Page 1

TECHNICAL INSTRUCTION MANUAL

For EX500 SERIAL SYSTEM

Gateway ( GW ) Unit

Rockwell Automation Remote I/O ( RIO ) : EX500 - GAB1 - X1

DeviceNet : EX500 - GDN1

PROFIBUS-DP : EX500 - GPR1

NO. EX## - OME0008

Input Unit Manifold

Input Manifold : EEX500 - IB1 - □□ ( -X1 )

Input Unit : EX500 - IB1 ( -X1 )

M8 Input Block ( PNP ) : EX500 - IE1 ( -X1 )

M8 Input Block ( NPN ) : EX500 - IE2 ( -X1 )

M12 Input Block ( PNP ) : EX500 - IE3 ( -X1 )

M12 Input Block ( NPN ) : EX500 - IE4 ( -X1 )

8 point unit Input Block ( PNP, M8 ) : EX500 - IE5 ( -X1 )

8 point unit Input Block ( NPN, M8 ) : EX500 - IE6 ( -X1 )

SI Unit

SV series : EX500 - S001 ( -X1 )

VQC series ( NPN output ( + COM. )) : EX500 - Q001 ( -X1 )

VQC series ( PNP output ( - COM. )) : EX500 - Q101 ( -X1 )

SMC CORPORATION

Page 2

EX500 Serial System EX## - OME0008

●●●● Safety Instructions ●

( Read carefully before handling. )

Thoroughly read this handling manual and related manuals mentioned here to ensure the safety and proper

operation of the product.

These safety instructions are intended to prevent hazardous situations and / or equipment damage. These

instructions indicate the level of potential hazard by labeling “ CAUTION “ or “ WARNING“ .

・

・Level of potential hazard

・ ・

●

● ●

! CAUTION : Operator error could result in injury or equipment damage.

! WARNING : Operator error could result in serious injury or loss of life .

・・・・Safety instructions for pneumatic equipment

!!!! WARNING

1. The compatibility of pneumatic equipment is the responsibility of the person who designs the

pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility with the

specific pneumatic system must be based on specifications, or post analysis, and / or tests to meet your

specific requirements.

2. Only trained personnel should operate pneumatically operated machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed by trained and experienced

operators.

3. Do not service machinery / equipment or attempt to remove components until safety is confirmed.

1.Inspection and maintenance of machinery / equipment should only be performed after confirmation of safe

locked-out control positions.

2. When equipment is to be removed, confirm the safety process as mentioned above.

Cut the supply pressure for the equipment and exhaust all residual compressed air in the system.

3. Before machinery / equipment is re-started, take measures to prevent quick extensions of the cylinder

piston rod etc. ( Bleed air into the system gradually to create back-pressure. )

4. Contact SMC if the product is to be used in any of the following conditions:

1. Conditions and environments beyond the given specifications, or if product is used outdoors.

2. Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles, medical

equipment, food and beverage, recreation equipment, emergency stop circuits, press applications,

or safety equipment.

3. An application which has the possibility of having negative effects on people, property, or animals,

requires special safety analysis.

・・・・Safety instructions for electric equipment

!!!! WARNING

1. The product specified here is designed to be used in ordinary factory automation equipment.

Prevent the use in machinery and / or equipment where human life may be directly injured and malfunction

or failure may cause enormous loss.

2. Do not use in the explosive atmosphere, the atmosphere of flammable gas, the corrosive atmosphere.

In these atmospheres, it may cause injury or fire.

3. Only The person who has professional knowledge should implement work of the carriage, the establishment,

the piping, the wiring, the operation, the handling, the maintenance, the check.

If not, it will cause in being shocked, the injury, the fire and so on.

4. Install a direct stop circuit outside that to stop operation immediately and then to shut the power supply.

5. Do not disassemble the product for modifications.

It may injure the person or damage the property.

6. Do not wipe this product with any chemical solvent.

- 1 -

Page 3

EX500 Serial System EX## - OME0008

!!!! CAUTION

1. Read this manual thoroughly, and operate this product within the range of the specification after observing

notes strictly.

2. Do not drop nor apply force to the product.

It may damage the unit, and may cause failure or malfunction.

3. Take appropriate measures to ensure that the specified power is supplied regardless of the condition of

power supply.

Use within specified voltage range. To use outside of specified voltage will cause malfunction, damage

to unit, electric shock, and fire.

4. Do not touch the terminal or internal circuit board while they are energized. It may cause malfunction,

damage to unit, and electric shock.

Turn the power supply OFF when increasing / decreasing the number of Input Block or the Manifold Valve,

and disconnecting the power supply.

5. Use within operating ambient temperature. Do not use where temperatures can rapidly change even though

it is within the specifications.

6. Foreign objects should be prevented from entering the product. Contamination by foreign objects, such as

wire chips will cause fire, breakage, and malfunction.

7. Use within the operating environment of the protection structure.

IP65 is achieved by proper mounting of Input Unit / Input Block and Manifold Valve with SI Unit and

by processing properly a cable with the M12 connector which is wiring each unit, and a cable which is wiring

for power supply, and a connector which is setting for communication, and by processing properly with

the water - proof cap when there is an unused port.

Take measures such as the covers to be used in the environment in which water splashes always.

8. Operate within the specified tightening torque.

It will be possible to damage the screw when the screw is tightening exceeds the range of the tightening

torque.

9. Take appropriate and sufficient countermeasures when installing systems in the following locations.

・ Locations subject to static electricity or other forms of noise.

・ Locations subject to strong electromagnetic fields.

・ Locations subject to possible exposure to radioactivities.

・ Locations close to power supplies.

10. Take appropriate measures to noise such as the noise filter and so on, when installing this product

in equipment.

11. This product is a component, which is installed in the final equipment and used.

Please confirm the adaptability of EMC instruction when being installed in equipment by the customer.

12. Do not detach the nameplate.

13. Carry out periodical checks to confirm correct operation.

Safety may not be maintained by unintentional malfunction or incorrect operation.

・・・・Safety instructions for cables

!!!! CAUTION

1. Pay attention to wrong wiring.

It will cause malfunction, fire and damage to the unit.

2. Do not wire the power line with the high-voltage wire to prevent the signal line from the noise serge.

It will cause the malfunction.

3. Confirm the non-conductivity of wiring. It will cause the unit to be damaged by the excessive electric

current flowing and voltage's being impressed, when there is an insufficient insulation resistance.

4. Do not bend cable repeatedly, or pull the cable, or put a heavy object on the cable.

- 2 -

Page 4

EX500 Serial System EX## - OME0008

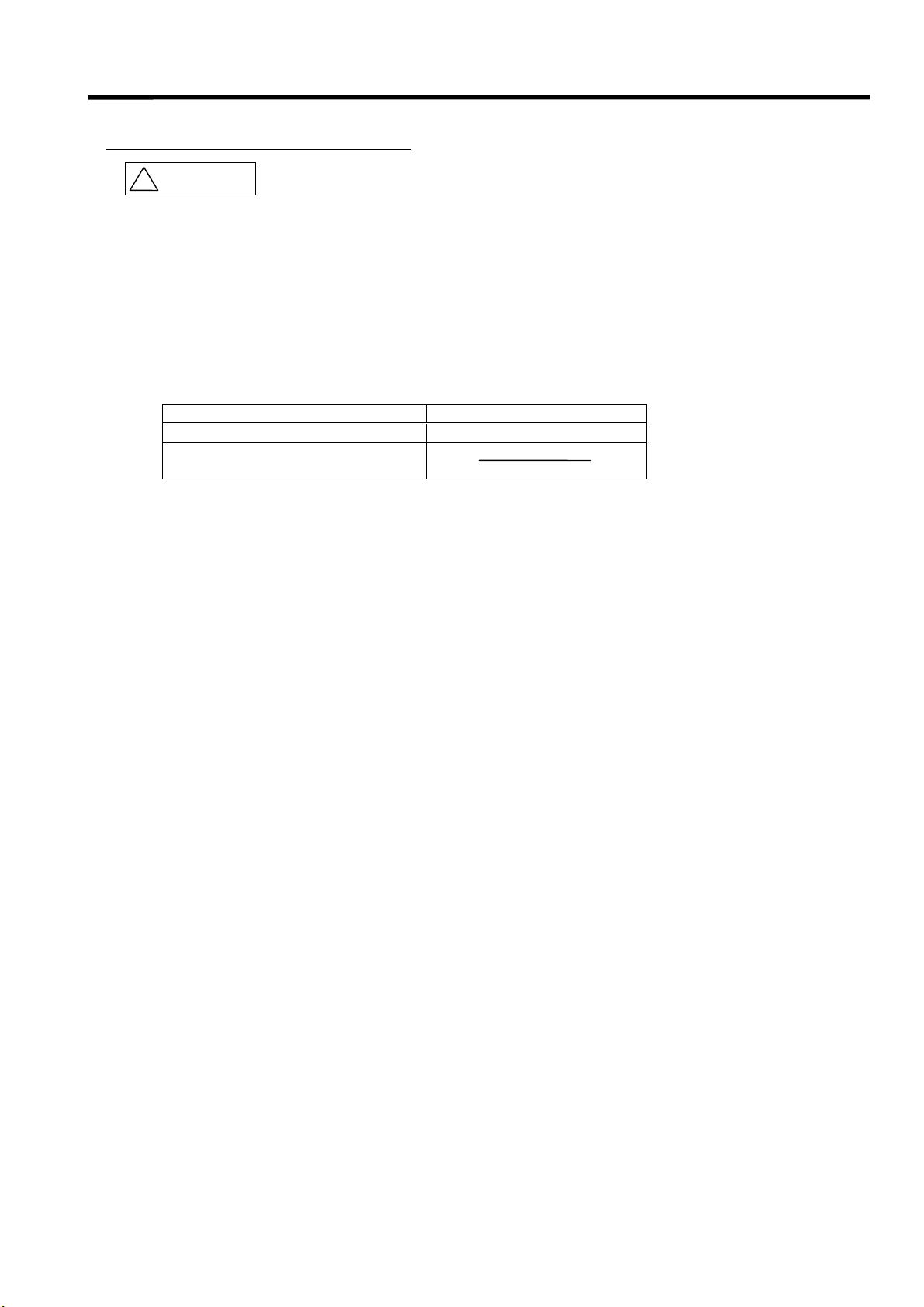

・・・・Safety instructions for power supply

!!!! CAUTION

1. Whether you use a single power supply or a dual power supply, two power lines have to be supplied

at all times ( for solenoid valve and for input and control ).

2. Choose UL recognized product for direct current power source to be mounted.

( 1 ) Limited voltage / current circuit complying with UL508

The power supply circuit made with the secondary winding of an isolating type transformer which satisfies

the following condition.

・ Max. voltage ( No load applied ) : 30Vrms ( 42.4V peak ) or less, and

・ Max. current : 8A or less ( Including a short circuit ), and restricted by the circuit protective device or

a fuse with rating in the table below

Open circuit volts ( V peak ) Amperes

0 to 20 [ V ] 5.0

Over 20 [ V ] to 30 [ V ]

* “ V ” is defined as the peak open circuit voltage.

( 2 ) Max. 30Vrms ( 42.4V peak ) or less circuit ( Class 2 circuit ) which is supplied by an isolating source

that complies with the requirements in the Standard for Class 2 Power Units, UL1310 or for Class 2

Transformers, UL1585.

