SMC Networks EX260-SPR1/3, EX260-SPR2/4, EX260-SPR5/7, EX260-SPR6/8, EX260-SDN1/3 Quick Start Manual

...Page 1

®

RoHS

IP67IP67 IP67 IP40

Top ported valve Bottom ported valve

Side ported valve

Mixed valve sizes manifold

7 mm width valve

Applicable Fieldbus protocols

EX260 Series

Fieldbus System

(Output device for driving 5 port solenoid valves)

Daisy-chain wiring

communication

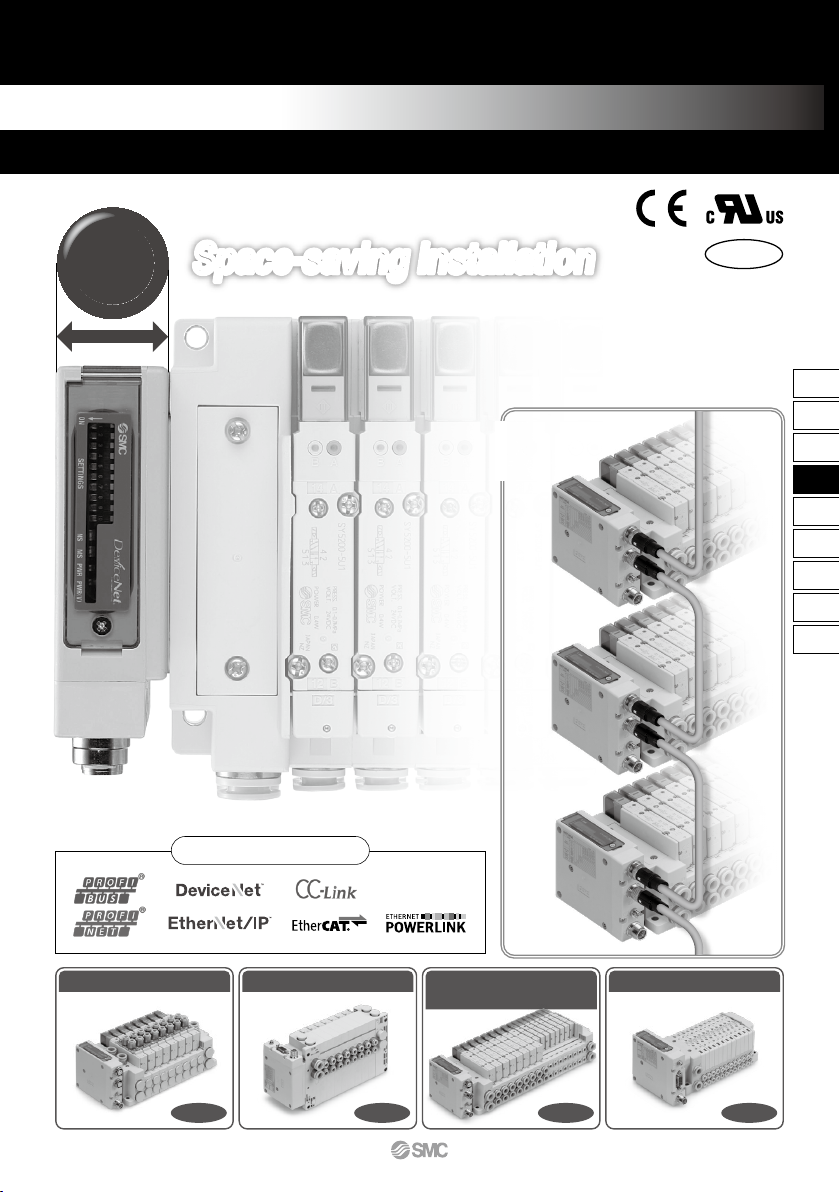

Space-saving InstallationSpace-saving Installation

Compact

28

mm

IP67

∗

∗

For units with D-sub connector, and when connect ed to S0700 manifolds, it is IP40 .

Drives up to 32 solenoids

789

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

A

Page 2

PWR

BUS IN

BUS OUT

E

3/5

1P

E

3/5

1P

B4A2 B4A2 B4A2 B4A2 B4A2

PWR

BUS IN

BUS OUT

E

3/5

1P

E

3/5

1P

B4A2 B4A2 B4A2 B4A2 B4A2

Product Specification Variations

M12 communication

connector

(PROFIBUS DP)

D-sub communication

connector

(PROFIBUS DP)

