Page 1

G**-SMV03EN

Caution

Caution indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Warning

Warning indicates a hazard with a medium level

of risk which, if not avoided, could result in death

or serious injury.

Danger

Danger indicates a hazard with a high level of risk

which, if not avoided, will result in death or

serious injury.

Model

G36-L

G46-L

Type

Back side thread

Port size

Note 1)

R 1/8

R 1/8, R 1/4

Fluid

Note 2) Note 3)

Air

Indication precision

Note 4)

±3%F.S. (Full span)

Material

Case (Surface

treatment)

Stainless steel (Black melamine painted)

Clear cover

Polycarbonate

(Part no.: G36-00-00-3)

Nylon

(Part no.: G36-00-00-3N)

Polycarbonate

(Part no.: G46-00-00-3)

Nylon

(Part no.: G46-00-00-3N)

Stud

Brass

Bourdon tube

Brass

Weight (kg)

0.04

0.05

Max operating frequency

5 cycles / sec

Attachment:

With cover ring

assembly

C

-

Part no.: 1305104-1A

C1 Part no.: 1305104-3A

Air quality required

5 µm or smaller

Impact and vibration

resistance

See sections 3.1.1 and 3.2.

B10

Note 5)

850,000 cycles

B10

D

Note 5)

1.7 million cycles

Standards

Complies with the basic and well-tried safety

principles of EN ISO 13849-2:2012.

Model

Pressure

range MPa

Note 1)

Green zone setting range MPa

Indication

unit

Connection

thread

Minimum

Maximum

G36-2-01-L□

0 to 0.2

0.01

0.1

MPa

R 1/8

G36-4-01-L□

0 to 0.4

0.02

0.2

G36-10-01-L□

0 to 1.0

0.05

0.5

G46-2-01 to

02-L□

0 to 0.2

0.01

0.1

R1/8

R1/4

G46-4-01 to

02-L□

0 to 0.4

0.02

0.2

G46-10-01 to

02-L□

0 to 1.0

0.05

0.5

Model

Pressure

range MPa

(psi)

Note 1)

Green zone setting range MPa

(psi)

Indication

unit

Connection

thread

Minimum

Maximum

G36-P2-01-L□X30

0 to 0.2

(0 to 30)

0.01 (2)

0.1 (14)

MPa

psi

R 1/8

G36-P4-01-L□X30

0 to 0.4

(0 to 60)

0.02 (4)

0.2 (28)

G36-P10-01L□-X30

0 to 1.0

(0 to 150)

0.05 (10)

0.5 (70)

G46-P2-01 to

02-L□-X30

0 to 0.2

(0 to 30)

0.01 (2)

0.1 (14)

R1/8

R1/4

G46-P4-01 to

02-L□-X30

0 to 0.4

(0 to 60)

0.02 (4)

0.2 (28)

G46-P10-01 to

02-L□-X30

0 to 1.0

(0 to 150)

0.05 (10)

0.5 (70)

ORIGINAL INSTRUCTIONS

Refer to Declaration of

Conformity for relevant

Directives

Instruction Manual

Pressure Gauge with Colour Zone Limit

Indicator

G36-L / G46-L Series

The intended use of the pressure gauge is to measure the internal

pressure of a vessel or system. The adjustable red and green zone

indicators help the user by improving visibility of the control range.

Validated according to ISO 13849, see section 2. Refer to product

catalogues for additional information.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)

*1)

ISO 4414: Pneumatic fluid power - - General rules relating to

systems.

ISO 4413: Hydraulic fluid power - - General rules relating to

systems.

IEC 60204-1: Safety of machinery - - Electrical equipment of

machines. (Part 1: General requirements)

*1)

, and other safety regulations.

1 Safety Instructions - continued

Only personnel with appropriate training should operate

machinery and equipment.

The product specified here may become unsafe if handled

incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

Do not service or attempt to remove product and

machinery/equipment until safety is confirmed.

1) The inspection and maintenance of machinery/equipment should

only be performed after measures to prevent falling or runaway of the

driven objects have been confirmed.

2) When the product is to be removed, confirm that the safety

measures as mentioned above are implemented and the power from

any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3) Before machinery/equipment is restarted, take measures to

prevent unexpected operation and malfunction.

