Page 1

Fieldbus system

CC-Link Compatible GW unit

Operation Manual

EX510-GMJ1

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2003-2017 SMC Corporation All Rights Reserved

EX※※-OMH0014-C

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

Page 2

1

Table of Contents

Thank you for purchasing an SMC fieldbus system EX510

series.

Please read this manual carefully before operating the product

and make sure you understand its capabilities and limitations.

Please keep this manual handy for future reference.

OPERATOR

•This operation manual has been written for those who have

knowledge of machinery and apparatuses that use fieldbus

system and have full knowledge of assembly, operation and

maintenance of such equipment.

•Please read this operation manual carefully and understand it

before assembling, operating or providing maintenance service

to the actuator.

Safety Instructions 2

Product Summary 6

Name of Parts/ Accessories 7

Dimensions 8

Settings 9

Specifications 11

Wiring 12

Display/ Switch Setting 19

Troubleshooting 23

Page 3

32

Safety Instructions

The product and this manual contain essential information to

protect users and others from possible injury and property

damage and to ensure correct handling.

Please check that you fully understand the definition of the

following messages (signs) before going on to read the text, and

always follow the instructions.

Please read the operation manual of related apparatus and

understand it before operating the actuator.

Read this manual and follow its instructions. Signal words such as

WARNING, CAUTION and NOTE, will be followed by important

safety information that must be carefully reviewed.

Indicates a potentially hazardous situation

which could result in death or serious

injury if you do not follow instructions.

Gives you helpful information.

Indicates a potentially hazardous situation

which if not avoided, may result in minor

injury or moderate injury.

Do not operate the product outside of the specifications.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not disassemble, modify (including change of printed

circuit board) or repair.

An injury or failure can result.

IMPORTANT MESSAGES

Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a

mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during

maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and

verify that the air is released before performing

maintenance.

Otherwise an injury can result.

After maintenance is complete, perform appropriate

functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

Provide grounding to assure the noise resistance of the

product.

Individual grounding should be provided close to the product with

a short cable.

Page 4

54

Safety Instructions (continued)

Note

•When conformity to UL is required, the SI unit should be used

with a UL1310 Class 2 power supply.

Follow the instructions given below when handling your product.

Or, it will have a risk of being damaged and operating failure.

•Operate product with the specified voltage.

•Reserve a space for maintenance.

•Do not remove labels.

•Do not drop, hit or apply excessive shock to the product.

•Follow the specified tightening torque.

•Never mount a product in a location that will be used as a

foothold.

•Do not bend or apply tensile force to cables, or apply force by

placing heavy load on them.

•Connect wires and cables correctly.

•Do not connect wires while the power is on.

•Do not lay wires or cables with power line or high-voltage line in

the same wiring route.

•Verify the insulation of wiring.

•Separate power line for solenoid valves from power line for

Input and control unit.

•Take appropriate measures against noise, such as using a

noise filter, when the product is incorporated into equipment.

•Select the proper type of protection according to the

environment of operation.

•Take sufficient shielding measures when installing at the

following place.

(1) A place where noise due to static electricity is generated

(2) A place where electric field strength is high

(3) A place where there is radioactive irradiation

(4) A place near power line

•Do not use the product near by a place where electric surges

are generated.

•When a surge-generating load such as a relay or solenoid is

driven directly, use an product with a built-in surge absorbing

element.

•The product is CE marked, but not immune to lightning strikes.

Take measures against lightning strikes in the system.

•Prevent foreign matter such as remnant of wires from entering

the product to avoid failure and malfunction.

•Mount the product in a place that is not exposed to vibration or

impact.

•Do not use the product in an environment that is exposed to

temperature cycle.

•Do not expose the product to direct sunlight.

•Keep the specified ambient temperature range.

•Do not expose the product to heat radiation from a heat source

located nearby.

•Set the switches by using a sharp-pointed screwdriver etc.