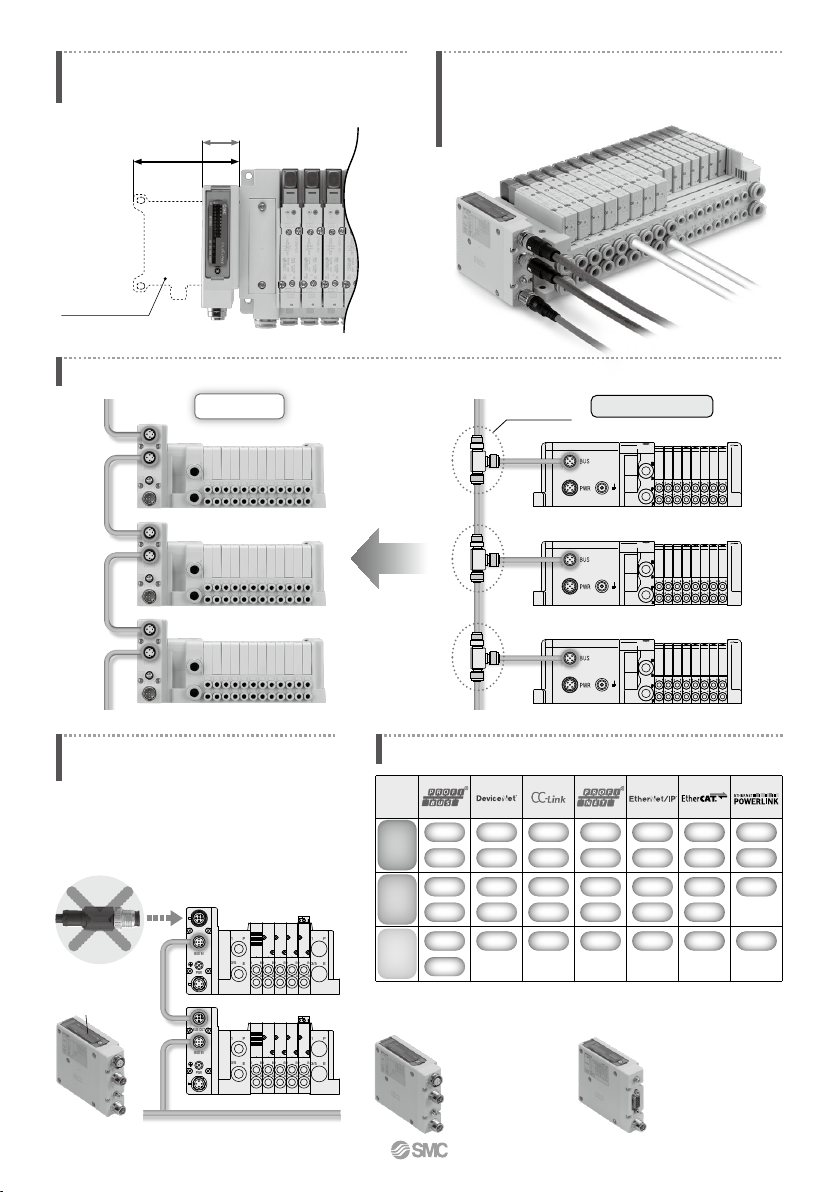

28.2 mm

81 mm

Communication connector examples

Fieldbus

EX260

Manifold length is shortened by the small

fieldbus output module (SI unit).

Wiring and piping from the same direction is possible.

(for side ported)

Effective for installation in locations where space is

limited above the valve.

Current model EX250

External branch connector is not necessary. Daisy-chain wiring is possible. Reduced wiring space

Branch connector

Current model (EX250)

External terminating resistor is not necessary.

(Only available for M12 PROFIBUS DP, CC-Link communication connectors)

ON/OFF switching is possible with an

internal terminating resistor. External

terminating resistor is not necessary.

External terminating resistor

Internal terminating

resistor

SI unit

16

32

PNP

NPN

M12

D-sub

16

32

PNP

NPN

M12

16

32

PNP

NPN

M12

16

32

PNP

NPN

M12

16

32

PNP

NPN

M12

Number of

outputs

Output

polarity

Communication

connector

16

32

PNP

NPN

M12

16

32

PNP

M12

790

A

Page 3

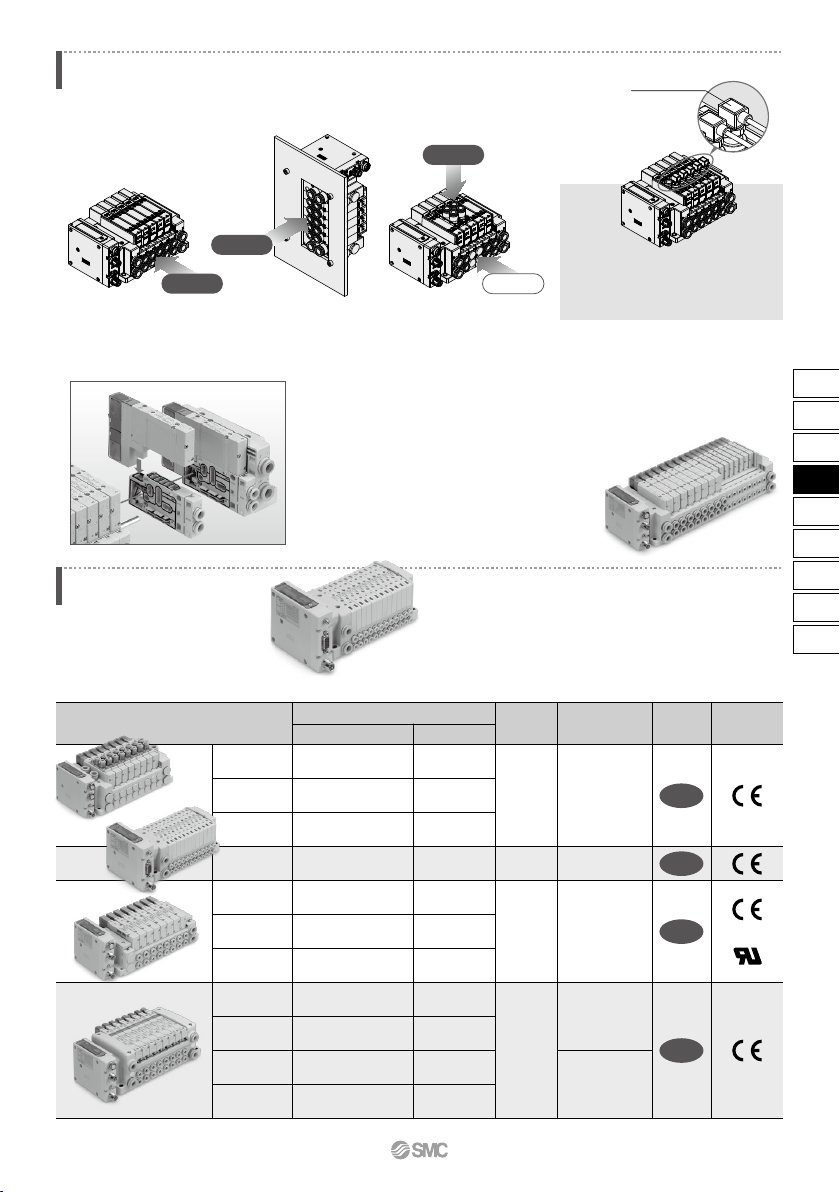

SY3000

SY5000

SY7000

S0700

SV1000

SV2000

SV3000

VQC1000

VQC2000

VQC4000

VQC5000

0.19

0.17

0.20

0.39

0.35

0.18

0.21

0.30

0.30

0.38

0.31

1.6

3.6

5.9

0.37

1.1

2.4

4.3

1.0

3.2

7.3

17

Series

Power

consumption

(W)

Enclosure Standards

Flow rate characteristics (4/2→5/3)

C [dm

3

/(s·bar)] b

Maximum

number of

solenoids

Applicable Valve Series

Note) For units with D-sub communication connector, it is IP40.

32

32

32

24

0.35 (standard)

0.1 (with powersaving circuit)

[Starting 0.4,

Holding 0.1]

0.6

0.95 (standard)

0.4 (Low wattage type)

0.4 (standard)

0.35

®

IP67

IP40

IP67

IP67

Side ported

Side ported

Bottom ported

Top ported

<Example of Use>

Valve piping direction variations

SY3000/5000/7000 Series

Pressure switch

Piping is possible from 3 directions.

Mixed mounting of top ported and side ported is possible.

By mounting top ported valves on side

ported and bottom ported type manifolds,

it is possible to detect the output of the

A/B port with a pressure switch.

Valves can be freely connected up to 24 stations.

Mixed valve sizes manifold

Valves with different sizes,

SY3000 and SY5000 or SY5000

and SY7000, can be mounted

on the same

manifold.

It is possible to connect only

the number of valves required,

from 1 to 24 stations, to suit

the application.

(Maximum number of

solenoids connected: 32)

7 mm width valves

can be connected.

