid temperature degC

Heating capacity W

Fluid: water

Ambient 15C

Ambient 25C

Ambient 35C

Page 31

Specifications

HEC002-A/HEC006-A 6-3

HEC002-A

HEC006-A

Fig. 6-3 Pump capacity

0.00

0.02

0.04

0.06

0.08

0.10

0 1 2 3 4

Flow rate L/min

Pressure MPa

Fluid: water

0.00

0.02

0.04

0.06

0.08

0.10

0.12

0 2 4 6 8 10

Flow rate L/min

Pressure MPa

Fluid: water

Page 32

Specifications

HEC002-A/HEC006-A

6-4

Page 33

Preparation for Operation

HEC002-A/HEC006-A 7-1

7 Preparation for Operation

7.1 Preparation for circulating fluid

The piping for circulating fluid is

connected as below.

1. The piping for circulating fluid

is located at the left side face.

2. The same fittings are used for IN and OUT of the

circulating fluid.

The fitting which can mate them needs to be prepared separately. When the fitting is connected, be

sure to hold the fitting (block) mounted at Thermo-con with spanner, etc.

Thread size of fitting for circulating fluid:

HEC002-A; Rc1/4

HEC006-A; Rc3/8

A plug is mounted on DRAIN port for circulating fluid. When the

piping for drain is connected, remove this plug beforehand.

Drain the circulating fluid before performing any

maintenance.

Width across flat of plug: 6mm

DRAIN port size: Rc1/4

Fluid other than water is not to be used as circulating fluid. Using such a

fluid might lead to fluid leakage and damage of the pump.

If a tank released to atmosphere is mounted outside, minimize the

piping resistance at RETURN of circulating fluid. If the piping

resistance is high, the causing the built-in reservoir of Thermo-con can

have negative pressure resulting in deformation and crack. The built-in

reservoir of Thermo-con is made of plastic and must not be subject to

negative pressure larger than -0.02MPa.

Once the plug is removed from the drain port, the leakage from it is not

guaranteed. Therefore, seal it with PTFE seal tape etc. and ensure there

is no leakage from it before operation.

Page 34

Preparation for Operation

HEC002-A/HEC006-A

7-2

7.2 Power supply

The power supply shall be connected with attached power supply cable.

Confirm the power supply at factory has enough capacity and the voltage is within specified value

beforehand (with reference to electrical specifications of the power supply). This unit is provided with the

power supply cable. The power supply cable shall be connected properly in accordance with Chapter 10

“Power Supply Cable”.

Electric specifications of the power supply

7.3 Grounding

Be sure to provide the grounding. Use medical plug with protection earth when the unit is used for

medical equipment. PE line of the power supply cable is available for grounding. Do not hold the

ground in common with the ones for equipment which generates strong electromagnetic noise or

high frequency.

7.4 Supply circulating fluid and drain

<Supply circulating fluid>

1. Confirm the power switch is turned off.

2. Take off the reservoir cap of the product.

3. Fill the circulating fluid for the reservoir. The inlet of the

reservoir is not so large and there is a possibility of spillage

of circulating fluid. Pay attention when filling the circulating

fluid.

Stop the filling once the level of fluid reaches “H” level.

4. Turn on the power switch to fill the piping with the fluid.

5. When the piping is filled with the circulating fluid, the level of

the reservoir lowers and low circulating fluid alarm (ERR20)

arises accordingly. Then, turn off the power supply once

again.

6. Repeat the step from 3 to 6 until ERR20 alarm doesn’t

appear anymore. Then, replace the cap on the reservoir and

tighten it securely.

7. Keep the fluid level between H and L of the level indicator.

8. Water pressure during normal operation becomes under 0.1

MPa.

<Drain circulating fluid>

1. Drain circulating fluid from the drain port. Open the reservoir cap would be helpful for draining.

2. To drain from the piping, blow the air (0.1MPa, about 1 minute) from Fluid IN to Fluid OUT. Tighten

the tank lid and drain port while blowing

Never touch the switch with wet hands to avoid electrical shock.

