Page 1

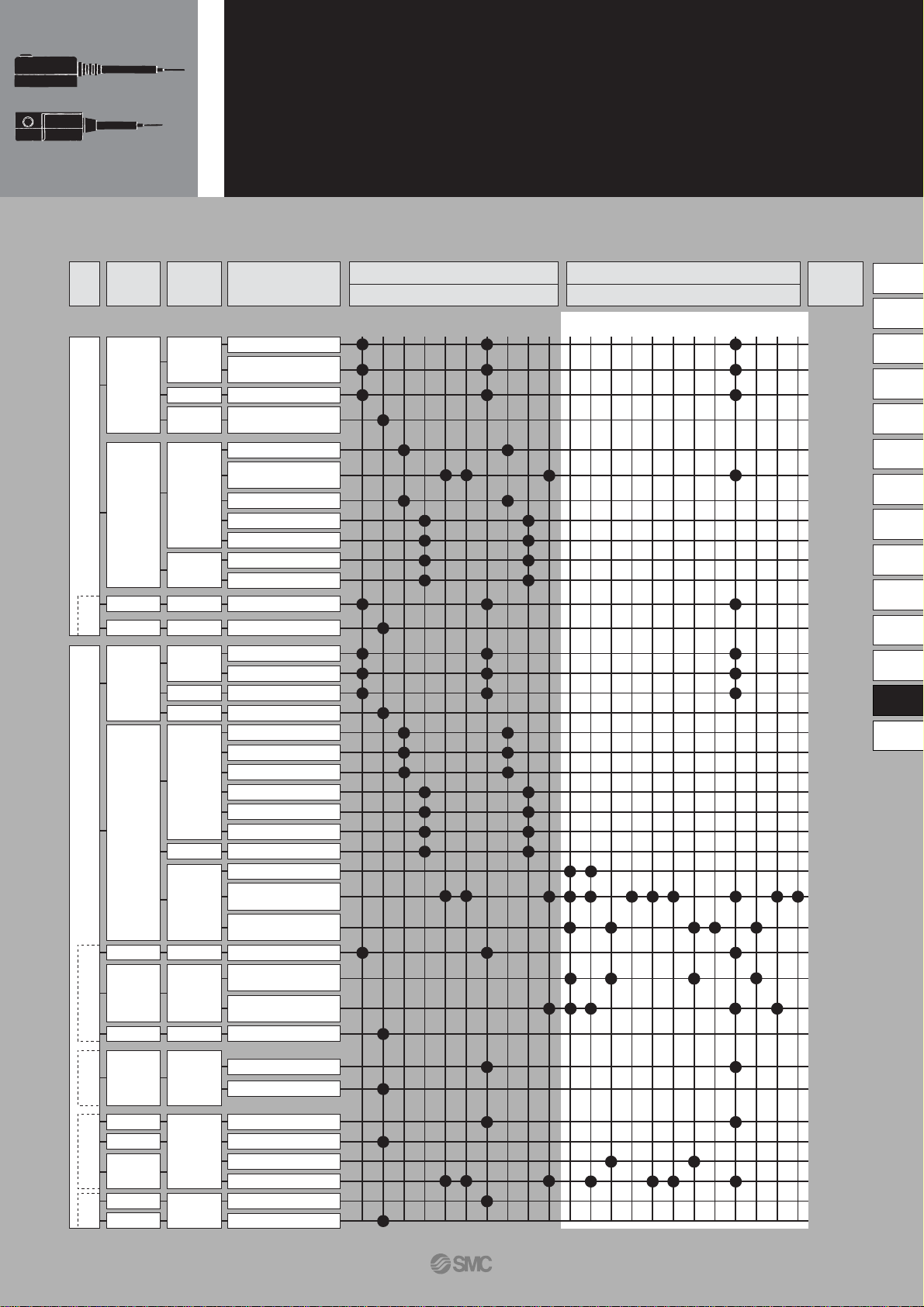

Auto Switch Guide

Reed Switches/Solid State Switches

For Air Grippers (Rotary Actuators)