It is possible to connect only the number of 7 mm

width valves required, from 1 to 24 stations.

(Maximum number of solenoids connected: 32)

S0700 Series

791

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

Page 4

M12

DN1

DN2

DN3

DN4

PR1

PR2

PR3

PR4

PR5

PR6

PR7

PR8

MJ1

MJ2

MJ3

MJ4

EC1

EC2

EC3

EC4

PN1

PN2

PN3

PN4

EN1

EN2

EN3

EN4

PL1

PL3

DeviceNet™

PROFIBUS DP

EtherCAT

PROFINET

POWERLINK

SI unit output polarity

32

16

32

16

32

16

32

16

32

16

32

16

32

16

32

16

M12

M12

D-sub

Note)

M12

M12

EtherNet/IP™

M12

M12

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

Sink/NPN (Positive common)

Source/PNP (Negative common)

QAN

QA

QBN

QB

NAN

NA

NBN

NB

NCN

NC

NDN

ND

VAN

VA

VBN

VB

DAN

DA

DBN

DB

FAN

FA

FBN

FB

EAN

EA

EBN

EB

GAN

GBN

Communication protocol

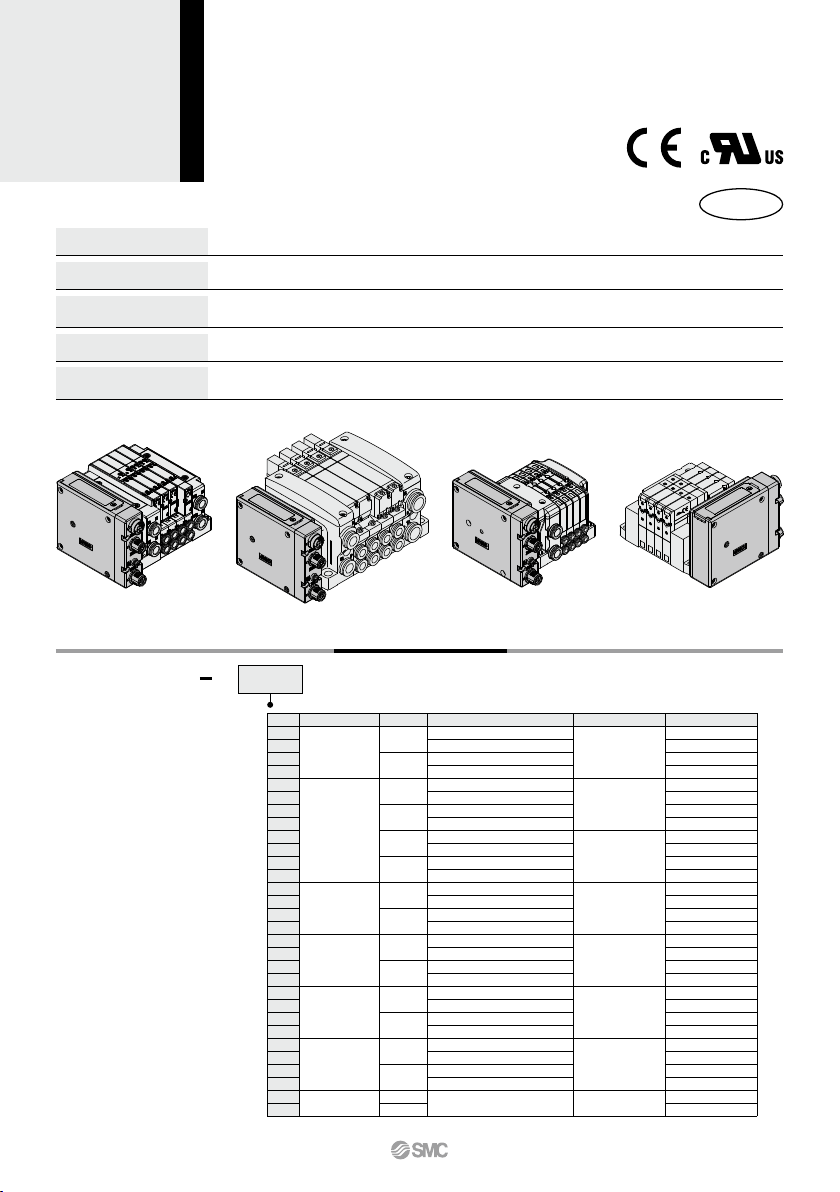

Compact design

Compact design for space saving

Number of outputs

Each 32/16 digital output type available in the series

Enclosure

IP67 (For units with D-sub connector, and when connected with S0700 manifolds, it is IP40.)

Output polarity

Each negative common (PNP) / positive common (NPN) type available in the series

(SI Unit compatible with POWERLINK is only negative common (PNP) type.)

Internal terminating resistor

ON/OFF switching is possible with an internal terminating resistor for communication.

(Only for units compatible with M12 PROFIBUS DP, CC-Link communication connectors)

SY3000/5000/7000 VQC1000/2000/4000/5000 S0700 SV1000/2000/3000

D

D

D

D

How to Order SI Units

PR1

EX260 S

Note)

Note) The SY3000/5000/7000, VQC1000/2000/4000/5000, and S0700 are not yet UL-compatible.

CC-Link

®

RoHS

Protocol

Symbol

Number of outputs

Communication connector

Manifold symbol

EX260 Series

SI Unit/For Output

Note) Enclosure is IP40 when the communication connector is D-sub.