Contact SMC beforehand and take special consideration of

safety measures if the product is to be used in any of the

following conditions.

1) Conditions and environments outside of the given specifications, or

use outdoors or in a place exposed to direct sunlight.

2) Installation on equipment in conjunction with atomic energy,

railways, air navigation, space, shipping, vehicles, military, medical

treatment, combustions and recreation, or equipment in contact with

food and beverages, emergency stop circuits, clutch and brake

circuits in press applications, safety equipment or other applications

unsuitable for the standard specification described in the product

catalogue.

3) An application which could have negative effects on people,

property, or animals requiring special safety analysis outside the

scope of ISO 13849 described in this document.

4) Use in an interlock circuit, which requires the provision of double

interlock for possible failure by using a mechanical protective

2 Specifications - continued

Table 1

Note 1) When mounting a pressure gauge, use caution not to tighten

excessively. Excessive tightening will cause product to be damaged.

Use a pipe tape for sealing.

Note 2) When using other fluids, please consult with SMC for fluid

compatibility information concerning corrosive potential.

Note 3) Avoid freezing as this may cause a malfunction.

Note 4) The guaranteed temperature range is 23°C ±5 °C.

Note 5) Under SMC test conditions. The B10 figure is estimated from

SMC life tests. The B10D figure is derived from B10 using the

assumption in EN ISO 13849-1:2015 Annex C. Contact SMC for details

2.1 Model Specifications (Standard)

Table 2

Note 1) Do not apply pressure more than the maximum display

pressure. This will cause a malfunction.

3 Installation - continued

3.1.1 Selection

Make sure that no direct impact or vibrations are applied to the body.

If operating under pressure pulsations or in high frequency

operations, please contact SMC.

3.1.2 Mounting

During transport and installation, do not apply shock to the product,

such as by dropping doing so will affect its precision.

For the installation posture, place it perpendicular to the ground, with

the zero point on the reading of a pressure gauge facing down.

Do not install it in an area that is exposed to high temperature or

humidity, because doing so will lead to improper operation.

To screw in the pressure gauge, make sure to turn the gauge by

placing a wrench over the square wrench flats. If the pressure gauge

is screwed in by holding it on some other area, air leakage or

damage may result.

Recommended tightening torque: R 1/8: set between 7 to 9 N.m,

R1/4: 12 to 14 N.m respectively.

3.2 Environment

Warning

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not use in an explosive atmosphere.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

product specifications.

Do not mount in a location exposed to radiant heat.

3.3 Piping

Caution

Before piping make sure to clean up chips, cutting oil, dust etc.

When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

ISO 10218-1: Manipulating industrial robots - - Safety. etc.

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

Read this manual before using the product, to ensure correct

handling, and read the manuals of related apparatus before use.

Keep this manual in a safe place for future reference.

To ensure safety of personnel and equipment the safety instructions

in this manual must be observed, along with other relevant safety

practices.

Warning

The compatibility of the product is the responsibility of the

person who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided

by the person who designs the equipment or decides its

specifications based on necessary analysis and test results. The

expected performance and safety assurance of the equipment will be

the responsibility of the person who has determined its compatibility

with the product. This person should also continuously review all

specifications of the product referring to its latest catalogue

information, with a view to giving due consideration to any possibility

of equipment failure when configuring the equipment.

function, and periodical checks to confirm proper operation.

Always ensure compliance with relevant safety laws and

standards.

All electrical work must be carried out in a safe manner by a qualified

person in compliance with applicable national regulations.

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

2 Specifications

2.1 Standard Specifications

2.2 Model Specifications (Made to Order)

Table 3

Note 1) Do not apply pressure more than the maximum display

pressure. This will cause a malfunction.

Note 2) Under the New Measurement Law, products for overseas use

only (SI unit type for use in Japan).

Caution

Special products might have specifications different from those shown

in this section. Contact SMC for specific drawings. These drawings will

give the appropriate specification details and compliance with the safety

principles of ISO 13849, if applicable.

3 Installation

3.1 Installation

Warning

Do not install the product unless the safety instructions have been read

and understood.

on the end of the pipe/fitting.

Tighten fittings to the specified tightening torque.