100

V *

- 3 -

Page 5

EX500 Serial System EX## - OME0008

- INDEX -

1. Outline 6

2. System Structure 6

3. Specification and Product numbers 7

3 -1 General specification of EX500 series 7

3 -2 Gateway ( GW ) Unit 8

3 -3 Input Unit Manifold 11

3 -3 -1 Input Manifold 11

3 -3 -2 Input Unit 11

3 -3 -3 Input Block 12

3 -4 SI Unit 13

3 -5 Applicable Manifold Valve series 13

3 -6 Option 14

3 -6 -1 Communication Connector / Cable 14

3 -6 -2 Branch Cable with M12 Connector 15

3 -6 -3 Power Supply Connector Cable 16

3 -6 -4 Terminal Plug 16

3 -6 -5 Water Proof Cap 16

4. How to operate EX500 - GAB1 - X1 ( Rockwell Automation Remote I/O ( RIO)) 17

4 -1 Applicable PLC 17

4 -2 Parts description 17

4 -3 LED display 18

4 -4 Operation setting 18

4 -4 -1 Operation setting switch ( SW1 ) 19

4 -4 -2 Operation setting switch ( SW2 ) 19

4 -4 -3 Terminating resistance setting switch ( SW3 ) 20

4 -5 Layout of scanner I/O 20

5. How to operate EX500 - GDN1 ( DeviceNet ) 21

5 -1 Connection style 21

5 -2 Parts description 22

5 -3 LED display 23

5 -4 Operation setting 23

5 -4 -1 Address setting switch ( SW1, 2 ) 24

5 -4 -2 Data rate setting switch ( SW3 ) 24

5 -5 I/O memory map 24

6. How to operate EX500 - GPR1 ( PROFIBUS - DP ) 25

6 -1 Communication wiring 25

6 -2 Parts description 25

6 -3 LED display 26

6 -4 Operation setting 26

6 -4 -1 Address setting switch ( SW1, 2, 3 ) 27

6 -4 -2 Terminating resistance setting switch ( SW4 ) 27

6 -5 I/O memory map 27

- 4 -

Page 6

EX500 Serial System EX## - OME0008

7. Input Unit Manifold 29

7 -1 Parts description 29

7 -2 Correspondence of input number and Input Block 29

7 -3 Exploded view / Input Unit Manifold 30

8. Manifold Valve 31

8 -1 Parts description 31

8 -2 Correspondence of output number and Manifold Valve 32

8 -3 How to install the SI Unit 33

9. Wiring 34

9 -1 Source wiring 34

9 -2 Communication wiring 35

9 -2 -1 Communication wiring to PLC 35

9 -2 -2 Communication wiring to the SI Unit and the Input Unit 35

10. Dimension 36

10 -1 Gateway ( GW ) Unit 36

10 -2 Input Unit Manifold 36

10 -3 Manifold Valve 37

11. Trouble shooting 38

- 5 -

Page 7

EX500 Serial System EX## - OME0008

(

)

1. Outline

A. Gateway ( GW ) Unit

( 1 ) The Gateway ( GW ) Unit can be connected with a PLC.

At present, Gateway ( GW ) Unit with the following communication protocols are available:

・ Remote I/O ( RIO ) System slaves to Rockwell Automation PLC and SLC series unit.

・ DeviceNet

・ PROFIBUS-DP

( 2 ) The Gateway ( GW ) Unit can be connected with Manifold Valve / Relay Output Module with the SI Unit,

and Input Unit / Input Block can be controlled in a decentralized fashion.

It is not necessary to supply power to I/O unit individually because power supply line is built in the

communication port.

( 3 ) Transmission delay time problem will not occur because the communication with each branch is running

by separate asynchronized transmission form from upper transmission form.

( 4 ) 16 input points per input manifold and 16 output points per output manifold can be controlled in a

decentralized fashion per one branch ( 1CH ) of GW Unit. GW Unit communication ports and in / output

can control 128 decentralized I/O points.

!!!! CAUTION

Maximum number of I/O points depends on the communication protocol and the host PLC.

B. Input / Output Unit

( 1 ) Input Unit Manifold ( Input Unit / Input Block )

The Input Block can be increased or decreased by two points. A maximum of 8 blocks can be used on a

single input manifold.

( 2 ) Output Manifold Valve / Relay Output Module with the SI Unit ( SV series , VQC series )

The SV series and the VQC series Manifold Valve can be used with the EX500 series SI Unit.

The number of Solenoid Valve and Relay Output Module can be increased / decreased by the block alone.

A maximum of 8 Double Solenoid Valve and / or 2 point Relay Output Module can be connected.

And a maximum of 16 Single Solenoid Valve and / or 1 point Relay Output Module can be connected with

each channel.

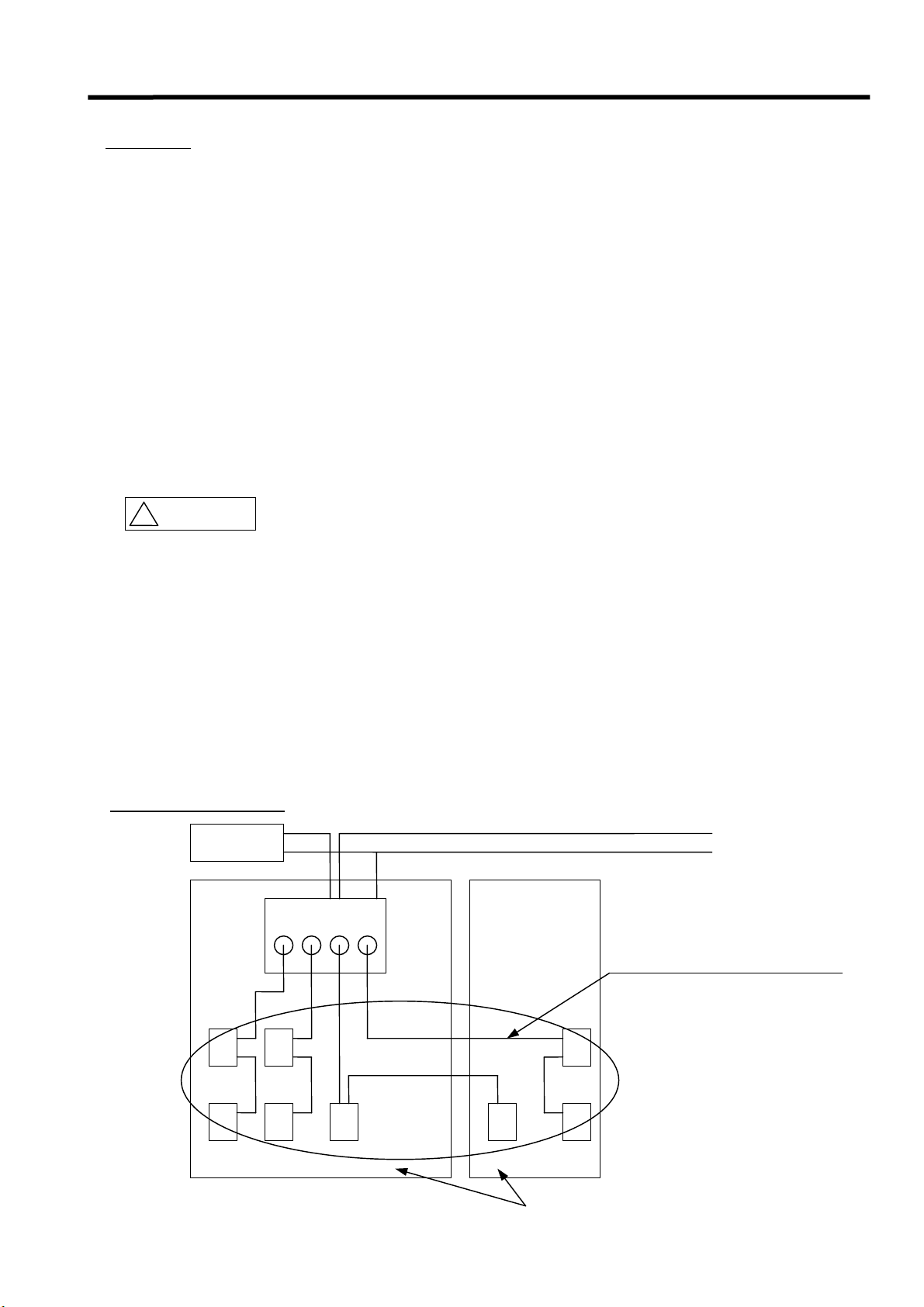

2. System Structure

Host

Remote I/O, DeviceNet, PROFIBUS-DP

Power source

Gateway (GW) Unit

24V DC

Communication line

+ Power supply line

A

B

A

B

A B

5m

A

5m

B

Tool

- 6 -

A : Manifold Valve / Relay Output

Module with the SI Unit

B : Input Unit / Input Block

Page 8

EX500 Serial System EX## - OME0008

3. Specification and Product numbers

3 -1. General specification of EX500 series

Item Specification

Enclosure IP65

Standard UL,CSA,CE

Withstand voltage 1500V AC 1min. ( between PE - external terminal package )

Insulation resistance

Momentary power failure 1m sec. or less

Ambient temperature +5℃ to +45℃

Ambient humidity 35% to 85%RH ( without condensation )

Preservation temperature - 25℃ to 70℃

Vibration proof

Shock resistance

Applicable altitude Less than 1000m above sea

2MΩor more

( 500VDC meg. between PE - external terminal package )

10Hz to 57Hz 0.35mm ( constant amplitude )

57Hz to 150Hz 5G ( constant speed )

2 hours per each direction of ±X,Y and Z

Peak value : 15G

3 times per each direction of ±X,Y and Z

・・・・EMC Directive ( 89 / 336 / EEC )