792

A

Page 5

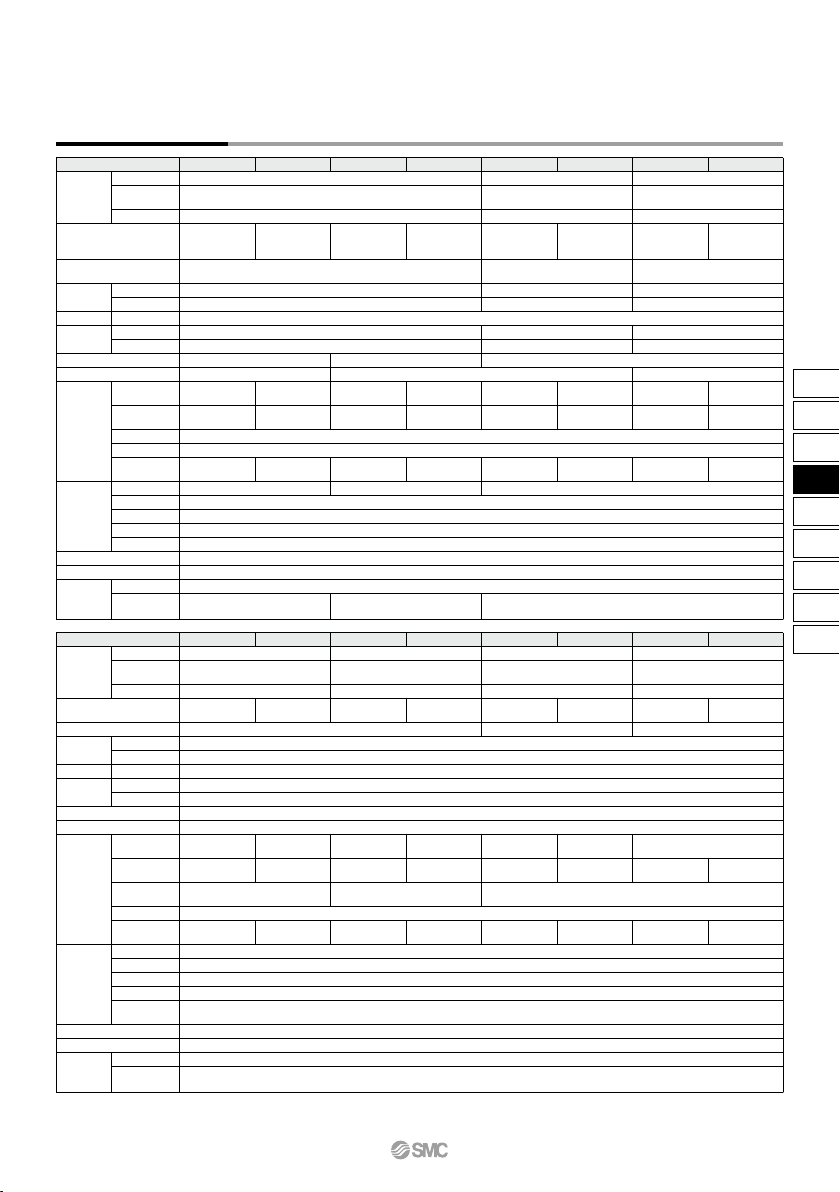

SI Unit Specifications

Model

EX260-SPR1/3 EX260-SPR2/4 EX260-SPR5/7 EX260-SPR6/8 EX260-SDN1/3 EX260-SDN2/4 EX260-SMJ1/3 EX260-SMJ2/4

125 k/250 k/500 kbps

156 k/625 k/

2.5 M/5 M/10 Mbps

M12

Built-in

—

—

22.8 to 26.4 VDC

11 to 25 VDC

100 mA or less

Applicable

system

I/O occupation area

(Inputs/Outputs)

Communication speed

Power supply

for control

Power supply for output

Communication connector specification

Terminating resistor switch

Power supply for

communication

Output

Environmental

resistance

Standards

Weight

Mounting screw

Accessories

IP67 IP40 IP67

–10 to 50°C

35 to 85%RH (No condensation)

500 VAC for 1 minute between terminals and housing

10 MΩ or more (500 VDC measured via megohmmeter) between terminals and housing

CE marking, UL (CSA) compatible

200 g

2 pcs.

24 VDC

Power supply voltage

Internal current consumption

Power supply voltage

Power supply voltage

Internal current consumption

Protocol

Version

Note 1)

Configuration file

Note 3)

Supplied current

Output type

Number of outputs

Load

Supplied voltage

Enclosure

Operating temperature range

Operating humidity range

Withstand voltage

Insulation resistance

Seal cap (for M12

connector socket)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

SPR1: 32 points

SPR3: 16 points

SPR2: 32 points

SPR4: 16 points

SPR5: 32 points

SPR7: 16 points

SPR6: 32 points

SPR8: 16 points

SDN1: 32 points

SDN3: 16 points

SDN2: 32 points

SDN4: 16 points

SPR1: 0/32

SPR3: 0/16

SPR2: 0/32

SPR4: 0/16

SPR5: 0/32

SPR7: 0/16

SPR6: 0/32

SPR8: 0/16

SDN1: 0/32

SDN3: 0/16

SDN2: 0/32

SDN4: 0/16

SMJ1: 32/32

SMJ3:

32/32

(1 station, remote I/O stations)

SMJ2: 32/32

SMJ4:

32/32

(1 station, remote I/O stations)

SPR1: Max. 2.0 A

SPR3: Max. 1.0 A

SPR2: Max. 2.0 A

SPR4: Max. 1.0 A

SPR5: Max. 2.0 A

SPR7: Max. 1.0 A

SPR6: Max. 2.0 A

SPR8: Max. 1.0 A

SDN1: Max. 2.0 A

SDN3: Max. 1.0 A

SDN2: Max. 2.0 A

SDN4: Max. 1.0 A

EX9-AWTS (1 pc.) — EX9-AWTS (1 pc.)

D-sub M12

None Built-in

Volume 1(Edition 3.5)

Volume 3(Edition 1.5)

9.6 k/19.2 k/45.45 k/93.75 k/

187.5 k/500 k/1.5 M/3 M/6 M/12 Mbps

21.6 to 26.4 VDC

100 mA or less

—

—

—

—

21.6 to 26.4 VDC

100 mA or less

PROFIBUS DP

DeviceNet™

CC-Link

DP-V0 Ver.1.10

—

GSD file EDS file

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

SMJ1: 32 points

SMJ3: 16 points

SMJ2: 32 points

SMJ4: 16 points

SMJ1: Max. 2.0 A

SMJ3: Max. 1.0 A

SMJ2: Max. 2.0 A

SMJ4: Max. 1.0 A

Solenoid valve with protective circuit for surge voltage of 24 VDC/1.5 W or less (SMC)

Model

EX260-SEC1/3 EX260-SEC2/4 EX260-SPN1/3 EX260-SPN2/4 EX260-SEN1/3 EX260-SEN2/4

Applicable

system

I/O occupation area

(Inputs/Outputs)

Communication speed

Power supply

for control

Power supply for output

Communication connector specification

Terminating resistor switch

Power supply for

communication

Output

Environmental

resistance

Standards

Weight

Mounting screw

Accessories

IP67

–10 to 50°C

35 to 85%RH (No condensation)

500 VAC for 1 minute between terminals and housing

CE marking, UL (CSA) compatible

200 g

2 pcs.

