SMC Networks EX245-SPN1A, EX245-SPN2A, EX245-EA2-1, EX245-EA2-2, EX245-SPN3A Operation Manual

...Page 1

No.EX※※-OMW0011-A

PRODUCT NAME

SI Unit

MODEL / Series / Product Number

EX245-SPN1A

EX245-SPN2A

EX245-SPN3A

PRODUCT NAME

Digital Input Module

MODEL / Series / Product Number

EX245-DX1

PRODUCT NAME

Digital Output Module

MODEL / Series / Product Number

EX245-DY1

PRODUCT NAME

End Plate

MODEL / Series / Product Number

EX245-EA2-1

EX245-EA2-2

EX245-EA2-3

EX245-EA2-4

EX245-EA2-5

Page 2

- 2 -

No.EX※※-OMW0011-A

Contents

1. Product Summary 10

1.1. Features 10

1.2. Structure 11

2. General Specifications 12

3. Installation 13

3.1. Mounting 13

3.2. Wiring 15

4. Commissioning 21

4.1. Configuration 21

4.2. Parameterisation 24

5. Diagnosis 27

5.1. Diagnostics data on I/O mapping 27

5.2. Maintenance alarm for the Fibre-optic cables 31

6. SI Unit 32

6.1. Parts and description 32

6.2. Specifications 34

6.3. Process data for valves 36

6.4. LED indicators 37

6.5. Block diagram 40

7. Digital Input Module - EX245-DX1 43

7.1. Parts and description 43

7.2. Specifications 44

7.3. Wiring 45

7.4. Process data 45

7.5. LED indicators 46

7.6. Block diagram 47

8. Digital Output Module - EX245-DY1 48

8.1. Parts and description 48

8.2. Specifications 49

8.3. Wiring 50

8.4. Process data 50

8.5. LED indicators 51

8.6. Block diagram 52

9. End Plate - EX245-EA2-1/2/3/4/5 53

9.1. Parts and description 53

9.2. Specifications 56

Page 3

- 3 -

No.EX※※-OMW0011-A

10. Accessories 57

10.1. Markers 57

10.2. Y Connector 58

10.3. Seal cap 60

10.4. Joint pack 62

11. Dimensions 63

11.1. The Input/Output Modules Manifold 63

12. Troubleshooting 64

12.1. EX245-SPN1A/SPN2A/SPN3A 64

12.2. EX245-DX1 66

12.3. EX245-DY1 66

Page 4

- 4 -

No.EX※※-OMW0011-A

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger".

They are all important notes for safety and must be followed in addition to International Standards

(ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems.

ISO 4413: Hydraulic fluid power -- General rules relating to systems.

IEC 60204-1: Safety of machinery -- Electrical equipment of machines. (Part 1: General requirements)

ISO 10218: Manipulating industrial robots -Safety.

etc.

Caution

Caution indicates a hazard with a low level of risk which, if not avoided, could

result in minor or moderate injury.

Warning

Warning indicates a hazard with a medium level of risk which, if not avoided,

could result in death or serious injury.

Danger

Danger indicates a hazard with a high level of risk which, if not avoided, will

result in death or serious injury.

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications

based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person

who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when

configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1. The inspection and maintenance of machinery/equipment should only be performed after measures to

prevent falling or runaway of the driven objects have been confirmed.

2. When the product is to be removed, confirm that the safety measures as mentioned above are

implemented and the power from any appropriate source is cut, and read and understand the specific

product precautions of all relevant products carefully.

3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the

product is to be used in any of the following conditions.

1. Conditions and environments outside of the given specifications, or use outdoors or in a place

exposed to direct sunlight.

2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or

other applications unsuitable for the standard specifications described in the product catalog.

3. An application which could have negative effects on people, property, or animals requiring special

safety analysis.

4. Use in an interlock circuit, which requires the provision of double interlock for possible failure by using

a mechanical protective function, and periodical checks to confirm proper operation.

Page 5

- 5 -

No.EX※※-OMW0011-A

Safety Instructions

Caution

1.The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following "Limited warranty and Disclaimer" and "Compliance

Requirements".

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered, whichever is first.2)

Also, the product may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other

damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers noted in the specified catalog for the particular products.

2) Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the

vacuum pad or failure due to the deterioration of rubber material are not covered by the

limited warranty.

Compliance Requirements

1. The use of SMC products with production equipment for the manufacture of weapons of mass

destruction (WMD) or any other weapon is strictly prohibited.

2. The exports of SMC products or technology from one country to another are governed by the

relevant security laws and regulation of the countries involved in the transaction. Prior to the

shipment of a SMC product to another country, assure that all local rules governing that export are

known and followed.

Page 6

- 6 -

No.EX※※-OMW0011-A

Operator

This operation manual is intended for those who have knowledge of machinery using pneumatic

equipment, and have sufficient knowledge of assembly, operation and maintenance of such

equipment. Only those persons are allowed to perform assembly, operation and maintenance.

Read and understand this operation manual carefully before assembling, operating or providing

maintenance to the product.

■Safety Instructions

Warning

■Do not disassemble, modify (including changing the printed circuit board) or repair.

An injury or failure can result.

■Do not operate or set with wet hands.

This may lead to an electric shock.

■Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

■Do not operate in an atmosphere containing flammable or explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

■If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

■The following instructions must be followed during maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the air is released before performing

maintenance.

Otherwise an injury can result.

Page 7

- 7 -

No.EX※※-OMW0011-A

Caution

■When handling the unit or assembling/replacing units:

•Do not touch the sharp metal parts of the connector or plug for connecting units.

•Take care not to hit your hand when disassembling the unit.

The connecting portions of the unit are firmly joined with seals.

•When joining units, take care not to get fingers caught between units.

An injury can result.

■After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

■Provide grounding to assure the noise resistance of the Fieldbus system.

Individual grounding should be provided close to the product with a short cable.

■NOTE

○Follow the instructions given below when designing, selecting and handling the product.

●The instructions on design and selection (installation, wiring, environment, adjustment, operation,

maintenance, etc.) described below must also be followed.

Product specifications

•Use the specified voltage.

Otherwise failure or malfunction can result.

•Reserve a space for maintenance.

Allow sufficient space for maintenance when designing the system.

•Do not remove any nameplates or labels.

This can lead to incorrect maintenance, or misreading of the operation manual, which could cause damage or

malfunction to the product.

It may also result in non-conformity to safety standards.

•Beware of inrush current when the power supply is turned on.

Some connected loads can apply an initial charge current which will activate the over current protection function,

causing the unit to malfunction.

Page 8

- 8 -

No.EX※※-OMW0011-A

●Product handling

Installation

•Do not drop, hit or apply excessive shock to the product.

Otherwise damage to the product can result, causing malfunction.

•Tighten to the specified tightening torque.

If the tightening torque is exceeded the mounting screws may be broken.

IP65 protection cannot be guaranteed if the screws are not tightened to the specified torque.

•If a large manifold valve is mounted, lift the unit so that stress is not applied to the connecting part while

transporting.

The stress may cause breakage of the connecting part. The unit may become very heavy depending on the

combination. Transportation/installation shall be performed by multiple operators.

•Never mount a product in a location that will be used as a foothold.

The product may be damaged if excessive force is applied by stepping or climbing onto it.

Wiring

•Avoid repeatedly bending or stretching the cables, or placing heavy load on them.

Repetitive bending stress or tensile stress can cause breakage of the cable.

•Wire correctly.

Incorrect wiring can break the product.

•Do not perform wiring while the power is on.

Otherwise damage to the SI Unit and/or input or output module can result, causing malfunction.

•Do not route wires and cables together with power or high voltage cables.

Otherwise the SI Unit and/or input or output module can malfunction due to interference of noise and surge voltage

from power and high voltage cables to the signal line.

Route the wires (piping) of the SI Unit and/or input or output module separately from power or high voltage cables.

•Confirm proper insulation of wiring.

Poor insulation (interference from another circuit, poor insulation between terminals, etc.) can lead to excess

voltage or current being applied to the product, causing damage.

•Take appropriate measures against noise, such as using a noise filter, when the Fieldbus system is

incorporated into equipment.

Otherwise noise can cause malfunction.

Environment

•Select the proper type of protection according to the environment of operation.

IP65 protection is achieved when the following conditions are met.

(1)The EX245-SPN1A/EX245-SPN2A and/or input or output module are connected properly with power/fieldbus

cable with Push Pull connector and I/O device cable with M12 connector.

The EX245-SPN3A and/or input or output module are connected properly with power cable with 7/8 inch

connector, fieldbus cable with M12 connector and I/O device cable with M12 connector.

(2)Suitable mounting of each unit and manifold valve.

(3)Be sure to fit a waterproof cap on any unused connectors.

If using in an environment that is exposed to water splashes, please take measures such as using a cover.

Do not use in an environment where moisture or water vapor are present. Otherwise failure and malfunction can

result.

•Do not use in a place where the product could be splashed by oil or chemicals.

If the product is to be used in an environment containing oils or chemicals such as coolant or cleaning solvent, even

for a short time, it may be adversely affected (damage, malfunction etc.).

•Do not use the product in an environment where corrosive gases or fluids could be splashed.

Otherwise damage to the product and malfunction can result.

•Do not use in an area where surges are generated.

If there is equipment generating large surge near the unit (magnetic type lifter, high frequency inductive furnace,

welding machine, motor, etc.), this can cause deterioration of the internal circuitry element of the unit or result in

damage. Take measures against the surge sources, and prevent the lines from coming into close contact.

Page 9

- 9 -

No.EX※※-OMW0011-A

•When a surge-generating load such as a relay, valve or lamp is driven directly, use a product with a

built-in surge absorbing element.

Direct drive of a load generating surge voltage can damage the product.

•The product is CE marked, but not immune to lightning strikes. Take measures against lightning strikes

in the system.

•Prevent foreign matter such as dust or wire debris from getting inside the product.

•Mount the product in a place that is not exposed to excessive vibration or impact.

Otherwise failure or malfunction can result.

•Do not use the product in an environment that is exposed to temperature cycle.

Heat cycles other than ordinary changes in temperature can adversely affect the inside of the product.

•Do not expose the product to direct sunlight.

If using in a location directly exposed to sunlight, shade the product from the sunlight.

Otherwise failure or malfunction can result.

•Keep within the specified ambient temperature range.

Otherwise malfunction can result.

•Do not operate close to a heat source, or in a location exposed to radiant heat.

Otherwise malfunction can result.

Adjustment and Operation

•Perform settings suitable for the operating conditions.

Incorrect setting can cause operation failure.

For details of each setting, refer to the SI Unit Operation Manual.

•Please refer to the IO Controller manufacturer's manual etc. for details of programming and addresses.

For the IO Controller protocol and programming refer to the relevant manufacturer's documentation.

Maintenance

•Turn off the power supply, stop the supplied air, exhaust the residual pressure and verif y the release of

air before performing maintenance.

There is a risk of unexpected malfunction.

•Perform regular maintenance and inspections.

There is a risk of unexpected malfunction.

•After maintenance is complete, perform appropriate functional inspections.

Stop operation if the equipment does not function properly.

Otherwise safety is not assured due to an unexpected malfunction or incorrect operation.

•Do not use solvents such as benzene, thinner etc. to clean each product.

They could damage the surface of the body and erase the markings on the body.

Use a soft cloth to remove stains.

For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed, then wipe up the stains

again with a dry cloth.

