SMC Networks EX180-SDN4 Series, EX180-SDN3 Series, EX180-SDN5 Series, EX180-SDN6 Series Installation & Maintenance Manual

I

nstallation & Maintenance Manual

Fieldbus system - SI unit

Type EX180 Series for DeviceNet

TM

EX180-SDN3 /SDN4 /SDN5 /SDN6

Fieldbus interface

connector (BUS)

Item Description

The connector for the DeviceNetTMbus line

( ).

6

Power supply

connector (PWR(V))

The connector for the power supply ( )

used to supply the power for the solenoid

valves.

7

FG terminal Functional Earth.

P

W

R

(

V

)

P

W

R

M

N

S

4

3

2

5

1

1

No.

2

3

Do not disassemble, modify (including changing the printed

circuit board) or repair.

An injury or failure can result.

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical

system.

•Check the product regularly for proper operation.

Otherwise malfunction can result, causing an accident.

The following instructions must be followed during maintenance:

•Turn off the power supply.

•Stop the air supply, exhaust the residual pressure and verify that the

air is released before performing maintenance.

Otherwise an injury can result.

S

afety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of

"Caution", "Warning" or "Danger". They are all important notes for safety

and must be followed in addition to International standards (ISO/IEC)

and other safety regulations.

Warning

CAUTION indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

WARNING indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

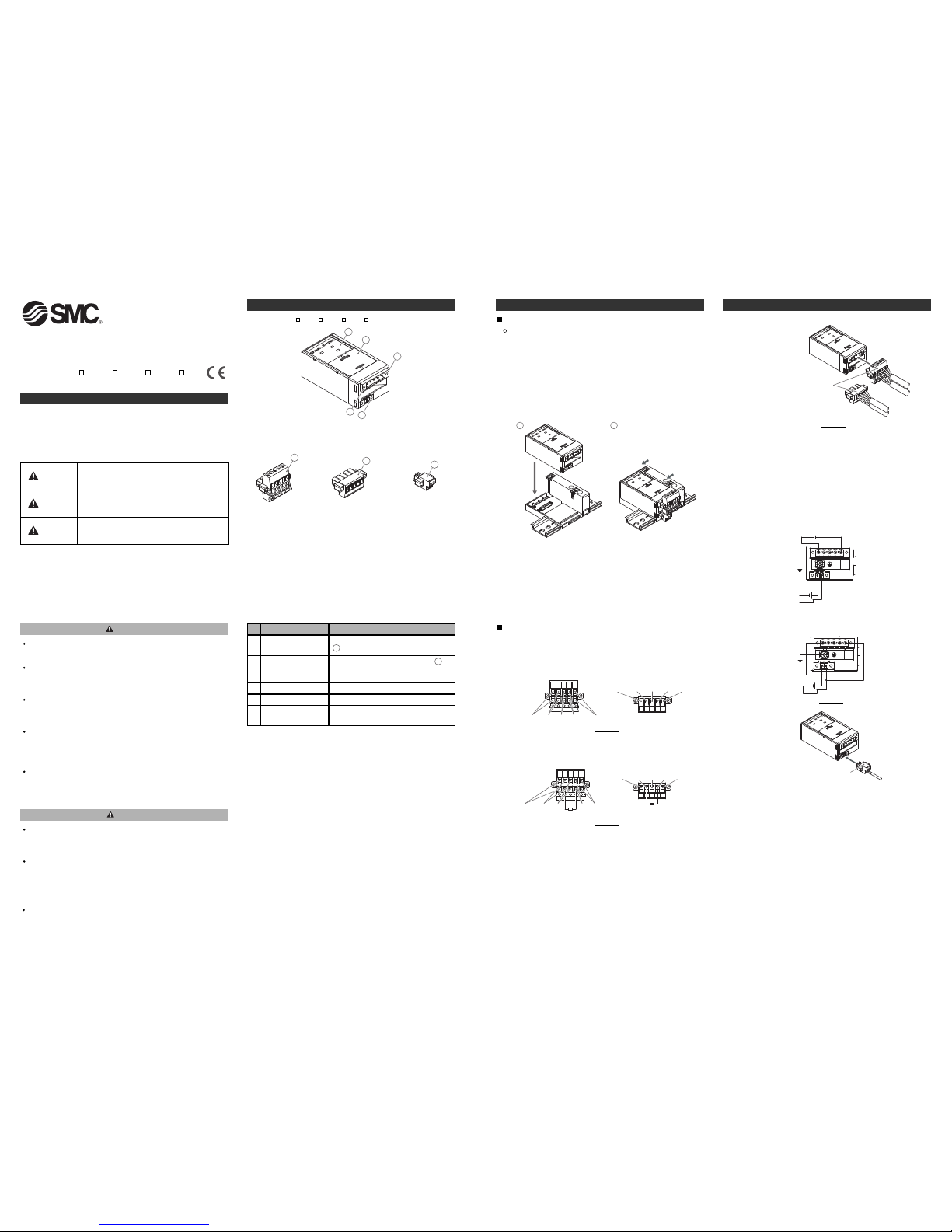

Summary of Product Parts Installation

<EX180-SDN3 /SDN4 /SDN5 /SDN6 >

E

X180-TFO09

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

NOTE

When conformity to UL is necessary the SI unit must be used with a UL

1310 Class2 power supply.

Caution

After maintenance is complete, perform appropriate functional

inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

Provide grounding to assure the safety and noise resistance of

the Fieldbus system.

Individual grounding should be provided close to the product with a

short cable.

Display LED diagnostic display.

Setting switches

Switches to set the MAC ID and

communication speed (inside the cover).

4

5

