SMC Networks EX600-W Series Manual

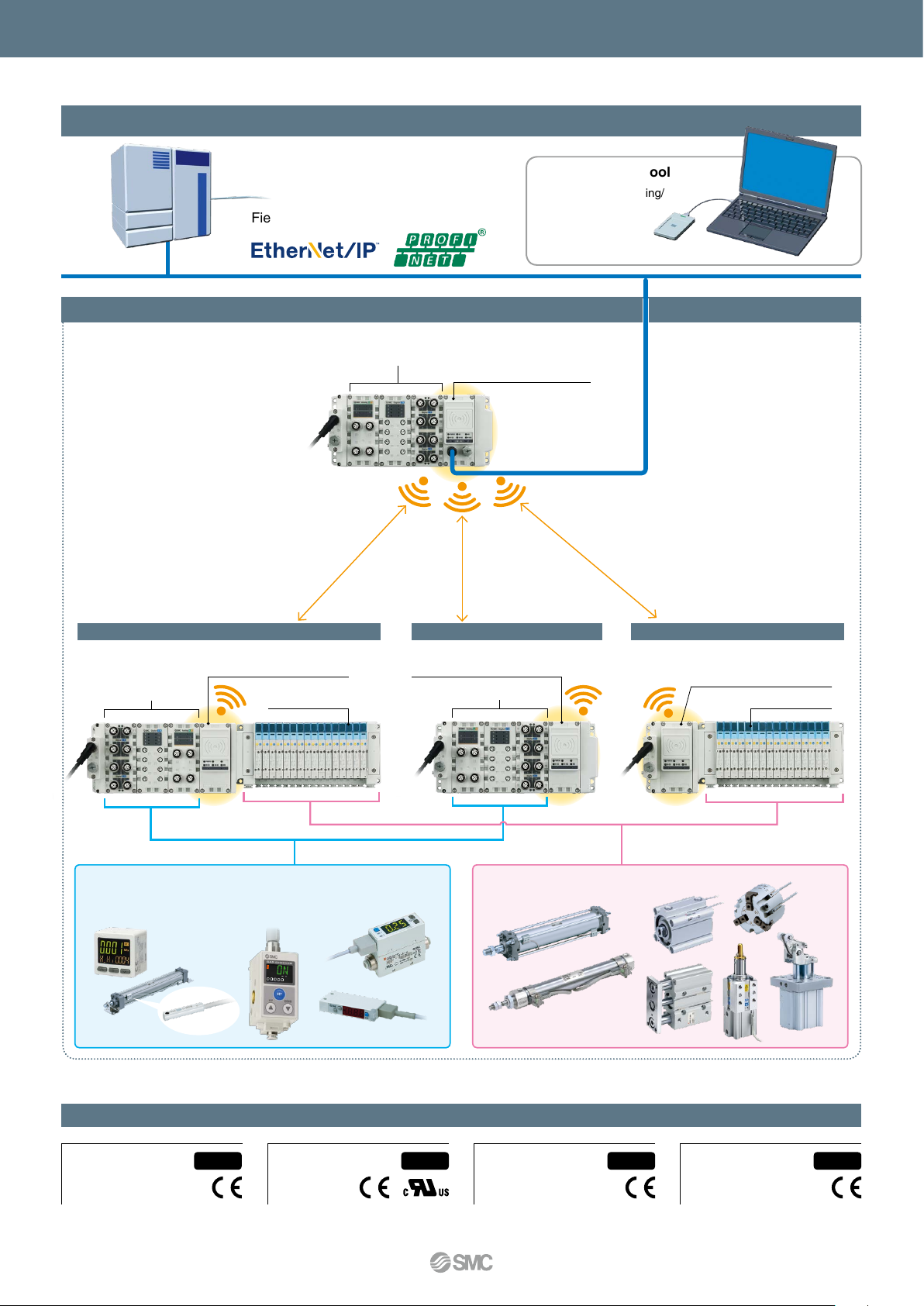

Wireless System

RoHS

Usable even in welding environments

Uses the 2.4 GHz ISM frequency band

Frequency hopping: Every 5 ms

Communication cables not

required

Reduced wiring work, space, and cost

Minimized disconnection risk

High-speed connectionNoise resistance

From power supply ON to start of

communication:

1

Min. 250 ms

*

*1 For remote

Number of I/O points

Max. 1280 inputs/1280 outputs

(Max. 128 inputs/128 outputs per module)

Communication response

Wireless communication signal

Response time:

5 ms

Compatible protocol

New

Material

handling robot

Remote

Remote moduleBase module

EX600-W Series

Base

Spot welding

Countries/Regions in which wireless is supported

This product cannot be used in countries where wireless is not

supported. Refer to page 23 for details on countries in which

the product can be used.

Country/Region Standards

Japan (Japanese radio law)

EU (CE marking/RE Directive)

USA (FCC)

Remote

CAT.E02-28B

B

Wireless System EX600-W Series

Provide safe and reliable communication

Uses the 2.4 GHz ISM frequency band

kHz MHz GHz

10 10 101 1100 100

Wireless System

Wireless LAN

Wireless

devices

Site

noise

welding machine

Electromagnetic heater, etc.