Page 10

- 10 -

No.EX※※-OMW0011-A

1. Product Summary

1.1. Features

SI Unit

The SI (Serial Interface) Unit represents a PROFINET IO-device for SMC pneumatic valves. It is

designed for digital data control by connecting compatible the EX245 Input/Output modules and for

use within rugged industrial environments, especially automotive plants. The SI Unit has the

following properties:

・ IP65 protection

・ Two connectors for supply voltages and two connectors for PROFINET IO connection,

EX245-SPN1A : 2 x Push Pull connectors (24 Volt) and 2 x Push Pull connectors (SCRJ)

EX245-SPN2A : 2 x Push Pull connectors (24 Volt) and 2 x Push Pull connectors (RJ45)

EX245-SPN3A : 2 x 7/8 inch 5 pins connectors and 2 x M12 4 pins socket D-coded connectors

・ Up to 32 solenoid valves

・ Up to 128 digital inputs

・ Up to 64 digital outputs independent of solenoid valves

・ Up to 8 modules (limited by the total current consumption)

・ FSU (Fast Start Up) supported

・ Conformance Class C (Only for IRT switch function) supported

・ MRP (Media Redundancy Protocol) and MRPD (Media Redundancy for Planned Duplication)

function supported

・ Shared device function supported

・ PROFIenergy function supported

・ Net Load Class Ⅲ of Security Level 1 supported

・ Built-in Web server function

・ A firmware update function

・ Maintenance alarm supported for the Fibre-optic cables for the EX245-SPN1A

・ Integrated diagnostic and protection function

・ Maximum loop through current between power connectors

is 16A (EX245-SPN1A/EX245-SPN2A), or is 6A (EX245-SPN3A)

・ Galvanically isolated power supplies

・ Free module configuration

Corresponding solenoid valve manifolds

・ JSY series JSY3000, JSY5000

・ SY series SY3000, SY5000

・ VQC series VQC2000, VQC4000

Compatible EX245 Input/Output modules

・ Digital Input Module : EX245-DX1 (16 digital inputs)

・ Digital Output Module : EX245-DY1 (8 digital outputs)

