SMC Networks EX500 Series,EX500-GMJ1 Instruction Manual

Reduced wiring system

EX500

-

GMJ1

Instruction Manual

CC-Link Comp

atible GW Unit

UR

L

http://www.smcworld.com

EX##-OMI0026

Thank you for purchasing the SMC reduced wiring system EX500 series.

Please read this instruction manual carefully and understand the contents before

use so that you can operate this unit safely and correctly.

Please keep this manual handy for future reference.

SAFETY

..........................................................................................................2

Product Summary

............................................................................................5

EX500

Part Names

...................................................................................................6

Dimensions

...................................................................................................7

Installation

.....................................................................................................7

Specification..................................................................................................8

Wiring

............................................................................................................9

Display/Switch setting

.................................................................................18

SI Unit

Part Names

.................................................................................................21

Dimensions

.................................................................................................22

Mounting/Wiring..........................................................................................23

Specification................................................................................................24

Display ........................................................................................................25

Input Unit Manifold

Part Names

.................................................................................................

26

Dimensions

.................................................................................................

27

Installation

...................................................................................................

28

Specification

................................................................................................

29

Wiring

..........................................................................................................

30

Display

........................................................................................................

31

EX9 Series General Purpose Output Block

Part Names

.................................................................................................

32

Dimensions .................................................................................................33

Mounting .....................................................................................................34

Wiring ..........................................................................................................35

Specification................................................................................................37

Display .......................................................................................................38

Option ............................................................................................................39

Troubleshooting.............................................................................................40

Appendix Table

.............................................................................................41

OPERA

TOR

This instruction manual has been written for those who have knowledge of

machines and equipments that use reduced wiring system as well as the

suf

ficient knowledge to assemble, operate, and maintain such devices.

Before performing assembly, operation and/or maintenance, please read

this manual carefully and underst

and the contents.

Content

s

SAFETY

The body of unit and this manual contain the essential information for the protection of

users and others from possible injury and property damage and to ensure correct

handling.

Please check that you fully understand the definitions of the following messages

( symbols ) before going on to read the body of this manual, and always follow the

instructions.

Please also read the instruction manuals etc. of related machines and equipments and

understand the contents before use.

Before performing maintenance:

Turn off power supply.

Stop air supply, exhaust compressed air in piping, and confirm the release to

atmosphere.

Otherwise injury can result.

IMPOR

Read this manual and follow its instructions. Signal words such as WARNING,

CAUTION and NOTE will be followed by important safety information that must be

carefully reviewed.

Indicates a potentially hazardous situation that could result in

death or severe injury if you do not follow instructions.

Indicates a potentially hazardous situation that, if not avoided,

may result in minor injury or moderate injury.

NOTE

Gives you helpful information.

TANT MESSAGES

Do not disassemble,

modify ( including modification of printed circuit board ) or repair.

Otherwise injury or failure can result.

Do not operate beyond specification range.

Otherwise fire, malfunction or damage to the reduced wiring system can result.

Confirm the specifications before operation.

Do not operate in atmosphere of flammable/explosive/corrosive gas.

Otherwise fire, explosion or corrosion can result.

This reduced wiring system is not explosion-proof type.

For use in interlock circuit:

Provide double interlock system by adding different type of protection

( such as mechanical protection ).

Check that the interlock circuit is working normally.

Otherwise accident caused by malfunction can result.

Conduct proper functional inspection after completing maintenance.

In the case of abnormality such as unit does not work normally, stop the operation.

Otherwise safety cannot be assured due to unintended malfunction.

Provide grounding to improve safety and noise resistance of reduced wiring sys

tem.

Provide grounding as close to the unit as possible to shorten distance for grounding.

Avoid mixing of CC-Link dedicated high-performance cable and other cables (

CC-Link dedicated cable and/or Version 1.10 compatible CC-Link dedicated

cable ).

Mixing can hinder normal data transmission and cause trouble.

Handling precautions

Use the following UL-recognized DC power supply to combine with.

1. UL508-compatible limited voltage/current circuit

A circuit using the secondary coil of an insulating transformer that meets following conditions as power source.