10 MΩ or more (500 VDC measured via megohmmeter) between terminals and housing

24 VDC

Power supply voltage

Internal current consumption

Power supply voltage

Power supply voltage

Internal current consumption

Protocol

Version

Note 1)

Configuration file

Note 3)

Supplied voltage

Output type

Number of outputs

Load

Supplied voltage

Enclosure

Operating temperature range

Operating humidity range

Withstand voltage

Insulation

resistance

Seal cap (for M12

connector socket)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

Source/PNP

(Negative common)

Sink/NPN

(Positive common)

SEC1: 32 points

SEC3: 16 points

SEC2: 32 points

SEC4: 16 points

SPN1: 32 points

SPN3: 16 points

SPN2: 32 points

SPN4: 16 points

SEN1: 32 points

SEN3: 16 points

SEN2: 32 points

SEN4: 16 points

SEC1: 0/32

SEC3: 0/16

SEC2: 0/32

SEC4: 0/16

SPN1: 0/32

SPN3: 0/16

SPN2: 0/32

SPN4: 0/16

SEN1: 16/32

SEN3: 16/16

SEN2: 16/32

SEN4: 16/16

SEC1: Max. 2.0 A

SEC3: Max. 1.0 A

SEC2: Max. 2.0 A

SEC4: Max. 1.0 A

SPN1: Max. 2.0 A

SPN3: Max. 1.0 A

SPN2: Max. 2.0 A

SPN4: Max. 1.0 A

SEN1: Max. 2.0 A

SEN3: Max. 1.0 A

SEN2: Max. 2.0 A

SEN4: Max. 1.0 A

EX9-AWTS (1 pc.)

Volume 1(Edition 3.8)

Volume 2(Edition 1.9)

21.6 to 26.4 VDC

100 mA or less

22.8 to 26.4 VDC

—

—

M12

None (Not required)

10 M/100 Mbps

Note 2)

100 Mbps

Note 2)

EtherCAT

Note 2)

EtherNet/IP™

Note 2)

Conformance

Test Record V.1.1

XML file

PROFINET

Note 2)

PROFINET Specification

Version 2.2

GSD file EDS file

Solenoid valve with protective circuit for surge

voltage of 24 VDC/1.5 W or less (SMC)

Solenoid valve with protective circuit for surge

voltage of 24 VDC/1.0 W or less (SMC)

Solenoid valve with protective circuit for surge

voltage of 24 VDC/1.5 W or less (SMC)

EX260-SPL1 EX260-SPL3

Source/PNP

(Negative common)

32 16

16/32 16/16

Max. 2 A Max. 1 A

EPSG DS 301 Version 1.2.0

100 Mbps

Note 2)

POWERLINK

XDD file

Note 1) Please note that the version is subject to change.

Note 2) Use a CAT5 or higher transmission cable for EtherCAT, PROFINET, EtherNet/IP™, POWERLINK.

Note 3) Each file can be downloaded from the SMC website, http://www.smcworld.com

For Output EX260 Series

793

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

A

Page 6

D-sub communication connector typeM12 communication connector type

90.9

28.2

102.4

90.9

102.4

28.2

21 20.6 16.4 9

76.5

28.75 29.25 9

76.5

SI Unit Dimensions

Part no.

Communication protocol

EX260-SPR1/-SPR2

-SPR3/-SPR4

PROFIBUS DP

5 pins, socket, B code

5 pins, plug, B code

5 pins, plug, A code

Note) The setting switch varies depending on the model.

Refer to the operation manual for details.

Please download it via the SMC website, http://www.smcworld.com

EX260-SDN

DeviceNet™

5 pins, socket, A code

5 pins, plug, A code

4 pins, plug, A code

EX260-SMJ

CC-Link

EX260-SEC

EX260-SPN

EX260-SEN

EX260-SPL

EtherCAT

PROFINET

EtherNet/IP™

POWERLINK

M3

Communication connector (M12) BUS OUT

Communication connector (M12) BUS IN

Ground terminal

Power connector (M12)

<Setting switch>

• Address switch

• Communication speed switch

• Terminating resistor switch

• Others

<LED indication>

• Communication state

• Unit power supply state

• Valve power supply state

Part no.

Communication protocol

EX260-SPR5/-SPR6/-SPR7/-SPR8

PROFIBUS DP

M3

9 pins, socket

5 pins, plug, A code

Ground terminal

Communication connector (D-sub) BUS IN/OUT

Power connector (M12)

D-sub communication connector type

Functions of SI Unit Parts

<Connector>

M12 communication connector type

<LED indication and setting switch>

5 pins, socket, A code

Note1)

4 pins, plug, A code

5 pins, plug, B code

4 pins, socket, D code

4 pins, socket, D code

5 pins

Note2)

, 4 pins

Note3)

,

plug, A code

EX260 Series

Note 1) Recommended mating M12

4-pin plug, part no.

PCA-1567717.

Note 2) For EtherCAT, PROFINET,

POWERLINK

Note 3) For EtherNet/IP™

794

A

Page 7

White/Orange

Orange

White/Green

Green

Accessories

q Communication cable with connector

For SI units compatible with

PROFIBUS DP, DeviceNet™, CC-Link

For SI units compatible with EtherCAT, PROFINET, EtherNet/IP™, POWERLINK

Refer to page 907 for details.

020EX9 AC EN

Cable length (L)

1000 [mm]

2000 [mm]

3000 [mm]

5000 [mm]

10000 [mm]

010

020

030

050

100

PSRJ

M12 plug (straight) ⇔ RJ-45 connector

PSRJ

Plug connector

pin arrangement

D code

Connections (Straight cable)

M12

RJ-45

Plug connector

pin arrangement

1

2

3

4

5

6

7

8

Terminal

no.

1

2

3

4

1

2

3

4

5

6

7

8

Terminal

no.

Shield

Pair

Pair

Core wire

colors

Connector specification

For SI units compatible with EtherCAT, PROFINET, EtherNet/IP™, POWERLINK

PCA 1446566

For SI units compatible with EtherCAT, PROFINET, EtherNet/IP™, POWERLINK

PCA 1446553

5000 [mm]

1446566

Cable length

Fieldwireable connector

(ø

6.5)

50500047.3

ø14.8

Plug connector

pin arrangement

D code

12

3 4

M12

SPEEDCON

ø

17.5

ø

19

≈ 61

Width across

flats 16

M12

For Output EX260 Series

12

3 4

Plug connector

pin arrangement

D code

12

3 4

1

2

3

4

White: RD+

Blue: RD–

Yellow: TD+

Orange: TD–

Connections

Terminal

no.

Wire guide color

Width across

flats 13

ø6.4

(47.3) (44)

L

ø14.8

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø6.5 mm

AWG22

1.5 mm

45.5 mm

Applicable cable

Cable O.D.

Cable cross section (Stranded wire)

4.0 to 8.0 mm

0.14 to 0.34 mm

2

/AWG26 to 22

Note) The table above shows the specifications for the applicable

cable. Adaptation for the connector may vary on account of

the conductor construction of the electric wire.

795

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

A

Page 8

w Power cable with connector (for SI units)

Accessories

EX500 AP

2

4 3

Socket connector

pin arrangement

A code

Socket connector

pin arrangement

A code

1

1

2

3

4

5

Terminal

no.