Page 11

- 11 -

No.EX※※-OMW0011-A

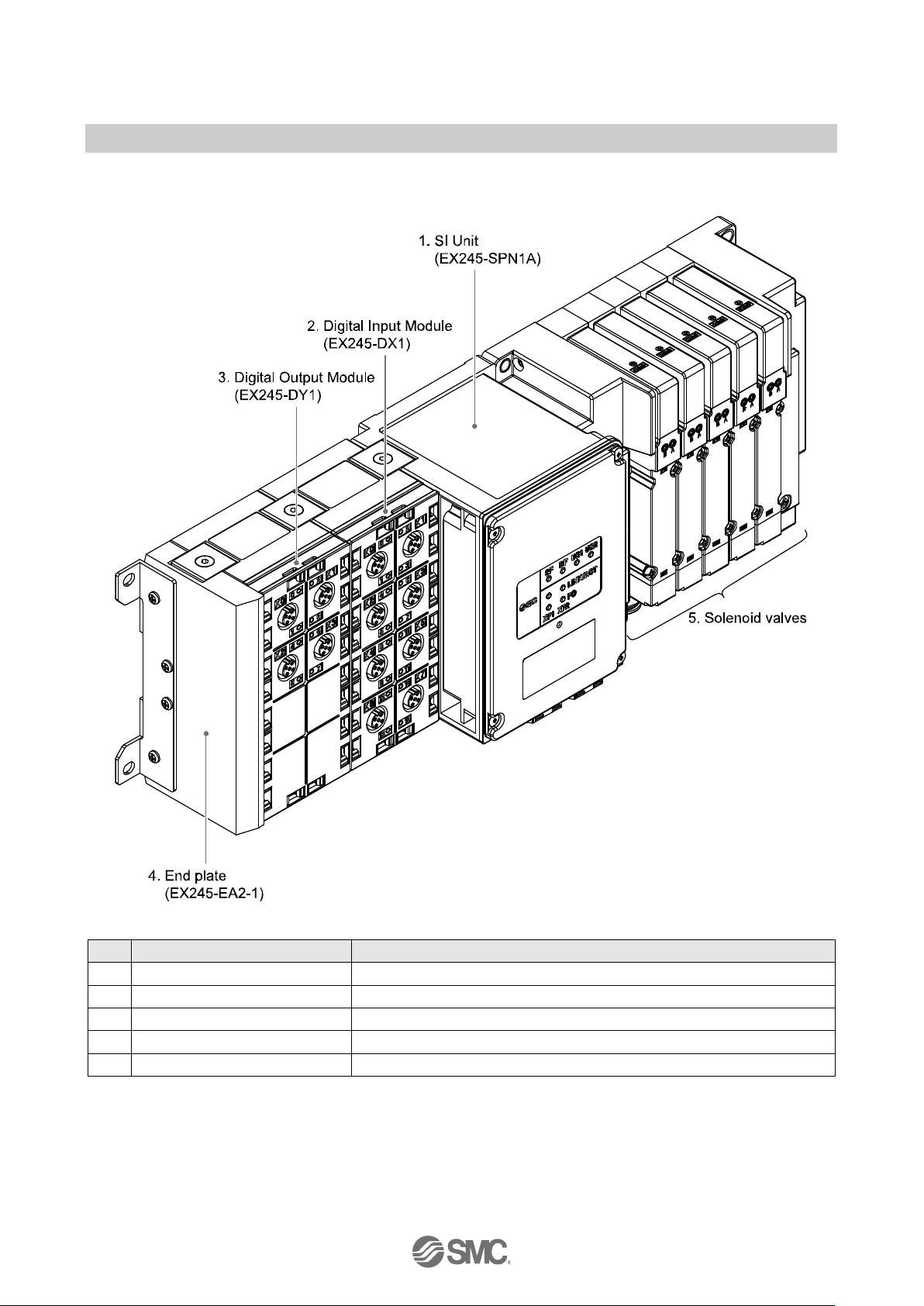

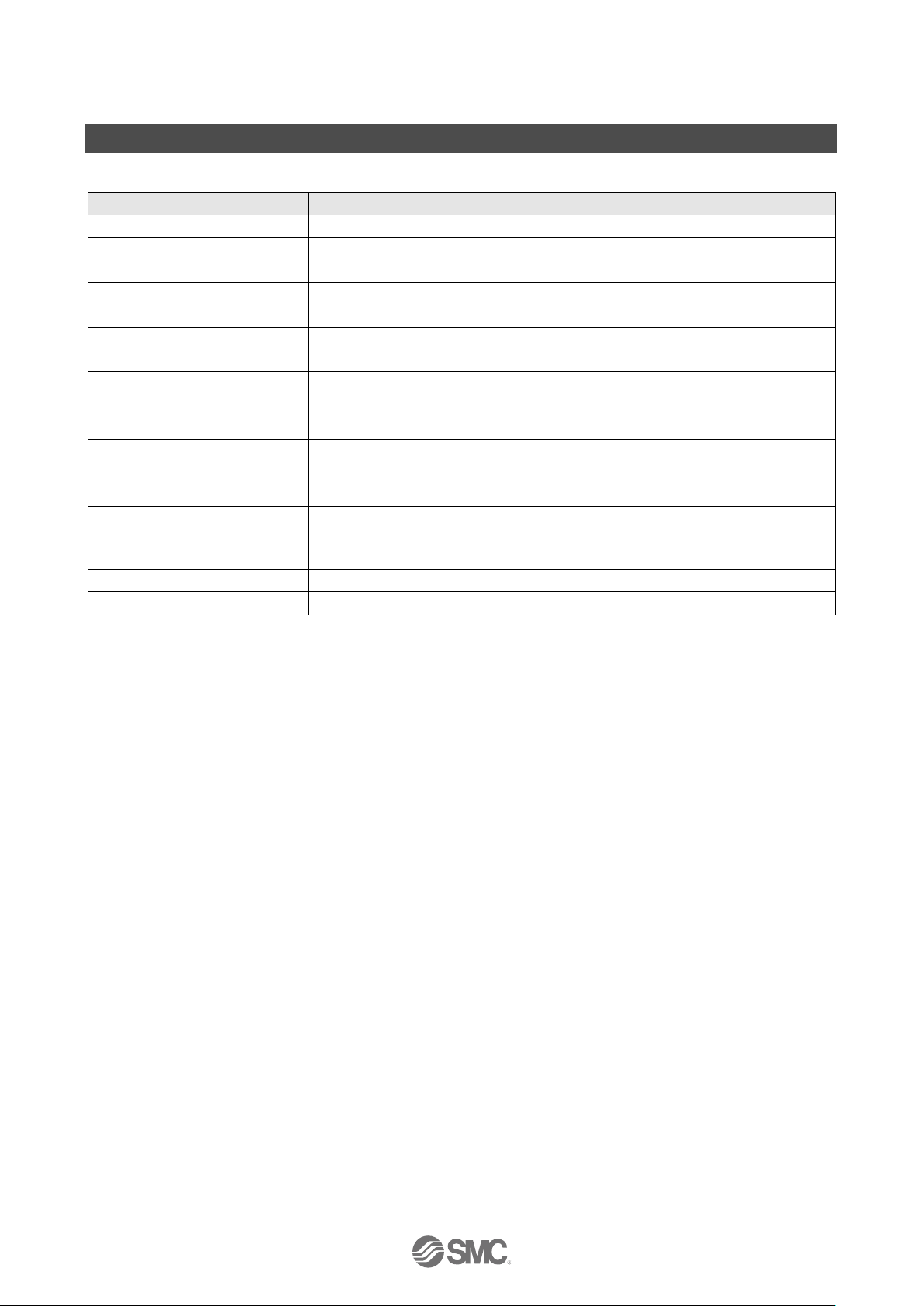

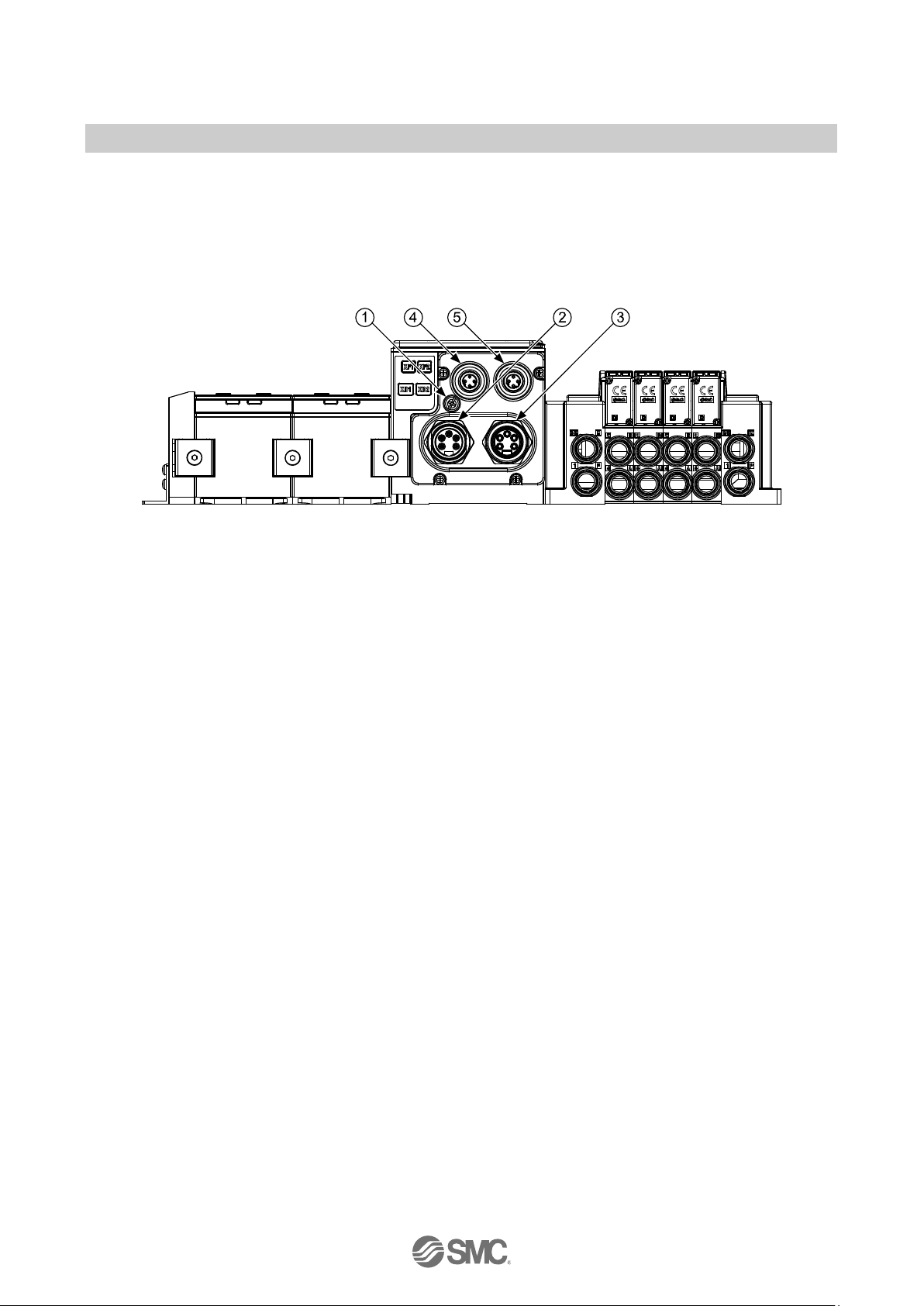

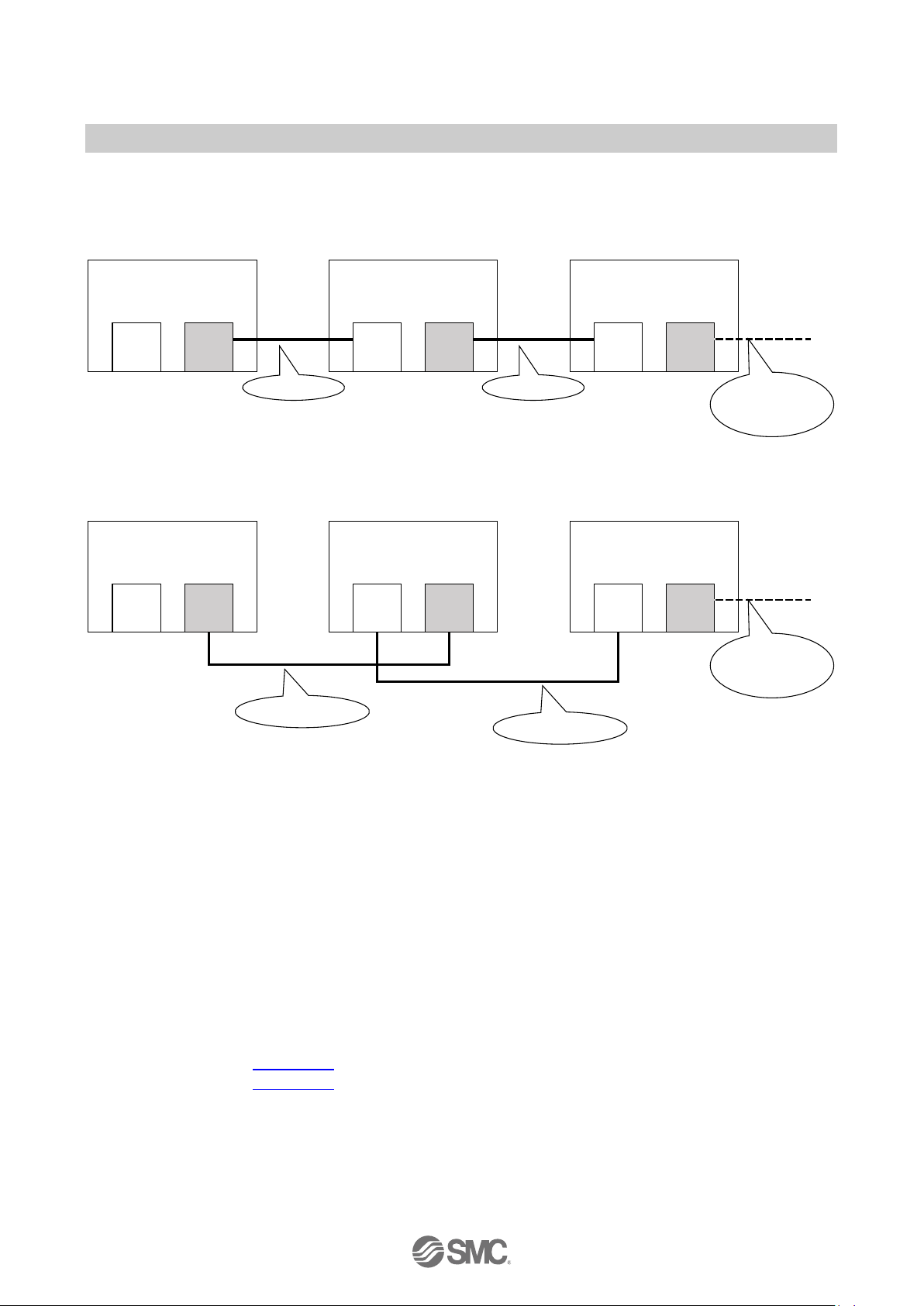

1.2. Structure

No.

Components

Function

1

SI Unit

Fieldbus, valve interface and supply voltage to modules

2

Digital Input Module

Supply voltage to sensors and input digital data

3

Digital Output Module

Output to electric loads

4

End plate

End plate of module side

5

Solenoid valves

Operate pneumatic devices

Fig. 1-1 System structure

Page 12

- 12 -

No.EX※※-OMW0011-A

2. General Specifications

Table. 2-1 EX245 series general specifications

Item

Specification

Rated voltage

24 V DC

Allowable instantaneous

electrical stop

1 msec maximum

Protection class

IP65 rating (when fully installed or fitted with protective cover)

(complies with IEC 60529)

Applicable standard

CE Marked

RoHS directive EN50581:2012

Withstand voltage

500 VAC 1 min. (between FE and all accessible terminals)

Insulation resistance

10 M ohm or more

(500 V DC is given between FE and all accessible terminals)

Ambient temperature

Operation: -10 °C to 50 °C

Storage: -20 °C to 60 °C

Ambient humidity

35% to 85% RH (non-condensing)

Vibration resistance

10 Hz to 57 Hz (constant amplitude) 0.75 mm

57 Hz to 150 Hz (constant acceleration) 49 m/s2

2 hours for each direction X, Y and Z

Impact resistance

147 m/s2 is given 3 times for each direction X, Y and Z

Operating environment

No corrosive gas

Page 13

- 13 -

No.EX※※-OMW0011-A

3. Installation

3.1. Mounting

Caution

To prevent manifold components being damaged, apply the recommended tightening torque.

Mount the manifold using the 6 mounting positions on the base with screws.

Required screws are as follows:

① 2 x M5 (End plate: torque = 1.5 Nm)

② 4 x M* (Valve manifold: refer to valve manifold catalogue)

Fig. 3-1 Required screws

All manifolds are mounted using 6 screws (except VQC4000 which uses 5 screws).

Page 14

- 14 -

No.EX※※-OMW0011-A

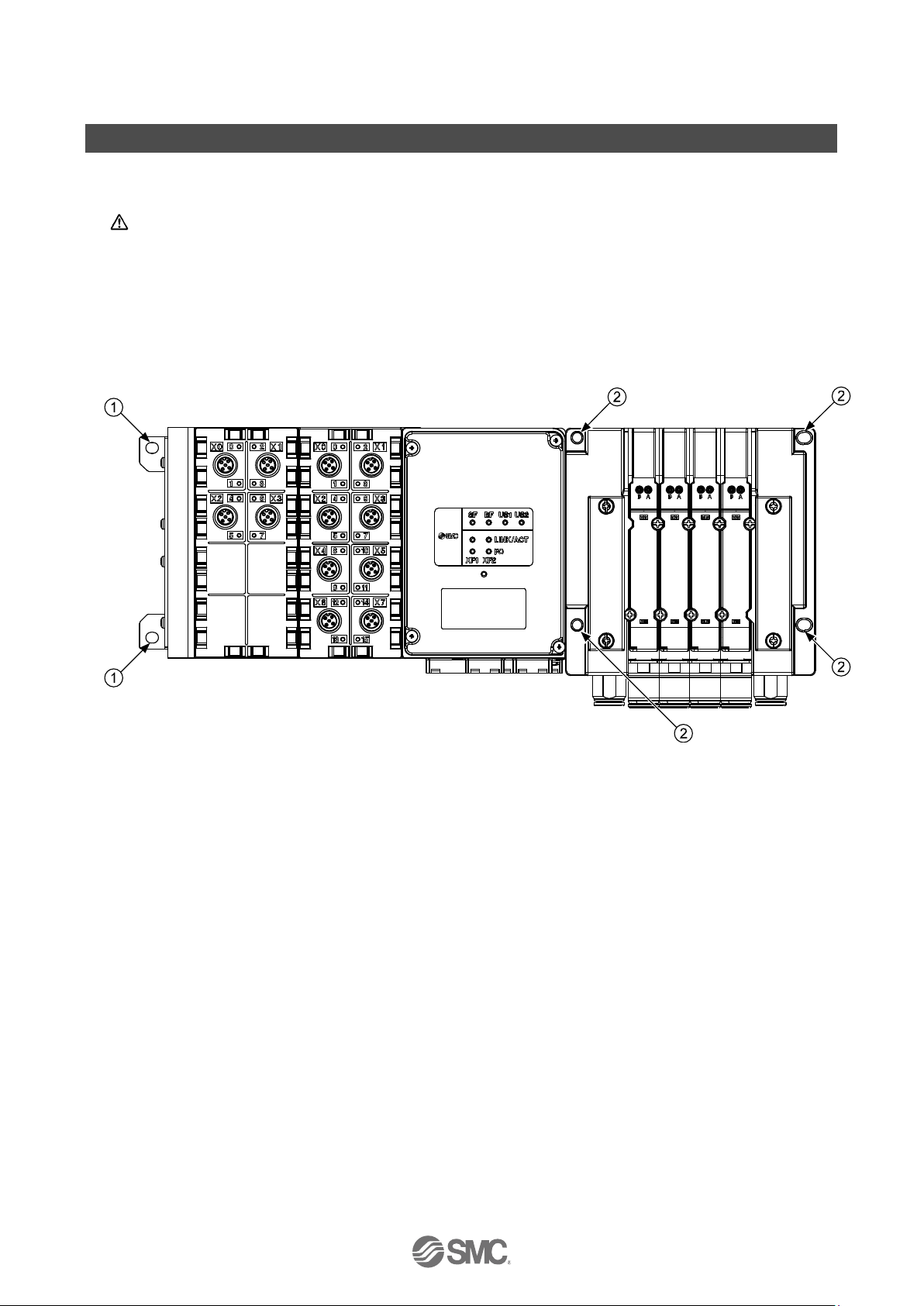

3.1.1. Valve manifold connection

Connect the valve manifold with the 2 screws on the SI Unit. (hexagonal socket wrench size 2.5)

For torque value, refer to valve manifold catalogue.

Fig. 3-2 Valve manifold connection

Caution

For a protection rating of IP65 to be ensured, apply the recommended tightening torque and make

sure that the O-ring is positioned correctly on the screw.

3.1.2. Module connection

Connect the SI Unit, the Input/Output modules and the End plate with the 2 modular adaptor assemblies

and a joint assembly. These are grouped together in the Joint pack, refer to the Section 10.4.

① 1 x Joint assembly

② 2 x Modular adaptor assembly (hexagonal socket wrench size 2.5, torque = 1.3 Nm)

Fig. 3-3 Module connection

Caution

・ For a protection rating of IP65 to be maintained, the End plate must be installed on the end of

module side correctly.

・ For a protection rating of IP65 to be ensured, modular adaptor assemblies and joint assembly

must be installed between each module correctly.

・ To prevent the modules and assemblies being damaged, apply the recommended tightening

torque.

Page 15

- 15 -

No.EX※※-OMW0011-A

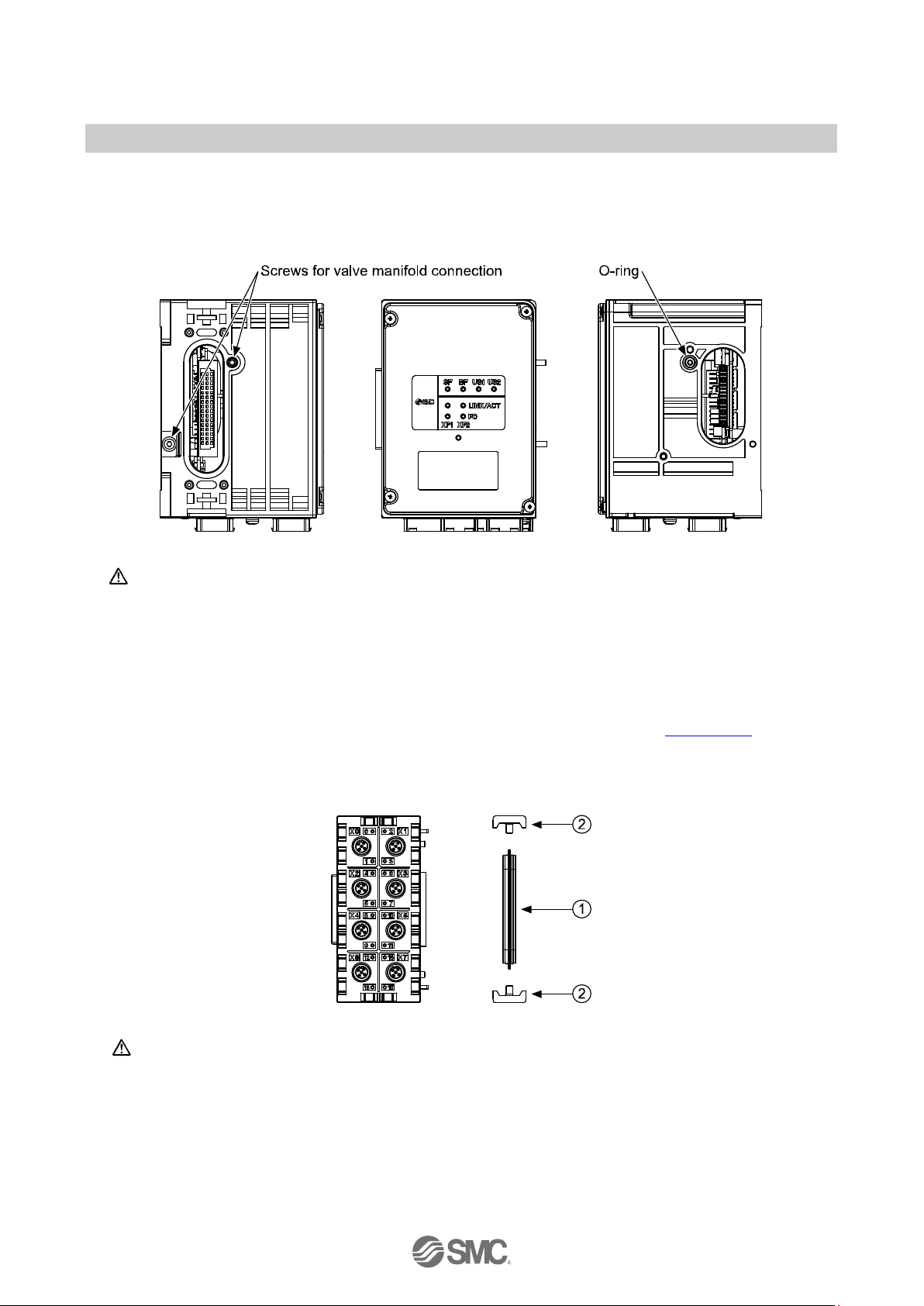

3.2. Wiring

Caution

To prevent damage, all voltages to the SI Unit must be turned off (i.e. de-energized) before the

modules are installed or removed.