Maximum voltage ( at no load ): 30Vrms ( 42.4Vpeak ) or below

Maximum current:

UL1310-compatible Class 2 power supply unit or circuit of max. 30Vrms ( 42.4Vpeak ) or

2.

less using a UL1585-compatible Class 2 transformer as power source. ( Class 2 circuit )

( 1 ) 8A or less ( including when short-circuited )

When limited by the circuit protector ( such as fuse )

( 2 )

having the following rating.

No-Load Voltage ( Vpeak ) Max. Current Rating ( A )

0 to 20 [V]

Above 20 [V] to 30 [V] 100/peak voltage

5.0

-

2 3

4 5

SAFETY

( continued )

Follow the instructions given below when handling your reduced wiring system.

Otherwise a damage or failure to cause a malfunction can result.

Operate the reduced wiring system at the specified voltage.

Reserve space for maintenance.

Do not remove any name plate or label.

Do not drop, hit or apply an excessive shock to the unit.

Follow the specified tightening torque.

Do not apply any excessive force to cables by repeated bending, tensioning or placing a

heavy object on the cables.

Connect wires and cables correctly.

Do not perform any wiring work while the power is on.

Do not use the reduced wiring system on the same wiring route as the power line or high

voltage line.

Confirm the insulation of wiring.

Perform the power supply wiring by dividing into two lines

---- one is for power supply for output and the other is for power supply for input and controlling GW/SI.

Take sufficient measures against noise such as noise filter when incorporating the reduced

wiring system into a machine or equipment.

Connect the shield wire of the dedicated cable for CC-Link to "SLD" of each unit.

Mount a terminal plug or a waterproof cap on each unused M12 connector for input/output

( communication connector, communication ports A - D, and power supply for input and

controlling GW/SI ).

Take sufficient shielding measures when operating the product in any of the following places.

( 1 ) A place where noise due to static electricity etc. is generated

( 2 ) A place of high electric field strength

( 3 ) A place where exposure to radioactivity is possible

( 4 ) A place near power cable

Do not operate the product in a place where there is a source of surge.

Use a surge absorbing element built-in type to directly drive the load that generates surge

voltage such as solenoid valve.

Prevent any foreign matter such as remnant of wires from getting inside the product when

opening the station number switch protective cover.

Install the reduced wiring system in a place free from vibration and impact.

Operate the product in the specified ambient temperature range.

Do not use in a place to be affected by the radiant heat from a surrounding heat source.

Set the DIP switch and rotary switche by using a sharp-pointed watchmakers screwdriver

etc.

Perform the maintenance regularly.

Conduct an appropriate functional inspection after completing the maintenance.

Do not use chemicals such as benzin and thinner to clean the product.