Core wire

colors

M12

Connections (PROFIBUS DP/EtherCAT/PROFINET/POWERLINK)

Cable length (L)

1000 [mm]

5000 [mm]

010

050

Connector specification

Straight

Angle

S

A

S

050

For SI units compatible with PROFIBUS DP, DeviceNet™, EtherCAT, PROFINET, EtherNet/IP™, POWERLINK

Brown: 24 VDC +10%/–5% (Solenoid valve power supply)

White: 0 V (Solenoid valve power supply)

Blue: 24 VDC ±10% (Control power supply)

Black: 0 V (Control power supply)

Green/Yellow: Not connected

1

2

3

4

5

Terminal

no.

Core wire

colors

Connections (DeviceNet™, EtherNet/IP™)

Brown: Not connected

Note 1)

, 24 VDC ±10% (Control power supply)

Note 2)

White: 24 VDC +10%/–5%

(Solenoid valve power supply)

Blue: Not connected

Note 1)

, 0 V (Control power supply)

Note 2)

Black: 0 V (Solenoid valve power supply)

Green/Yellow: Not connected

Straight connector type

2

4 3

5

1

M12

Angle connector type

5

SPEEDCON

PCA

Cable length (L)

1500 [mm]

3000 [mm]

5000 [mm]

1401804

1401805

1401806

1401804

4 3

21

ø14.8

M12

SPEEDCON

44.5 L 50

ø5.0

5

Socket connector

pin arrangement

A code

Note 1) For DeviceNet™

Note 2) For EtherNet/IP™

1

2

3

4

5

Terminal

no.

Core wire

colors

Connections (PROFIBUS DP/EtherCAT/PROFINET/POWERLINK)

Brown: 24 VDC +10%/–5% (Solenoid valve power supply)

White: 0 V (Solenoid valve power supply)

Blue: 24 VDC ±10% (Control power supply)

Black: 0 V (Control power supply)

Gray: Not connected

1

2

3

4

5

Terminal

no.

Core wire

colors

Connections (DeviceNet™, EtherNet/IP™)

Brown: Not connected

Note 1)

, 24 VDC ±10% (Control power supply)

Note 2)

White: 24 VDC +10%/–5%

(Solenoid valve power supply)

Blue: Not connected

Note 1)

, 0 V (Control power supply)

Note 2)

Black: 0 V (Solenoid valve power supply)

Gray: Not connected

Note 1) For DeviceNet™

Note 2) For EtherNet/IP™

EX260 Series

ø14.9

25.3

28.3

30

5

50

L

ø6

ø14.9

40.7

27

L

ø6

30

5

50

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø6 mm

AWG22

1.5 mm

40 mm

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø6 mm

AWG22

1.5 mm

40 mm

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø5.0 mm

AWG22

1.27 mm

21.7 mm

796

B

Page 9

w Power cable with connector (for SI units)

Accessories

e Seal cap: For M12 connector socket

EX9 AW

Use this on ports that are not being used for communication connector (M12

connector socket).

Use of this seal cap maintains the integrity of the IP67 enclosure.

Note) Tighten the seal cap with the prescribed tightening torque. (For M12: 0.1 N·m)

TS

Connector type

For M12 connector socket (10 pcs.)

For M12 connector socket

M12 x 1

14

10.2

14

For

SI units compatible with

CC-Link

Straight connector type

TS

EX9 AC 1

Cable length (L)

1000 [mm]

3000 [mm]

5000 [mm]

010

030

050

050

SPEEDCON

PCA

Cable length (L)

1500 [mm]

3000 [mm]

5000 [mm]

1401807

1401808

1401809

1401807

2

4 3

5

1

Socket connector

pin arrangement

B code

M12

48.1

L

30505

ø6.4

Connections

1

2

3

4

5

Terminal

no.

Cable core

wire colors

4 3

21

M12

SPEEDCON

ø14.8

50L44.5

ø5.0

5

Socket connector

pin arrangement

B code

Brown: 24 VDC +10%/–5% (Solenoid valve power supply)

White: 0 V (Solenoid valve power supply)

Blue: 24 VDC ±10% (Control power supply)

Black: 0 V (Control power supply)

Green/Yellow: Not connected

Connections

1

2

3

4

5

Terminal

no.

Cable core

wire colors

Brown: 24 VDC +10%/–5% (Solenoid valve power supply)

White: 0 V (Solenoid valve power supply)

Blue: 24 VDC ±10% (Control power supply)

Black: 0 V (Control power supply)

Gray: Not connected

For Output EX260 Series

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø6.4 mm

AWG22

1.65 mm

59 mm

Item Specifications

Cable O.D.

Nominal cross section

Wire diameter (Including insulator)

Min. bending radius

ø5.0 mm

AWG22

1.27 mm

21.7 mm

797

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

A

Page 10

Design/Selection

1. Use this product within the specification range.

Using beyond the specified specifications range can cause

fire, malfunction, or damage to the system.

Check the specifications before operation.

2. When using for an interlock circuit:

• Provide a multiple interlock system which is

operated by another system (such as mechanical

protection function).

• Perform an inspection to confirm that it is working

properly.

This may cause possible injury due to malfunction.

Warning

Mounting

4. When lifting a large size manifold solenoid valve

unit, take care to avoid causing stress to the valve

connection joint.

The connection parts of the unit may be damaged. Because

the unit may be heavy, carrying and installation should be

performed by more than one operator to avoid strain or injury.

5. When placing a manifold, mount it on a flat surface.

Torsion in the whole manifold can lead to trouble such as air

leakage or defective insulation.

Wiring

1. Check the grounding to maintain the safety of the

reduced wiring system and for anti-noise

performance.

Provide a specific grounding as close to the unit as possible to

minimize the distance to grounding.

2. Avoid repeatedly bending or stretching the cable

and applying a heavy object or force to it.

Wiring applying repeated bending and tensile stress to the

cable can break the circuit.

3. Avoid miswiring.

If miswired, there is a danger of malfunction or damage to the

reduced wiring system.

4. Do not wire while energizing the product.

There is a danger of malfunction or damage to the reduced

wiring system or output device.

5. Avoid wiring the power line and high pressure line

in parallel.

Noise or surge produced by signal line resulting from the power

line or high pressure line could cause malfunction.Wiring of the

reduced wiring system or output device and the power line or

high pressure line should be separated from each other.

6. Check the wiring insulation.

Defective insulation (contact with other circuits, improper

insulation between terminals, etc.) may cause damage to the

reduced wiring system or output device due to excessive

voltage and current.

7. When a reduced wiring system is installed in

machinery/equipment, provide adequate protection

against noise by using noise filters, etc.

Noise in signal lines may cause malfunction.

1. When applicable to UL, use a Class 2 power supply unit

conforming to UL1310 for direct current power supply.

2. Use this product within the specified voltage range.

Using beyond the specified voltage range is likely to cause the

units and connecting devices to be damaged or to malfunction.