ERR20

ON

AC100-240V, 50/60Hz

Single phase

Page 35

Preparation for Operation

HEC002-A/HEC006-A 7-3

Operation of the pump with the plenty of air left in the piping for

prolonged period may cause the pump to break. Exhaust the air enough

from the piping before starting operation of the pump.

Take enough care not to spill the feed water over the case when

supplying water to the reservoir. When it is spilt by mistake, wipe it off

immediately and supply the power after it dries. If this procedure is

neglected, it may cause breakdown of the equipment.

Do not perform operation under the condition which lowers the flow rate

significantly, such as closing the valve. Other wise, the temperature

might be beyond control.

If the fluid with low conductivity such as DI water is used as circulating

fluid, it causes static electricity due to friction and damages the

temperature sensor and other electric components of this unit. Take a

measure to minimize static electricity from circulating fluid.

If the power switch is turned on without circulating fluid, the pump is

damaged.

The product is damaged when driving for a long term with the

temperature staggered periodically after reaching the target temperature.

Please set the PID value again by using auto-tuning function (see

section 5.3).

7.5 Check・Repair

The following checks shall be performed before operation.

7.5.1 Daily check

1) Indication of display panel : Check temperature condition and confirm whether or not the alarm

occurs.

2) Filter : Confirm there is not attachment of the dust on the filter at suction port. A lot of attachment

may impair performance. We will recommend the removal of dust once every three months.

3) Confirm there is no leakage of circulating fluid or no bending or crush of the piping of circulating

fluid.

4) Confirm there is no abnormal sound or smell or abnormal heating of the case.

Page 36

Preparation for Operation

HEC002-A/HEC006-A

7-4

Remove the dust attached to a filter by vacuum cleaner to prevent

degrading of performance. The recommended interval of removal is

once per 3 months. Do not use water or boiled water since it leads to

generation of rust at a frame.

7.5.2 Check after seismic vibration and impact

1) Piping: Confirm there is no defect including disconnection in piping.

2) Electrical wiring: Confirm there is disconnection of the connector from the cable.

3) Mounting condition: If the Thermo-con is mounted for operation, confirm the Thermo-con is

mounted securely.

4) Circulating fluid: Confirm there is no leakage.

5) Others: Confirm there is no abnormal sound or smell or abnormal heating of the case.

7.5.3 Repair and maintenance

The repair and maintenance services of this unit are performed only at our factory. The service requiring

a trip regardless of inside and outside of Japan is not provided. Also, when this unit is returned for these

purposes, drain the fluid from Thermo-con.

Additionally, it is recommended to prepare spare units to minimize downtime due to those repair and

maintenance services.

Drain the fluid from Thermo-con when it is returned for the repair and

maintenance service. If the fluid is left inside, an accident and damage

can result during transportation.

After washing with DI water, return the product when the fluid was other

than water. The acceptance might be refused according to the state of

the product.

Page 37

Operation

HEC002-A/HEC006-A 8-1

8 Operation

This chapter describes the detailed information on how to operate.

8.1 Condition after power up

1.Indication of software version

When power is turned on, software version is

indicated on display panel for approx. 1 sec.

(Ex. : 1.0)

Please do not use devices that generate electromagnetic radiation such

as cellular phones near the product. There is a possibility that the

product malfunctions.

8.2 How to operate

1. The different 3 levels are available depending on the content,

which needs to be set.

Level 1 : Used in normal operation. Setting of target temp.

and offset are included.( Refer to 8.3.)

Level 2 : Used at maintenance and initial setting and the

setting of controller PID is included.( Refer to

8.4.)

Level 3 : Used rarely for the purpose other than initial

setting and communication setting is included.(

Refer to 8.5)

2. [SEL] key

Used to show the item, which needs to be changed in

selected mode level.

3. [ ] key (up/down key)

Used to change the value of the item shown by [SEL] key.

4. [RET] key

Used to fix the value changed by [ ]key. Press once

again to return to current temp. indication.