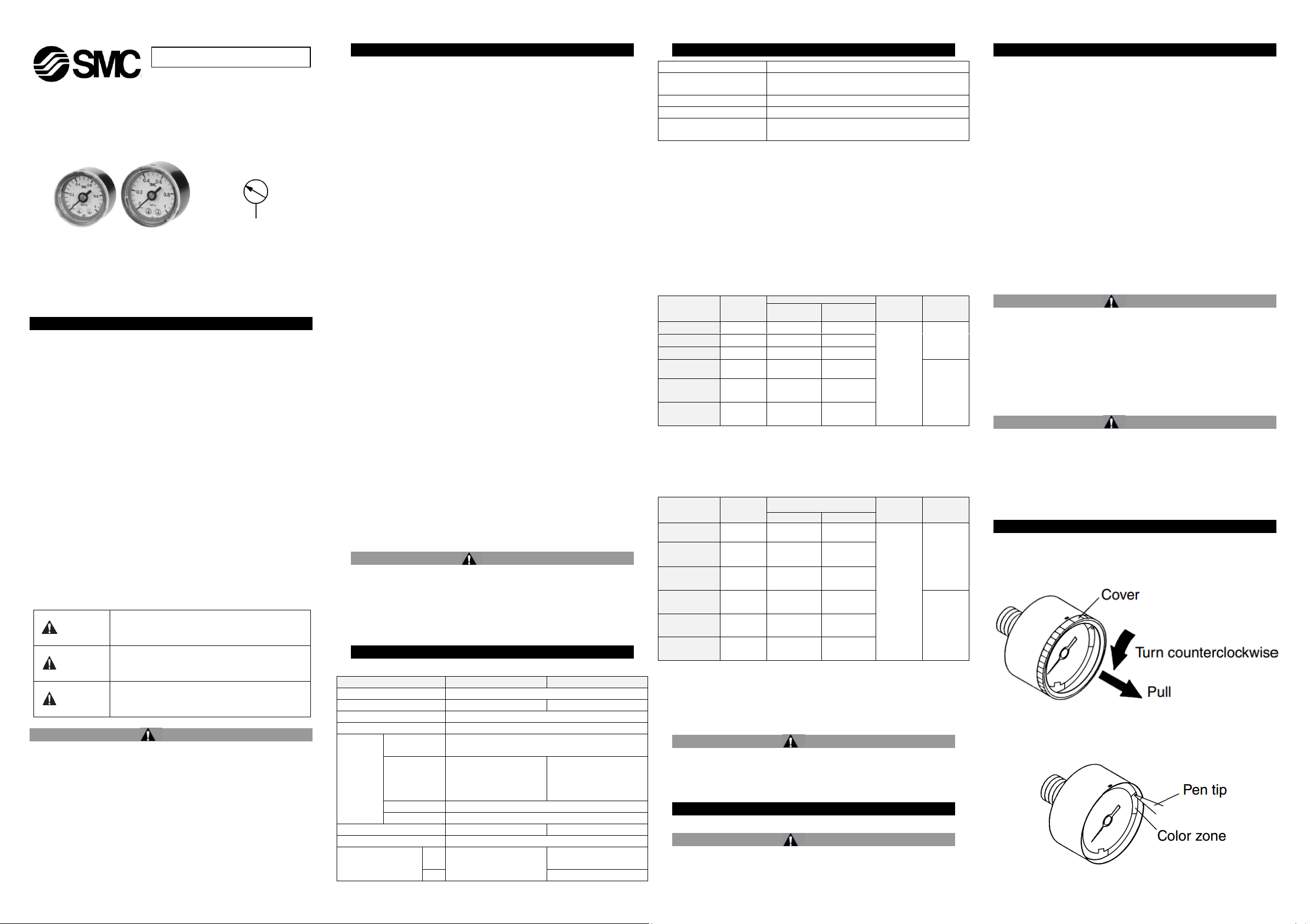

4 Settings

4.1 Procedure for Setting the Limit Gauge Indicator

1) Before setting the colour zone (red), turn the cover counter clockwise

(approximately 6 to 7 mm) until it stops. Then remove by pulling it

towards you.

2) Use a pen tip to set the colour zone (red). Be careful not to bend the

other needle or damage the dial plate.