•Turn off the power supply, stop the supplied air, exhaust the

residual pressure and verify the release of air before performing

maintenance.

•Perform maintenance and check regularly.

•Perform a proper functional check.

•Do not use solvents such as benzene, thinner etc. to clean the

product.

Page 5

76

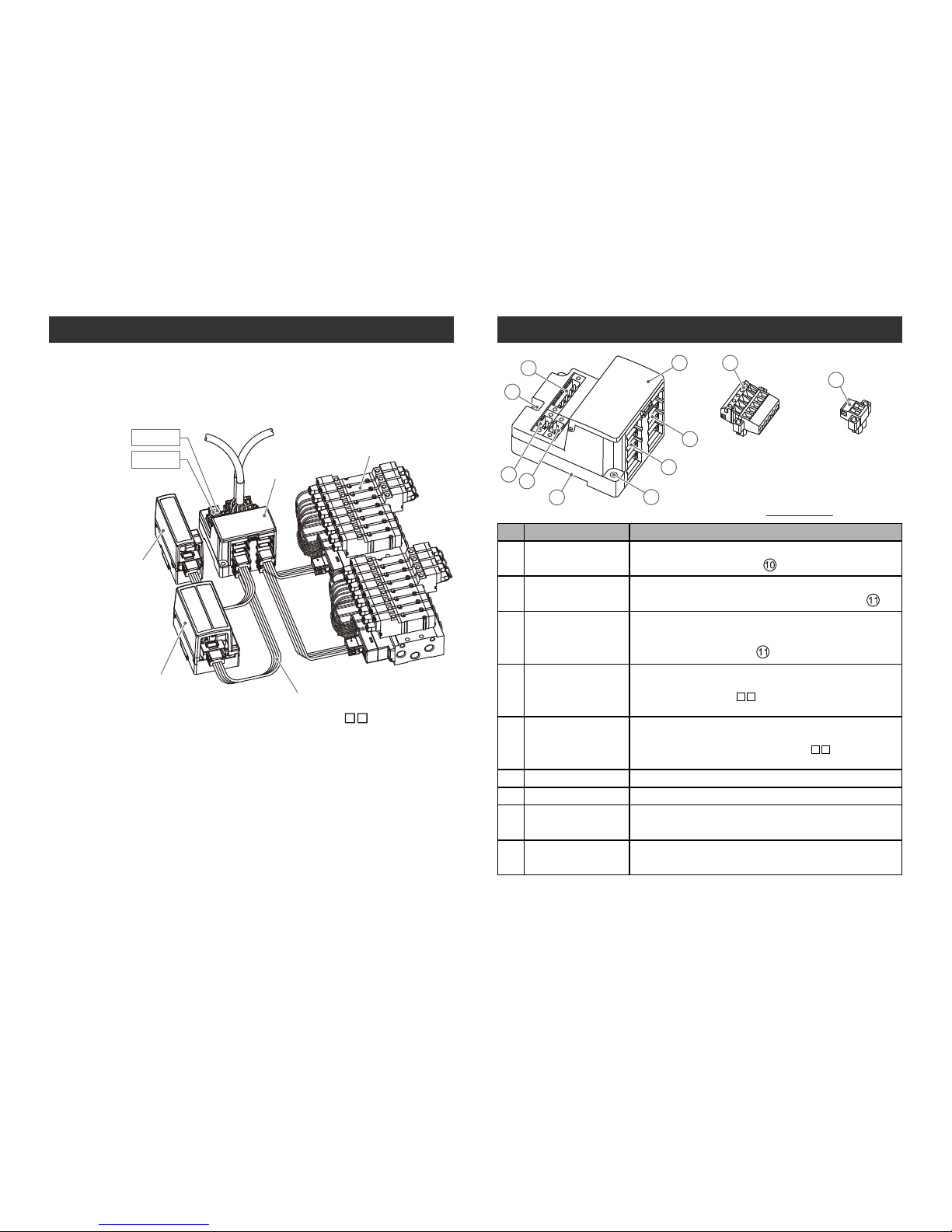

Product Summary

System structure

( )