EN50081-2 / 1993, EN55011 / 1998 +A1 : 1999, EN50082-2 / 1995, EN61000-6-2 / 1999

Electromagnetic Emission

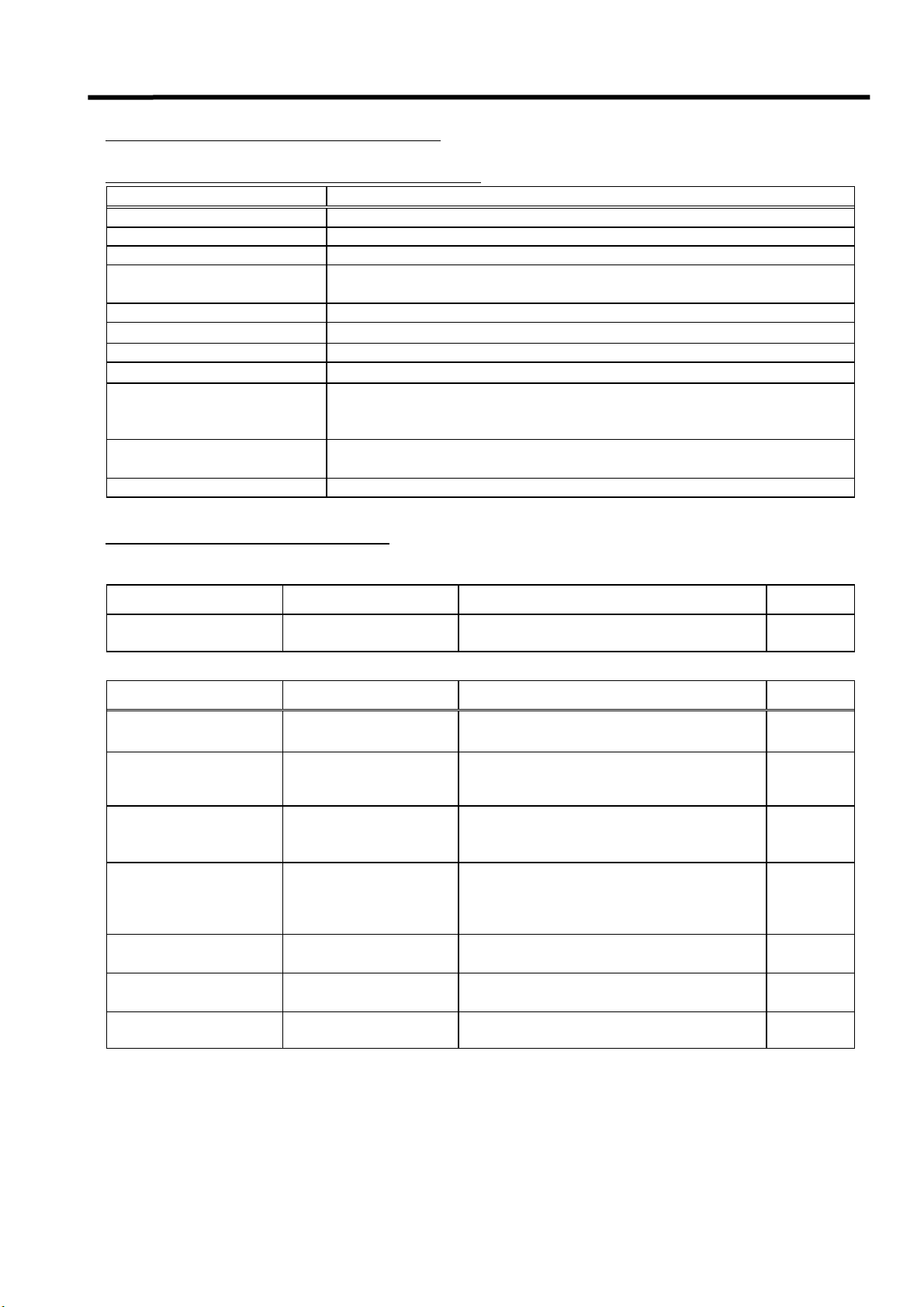

Item Test Procedure Specification Criterion

Radiated Electric Field

Strength

Electromagnetic Susceptibility ( Immunity )

Item Test Procedure Specification Criterion

ESD

RS :

Radiated Susceptibility

( amplitude modulated)

RS :

Radiated Susceptibility

( pulse modulated )

CS :

Conductive

Susceptibility

( amplitude modulated)

EFT / Burst,

DC power lines

EFT / Burst,

control lines

Surge,

interface lines

EN55011 : 1998 +A1

: 1999

EN61000-4-2 : 1995 /

A1 : 1998

EN61000-4-3 : 1996 /

A1 : 1998

ENV50204 : 1995

EN61000-4-6 : 1996

EN61000-4-4 : 1995

EN61000-4-4 : 1995

EN61000-4-5 : 1995 ±1kV ( Common ) B

30MHz to 230MHz, 230MHz to 1GHz

( Distance : 10m )

±4kV contact

±8kV air discharge

80MHz to 1000MHz

10V / m ( 1kHz AM 80% )

900±5MHz

10V / m

( 200Hz Pulse Mod. Duty 50% )

0.15MHz to 80 MHz

10V ( 1kHz AM 80% )

±2kV

( 5 / 50ns, 5kHz )

±2kV

( 5 / 50ns, 5kHz )

Group 1

Class A

B

A

A

A

B

B

- 7 -

Page 9

EX500 Serial System EX## - OME0008

3 -2. Gateway ( GW ) Unit

How to Order

EX500-GDN1

Network communication

protocol

DN DeviceNet

PR PROFIBUS-DP PROFIBUS-DP

AB Remote I/O ( RIO ) -X1 Remote I/O ( RIO )

GW Unit compatible

DeviceNet

Nil

Gateway ( GW ) Unit

B

U

S

R

U

N

S

O

L

C

O

M

E

R

R

G

2

4

V

D

C

A

T

E

E

X

W

5

A

0

Y

0

U

S

N

E

I

T

R

I

E

S

S

S

S

S

M

M

M

M

C

C

C

C

S

E

R

I

A

L

I

P

N

O

C

M

.

A

O

D

D

I

E

E

N

P

I

U

N

T

/

V

J

O

O

A

I

U

L

P

P

T

T

6

A

P

A

5

N

U

G

T

E

6

2

4

E

4

/

V

X

6

D

4

C

5

/

0

2

0

0

0

m

-

A

G

A

C

B

O

M

1

-

D

X

C

T

Y

P

1

E

1

U

S

R

E

P

.

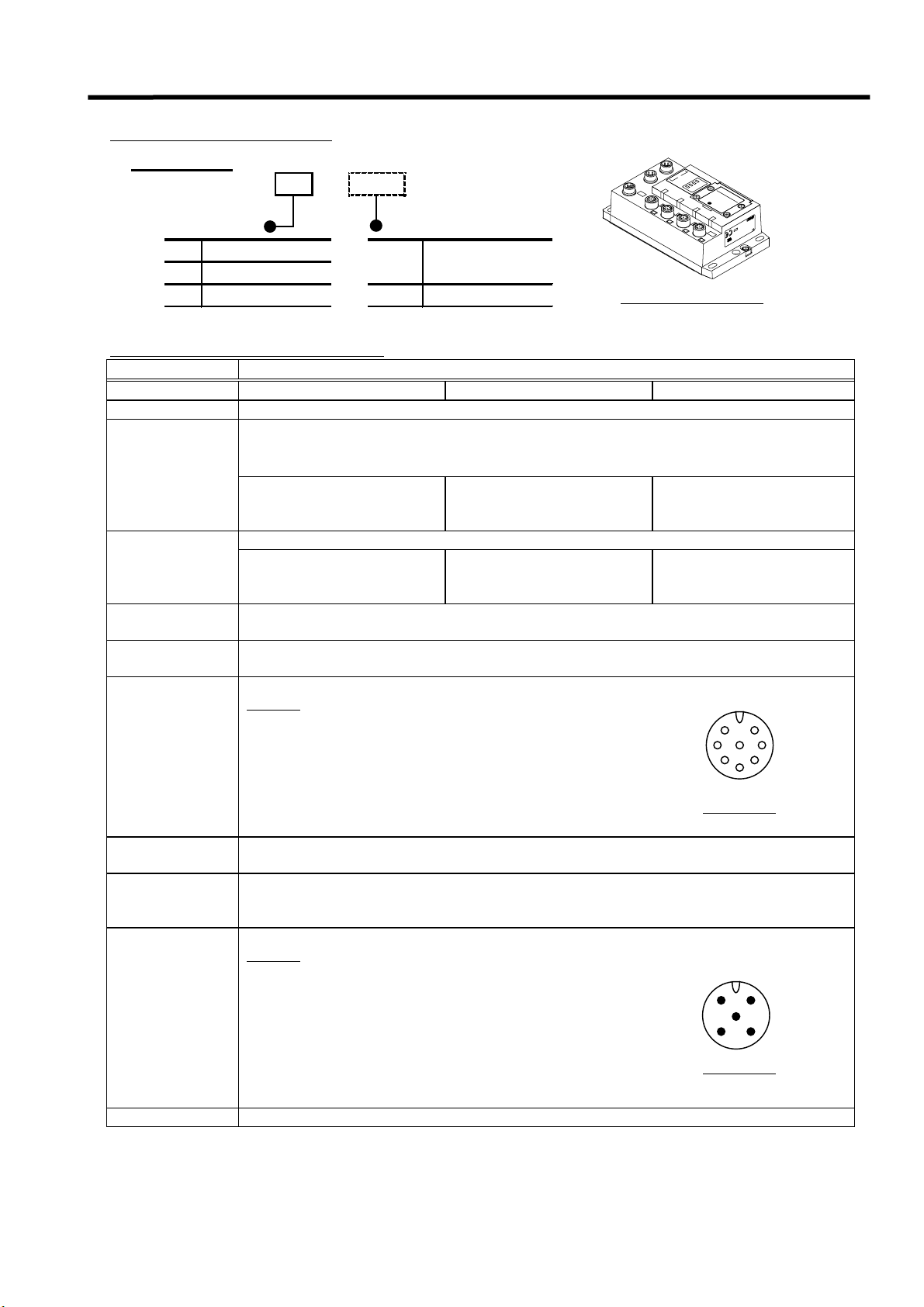

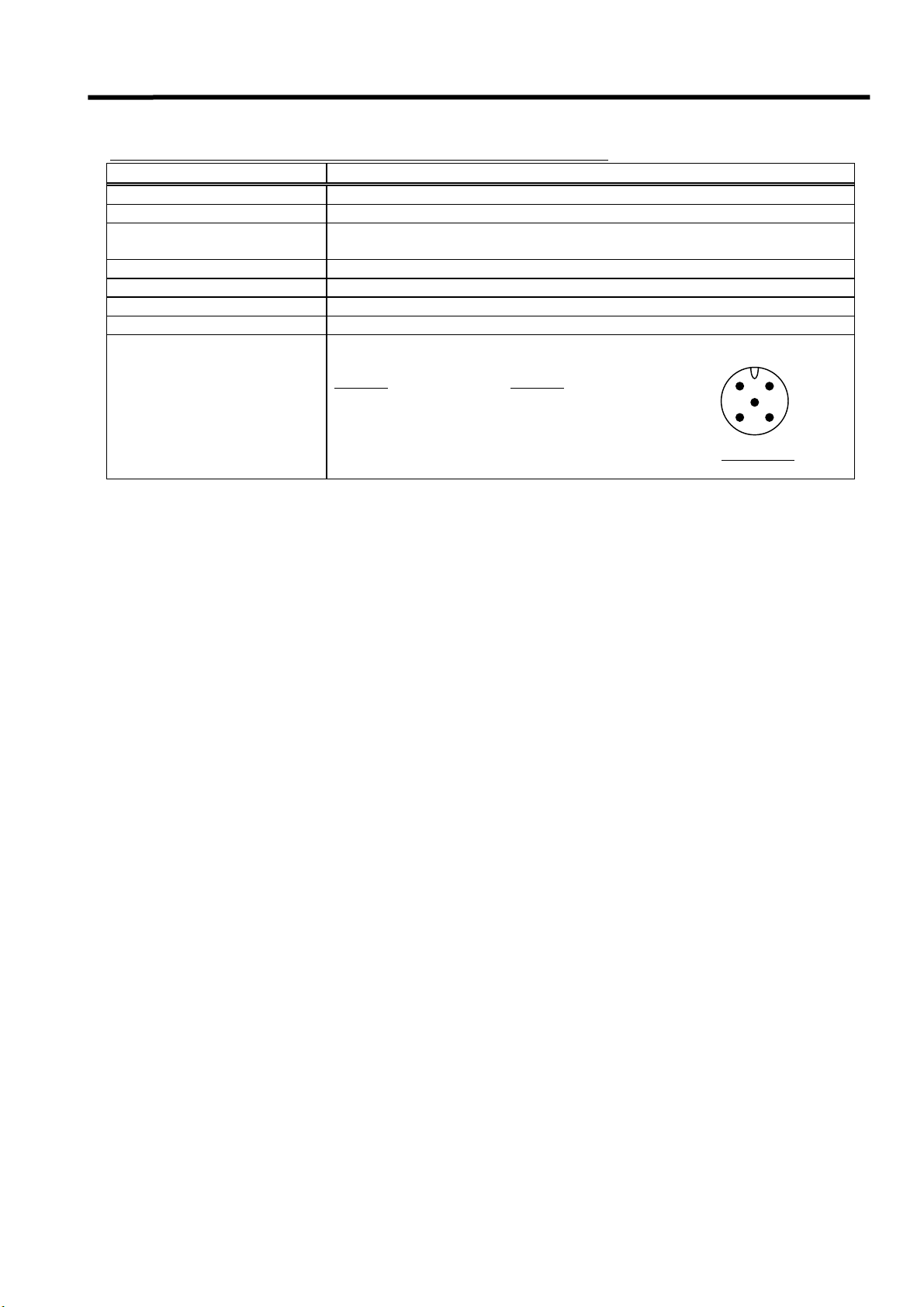

Gateway ( GW ) Unit specification

Item Specification

Models EX500 - GAB1 - X1 EX500 - GDN1 EX500 - GPR1

Rated voltage 24V DC

Input and control power supply : 24V DC ±10%

Solenoid valve power supply : 24V DC +10% / -5%

Power supply

voltage

Current

consumption

Input / Output

points

Input / Output

branches

Branch

connector

M12 connector ( 8 pin, socket )

Pin NO.