Wire the grounding cable, the PROFINET cables and the power cable.

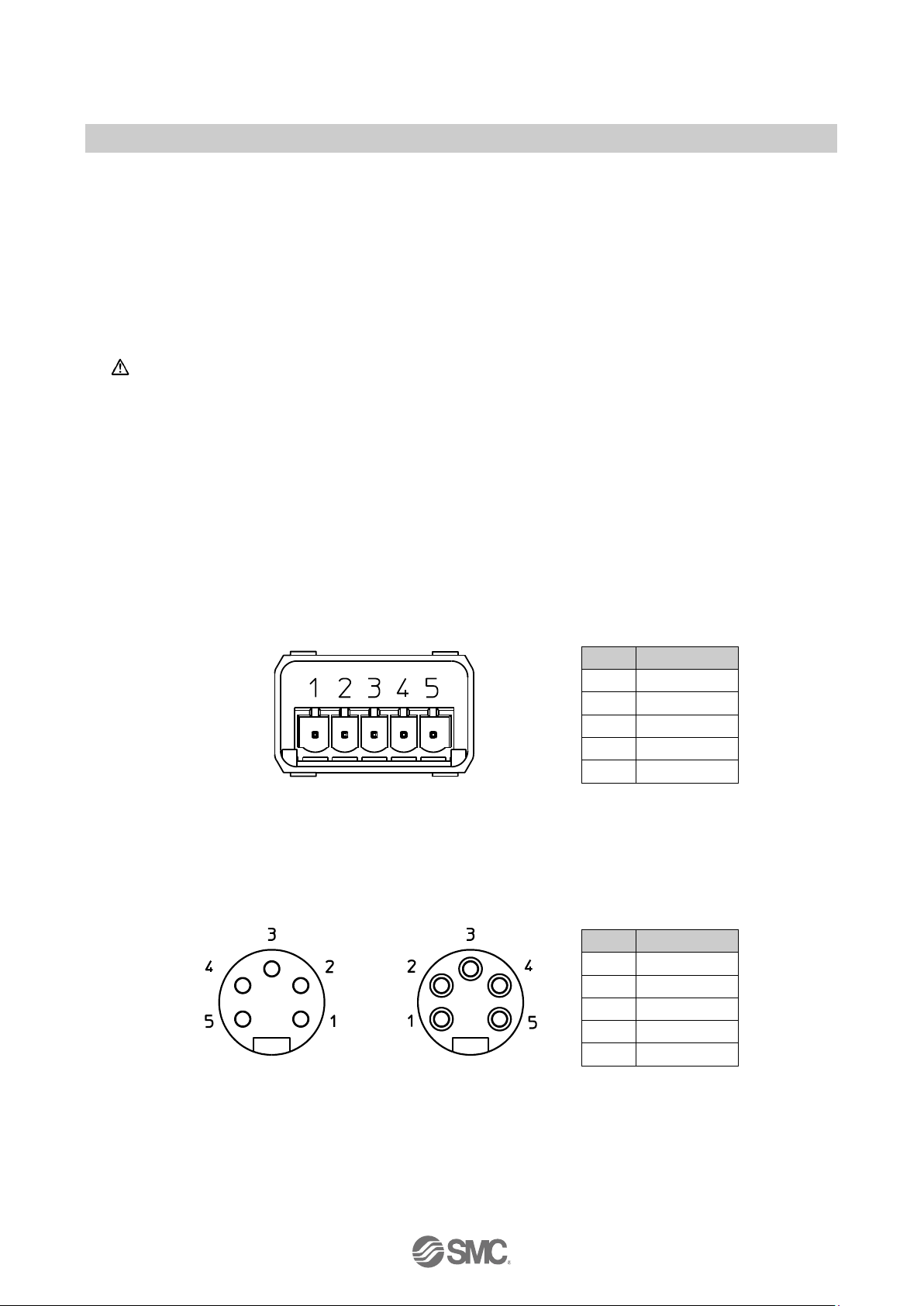

EX245-SPN1A

① M4, FE terminal screw (torque = 0.7 - 0.8 Nm)

② Push Pull connector (24 Volt), Power connection (XD1)

③ Push Pull connector (24 Volt), Power connection (XD2)

④ Push Pull connector (SCRJ), PROFINET connection Port1 (XF1)

⑤ Push Pull connector (SCRJ), PROFINET connection Port2 (XF2)

EX245-SPN2A

① M4, FE terminal screw (torque = 0.7 - 0.8 Nm)

② Push Pull connector (24 Volt), Power connection (XD1)

③ Push Pull connector (24 Volt), Power connection (XD2)

④ Push Pull connector (RJ45), PROFINET connection Port1 (XF1), Port type: MDI

⑤ Push Pull connector (RJ45), PROFINET connection Port2 (XF2), Port type: MDI-X

Fig. 3-4 Screw and connector allocation (EX245-SPN1A/SPN2A)

Page 16

- 16 -

No.EX※※-OMW0011-A

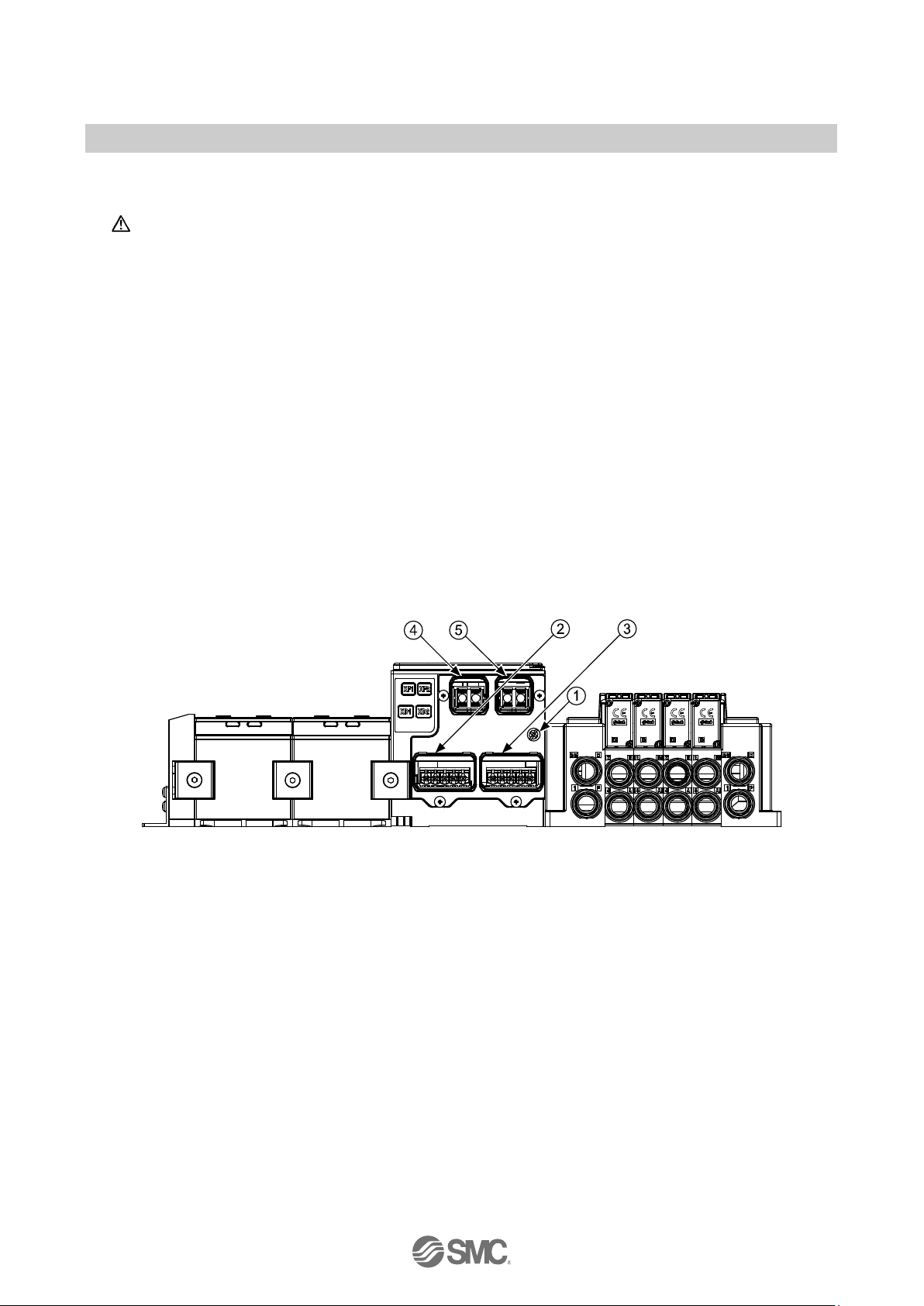

EX245-SPN3A

① M4, FE terminal screw (torque = 0.7 - 0.8 Nm)

② 7/8 inch 5 pins plug connector, Power connection (XD1)

③ 7/8 inch 5 pins socket connector, Power connection (XD2)

④ M12 4 pins socket D-coded connector, PROFINET connection Port1 (XF1), Port type: MDI

⑤ M12 4 pins socket D-coded connector, PROFINET connection Port2 (XF2), Port type: MDI-X

Fig. 3-5 Screw and connector allocation (EX245-SPN3A)

Page 17

- 17 -

No.EX※※-OMW0011-A

3.2.1. Power/Bus connection

The SI Unit has two Power connectors (XD1/XD2) and two PROFINET communication

connectors (XF1/XF2). If only one connector is used, cover the unused connector with a seal cap so

that the protection rating of IP65 is maintained.

The supply for the logic/sensors “US1” and the supply for the valves/loads “US2” provide the

connected modules and the valve coils via the SI Unit.

The two supplies are isolated electrically and can be switched independently.

Caution

・ Seal caps must be fitted to all unused bus & power connector ports to ensure an IP65 rating.

・ Seal caps must be fitted to all unused bus connector ports to prevent eye exposure to the light

beam from the SCRJ connectors for the EX245-SPN1A

・ Power and bus lines must be installed correctly.

・ To prevent manifold components of the SI Unit from being damaged the supply lines for the

electronics and for the load voltage must be protected externally with a fuse.

・ Maximum loop through current between power connectors on each SI Unit must not be

exceeded.

・ The EX245-SPN1A makes use of a CLASS 1 LASER product. Do not stare into beam visible at

XF1/XF2.