6

Communication connector for DeviceNetTM(1 pc.)

6

(EX180-CDN1)

(EX180-CDN2)

EX180-SDN3/4/5/6 EX180-SDN3A/4A/5A/6A

7

Power supply

connector (1 pcs.)

(EX180-CP1)

<Accessories>

General Instructions on Installation

Applicable valve series

The EX180 series SI unit can be mounted on the following valve

manifolds.

SJ2000/3000, S0700 series

∗: Refer to the catalogues and operation manuals for details of the solenoid

v

alves and manifolds.

•How to mount the manifold

1. Mount the SI unit to the manifold so that the mounting guide of the

SI unit case mates with the manifold groove.

2. Secure the SI unit using the two sliding locks.

P

W

R

(

V

)

P

W

R

M

N

S

P

W

R

(

V

)

P

W

R

M

N

S

1

2

Wiring

1. Wiring for communication

Wiring of the DeviceNetTMcommunication cable and connector is

shown below.

(1)Connect the signal wires to the assigned pins. (Figure 1)

The required tightening torque is 0.5 to 0.6 Nm.

V+

CAN_H

Drain

CAN_L

V-

White Drain Blue Black

Red

White Drain Blue

Black

Red

V+

CAN_H

Drain

CAN_L

V-

Installation (Continued)

Figure 1

(2)A bus termination is required at both ends of the

DeviceNetTMbus

segment as shown in Figure 2.

The specification of the terminating resistor is 121 Ω ±1%, 1/4 W.

V+

CAN_H

Drain

CAN_L

V-

Terminating resistor

White Drain Blue BlackRed

White Drain Blue BlackRed

V+

CAN_H

Drain

CAN_L

V-

Terminating resistor

Figure 2

(3)How to connect.

P

W

R

(

V

)

P

W

R

M

N

S

Communication connector

for DeviceNet

TM

Figure 3

2. Wiring of the power supply

Connect the power supply to the power supply connector (1 pc.).

The EX180 power supply structure consists of two supplies.

These supplies can be operated using a single or dual power supply

system.

Connect the wires to the assigned pins. (Figure 4, Figure 5)

The required tightening torque is 0.22 to 0.25 Nm.

•Note

Connect the FG terminal to ground with a ground resistance of

100 Ω or less.

DeviceNet

TM

power supply

24 VDC

Solenoid valve

power supply

24 VDC

24 VDC

Figure 4

A. Dual power supplies

B. Single power supply

P

W

R

(

V

)

P

W

R

M

N

S

Power supply connector

Figure 5

CLR

HOLD01

Clear all outputs.