Applicable Auto Switch

Type

mounting

Reed switchSolid state switch

2-color

indication

2-color

indication

Auto

switch

Rail

Direct

Rail

Tie-rod

Rail

Direct

Rail

Direct

Tie-rod

Electrical

entry

Grommet

Connector

Grommet

Grommet

Connector

Grommet

Grommet

Grommet

Connector

Grommet

Grommet

Connector

Grommet

Grommet

Grommet

Grommet

Auto switch model

D-A72/A73/A80

D-A72H/A73H

D-A76H/A80H

D-A73C/A80C

D-A53/A54/A56

D-A64/A67

D-A90/A93/A96

D-A90V/A93V/A96V

D-90A/93A

D-R731/R732

D-R801/R802

D-R731C/R732C

D-R801C/R802C

D-A79W

D-A59W

D-F79/F7P/J79

D-F7NV/F7PV/F7BV

D-F59/F5P/J51/J59

D-S991/S992/S99V1/S99V2

D-T991/T992/T99V1/T99V2

D-S9P1/S9P2/S9PV1/S9PV2

D-S791/S792

D-T791/T792

D-S7P1/S7P2

D-T791C/T792C

D-F8N/F8P/F8B

D-M9N/M9P/M9B

D-M9NV/M9PV/M9BV

D-Y59A/Y7P/Y59B

D-Y69A/Y7PV/Y69B

D-F79W/F7PW/J79W

D-Y7NW/Y7PW/Y7BW

D-Y7NWV/Y7PWV/Y7BWV

D-F9NW/F9PW/F9BW

D-F9NWV/F9PWV/F9BWV

D-F59W/F5PW/J59W

D-90/97

D-J79C

Applicable rotary actuators

Size

CDRA1 CDRB CDRQ2

30 50-100 10/15 20-100 10/15 20-40 32/40 1/3 7/20 10-200 10-25 10-25 10-2510-40 10-30 16-25 32-125 10-25 32-63 20-50

MRQ

MDSUB

MSQ

MHZ2 MHZJ2

Applicable air grippers

Size

MHL2 MDHR MHS

MHK MHS MHC2 MHT2

12-25

MHW2

MHY MRHQ

10-25

Page

12-13-7

12-13-8

12-13-9

—

—

12-13-10

—

—

—

—

—

12-13-11

—

12-13-12

12-13-13

12-13-14

—

—

—

—

—

—

—

—

12-13-15

12-13-16

12-13-17

12-13-18

12-13-19

12-13-20

—

1

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

Rail

2-color indication

With diagnosis output

Rail

Tie-rod

Direct

Water resistant

2-color indication

Rail

Tie-rod

With timer

Note) As for the applicable auto switches on Rotary Actuators, refer to pages in Best Pneumatics Vol. 11.

Grommet

Grommet

Grommet

D-F79F

D-F59F

D-F7BAL/F7BAVL

D-F5BAL

D-Y7BAL

D-F9BAL

D-F7NTL

D-F5NTL

12-13-21

—

12-13-22

—

12-13-24

12-13-23

—

—

12-13-1

Page 2

1. Check the specifications.

Read the specifications carefully and use this product

appropriately. The product may be damaged or malfunction if it

is used outside the range of specifications of current current,

voltage, temperature or impact.

2. Use caution when multiple cylinders are used

and close to each other.

When two or more auto switch cylinders are lined up in close

proximity to each other, magnetic field interference may cause

the switches to malfunction. Maintain a minimum cylinder

separation of 40 mm. (When the allowable interval is specified

for each cylinder series, use the indicated value.)

3. Use caution to the ON time of a switch at the

intermediate position of stroke.

When an auto switch is placed at an intermediate position of

the stroke and a load is driven at the time the piston passes,

the auto switch will operate, but if the speed is too great, the

operating time will be shortened and the load may not operate

properly. The maximum detectable piston speed is:

In cases of high piston speed, the use of an auto switch (DF5NT/F7NT/G5NT and M5T) with a built-in OFF delay timer

(≅ 200 ms) makes it possible to extend the load operating time.

4. Wiring should be kept as short as possible.

<Reed switches>

As the length of the wiring to a load gets longer, the rush

current at switching ON becomes greater, and this may

shorten the product’s life. (The switch will stay ON all the time.)

1) For an auto switch without a connect protection circuit, use

a contact protection box when the wire length is 5 m or

longer.

