SMC Networks EX260-SDN1, EX260-SDN2, EX260-SDN3, EX260-SDN4 Installation & Maintenance Manual

Installation & Maintenance Manual

Fieldbus device (SI unit)

EX260 Series for DeviceNet

T

M

E

X260-TFN21

Safety Instructions

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

•Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

•Keep this manual in a safe place for future reference.

•These instructions indicate the level of potential hazard with the labels

of "Caution", "Warning" or "Danger", followed by important safety

information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

WARNING indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

CAUTION indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

S

ummary of Product element

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

NOTE

•When conformity to UL is necessary the SI unit must be used with a

UL 1310 Class2 power supply.

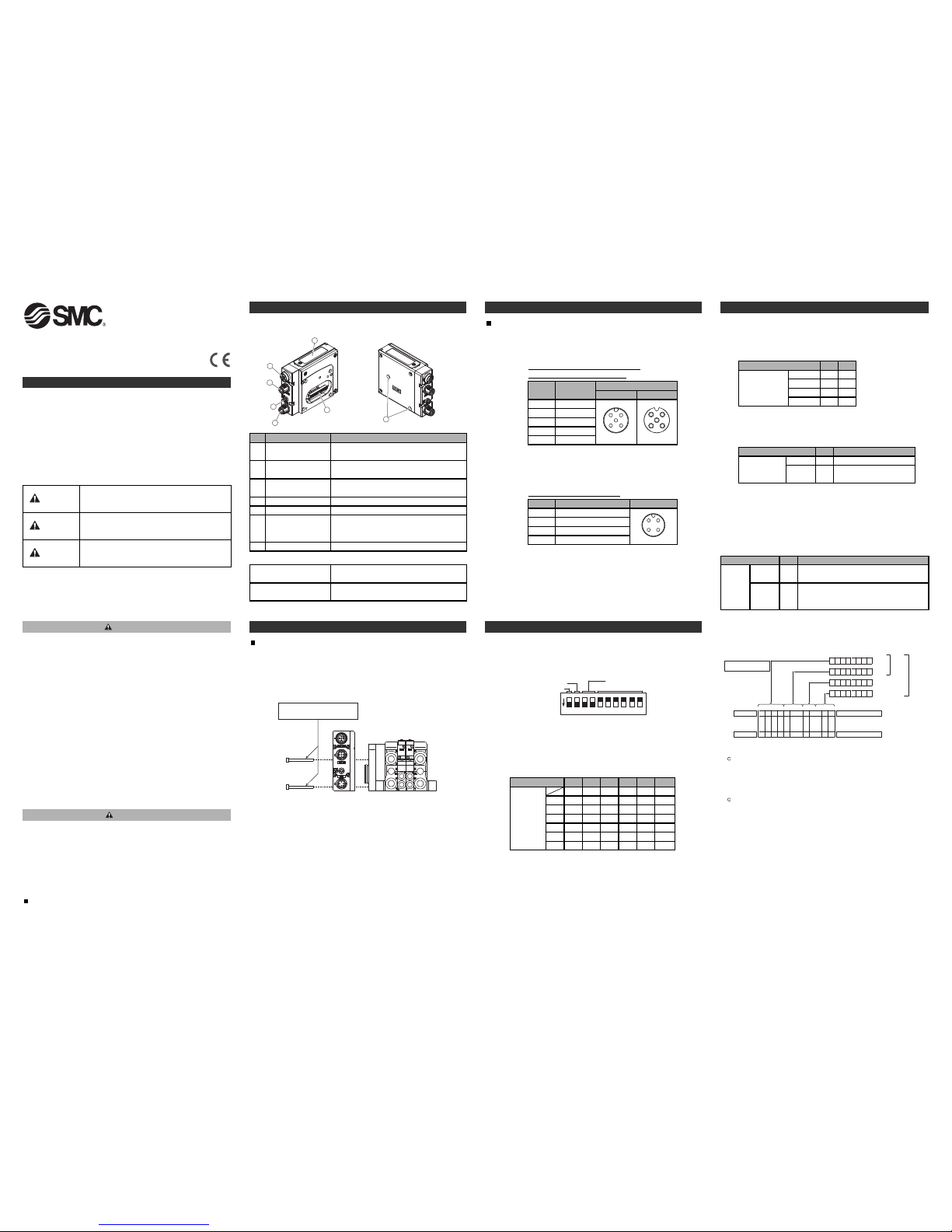

<EX260-SDN1/-SDN2/-SDN3/-SDN4>

1

3

4

2

5

6

7

Fieldbus interface

connector (BUS OUT)

Element Description

DeviceNetTMconnection

(M12 5-pole socket, A-coded)

Fieldbus interface

connector (BUS IN)

DeviceNetTMconnection

(M12 5-pole plug, A-coded)

Ground terminal Functional earth (M3 screw)

Output connector Output signal interface for valve manifold

1

No.