RFID

Bluetooth

AC/DC

Motor driver/

* ISM (Industrial, Scientific and Medical) radio bands: Radio bands reserved for the use of radio frequency energy for industrial,

scientific and medical purposes.

Provide stable communication

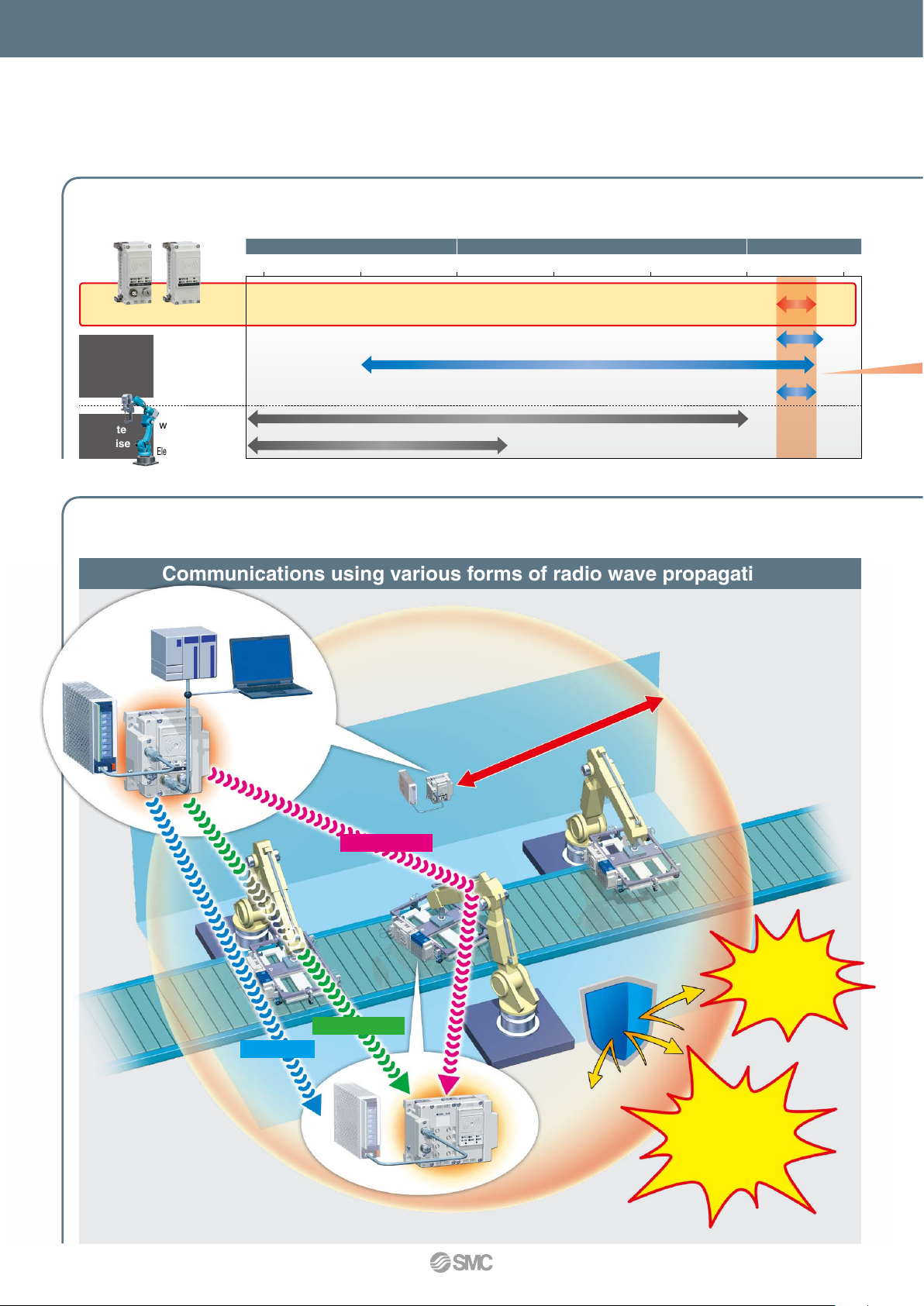

Communications using various forms of radio wave propagation

PLC

Powe r

supply

Base

Reflected wave

Transmitted wave

Direct wave

Communication possible

Automatic restoration

of communication

If the number of retries exceeds the stipulated value (32 times), a disconnection flag will

be output. The system will enter resync mode

and synchronization will be established. Once

completed, the normal operating conditions

will be restored, the disconnection flag will be

canceled, and control will resume.