Power connectors

Pin

Remarks

1

24V (US1)

2

0V (US1)

3

24V (US2)

4

0V (US2)

5

FE

View of Push Pull

connector (XD1/XD2)

Fig. 3-6 Pin allocation of Push Pull connector (24 Volt) for EX245-SPN1A/SPN2A

Pin

Remarks

1

0V (US2)

2

0V (US1)

3

FE 4 24V(US1)

5

24V(US2)

View of 7/8 inch 5 pins

plug connector (XD1)

View of 7/8 inch 5 pins

socket connector (XD2)

Fig. 3-7 Pin allocation of 7/8 inch 5 pins connector for EX245-SPN3A

Page 18

- 18 -

No.EX※※-OMW0011-A

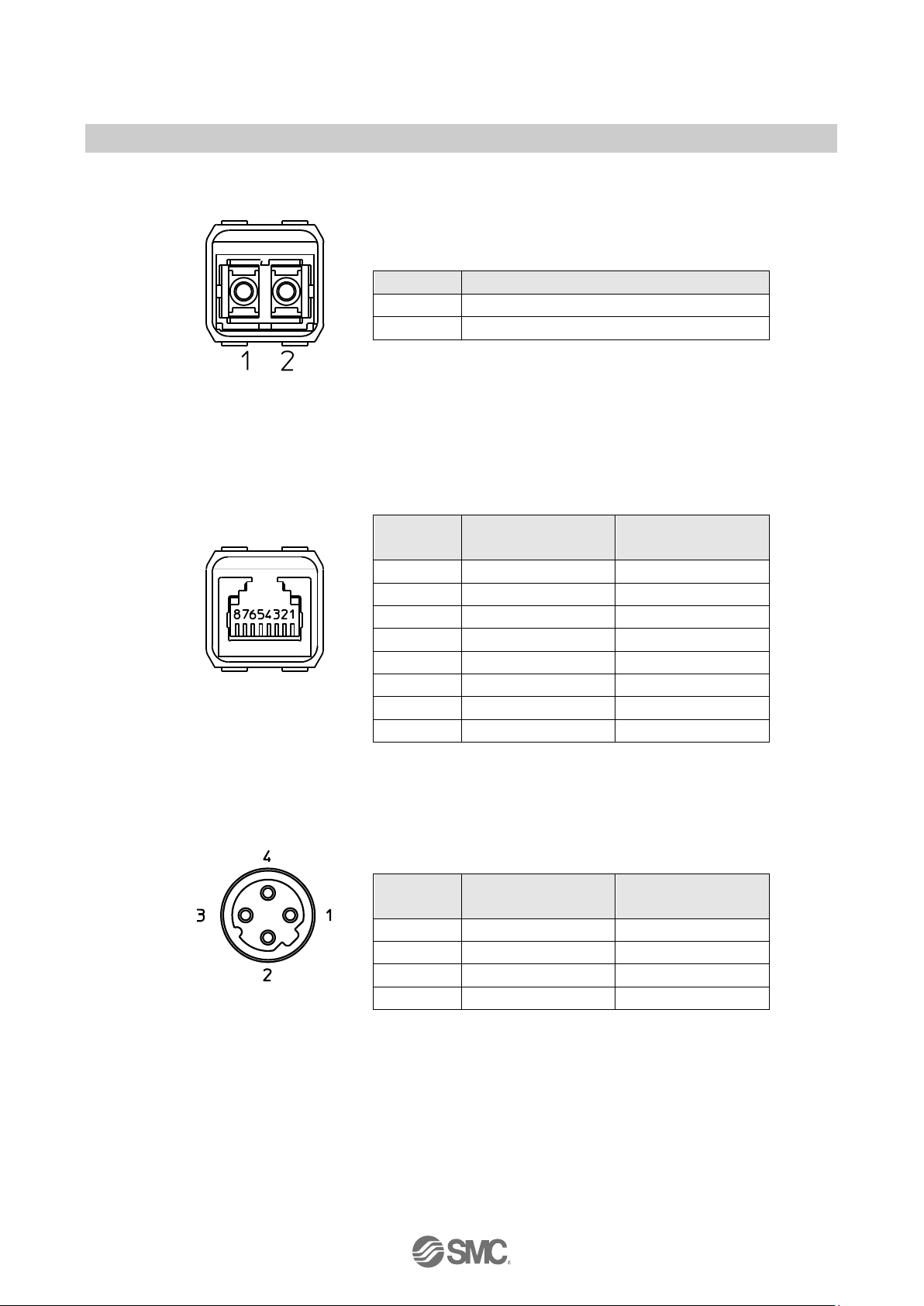

PROFINET communication connectors

Pin

Port1/Port2

1

TX Transmit Data

2

RX Receive Data

View of Push Pull

connector (XF1/XF2)

Fig. 3-8 Pin allocation of Push Pull connector (SCRJ) for EX245-SPN1A

Pin

Port1 (XF1)

Port type: MDI

Port2 (XF2)

Port type: MDI-X

1

TD+ Transmit data+

RD+ Receive data+

2

TD- Transmit data-

RD- Receive data-

3

RD+ Receive data+

TD+ Transmit data+

4 - -

5 - -

6

RD- Receive data-

TD- Transmit data-

View of Push Pull

connector (XF1/XF2)

7 - -

8 - -

Fig. 3-9 Pin allocation of Push Pull connector (RJ45) for EX245-SPN2A

Pin

Port1 (XF1)

Port type: MDI

Port2 (XF2)

Port type: MDI-X

1

TD+ Transmit data+

RD+ Receive data+

2

RD+ Receive data+

TD+ Transmit data+

3

TD- Transmit data-

RD- Receive data-

4

RD- Receive data-

TD- Transmit data-

View of M12 4 pins socket

D-coded connector

(XF1/XF2)

Fig. 3-10 Pin allocation of M12 4 pins socket D-coded connector for EX245-SPN3A

Page 19

- 19 -

No.EX※※-OMW0011-A

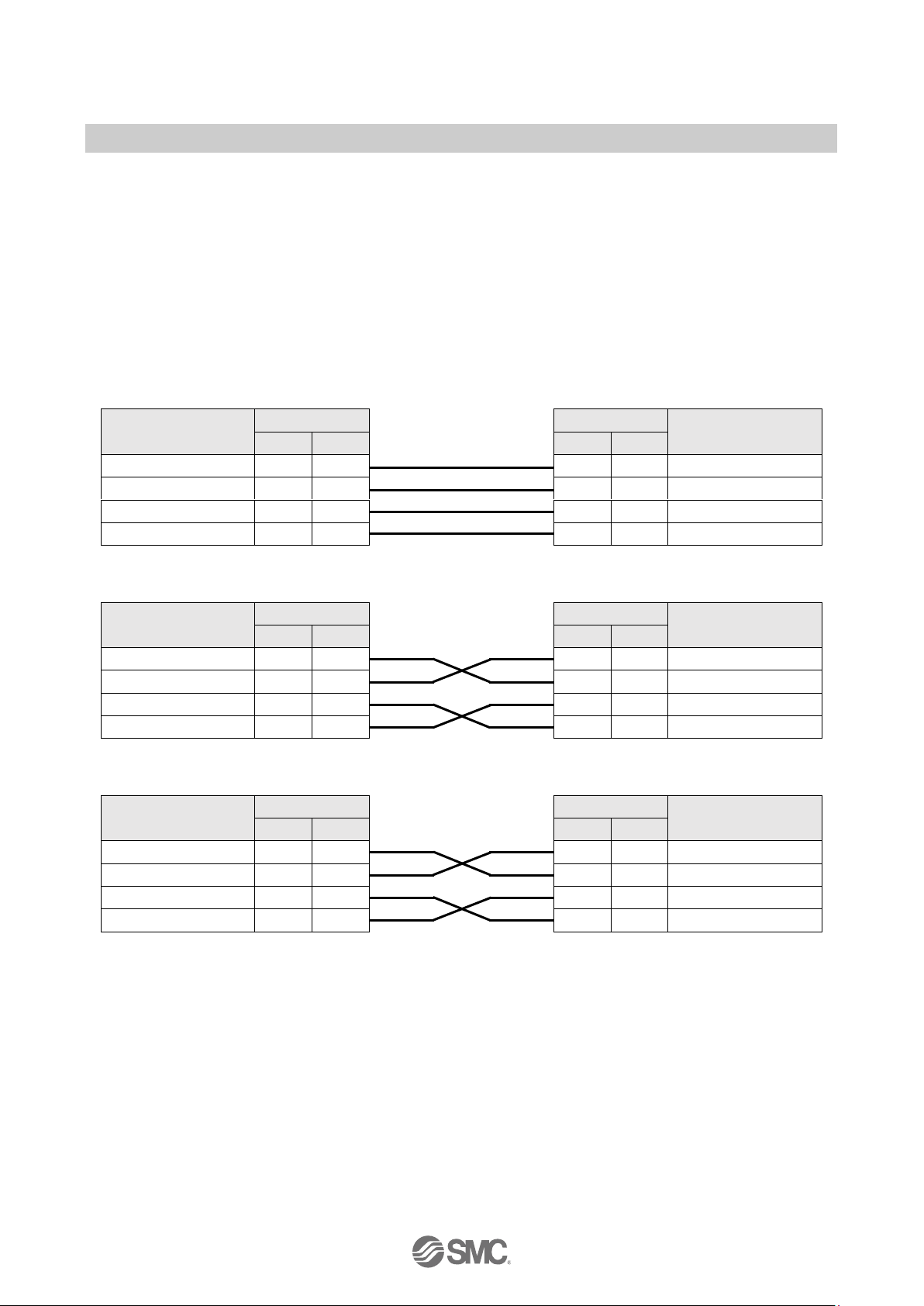

NOTE

・ When you use the EX245-SPN2A/EX245-SPN3A and the Autonegotiation function is disabled,

you must select the correct network cable, refer to Fig 3-11, 3-12.

・ Auto crossover function is not available when the Autonegotiation function is disabled.

・ Auto crossover function shall be capable of switching over their twisted pair ports automatically

between MDI and MDI-X pin assignment.

The following figure Fig. 3-11 shows examples on the use of two different cable types.

Patch cable

MDI

Pin Pin

MDI-X

RJ45

M12

RJ45

M12

TD+ Transmit data+

1 1 1 1

RD+ Receive data+

RD+ Receive data+

3 2 3 2

TD+ Transmit data+

TD- Transmit data-

2 3 2 3

RD- Receive data-

RD- Receive data-

6 4 6 4

TD- Transmit data-

Crossover cable

MDI

Pin Pin

MDI

RJ45

M12

RJ45

M12

TD+ Transmit data+

1 1 1 1

TD+ Transmit data+

RD+ Receive data+

3 2 3 2

RD+ Receive data+

TD- Transmit data-

2 3 2 3

TD- Transmit data-

RD- Receive data-

6 4 6 4

RD- Receive data-

Crossover cable

MDI-X

Pin Pin

MDI-X

RJ45

M12

RJ45

M12

RD+ Receive data+

1 1 1 1

RD+ Receive data+

TD+ Transmit data+

3 2 3 2

TD+ Transmit data+

RD- Receive data-

2 3 2 3

RD- Receive data-

TD- Transmit data-

6 4 6 4

TD- Transmit data-

Fig. 3-11 Patch and Crossover Cable details

Page 20

- 20 -

No.EX※※-OMW0011-A

Connection example

Case 1

EX245-SPN2A/SPN3A

- Priorized startup (FSU)

- Disable Autonegotiation

Port 1

MDI

Port 2

MDI-X

Port *

MDI

Port #

MDI-X

Port 1

MDI

Port 2

MDI-X

IO controller or Switch

- Disable Autonegotiation

EX245-SPN2A/SPN3A

- Priorized startup (FSU)

- Disable Autonegotiation

Patch Cable

Patch Cable

Cable type

dependent upon

next port settings

Case 2

Port 2

MDI-X

Port 1

MDI

Port 2

MDI-X

IO controller or Switch

- Disable Autonegotiation

EX245-SPN2A/SPN3A

- Priorized startup (FSU)

- Disable Autonegotiation

EX245-SPN2A/SPN3A

- Priorized startup (FSU)

- Disable Autonegotiation

Port *

MDI

Port #

MDI-X

Port 1

MDI

Crossover Cable

Crossover Cable

Cable type

dependent upon

next port setti ngs

Fig. 3-12 Connection examples when using Disable Autonegotiation

3.2.2. FE terminal

The SI Unit must be connected to FE (Functional Earth) to divert electromagnetic interference. The

FE terminal and the FE pin of the two power connectors (XD1/XD2) are internally connected. Please

connect at least one of these three FEs to ground potential. For maximum protection the FE cable

should be as thick and short as reasonably possible. If it is difficult to shorten the power cable, it is

recommended to use the FE terminal screw.

3.2.3. Sensor/Load connection

Regarding the wiring of each module, refer to following section:

・ EX245-DX1 : Section 7.3

・ EX245-DY1 : Section 8.3

Page 21

- 21 -

No.EX※※-OMW0011-A

4. Commissioning

4.1. Configuration

The SI Unit is a modular station that consists of several modules. Setup your PROFINET IO

Controller’s software to reflect the configuration of your system.

4.1.1. GSD file and symbol files

In order to configure the SI Unit with your PROFINET IO Controller’s software the appropriate GSD

file is required. The GSD file contains all of necessary information to configure the SI Unit on your

PROFINET IO Controller’s software.

In order to represent the SI Unit in your PROFINET IO Controller’s software the appropriate symbol

files are required.

Current GSD file and symbol files name are as follows.

・ GSD file : GSDML-V2.3*-SMC-EX245-SPN-********.xml

・ Symbol files: GSDML-0083-0011-EX245.bmp

4.1.2. Head modules

The GSD file contains the description for two Head modules and three SI Units.

