SMC Networks EX121-SDN1, EX122-SDN1, EX124D/U-SDN1, EX124D-SDN1, EX124U-SDN1 Operation Manual

Page 1

OPERATION MANUAL

SMC Corporation

SI unit

EX120-SDN1

Doc.No. EX## -OME0015

EX121-SDN1

EX122-SDN1

EX124D/U-SDN1

Page 2

Contents

1.Safety instructions ------------------------------------------------------ P3

2.Specifications

2-1.General specifications ------------------------------------------------------ P4

2-2.Electrical and network specifications ------------------------------------------------------ P4

2-3.Applicable solenoid valve series ------------------------------------------------------ P5

3.Wiring and setting

3-1.Connection type ------------------------------------------------------ P5

3-2.Address setting ------------------------------------------------------ P8

4.LED indicator and Physical dimensions

4-1.LED indication ------------------------------------------------------ P9

4-2.Physical dimensions ------------------------------------------------------ P9

5.EDS(Electronic Data Sheet) File ------------------------------------------------------ P12

6.Trouble Shooting ------------------------------------------------------ P13

SMC CORPORATION

Doc.No.EX

##-OME0015

- 2 -

Page 3

SMC CORPORATION

Doc.No.EX

##-OME0015

1.Safety instructions

These safety instructions are intended to prevent a hazardous situation and/or equipment damage. These instructions indicate

the level of potential hazard by label of "CAUTION" , "WARNING".

To ensure safety, be sure to observe ISO, JIS and other safety practices.

CAUTION: Operator error could result in injury or equipment damage.

WARNING: Operator error could result in serious injury or loss of life.

CAUTION

Thoroughly read this manual and operate the product within the specified range. Follow the instructions.

Do not drop or impart any impact to the product.

Use within specified voltage range. Use outside of specified voltage will cause malfunction, damage of unit, electric shock, and

fire.

Do not touch the terminal or internal circuit board while they are energized. It may cause malfunction, damage to unit, and

electric shock.

Use within operating ambient temperature. Do not use where temperature can rapidly change even thought it is within the

specifications.

Foreign objects should be prevented from entering the product. Contamination by foreign objects, such as wire chips will cause

fire, breakage, and malfunction.

Use within the operating environment of the protection structure. In case of IP20, avoid use in the place where water and oil

scatter. To realize IP65, install manifold properly and give some prevention against splash of liguid to electrical entry.

Carry out periodical checks to confirm correct operation. Safety may not be maintained by unintentional malfunction or incorrect

operation. Design must consider the space necessary for maintenance.

As the contents of this manual is sometimes changed without the previous announcement, understand them beforehand,

please.

SI unit is not explosion proof. Operation in explosive enviromment may cause explosion accident.

WARNING

The product specified here is designed to be used in standard factory automation equipment. Do not use in machinery and/or

equipment where operators may be injured, and malfunction or failure may cause loss of life.

Do not disassemble to repair or modify the product.

Connection

CAUTION

Power of the product and all other equipments should be turned off while wiring.

Tighten the wiring with connector and tarminal screw completely. Short circuit, fire, and malfunction will be caused if connector

and tarminal screw are not tightened enough.

Avoid incorrect wiring. It may damage the product and/or other equipments.

Ensure that the FG terminal is correctly grounded.

Power with correct capacity should be prepared by considering the in-rush current when starting.

Influence of noise should be avoided for the wiring. Wiring should be separated from power cables and high voltage cables.

Ensure that the power is within the specified voltage range.

Ensure that the cable is capable of supporting the solenoid valve and SI unit in terms of rating.

Applicable solenoid valves

CAUTION

SMC offers no guarantee against malfunction and damage of unit when valves not described to “2-3.Applicable solenoid

valve series” and loads which is not valve are connected.