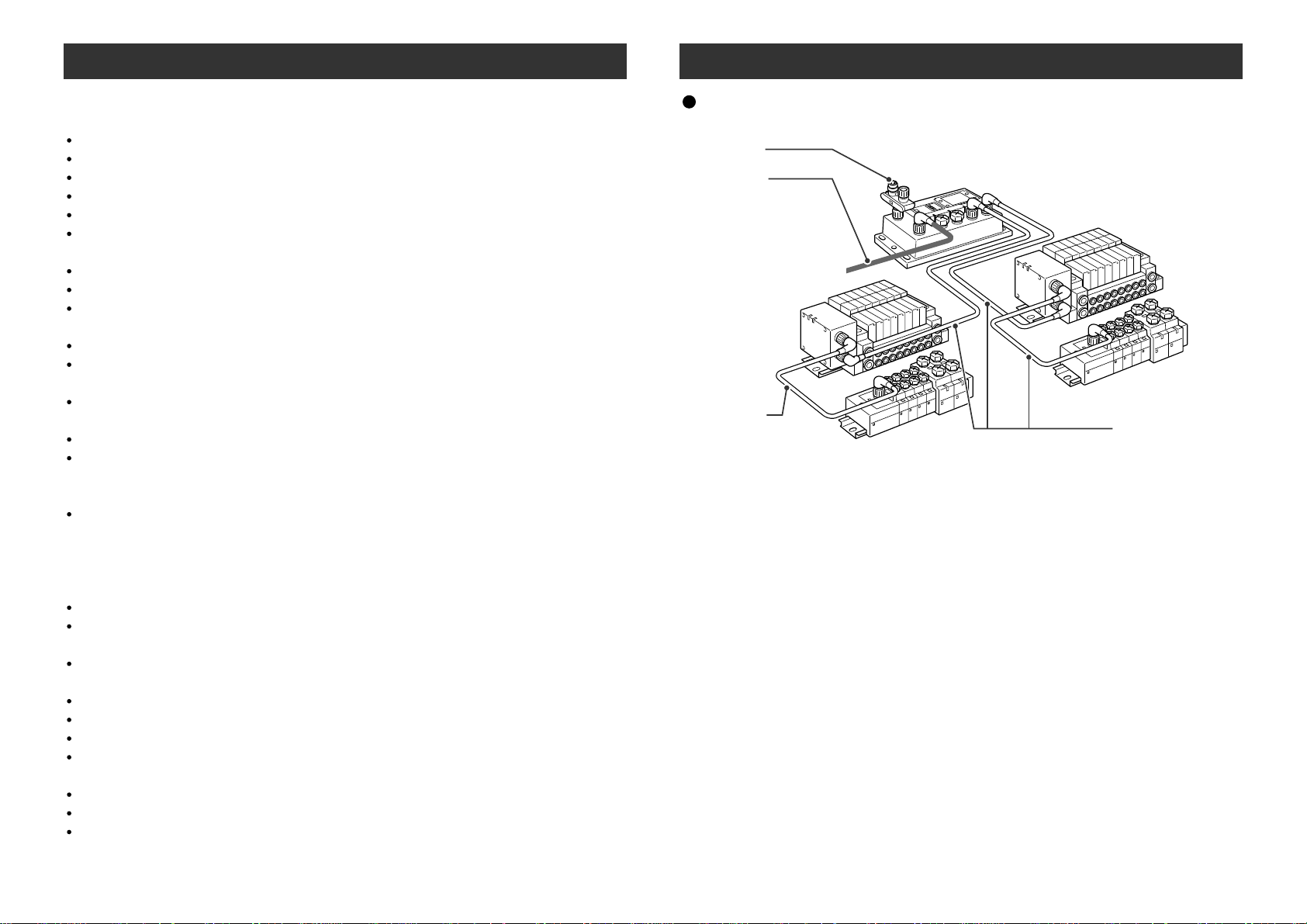

Product Summary

System configuration

GW unit

Manifold valve

with SI unit

( SV/VQC series )

Input unit

manifold

BUS adapter

Power supply

connector cable

( DC24V for solenoid

valves/output, DC24V for

input and controlling GW/SI )

Branch cable

with M12 connector

Branch cable

with M12 connector

Input unit manifold

Manifold valve

with SI unit

( SV/VQC series )

The reduced wiring system is connected to various kinds of fieldbus and realizes the

reduced wiring and decentralized installation of I/O devices . The signals to/from

fieldbus are exchanged by GW unit, and the signals to/from decentralized I/O devices

are collected and delivered by GW unit.

The maximum number of connections of manifold valve/Input unit manifold is

16/branch x 4 branches = 64 points each for output and input.

As the cables with connectors are used for all wiring between devices, the system

complies with the IP65 environment.

EX500 Part Names

Accessory

Communication

connector

1

2

3

4

5

6

7

8

Note1: For wiring method, refer to subsection "Wiring" ( page 9 ) of section "EX500" in this

manual.

Note2: For display and setting method, refer to subsection "Display/Switch Setting" ( page 18 )

of section "EX500" in this manual.

Power supply connector

Communication port A

( COM A )

Communication port B

( COM B )

Communication port C

( COM C )

Communication port D

( COM D )

Display

Connect with CC-Link line by using the accessory

bus adapter . ( Note1 )

Name

No.

Application

Supply power for output devices such as solenoid

valve, for input devices such as sensor, and for

controlling GW/SI by using power supply connector

cable. ( Note1 )

Display the power supply status and communication

status with PLC. ( Note2 )

Station number switch

protective cover

Set station numbers and transmission speed by

using the switches under this cover. ( Note2 )

Connect SI unit ( manifold valve ) or Input unit by

using branch cable with M12 connectors. ( Note1 )

Dimensions ( unit: mm )

88

160

136

48.8

46

10

L

L

93.5 or less

EX500 body

unit side

OUT

IN

36.5

45

18.5

Cutout Dimensions for Mounting (Tolerance : 0.2)

148

68 5

4 M5

*

Tightening torque :

(1.5 0.2 ) Nm

Bus adapter ( accessory )

Inst

allation ( unit: mm )

Thread mounting

Secure at four positions with screws with head diameter of 5.2 or more and thread

length of 15mm or more.