2

4

5

2 pcs. M3x30 screw for connection to the valve

manifold

Seal cap

1 pc. seal cap for unused fieldbus interface

connector (BUS OUT)

Accessories

LED and switch

Bus status−specific and SI unit−specific LEDs

Switches for setting of node address and

operating mode

Mounting hole

Mounting hole for connection to the valve manifold

6

7

Power supply

connector

Power supply with load voltage for valves

(M12 4-pole plug, A-coded)

3

Hexagon socket head cap

screw

•Do not disassemble, modify (including changing the printed circuit

board) or repair.

An injury or failure can result.

•Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

•Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

•If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical

system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

•The following instructions must be followed during maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the

air is released before performing maintenance.

Otherwise an injury can result.

•After maintenance is complete, perform appropriate functional

inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

•Provide grounding to assure the safety and noise resistance of the

Fieldbus system.

Individual grounding should be provided close to the product with a

short cable.

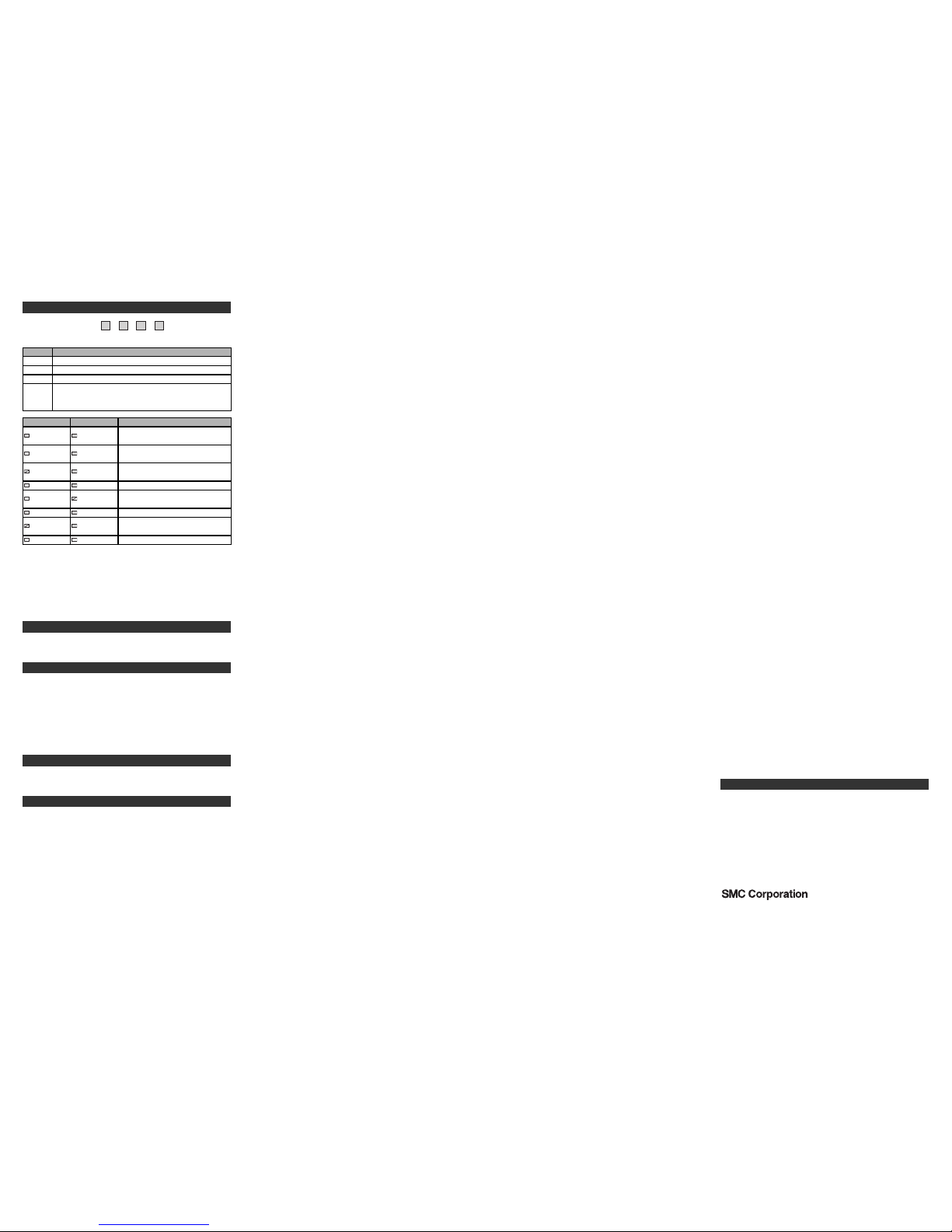

Installation

General instructions on installation and maintenance

Connect valve manifold to the SI unit.

Connectable valve manifolds are the same as for EX250 series SI unit.

Refer to the EX250 series valve manifold section in the valve catalogue

for valve manifold dimensions.

M3 hexagon screw

Tightening torque 0.6 Nm

Valve manifold

∗: Thread size: M3×30

Replacement of the SI unit

•Remove the M3 hexagon screws from the SI unit and release the

SI unit from the valve manifold.

•Replace the SI unit.

•Tighten the screws with the specified tightening torque. (0.6 Nm)

Precautions for maintenance

•Be sure to switch off the power.

•Check there is no foreign matter inside the SI unit.

•Check there is no damage and no foreign matter being stuck to the

gasket.

•Be sure to tighten the screws with the specified torque.