Table. 4-1 Head modules

Head module

Available SI Unit

EX245-SPN FX

EX245-SPN1A

EX245-SPN Cu

EX245-SPN2A

EX245-SPN3A

Page 22

- 22 -

No.EX※※-OMW0011-A

4.1.3. Modules

The SI Unit can consists of the following modules.

Table. 4-2 Overview of modules for the SI Unit

Module

Occupied bytes

Allowable slot

(Number / Name)

Note

Input

Output

Diagnostics type 1

4 bytes

-

1 / Diagnostics

Refer to the Section 5.1.1

Diagnostics type 1

shared

4 bytes

-

1 / Diagnostics

Refer to the Section 5.1.1

and Table 4-3

Diagnostics type 2

4 bytes

-

1 / Diagnostics

Refer to the Section 5.1.2

Diagnostics type 2

shared

4 bytes

-

1 / Diagnostics

Refer to the Section 5.1.2

and Table 4-3

16 Valves

-

2 bytes

2 / Valves

Refer to the Section 6.3

16 Valves shared

-

2 bytes

2 / Valves

Refer to the Section 6.3

and Table 4-3

32 Valves

-

4 bytes

2 / Valves

Refer to the Section 6.3

32 Valves shared

-

4 bytes

2 / Valves

Refer to the Section 6.3

and Table 4-3

EX245-DX1

2 bytes

-

3..10 / module 1..8

Refer to the Section 7.4

EX245-DX1 shared

2 bytes

-

3..10 / module 1..8

Refer to the Section 7.4

and Table 4-3

EX245-DY1

-

1 byte

3..10 / module 1..8

Refer to the Section 8.4

EX245-DY1 shared

-

1 byte

3..10 / module 1..8

Refer to the Section 8.4

and Table 4-3

4.1.4. Sub modules

Using the module named as “shared”, other PROFINET IO Controllers can use the copied input data

in the sub modules.

Table. 4-3 Overview of Sub modules for the SI Unit

Sub module

Occupied input bytes

Bytes to be copied

Diagnostics type 1

shared

4 bytes

4 bytes input data for diagnostics.

Refer to the Section 5.1.1.

Diagnostics type 2

shared

4 bytes

4 bytes input data for diagnostics.

Refer to the Section 5.1.2

16 Valves shared

2 bytes

2 bytes output data for valve outputs.

Refer to the Section 6.3

32 Valves shared

4 bytes

4 bytes output data for valve outputs.

Refer to the Section 6.3

EX245-DX1 shared

2 bytes

2 bytes input data for EX245-DX1 inputs.

Refer to the Section 7.4

EX245-DY1 shared

1 byte

1 byte output data for EX245-DY1 outputs.

Refer to the Section 8.4

Page 23

- 23 -

No.EX※※-OMW0011-A

4.1.5. Configuration steps

Enter the modules in your configuration program corresponding to the actual module layout and a

"Diagnostics type" module if required (Refer to the Section 5.1). If the configuration does not match

the actual layout, the connection to the IO Controller will not be established.

Configuration steps:

・ When using the EX245-SPN1A, choose the Head module “EX245-SPN FX” on the

configuration software. When using the EX245-SPN2A/EX245-SPN3A, choose the Head

module “EX245-SPN Cu”.

・ Enter the "Diagnostics type 1/2" modules in Diagnostics slot if required.

・ Enter the "16/32 Valves" module in Valves slot if use valves.

・ Enter the modules “EX245-DX1” and “EX245-DY1” in each module slot if modules are

connected (max. 8 modules).

Example of a configuration

Slot name

Actual module

Configuration module

Input bytes

Output bytes

Diagnositics

-

Diagnostics type 1

4

-

Valves

4 x Double solenoid

Valves

16 Valves - 2

Module 1

EX245-DX1

EX245-DX1

2

-

Module 2

EX245-DX1

EX245-DX1

2

-

Module 3

EX245-DX1

EX245-DX1

2

-

Module 4

EX245-DY1

EX245-DY1

-

1

Module 5

EX245-DY1

EX245-DY1

-

1

Fig. 4-1 Example of assignment of modules

Diagnostics slot

Diagnostics type 1

Page 24

- 24 -

No.EX※※-OMW0011-A

4.2. Parameterisation

4.2.1. Module parameters

・ Module parameters for valves

The "16 Valves" has the following module parameters.

Table. 4-4 Module parameters of the “16 Valves”

Name

Range of values

Default

Meaning

Valve Output 0

Force to OFF

Force to ON

Hold last state

Force to OFF

When a bus fault occurs, the output

can be made to react in one of the

following ways:

Force to OFF

Force to ON

Hold last state

Valve Output 1

Force to OFF

Force to ON

Hold last state

Force to OFF

… … …

Valve Output 15

Force to OFF

Force to ON

Hold last state

Force to OFF

The "32 Valves" has the following module parameters.

Table. 4-5 Module parameters of the “32 Valves”

Name

Range of values

Default

Meaning

Valve Output 0

Force to OFF

Force to ON

Hold last state

Force to OFF

When a bus fault occurs, the output

can be made to react in one of the

following ways:

Force to OFF

Force to ON

Hold last state

Valve Output 1

Force to OFF

Force to ON

Hold last state

Force to OFF

… … …

Valve Output 31

Force to OFF

Force to ON

Hold last state

Force to OFF

Page 25

- 25 -

No.EX※※-OMW0011-A

・ Module parameters for EX245-DX1

The EX245-DX1 has the following module parameter.

Table. 4-6 Module parameter of “EX245-DX1”

Name

Range of values

Default

Meaning

Input filter

Enable

Disable

Enable

Sets the time to ignore the input signal

change per module as follows:

Enable : 8 msec

Disable : No input filter

・ Module parameters for EX245-DY1

The EX245-DY1 has the following module parameters.

Table. 4-7 Module parameters of “EX245-DY1”

Name

Range of values

Default

Meaning

Digital Output 0

Force to OFF

Force to ON

Hold last state

Force to OFF

When a bus fault occurs, the output can

be made to react in one of the following

ways:

Force to OFF

Force to ON

Hold last state

Digital Output 1

Force to OFF

Force to ON

Hold last state

Force to OFF

… … …

Digital Output 7

Force to OFF

Force to ON

Hold last state

Force to OFF

Page 26

- 26 -

No.EX※※-OMW0011-A

4.2.2. Energy saving mode for PROFIenergy

Each module has the following module parameters for PROFIenergy.

The SI Unit starts the energy saving mode when the SI Unit receives the PROFIenergy command.

Regarding the LED indicator during energy saving mode, refer to the Section 6.4.6.

Table. 4-8 PROFIenergy parameters of “16/32 Valves”

Parameters

Range of values

Explanation

Valves supply

Output value

Valves output

operation at pause

Proceed

ON

Depending on valves behavior

Force to OFF

(Default)

OFF

Fixed 0x00

Hold last status

Hold last value

Table. 4-9 PROFIenergy parameters of “EX245-DX1”

Parameters

Range of

values

Explanation

Switch/sensor

supply

Input value

LED indicator of EX245-DX1

Sensor supply

and input value at

pause

Proceed

ON

Depending on

switch/sensor

behavior

Depending on switch/sensor

behavior

Shut down,

Clear value

(Default)

OFF

Fixed 0x00

OFF

Shut down,

Hold last

status

Hold last value

Table. 4-10 PROFIenergy parameters of “EX245-DY1”

Parameters

Range of

values

Explanation

Load supply

Output value

LED indicator of EX245-DY1

Digital output

operation at

pause

Proceed

ON

Depending on

load behavior

Depending on load behavior

Force to OFF

(Default)

OFF

Fixed 0x00

OFF

Hold last

status

Hold last value

Page 27

- 27 -

No.EX※※-OMW0011-A

5. Diagnosis

5.1. Diagnostics data on I/O mapping

The SI Unit can be allocated diagnostics data as digital input data on I/O mapping, if one of the

module, Diagnostics type 1 or Diagnostics type 2, is configured. Use PROFINET IO Controller’s

software to select a requested diagnostics type to allocate the diagnostics data on I/O mapping.

5.1.1. Diagnostics type 1

Table. 5-1 Overview of Diagnostics type 1

Byte

Description

0

General diagnostics 1

1

General diagnostics 2

2

Valve diagnostics 1

3

Valve diagnostics 2

・ General diagnostics 1

Table. 5-2 General diagnostics 1

Bit

Description

Explanation

0

System fault

0: No error on Diagnostics data on I/O mapping

1: At least one error on Diagnostics data on I/O mapping has occurred

1

Valve-coil(s) short circuit

0: No valve coil(s) have a short circuit

1: At least one valve coil has a short circuit

2

Module error

0: No module has an error

1: At least one connected module has an error

3

Changed module layout

0: Module has not disconnected.

1: At least one module has disconnected.

4

US1 Diagnostics

0: US1 present

1: US1 has dropped (< approx. 19.2V DC)

5

Reserved

Fixed 0

6

Reserved

Fixed 0

7

Reserved

Fixed 0

Page 28

- 28 -

No.EX※※-OMW0011-A

・ General diagnostics 2

Table. 5-3 General diagnostics 2

Bit

Description

Explanation

0

Module 1 error

0: No error or not connected, 1: Module 1 has an error

1

Module 2 error

0: No error or not connected, 1: Module 2 has an error

2

Module 3 error

0: No error or not connected, 1: Module 3 has an error

3

Module 4 error

0: No error or not connected, 1: Module 4 has an error

4

Module 5 error

0: No error or not connected, 1: Module 5 has an error

5

Module 6 error

0: No error or not connected, 1: Module 6 has an error

6

Module 7 error

0: No error or not connected, 1: Module 7 has an error

7

Module 8 error

0: No error or not connected, 1: Module 8 has an error

・ Valve diagnostics 1

Table. 5-4 Valve diagnostics 1

Bit

Description

Explanation

0

Valve 0, 1 diagnostics

0: No error, 1: Short circuit

1

Valve 2, 3 diagnostics

0: No error, 1: Short circuit

2

Valve 4, 5 diagnostics

0: No error, 1: Short circuit

3

Valve 6, 7 diagnostics

0: No error, 1: Short circuit

4

Valve 8, 9 diagnostics

0: No error, 1: Short circuit

5

Valve 10, 11 diagnostics

0: No error, 1: Short circuit

6

Valve 12, 13 diagnostics

0: No error, 1: Short circuit

7

Valve 14, 15 diagnostics

0: No error, 1: Short circuit

・ Valve diagnostics 2

Table. 5-5 Valve diagnostics 2

Bit

Description

Explanation

0

Valve 16, 17 diagnostics

0: No error, 1: Short circuit

1

Valve 18, 19 diagnostics

0: No error, 1: Short circuit

2

Valve 20, 21 diagnostics

0: No error, 1: Short circuit

3

Valve 22, 23 diagnostics

0: No error, 1: Short circuit

4

Valve 24, 25 diagnostics

0: No error, 1: Short circuit

5

Valve 26, 27 diagnostics

0: No error, 1: Short circuit

6

Valve 28, 29 diagnostics

0: No error, 1: Short circuit

7

Valve 30, 31 diagnostics

0: No error, 1: Short circuit

Page 29

- 29 -

No.EX※※-OMW0011-A

5.1.2. Diagnostics type 2

Table. 5-6 Overview of Diagnostics type 2

Byte

Description

0

General diagnostics 1

1

Valve diagnostics 1

2

General diagnostics 2

3

Valve diagnostics 2

・ General diagnostics 1

Table. 5-7 General Diagnostics 1

Bit

Description

Explanation

0

Maximum number of valves

0: 16 Valves

1: 32 Valves or no “Valves” module

1

Valve coil(s) short circuit

0: No valve coil(s) have a short circuit

1: At least one valve coil has a short circuit

2

US1 diagnostics 1

0: US1 present

1: US1 has dropped (< approx. 19.2 V DC)

3

Reserved

Fixed 0

…

… … 7

Reserved

Fixed 0

・ Valve diagnostics 1

Table. 5-8 Valve diagnostics 1

Bit

Description

Explanation

0

Valve 0, 1 diagnostics

0: Short circuit, 1: No error

1

Valve 2, 3 diagnostics

0: Short circuit, 1: No error

2

Valve 4, 5 diagnostics

0: Short circuit, 1: No error

3

Valve 6, 7 diagnostics

0: Short circuit, 1: No error

4

Valve 8, 9 diagnostics

0: Short circuit, 1: No error

5

Valve 10, 11 diagnostics

0: Short circuit, 1: No error

6

Valve 12, 13 diagnostics

0: Short circuit, 1: No error

7

Valve 14, 15 diagnostics

0: Short circuit, 1: No error

Page 30

- 30 -

No.EX※※-OMW0011-A

・ General diagnostics 2

Table. 5-9 General diagnostics 2

Bit

Description

Explanation

0

Module 1 diagnostics

0: No error or not connected, 1: Module 1 has an error

1

Module 2 diagnostics

0: No error or not connected, 1: Module 2 has an error

2

Module 3 diagnostics

0: No error or not connected, 1: Module 3 has an error

3

Module 4 diagnostics

0: No error or not connected, 1: Module 4 has an error

4

Module 5 diagnostics

0: No error or not connected, 1: Module 5 has an error

5

Module 6 diagnostics

0: No error or not connected, 1: Module 6 has an error

6

Module 7 diagnostics

0: No error or not connected, 1: Module 7 has an error

7

Module 8 diagnostics

0: No error or not connected, 1: Module 8 has an error

・ Valve diagnostics 2

Table. 5-10 Valve diagnostics 2

Bit

Description

Explanation

0

Valve 16, 17 diagnostics

0: Short circuit, 1: No error

1

Valve 18, 19 diagnostics

0: Short circuit, 1: No error

2

Valve 20, 21 diagnostics

0: Short circuit, 1: No error

3

Valve 22, 23 diagnostics

0: Short circuit, 1: No error

4

Valve 24, 25 diagnostics

0: Short circuit, 1: No error

5

Valve 26, 27 diagnostics

0: Short circuit, 1: No error

6

Valve 28, 29 diagnostics

0: Short circuit, 1: No error

7

Valve 30, 31 diagnostics

0: Short circuit, 1: No error

Page 31

- 31 -

No.EX※※-OMW0011-A

5.2. Maintenance alarm for the Fibre-optic cables

When the strength margin of the Fibre-optic communication is not enough, the EX245-SPN1A

issues a "Maintenance alarm" for the Fibre-optic cable, if monitor setting of communication port is

enable.