3. Do not install a unit in a place where it can be used

as a foothold.

Applying any excessive load such as stepping on the unit by

mistake or placing a foot on it, will cause it to break.

4. Keep the surrounding space free for maintenance.

When designing a system, take into consideration the amount

of free space needed for performing maintenance.

5. Do not remove the name plate.

Improper maintenance or incorrect use of operation manual

can cause failure and malfunction. Also, there is a risk of

losing conformity with safety standards.

1. When handling and assembling units:

• Do not apply excessive force to the unit when

disassembling.

The connecting portions of the unit are firmly joined with

seals.

• When joining units, take care not to get fingers

caught between units.

Injury can result.

2. Do not drop, bump, or apply excessive impact.

Otherwise, the unit can become damaged, malfunction, or fail

to function.

3. Observe the tightening torque range.

Tightening outside of the allowable torque range will likely

damage the screw.

IP67 cannot be guaranteed if the screws are not tightened to

the specified torque.

Mounting

EX260 Series

Specific Product Precautions 1

Be sure to read this before handling the products. Refer to back page 50 for Safety

Instructions and pages 3 to 9 for 3/4/5 Port Solenoid Valve Precautions.

Caution

Caution

Caution

Caution

798

Page 11

Wiring

Operating Environment

1. Do not use in an atmosphere containing an

inflammable gas or explosive gas.

Use in such an atmosphere is likely to cause a fire or

explosion. This system is not explosion-proof.

Operating Environment

2. Provide adequate protection when operating in

locations such as the following.

Failure to do so may cause damage or malfunction.

The effect of countermeasures should be checked in individual

equipment and machine.

1) Where noise is generated by static electricity, etc.

2) Where there is a strong electric field

3) Where there is a danger of exposure to radiation

4) When in close proximity to power lines or high voltage lines

3. Do not use in an environment where oil and chemicals

are used.

Operating in environments with coolants, cleaning solvents,

various oils or chemicals may cause adverse effects (damage,

malfunction) to the unit even in a short period of time.

4. Do not use in an environment where the product

could be exposed to corrosive gas or liquid.

This may damage the unit and cause it to malfunction.

5. Do not use in locations with sources of surge

generation.

Installation of the unit in an area around the equipment

(electromagnetic lifters, high frequency induction furnaces,

welding machine, motors, etc.), which generates the large

surge voltage could cause to deteriorate an internal circuitry

element of the unit or result in damage. Implement

countermeasures against the surge from the generating

source, and avoid touching the lines with each other.

6. The product is CE marked, but not immune to

lightning strikes. Take measures against lightning

strikes in your system.

7. Keep dust, wire scraps and other extraneous

material from getting inside the product.

This may cause malfunction or damage.

8. Mount the unit in such locations, where no vibration

or shock is affected.

This may cause malfunction or damage.

9. D o not use in places where there are cyclic

temperature changes.

In case that the cyclic temperature is beyond normal

temperature changes, the internal unit is likely to be adversely

effec-ted.

10. Do not use in direct sunlight.

Do not use in direct sunlight. It may cause malfunction or

damage.

11. Use this product within the specified ambient

temperature range.

This may cause malfunction.

12. Do not use in places where there is radiated heat

around it.

Such a place is likely to cause malfunction.

1. Select the proper type of enclosure according to the

environment of operation.

IP67 is achieved when the following conditions are met.

1) Provide appropriate wiring between all units using electrical

wiring cables, communication connectors and cables with

M12 connectors.

2) Suitable mounting of each unit and manifold valve.

3) Be sure to mount a seal cap on any unused connectors.

If using in an environment that is exposed to water splashes,

please take measures such as using a cover.

When the enclosure is IP40, do not use in an operating

environment or atmosphere where it may come in contact with

corrosive gas, chemical agents, seawater, water, or water vapor.

When connected to the EX260-SPR5/6/7/8, manifold

enclosure is IP40.

Caution

Caution

Caution

Warning

8. When connecting wires of output device, prevent

water, solvent or oil from entering inside the

connector section.

This can cause damage, equipment failure or malfunction.

9. Avoid wiring patterns in which excessive stress is

applied to the connector.

This may cause malfunction or damage to the unit due to

contact failure.

10. Select connectors that are ø16 or less if mounting

manifolds directly using fieldwireable connectors

for SI unit power supply wiring.

Using large diameter connectors causes interference with the

mounting surface.

The following cables with connectors are recommended.

For EX260-SPR/-SDN/-SEC/-SPN/-SEN/-SPL

<Cable with connector>

EX500-AP-

PCA-1401804/-1401805/-1401806

For EX260-SMJ

<Cable with connector>

EX9-AC-1

PCA-1401807/-1401808/-1401809

EX260 Series

Specific Product Precautions 2

Be sure to read this before handling the products. Refer to back page 50 for Safety

Instructions and pages 3 to 9 for 3/4/5 Port Solenoid Valve Precautions.

799

EX12

EX140

EX180

EX260

EX250

EX600

EX500

EX510

PCA

EX

EX260

A

Page 12

Adjustment/Operation

Warning

1. Do not perform operation or setting with wet hands.

There is a risk of electrical shock.

Maintenance

1. Do not disassemble, modify (including circuit board

replacement) or repair this product.

Such actions are likely to cause injuries or breakage.

2. When an inspection is performed,

• Turn off the power supply.

• Stop the air supply, exhaust the residual pressurein

piping and verify that the air is released before

performing maintenance work.

Unexpected malfunction of system components and injury

can result.

Trademark

DeviceNet™ is a trademark of ODVA.

EtherNet/IP™ is a trademark of ODVA.

EtherCAT

®

is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

1. Use a watchmakers’ screwdriver with thin blade for

the setting of each switch of the SI unit.

When setting the switch, do not touch other unrelated

parts.

This may cause parts damage or malfunction due to a short

circuit.

2.

Provide adequate setting for the operating conditions.

Failure to do so could result in malfunction.

Refer to the operation manual for setting of the switches.

3. For details on programming and address setting,

refer to the manual from the PLC manufacturer.

The content of programming related to protocol is designed by

the manufacturer of the PLC used.

4. For the EX260-SPN, the side of the SI unit may

become hot.

It may cause burns.

1. When handling and replacing the unit:

• Do not apply excessive force to the unit when

disassembling.

The connecting portions of the unit are firmly joined with

seals.

• When joining units, take care not to get fingers

caught between units.

Injury can result.

2. Perform periodic inspection.

Unexpected malfunction in the system composition devices is

likely to occur due to malfunction of machinery or equipment.

3. A fter maintenance, make sure to perform an

appropriate functionality inspection.

In cases of abnormality such as faulty operation, stop

operation. Unexpected malfunction in the system composition

devices is likely to occur.