in a 10 m radius

Noise in

electronic

circuits

Interference

from other

wireless

Remote

A

1

equipment

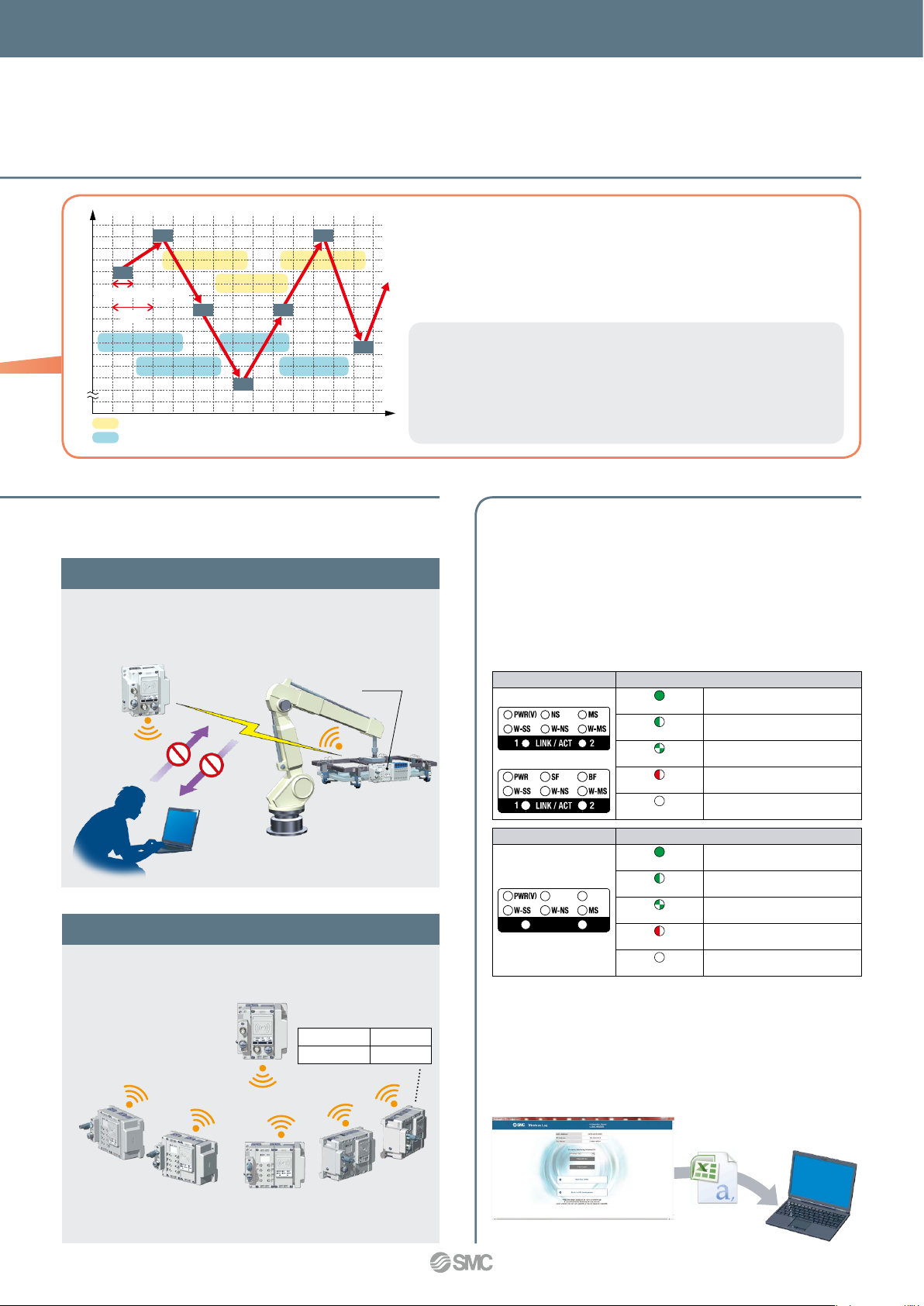

Frequency

Actual communication time

Communication frequency interference (for example, Wi-Fi)

5 ms

Frequency of the radio wave interference

Time

Wireless System EX600-W Series

Frequency hopping: Every 5 ms

A stable wireless environment is established using an original

protocol which is not affected by interference. Interference from other

wireless equipment is prevented.

Frequency Hopping

The communication technology rapidly changes frequency (hopping), to

prevent interference from other wireless equipment. When the frequency of

Wi-Fi and other wireless communications compete, or radio wave interference

is present, then other frequencies are used for communication. For details,

refer to technical data on page 23.

High security using encryption

Unauthorized access from outside is prevented by using

data encryption.

Base

Unauthorized access/

data falsification

Unauthorized

wiretapping

Remote

Removing

device

Point-to-Multipoint communication

Registration and communication of up to 127 remote

modules is possible.

Remote 1

Remote 2

* 1 to 15 units are recommended for simultaneous operation.

* It is possible to install multiple bases in the same area.

Base

Remote 3

EtherNet/IP™

PROFINET

Remote 4

Max. 127 units

Max. 31 units

Wireless communication status can be monitored.

<Monitoring the remote communication status>

The wireless system connection can be monitored during operation

according to the diagnostic data.

The installation location can be ascertained according to the intensity

level of the radio wave received by the unit display.

[Diagnostic data]

* When communication from the remote cannot be received

* When communication retry has exceeded the upper limit (32 times)

[Unit display]

For Base

EtherNet/IP™

PROFINET

For remote

* A received radio wave intensity level of 1 means the intensity is weak. Add

a base so that the wave intensity becomes level 3 or 2. Alternatively

remove the obstacle between the base and remote, or reduce the distance

between the base and remote.

