Page 1

Summary of Product elements

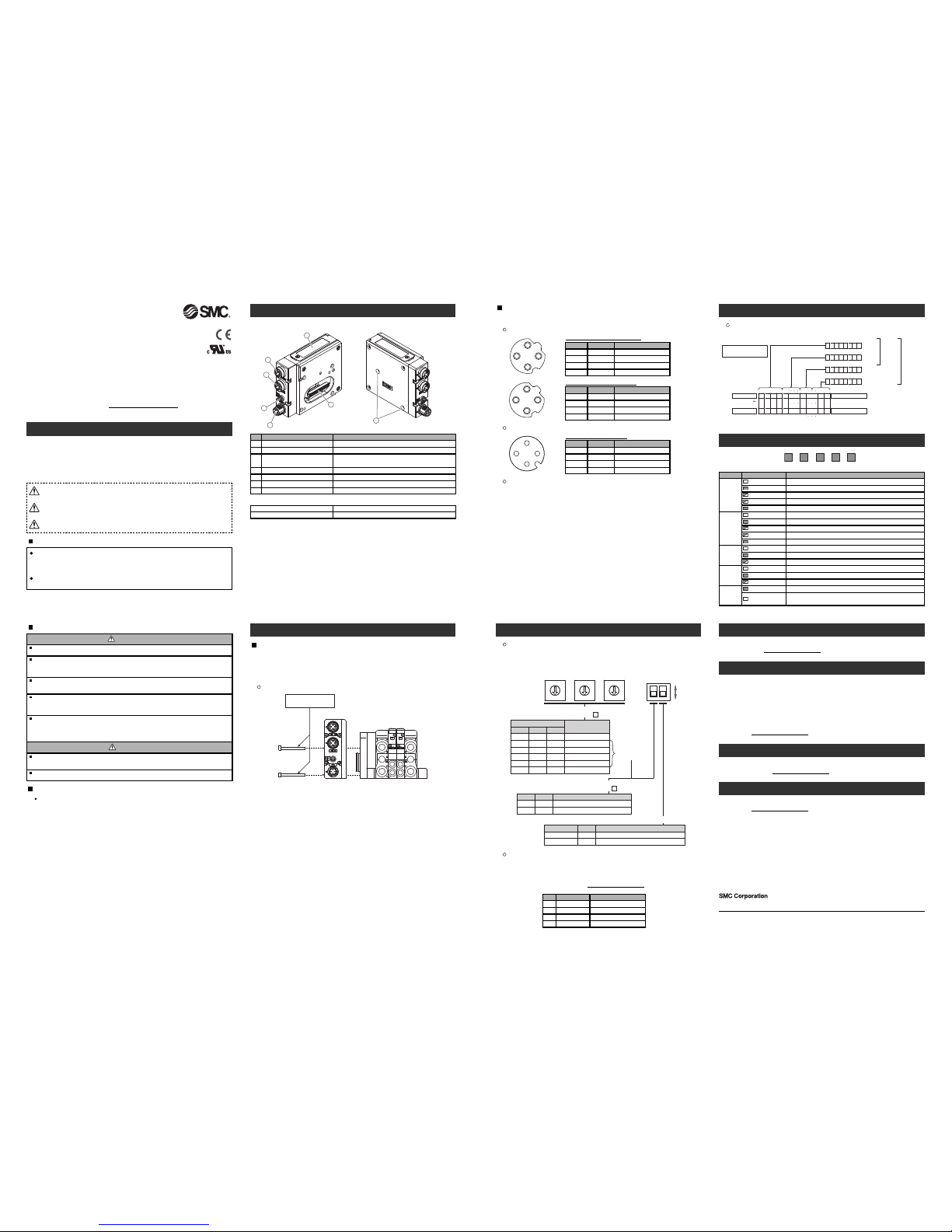

<EX260-SEN1/-SEN2/-SEN3/-SEN4>

1

3

4

5

2

6

Installation

7

General instructions on installation and maintenance

Connect valve manifold to the SI unit.

Connectable valve manifolds are the same as for EX250 series SI unit.

Refer to the EX250 series valve manifold section in the valve catalogue for valve

manifold dimensions.