If the FO LED of the EX245-SPN1A is flashing (more than 0 dB but less than 2 dB) or ON (the

margin is 0 dB), refer to the Section 6.4.5.

In order to recover from this alarm, please check in the following order.

Example

Step 1: Check/exchange ① the Fibre-optic cable.

Step 2: Check/exchange ② the previous device.

Step 3: Check/exchange ③ the EX245-SPN1A.

EX245-SPN1A

Port1

Port2

FO1: ON

Previous Device

Port

Next Device

Port

②

①

③

FO2: OFF

Page 32

- 32 -

No.EX※※-OMW0011-A

6. SI Unit

6.1. Parts and description

EX245-SPN1A

EX245-SPN2A

Fig. 6-1 Allocation of parts on the EX245-SPN1A/SPN2A

Page 33

- 33 -

No.EX※※-OMW0011-A

EX245-SPN3A

Fig. 6-2 Allocation of parts on the EX245-SPN3A

Page 34

- 34 -

No.EX※※-OMW0011-A

6.2. Specifications

Table. 6-1 Specifications

Item

Description

EX245-SPN1A

EX245-SPN2A

EX245-SPN3A

General

Dimensions (W x L x H) in mm

85 x 127.5 x 89.5

85 x 147.7 x 89.5

Weight

465 g

540 g

Housing materials

PBT

Maximum number of modules

8

Maximum number of digital inputs

128

Maximum number of digital outputs

64 (independent of solenoid valves)

Electrical

Internal current consumption

at 24 V DC (Via US1)

300 mA or less

200 mA or less

Protection against polarity reversal

Yes (US1 and US2)

Loop through current between power

connector

16 A or less

6 A or less *

US1

Operating voltage

24 V DC +20%/-15%

Under-voltage detection

Detected : < approx. 19.2 V DC

Max. current

6 A total

US2

Operating voltage

24 V DC +20%/-15%

Max. current

4 A

Voltage drop to valve supply

Max. 1.2 V at 24 V DC

Galvanic isolation

Yes (between US1 and US2)

Solenoid valve

Applicable series

JSY series

JSY3000, JSY5000

SY series

SY3000, SY5000

VQC series

VQC2000, VQC4000

Max. number of solenoid valves

32 solenoid coils

Load

Solenoid valve with surge voltage suppressor of 24 V DC,

1 W or less (SMC)

Output type of solenoid

Source/PNP (negative common)

Over current protection

Yes

Over current detection

Yes

NOTE

・ Maximum permissible current of 7/8 inch 5 pins plug connector is 10A.

So for example, the EX245-SPN3A can use 4A and a loop through current of 6A can be drawn

between connectors “XD1” and “XD2”

Page 35

- 35 -

No.EX※※-OMW0011-A

Table. 6-2 Specifications (continued)

Item

Description

EX245-SPN1A

EX245-SPN2A

EX245-SPN3A

Fieldbus

Bus protocol

PROFINET I/O

Conformance Class C

Yes (Only for IRT switch function)

FSU (Fast Start Up)

Yes

MRP (Media Redundancy Protocol)

Yes

MRPD (Media Redundancy for

Planned Duplication)

Yes

Shared device

Yes

PROFIenergy

Yes

Web server function

Yes

Firmware update

Yes

Net Load Class Ⅲ

Yes

Maintenance alarm for the Fibre-optic

cable

Yes

-

Vendor ID

0083h

Device ID

0011h

GSD file

GSDML-V2.3*-SMC-EX245-SPN-********.xml

Page 36

- 36 -

No.EX※※-OMW0011-A

6.3. Process data for valves

The SI Unit occupies 2 or 4 bytes of output data for valves. The counting of valve coils starts at the

SI Unit from left to right.

Byte

Output data

16 Valves

32 Valves

0

Valve coils 0-7

Valve coils 0-7

1

Valve coils 8-15

Valve coils 8-15

2

Valve coils 16-23

3

Valve coils 24-31

Fig. 6-3 The process data for valves

Page 37

- 37 -

No.EX※※-OMW0011-A

6.4. LED indicators

The LED indicators are arranged on the SI Unit as shown in the illustration below.

The layout of the LINK/ACT LEDs and FO LEDs are for port1 on the left side (XF1) and for port2 on

the right side (XF2).

EX245-SPN1A EX245-SPN2A/EX245-SPN3A

Designation

Description

Colour

SF

System fault

Red

BF

Bus fault

Red

US1

Supply for the logic/sensors

Green

US2

Supply for the valves/loads

Green

LINK/ACT

A combination of LINK LED and ACT LED

Connection status via Ethernet (LINK: Green)

Data exchange status (ACT: Orange)

Green/Orange

FO

Fibre-Optic communication diagnostics

Orange

Fig. 6-4 LED indicators of the SI Unit

Page 38

- 38 -

No.EX※※-OMW0011-A

6.4.1. SF and BF indicators

Table. 6-3 SF and BF indicators

SF

BF

Meaning

OFF

OFF

No fault (The SI Unit is currently exchanging data with the IO Controller without

errors).

ON

---

One of the following may have occurred.

・ US1 is below the permissible level (< approx. 19.2 V DC).

・ The valve coil has a short circuit or the connected module has a short circuit.

・ The connected module has disconnected.

---

ON

One of the following may have occurred.

・ The connection to the IO Controller is nothing, or disconnection to the IO

Controller.

・ Device name is not correct.

・ IP address is not set or not correct.

・ The GSD file is not correct.

・ The configuration data sent by the IO Controller does not match the actual

layout.

Alternately flash

at 1 Hz

One of the following may have occurred.

・ During firmware update.

・ During forced output mode by Web server function.

Simultaneously flash

at 1 Hz

Firmware update failed.

6.4.2. US1 indicator

Table. 6-4 US1 indicator

US1

Meaning

OFF

US1 is not present.

Flash at 1 Hz

US1 is present but is below the permissible level (< approx. 19.2 V DC).

ON

US1 is present.

6.4.3. US2 indicator

Table. 6-5 US2 indicator

US2

Meaning

OFF

US2 is not present.

ON

US2 is present.

SF ON SF OFF

BF ON BF OFF

SF ON SF OFF

BF OFF BF ON

⇔

⇔

Page 39

- 39 -

No.EX※※-OMW0011-A

6.4.4. LINK/ACT indicator

Table. 6-6 LINK/ACT indicator

LINK/ACT

Meaning

Green ON

Connection via Ethernet to the SI Unit via Port 1/2 (XF1/XF2)

Green OFF

No connection established via Port 1/2 (XF1/XF2)

Orange ON

Transmission or reception of Ethernet telegrams on Port 1/2 (XF1/XF2)

Orange OFF

No transmission or reception of Ethernet telegrams on Port 1/2 (XF1/XF2)

Green Flash

at 1 Hz

Received node flash request

6.4.5. FO indicator

Table. 6-7 FO indicator

FO 1/2

Meaning

OFF

No fault.

The strength margin of the Fibre-optic communication is more than 2 dB on Port 1/2

(XF1/XF2).

Flash

at 1 Hz

The strength margin of the Fibre-optic communication is more than 0 dB but less than 2 dB on

Port 1/2 (XF1/XF2).

ON

The strength margin of the Fibre-optic communication is 0 dB on Port 1/2 (XF1/XF2).

NOTE

・ If monitor setting of communication port is enable, the FO indicator shows the status of the

maintenance alarm for the Fibre-optic cables, refer to the Section 5.2.

6.4.6. LED indicator during energy saving mode for PROFIenergy

Table. 6-8 LED indicator during energy saving mode for PROFIenergy

LED

Indicator

LINK/ACT

OFF

FO

OFF

SF

OFF

BF

OFF

US1

0.5 sec ON ⇔ 3 sec OFF

US2

OFF

NOTE

・ For module parameter of PROFIenergy, refer to the Section 4.2.2.

Page 40

- 40 -

No.EX※※-OMW0011-A

6.5. Block diagram

The following figure shows the block diagram of each SI Unit.

Fig. 6-5 Block diagram of the EX245-SPN1A

Page 41

- 41 -

No.EX※※-OMW0011-A

Fig. 6-6 Block diagram of the EX245-SPN2A

Page 42

- 42 -

No.EX※※-OMW0011-A

Fig. 6-7 Block diagram of the EX245-SPN3A

Page 43

- 43 -

No.EX※※-OMW0011-A

7. Digital Input Module - EX245-DX1

7.1. Parts and description

Fig. 7-1 Allocation of parts on the EX245-DX1

Page 44

- 44 -

No.EX※※-OMW0011-A

7.2. Specifications

Table. 7-1 EX245-DX1 specifications

Item

Description

General

Dimensions (W x L x H) in mm

54 x 120 x 61

Weight

265 g

Housing material

Nylon, PBT

Electrical

Rated supply voltage

24 V DC

Voltage drop to sensor supply

Max. 1.6 V

Internal current consumption at 24V DC

50 mA or less

Input connection type

8 x M12, 5 pins socket with double allocation

Over Voltage protection

Yes, more than 28 V DC at US1(sensor/input)

Over current protection

Yes

Sensor supply current per connector

Max. 0.5 A

Sensor supply current per module

Max. 2 A

Status indication

Yes, per input

Over current indication

Yes, per connector

Digital input

Number of inputs

16

Input type

PNP

Signal 1

11 to 30 V

Signal 0

-3 to 5 V

Permissible residual current

Max. 1.5 mA

Input current signal

Typ. 4.5 mA

Page 45

- 45 -

No.EX※※-OMW0011-A

7.3. Wiring

Caution

・ To prevent damage, all power for the SI Unit and modules must be turned off (i.e. de-energized)

before the modules are installed or removed.

・ For a protection rating of IP65 to be ensured, all covering caps must be screwed down correctly

after wiring and setting have been performed.

・ For a protection rating of IP65 to be ensured, sockets that are not used must be fitted with the

M12 Seal cap.

Pin allocation of the M12, 5 pins socket connector as shown in the following table:

Table. 7-2 Pin allocation of the connector for EX245-DX1

Pin

Allocation

View of connector (module side)

1

24 V 2

DI (input signal "n+1")

3

0 V (US1)

4

DI (input signal "n")

5

FE/Shield

7.4. Process data

The EX245-DX1 occupies 2 bytes of input data. The following table shows the allocation of the

digital inputs and the process image.

Table. 7-3 Digital input allocation and the process data

Connector position

Connector designation

X0

X1

X2

X3

X4

X5

X6

X7

Input

Pin 2

Bit 1

Bit 3

Bit 5

Bit 7

Bit 9

Bit 11

Bit 13

Bit 15

Pin 4

Bit 0

Bit 2

Bit 4

Bit 6

Bit 8

Bit 10

Bit 12

Bit 14

1 2 4

3

5

Page 46

- 46 -

No.EX※※-OMW0011-A

7.5. LED indicators

The status indicators are arranged on the EX245-DX1 as shown in the illustration below.

0 to15

Description

OFF

Input is not activated and no errors.

Green ON

Input is activated.

Red ON

Short circuit is detected.