Hold the last state before communication error.

::

The default setting is all switches ON, so the MAC ID is set to 63.

The MAC ID should be set in the range of 0 to 63.

500 kbps

Invalid

250 kbps

125 kbps

Communication

speed

0

1

1

0

No.7

1

1

0

0

No.8

Factory default setting is125 kbps.

Factory default setting is HW mode.

The MAC ID and communication speed will be retained if the unit is powered off and software mode

is selected (DIP switch 10).

If HW mode is selected then the settings stored using SW mode will be replaced by the HW settings.

1

1

0

0

0

1

1

0

0

0

:

1

1

0

0

0

32 16 8

::

1

1

0

0

0

1

1

1

0

0

:

0

1

0

0

1

421

No.1 No.2 No.3 No.4 No.5

#62

#63

:

#2

#0

MAC ID

setting

#1

No.6

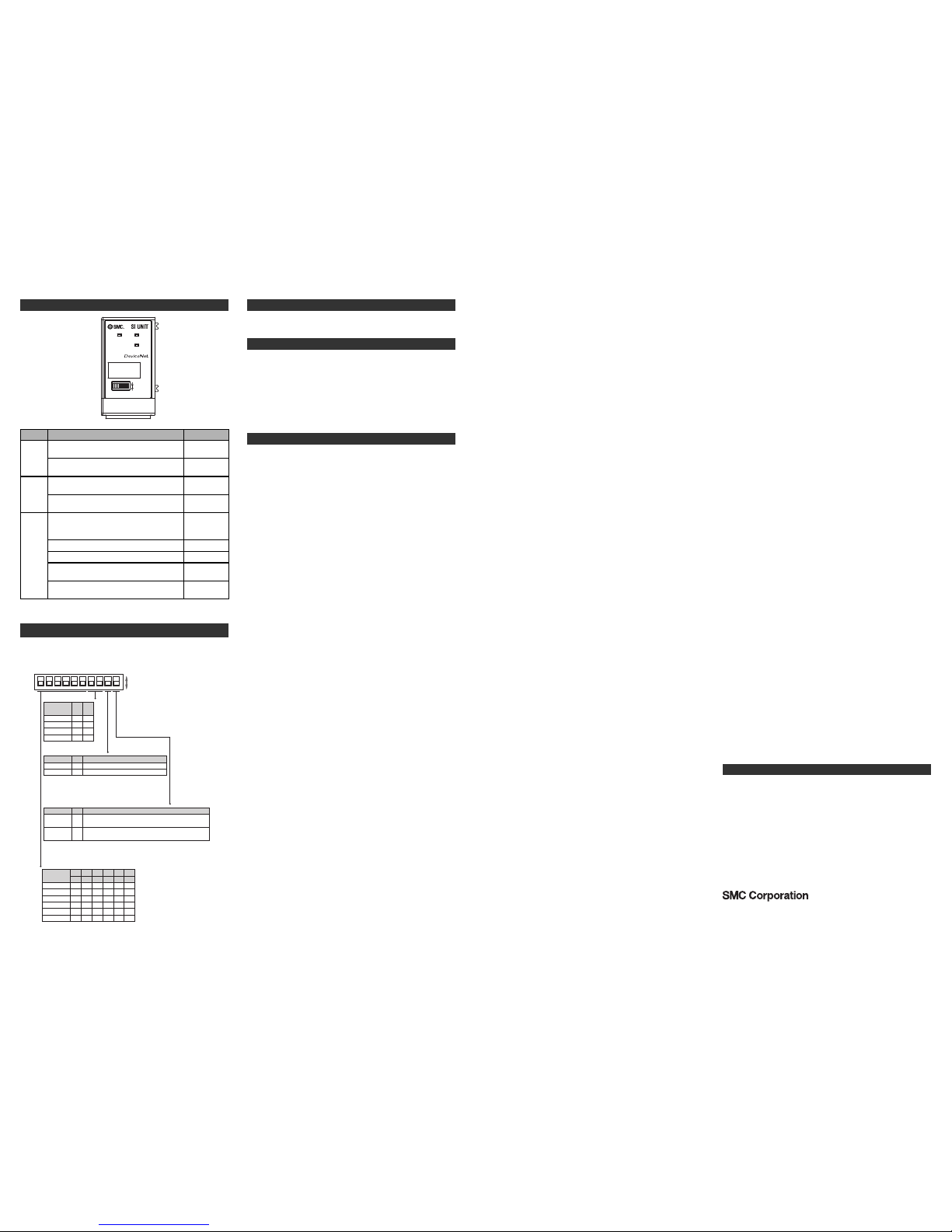

1ON2345678910

1

DIP SW

0

C

ommunication speed setting

HOLD/CLR setting

01HW

SW/HW

SW

No.10

Setting of the MAC ID and communication speed can be carried out

using the DIP switches No.1 to 8.

Description

SW/HW mode setting

MAC ID setting

HOLD/CLR No.9 Description

Setting of the MAC ID and communication speed can be carried out

via the DeviceNet network. DIP switches No.1 to 8 will be invalid.

Factory default setting is CLEAR.

It is possible to set the output condition in the event of a communication

error individually via the DeviceNet

TM

network.

If the output condition is set via the DeviceNetTM Network then the setting

of DIP switch 9 is invalid.

E

X180-TFO09

Contacts

AUSTRIA (43) 2262 62280-0

NETHERLANDS (31) 20 531 8888

BELGIUM (32) 3 355 1464

NORWAY (47) 67 12 90 20

CZECH REP. (420) 541 424 611

POLAND (48) 22 211 9600 DENMARK (45) 7025 2900

PORTUGAL (351) 21 471 1880

FINLAND (358) 207 513513

SLOVAKIA (421) 2 444 56725 FRANCE (33) 1 6476 1000

SLOVENIA (386) 73 885 412GERMANY (49) 6103 4020

SPAIN (34) 945 184 100 GREECE (30) 210 271 7265

SWEDEN (46) 8 603 1200

HUNGARY (36) 23 511 390

SWITZERLAND (41) 52 396 3131 IRELAND (353) 1 403 9000