1. RD + 2. RD -

3. TD + 4. TD -

5. 24V DC ( for solenoid valve)

6. 0V DC ( for solenoid valve)

7. 24V DC ( for power source )

8. 0V DC ( for power source )

( Warning of voltage drop given lower than approx. 20V )

Communication power

-

supply for DeviceNet :

11V DC to 25V DC

200mA or less ( only GW Unit )

Communication power

-

supply for DeviceNet :

50mA or less

Maximum 64 inputs / Maximum 64 outputs

4 branches ( one branch 16 inputs / 16 outputs )

7

-

-

1

8

6

5

For GW Unit

2

3

Length of branch

cable

Communication

form

Less than 5m ( Less than 10m Max. Length )

Communication protocol : SMC original protocol

Communication speed : 750 k bit / sec. ( DeviceNet, PROFIBUS-DP )

: 500 k bit / sec. ( Remote I/O (RIO))

M12 connector ( 5 pin, plug )

Pin NO.

1. 0V ( for solenoid valve)

Power

Supply

connector

2. 24V DC + 10% / - 5% 3A Max.

( for solenoid valve)

3. 0V ( for power source ( input and control ) )

4. 24V DC±10% 3A Max.

( for power source ( input and control ) )

5. PE ( Protective earth )

Weight 470g

- 8 -

2

5

3

For GW Unit

1

4

Page 10

EX500 Serial System EX## - OME0008

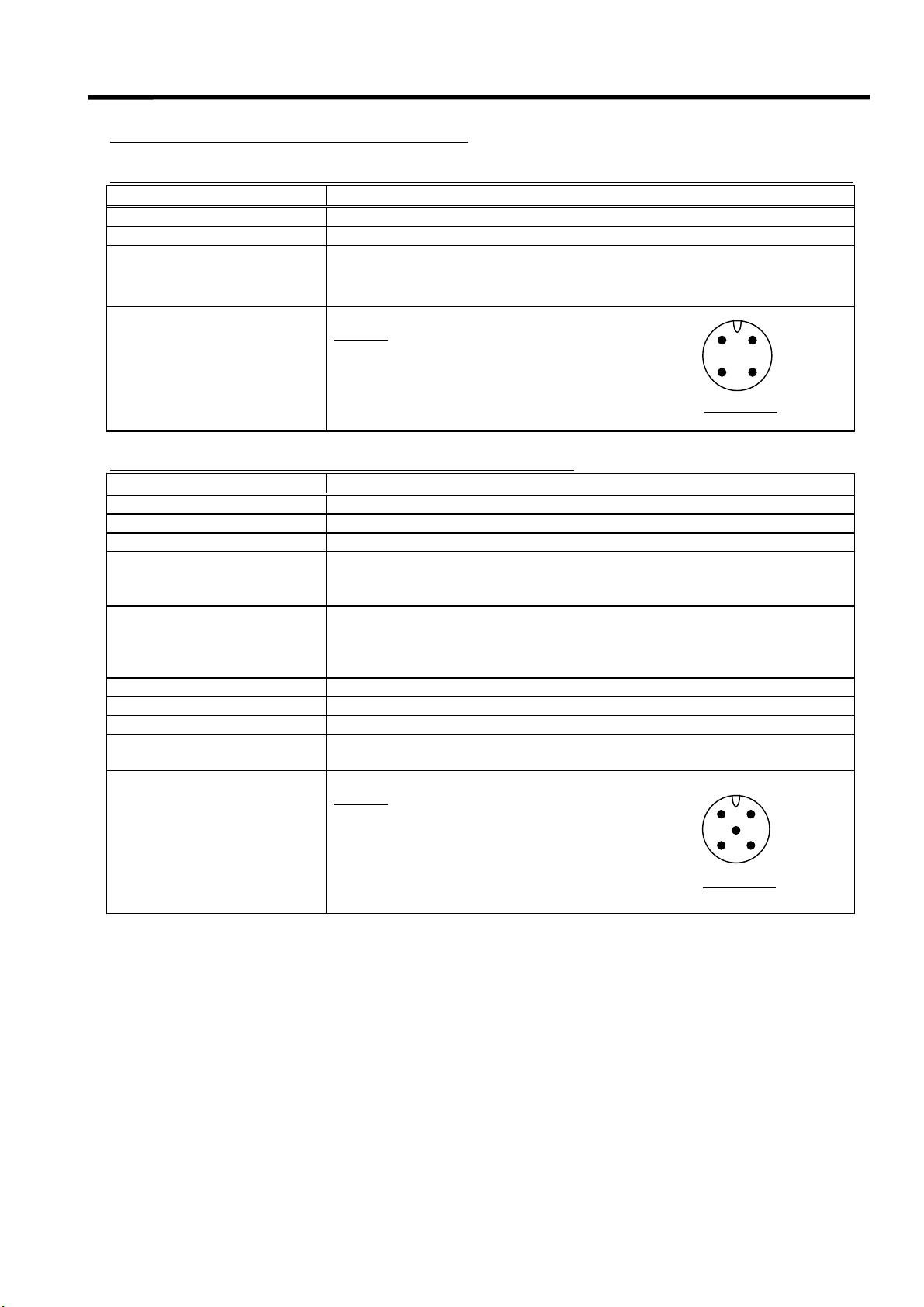

・・・・Communication specification for each PLC

Rockwell Automation Remote I/O communication specification ( RIO ) ( EX500 - GAB1 - X1 )

Item Specification

Applicable PLC Rockwell Automation Remote I/O PLC

Communication speed 57.6 k bit / sec. , 115.2 k bit / sec. , 230.4 k bit / sec.

Cable distance

( Terminating resistor size )

57.6 k bit / sec. : 3048 m [ 10000 feet ] ( 150Ω)

115.2 k bit / sec. : 1524 m [ 5000 feet ] ( 150Ω)

230.4 k bit / sec. : 762 m [ 2500 feet ] ( 82Ω)

M12 connector ( 4 pin, plug )

Pin NO.

2

1

1. Line1 ( Blue )

Communication connector

2. N. C.

3. Line2 ( Clear )

4. Shield ( Shield )

3

For GW Unit

4

DeviceNet communication specification ( EX500 - GDN1 )

Item Specification

Communication protocol DeviceNet Release 2.0

Slave ( branch ) type Group2 Only Server

MAC ID setting range 0 to 63

Vender code : 7 ( SMC corp. )

Device information

Corresponding message

I/O message size Input : 8 byte , Output : 8 byte

Communication speed 125 k bit / sec. , 250 k bit / sec. , 500 k bit / sec.

Cable distance Refer to section 5 -1

Isolation

Communication connector

Product type : 12 ( Communication Adapter )

Product code : 5001

Duplicate MAC ID Check Message

Group2 Only Unconnected Explicit Message

Explicit Message

Poll I/O Message

Photo coupler

( between CAN transceiver - main circuit )

M12 connector ( 5 pin, plug )

Pin NO.

1. DRAIN

2. V+

3. V-

4. CAN_H

5. CAN_L

2

5

3

For GW Unit

1

4

- 9 -

Page 11

EX500 Serial System EX## - OME0008

PROFIBUS-DP communication specification ( EX500 - GPR1 )

Item Specification

Protocol PROFIBUS-DP ( EN50170 )

Bus interface EIA RS - 485

Communication speed

Cable distance Refer to section 6 -1

Freeze function Available

Synchronous function Available

ID number 1405 hex

Communication connector

9.6 / 19.2 / 93.75 / 187.5 / 500 k bit / sec.

1.5 / 3 / 6 / 12 M bit / sec.

M12 connector ( 5 pin, plug )

IN

Pin NO.

1. VP

2. RxD / TxD ( N )

3. DGND

4. RxD / TxD ( P )

5. Shield

OUT

Pin NO.

1. N.C.

2. RxD / TxD ( N )

3. N.C.

4. RxD / TxD ( P )

5. Shield

2

5

3

For GW Unit

1

4

- 10 -

Page 12

EX500 Serial System EX## - OME0008

3 -3. Input Unit Manifold

The Input Unit Manifold can have various combinations depending on the number of stations and type of

the sensor connector.

When placing an order, the input manifold part number and the input block part number are entered together.

But only one sensor type has to be specified per manifold ( either NPN or PNP ).

M8 Input Block M12 Input Block M8 and M12 mixed

3 -3 -1. Input Manifold

The Input Manifold includes Input Unit ( EX500 - IB1 ( -X1 ) ), End Block and DIN rail.

How to Order

EEX5 0 0 - I B1-E8

E

X

V

Input Unit Specification

Connector type

E M8 connector

T M12 connector

M M8, M12 mixed Stations

1

:

8

GW Unit compatible

DeviceNet

Nil

PROFIBUS-DP

-X1 Remote I/O ( RIO )

1 station

:

8 stations

5

O

0

L

T

0

A

I

-

G

N

I

E

P

U

B

I

2

T

P

1

4

V

C

D

S

O

C

E

D

/

R

E

6

I

5

A

0

L

m

N

A

o

.

1

6

I

P

6

5

C

M

A

D

E

I

T

N

J

A

P

A

N

R

Y

U

P

S

E

1

Input Manifold

3 -3 -2. Input Unit

How to Order

EX500- IB1

GW Unit compatible

DeviceNet

Nil

PROFIBUS-DP

-X1 Remote I/O ( RIO )

Input Unit specification

Item Specification

Current source type Input Block ( PNP )

Connecting block

Current sink type input Block ( NPN )

Number of connecting block 8 blocks Max.

Power supply for block 24V DC

Current supply for block 0.65A Max.

Current consumption 100mA or less ( in case of rated voltage )

Short circuit protection

1A Typ. for each unit ( supply power cut )

Cut the power for power source once and then supply it again for return.

M12 connector ( 8 pin, plug )

Pin NO.

1. RD + 2. RD -

Communication connector

3. N. C. 4. N. C.

5. N. C. 6. N. C.

7. 24V DC ( for power source )

8. 0V DC ( for power source )

Weight 100g ( Input Unit + End Block )

or

E

X

V

5

O

0

L

T

0

A

I

-

N

G

I

E

P

U

B

I

2

T

P

1

4

V

C

D

S

O

C

E

D

/

R

E

6

I

5

A

0

L

m

N

A

o

.