Page 1 of 2

Page 2

G**-SMV03EN

AUSTRIA

SMC Pneumatik GmbH,Girakstrasse 8, AT-2100

Korneuburg, Austria

BELGIUM

SMC Pneumatics N.V. ⁄ S.A. Nijverheidsstraat 20, B-2160

Wommelgem, Belgium

BULGARIA

SMC Industrial Automation Bulgaria EOOD, Business

Park Sofia, Building 8-6th floor, BG-1715 Sofia, Bulgaria

CROATIA

SMC IndustrijskaAutomatikad.o.o. ZagrebačkaAvenija

104,10 000 Zagreb

CZECH REP.

SMC Industrial Automation CZ s.r.o. Hudcova 78a, CZ61200 Brno, Czech Republic

DENMARK

SMC Pneumatik A ⁄ S,Egeskovvej 1, DK-8700 Horsens,

Denmark

ESTONIA

SMC Pneumatics Estonia Oü,Laki 12, EE-10621 Tallinn,

Estonia

FINLAND

SMC Pneumatics Finland Oy, PL72, Tiistinniityntie 4, SF02031 Espoo, Finland

FRANCE

SMC France, 1, Boulevard de Strasbourg, Parc Gustave

Eiffel, Bussy Saint Georges, F-77607 Marne La

ValleeCedex 3, France

GERMANY

SMC Pneumatik GmbH, Boschring 13-15, 63329

Egelsbach, Germany

GREECE

SMC Italia Hellas Branch, Anagenniseos 7-9-P.C. 14342

N.Philadelphia, Athens, Greece

HUNGARY

SMC Hungary IpariAutomatizálásiKft.Torbágy u. 19, HU2045 Törökbálint, Hungary

IRELAND

SMC Pneumatics (Ireland) Ltd.2002 Citywest Business

Campus, Naas Road, Saggart, Co. Dublin, Ireland

ITALY

SMC Italia S.p.A.Via Garibaldi 62, I-20061Carugate,

(Milano), Italy

LATVIA

SMC Pneumatics Latvia SIA, Dzelzavas str. 120g, Riga,

LV-1021, Latvia

LITHUANIA

UAB “SMC Pneumatics”, Oslo g. 1, LT-04123 Vilnius,

Lithuania

NETHERLANDS

SMC Pneumatics B.V.De Ruyterkade 120, NL-1011 AB

Amsterdam, the Netherlands

NORWAY

SMC Pneumatics Norway AS, Vollsveien 13 C,

GranfosNæringspark, N-1366 Lysaker, Norway

POLAND

SMC Industrial Automation, Polska Sp z o.o.

02-826 Warszawa, ul. Poloneza 89

PORTUGAL

SMC España S.A. Zuazobidea 14, 01015 Vitoria, Spain

ROMANIA

SMC Romania S.r.l. StrFrunzei 29, Sector 2, Bucharest,

Romania

RUSSIA

SMC Pneumatik LLC. Business centre, building 3, 15

Kondratjevskij prospect, St.Petersburg, Russia, 195197

SLOVAKIA

SMC PriemyselnáAutomatizáciaSpols.r.o. Fantranská

1223, Teplickanadvahom, 01301, Slovakia

SLOVENIA

SMC IndustrijskaAvtomatikad.o.o. Mirnskacesta 7, SLO8210 Trebnje, Slovenia

SPAIN

SMC España S.A. Zuazobidea 14, 01015 Vitoria, Spain

SWEDEN

SMC Pneumatics Sweden AB,Ekhagsvägen 29-31, SE141 71 Segeltorp, Sweden

SWITZERLAND

SMC Pneumatik AG,Dorfstrasse 7, Postfach, 8484

Weisslingen, Switzerland

TURKEY

SMC PnömatikSanayiTicaretveServis A.Ş.