- 3 -

Page 4

- 4 -

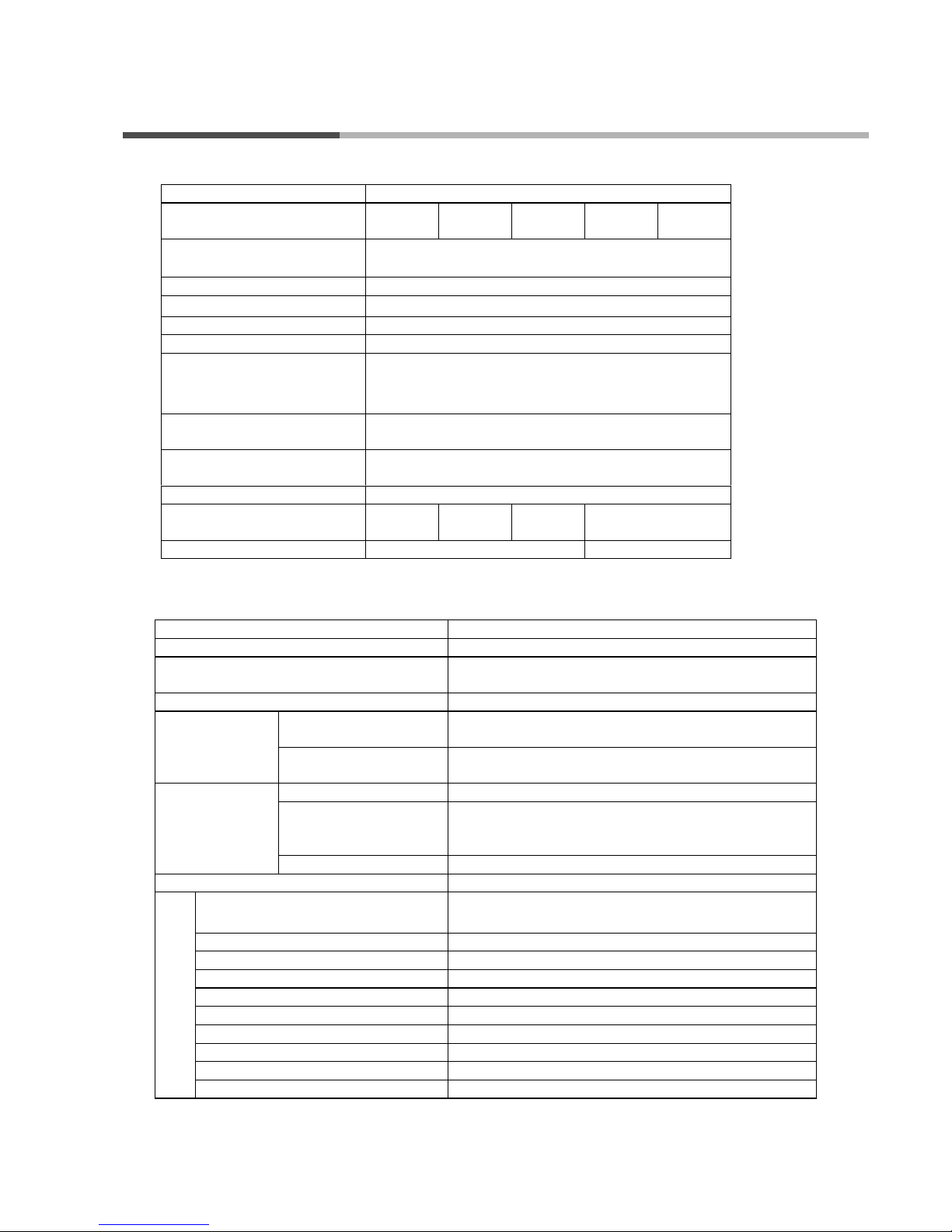

2-1. General specifications

Item Specifications

Model EX120

-SDN1

EX121

-SDN1

EX122

-SDN1

EX124D

-SDN1

EX124U

-SDN1

Operating ambient temp. 0 to +55(with 8 points of valve ON)

0 to +50℃(with 16 points of valve ON)

Operating ambient humidity 35 to 85%RH(No dew condensation)

Storage ambient temp.

-20 to +60℃

Vibration proof 50m/s2 (comply with JIS C 0911)

Impact proof 100m/s2 (comply with JIS C 0912)

Noise immunity

Normal mode ±1500 V Pulse 1µs

Common mode ±1500 V Pulse 1µs

Radiation 1000 V ±Pulse 1µs

Withstand voltage AC1000V for 1 min. between FG and external

terminal package.