Fig. 7-2 Status indicators of the EX245-DX1

Page 47

- 47 -

No.EX※※-OMW0011-A

7.6. Block diagram

The following figure shows the block diagram of the EX245-DX1.

Fig. 7-3 Block diagram of the EX245-DX1

Page 48

- 48 -

No.EX※※-OMW0011-A

8. Digital Output Module - EX245-DY1

8.1. Parts and description

Fig. 8-1 Allocation of parts on the EX245-DY1

Page 49

- 49 -

No.EX※※-OMW0011-A

8.2. Specifications

Table. 8-1 EX245-DY1 specifications

Item

Description

General

Dimensions (W x L x H) in mm

54 x 120 x 61

Weight

255 g

Housing material

Nylon, PBT

Electrical

Rated supply voltage

24 V DC

Voltage drop to load supply

Max. 1.6 V

Internal current consumption at 24 V DC

50 mA or less

Load connection

4 x M12, 5 pins socket with double allocation

Over Voltage protection

Yes, more than 28 V DC at US2(solenoid/output)

Over current protection

Yes

Output current per output

Max.0.5 A

Output current per module

Max.2 A

Status indication

Yes, per output

Over current indication

Yes, per output

Digital output

Number of outputs

8

Output type

PNP

Page 50

- 50 -

No.EX※※-OMW0011-A

8.3. Wiring

Caution

・ To prevent damage, all power for the SI Unit and modules must be turned off (i.e. de-energized)

before the modules are installed or removed.

・ For a protection rating of IP65 to be ensured, all covering caps must be screwed down correctly

after wiring and setting have been performed.

・ For a protection rating of IP65 to be ensured, sockets that are not used must be fitted with the

Seal cap.

Pin allocation of the M12, 5 pins socket connector as shown in the following table:

Table. 8-2 Pin allocation of the connector for EX245-DY1

Pin

Allocation

View of connector (module side)

1

N.C.

2 DO (output signal "n+1")

3

0 V (valves/loads)

4

DO (output signal "n")

5

FE/Shield

8.4. Process data

The EX245-DY1 occupies 1 byte of output data. The following table shows the allocation of the

digital outputs and the process image.

Table. 8-3 Digital output allocation and the process data

Connector position

Connector designation

X0

X1

X2

X3

Output

Pin 2

Bit 1

Bit 3

Bit 5

Bit 7

Pin 4

Bit 0

Bit 2

Bit 4

Bit 6

1 2 4 3 5

Page 51

- 51 -

No.EX※※-OMW0011-A

8.5. LED indicators

The status indicators are arranged on the EX245-DY1 as shown in the illustration below.

0 to 7

Description

OFF

Output is not activated and no errors.

Green ON

Output is activated.

Red ON

Short circuit is detected.

Fig. 8-2 Status indicators of the EX245-DY1

Page 52

- 52 -

No.EX※※-OMW0011-A

8.6. Block diagram

The following figure shows the block diagram of the EX245-DY1.

Fig. 8-3 Block diagram of the EX245-DY1

Page 53

- 53 -

No.EX※※-OMW0011-A

9. End Plate - EX245-EA2-1/2/3/4/5

9.1. Parts and description

Fig. 9-1 Allocation of parts on the EX245-EA2-1

Fig. 9-2 Allocation of parts on the EX245-EA2-2

Page 54

- 54 -

No.EX※※-OMW0011-A

Fig. 9-3 Allocation of parts on the EX245-EA2-3

Fig. 9-4 Allocation of parts on the EX245-EA2-4

Page 55

- 55 -

No.EX※※-OMW0011-A

Fig. 9-5 Allocation of parts on the EX245-EA2-5

Page 56

- 56 -

No.EX※※-OMW0011-A

9.2. Specifications

Table. 9-1 EX245-EA2-1 specifications

Item

Description

Dimensions (W x L x H) in mm

28.6 x 120 x 61.5

Weight

120 g

Housing material

Nylon

Table. 9-2 EX245-EA2-2 specifications

Item

Description

Dimensions (W x L x H) in mm

14 x 120 x 61.5

Weight

85 g

Housing material

Nylon

NOTE

・ EX245-EA2-2 can be used to have a special bracket which must be assembled with 4

Cross-recessed head tapping screws (3x6, torque: 0.8±0.05 N•m)

Table. 9-3 EX245-EA2-3 specifications

Item

Description

Dimensions (W x L x H) in mm

27.6 x 120 x 61.5

Weight

120 g

Housing material

Nylon

Table. 9-4 EX245-EA2-4 specifications

Item

Description

Dimensions (W x L x H) in mm

28.6 x 160 x 61.5

Weight

150 g

Housing material

Nylon

Table. 9-5 EX245-EA2-5 specifications

Item

Description

Dimensions (W x L x H) in mm

27.6 x 120 x 61.5

Weight

120 g

Housing material

Nylon

Page 57

- 57 -

No.EX※※-OMW0011-A

10. Accessories

10.1. Markers

Markers are available in single sheets each containing 88 pieces,

For the EX245-DX1 and EX245-DY1 use the part No.EX600-ZT1.

Model No.:EX600-ZT1

Fig. 10-1 EX600-ZT1

Page 58

- 58 -

No.EX※※-OMW0011-A

10.2. Y Connector

Y connectors can be used with the EX245-DX1 and EX245-DY1.

There are two options –

2 x M12 to M12

2 x M8 to M12

Model No.:PCA-1557785

(Y branch Connector (2 x M12 to M12))

Fig. 10-2 PCA-1557785

Page 59

- 59 -

No.EX※※-OMW0011-A

Model No.:PCA-1557798

(Y branch Connector (2 x M8 to M12))

Fig. 10-3 PCA-1557798

Page 60

- 60 -

No.EX※※-OMW0011-A

10.3. Seal cap

Model No.: EX9-AWTS

(10 pieces for M12 socket connectors)

The EX9-AWTS can be used with the EX245-SPN3A, EX245-DX1 and EX245-DY1.

Mount the seal cap in the unused sockets.

IP65 rating is maintained by using the seal cap properly.

Fig. 10-4 EX9-AWTS

NOTE

・ Tighten the seal caps to the tightening torque specified (0.2N•m)

・ In case of the EX245-SPN3A, M12 Seal caps is fitted to PROFINET connection Port2 (XF2)

when shipped from factory.

Page 61

- 61 -

No.EX※※-OMW0011-A

Model No.:EX245-AWP

(10 pieces for Push Pull connectors of power connection)

The EX245-AWP can be used with the EX245-SPN1A/EX245-SPN2A.

Mount the seal cap in the unused connector.

IP65 rating is maintained by using the seal cap properly.

Fig. 10-5 EX245-AWP

Model No.:EX245-AWC

(10 pieces for Push Pull connectors of PROFINET connection)

The EX245-AWC can be used with the EX245-SPN1A/EX245-SPN2A.

Mount the seal cap in the unused connector.

IP65 rating is maintained by using the seal cap properly.

Fig. 10-6 EX245-AWC

NOTE

・ In case of the EX245-SPN1A or EX245-SPN2A, the Seal caps is fitted to all bus & power

connector when shipped from factory.

Page 62

- 62 -

No.EX※※-OMW0011-A

10.4. Joint pack

One "Joint assembly" and two "Modular adaptor assembly" are contained in one "Joint pack".

Model No.: EX245-ZJP

Joint assembly

Modular adaptor assembly

Fig. 10-7 EX245-ZJP

NOTE

・ One Joint pack is attached to the EX245-DX1, EX245-DY1 and EX245-EA2-1/2/3/4/5.

・ Regarding mounting, refer to the Section 3.1.2.

Page 63

- 63 -

No.EX※※-OMW0011-A

11. Dimensions

11.1. The Input/Output Modules Manifold

Fig. 11-1 Dimensions of the Modules manifold

NOTE

・ Fig. 11-1 shows when the EX245-EA2-1 is used.

The following table shows the length of the Input/Output Modules manifold.

Table. 11-1 Length the EX245-SPN1A/SPN2A/SPN3A manifold

n 0 1 2 3 4 5 6 7

8

L

113.6

167.6

221.6

275.6

329.6

383.6

437.6

491.6

545.6

Formulas: L = 54n + 113.6 (max. 8 modules) (Dimensions in mm)

Page 64

- 64 -

No.EX※※-OMW0011-A

12. Troubleshooting

12.1. EX245-SPN1A/SPN2A/SPN3A

Table. 12-1 Troubleshooting for bus communication

No.

Problem

Possible cause

Remedy

1

BF indicator is ON.

LINK indicator is OFF.

ACT indicator is OFF.

The SI Unit is not connecting to any

bus.

Check the cable connection.

2

BF indicator is ON.

LINK indicator is ON.

ACT indicator is ON.

The SI Unit is physically connected to

the IO Controller but the following

problem has occurred.

---

No bus communication.

Check the cable.

Connect to the PROFINET bus

communication.

The IO Controller is defective.

Check the IO Controller.

Device name is not correct.

Check the device names.

The GSD file is not correct.

Check the GSD file.

The configuration data sent by the IO

Controller does not match the actual

layout.

Configure the SI unit according to

the actual layout.

Table. 12-2 Troubleshooting for the problem with display on SF LED

No.

Problem

Possible cause

Remedy

1

SF indicator is ON.

US1 is below the permissible level

(< approx. 19.2 V DC).

Check the power supply.

The valve coil has a short circuit or the

connected module has a short circuit.

Check the solenoid valve for a

short circuit and the module

error/layout.

The connected module has

disconnected.

Check the connected module.

Table. 12-3 Troubleshooting for the problem with display on SF and BF LED

No.

Problem

Possible cause

Remedy

1

SF and BF indicators

are flashing alternately.

During firmware update.

---

During forced output mode by Web

server function.

---

2

SF and BF indicators

are flashing

simultaneously.

Firmware update failed.

Update the firmware again.

Page 65

- 65 -

No.EX※※-OMW0011-A

Table. 12-4 Troubleshooting for the problem with display on US1/US2 LED

No.

Problem

Possible cause

Remedy

1

US1 indicator is OFF.

Incorrect wiring.

Check the cable.

Check the wiring and pin numbers.

US1 is not present.

Check the supply for the

logic/sensors of the SI Unit.

2

US1 indicator is

flashing.

US1 is below the permissible level (<

approx. 19.2 V DC).

Check the supply for the

logic/sensors of the SI Unit.

3

US2 indicator is OFF.

Incorrect wiring.

Check the cable.

Check the wiring and pin numbers.

US2 is not present.

Check the supply for the

valves/loads.

Table. 12-5 Troubleshooting for malfunction of the solenoid valve

No.

Problem

Possible cause

Remedy

1

A solenoid valve is not

operating.

Incorrect mounting of valve manifold.

Check the mounting of the SI Unit

and valve manifold.

Solenoid valve is faulty.

Check the solenoid valve.

US2 is not present.

Check the supply for the valves.

Check the wiring and pin numbers.

Table. 12-6 Troubleshooting for the problem with display on FO LED

No.

Problem

Possible cause

Remedy

1

FO1 or FO2 indicator is

flashing.

The strength margin of the Fibre-optic

communication is more than 0 dB but

less than 2 dB on Port 1/2 (XF1/XF2).

Check the Fibre-optic cable.

2

FO1 or FO2 indicator is

ON.

The strength margin of the Fibre-optic

communication is 0 dB on Port 1/2

(XF1/XF2).

Check the Fibre-optic cable.

Page 66

- 66 -

No.EX※※-OMW0011-A

12.2. EX245-DX1

Table. 12-7 Troubleshooting for EX245-DX1

No.

Problem

Possible cause

Remedy

1

Signals cannot be

received even with

sensor.

Incorrect wiring.

Check the wiring and pin numbers.

US1 is not present.

Check the supply for the sensors.

Sensor is faulty.

Check the sensor.

2

Status indicator is red

ON.

“Pin 1: 24 V” and “Pin 3: 0 V” of the

sensor connection have over current.

Check the sensor.

Check the cable.

Check the wiring and pin numbers.

12.3. EX245-DY1

Table. 12-8 Troubleshooting for EX245-DY1

No.

Problem

Possible cause

Remedy

1

A load is not operating.

Incorrect wiring.

Check the wiring and pin numbers.

US2 is not present.

Check the supply for the loads.

Load is faulty.

Check the load.

2

Status indicator is red

ON.

“Pin 2/4: output signal” and “Pin 3: 0V”

of the load connection have over

current.

Check the load.

Check the cable.

Check the wiring and pin numbers.

Page 67

No.EX※※-OMW0011-A

Revision

A: Minor update (correction of sentences, etc.).

[March 2019]

4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN

Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362

URL http://www.smcworld.com

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2018-2019 SMC Corporation All Rights Reserved.

Loading...

Loading...