<Communication status can be downloaded by a PC>

By connecting the base to a PC, it is possible to view log files which show the number of

retries or the received radio wave intensity. Log files are accessed by using a web browser to

connect to the built-in web server. The wireless environment and installation location can be

optimized by checking the number of retries and received radio wave intensity.

Web screen example

W-SS (Radio wave receiving intensity (For communication from remote to base))

Green LED is ON.

Green LED flashes. (1 Hz)

Green LED flashes. (2 Hz)

Red LED flashes.

OFF

W-SS (Radio wave receiving intensity (For communication from base to remote))

Green LED is ON.

Green LED flashes. (1 Hz)

Green LED flashes. (2 Hz)

Red LED flashes.

OFF

Received power level of all remotes is 3.

There are connected remotes with

received power level 2.

There are connected remotes with

received power level 1.

No remotes connected.

Remote module is not registered.

Received power level is 3.

Received power level is 2.

Received power level is 1.

Wireless communication is not connected.

Base module is not registered.

The log files showing the number of retries

or the received radio wave intensity, can

be downloaded in the form of a CSV file.

PC

A

2

Wireless System EX600-W Series

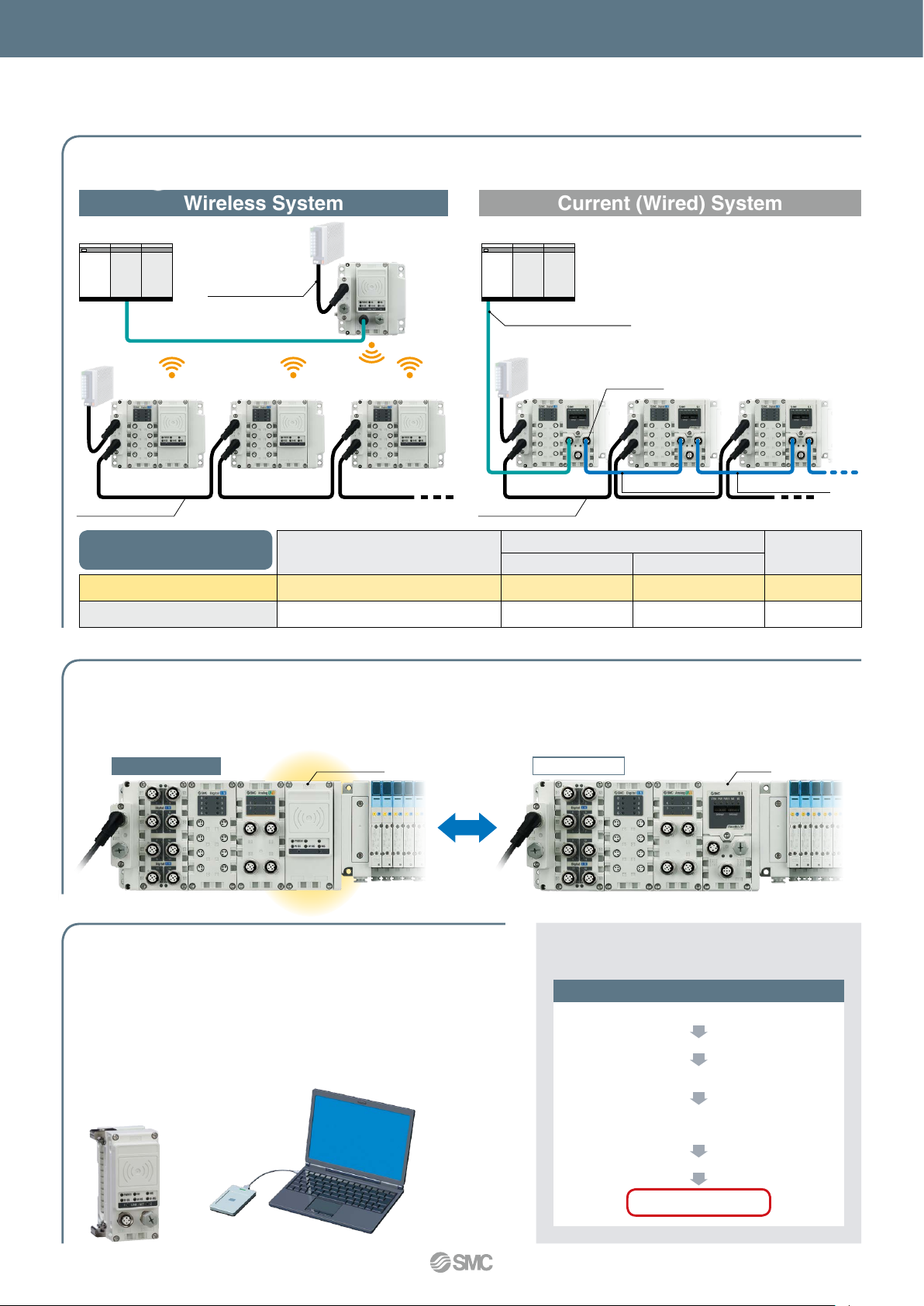

Wiring material cost and installation work-hours can be reduced.

