SMC Networks EX600-HT1 Installation & Maintenance Manual

EX600-TFM07GB

Installation & Maintenance Manual

Fieldbus System - Handheld terminal

Type EX600-HT1

1. Safety Instructions

WARNING

CAUTION

Do not operate the product beyond the specification range.

Do not use the product for flammable or harmful gases or liquids.

Fire, malfunction, or damage to the product can result.

Please confirm the specifications before use.

Do not operate the product in an environment where flammable

or explosive gases may be present.

Fire or an explosion can result.

This product is not designed to be explosion proof.

The following instructions must be followed during maintenance:

• Turn off the power supply.

• Stop the air supply, exhaust the residual pressure and make sure that

the air is released to atmosphere before performing maintenance.

Otherwise injury can result.

Do not apply pressure to the LCD display.

This may cause damage or injury.

Do not operate the device with wet hands.

There is a risk of electric shock.

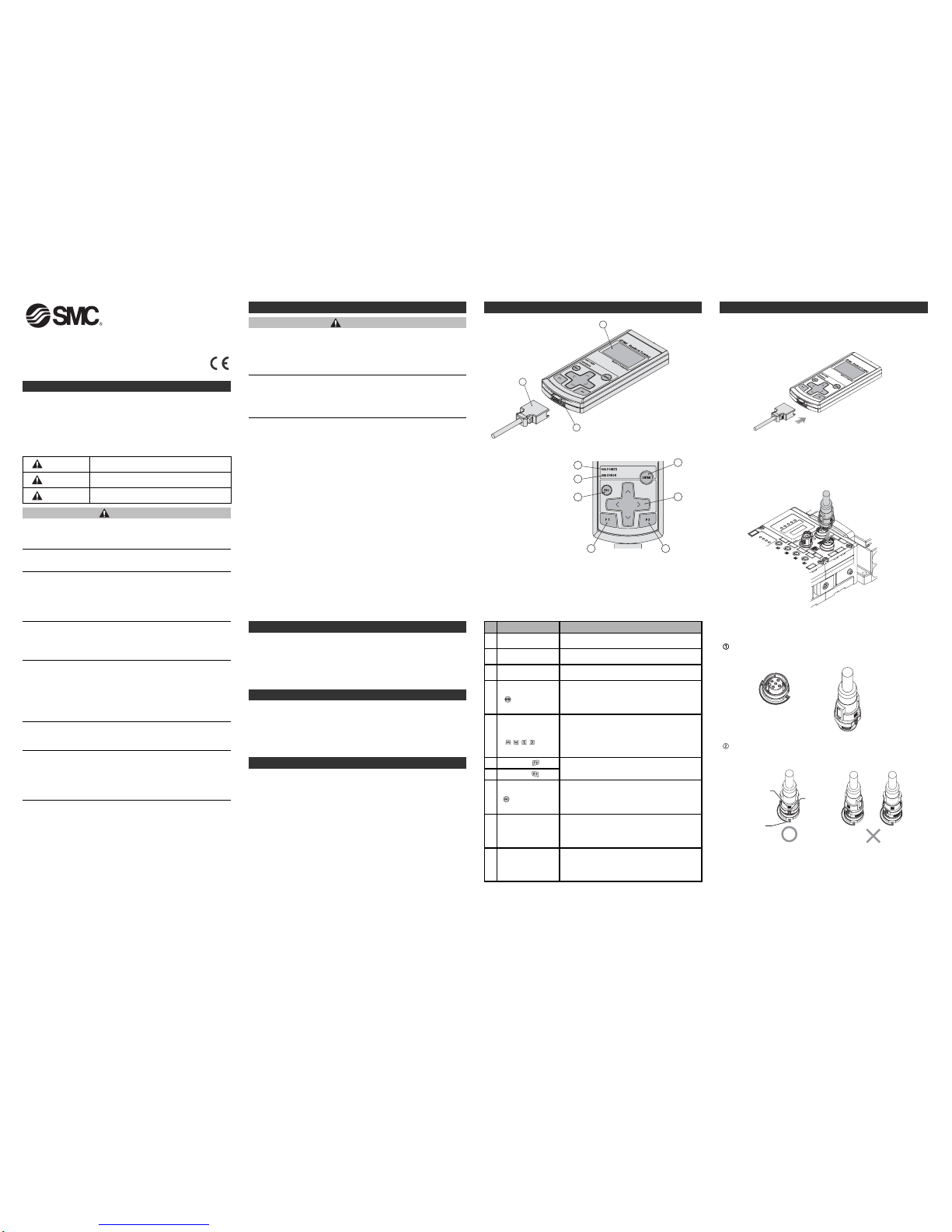

5. Names / Functions of individual Parts

No.

Name

Description

3

Handheld Terminal

cable

Cable to connect the SI Unit to the Handheld

Terminal.