( )

Power supply

for output

Power supply

for input and

controling GW

24 VDC

24 VDC

GW unit

Input unit

1 connector

2 inputs type

Input unit

1 connector

1 input type

connecting to

4 sets maximum

Branch cable

(EX510-FC )

Valve manifold

with SI unit

connecting to

4 sets maximum

Connecting to bus

at upper level

(CC-Link)

( )

( )

The system which realizes wiring saving and distributed

installation by connecting to CC-Link. The signal to CC-Link is

transmitted by GW unit, and the signal to input/output device

which is installed discretely is collected by GW unit.

Name of Parts/ Accessories

Communication

connector for

CC-Link

(1 piece)

Power supply

connector

(2 pieces)

Accessory

10

11

8

4

7

5

1

6

9

2

3

No. Parts Purpose

1

Communication

socket (BUS)

Connect to CC-Link line with an accessory

connector for CC-Link ( ). ∗

2

Power supply

socket (PWR(V))

Supplying power for output instruments such as a

solenoid valve with an accessory connector ( ). ∗

3

Power supply

socket (PWR)

Supplying power for controlling GW and for

input instruments such as a sensor with an

accessory connector

()

. ∗

4

GW unit side

branch connector

(for input)

Connecting an input unit etc. by using branch

cables (EX510-FC ).

5

GW unit side

branch connector

(for output)

Connecting SI unit (manifold valve) etc. by

using branch cables (EX510-FC ).

6 FG terminal Used for grounding

7 Mounting hole

Used when a unit is mounted with two M4 screws.

8

DIN rail mounting

slot

Used when a unit is mounted to DIN rail.

9

Display/ switch

setting part

Sets up the switch on such as LED display and

address, I/O points.

∗: For wiring method, refer to "Wring" in the "Operation Manual".

Page 6

98

Dimensions (in mm)

64

25.7

COM A

COM B

COM C

COM D

O

UTPUTINPUT

60 80

16

PWR

(

V)

P

WR

B

US

Settings

Perspective drawing

(tolerance 0.2)

16

PWR

(

V)

PWR

B

US

OUTPUT

INPUT

70 5

54 5

2 × M4

∗: Tightening torque

: 0.8 Nm

DIN rail

PWR

(V)

PWR

BUS

Mounted by screw

Mounted on DIN rail

Page 7

1110

Mounting Removal

Claw 1

Claw 2

DIN rail fixing plate

1

2

3

4

Put Claw 1 of the body under DIN rail and push it upward.

Push down Claw 2 to the opposite rail until the claw clicks

securely on to rail.

(Mounting procedure and )

For removing, lever up the DIN rail fixing plate of the body with a

flat blade screwdriver, and remove it by tilting Claw 2 side forward.

(Removal procedure and )

Settings (continued)

Specifications

Basic specifications

Compatible system

Number of station occupied

CC-Link Ver.1.10

3 stations (it is possible to change for 2 stations)

Station type Remote device station

Rated voltage

Power supply

voltage

24 VDC

Power supply for input and controlling GW: 24 VDC ±10%

Power supply for output: 24 VDC+10%/-5%

(Warning for voltage drop is given at approx. 20 V)

Rated current

Input/ output

point

Power supply for input and controlling GW: Max. 4.1 A

(Inside GW unit: 0.1 A, input unit: 4 A)

Current for output: Max. 6 A

Input point: Max. 64/ Output point: Max. 64

(Changeable by switch settings)

Operation

temp. range

-10 to 50 oC

Higher-level bus

Communication speed

156 kbps

20 cm and more

625 kbps 2.5 Mbps

Cable length between stations

1200 m

900 m 400 m

5 Mbps 10 Mbps

160 m 100 m

Maximum extended cable length

Lower level bus

Number of branches for

input/ output

4 branches for input

4 branches for output

Communication type

Communication protocol: Dedicated for SMC

Communication speed : 750 kbps

Current for input branch

Max. 1 A per branch

Current for output

branch

Max. 1.5 A per branch

Branch cable length

At 0.75 A per branch: 20 m or less

At 1.0 A per branch : 16 m or less

At 1.5 A per branch : 10 m or less

∗1: Input terminals are not isolated from Power source.