4. Do not use benzene and thinner for cleaning units.

Damage to the surface or erasure of the display can result.

Wipe off any stains with a soft cloth.

If the stain is persistent, wipe off with a cloth soaked in a

dilute solution of neutral detergent and wrung out tightly,

and then finish with a dry cloth.

Other

1. Refer to the catalog of each series for Common

Precautions and Specific Product Precautions on

manifold solenoid valves.

Caution

Caution

Caution

Warning

EX260 Series

Specific Product Precautions 3

Be sure to read this before handling the products. Refer to back page 50 for Safety

Instructions and pages 3 to 9 for 3/4/5 Port Solenoid Valve Precautions.

800

Page 13

Contact our sales office for delivery dates

and prices as this is a special model.

Specialized Product

IO-Link Compatible SI Unit

EX260-SIL1-X207/X210

IO-Link communication enables users to check

Features

PLC

unit information and monitor unit status, in

addition to ON/OFF valve control.

PC

Point to Group

P. G . information

IO-Link is an open communication interface technology between the sensor/actuator and the I/O terminal that is an international standard IEC61131-9.

Various fieldbusses

IO-Link master

IO-Link communication

IO-Link Compatible Device:

SI Unit

EX260-SIL1-X207/X210

Send and receive ON/OFF signals + unit information/status

Sending and receiving of unit information, error

detection, or condition monitoring data

<Unit Information> Manufacturer’s name, product number, version information

<Error Detection> Output wiring disconnection, short circuit

<Conditioning Monitoring> Number of valve operations, operation threshold exceeded

Application Example

Supporting periodic cylinder maintenance

The replacement time of the cylinder connected to the valve

can be predicted by counting the number of valve operation

instructions. This enables periodic maintenance to be

performed before any unexpected cylinder failure occurs.

Currently at 10 million

operations

Currently at 5 million

operations

Port class B compliant: X210

Port class A compliant: X207

Supports data update cycles of 1 ms or less

Shortest data update cycle: 0.8 ms

The data update cycle can be set for the IO-Link master based

on the SI unit’s shortest data update cycle of 0.8 ms.

IO-Link master and SI unit can be connected with one cable

Signal wire and valve power supply wire can be connected

with the same cable.

Also applicable to the types in which the signal wire and valve

power supply wire are connected with individual cables.

(Port class A compliant: X207 specifications)

(Port class B compliant: X210 specifications)

Uses 4-wire or 5-wire unshielded cables

Special communication cables are not necessary.

A conventional 4-wire or 5-wire unshielded cable can be used

for input and output of sensors, switches, etc.

(Recommended specifications: Conductor resistance 3 Ω, Wireto-wire capacitance 3 nF or less, 20 m or less)

Caution

©2017 SMC Corporation All Rights Reserved

To ensure the safest possible operation of this product, please be sure to thoroughly read the

“Safety Instructions” in our “Best Pneumatics” catalog before use.

4-14-1, SOTO-KANDA, CHIYODA-KU, TOKYO 101-0021, JAPAN

URL: http://www.smcworld.com

SP165X-022E

P: VS

Page 14

IO-Link Compatible SI Unit

EX260-SIL1-X207/X210

Specifications

Specialized Product

Point to Group

P. G . information

Item

Protocol IO-Link version 1.1

Communication speed COM2 (38.4 kbps)/COM3 (230.4 kbps) (Selected by DIP switch)

IO-Link port class

(Communication connector)

IO-Link type Device

Vendor ID 131

Process data size 0 byte input/4 bytes output

Number of outputs 32 outputs

Output type PNP (Negative common)/Source

Connected load Solenoid valve with surge voltage suppressor of 24 VDC and 1.5 W or less (manufactured by SMC)

Output

Solenoid valve power supply

Residual voltage 0.4 VDC or less

Control unit power supply

Weight 200 g or less

Standards CE marking, UL/CSA

(Valve power supplied from the valve power supply connector)

EX260-SIL1-X207 EX260-SIL1-X210

Class A

(Valve power supplied from the communication connector)

22.8 to 26.4 VDC

2 A or less (according to the solenoid valve station specification)

18 to 30 VDC

0.1 A or less

Class B

IODD files are required to configure this product.

Please contact SMC for the IODD files.

Also, please contact SMC for the operation manual.

Wiring Specifications

Suffix Communication connector Power supply connector for solenoid valve

M12 4-pin plug, A-coded M12 5-pin plug, A-coded

No.

X207

X210

No.

1

2

3

4

M12 5-pin plug, A-coded

No.

1

2

3

4

5

Designation

L+ +24 V for control unit

— Unused

L− 0 V for control unit

C/Q IO-Link communication data

Designation

L+ +24 V for control unit

SV24V +24 V for solenoid valve

L− 0 V for control unit

C/Q IO-Link communication data

SV0V 0 V for solenoid valve

Description

Description

Designation

— Unused

1

SV24V +24 V for solenoid valve

2

— Unused

3

— Unused

4

SV0V 0 V for solenoid valve

5

Description

Page 15

Output connector (34 pins, Receptacle)

Output common (0 V)

Solenoid output 0

Solenoid output 2

Solenoid output 4

Solenoid output 6

Solenoid output 8

Solenoid output 10

Solenoid output 12

Solenoid output 14

Solenoid output 16

Solenoid output 18

Solenoid output 20

Solenoid output 22

Solenoid output 24

Solenoid output 26

Solenoid output 28

Solenoid output 30

Output common (0 V)

Solenoid output 1

Solenoid output 3

Solenoid output 5

Solenoid output 7

Solenoid output 9

Solenoid output 11

Solenoid output 13

Solenoid output 15

Solenoid output 17

Solenoid output 19

Solenoid output 21

Solenoid output 23

Solenoid output 25

Solenoid output 27

Solenoid output 29

Solenoid output 31

DescriptionDesignationNo. DescriptionDesignationNo.

Communication connector

Ground terminal (M3)

Power supply connector (PWR)

Output connector (34 pins)

IO-Link Compatible SI Unit

EX260-SIL1-X207/X210

How to Order

Specialized Product

Point to Group

P. G . information

EX260

Communication protocol

IL

Output specification

32 outputs, PNP (Negative common)/Source

1

IO-Link

1S IL

X207

IO-Link port class

X207

X210

IO-Link port Class A, Valve power

supplied from another connector

IO-Link port Class B

Dimensions [mm]

EX260-SIL1-X207 (The X210 is not provided with a power supply connector.)

Caution

• For dimensions when combined with the valve manifold, use the

dimensions of the valve manifold where the standard EX260 series unit

is mounted.

• Order the valve manifold separately. Specify “no SI unit” and “negative

common” for the valve manifold specifications.

Loading...

Loading...