5

Cursor move

button

()

,,,

This button is used to move the cursor in LCD

display upward/downward and right/left

direction. Select the required item using this

button. Use this button to increase/decrease or

turn ON/OFF the setting value.

10 Power LED

The Power LED (Green) turns ON when the

Handheld Terminal is connected with an EX600

SI Unit and power supply for Control/Input is

ON.

4

ENTER button

()

In selecting screen, this button is used for

selecting the required item. In setting screen,

pressing this button registers the selected

contents.

6

F2 button ( )

This button functions according to the indication

or instruction displayed on the screen.

7

F1 button ( )

8

Escape button

()

In selecting screen, this button is used to return

to the previous screen. Pressing this button

cancels the setting contents.

1

LCD display

2 Connector

Connector for Handheld Terminal cable.

Displays the operation items and information

about the unit.

9 Error LED

The Error LED (Red) turns ON when EX600

diagnostics error occurs. (Refer to the

"Troubleshooting" and "Error Code" section for

further details.)

Mark at cable end

Mark on the unit

Projected

portion

6. Wiring

2. How to Order

3. Specifications

4. Outline dimensions(mm)

<SPEEDCON Wiring method>

Set the projected portion of the cable connector metal ring (plug /

socket) to the mark at cable end.

Push the connector straight to insert it into the receptacle of the unit.

If inserted without aligning the mark, the connector will not mate with

the receptacle.

Refer to the catalogue or operation manual for this product.

Refer to the catalogue or operation manual for this product.

Refer to the catalogue or operation manual for this product.

The forced input/output function is used to change the signal

status forcibly.

When operating this function, be sure to check the safety of the

surroundings and the installation.

Otherwise injury or equipment damage could result.

Erroneous parameter setting can result in malfunction.

Be sure to confirm the settings.

Otherwise injury or equipment damage could result.

When setting the parameters to the factory defaults, unpredictable

operation of connected equipment may occur.

It is essential to carry out this operation paying attention to safety.

Otherwise injury or equipment damage could result.

1

3

2

4

5

67

8

9

10

1. Safety Instructions

(continued)

Perform a proper functional check after completing maintenance.

Stop operation if the equipment does not function properly.

Safety cannot be assured due to unexpected malfunction.

Switching the HOLD/ CLEAR function selection mode, will switch

the operation of the input / output signal and emergency stop, so

pay due attention to safety when setting.

There is a risk of injury and equipment damage.

Do not disassemble, modify (including change of printed circuit

board) or repair this product.

Injury or failure can result.

<Wiring Method

(connecting Handheld Terminal connector)

>

When inserting the connector into the Handheld Terminal, insert

the connector straight in until it clicks into place.

<Wiring Method (connecting to the SI Unit)>

The M12 cable connector is connected to the "connector for

Handheld Terminal" on the SI Unit. The method of connecting

the cable to the SI Unit is explained in the "<SPEEDCON Wiring

method>" section.

If instructions are not followed there is a

possibility of serious injury or loss of life.

If instructions are not followed there is a

possibility of injury or equipment damage.

In extreme conditions, there is a possible result

of serious injury or loss of life.

DANGER

WARNING

CAUTION

These safety instructions are intended to prevent hazardous situations

and/or equipment damage.

These instructions indicate the level of potential hazard by label of

"DANGER", "WARNING"or "CAUTION", followed by important safety

information which must be carefully followed.

To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

EX600-TFM07GB

6. Wiring

(continued)

Turn-lock mechanism

of the connector

Turn the connector clockwise. It stops when turned 1/4 turn.Turn it

further. When the connector is turned 1/2 turn from the original position, the projected portion is set at the diagonal position to the mark

and the turn is completed. Check that the connector is securely

locked.

If the connector is turned excessively, it will become difficult to

remove.

<Basic Operation>

Turning ON the power

(1) When the SI Unit and the Handheld

Terminal are connected with the cable,

the power is supplied to the Handheld

Terminal.

(2) The POWER LED (green) turns ON

and the start up screen is displayed on

the LCD display.

(3) After about 2 seconds, the Main Menu

screen is displayed.

Turning off the Power

During Main Menu screen, remove the

cable connected to the SI Unit.

SI Interface

Ver.X.X.

After

2 seconds

Main Menu

1.I/O monitor

2.Diagnosis Data

3.Sys. Configuration

4.Parameter Setting

5.Terminal Setting

Notes

- Be sure to put seal caps on any unused connectors of the EX600 SI

Unit. Appropriate use of seal caps enables the unit to achieve IP67

protection.

- The cable can be removed only when the Handheld Terminal displays the Main Menu screen. Do not remove the cable while at any

other screen, or this may cause equipment malfunction.