Current (Wired) SystemWireless System

Power supply

Power supply line

Powe r

supply

Remote 1 Remote 2 Remote 3

Power supply line Power supply line

SI unit: Comparison when

15 units are connected

Wireless system

Communication line q

Number of communication devices

Current (Wired)

Base

…

3 units

Base: 1 unit

Remote: 15 units

SI unit: 15 units

15 units

PLCPLC

Communication line q

Powe r

supply

1 unit1 unit 2 units 3 units

SI unit

Communication line

q w

1 line

(Connector at one end)

1 line

(Connector at one end)

Interchangeability maintained

Connection interchangeability between EX600 series SI units is maintained.

Replacement of wireless and wired systems is possible.

Wireless system Wired system

Connector

2 units

Communication line w

— 1 place

14 lines

(Connector at both ends)

* Maximum I/O of base/remote

…

15 units

Communication line w

Communication

connectors

required

29 places

module is limited to 128 points.

SI unitWireless unit

NFC

contactless communication

(NFC: Near Field Communication)

Settings are possible using an NFC reader/writer and setting software.

(Some items can be set even when there is no power supplied.)

¡Write IP address to the base

¡Set the I/O points for the system and unit

¡Pairing of the base and remote

¡I/O monitoring

NFC reader/

writer

PC + Setting software

B

3

Configuration File

From SMC website

Documents/Download

Instruction Manuals

Fieldbus System

Serial Transmission System

EtherNet/IP™ Compatible

PROFINET Compatible

I/O Configurator for NFC

Configuration File

or

Wireless System EX600-W Series

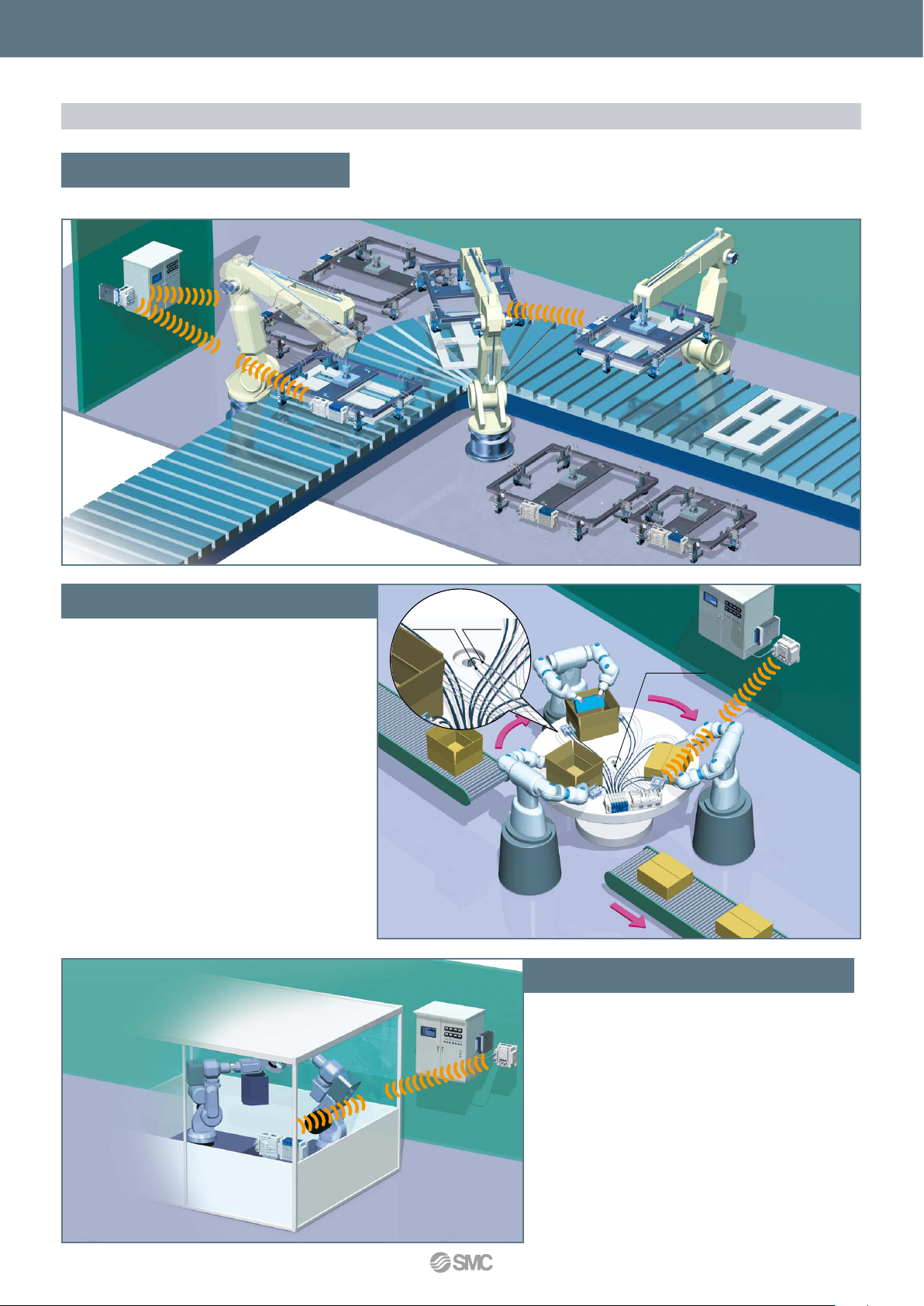

Application Examples

Tool change

Rotary table

¡Minimized disconnection risk

¡ Smaller diameter communication

cable/tubing

¡Communication cable is not necessary for moving parts.