6 7

8 9

Specification

Basic specifications

Rated voltage DC24V

Range of power

supply voltage

Power supply for input and controlling GW/SI: DC24V

10%

Power supply for output: DC24V+10%/-5% ( Voltage drop

warning at around 20V )

Rated current Power supply for input and controlling GW/SI: 3.0A

Inside GW unit: 0.2A

Input device and SI control section: 2.8A

Power supply for solenoid valves and output: 3A

Number of input/

output points

Input point: max. 64/Output point: max 64

Higher-level bus

Compatible system

CC-Link Ver.1.10 ( Note )

Lower-level bus

Number of branches for

input/output

4 branches ( 16 points/branch ) for input

4 branches ( 16 points/branch ) for output

Communication method Protocol: Dedicated for SMC

Speed:

750kbps

Branch current for input

( Note )

Max. 0.5 [A] per branch ( when SI unit and input

devices are connected )

Branch current for output Max. 0.65 [A] per branch

( when SI unit EX500-S 01 is connected )

Max. 0.75 [A] per branch

( when SI unit EX500-Q

is connected )

Branch cable length 5m or less per branch

( total extended length: 10m or less )

Number of stations occupied

Station type

3 stations

Remote device station

Transmission speed

156kbps

625kbps

2.5Mbps 5Mbps 10Mbps

Cable length between stations

Maximum extended cable length

20cm or more

1200m 900m 400m 160m 100m

Note:

The data shown above are those when all devices, cables, etc. are Ver. 1.10- compati

-

ble. For other connection and details, please contact CC-Link Partner Association.