2) Even if an auto switch has a built-in contact protection

circuit, when the wiring is more than 30 m long, it is not able

to adequately absorb the rush current and its life may be

reduced. It is again necessary to connect a contact

protection box in order to extend its life. Please contact

SMC in this case.

<Solid state switches>

3) Although wire length should not affect switch function, use a

wire 100 m or shorter.

5. Use caution to the internal voltage drop of a

switch.

<Reed switches>

1) Switches with an indicator light (Except D-A56/A76H/A96/

A96V/C76/E76A/Z76)

• If auto switches are connected in series as shown below,

take note that there will be a large voltage drop because of

internal resistance in the light emitting diodes. (Refer to

internal voltage drop in the auto switch specifications.)

[The voltage drop will be “n” times larger when “n” auto

switches are connected.]

Even though an auto switch operates normally, the load

may not operate.

• Similarly, when operating below a specified voltage, it is

possible that the load may be ineffective even though the

auto switch function is normal. Therefore, the formula below

should be satisfied after confirming the minimum operating

voltage of the load.

2) If the internal resistance of a light emitting diode causes a

problem, select a switch without an indicator for right

(MODEL D-A6/A80/A80H/A90/A90V/C80/R80/90/E80A/

Z80)

<Solid state switches>

3) Generally, the internal voltage drop will be greater with a 2wire solid state auto switch than with a reed switch. Take

the same precautions as in 1).

Also note that a 12 VDC relay is not applicable.

6. Use caution to the leakage current.

<Solid state switches>

With a 2-wire solid state auto switch, current (leakage current)

flows to the load to operate the internal circuit even when in

the OFF state.

If the condition given in the above formula is not met, it will not

reset correctly (stays ON). Use a 3-wire switch if this

specification cannot be satisfied.

Moreover, leakage current flow to the load will be “n” times

larger when “n” auto switches are connected in parallel.

7. Do not use a load that generates surge voltage.

<Reed switches>

If driving a load such as a relay that generates a surge

voltage, use a switch with a built-in contact protection circuit or

use a contact protection box.

<Solid state switches>

Although a zener diode for surge protection is connected at

the output side of a solid state auto switch, damage may still

occur if the surge is applied repeatedly. When a load, such as

a relay or solenoid, which generates surge is directly driven,

use a type of switch with a built-in surge absorbing element.

8. Cautions for use in an interlock circuit

When an auto switch is used for an interlock signal requiring

high reliability, devise a double interlock system to avoid

trouble by providing a mechanical protection function, or by

also using another switch (sensor) together with the auto

switch.

Also perform periodic maintenance inspections and confirm

proper operation.

9. Ensure sufficient space for maintenance

activities.

When designing an application, be sure to allow sufficient

space for maintenance and inspection.

Design and Selection

V (mm/s) =

Auto switch operating range (mm)

Load operating time (ms)

x 1000

Load

Supply

voltage

–

Internal voltage

drop of switch

>

Minimum operating

voltage of load

Current to operate load (OFF condition) > Leakage current

Warning

Auto Switches

Precautions 1

Be sure to read before handling.

For detailed precautions on every series, refer to main text.