1

6

I

P

6

5

M

A

D

E

I

N

J

A

Input Unit

C

R

T

Y

U

S

P

E

1

P

A

N

2

3

1

8

7

6

5

For Input Unit

- 11 -

Page 13

EX500 Serial System EX## - OME0008

3 -3 -3. Input Block

How to Order

EX5 00 - I E1

E

X

5

0

0

I

E

1

2

4

(

V

D

P

C

N

/

6

P

C

0

)

m

R

A

/

I

P

6

5

U

S

T

Y

P

E

1

M

A

D

E

I

Connector type GW Unit compatible

Input specification

1 M8 connector, PNP

2 M8 connector, NPN

DeviceNet

Nil

PROFIBUS-DP

-X1 Remote I/O ( RIO )

3 M12 connector, PNP

4 M12 connector, NPN

5 8 point unit, M8 connector, PNP

6 8 point unit, M8 connector, NPN

N

J

A

P

A

N

M8 Input Block

E

X

V

5

O

0

L

T

0

A

-

G

I

E

I

P

E

2

C

4

5

O

V

S

D

D

E

E

(

C

R

/

P

I

2

N

A

4

L

0

P

N

m

o

)

A

.

I

P

6

C

5

M

R

A

D

E

I

T

N

Y

U

S

P

J

E

A

P

1

A

N

E

X

5

0

0

V

-

O

L

I

T

E

A

G

3

I

E

(

P

P

C

O

N

D

P

E

2

)

4

V

D

C

/

6

C

0

R

m

A

T

I

P

Y

U

6

P

S

5

E

1

M

A

D

E

I

N

J

A

P

A

N

M12 Input Block

Input Block specification

8 point unit Input Block ( M8 )

Item Specification

Corresponding sensor Current source type ( PNP output ) Current sink type ( NPN output )

M8 connector ( 3 pin, socket )

Pin NO.

1. power supply (24V DC )

3. power supply ( 0V )

4. input

Sensor connector

For Input Block

M12 connector ( 4 pin, socket )

Pin NO.

1. power supply (24V DC )

2. ( input ) *Note

3. power supply ( 0V )

4. input

1

4

For Input Block

Input points 2 points / 8 points ( M8 only )

Rated voltage 24V DC

Logical ” 1 ” input voltage

Logical ” 0 ” input voltage

Logical ” 1 ” input current

Logical ” 0 ” allowable current

15V to 26.4V 0V to 8V

0V to 5V 19V to 26.4V

5mA Typ. - 5mA Typ.

1.5mA - 1.5mA

Input delay 1m sec. or less

Display LED ( green - colored ) light up

Insulation Nothing

Sensor supply current 30mA Max. / sensor

Weight [ M8 : 20g ] [ M12 : 40g ] [ 8 points ( M8) : 55g ]

2

3

Note) Internal circuit of the M12 Input Block and the position of the key for installing the sensor

connector of the M12 Input Block.

Each No.2 pin of each sensor connector of the M12 Input

Block is connected to the next No.4 pin which is the sensor

signal input pin of the connector.

Therefore, it is possible to incorporate the two input signals

of the sensor into one cable. ( just like a Y connection )

Input “0” ( n ) side

0

3

4

1

2

Key

Input “1” ( n + 1 ) side

Key

2

1

4

Confirm the specification of the output signal when

connecting the sensor. It will cause the malfunction.

The position of the key for installing the sensor connector

Input “1” ( n + 1 )

Input “0” ( n )

of the M12 Input Block refers to the right figure.

Confirm the type of the sensor connector when

selecting a sensor.

Figure of M12 Input Block ( the top of view )

- 12 -

1

3

Page 14

EX500 Serial System EX## - OME0008

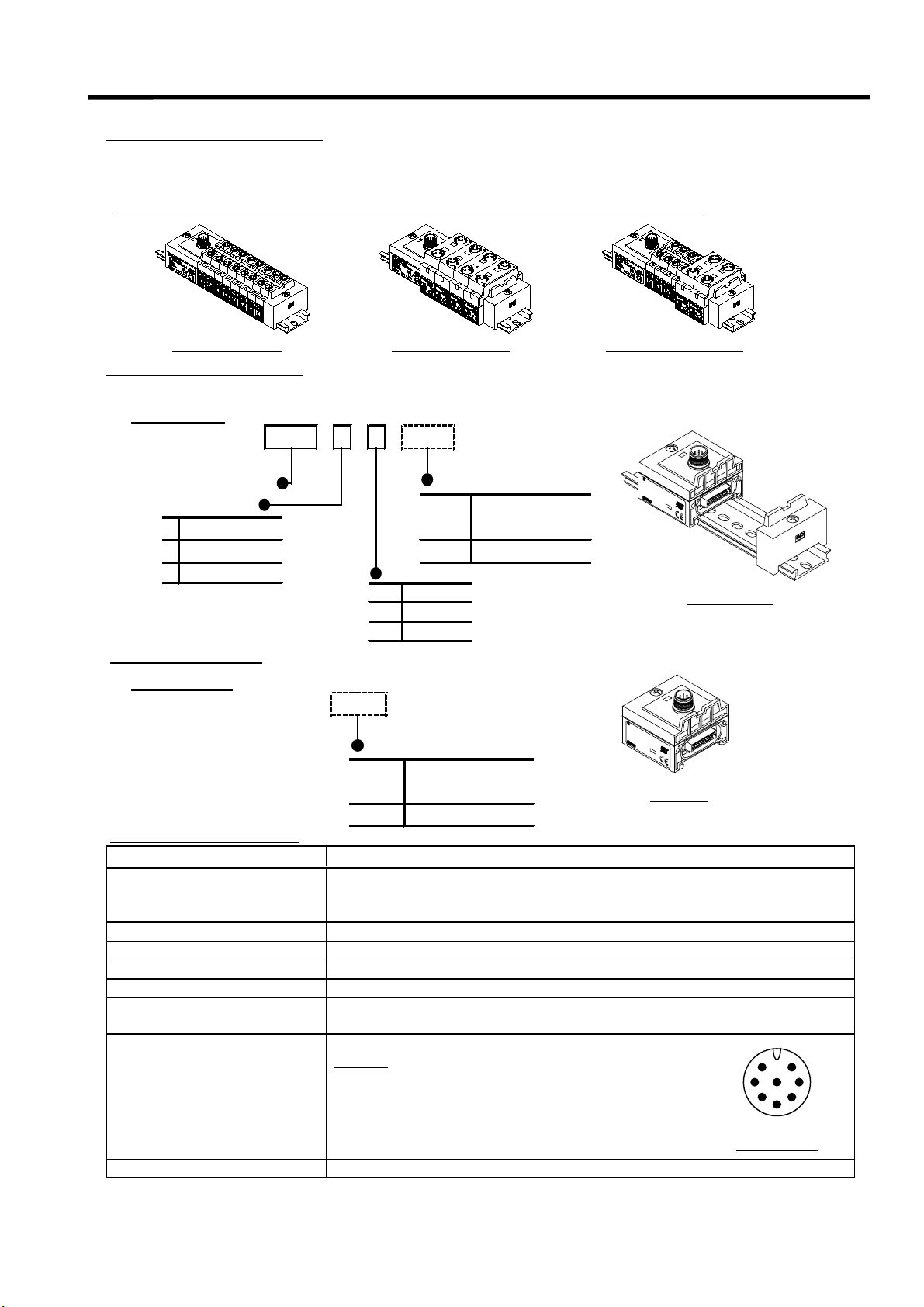

3 -4. SI Unit

SI Unit for SV series Manifold Valve SI Unit for VQC series Manifold Valve

How to Order

EX500-S001

How to Order

EX500-Q101

GW Unit compatible

DeviceNet

Nil

PROFIBUS-DP

-X1 Remote I/O ( RIO )

Output specification

0 NPN output ( + COM. )

1 PNP output ( - COM. )

GW Unit compatible

DeviceNet

Nil

PROFIBUS-DP

-X1 Remote I/O ( RIO )

SI Unit specification

Item Specification

Models EX500 - S001 ( -X1 ) EX500 - Q□01 ( -X1 )

Connecting

block

Number

of

connecting block

Power supply for block

Current supply for block

Current consumption

Short circuit

protection

Communication

connector

Weight 115g 105g

Solenoid valve ( Single , Double )

Relay Output Module ( 1 output , 2 output )

Double solenoid valve , : 8 blocks Max.

Relay Output Module ( 2 output )

Single solenoid valve , : 16 blocks Max.

Relay Output Module ( 1 output )

Solenoid valve ( Single , Double )

Double solenoid valve : 8 blocks Max.

Single solenoid valve : 16 blocks Max.

24V DC

0.65A Max. 0.75A Max.

100mA or less ( in case of rated voltage )

Use current limit driver

Once the driver circuit is shorted, current is limited in order to de-energize the load.

Once the short circuit is fixed, the unit will self recover.

Connecting with Input Unit. M12 connector ( 8 pin, socket )

C1

Pin NO.

1. RD + 2. RD -

or

3. N. C. 4. N. C.

5. N. C. 6. N. C.

“ 0 “

7. 24V DC ( for power source )

8. 0V DC ( for power source )

Connecting with GW Unit. M12 connector ( 8 pin, plug )

C2

or

“ 1“

Pin NO.

1. RD + 2. RD -

3. TD + 4. TD -

5. 24V DC ( for solenoid valve)

6. 0V DC ( for solenoid valve)

7. 24V DC ( for power source )

8. 0V DC ( for power source )

1

7

6

For SI Unit

2

3

For SI Unit

2

8

3

5

1

8

7

6

5

3 -5. Applicable Manifold Valve series

Series

SV1000

SV2000

SV3000 -

SV4000 VQC1000 VQC2000 VQC4000 -

Refer to the Catalogues or Technical Instruction Manual of SV and VQC series Manifold Valve

for more details.

Manifold Applicable cylinder size ( mm )

Cassette

type

○○○○○

○○○○○

Tie-rod

type

○

○○

○

○○

40 50 63 80 100 125

○○○○

○○○○

○○○○

○○○○

○○○○

- 13 -

Page 15

EX500 Serial System EX## - OME0008

L

3 -6. Option

3 -6 -1. Communication Connector / Cable

1. Communication Connector for Remote I/O ( RIO ) ( EX500 - GAB1 -X1 )

How to Order

EX500 -AC000-AB

1

×

2

1

M

2

1

3

4

φ14.9

43.2

Applicable cable diameter

φ6 (φ5~φ6 )

Rated voltage 125V DC

Rated current 3A

Contact

resistance

( connector part )

φ14.2

.

Insulation

resistance

Withstand

voltage

( connector part )

Electric specification

40m ohms or less

( At 20mV DC or less, 100mA or less )

1000M ohms or more ( At 500V DC )

1500V AC 1min.

( Leak current 1mA or less )

2. Communication Connector Cable for DeviceNet ( EX500 - GDN1 )

How to Order

EX500 -AC050-DN

Rated voltage 125V DC

Electric specification

Rated current 3A

Contact

resistance

( connector part )

Insulation

resistance

Withstand

voltage

( connector part )

40m ohms or less

( At 20mV DC or less, 100mA or less )

1000M ohms or more ( At 500V DC )

1500V AC 1min.

( Leak current 1mA or less )

M12

L : Cable length

010 1m

050 5m

φ7

1

5

2

43

Socket connector

Pin assignment

Outside

diameter

Sheath color

φ14.9

40.7

L

Cable specification

Signal AWG24 ( 41 / 0.08 )

Power supply AWG22 ( 19 / 0.16 )

Drain AWG22 ( 19 / 0.16 ) -

Φ7

Light blue

- 14 -

50

Terminal NO.