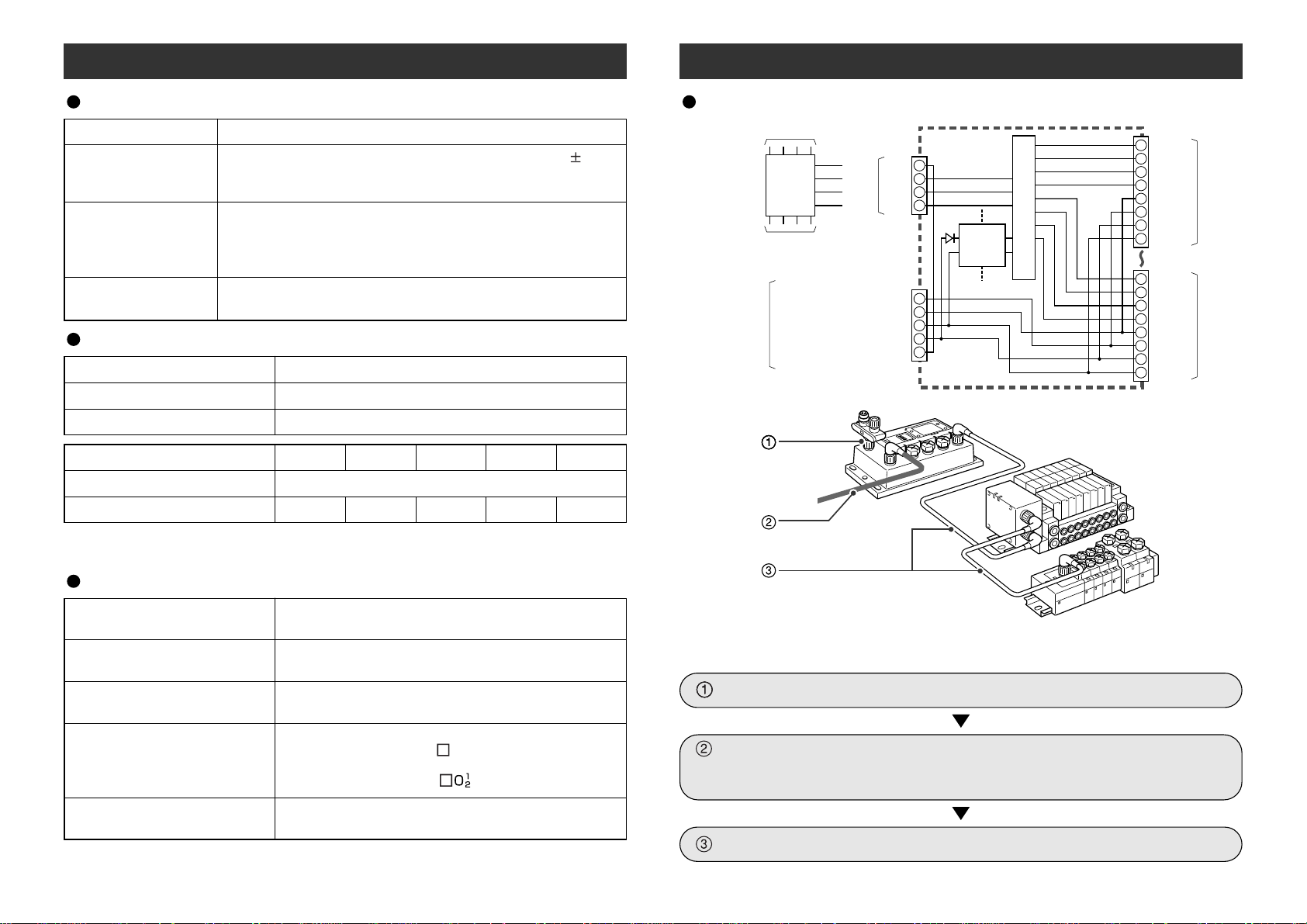

Wiring

The wirings are described in the following order.

Communication wiring: Connection with CC-Link line

Power supply wiring:

Connections of power supplies for solenoid

valves/output devices, and for input

devices and controlling GW/SI

1

IN

Bus

adapter

OUT

SLD

2

DB

3

DG

4

DA

DC-DC

converter

(insulation)

1

0V

2

+24V

3

0V

4

+24V

5

PE

Power supply

connector

Power supply

for output

Power supply

for input and

controlling GW/SI

1

RD+

2

RD -

3

TD+

4

TD -

5

+24V

6

0V

7

+24V

8

0V

COM A

1

RD+

2

RD -

3

TD+

4

TD -

5

+24V

6

0V

7

+24V

8

0V

COM D

Communication

connector

Internal circuit

Internal circuit

(

)

Note:

Total value of maximum current consumption and maximum load current of input devices

to connect.

Branch wiring: Connection from GW unit to SI unit or Input unit

iring ( continued )