2

12-13-2

Page 3

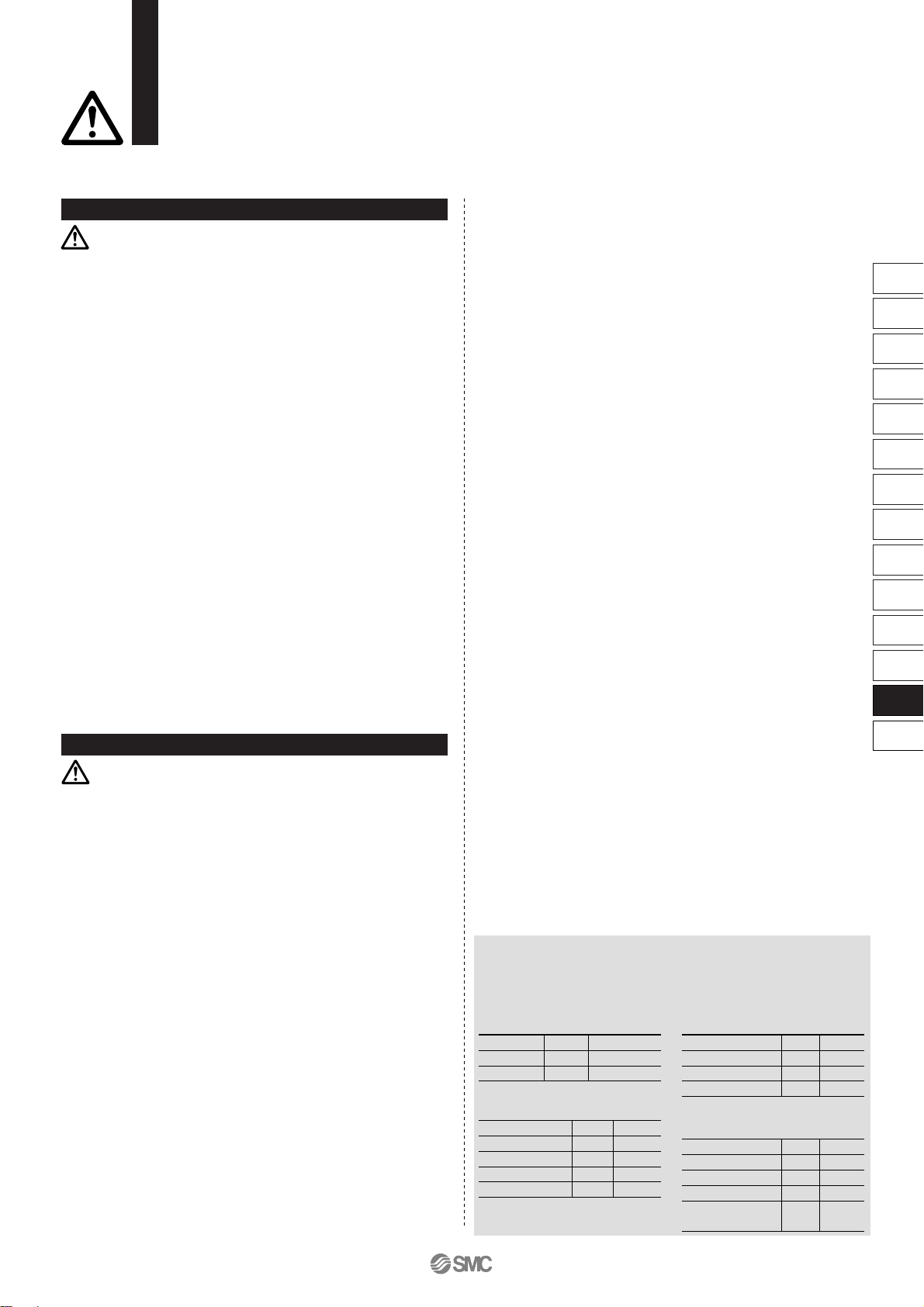

Auto Switches

Precautions 2

Be sure to read before handling.

For detailed precautions on every series, refer to main text.