1

2

3

4

5

Blue /

White

Red /

Black

Cable core

sheth color

: DRAIN

Red : V+

Black : V-

White : CAN H

Blue : CAN

Wiring

Terminal NO. Cable color / Signal name

1

2

3

4

5

Bare

Red

Black

White

Blue

DRAIN

V+

V-

CAN H

CAN L

Page 16

EX500 Serial System EX## - OME0008

3 -6 -2. Branch Cable with M12 Connector

How to Order

EX500-AC030-SSPS

L : Cable length Connector specification

003 0.3m

005 0.5m

010 1m

030 3m

050 5m

Electric specification

Rated voltage 36V DC

Rated current 1.5A

Contact

resistance

( connector part )

Insulation

resistance

Withstand

voltage

( connector part )

40m ohms or less

( At 20mV DC or less, 100mA or less )

1000M ohms or more ( At 500V DC )

1000V AC 1min.

( Leak current 1mA or less )

SSPS

SAPA

Socket side : Straight, Plug side : Straight

Socket side : Angled, Plug side : Angled

M12

M12

28.3

L

48

φ6

φ14.9

52

φ16

M12

Straight connector type

M12

φ6

32.3

31.3 31.3

L

Angled connector type

8

7

6

Socket connector Plug connector

2

1

3

4

5

Terminal NO.

11

22

33

44

55

66

77

88

Cable core

sheath color

White

Brown

Green

Yellow

Gray

Pink

Blue

Shield

8

1

2

3

4

5

Pin assignmentPin assignment

Wiring

- 15 -

7

6

Page 17

EX500 Serial System EX## - OME0008

A

W

3 -6 -3. Power Supply Connector Cable

How to Order

EX5 00 -AP050-S

L : Cable length

010 1m

050 5m

Connector

spesification

Straight

S

Angled

A

Rated voltage 125V DC

Rated current 3A

Contact

resistance

( connector part )

Insulation

resistance

Withstand

voltage

( connector part )

Electric specification

40m ohms or less

( At 20mV DC or less, 100mA or less )

1000M ohms or more ( At 500V DC )

1500V AC 1min.

( Leak current 1mA or less )

M12

φ6

28.3

31.3

M12

φ6

18

φ14.9

34

48

L

30 5

50

Straight connector type Angled connector type

Teminal NO.

1

5

43

Socket connector

Pin assignment

2

1

2

3

4

5

3 -6 -4. Terminal Plug

Wiring

Cable core

sheath color

Brown : 0V ( for solenoid valve )

White : 24V DC +10% / -5% ( for solenoid valve )

Blue : 0V ( for power source )

Black : 24V DC

Gray : PE

±

10% ( for power source )

Terminal NO. Cable color / Signal name

1 Brown 0V ( for solenoid valve)

2 White 24V DC +10% / -5%

3 Blue 0V ( for power source)

4Black

5Gray PE

When Input Unit Manifold is not required, a Terminal Plug should be hooked up with port C1 ( for SV Valve

Manifold ) or port 0 ( for VQC Valve Manifold ).

Without this plug, the communication LED of GW Unit will not light up.

How to Order

EX500 -AC000 - S

M12

8

2

1

3

4

5

Plug connector

Pin assignment

7

φ16

6

44.7

Rated voltage 36V DC

Rated current 1.5A

Contact

resistance

( connector part )

Insulation

resistance

Withstand

voltage

( connector part )

Electric specification

40m ohms or less

( At 20mV DC or less, 100mA or less )

1000M ohms or more ( At 500V DC )

1000V AC 1min.

( Leak current 1mA or less )

30 5

50L

( for solenoid valve)

24V DC ±10%

( for power source)

3 -6 -5. Water Proof Cap

To accommodate the product’s water proof feature, a Water Proof Cap is used for an open port in the GW Unit

and the Input Block. The Cap is supplied with the product when ordered.

Tighten the Water Proof Cap with the specified tightening torque. ( M8 : 0.05 N・

How to Order

EX500 -

Connector

specification

ES

M8 connector ( socket ) / 10 pcs.

TP

M12 connector ( plug ) / 1 pc.

TS

M12 connector ( socket ) / 10 pcs.

- 16 -

・m, M12 : 0.1 N・・・・m )

・・

Page 18

EX500 Serial System EX## - OME0008

4. How to operate EX500 - GAB1 - X1 ( Rockwell Automation Remote I/O ( RIO))

4 -1. Applicable PLC

Applicable PLCs in which Rockwell Automation Remote I/O ( RIO ) system is installed.

Please contact Rockwell Automation for more details.

・

・Representative PLC

・・

SLC500

PLC - 2 / 20 PLC - 2 / 30 PLC - 3 / 10

PLC - 5 / 11 PLC - 5 / 15 PLC - 5 / 20 PLC - 5 / 25

PLC - 5 / 30 PLC - 5 / 40 PLC - 5 / 40L PLC - 5 / 60

PLC - 5 / 60L PLC - 5 / 80

PLC - 5 / 250 PLC - 5 / VME PLC - 5 / V40B

4 -2. Parts description

Fieldbus connector

(1771 Remote I/O)

Power supply connector

Communication port A

Communication port B

Communication port C

Communication port D

B

U

S

R

U

N

S

O

L

C

O

M

E

R

2

4

V

D

C

R

LED display window

G

A

T

E

E

W

X

A

5

Y

0

0

U

N

S

I

E

T

R

I

E

S

S

S

S

S

M

M

M

M

C

C

C

C

J

A

P

A

N

C

O

M

D

C

X

T

Y

P

E

1

1

U

S

R

Station switch protection cover

S

E

R

I

A

L

I

P

N

O

C

M

.

O

A

D

D

I

E

N

E

P

U

I

T

N

/

V

O

O

I

U

L

P

T

T

6

P

A

5

U

G

T

E

6

2

E

4

4

/

V

X

6

D

4

C

5

/

0

2

0

0

0

m

-

A

G

A

B

1

-

E

P

a. Fieldbus connector : Port for PLC connection.

b. Power supply connector : The power source for Input Unit, SI Unit, and control and

for the solenoid valve is connected through this port.

c. Communication port : Input Unit Manifold or the Manifold Valve with the SI Unit

is connected through this port.

d. LED display window : The state of the power source supply and the PLC

communication is displayed. ( Refer to section 4 -3 )

e. Station switch protection cover : Switches for the operation setting are inside.

( Refer to section 4 -4 )

!!!! CAUTION

The station switch protection cover should be tightened with specified tightening torque

after it is opened. ( Tightening torque : 0.6 N・m )

- 17 -

Page 19

EX500 Serial System EX## - OME0008

4 -3. LED display

GATEWAY UNIT

RUN

BUS

SOL

COM

ERR

COM A COM B COM C COM D

Display Content

RUN

SOL

COM

ERR

COM A

COM B

COM C

COM D

Source ON : Lights

Source OFF : Lights off

Solenoid valve source voltage is normal :Lights

Voltage lowered to 20V or less :Lights off

RIO communication is normal : Lights

RIO communication is abnormal : Lights off

RIO communication is abnormal : Lights

RIO communication is normal : Lights off

Communication port A is receiving data : Lights

Communication port A has no data : Lights off

Communication port B is receiving data : Lights

Communication port B has no data : Lights off

Communication port C is receiving data : Lights

Communication port C has no data : Lights off

Communication port D is receiving data : Lights

Communication port D has no data : Lights off

EX500 SERIES

!!!! CAUTION

When the Input Unit Manifold is not connected, the respective COM LED of the GW Unit will not light up.

To monitor the status of COM port, it is necessary to use a Terminal Plug.

The COM LED will light up when a Terminal Plug is used. ( Refer to section 3 -6 -4 )

4 -4. Operation setting

Turn the power supply OFF when setting switches.

Open the station switch protection cover and set the dip switch with a flat blade screw driver.

ON

12345678

SW1 SW2 SW3

ON

1234

- 18 -

Page 20

EX500 Serial System EX## - OME0008

)

A

)

O

4 -4 -1. Operation setting switch ( SW1 )

This switch sets RACK Address / Starting Quarter.

( 1 ) RACK Address ( 6 bit setting )

0 to 74 ( OCT : octal number ) 61 types

of setting are available.

SW1

( 2 ) Starting Quarter ( 2 bit setting )

Three types of setting

( First, Second, Third )

are available.

4 -4 -2. Operation setting switch ( SW2 )

( 1 ) Last RACK ( 1 bit setting )

With Last RACK, the switch is set as “ 1 ” ( ON ).

RACK

ON ( 1 )

OFF ( 0 )

SW1 NO.

RACK 2000010

Address |

Starting Second 0 1

Quarter Third 1 0

N

12345678

32 16 8 4 2 1

0000000

1000001

73111011

74111100

Last RACK ( 1bit ) Mode ( 1bit

ddress ( 6bit

EX.)

111100b→74o

First 0 0

Fourth - -

Data Rate

( 2bit )

Starting Quarter ( 2bit )

01→ Second

( 2 ) Data Rate ( 2 bit setting )

Set data communication rate.

57.6 k bit / sec. : 00

115.2 k bit / sec. : 01

230.4 k bit / sec. : 1X

Data Rate 57.6 k bit / sec. 0 0

( 3 ) Mode ( 1 bit setting )

Setting Operation

0

Clear

1

Hold

If “ 0 ” ( OFF ) set , output status is cleared and held temporarily when Remote I/O ( RIO )

has communication error.

When returned to normal signal, the communication will automatically be recovered.

If “ 1 ” ( ON ) set , operation held temporarily holding the last normal output signal when

Remote I/O ( RIO ) has communication error.

When returned to normal signal, the communication will automatically be recovered.

ON ( 1 )

SW2

OFF ( 0 )

SW2 NO. 1234

Last

RACK

Mode Clear 0

ON

1234

NO 0

YES 1

115.2 k bit / sec. 0 1

230.4 k bit / sec. 1 X

Hold 1

- 19 -

Page 21

EX500 Serial System EX## - OME0008

4 -4 -3. Terminating resistance setting switch ( SW3 )

Set termination resistance.

①150Ω ②82Ω ③No resistance

Data Rate

57.6 k bit / sec. : 150Ω

115.2 k bit / sec. : 150Ω

230.4 k bit / sec. : 82Ω

State of SW3

4 -5. Layout of scanner I/O

I/O mapping image at the Gateway (GW ) Unit communication port is shown in examples 1 and 2.

In this product, regardless of the quantity of the I/O equipment, continuous 4 Groups are automatically

occupied. ( 1/2 RACK occupation ).

Each communication port occupies all of 16 points in corresponding Group.

Ex.1 ) RACK Address = 0

Starting Quarter = First

Bit Number( decimal ) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RACK0 Group0

RIO RACK0 Group1

LOGICAL RACK0 Group2

RACK0 RACK0 Group3

RACK0 Group4

RACK0 Group5

RACK0 Group6

RACK0 Group7

RACK1 Group0

RIO RACK1 Group1

LOGICAL RACK1 Group2

RACK1 RACK1 Group3

RACK1 Group4

RACK1 Group5

RACK1 Group6

RACK1 Group7

COM A occupied

COM B occupied

COM C occupied

COM D occupied

Ex.2 ) RACK Address = 1

Starting Quarter = Third

Bit Number( decimal ) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RACK0 Group0

RIO RACK0 Group1

LOGICAL RACK0 Group2

RACK0 RACK0 Group3

RACK0 Group4

RACK0 Group5

RACK0 Group6

RACK0 Group7

RACK1 Group0

RIO RACK1 Group1

LOGICAL RACK1 Group2

RACK1 RACK1 Group3

RACK1 Group4

RACK1 Group5

RACK1 Group6

RACK1 Group7

- 20 -

COM A occupied

COM B occupied

COM C occupied

COM D occupied

Page 22

EX500 Serial System EX## - OME0008

5. How to operate EX500 - GDN1 ( DeviceNet )

5 -1. Connection style

DeviceNet unit can be connected by T branch, Multi branch and Branch line branch.