¡Minimized disconnection risk

¡Shorter time for establishing communication (startup time)

Wired system

Power supply lineCommunication line

Power supply

line only

Blocking of radio waves

* The radio waves must not be blocked by nearby conductive

objects such as metal enclosures or covers.

4

Wireless System EX600-W Series

System Examples

Fieldbus

PLC

Wireless Network

Setting/Monitor tool

Initial setting/monitoring/

pairing are possible.

PC

Combination Example

Remote module No. 1

EX600

I/O unit

p. 7

Refer to the Web Catalog. p. 7

q

Solenoid valve

EX600 I/O unit Base module

Combination Example

Remote module No. 2

p. 7

EX600 I/O unit

Number of I/O points:

Max. 1280 inputs

1280 outputs

w

Combination Example

Remote module No. 3

p. 7

Solenoid valve

e

Other products

Pressure switch, flow switch, auto switch, and other switches

(proximate sensor, photoelectric switch, limit switch, etc.)

Various actuators

Applicable Manifold Solenoid Valves

SY Series SV Series S0700 Series

A

5

IP67 IP67 IP67IP40

®

VQC Series

CONTENTS

Wireless System

EX600-W Series

Remote moduleBase module

How to Order

Wireless Unit ······························································· p. 7

Digital Input Unit ·························································· p. 7

Digital Output Unit ······················································· p. 7

Digital Input/Output Unit ·············································· p. 7

Analog Input Unit ························································ p. 8

Analog Output Unit ······················································ p. 8

Analog Input/Output Unit ············································· p. 8

End Plate (D side) ······················································· p. 8

End Plate (U side) ······················································· p. 8

Ordering Example of the Base Module ······················· p. 9

Ordering Example of the Remote Module ·················· p. 9

Specifications

Base Module ····························································· p. 10

Remote Module ························································· p. 12

End Plate (D side) ····················································· p. 12

Dimensions ································································· p. 13

LED Display ································································· p. 15

Accessories

End Plate Bracket

q

Valve Plate

w

Reinforcing Brace

e

Seal Cap

r

Marker (1 sheet, 88 pcs.)

t

Communication Cable with Connector/

y

Communication Connector ··································· p. 19

Power Supply Cable with M12 Connector (A-coded)

u

Power Supply Cable with M12 Connector (B-coded)

u

Power Supply Cable with 7/8 Inch Connector/

i

Power Supply Connector ······································ p. 22

·······························································

·················································

····························································

·················································

······································

······

······

p. 18

p. 18

p. 18

p. 18

p. 19

p. 20

p. 21

Technical Data ············································································································································································ p. 23

Important ···················································································································································································· p. 23

Safety Instructions ···························································································································································· Back cover