1

2

3

4

1

2

3

4

P

ower supply connector layout

1

432

G

round terminal

C

onnect the ground terminal to ground.

R

esistance to ground should be 100 ohms or less.

Setting

M3 hexagon screw

Tightening torque 0.6 Nm

Valve manifold

∗: Thread size: M3 x 30

Replacement of the SI unit

•Remove the M3 hexagon screws from the SI unit and release the SI unit from the

valve manifold.

•Replace the SI unit.

•Tighten the screws with the specified tightening torque. (0.6 Nm)

Precautions for maintenance

•Be sure to switch off the power.

•Check there is no foreign matter inside the SI unit.

•Check there is no damage and no foreign matter on the gasket.

•Be sure to tighten the screws with the specified torque.

If the SI unit is not assembled properly, inside PCBs may be damaged or liquid and/or

dust may enter into the unit.

Connecting cables

S

elect the appropriate cables to mate with the connectors mounted on the SI unit.

Troubleshooting

Technical documentation giving detailed troubleshooting information can be found on the

SMC website (URL http://www.smcworld.com

).

Specifications

Connected load: 24 VDC Solenoid valve with surge voltage suppressor of 1.5 W or less

(manufactured by SMC)

Current consumption of power supply for SI unit operation: 0.1 A max.

Ambient temperature for operation: -10 to 50

o

C

Ambient temperature for storage: -20 to 60

o

C

Pollution degree 3: (UL508)

Technical documentation giving detailed specification information can be found on the SMC

website (URL http://www.smcworld.com

).

Outline Dimensions

Technical documentation giving detailed outline dimensions information can be found on

the SMC website (URL http://www.smcworld.com

).

Accessories

Technical documentation giving detailed accessories information can be found on the SMC

website (URL http://www.smcworld.com

).

Assembly and disassembly of the SI unit

NOTE

The direct current power supply to combine should be UL1310 Class2 power

supply when conformity to UL is necessary.

Safety Instructions

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the product in an interlocking circuit:

•

Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance.

Otherwise an injury can result.

Fieldbus device

Operation Manual

EX260 Series for EtherNet/IP

TM

T

hank you for purchasing an SMC EX260 Series Fieldbus device (Hereinafter

referred to as "SI unit" ).

Please read this manual carefully before operating the product and make sure you

u

nderstand its capabilities and limitations.

Please keep this manual handy for future reference.

T

o obtain more detailed information about operating this product, please

refer to the SMC website (URL http://www.smcworld.com

) or contact SMC

directly.

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or

equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety and must

be followed in addition to International standards (ISO/IEC) and other safety

regulations.

Warning

Caution

After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

C

AUTION indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Caution:

Warning:

Danger:

W

ARNING indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

D

ANGER indicates a hazard with a high level of risk which, if

n

ot avoided, will result in death or serious injury.

Fieldbus interface connector (BUS OUT)

E

lement

D

escription

EtherNet/IPTMconnection PORT 2 (M12 4-pin socket, D-coded)

F

ieldbus interface connector (BUS IN)EtherNet/IP

T

M

c

onnection PORT 1 (M12 4-pin socket, D-coded)

G

round terminal

F

unctional earth (M3 screw)

Output connector Output signal interface for valve manifold

1

N

o.

2

4

5

2

pcs. M3 x 30 screw for connection to the valve manifold

Seal cap

1 pc. seal cap for unused fieldbus interface connector (BUS OUT)

Accessories

L

ED

B

us status−specific and SI unit−specific LEDs

Mounting hole Mounting hole for connection to the valve manifold

6

7

Power supply connector

P

ower supply with load voltage for valves and operating voltage for SI unit

(M12 4-pin plug, A-coded)

3

H

exagon socket head cap screw

BUS OUT: M12 4-pin socket D-coded

TD+

Designation Description

Transmit Data +

RD+ Receive Data +

TD- Transmit Data -

1

N

o.

2

3

RD-R

eceive Data -

4

BUS IN: M12 4-pin socket D-coded

TD+

D

esignationDescription

Transmit Data +

RD+ Receive Data +

TD- Transmit Data -

1

No.