Total extension length of trunk and stay is different depending on communication speed and thickness of

communication cable.

EX500 series can be connected only by T branch.

Terminating resistance

Multi branch

Branch line

Node Node

・・・・Wiring length

of

Network

Total length of branch line

Terminating resistance 121 ohms, 1/2W ( TURCK p / n = RSM57TR2 )

Multi branch

T branch

Node Node

Max. 6m

Branch line

Node

Node

Branch line

125 250 500

Communication speed ( k bit / sec. )

Thick cable 500m or less 250m or less 100m or less Max. length

Thin cable 100m or less

156m or less 78m or less 39m or less

Note : Max. length of a branch line is up to 6m.

Main

Multi

Terminating resistance

Branch line branch

Node

Node

Node

・

・Cable specification

・・

Item

Conductor

section area

Color

Signal Power Signal Power

0.82mm

Blue ( CAN-L )

White ( CAN-H )

Thick cable Thin cable

2

1.65mm

Red ( 24VDC ),

Black ( 0VDC )

2

0.20mm

2

Blue, W hite Red, Black

Impedance 120 ohms±10% - 120 ohms±10% -

Propagation

delay

1.36ns / ft - 1.36ns / ft -

( Maximum )

Attenuation

rate

( Maximum )

500kHz : 0.25dB / ft 500kHz : 0.50dB / ft

125kHz : 0.13dB / ft 125kHz : 0.29dB / ft

1.00MHz : 0.40dB / ft

-

1.00MHz : 0.70dB / ft

Conductor

resistance

6.9 ohms / 1000ft 3.6 ohms / 1000ft 28 ohms / 1000ft 17.5 ohms / 1000ft

( Maximum )

1ft ≒ 0.3048m

0.33mm

-

2

- 21 -

Page 23

EX500 Serial System EX## - OME0008

5 -2. Parts description

Fieldbus connector

(DeviceNet)

Power supply connector

B

U

S

D

e

V

2

4

V

D

C

M

S

N

S

S

i

O

c

L

e

N

C

O

N

F

O

e

R

M

A

N

C

t

E

T

E

S

T

T

M

E

D

C

Communication port A

Communication port B

Communication port C

Communication port D

a. Fieldbus connector : Port for PLC connection.

b. Power supply connector : The power source for Input Unit, SI Unit, and control and

for the solenoid valve is connected through this port.

c. Communication port : Input Unit Manifold or the Manifold Valve with

the SI Unit is connected through this port.

d. LED display window : The status of power source supply and the PLC

communication is displayed here. ( Refer to section 5 -3 )

e. Station switch protection cover : Rotary switches for the operation setting are inside.

( Refer to section 5 -4 )

LED display window

G

A

T

E

E

W

X

A

5

Y

0

0

U

N

S

I

E

T

R

I

E

S

S

S

S

S

M

M

M

M

C

C

C

C

I

N

J

A

P

A

N

6

4

0

m

O

M

D

A

1

T

Y

P

E

C

1

U

S

R

Station switch protection cover

S

E

R

I

A

I

L

P

N

C

M

O

O

A

I

.

D

D

N

E

E

P

U

T

V

/

O

O

L

U

I

T

T

P

A

P

6

G

U

E

5

T

E

2

6

X

4

4

V

5

/

D

0

C

/

0

2

-

0

G

D

N

E

P

!!!! CAUTION

The station switch protection cover should be tightened with specified tightening torque

after it is opened. ( Tightening torque : 0.6 N・m )

- 22 -

Page 24

EX500 Serial System EX## - OME0008

5 -3. LED display

GATEWAY UNIT

BUS

MS

NS

SOL

COM A COM B COM C COM D

Display Content

MS

Operating in a normal condition : Green lights

Recoverable fault ( Memory is abnormal ) : Red lights

Not online : Lights off

Online , Not Allocated : Green flashing

NS

Online , Allocated : Green lights

Connection Time - Out : Red flashing

Critical Link Failure : Red lights

SOL

COM A

COM B

COM C

COM D

Solenoid valve source voltage is normal : Lights

Voltage lowered to 20V or less : Lights off

Communication port A is receiving data : Lights

Communication port A has no data : Lights off

Communication port B is receiving data : Lights

Communication port B has no data : Lights off

Communication port C is receiving data : Lights

Communication port C has no data : Lights off

Communication port D is receiving data : Lights

Communication port D has no data : Lights off

EX500 SERIES

!!!! CAUTION

When the Input Unit Manifold is not connected, the respective COM LED of the GW Unit will not light up.

To monitor the status of COM port, it is necessary to use a Terminal Plug.

The COM LED will light up when a Terminal Plug is used. ( Refer to section 3 -6 -4 )

5 -4. Operation setting

Turn the power supply OFF when setting switches.

Open the station switch protection cover and set the rotary switch with a flat blade screw driver.

0

1

2

3

4

5

SW1 SW3SW2

9

8

7

6

Figure of setting switch

- 23 -

Page 25

EX500 Serial System EX## - OME0008

5 -4 -1. Address setting switch ( SW1, 2 )

These switches set node address. The setting is shown in Table 1.

5 -4 -2. Data rate setting switch ( SW3 )

This switch set data rate. The setting is shown in Table 2.

The factory default address and data rate are 63 and 125 k bit / sec. respectively.

X10 X1

SW1

SW1 SW2 NODE ADDRESS

00 0

01 1

02 2

||

63 63

64

|PGM

99

SW2

Table 1 Table 2

SW3

SW3 DATA RATE

0 125 k bit / sec.

1 250 k bit / sec.

2 500 k bit / sec.

3

|PGM

9

When PGM mode is chosen, the address

and data rate are set through network.

5 -5. I/O memory map

The GW Unit can control 128 input / output points in total. Regardless of I/O points of the equipment,

it always occupies each data memory area for 64 inputs and 64 outputs.

Once the address is assigned in the GW Unit, every port then corresponds to a specific “Word” respectively.

So “Word (n)” always corresponds to COM A, “Word (n+1)” corresponds to COM B, and so on.

Ex.) n = 1

In case of the input data, the sensor signal data of the Input Manifold which was connected with

the COM A port, occupies "Word1" of the I/O memory mapping.

If a sensor signal is stored in the "0 bit" of the Input Manifold, it becomes like the Figure below.

In the same way, in the case of the output data, the contents displayed in "Word1" of the

I/O memory mapping is output by the COM A port.

( m,n=0 - )

Word ( n ) COM A 1

Word ( n+1 ) COM B

Word ( n+2 ) COM C

Word ( n+3 ) COM D

:

:

Branch

connector

:

:

MSB LSB MSB LSB

15 8 7 0

Byte (m+1) Byte (m)

Byte (m+3) Byte (m+2)

Byte (m+5) Byte (m+4)

Byte (m+7) Byte (m+6)

Data ( 2 byte )

!!!! CAUTION

Read carefully the user manual of PLC which is used as a master.

The method of PLC setup, reading from or writing to memory differ from one PLC manufacturer to another.

- 24 -

Page 26

EX500 Serial System EX## - OME0008

6. How to operate EX500 - GPR1 ( PROFIBUS-DP )

6 -1. Communication wiring

・・・・Cable specification

A twisted pair cable with shield is used in the

communication wiring of PROFIBUS- DP.

A maximum length of cable depend on

communication speed.

The specification of cable length is based on

TYPE A cable which has parameters shown below.

・

・Communication speed and Longest wiring length

・・

Communication

speed

Wiring

length

9.6

[k bit/sec]

19.2

[k bit/sec]

1200

[m]

93.75

[k bit/sec]

[k bit/sec]

・・・・Terminating resistance

It is necessary to attach terminating

resistance to the units located at the

Data Line

ends of transmission line.

Refer to section 6 -4 -2, for setting

the terminating resistance.

Data Line

6 -2. Parts description

Fieldbus connector

(PROFIBUS-DP)

Impedance 135 ohms to 165 ohms

Capacitance between

conductors

30 pF / m or less

Conductor resistance 110 ohms / km

Cable diameter 0.64 mm

Conductor area 0.34 mm2 or more

187.5

1000

[m]

VP

390 ohms

RxD/TxD-P

220 ohms

RxD/TxD-N

390 ohms

DGND

500

[k bit/sec]

400

[m]

1.5

[M bit/sec]12[M bit/sec]

200

[m]

100

[m]

LED display window

Station switch protection cover

Power supply connector

I

N

P

R

P

R

O

B

C

E

O

S

S

F

U

I

E

L

F

D

B

U

S

S

I

R

B

U

S

O

U

Communication port A

T

2

4

V

D

C

R

U

S

N

O

L

B

F

D

I

A

G

A

T

E

E

W

X

A

5

Y

0

0

U

S

N

E

I

T

R

I

E

S

S

S

S

S

M

M

M

M

C

C

C

C

S

E

R

I

A

I

P

L

C

N

M

O

O

I

A

N

D

.

D

P

E

E

U

T

I

V

N

/

O

I

O

P

J

L

U

A

6

T

5

T

P

A

P

A

G

U

N

E

E

T

2

X

6

4

4

V

5

/

D

6

0

C

4

0

/

2

-

C

O

M

D

0

0

G

m

A

P

T

R

Y

C

P

1

E

1

U

S

R

E

P

Communication port B

Communication port C

Communication port D

a. Fieldbus connector : Port for PLC connection.

b. Power supply connector : The power source for Input Unit, SI Unit, and control and

for the solenoid valve is connected through this port.

c. Communication port : Input Unit Manifold or the Manifold Valve with

the SI Unit is connected through this port.

d. LED display window : The state of the power source supply and the PLC

communication is displayed. ( Refer to section 6 -3 )

e. Station switch protection cover : Switches for the operation setting are inside.

( Refer to section 6 -4 )

!!!! CAUTION

The station switch protection cover should be tightened with specified tightening torque

after it is opened. ( Tightening torque : 0.6 N・m )

- 25 -

Page 27

EX500 Serial System EX## - OME0008

6 -3. LED display

GATEWAY UNIT

EX500 SERIES

IN

OUT

BUS

PROCESS FIELD B US

BUS

OI

FRP

R

RUN

SOL

BF

DIA

COM A COM B COM C COM D

Display Content

RUN

SOL

BF

DIA

COM A

COM B

COM C

COM D

Source ON : Lights

Source OFF : Lights off

Solenoid valve source voltage is normal :Lights

Voltage lowered to 20V or less :Lights off

PROFIBUS-DP communication is normal : Lights off

PROFIBUS-DP communication is abnormal : Lights

DIA is abnormal : Lights

DIA is normal : Lights off

Communication port A is receiving data : Lights

Communication port A has no data : Lights off

Communication port B is receiving data : Lights

Communication port B has no data : Lights off

Communication port C is receiving data : Lights

Communication port C has no data : Lights off

Communication port D is receiving data : Lights

Communication port D has no data : Lights off

!!!! CAUTION

When the Input Unit Manifold is not connected, the respective COM LED of the GW Unit will not light up.

To monitor the status of COM port, it is necessary to use a Terminal Plug.

The COM LED will light up when a Terminal Plug is used. ( Refer to section 3 -6 -4 )

6 -4. Operation setting

Turn the power supply OFF when setting switches.

Open the station switch protection cover and set the dip switch with a flat blade screw driver.

0

1

4

5

ON

12

SW3SW4

9

8

7

SW1SW2

6

Figure of setting switch

2

3

- 26 -

Page 28

EX500 Serial System EX## - OME0008

6 -4 -1. Address setting switch ( SW1, 2, 3 )

These switches set node address. The setting is shown in the following figure.