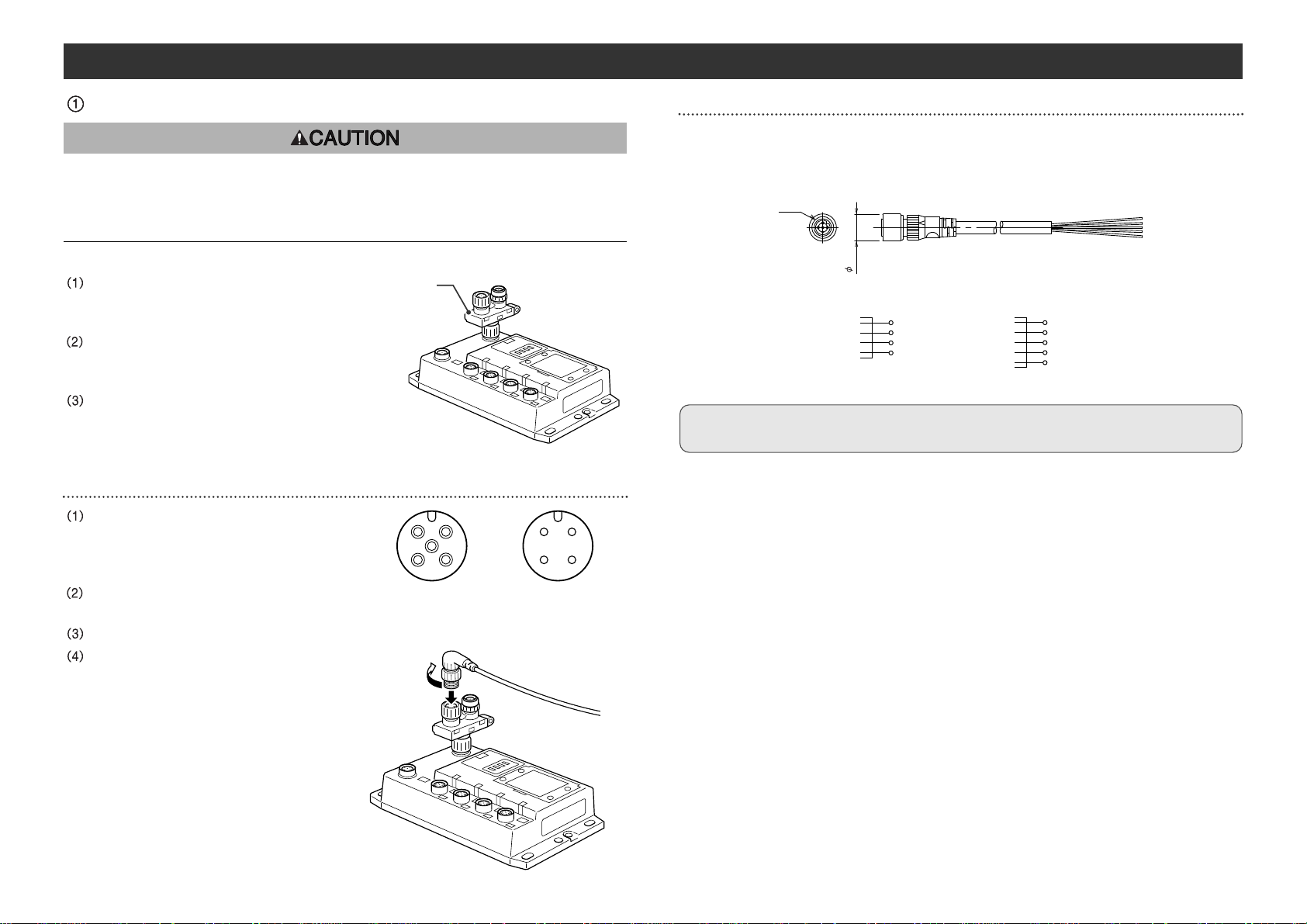

Align with key groove, plug the

bus adapter into the communication

connector.

Tighten the lock nut by turning it

clockwise by hand, and confirm that the

connector does not move.

Connect the cables with CC-Link communication

connectors to the mating CC-Link communication

connectors ( bus adapter ) as shown below.

Cable connection

Align the key groove with the IN

connector ( plug ) of the bus adapter of

GW unit, fit on the CC-Link communication

cable ( socket ).

Tighten the lock nut on cable side by

turning it clockwise by hand.

Confirm that the connector portion does not move.

Similar to the above, connect the other

communication cable ( plug ) to the

OUT connector of the bus adapter.

If this EX500 is the terminal of CC-Link

connection, connect the terminal resistor.

Refer to "Connection of terminal resistor"

( page 12 ) in this manual.

Avoid the mixing of CC-Link dedicated high-performance cable and other cables

( CC-Link dedicated cable and/or Version 1.10 compatible CC-Link dedicated

cable ).

The mixing can hinder the normal data transmission and cause a problem.

Pin layout and connection diagram of cable with CC-Link communication connectors

Connect the communication cable with socket-type M12 connector on IN side and plugtype M12 connector on OUT side.

For cable to be used, refer to "Appendix Table" ( page 41 ) in this manual.

IN side

SLD

DB

DG

DA

1

2

3

4

Shield

White

Yellow

Blue

Connection Diagram

OUT side

Connection Diagram

SLD

DB

DG

DA

NC

1

2

3

4

5

Shield

White

Yellow

Blue

NC

M12

14.9

NOTE

Connect the shield wire of CC-Link dedicated cable to "SLD" of each unit.

1 2

4 3

OUT

2 1

3 4

IN

5

Bus adapter

W

Communication wiring

10 11

Loading...

Loading...