GülbaharCaddesi, Aydın Plaza, No: 9 ⁄ 4 Güneşli –

34212 , Istanbul

UK

SMC Pneumatics (U.K.) Ltd. Vincent Avenue, Crownhill,

Milton Keynes, Buckinghamshire MK8 0AN, United

Kingdom

URL :

http// www.smcworld.com (Global) http// www.smceu.com (Europe)

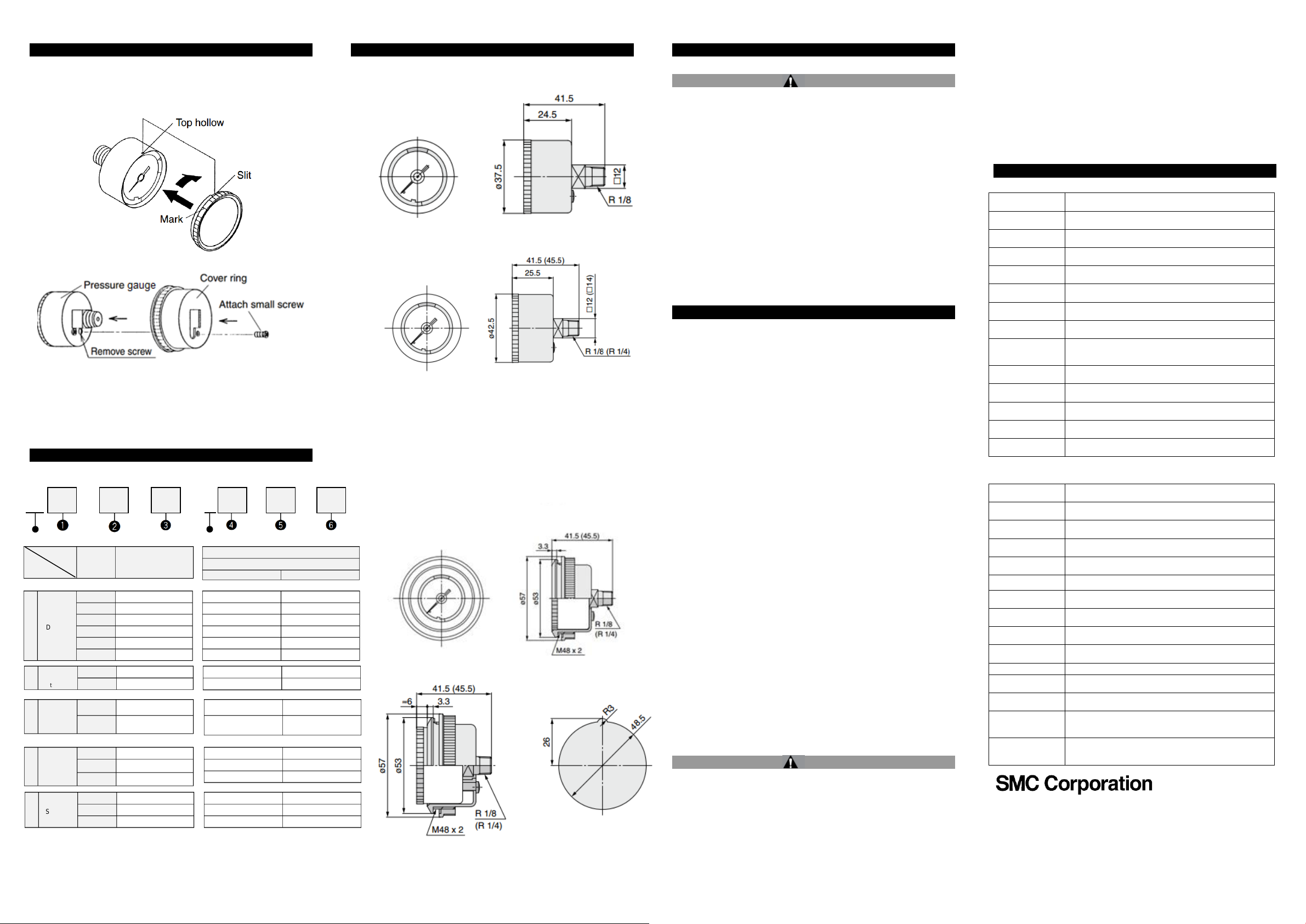

G 36 – 10 – 01 – L – –

Pressure gauge

Color zone type

Symbol

❶

Size

G36

G46

● ● ● ● ● ● ○

(2) ○ (2) ○ (2)

○

(2)

○

(2)

○

(2)

Pressure

2

0.2 MPa

4

0.4 MPa

10

1.0 MPa

P2

(1)