5. [AT] key

Used to start auto tuning in auto tuning mode (control

operation mode : 2). When pressed during auto tuning, the

auto tuning is stopped. ( Refer to 5.3)

Operation

+

Operation

+

Operation

S O F T V E S I O N

1 . 0

Page 38

Operation

HEC002-A/HEC006-A

8-2

8.3 Setting Mode, Level 1

The method to enter to and return from setting mode Level 1 and which mode can be set in the level are

explained below.

8.3.1 How to enter and return

Press [SEL] key while power is turned on. Then, the indication on [MODE] is changed depending on the

number of press and the data in the indicated mode can be set. To return to current temperature

indication, press [RET] key.

When no input is done within 1 minute regardless of setting mode, the

current temperature indication is returned automatically.

8.3.2 Available mode in Level 1

The mode which can be set in setting mode Level 1 is as shown on Table 8-1. The mode available in

Level 1 is supposed to be used in normal operation including target temp. and offset.

The inputted data is written in EEPROM and memorized after the power

supply is turned off. The writing can be done up to 1 million times.

Table8-1 Available mode in Level 1

No.

Modes

Setting contents

Setting range

(Min. increment)

Default

1

Target Temp.

(No indication on display)

Sets target temp. for control.

10.0 to 60.0 C

(0.1 C)

25.0

2

Control Operation

Selects control operation mode from

those shown below.

0 : Pump stop(No control)

1 : Normal(normal control operation)

2 : AT(auto tuning)

3: Learn (learning control)

4: External (external tune control)

0,1,2,3,4

1

3

External Sensor Sampling

Cycle

Sets sampling cycle for learning

control or external tune control. (Not

indicated during normal control.)

10 to 999sec

(1sec)

180

4

Offset Value

Indicates the offset value of the

circulating fluid temperature used as

reference value by the controller (SV

+ Offset).

-9.99 to 9.99 C

(0.01 C)

0.00

5

Allowable Upper

Temp. Range

Sets upper limit of temp. range which

causes the warning to arise.

0.1 to 10.0 C

(0.1 C)

1.5

6

Allowable Lower

Temp. Range

Sets lower limit of temp. range which

causes the warning to arise.

0.1 to 10.0 C

(0.1 C)

1.5

Page 39

Operation

HEC002-A/HEC006-A 8-3

7

High Temp. Cutoff

Sets upper limit of temp. which the

internal temp. sensor detects and

judges the unit should be shut off.

11.0 to 70.0 C

(0.1 C)

70.0

8

Low Temp. Cutoff

Sets lower limit of temp. which the

internal temp. sensor detects and

judges the unit should be shut off.

0.0 to 59.0 C

(0.1 C)

0.0

* How to return default value: Turn on the power supply with pressing [SEL] and [RET] keys,.

At this time, the settings of Level 2 and Level 3 are also reset.

8.4 Setting mode, Level 2

The method to enter to and return from setting mode Level 2 and which mode can be set in the level are

explained below.

8.4.1 How to enter and return

Press [SEL] and [ ] keys at the same time while power is turned on. Then, the indication on [MODE] is

changed depending on the number of press and the data in the indicated mode can be set. To return to

current temp. indication, press [RET] key twice.

When no input is done within 1 minute regardless of setting mode, the

current temperature indication is returned automatically.

8.4.2 Available mode in Level 2

The mode, which can be set in setting mode Level 2, is as shown on Table 8-2. The mode available in

Level 2 is supposed to be used normally for initial setting and maintenance and control PID is included.

The inputted data is written in EEPROM and memorized after the power

supply is turned off. The writing can be done up to 1 million times.

Page 40

Operation

HEC002-A/HEC006-A

8-4

Table8-2 Available mode in Level 2

No.

Modes

Setting contents

Setting range

(Min. increment)

Default

1

Fine Control of

Internal Sensor

Sets the fine adjusting value to

calibrate the internal temp. sensor.

-9.99 to 9.99 C

(0.01 C)

0.00

2

Fine Control of

External Sensor

Sets the fine adjusting value to

calibrate the external temp. sensor

available optionally.

-9.99 to 9.99 C

(0.01 C)

0.00

3

PB Range

Sets PB (Proportional Band) range used

for PID control.

0.3 to 9.9 C

(0.1 C)

0.6

(2.0)

4

ARW Range

Sets integral operation range of PID

control.