UNITED KINGDOM (44) 1908 563888

ITALY (39) 02 92711

URL http://www.smcworld.com (Global) http://www.smceu.com (Europe)

Specifications are subject to change without prior notice from the manufacturer.

© 2011 SMC Corporation All Rights Reserved.

BULGARIA (359) 2 974 4492

ESTONIA (372) 651 0370

ROMANIA (40) 21 320 5111

LATVIA (371) 781 77 00

LITHUANIA (370) 5 264 8126

Specification

Connected load: 24 VDC Solenoid valve with light and surge voltage

suppressor of 1 W or less (manufactured by SMC)

Current consumption of power supply for SI unit operation: 0.1 A max.

Ambient temperature for operation: -10 to 50 ℃

Ambient temperature for storage: -20 to 60 oC

Pollution degree 2: (UL508)

Refer to the SMC website (URL http://www.smcworld.com) for more

information about the product specifications.

Outline Dimensions

Refer to the SMC website (URL http://www.smcworld.com) for more

information about outline dimensions.

Troubleshooting

Refer to the SMC website (URL http://www.smcworld.com) for more

information about troubleshooting.

Setting of the DIP switches should only be carried out with the power

supply turned off.

Open the cover and set the DIP switches with a small flat blade screwdriver.

Setting

LED Display

PWR(V) PWR

MNS

DIP SW

1

ON

0

LED Description

MNS

Communication power supply for DeviceNet

TM

is OFF, off line or a MAC ID duplication is

present

PWR(V)

Solenoid valve power supply is supplied at the

specified voltage

PWR

Communication power supply for DeviceNet

TM

is supplied

Solenoid valve power supply is not supplied at

the specified voltage

I/O connection time out (Minor communication

error)

I/O connection is waiting (On line status)

I/O connection is established (On line status)

Communication power supply for DeviceNet

TM

is not supplied

MAC ID duplication error or BUS OFF error

(Serious communication error)

LED status

ON

OFF

Green flashing

Green ON

Red flashing

Red ON

ON

OFF

OFF

Loading...

Loading...