∗2: Do not connect outside Power source to Input and Output terminals.

Page 8

1312

Internal circuit

DC-DC

converter

(Insulation)

+24 V

0 V

COM D

INPUTOUTPUT

+24 V

RD+

RD0 V

+24 V

0 V

Power supply

for output

Power supply

for input and

controlling GW

+24 V

TD+

TD0 V

COM A

INPUTOUTPUT

+24 V

RD+

RD0 V

+24 V

TD+

TD0 V

(Brown)

DA

DB

DG

SLD

FG

FG

Wiring

Internal circuit

Insulating cap

Brown

Black

White

Blue

Cover Body Branch cable

Pin no. display

Branch wiring

The wiring between each unit should use branch cables, and be

connected with branch connectors.

SI unit and Input unit have 2 branch connectors for each.

Pressure welding for branch connector

The method of pressure welding for branch connector is

explained.

(1)Components

(2)Working procedure

Set a branch cable to the cover.

1) Set the brown wire of the branch

cable so that it comes to the pin #1.

2) Meet the cable end to the insulating

cap at the cover.

3) Fold the cover so that the branch

cable can be put between the cover.

4) Fix the latch tip by inserting to

a hole for fixing latch.

Note) Check the color of wire written on a

branch connector and the color of

branch cable are same.

Fix to a body tentatively.

Fit 4 latches on a body to 4 ditches on

the cover, and press them until the

latch engages to the level 1.

Pin #1: Brown wire

Hold for

fixing latch

Latch

Page 9

1514

Wiring (continued)

Wiring of branch cables

4 branches for input

4 branches for output

To SI unit

To Input unit

COM D

COM C

COM B

COM A

Branch connector

at cable side

Branch cable

Branch connector

at GW unit side

Insert branch connector on the table side from the bottom

(COM A, B, C, D of branch connector of GW unit side).

Press fitting

Press the cover to the body with plier etc.

Confirmation

It is completed with a check on 4 latches

engaging.

NOTE

1. Select a branch cable length suitable to avoid stress

being applied to the branch connector and cable,

and provide sufficient cable length for maintenance.

2. Do not pull the branch connector and branch cable

after wiring. There is a risk of damage.

3. Do not open and close the branch connector hook

repeatedly. There is a risk of damage.

4. Cut the branch cable and replace the branch

connector when the branch connector hook is broken

or no longer functions.

5. Use SMC branch connector

(product No.: EX510-LC1) and branch cable

(product No.: EX510-FC ). Usage of other branch

connector or cable is out of the applicable range of

product guarantee.

DA DB DG

SLD

FG

White Yellow

Yellow

Shield

White Shield

Blue

Blue

Drawing 1

E

X

5

1

0

4

3

2

1

Communication wiring

Connect CC-Link dedicated cables to the communication

connector for CC-Link.

(1) Make sure to connect the signal cables to designated pins

(Refer to Drawing 1).

And tighten the connector surely to 0.5 to 0.6 Nm tightening

torque.

Page 10

1716

Communication connector

for CC-Link

Drawing 4

Wiring (continued)

(4) Refer to Drawing 4 about how to connect to the unit.(2) Make sure to connect a "terminating resistor" to the units at

the both ends of the system (Refer to Drawing 2).

DA

Terminal

resister

Master unit

CC-Link

dedicated

cable

CC-Link

dedicated

cable

(Blue)

(White)

(Yellow)

DB

DG

SLD

FG

Terminal

resister

DA

Remote unit

DB

DG

SLD

FG

DA

Local unit

DB

DG

SLD

FG

Drawing 2

Connect the terminal resistor between "DA-DB"

(Refer to Drawing 3).