Insulation resistance DC500V, 2MΩ between FG and external terminal

package.

Operating environment No corrosive gas and no dust

Weight 110g

or less

140g

or less

130g

or less

240g

or less

Protection class IP20 IP65

2-2. Electrical and network specifications

Item Specifications

Applicable system DeviceNet Release 2.0

Power supply voltage for communication DC11V to DC25V

(supplied by communication connector)

Power supply voltage for solenoid valve DC24V +10% -5%

Communication and

Internal power supply

90mA or less (DC24V)Consumption

current

Power supply for

Solenoid valve

1.5A or less (DC24V)

Output style NPN output (Open collector)

Connected load DC24V, Solenoid valve with lamp-surge voltage

protection circuit of 2.1W or less.

(made by SMC)

Solenoid valve

Connection

spec.

Insulation type Opt-coupler insulation type

Residual voltage 0.4V DC or less

Applicable DeviceNet

VolumeⅠ- Release 1.2

VolumeⅡ- Release 1.1

MAC ID setting range 0 to 63 (Set by Dip switch)

Baud Rate (Transmission speed) 500kbps, 250kbps, 125kbps (Set by Dip switch)

Slave (branch station) type Group 2 only server

Connection type T branch type, Multi drop type

Device type 16

Product code 288

Revision Referred to EDS file.

Vendor ID 7

Network connection spec.

Corresponding message Polled command (I/O message ), Explicit message

2. Specifications

SMC CORPORATION

Doc.No.EX

##-OME0015

Page 5

- 5 -

3. Wiring and Setting

2-3. Applicable solenoid valve series

SI unit Valve series

EX120 VQ1000, VQ2000

EX121 VQ1000, VQ2000, SX3000, SX5000

EX122 SY3000, SY5000

EX124U/D VQ2000, VQ4000, VQ5000

Terminal resistance

Node

Node

NodeNode

Node

Node

Node

Node

Node

Branch

line

Branch

line

Branch

line

T branch

Branch line

branch

Main line

Multi branch

Terminal resistance

Communication

distance

Baud rate

Total length of

trunk

Length of

branch line

Total length of

branch line

500 kbps 100m or less 39m or less

250 kbps 250m or less 78m or less

Thick cable

125 kbps 500m or less

6m or less

156m or less

Thin cable Common 100m or less

――――――

Terminal resistance 121 ohm (1/2W)

Length of cable

3-1.Connection type

DeviceNet can be connected by T branch, Multi branch, Branch line branch and Multi drop. Total

extension length of trunk and Branch line is different for different Baud rate and thickness of

communication cable.

SI unit I/O data (Receiving and sending data of polled command)

Item Output(Poll request) Input(Poll response)

Occupied byte 2 byte

(Solenoid valve output)

2 byte

Address +0 Output No. 0 to 7Sending/

receiving data

Address +1

Output No. 8 to 15

Bit of each output data and corresponding solenoid valve no.

Offset MSB LSB

0 No.7 No.6 No.5 No.4 No.3 No.2 No.1 No.0

1 No.15 No.14 No.13 No.12 No.11 No.10 No.9 No.8

SMC CORPORATION

Doc.No.EX

##-OME0015

*) Mapping method of sending / receiving data is different by PLC.

For further information, refer to the manual for PLC master (scanner)

Page 6

- 6 -

Cable specification

CAUTION

For Multi drop connection, prepare plug connector for T branch separately.

(Example, TMSTBP 2.5...- STF -5.08 made by Phoenix Contact Corp.)

Use DeviceNet special cable for communication cable.

Be sure to connect DeviceNet special terminal resistor with both ends of trunk.