The address per one segment can be set in 32 node in case of no Repeater used and is set a maximum

of 126 node in case of a Repeater used.

ON

X100

X10

X1

12

SW3

SW3

12

ON 1

OFF

N.C

0

SW2

SW1

SW2 SW 1

0

|

9

0

|

9

6 -4 -2. Terminating resistance setting switch ( SW4 )

This switch is to set the terminating resistance.

The setting is shown in three figures on right.

①resistance

ON OFF OFF

② No resistance

ON OFF OFF

State of SW4

③ No resistance

ON OFF OFF

6 -5. I/O memory map

The GW Unit can control 128 input / output points in total. Regardless of I/O points of the equipment,

it always occupies each data memory area for 64 inputs and 64 outputs.

Once the address is assigned in the GW Unit, every port then corresponds to a specific “Word” respectively.

So “Word (n)” always corresponds to COM A, “Word (n+1)” corresponds to COM B, and so on.

Ex.) n = 1

In case of the input data, the sensor signal data of the Input Manifold which was connected with

the COM A port, occupies "Word1" of the I/O memory mapping.

If a sensor signal is stored in the "0 bit" of the Input Manifold, it becomes like the Figure below.

In the same way, in the case of the output data, the contents displayed in "Word1" of the

I/O memory mapping is output by the COM A port.

・・・・In case of corresponding with “ Word “

( m,n=0 - )

Branch

connector

MSB LSB MSB LSB

15 8 7 0

Word ( n ) COM A 1

Word ( n+1 ) COM B

Word ( n+2 ) COM C

Word ( n+3 ) COM D

:

:

:

:

Byte (m+1) Byte (m)

Byte (m+3) Byte (m+2)

Byte (m+5) Byte (m+4)

Byte (m+7) Byte (m+6)

Data ( 2 byte )

- 27 -

Page 29

EX500 Serial System EX## - OME0008

・・・・In case of corresponding with “ Double Word “

( m,n=0 - )

Branch

connector

MSB LSB MSB LSB MSB LSB MSB LSB

7 0 7 0 7 0 7 0

Data ( 4 byte )

Double Word

( n, n+1 )

Double Word

( n+2, n+3 )

:

:

COM A

/ COM B

COM C

/ COM D

:

:

Byte (m) Byte (m+1) Byte (m+2) Byte (m+3)

Byte (m+4) Byte (m+5) Byte (m+6) Byte (m+7)

1

!!!! CAUTION

Read carefully the user manual of PLC which is used as a master.

The method of PLC setup, reading from or writing to memory differ from one PLC manufacturer to another.

- 28 -

Page 30

EX500 Serial System EX## - OME0008

0000000

0

7. Input Unit Manifold

7 -1. Parts description

The Input Unit Manifold is composed of Input Unit ( EX500 - IB1 ( -X1 ) ), Input Block ( EX500 - IE□ ( -X1 ) ),

End Block and DIN rail.

The Input Unit Manifold can have various combinations depending on the number of input and type of the

sensor connector.

Input Block of different sensor specification can not be mixed. All blocks should be either PNP type

or NPN type.

Power LED

Communication connector

Sensor connector

Indicator LED

E

X

V

Input Unit

5

O

0

L

T

0

A

I

-

G

N

I

P

E

U

B

I

T

2

1

P

4

V

D

C

S

C

O

E

/

D

R

E

6

I

5

A

0

L

m

N

A

o

.

1

6

I

P

6

5

M

A

D

E

I

N

J

A

P

A

N

M8 Input Block

C

R

E

X

5

T

0

0

Y

-

U

I

S

P

E

1

2

E

4

(

V

D

1

P

C

N

/

6

P

0

)

C

m

R

A

/

I

P

6

5

E

U

S

X

T

5

Y

0

P

0

E

-

1

I

E

1

2

4

(

V

D

P

C

N

/

6

P

0

)

m

C

R

A

/

I

P

6

M

5

A

U

D

E

I

N

J

A

E

S

X

T

5

Y

0

P

0

E

-

1

I

E

P

A

N

1

2

4

(

V

D

P

C

N

/

6

P

0

)

m

C

R

A

/

I

P

6

M

5

A

U

D

E

I

N

J

A

E

S

X

T

5

Y

0

P

0

E

-

1

I

E

P

A

N

1

2

4

(

V

D

P

C

N

/

6

P

0

)

C

m

A

R

/

I

P

6

M

5

A

D

E

I

N

J

A

P

E

U

S

X

T

5

Y

0

P

0

E

-

1

I

E

1

2

4

A

N

(

V

D

P

C

N

/

6

P

0

)

C

m

A

R

/

I

P

6

M

5

A

U

D

E

I

N

J

A

P

E

S

X

T

5

Y

0

P

0

E

-

1

I

E

1

2

4

A

N

(

V

D

P

C

N

/

6

P

0

)

C

m

R

A

/

I

P

6

M

5

A

U

D

E

I

N

J

A

P

E

S

X

T

5

Y

0

P

0

E

-

1

I

E

1

2

4

A

N

(

V

D

P

C

N

/

6

P

0

)

C

m

R

A

/

I

P

6

M

5

A

D

E

I

N

J

A

E

U

S

X

T

5

Y

0

P

0

E

-

1

I

E

P

A

N

1

2

4

(

V

D

P

C

N

/

6

P

0

)

m

C

R

A

/

I

P

6

M

5

A

U

D

S

E

T

Y

I

P

N

E

1

J

A

P

A

N

M

A

D

E

I

N

J

A

P

A

N

Marker

End Block

a. Communication connector : GW Unit or Manifold Valve with SI Unit is connected here.

b. Power LED : Lights up when power source is ON.

Flashing LED indicates the presence of a short circuit.

Power supply must be reset after fixing the short circuit.

Lights off when power source is OFF.

c. Sensor connector : Sensor is connected.

d. Indicator LED : Lights up when sensor signal is ON. ( logical “ 1 “ )

Lights off when sensor signal is OFF. ( logical “ 0 “ )

e. Marker : Can be used for identifying input number.

7 -2. Correspondence of input number and Input Block

Each Input Unit Manifold can have up to 8 Input Blocks (16 input points ).

The first Input Block is always next to Input Unit.

Refer to section 3 -3 for pin out of connectors used on Input Unit and Input Block.

Input Unit

0

2

1111 1111

6

4

14

1

3

7

5

981110131215

- 29 -

Page 31

EX500 Serial System EX## - OME0008

7 -3. Exploded view / Input Unit Manifold

2

a

E

X

V

5

O

0

L

T

0

I

A

-

N

G

P

I

E

U

B

I

T

2

P

1

4

V

C

D

O

S

C

D

E

/

R

6

E

5

I

0

A

m

L

N

A

o

.

1

6

I

P

6

5

C

M

R

A

D

E

I

T

N

Y

U

S

P

J

E

A

P

1

A

N

4

E

X

V

5

O

0

L

T

0

A

-

G

I

I

E

P

E

2

C

5

4

O

V

D

S

D

E

(

E

C

R

/

P

I

2

N

A

4

L

P

0

N

m

)

o

A

.

I

P

6

C

5

M

R

A

D

E

I

T

N

Y

U

S

P

J

A

E

P

1

A

N

1

3

E

X

5

0

0

-

I

E

1

2

4

(

V

D

P

C

N

/

6

P

0

C

)

m

R

A

/

I

P

6

5

U

S

T

Y

P

E

1

M

A

D

E

I

N

J

A

P

A

N

E

X

5

0

0

V

-

O

I

L

T

E

A

G

3

I

(

E

P

P

C

N

O

D

P

E

2

)

4

V

D

C

/

6

C

0

R

m

A

T

I

P

Y

U

6

P

S

5

E

1

M

A

D

E

I

N

J

A

P

A

N

E

X

5

0

0

-

I

E

2

1

4

V

(

D

P

C

/

N

6

P

0

C

m

)

R

A

/

I

P

6

5

E

U

S

X

T

5

Y

0

P

0

E

-

1

I

E

2

1

4

V

(

D

P

C

/

N

6

P

0

m

C

)

R

A

/

I

P

M

6

5

A

U

D

S

E

T

Y

I

P

N

E

1

J

A

P

A

N

M

A

D

E

I

N

J

A

P

A

N

a

5

E

X

5

0

0

-

V

O

I

L

T

E

A

3

G

I

E

(

P

P

C

N

O

D

P

2

E

)

4

V

D

C

/

6

C

0

R

m

A

E

X

T

I

5

P

0

Y

U

6

P

S

5

0

E

V

-

O

1

I

L

T

E

A

G

3

I

(

E

P

P

C

N

O

D

P

E

2

)

4

V

D

C

M

/

6

A

C

D

0

R

m

E

A

I

N

J

T

I

A

P

Y

P

U

A

6

P

S

5

N

E

1

M

A

D

E

I

N

J

A

P

A

N

6

・・・・Parts list

NO. Parts name

Input Unit EX500 - IB1 EX500 - IB1 -X1

①

Input Block

②

( M8 connector )

Input Block

③

( M12 connector )

8 point unit Input Block

④

( M8 connector )

End Block EX500 - EB1

⑤

DIN rail VZ1000 - 11 - 1 - □

⑥

For standard For RIO

EX500 - IE□ EX500 - IE□ -X1 PNP … □: 1, NPN … □: 2

EX500 - IE□ EX500 - IE□ -X1 PNP … □: 3, NPN … □: 4

EX500 - IE□ EX500 - IE□ -X1 PNP … □: 5, NPN … □: 6

・・・・Addition of the Input Block

Loose two screws a which are holding the End Block and the Input Unit until they rotate freely.

1

Add a new Input Block on a desired location on DIN rail.

2

Press the whole assembly together to make a good connection between Input Blocks.

3

Tight the two screws a to secure the assembly on DIN rail connected together.

4

Parts number

Note

□ : Length

( Refer to the Valve Catalogues )

!!!! CAUTION

Tight the screws with specified tightening torque. ( Tightening torque : 0.6 N・m )

- 30 -

Page 32

EX500 Serial System EX## - OME0008

8. Manifold Valve

8 -1. Parts description

Refer to the Catalogues or Technical Instruction Manual of SV and VQC series Manifold Valve

for more details.

SV series

P

W

R

C

O

Power LED

Communication LED

M

1

E

X

V

O

5

L

T

0

A

O

G

U

E

0

T

P

2

U

4

-

I

T

V

P

D

S

C

C

/

O

0

S

6

D

E

5

E

R

0

0

I

m

A

A

1

L

N

O

.

1

6

I

P

6

5

C

M

A

D

E

T

I

Y

N

J

A

P

A

N

C

R

P

U

E

2

S

1

C

Communication connector ( C1 )

Communication connector ( C2 )

M

O

C

R

W

P

VQC series

Communication LED

Power LED

E

X

5

V

O

L

T

O

U

T

P

I

P

C

S

E

R

I

SI Unit for VQC series Manifold

a. Communication connector : “C1“ or “0“ port … Input Unit is connected here.

b. Power LED : Lights up when power source is ON.

c. Communication LED : Lights up when receiving data from the GW Unit.

SI Unit for SV series Manifold

s

e

0

i

r

0

e

5

s

C

X

E

M

S

M

O

C

R

W

T

P

I

N

U

I

S

S

I

U

N

0

I

0

T

-

Q

*

*

*

(

N

A

G

P

E

N

2

)

4

U

V

T

D

C

7

1

5

0

O

6

D

m

A

E

I

A

P

L

6