DA DB DG

SLD

FG

Yellow

White ShieldBlue

Terminating resistor

Drawing 3

(3) The terminal resistor to connecct differs depending on a

cable to use at CC-Link system. Refer to table below.

Cable type Terminal resistor

110 Ω 1/2 W

(brown, brown, brown)

CC-Link dedicated cable

CC-Link dedicated cable compatible to Ver.1.10

130 Ω 1/2 W

(brown, orange, brown)

CC-Link dedicated high performance cable

NOTE

1. CC-Link dedicated high performance cable cannot

be mixed with other cables (CC-Link dedicated

cable, CC-Link dedicated cable compatible with

Ver.1.10).

If mixed, normal transmission of data cannot be

assured.

2. Connect the shield line of CC-Link dedicated cable to

"SLD" of each unit.

Page 11

1918

Wiring (continued)

A. For dual power

supply use

B. For single power

supply use

24 VDC

24 VDC

24 VDC

Display/ Switch Setting

SW1

OFF

ON

OFF

ON

COM C COM DCOM A COM B

SW2

L RUN L ERRPWR(V) PWR

INPUT

Setting for Display

Display

Meaning

PWR

(V)

The power for output is supplied at specified voltage: Lights up

The power for output is not supplied at specified voltage: Goes off

PWR

The power for input and GW unit controlling part is supplied: Lights up

The power for input and GW unit controlling part is not supplied: Goes off

L RUN

Normally communication: Lights up

Communication interrupted: Goes off

L ERR

Communication error: Lights up

Setting of station number and of transmitting speed setting

switch is changed during powered: Lights up

(Blink with 0.4 s interval)

Normally communicating: Goes off

COM A

COM A is receiving data: Lights up ∗

COM A is having no data to receive: Goes off

COM B

COM B is receiving data: Lights up ∗

COM B is having no data to receive: Goes off

COM C

COM C is receiving data: Lights up ∗

COM C is having no data to receive: Goes off

COM D

COM D is receiving data: Lights up ∗

COM D is having no data to receive: Goes off

∗: It is lit when input unit is connected and communicating normally.

Power supply wiring

Connect power supply wiring to the two power supply 2-pin

connectors. Power supply structure consists of 2 systems, but it

can be used with both single power supply and separate power

supply.

Individual power supply for other units is not necessary.

Make sure of connection with the designated pin. Tighten the

connector securely to 0.5 to 0.6 Nm tightening torque.

Power supply connector

Power supply

for output

Power supply

for input and

controlling GW

Power supply connector

PWR

(V)

PWR

0V

24V

24V

0V

Note: A secure earth connection (Protection class 3) should be

performed for FG terminal.

(SLD, FG and FG terminal in communication connector for

CC-Link are connected inside of GW unit.)

Page 12

2120

Station number setting (Switch No.1 to 7)

Set tens digit of station number 10, 20 and 40, and set ones digit

of station number 1, 2, 4 and 8.

All setting are turned OFF at shipment and no station number is set.

Make sure to set the station number in the range of 1 to 62

(with 3 stations occupied).

10987654321

2148102040

ON

SW1

OFF

ON

Tens digit Ones digit Transmission speed

Switch setting

Make sure that switch setting is performed with power supply turned off.

Open the cover, and set DIP switch with a small flat blade

screwdriver, etc.

Display/ Switch Setting (continued)

Setting of address and communication speed (SW1)

Setting of address and communication speed are performed with

SW1.

Swtting of transmission speed (Switch No.8 to 10)

Make sure to set the transmission speed in the range as follows.

All setting are turned OFF at shipment, set to 156 kbps.