<Power Saving>

When the power supply is ON, and the button is pressed for

2 seconds or more the Handheld Terminal will enter power

saving mode.

The LCD display will turn OFF. Pressing the button again will

recover from the power saving mode.

7. Setting

7. Setting

(continued)

<Main Menu>

The Handheld Terminal has five

modes for the various functions.

Each mode is composed of layers

with more detailed contents

enabling setting and checking of

each item.

Mode Selection Screen

Main Menu

1.I/O monitor

2.Diagnosis Data

3.Sys. Configuration

4.Parameter Setting

5.Terminal Setting

No.

1

2

3

4

5

Mode

I/O Monitor mode

Diagnosis Data

mode

System

Configuration

mode

Parameter Setting

mode

Terminal Setting

mode

Description

This mode displays the I/O status of the unit and

carries out forced I/O.

This mode displays the I/O status of the unit, the

detailed error contents and error log.

This mode is used to configure the following

system operations:

(1)Input the tag name of each unit.

(2)Update the memorized information of manifold

configuration.

(3)Change the hold/clear function to SW setting of

the SI unit or setting by the Handheld Terminal.

(4)Clear the ON/OFF counter of each I/O Unit.

(5)Reset the parameter of each unit to the factory

default value.

(6)Clear all error logs.

This mode is used to set each parameter type.

This mode is used to set the following:

(1)Set the contrast of the LCD display screen.

--> 9 levels

(2)Set the brightness of the LCD display screen.

--> 5 levels

(3)Set the click sound level for button operation.

--> 5 levels

(4)Set the time before entering power saving

mode when there is no operation.

--> None, 1 min, 3 min, 7 min, 10 min

(5)Cancel the operation settings of the Handheld

Terminal and return to the initial setting values.

(6)Change the password.

8.Trouble Shooting

Indication

Power LED

is OFF

LCD display

is not active

"Warning

System

access is not

completed" is

displayed on

the LCD

screen

is

displayed on

the LCD

screen.

?

ERROR LED

is ON

Problem

EX600 Power

supply voltage

level for control /

input is not within

specification.

The cable for the

handheld terminal

is defective.

Handheld terminal

is in power save

mode.

LCD is damaged.

The handheld

terminal cable is

defective.

A connection

between the units

is defective.

Manifold

configuration

memory error has

occurred.

Connection

between the units

is defective.

EX600 diagnostic

error has

occurred.

Investigation method

- Check if "PWR" LED

on the SI Unit is

green.

- Confirm that the

regulated power

supply voltage is

supplied to the

endplate.

- Confirm the

Handheld terminal

cable is connected

correctly.

- Confirm the integrity

of the connection of

the Handheld

terminal cable.

Press ESC button.

Confirm that the LCD

is active.

If LCD does not

become active after

initial checks above,

LCD is damaged.

- Confirm that the

Handheld terminal

cable is connected

correctly.

- Confirm there is no

loose connection in

the Handheld

terminal cable.

Confirm if SI Unit

"ST(M)" LED is green.

Confirm if configuration

memory is in active

state and manifold

configuration is

correct.

Confirm the SI Unit

"ST(M)" LED is green.

Confirm error content

through diagnostic

data mode.

Counter-measure

Supply voltage of

24V 10% to the

power supply for

control / input.

Refer to the

manual of the

corresponding

unit.

- Reconnect the

cable correctly.

- Ensure the cable

connections are

secure.

Same as left.

Stop operation

and contact SMC

sales office.

- Reconnect the

cable correctly.

- Ensure the cable

connections are

secure.

If LED is flashing

red and green,

there is a

connection fault

between the units.

Re-make and

then confirm the

connection

between the units.

Please refer to

respective unit's

operation manual

to clear the error.

If the LED is

flashing red and

green, there is a

connection fault

between the units.

Re-make and

then confirm the

connection

between the units.

Refer to error

code list and

respective unit's

operation manual

for counter

measure to the

error.

9. Contact

AUSTRIA (43) 2262 62280 NETHERLANDS (31) 20 531 8888

BELGIUM (32) 3 355 1464 NORWAY (47) 67 12 90 20

CZECH REP. (420) 541 424 611 POLAND (48) 22 211 9600

DENMARK (45) 7025 2900 PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513 SLOVAKIA (421) 2 444 56725

FRANCE (33) 1 6476 1000 SLOVENIA (386) 73 885 412

GERMANY (49) 6103 4020 SPAIN (34) 945 184 100

GREECE (30) 210 271 7265 SWEDEN (46) 8 603 1200

HUNGARY (36) 23 511 390 SWITZERLAND (41) 52 396 3131

IRELAND (353) 1 403 9000 UNITED KINGDOM (44) 1908 563888

ITALY (39) 02 92711

URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© SMC Corporation All Rights Reserved.

Loading...

Loading...