A

6

Wireless System

EX600-W Series

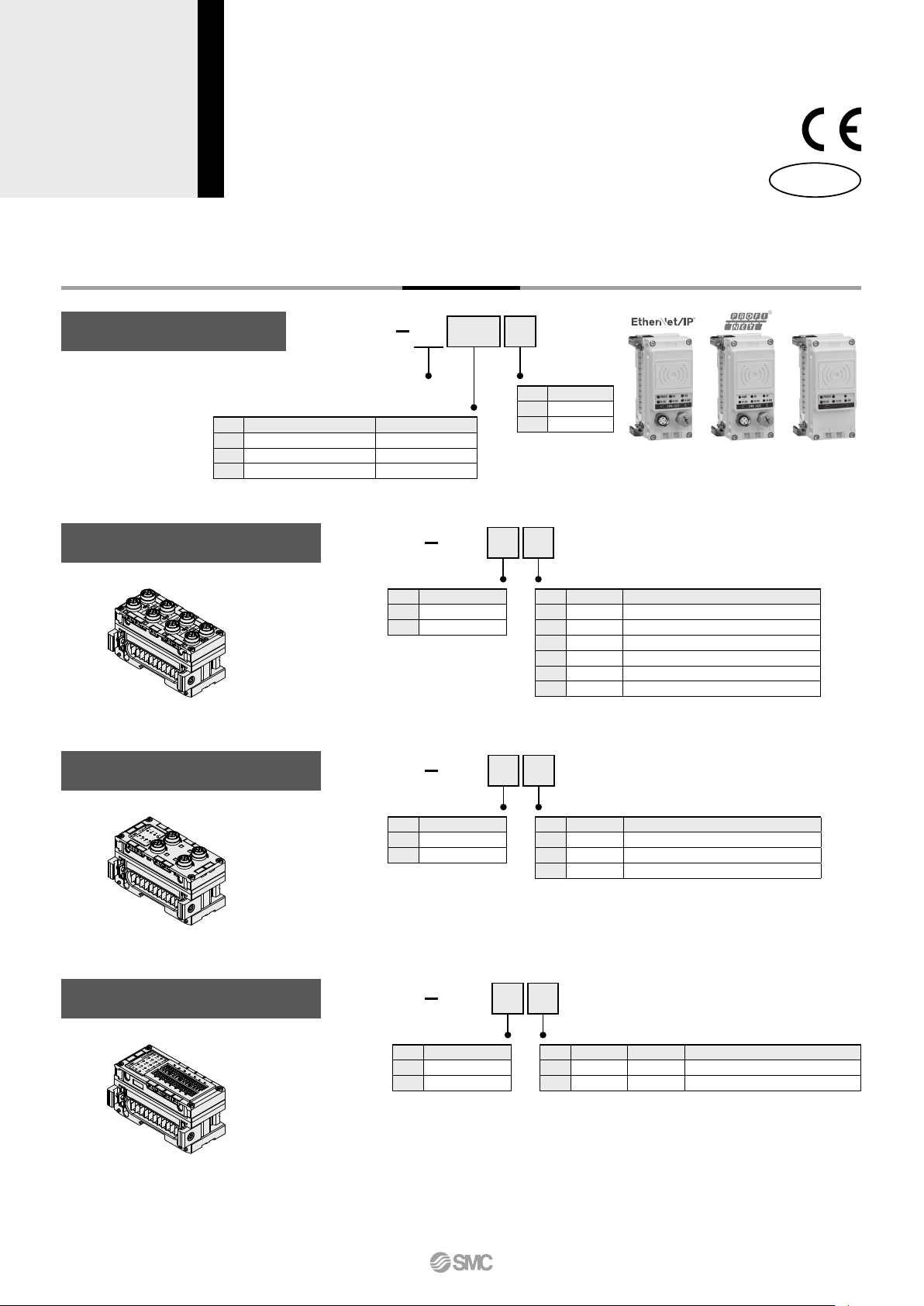

Wireless Unit

Symbol

EN

PN

SV

Digital Input Unit

* For specifications, refer to the Fieldbus

How to Order

ENWEX600 1

Wireless compatible Output type

P

Symbol

1

2

D

Symbol

B

C

C1

D

E

F

Protocol

Specifications Note

Base module For EtherNet/IP™

Base module For PROFINET

Remote module —

DXEX600

Input type Number of inputs and Connector

Symbol

Description

P

N

system EX600 series in the Web

Catalog.

PNP

NPN

Specifications

PNP

NPN

Base module Remote

Number of inputs

8 inputs M12 connector (5 pins) 4 pcs.

8 inputs M8 connector (3 pins) 8 pcs.

8 inputs

16 inputs M12 connector (5 pins) 8 pcs.

16 inputs D-sub connector (25 pins)

16 inputs Spring type terminal block (32 pins)

M8 connector (3 pins) 8 pcs., With open-circuit detection

Connector

RoHS

module

Digital Output Unit

* For specifications, refer to the Fieldbus

system EX600 series in the Web

Catalog.

Digital Input/Output Unit

* For specifications, refer to the Fieldbus

system EX600 series in the Web

Catalog.

DYEX600

Output type Number of outputs and Connector

Symbol

Description

P

N

DMEX600

Input/Output type Number of inputs/outputs and Connector

Symbol

Description

P

N

PNP

NPN

PNP

NPN

P

P

B

Symbol

B

E

F

F

Symbol

E

F

Number of outputs

8 outputs

16 outputs

16 outputs

Number of inputs

8 inputs 8 outputs

8 inputs 8 outputs

M12 connector (5 pins) 4 pcs.

Spring type terminal block (32 pins)

Number of outputs

Connector

D-sub connector (25 pins)

Connector

D-sub connector (25 pins)

Spring type terminal block (32 pins)