If the SI unit is not assembled properly, inside PCBs may be damaged or

liquid and/or dust may enter into the unit.

Assembly and disassembly of the SI unit

I

nstallation (Continued)

Connecting cables

Select the appropriate cables to mate with the connectors mounted on the

SI unit.

Fieldbus interface connector layout

Warning

Caution

BUS OUT: M12 5-pole socket A-coded

DRAIN

Designation

Contact layout

BUS IN

V+

V-

CAN_L

1

No.

2

3

5

CAN_H4

2

5

43

1

1

5

4

3

2

BUS OUT

BUS IN: M12

5-pole plug A-coded

Note: To avoid causing disruption of “downstream” devices whilst

replacing SI unit, use a DeviceNetTMtap rather than making

connections to the BUS OUT connector.

Power supply connector layout

Ground terminal

Connect the ground terminal to ground.

Resistance to ground should be 100 ohms or less.

−

Designation

Contact layout

+24 V for solenoid valve

−

1

No.

2

3

0 V for solenoid valve4

1

3

4

2

PWR: M12 4-pole plug A-coded

Switch setting

Set the DeviceNet

TM

node address (MAC ID), DeviceNetTMcommunication

speed and fail safe mode of the SI unit using the 10-element switch.

Communication speed

Address

HW/SW

HOLD/CLEAR

9 107 85 63 41 2

ON

Setting

Note: Be sure to switch off the power supply before setting the switches.

MAC ID

Switch No. No.6No.5 No.8No.7 No.10No.9

Address setting (switch No. 5 to 10)

The DeviceNet

TM

address (MAC ID) is binary coded and can be set from

0 to 63

Note: Factory default setting is 63.

1632 4

8

12

00 00 000

00 00 101

00 00 012

:: :: :::

11 11 0162

11 11 1163

0: OFF, 1: ON

S

etting (Continued)

Communication speed setting (switch No. 3 to 4)

The DeviceNetTMcommunication speed is binary coded and can be

set to 125 kbps, 250 kbps and 500 kbps.

N

ote: Factory default setting is 125 kbps.

Communication

speed

Switch No. No.4No.3

00

10250 kbps

01500 kbps

11

-

0: OFF, 1: ON

125 kbps

Note: Each output can be set individually over the network.

HOLD/CLEAR setting (switch No.2)

Set the reaction of outputs to the communication error

(All outputs will be set under the same conditions)

N

ote: Factory default setting is CLEAR.