0.2 MPa, 30 psi

P4

(1)

0.4 MPa, 60 psi

P10

(1)

1.0 MPa, 150 psi

thread

01

R 1/8

02

R 1/4

material

Nil

Polycarbonate

N

Nylon

Nil

Without cover ring assy

C

Clear cover has no

protrusion (irremovable)

C1

Clear cover has protrusion

(removable)

ation

Nil

-

X2

Stud parts nickel plated

X30

Both MPa and psi

●

●

-

●

●

●

●

●

-

●

-

●

-

●

●

●

●

-

○

(2)

○

(2)

❷

❸ ❹ ❺

❻

G36-□□-01-L(N)

G46-□□-01 to 02-L(N)

G46-□□-01 to 02-L(N)-C

G46-□□-01 to 02-L(N)–C1

With cover ring assembly

(For panel mount)

Type C

(Clear cover is not removable.)

Type C1

(Clear cover is removable.)

Panel fitting dimensions

Plate thickness Max. 3.5 t

4 Settings - continued

3) After completing the setting, replace the cover. Fit the cover by

aligning the cut-out in the cover to the groove on the top of the black

case. Turn the cover clockwise (approximately 6 to 7 mm) until it

stops. Make sure that the matching mark on the cover is aligned with

the groove on the top of the case.

4.2 Procedure for Assembling the Cover Ring Assembly

1) Remove the small screw (1 position) from the pressure gauge.

2) Place the cover ring on the pressure gauge.

3) Using the small screw that is provided with the cover ring, install the

cover ring. The installation torque is 0.3 to 0.5 N.m.

5 How to Order

6 Outline Dimensions (mm)

7 Maintenance

7.1 General Maintenance

Caution

Not following proper maintenance procedures could cause the

product to malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous.

Maintenance of pneumatic systems should be performed only by

qualified personnel.

Before performing maintenance, turn off the power supply and be

sure to cut off the supply pressure. Confirm that the air is released to

atmosphere.

After installation and maintenance, apply operating pressure and

9 Contacts

power to the equipment and perform appropriate functional and

leakage tests to make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance,

ensure they are reconnected correctly and safety checks are carried

out as required to ensure continued compliance with applicable

national regulations.

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

maintenance instructions.

8 Limitations of Use

8.1 Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty

and Disclaimer” and “Compliance Requirements”. Read and

accept them before using the product.

Limited warranty and Disclaimer

1) The warranty period of the product is 1 year in service or 1.5 years

after the product is delivered, whichever is first

(1)

. Also, the product

may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

Description

Max.

Display

Connection

Clear

cover

Attach-

ment

Special

Specific-

Note 1) This symbol must be used with Special specification “X30.”

Note 2) Under the New Measurement Law, products for overseas use

only (SI unit type for use in Japan)

2) For any failure or damage reported within the warranty period

which is clearly our responsibility, a replacement product or

necessary parts will be provided.

This limited warranty applies only to our product independently, and

not to any other damage incurred due to the failure of the product.

3) Prior to using SMC products, please read and understand the

warranty terms and disclaimers noted in the specified catalogue for

the particular products.

(1)

Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after

it is delivered. Also, even within the warranty period, the wear of a

product due to the use of the vacuum pad or failure due to the

deterioration of rubber material are not covered by the limited

warranty.

Compliance Requirements

1) The use of SMC products with production equipment for the

manufacture of weapons of mass destruction (WMD) or any other

weapon is strictly prohibited.

2) The exports of SMC products or technology from one country to

another are governed by the relevant security laws and regulations of

the countries involved in the transaction. Prior to the shipment of a

SMC product to another country, assure that all local rules governing

that export are known and followed.

Caution

SMC products are not intended for use as instruments for legal

metrology.

Measurement instruments that SMC manufactures or sells have not

been qualified by type approval tests relevant to the metrology

(measurement) laws of each country.

Therefore, SMC products cannot be used for business or certification

ordained by the metrology (measurement) laws of each country.

'SMC Corporation, Akihabara UDX15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo

101 0021

Specifications are subject to change without prior notice from the manufacturer.

© 2017 SMC Corporation All Rights Reserved.

Template DKP50047-F-085E

Page 2 of 2

Loading...

Loading...