A

7

Wireless System

How to Order

EX600-W Series

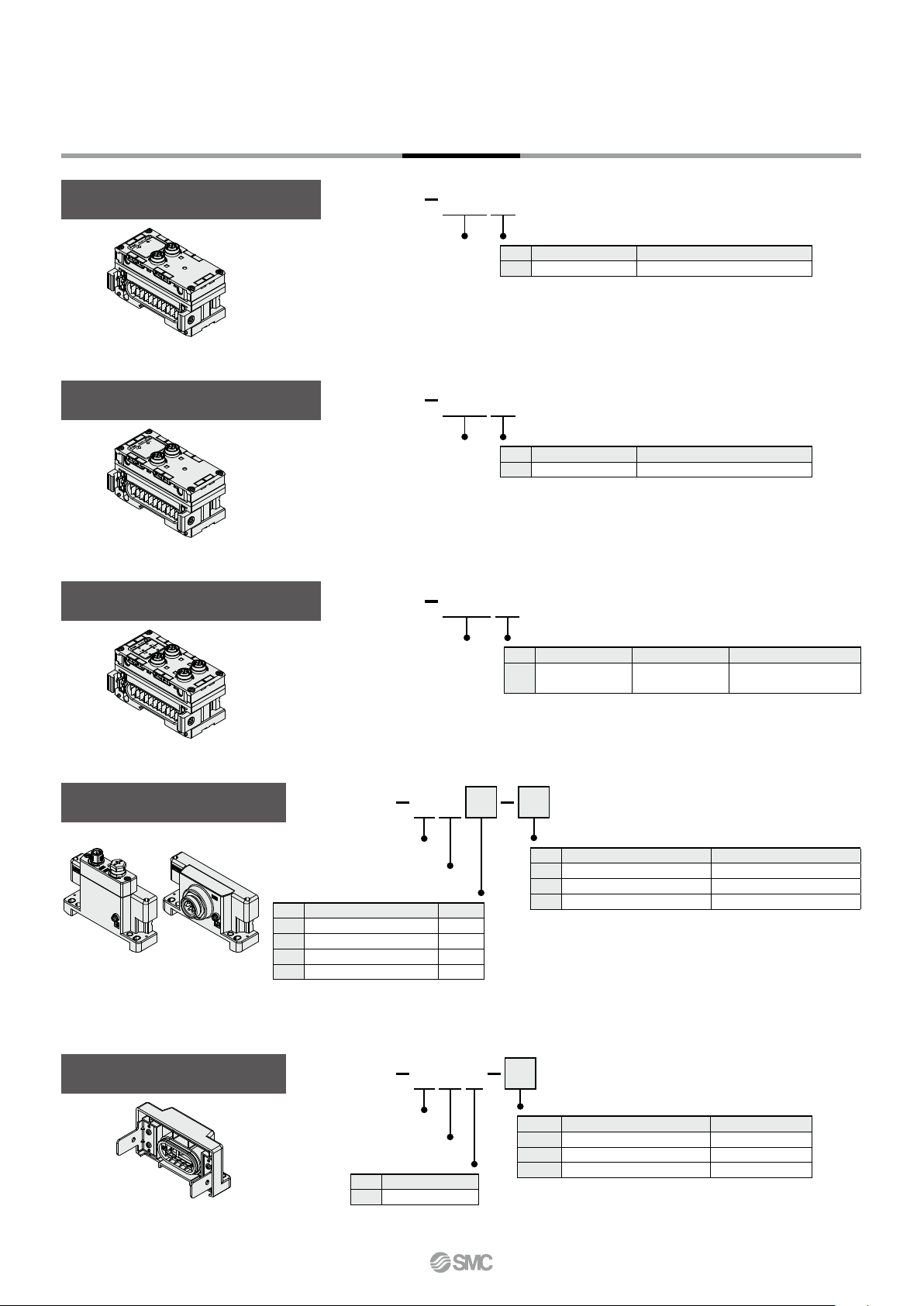

Analog Input Unit

* For specifications, refer to the Fieldbus

system EX600 series in the Web

Catalog.

Analog Output Unit

* For specifications, refer to the Fieldbus

system EX600 series in the Web

Catalog.

Analog Input/Output Unit

* For specifications, refer to the Fieldbus

system EX600 series in the Web

Catalog.

AXEX600

Analog input

AYEX600

Analog output

AMEX600

Analog input/output

A

Number of input channels and Connector

Symbol

Number of input channels

2 channels M12 connector (5 pins) 2 pcs.

A

Connector

A

Number of output channels and Connector

Symbol

Number of output channels

2 channels M12 connector (5 pins) 2 pcs.

A

Connector

B

Number of input/output channels and Connector

Symbol

Number of input channels Number of output channels

2 channels 2 channels

B

Connector

M12 connector (5 pins)

4 pcs.

End Plate (D side)

For M12 For 7/8 inch

End Plate (U side)

E DEX600 2 2

End plate

End plate mounting position: D side

Power supply connector

Symbol

Power supply connector

M12 (5 pins) B-coded IN

2

7/8 inch (5 pins) IN

3

M12 (4/5 pins) A-coded

4

M12 (4/5 pins) A-coded

5

*1 The pin layout for “4” and “5” pin connector

is different.

Refer to the dimensions on page 14.

Specifications

1

*

IN/OUT

1

*

IN/OUT

E U 1EX600 2

End plate

End plate mounting position: U side

Specifications

Symbol

Specifications

Waterproof cover

1

Mounting method

Symbol

Nil

2

3

* When the end plate (U side) is used, the symbol for the

mounting method must be the same as the D side.

Mounting method

Symbol Description Note

Nil

2

3

* When the end plate (D side) is used, the symbol for the

mounting method must be the same as the U side.

Description Note

Without DIN rail mounting bracket

With DIN rail mounting bracket

With DIN rail mounting bracket

Without DIN rail mounting bracket

With DIN rail mounting bracket

With DIN rail mounting bracket

For SV, S0700, VQC series

For EX600-ED-2

For EX600-ED-3

—

For SY series

—

8

Loading...

Loading...