SMC CORPORATION

Doc.No.EX

##-OME0015

Thick cable Thin cable

Item

Communication

Signal

Power upply

Communication

Signal

Power supply

Conductor

cross section

0.82 mm

2

1.65 mm

2

0.20 mm

2

0.33 mm

2

Colors Blue, W hite Red, Black Blue, W hite Red, Black

Impedance

120

Ω±

10%(1MHz)

――

120

Ω±

10%(1MHz)

――

Propagation

delay

1.36ns / ft(max) ―― 1.36ns / ft(max)

――

Attenuation

rate

500k:0.25dB / ft

125k:0.13dB / ft

1.00M:0.40dB / ft

――

500k:0.50dB / ft

125k:0.29dB / ft

1.00M:0.70dB / ft

――

Conductor

resistance

6.9Ω /

1000ft(max)

3.6Ω /

1000ft

(max)

28Ω /

1000ft(max)

17.5Ω /

1000ft(max)

Page 7

Wiring of cable for solenoid valve power supply and communication

Communication connector for DeviceNet

Terminal Wire color Connected to

V- Black (-) side of power supply cable

CANL Blue Low side of communication cable

FG - Ground / Shield

CANH White High side of communication cable

V+ Red (+) side of power supply cable

Power supply connector for solenoid valve

Terminal Wire color Connected to

24V - (+) side of solenoid valve source supply

0V - (-) side of Solenoid valve source supply

CAUTION

• Before wiring, be sure to turn power supply off.

• Screw for connectors is M3. Tighten them properly by torque of 0.5 to 0.6 [N·m].

• SI unit isn’t available for monitoring of power supply for solenoid valve.

• Do not put cable specified by DeviceNet with/near high voltage line or strong

electric line such as driving line.

- 7 -

SMC CORPORATION

Doc.No.EX

##-OME0015

Page 8

3-2. Address setting

Before setting of address by DIP switch, turn power supply for communication cable in SI

unit “OFF”.

Setting (binary) of following items is available by DIP switch installed to cover.

1) Node address (00 to 63)

2) Communication speed (125kbps, 250kbps, 500kbps)

- 8 -

SMC CORPORATION

Doc.No.EX

##-OME0015

<Setting of node address>

SW1 SW2 SW3 SW4 SW5 SW6

Node

address

12481632

#0 000000

#1 100000

#2 010000

:

:

:

#62 011111

#63 111111

<Setting of communication speed>

Setting Max. transmission distance (m)

Length of trunk

SW7 SW8

Communication

speed (kbps)

Thick

cable

Think

cable

Length

of

branch

line

Total length

of

branch line

0 0 125 500 156

1 0 250 250 78

0 1 500 125

100 6

39

1 1 Not used Not used

CAUTION

• When shipped, node address of 63 and communication speed of 125kbps are set in

advance.

• When communication error occurs, output condition is cleared.

ON

Page 9

4.LED indicator and Physical dimensions

- 9 -

Indication Contents

PWR Green Lights up when power for DeviceNet line is supplied.

Lights off SI unit isn’t on line or power supply for communication

line isn’t turned on.

Green

flashing

Waiting for connection (ON line)

Green

lights up

Connection completed (ON line)

Red

flashing

Connection time out (Minor communication error)

MOD / NET

Red

lights up

MAC ID duplication error or BUS OFF error

(Major communication error)

4-1 LED indication

EX120-SDN1

EX121-SDN1

EX122-SDN1

EX124D-SDN1

EX124U-SDN1

4-2 Physical dimensions

SI unit (EX120-SDN1)

SMC CORPORATION

Doc.No.EX

##-OME0015

1

1

1

1

0

0

2233445566778

8

0

0

11224488161632

32

00000000000

0

1100110000000

0

2211000000000

0

626211001111111

1

636311111111111

1

STATION

STATION

ADDRESS

ADDRESS

TRANSMIT

TRANSMIT

SPEED

SPEED

125K

125K

250K

250K

500K

500K

000

0

110

0

001

1

111

1

SWITCH

SWITCH

SETTINGS

SETTINGS

ON

ON

SERIAL UNIT

SERIAL UNIT

SMC

SMC

28.8

28.8

10.2

10.2

Page 10

- 10 -

SI unit (EX122-SDN1)

SI unit (EX121-SDN1)