ARW: Anti Reset Windup

0.3 to 9.9 C

(0.1 C)

1.0

(2.2) 5 I Constant

Sets integral time used for PID control.

1 to 999sec

(1sec)

150

(50)

6

D Constant

Sets differential time used for PID

control.

When 0 is set, differential operation is

not made.

0.0 to 99.9sec

(0.1sec)

0.0

7

Heating/Cooling Ratio

Sets output ratio of cooling to heating to

compensate difference of gain between

them.

10 to 999%

(1%)

200

8

Overload Judging

Temp. Range

Sets the temp. range for judgment of

overload(accompanying abnormal

output alarm ERR15).

0.1 to 9.9 C

(0.1 C)

0.2

9

Overload Judging Time

Sets time for judgment of overload

(accompanying abnormal output alarm

ERR15). When 0 is set, the alarm

doesn’t arise.

0 to 99min

(1min)

10

10

Output Ratio

Shows output ratio of thermo module

by 1%. The prefix symbol “-” stands for

cooling and no prefix stands for

heating.

-100 to 100%

(1%)

-

11

Upper/Lower Temp.

Alarm Sequence

Determines whether or not temp.

upper/lower limit alarm is output when

power is turned on.

On : Output

Off : Not output

On, Off

Off

* How to return default value: Turn on the power supply with pressing [SEL] and [RET] keys. At this time, the

settings of Level 1 and Level 3 are also reset.

* The default value indicated in ( ) is an optimal value. The value is inputted at that time of shipment factory. If

turn on the power supply with pressing [SEL] and [RET] keys, set up the value indicated in ( ).

Page 41

Operation

HEC002-A/HEC006-A 8-5

8.5 Setting mode, Level 3

The method to enter to and return from setting mode Level 3 and which mode can be set in the level are

explained below.

8.5.1 How to enter and return

Press [SEL] and [ ] keys at the same time while power is turned on. Then, the indication on [MODE] is

changed depending on the number of press and the data in the indicated mode can be set. To return to

current temp. indication, press [RET] key twice.

When no input is done within 1 minute regardless of setting mode, the

current temperature indication is returned automatically.

8.5.2 Available mode in Level 3

The mode, which can be set in setting mode Level 3, is as shown on Table 8-3. The mode available in

Level 3 is supposed not to be used normally for the purpose other than initial setting and the setting

related to communication is included.

The inputted data is written in EEPROM and memorized after the power

supply is turned off. The writing can be done up to 1 million times.

Table8-3 Available mode in Level 3

No.

Modes

Setting contents

Setting range

(Min. increment)

Default

1

Unit Number

Sets the unit No. used. This is

applicable only when multiple Thermocon is used.

0 to F (Hex decimal)

0

2

Baud Rate

Sets baud rate for communication.

600,1200,2400,4800

9600,19200b/s

1200

3

Parity Bit

Sets parity bit for communication.

Without : No parity

Odd : Odd

Even : Even

Without, Odd, Even

Without

4

Data Length

Sets data length for communication.

7Bits, 8Bits

8

5

Stop Bit

Sets stop bit for communication.

1Bit, 2Bits

1

* How to return default value: Turn on the power supply with pressing [SEL] and [RET] keys. At this time, the

settings of Level 1 and Level 2 are also reset.

Page 42

Operation

HEC002-A/HEC006-A

8-6

8.6 Detail of setting mode level

The each setting mode level is explained below in detail.

8.6.1 Setting mode, Level 1

1. Indication of current temperature [PV]

Indication range: -9.9 to 80.0 C

Min. increment: 0.1 C

Indicated content: #1 Temperature detected by internal temp. sensor

#2 Temperature detected by external temp. sensor

(When the external sensor is not connected,

“HHH” would be indicated.)

#1 and #2 change when [ ] or [ ] is pressed.

2. Target temperature (no indication on display)

Setting range : 10.0 to 60.0 C

Min. increment : 0.1 C

Indicated content : [SV] : Target temp.(Ex. : 25.0 C)

Function : Sets target temperature

3. Control Operation

Setting range : 0,1,2,3,4

Indicated content : Number and description of control

operation mode.(Ex. : 1:Normal)

Function : Selects control operation mode from those

shown below.