2

3

RD- Receive Data -4

PWR: M12 4-pin plug A-coded

S

I24 V

Designation Description

+

24 V for SI unit operation

S

V24 V+24 V for solenoid valve

SI0 V 0 V for SI unit operation

1

No.

2

3

SV0 V 0 V for solenoid valve4

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

EtherNet/IPTMis a trademark of ODVA.

© 2012 SMC Corporation All Rights Reserved

Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

URL http://www.smcworld.com

Provide grounding to assure the safety and noise resistance of the Serial system.

Individual grounding should be provided close to the product with a short cable.

LED indication

F

ieldbus interface connector layout

Switch setting

The switches should only be set with the power supply turned off.

Open the cover and set the rotary switches and DIP switch with a small flat blade

screwdriver.

Operator

This operation manual is intended for those who have knowledge of machinery

using pneumatic equipment, and have sufficient knowledge of assembly,

operation and maintenance of such equipment. Only those persons are

allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling,

operating or providing maintenance to the product.

Configuration

In order to configure the SI unit for the EtherNet/IP

TM

network, the appropriate device

master file (EDS file) for the SI unit will be required.

Technical documentation giving detailed configuration information and the EDS file can

be found on the SMC website (URL http://www.smcworld.com

).

Setting

Bit: 70

Bit: 7

0

Bit: 70

Bit: 70

012

46

357

891

6

17

3

0

31

2

8

29

64

64

1

3571 1 57

Output No.

Output No.

B

it No.

B

it No.

Valve manifold

Solenoid on side A

Solenoid on side B

Side D

0: Solenoid valve: OFF

1: Solenoid valve: ON

Byte

0 Offset

Byte

1 Offset

Byte

2 Offset

Byte

3 Offset

(SI unit side)

2000

16 outputs

t

ype

3

2 outputs

type

EX260-SEN1

Model number EDS file

ex260_sen1_24_v∗∗.eds

EX260-SEN2

1

2

EDS file

O

utput number assignment

O

utput numbering starts at zero and refers to the solenoid position on the manifold.

x100

IP address x

×10 ×1

0

5

2

7

8

3

9

4

1

6

0

5

2

7

8

3

9

4

1

6

0

5

2

7

8

3

9

4

1

6

12

DIP SW

∗: The values of 256 or more are not used.

0

0

0

Setting

2

:

1

Remote control

X

:

254

DHCP mode

1

2

0

:

554

5

01OFF

ON

The IP address is set to “192.168.0.X.

The IP address is set to “192.168.1.X.

Y No.1 Description

CLEAR

HOLD

OFFONClear all outputs.

Hold the last state before communication error.

HOLD/CLEAR No.2 Description

×10

0

0

0

:

2

2

×100 ×1

ON

OFF

Manual set up

of IP address

IP address

192.168. Y . X

IP address

192.168. Y . X

HOLD/CLEAR setting

MSNS

L/A1 L/A2

PWR(V)

N

S

LED LED Status

OFF

G

reen flashing

TheSI unit operating voltage is not supplied or the IP address is not set.

EtherNet/IPTMcommunications not established.

MS

O

FF

G

reen ON

TheSI unit operating valtage is not supplied.

Operatingnormally.

Red ON

Unrecoverableerror.

L

/A1

OFF

G

reen ON

BUS IN side: No Link, No Activity

B

US IN side: Link, No Activity

PWR(V)

Green ON

OFF

Load voltage for the valve is supplied

Load voltage for the valve is not supplied or is outside the tolerance range

(

19 V or less)

Description

L/A2

O

FF

Green ON

B

US OUT side: No Link, No Activity

BUS OUT side: Link, No Activity

Green flashing

BUS IN side: Link, Activity

Green flashing

Settingerror.

Red flashing

Recoverableerror.

Green flashing

BUS OUT side: Link, Activity

Green ON

EtherNet/IPTMcommunications established.

Red flashing

EtherNet/IP

T

M

communications time out.

R

ed ON

IPaddress duplicated.

ex260_sen2_24_v**.eds

EX260-SEN3 ex260_sen3_22_v**.eds

EX260-SEN4

3

4

ex260_sen4_22_v**.eds

Loading...

Loading...