SMC CORPORATION

Doc.No.EX

##-OME0015

1

1

1

1

0

0

2233445566778

8

0

0

11224488161632

32

00000000000

0

1100110000000

0

2211000000000

0

626211001111111

1

636311111111111

1

STATION

STATION

ADDRESS

ADDRESS

TRANSMIT

TRANSMIT

SPEED

SPEED

125K

125K

250K

250K

500K

500K

000

0

110

0

001

1

111

1

SWITCH

SWITCH

SETTINGS

SETTINGS

ON

ON

Flat cable length about 70mm

Flat cable length about 70mm

SERIAL UNIT

SERIAL UNIT

SMC

SMC

64

64

60.8

60.8

66.1

66.1

28.8

28.8

2

2

10.2

10.2

5.4

5.4

Page 11

SI unit (EX124D-SDN1)

SI unit (EX124U-SDN1)

- 11 -

SMC CORPORATION

Doc.No.EX

##-OME0015

4-G(PF)1/2

19

19.8

114

5.5

67

(72.5)

53.8

11.6

Page 12

5.EDS (Electronic Data Sheet) File

SMC CORPORATION

Doc.No.EX

##-OME0015

The EDS File is a file which described ID information on SI unit and important information in the

operation.

The DeviceNet controller or scanner automatically recognizes the SI unit by referring to the EDS File.

* Please refer to the undermentioned list when DeviceNet controller or the scanner dose not

automatically recognize the EDS File.

- 12 -

$ Electronic Data Sheet File for

$ SMC EX120-SDN1 Serial Interface Unit

[File]

DescText = "SMC EX120-SDN1 EDS File";

CreateDate = 05-20-1999; $ created

CreateTime = 10:30:00;

Revision = 1.1; $ Revision of EDS

[Device]

VendCode = 7;

VendName = "SMC Corp.";

ProdType = 16;

ProdTypeStr = "General Motion Controller";

ProdCode = 288;

MajRev = 2; $ Device Major Revision

MinRev = 7; $ Device Minor Revision

ProdName = "Valve Manifold SIU";

Catalog = "EX120-SDN1";

[IO_Info]

Default = 0x0001; $ Poll(Bit 0)

PollInfo = 0x0001 , 1 , 1; $ Prod. Cnxn=1

$ Cons. Cnxn=1

Input1 = 2, $ 2 byte

0, $ All bits are significant

0x0001, $ Poll Only Connection

"Solenoid Status", $ Name String

6, $ Path Size

"20 04 24 05 30 03", $ Assy Obj Inst 5 Attr 3

""; $ Help String

Output1 = 2, $ 2 byte

0, $ All bits are significant

0x0001, $ Poll Only Connection

"Solenoid Output", $ Name String

6, $ Path Size

"20 04 24 23 30 03", $ Assy Obj Inst 23 Attr 3

""; $ Help String

Page 13

6. Trouble Shooting

- 13 -

MOD/NET LED Cause & Countermeasure

Lights off PWR LED lights off

<Countermeasure>

Confirm that power for SI unit circuit is supplied.

Confirm correct wiring.

If above countermeasures do not improve status, please exchange SI unit.

PWR LED lights up

<Countermeasure>

Confirm that baud rate is set correctly.

If MOD/NET LED lights off in spite of baud rate is set correctly, change SI unit.

Green flashing Connection waiting

Shows communication waiting status between SI unit and master.

<Countermeasure>

Confirm master operate correctly.

If using scan list, ensure slave is recorded to scan list correctly.

Red flashing Communication wire disconnected error

<Countermeasure>

Confirm communication wire is not disconnected.

<Remark>

Red flashing if master power source is turned off during communication.

Red lights up Node address overlapping error

<Countermeasure>

Confirm there is no overlapping on the node address.

BUS OFF error

Detects communication error.

<Countermeasure>

Case 1

Communication error due to noise.

Confirm there is no component or high voltage cable that generate noise

around communication wire.

Make some distances between communication wire and noise source.

Case2

Communication cable problem.

Confirm terminal resistance (121ohm) connects to the both ends of

communication wire that is main wire of communication wire.

If red MOD/NET LED is still lights up in spite of above countermeasures,

change SI unit.

CAUTION

When red MOD/NET LED is lit, even if cause is solved, SI unit do not do auto-recovery. In

this case, please reset the power to SI unit circuit (Communication/Internal power supply).

SI unit isn’t available for monitoring of power supply for solved valve.

SMC CORPORATION

Doc.No.EX

##-OME0015

Loading...

Loading...