0 : Stop of control (Pump Stop)

1 : Normal (normal control operation)

2 : AT (auto tuning)

3 : Learning control (Learn)

4 : External tune control (External)

When a learning control and an external tuning control are selected, measurement temperature (#2) of

an external temperature sensor is displayed.

When an external tuning control is selected, the target temperature is changed at any time. When the

control mode changes from external tune mode to normal mode, the target temperature returns to the

previous value.

<How to perform auto tuning>

1) Select “2” in control operation.

2) Press [AT] key to light up “AT” indicator. The auto tuning starts.

3) To stop auto tuning, press [AT] key again. (“AT” indicator goes off.)

4) When auto tuning is finished, “AT” indicator goes off. If the auto tuning is not finished within

20min, [ERR19] (AT error) arises.

5) If the auto tuning fails, change the PID values to the set values at the time of shipment from

factory or input the optimum values.

4. External sensor sampling cycle setting mode

[External sensor sampling cycle]

Setting range: 10 to 999sec

Min. increment: 1sec

Indicated content: External sensor sampling cycle

(Ex.: 180sec)

Function: Sets sampling cycle of external sensor for learning control or external tune control.

P V < 2 3 . 0 C # 1

S V 2 5 . 0 C

M O D E

C o n t r o l

O p e r a t i o n

M O D E < 1 : N o r m a l

P V 2 3 . 0 C # 1

S V < 2 5 . 0 C

M O D E

E x t e r n a l S e n s o r

S a m p l i n g C y c l e

M O D E < 1 8 0 s e c

P V < 2 3 . 0 C # 2

S V 2 5 . 0 C

M O D E

Page 43

Operation

HEC002-A/HEC006-A 8-7

5. Offset Value

Setting range : -9.99 to 9.99 C

Min. increment : 0.01 C

Indicated content : Offset value(Ex. : -0.15 C)

Function : It allows the change of the difference between

the controller reference value and set value by

offset.

For example, if -0.15 C is set here, the actual reference temperature for control is

lower than the indicated SV by 0.15 C.

6. Allowable Upper Temp. Range

Setting range : 0.1 to 10.0 C

Min. increment : 0.1 C

Indicated content : Temp. from target to upper limit

(Ex.: 1.5 C)

Function : Sets upper limit of temp. where the warning arises. The difference between target

temp. and upper limit temp. should be input. Therefore, if the target temp. is 23.0

C and 1.5 C is set in this item, the warning [WRN] arises when temp. exceeds

24.5 C.

7. Allowable Lower Temp. Range

Setting range : 0.1 to 10.0 C

Min. increment : 0.1 C

Indicated content : Temp. from target to lower limit

(Ex. : 1.5 C)

Function : Sets lower limit of temp. where the warning arises. The difference between target

temp. and lower limit temp. should be input. Therefore, if the target temp. is 23.0

C and 1.5 C is set in this item, the warning [WRN] arises when temp. lowers

21.5 C.

8. High Temp. Cutoff

Setting range : 11.0 to 70.0 C

Min. increment : 0.1 C

Indicated content : High temp. cutoff by internal temp.

sensor (Ex. : 70.0 C).

Function : Sets upper limit of temp. at which the internal temp. sensor detects and judges the

unit should be shut off. When the temp. set in this item is reached, the alarm

[ERR12] arises.

9. Low Temp. Cutoff

Setting range : 0.0 to 59.0 C

Min. increment : 0.1 C

Indicated content : Low temp. cutoff by internal temp.

sensor (Ex. : 0.0 C)

Function : Sets lower limit of temp. at which the internal temp. sensor detects and judges the

unit should be shut off. When the temp. set in this item is reached, the alarm

[ERR13] arises.

O f f s e t V a l u e

M O D E < - 0 . 1 5 C

A l l o w a b l e U p p e r

T e m p . R a n g e

M O D E < 1 . 5 C

A l l o w a b l e L o w e r

T e m p . R a n g e

M O D E < 1 . 5 C

H i g h T e m p .