Transmission speed

156 kbps

625 kbps

2.5 Mbps

5 Mbps

No.8

OFF

OFF

OFF

OFF

No.9

OFF

OFF

ON

ON

No.10

OFF

ON

OFF

ON

10 Mbps

ON OFF OFF

40

(No.1)

1

Station

number

2

3

4

:

10

11

:

62

63

∗

∗: Station number 63 can be set for 2 stations occupied type.

20

(No.2)

10

(No.3)

8

(No.4)

Tens digit (Switch No.) Ones digit (Switch No.)

4

(No.5)

2

(No.6)

OFF

OFF

OFF OFF OFF

OFF

OFF OFF

OFF

OFF OFF ON

OFF OFF

OFF

OFF OFF ON

OFF

OFF

OFF

OFF ON

OFF

:

:

: : :

:

OFF

OFF

ON OFF OFF

OFF

OFF

OFF

ON OFF OFF

OFF

: :

:

: : :

ON

ON

OFF OFF OFF

ON

ON

ON

OFF

OFF OFF

ON

1

(No.7)

ON

OFF

ON

OFF

:

OFF

ON

:

OFF

ON

Setting of HOLD/CLR, number of stations occupied

and mode (SW2)

Setting of HOLD/CLR, number of stations occupied and mode

are performed with SW2.

654321

ON

SW2

OFF

ON

Unused

∗

Mode setting

Setting of the number

of stations occupied

HOLD/CLR setting

∗: Switch No.5 and No.6 are unused. (Turn them OFF.)

HOLD/CLR No.1

Function

CLR

OFF

HOLD

ON

Output is cleared when an error occurs.

Output is held when an error occurs.

HOLD/CLR setting (Switch No.1)

The setting is as follows.

The setting at shipment is turned OFF, set to CLR.

Page 13

2322

Display/ Switch Setting (continued)

Troubleshooting

Overall system

1

2

3

Remedy/ Disposal

•Check the power for output (24 VDC) is supplied.

•Check the branch cable is connected to SI unit.

•Check the LED for power supply (PWR) and the

LED for communication (COM) at SI unit are ON.

•Ensure output branch current does not exceed the

specification range.

•Program it after checking the wiring specification

of manifold block assembly.

•Check the power for input and controlling GW

(24 VDC) is supplied.

•Check the input unit indication LED is ON.

•Ensure input branch current does not exceed the

specification range.

•Check the connection of UNLIT COM port branch

to input unit.

4

COM A-D is

not LIT

Signals

cannot be

received

even with a

sensor

Solenoid

valve is not

working

Valve is not

working as

program

directs

No. Item

Station setting

No.2

The max. available number

of I/O point

2 station-occupied

OFF

3 station-occupied

ON

No.3

ON

OFF

Input 32/ Output 32

Input 64/ Output 64

Setting of the number of stations occupied

(Switch No.2 to 3)

The setting of the number of stations occupied is performed with

switch No.2 to 3.

3 stations are occupied at shipment.

Mode

No.4

Number of branch

A OFF

B

ON

16 points per port

8 points per port

Valid port

COM A and B

COM A to D

Mode setting (Switch No.4)

Mode setting of each port is available only when 2 stations are

occupied.

No.4 is used for mode setting.

The default setting is mode A.

Page 14

2524

CC-Link compatible communication

No.

1

2

3

Item

PWR LED is

goes off

PWR(V) LED is

goes off

RUN LED is

goes off/

ERR LED is

lights up

Remedy/ Disposal

•Check the power supply for input and controlling

GW (24 VDC) is supplied.

•Check the power for output (24 VDC) is supplied.

•Check the power supply voltage for output is

getting as low as under 20 V.

•Check the signal line from PLC is correctly

connected.

•Check the wiring and pin numbers.

•Check the address setting is correct.

Troubleshooting (continued)

4

ERR LED is

flushing

•Check the communication speed setting/ station

number setting is changed halfway.

∗: Refer to "Operation Manual" for detail of troubleshooting.

<MEMO>

Loading...

Loading...