HOLD/CLEAR

Switch No. DescriptionNo.2

0

Hold the last state before

communication error

1

HOLD

CLEAR

Clear all outputs

0: OFF, 1: ON

HW/SW mode setting (switch No.1)

Modifications to the address and speed can be made locally or over

the network.

Local setting: Hardware mode (Hereinafter referred to as “HW mode”)

Network setting: Software mode (Hereinafter referred to as “SW mode”)

Note: Factory default setting is "HW mode".

HW/SW

Switch No. DescriptionNo.1

0

Set the address and speed over the

DeviceNetTMnetwork

(Switch setting is invalid)

1SW

HW

Set the address and speed locally using the

SI unit switches

0: OFF, 1: ON

Output number assignment

The output number refers to the solenoid position on the manifold and

starts at zero.

Bit: 7 0

Bit: 7

0

Bit: 7

0

Bit: 7

0

01246

35789161730312829

64

・・・・・・

・・・

・・・

・・・

・・・

64

13571 1 57

Output No.

Output No.

Bit No.

Bit No.

→

Valve manifold

Solenoid on side A

Solenoid on side B

Side D

0

: Solenoid valve: OFF

1: Solenoid valve: ON

Byte

0 Offset

Byte

1 Offset

Byte

2 Offset

Byte

3 Offset

(SI unit side)

200

0

16 outputs

t

ype

32 outputs

type

Setting over the DeviceNetTMnetwork

Technical documentation giving detailed information about setting

the unit over the DeviceNetTMnetwork can be found on the SMC

website (URL http://www.smcworld.com)

Diagnostic information

Technical documentation giving detailed diagnostic information can

be found on the SMC website (URL http://www.smcworld.com)

E

X260-TFN21

Contacts

AUSTRIA (43) 2262 62280 NETHERLANDS (31) 20 531 8888

BELGIUM (32) 3 355 1464 NORWAY (47) 67 12 90 20

CZECH REP. (420) 541 424 611 POLAND (48) 22 211 9600

DENMARK (45) 7025 2900 PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513 SLOVAKIA (421) 2 444 56725

FRANCE (33) 1 6476 1000 SLOVENIA (386) 73 885 412

GERMANY (49) 6103 4020 SPAIN (34) 945 184 100

GREECE (30) 210 271 7265 SWEDEN (46) 8 603 1200

HUNGARY (36) 23 511 390 SWITZERLAND (41) 52 396 3131

IRELAND (353) 1 403 9000 UNITED KINGDOM (44) 1908 563888

ITALY (39) 02 92711

URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2010 SMC Corporation All Rights Reserved.

L

ED indication

N

S

M

S PWR PWR(V)

PWR (V)

LED Description

Turns ON in green when load voltage for the valve is supplied

Turns OFF when load voltage for the valve is not supplied or

outside tolerance range (19 V or less)

PWR Turns ON in green when network power is supplied

NS Network status (See the table below for details)

MS SI unit status (See the table below for details)

Green On

MS status

Description

On-line state, The device has

connections in the established state

Green On

Off-line state, The device has not

completed the Dup_MAC_ID test yet

Green On

On-line state, The device has no

connections in the established state

Green On

NS status

Off

Green flashing

Red On Off-line state, Watchdog timer error

Red flashing

Wrong switch setting, Parameter

writing error

Green On Bus-off state, Duplicate MAC ID

Off

Off

Red On

Green On

I/O Connection is in the Timed-Out

state

Off No network power present

Red flashing

Off

Troubleshooting

Technical documentation giving detailed troubleshooting information can

be found on the SMC website (URL http://www.smcworld.com).

Specifications

Connected load: 24 VDC Solenoid valve with light and surge voltage

suppressor of 1.5 W or less (manufactured by SMC)

Current consumption of power supply for SI unit operation: 0.1 A max.

Ambient temperature for operation: -10 to 50 ℃

Ambient temperature for storage: -20 to 60 ℃

Pollution degree 2: (UL508)

Technical documentation giving detailed specifications can be found on

the SMC website (URL http://www.smcworld.com).

Technical documentation giving detailed outline dimensions can be

found on the SMC website (URL http://www.smcworld.com).

Technical documentation giving detailed accessories information can be

found on the SMC website (URL http://www.smcworld.com).

Outline Dimensions

Accessories

Loading...

Loading...