C u t o f f

M O D E < 7 0 . 0 C

L o w T e m p . C u t o f f

M O D E < 0 . 0 C

Page 44

Operation

HEC002-A/HEC006-A

8-8

8.6.2 Setting mode, Level 2

1. Fine Control of Internal Sensor

Setting range : -9.99 to 9.99 C

Min. increment : 0.01 C

Indicated content : Fine adjusting value for internal

temp. Sensor (Ex. : -0.07 C)

Function : Sets the fine adjusting value to calibrate the internal temp. sensor. If -0.07 C is set

in this item, the reading of temp. sensor is higher by 0.07 C and actually, the temp. is

controlled to lower one by 0.07 C.

2. Fine Control of External Sensor

Setting range : -9.99 to 9.99 C

Min. increment : 0.01 C

Indicated content : Fine adjustment value for external

temp. sensor(Ex. : 0.05 C)

Function : Sets the fine adjusting value to calibrate the external temp. sensor if it is mounted

optionally. If 0.05 C is set in this item, the reading of temp. sensor is lower by 0.05

C and actually, the temp. is controlled to higher one by 0.05 C.

3. PB Range

Setting range : 0.3 to 9.9 C

Min. increment : 0.1 C

Indicated content : PB range(Ex. : 2.0 C)

Function : Sets PB (Proportional Band) range used for

PID control.

4. ARW Range

Setting range : 0.3 to 9.9 C

Min. increment : 0.1 C

Indicated content : ARW range (Ex.: 2.2 C)

Function : Sets integral operation range of PID control. If this value is set less than PB range,

the set temperature can’t be achieved. Therefore set it above PB range.

ARW: Anti Reset Windup

5. I Constant

Setting range : 1 to 999sec

Min. increment : 1sec

Indicated content : I constant(Ex. : 50sec)

Function : Sets integral time used for PID control.

F i n e C o n t r o l o f

I n t e r n a l S e n s o r

M O D E < - 0 . 0 7 C

F i n e C o n t r o l o f

E x t e r n a l S e n s o r

M O D E < 0 . 0 5 C

P B R a n g e

M O D E < 2 . 0 C

A R W R a n g e

M O D E < 2 . 2 C

I C o n s t a n t

M O D E < 5 0 C

Page 45

Operation

HEC002-A/HEC006-A 8-9

6. D Constant

Setting range : 0.0 to 99.9sec

Min. increment : 0.1sec

Indicated content : D constant(Ex. : 0.0sec)

Function : Sets differential time used for PID control.

When 0 is set, this function becomes invalid.

7. Heating/Cooling Ratio

Setting range : 10 to 999%

Min. increment : 1%

Indicated content : Heating/cooling gain ratio(Ex. : 200%)

Function: Sets output ratio of cooling to heating to

compensate difference of gain between them.

8. Overload Judging Temp. Range

Setting range : 0.1 to 9.9 C

Min. increment : 0.1 C

Indicated content : Overload judging temp. range (Ex. :

0.2 C)

Function : Sets the temp. range for judgment of product

overload (accompanying abnormal output

alarm ERR15).

9.Overload Judging Time

Setting range : 0 to 99min

Min. increment : 1min

Indicated content : Overload judging time(Ex. : 10min)

Function : Sets time for judgment of product overload

(accompanying abnormal output alarm

ERR15). When 0 is set, the alarm doesn’t

arise.

10. Output indication mode [Output Ratio]

Setting range : -100 to 100%

Min. increment : 1%

Indicated content: Thermo module output ratio (Ex.: -73%)

Function: Indicates Thermo module output ratio with

increment of 1%. “+” is not indicated but “+”

means heating and “-“ means cooling.

11.Upper/Lower Temp. Alarm Sequence

Setting range : On, Off

Indicated content : Use of temp. upper/lower limit alarm

sequence(Ex. : Off)

Function : Determines whether or not temp. upper/lower

limit alarm is output when power is turned on.

On : Output

Off : Not output (Alarm for high and low temperature limit is not detected until the