3

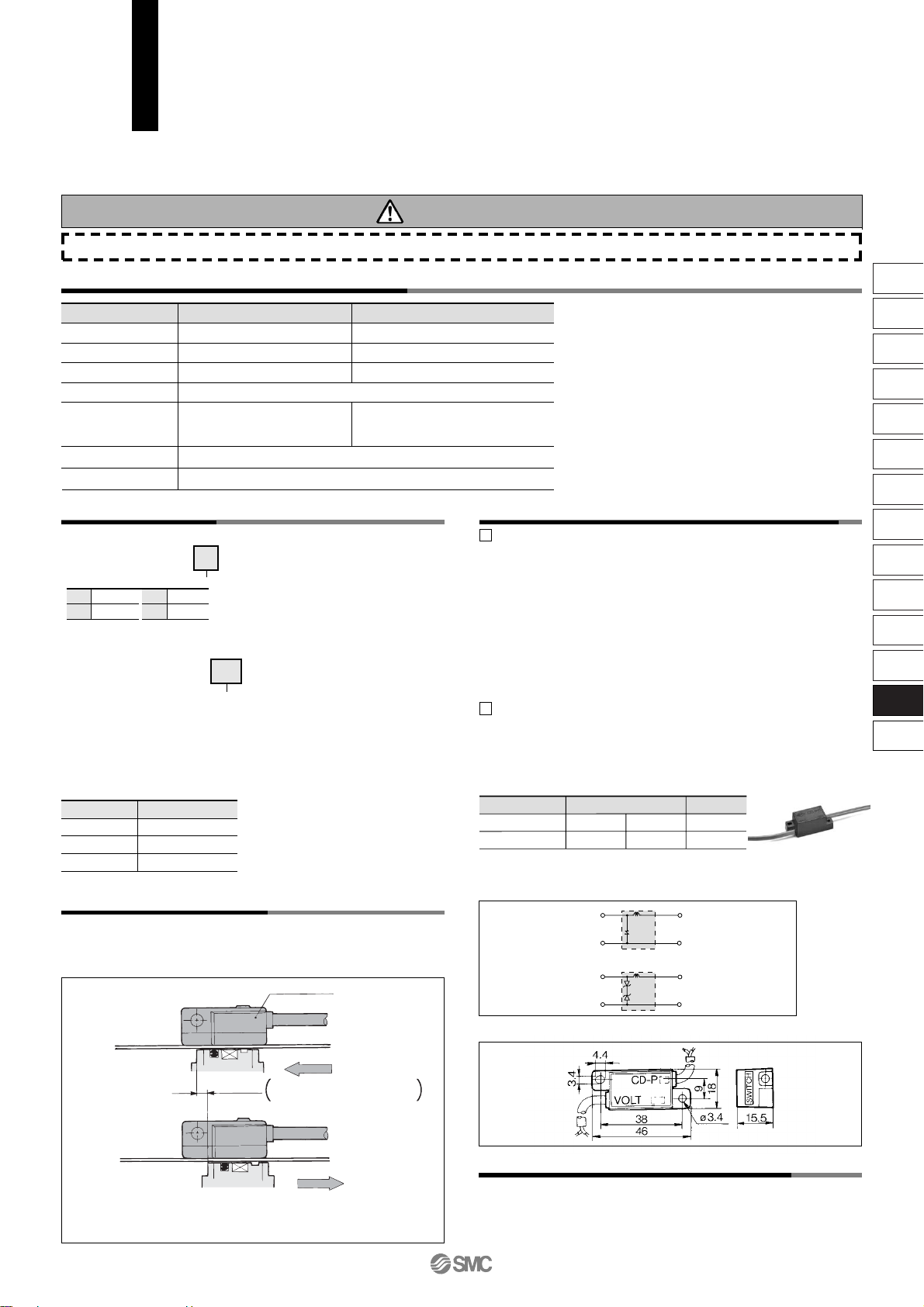

Mounting and Adjustment

Warning

1. Do not drop or bump.

Do not drop, bump, or apply excessive impacts (300 m/s2 or

more for reed switches and 1000 m/s

switches) while handling. Although the body of the switch may

not be damaged, the inside of the switch could be damaged

and cause a malfunction.

2

or more for solid state

2. Do not carry a cylinder by the auto switch lead

wires.

Never carry a cylinder by its lead wires. This may not only

cause broken lead wires, but it may cause internal elements of

the switch to be damaged by the stress.

3. Mount switches using the proper tightening

torque.

When a switch is tightened beyond the range of fastening

torque, the mounting screws or switch may be damaged.

On the other hand, tightening below the range of fastening

torque may alllow the switch to slip out of position. (Refer to

switch mounting for each series regarding switch mounting,

moving, and fastening torque, etc.)

4. Mount a switch at the center of the operating

range.

Adjust the mounting position of an auto switch so that the

piston stops at the center of the operating range (the range in

which a switch is ON). (The mounting positions shown in the

catalog indicate the optimum position at the stroke end.) If

mounted at the end of the operating range (around the

borderline of ON and OFF), the operation will be unstable.

Wiring

Warning

1. Avoid repeatedly bending or stretching lead

wires.

Broken lead wires will result from repeatedly applying bending

stress or stretching force to the lead wires.

2. Be sure to connect the load before power is

applied.

<2-wire type>

If the power is turned on when an auto switch is not connected

to a load, the switch will be instantly damaged because of

excess current.

3. Confirm proper insulation of wiring.

Be certain that there is no faulty wiring insulation (contact with

other circuits, ground fault, improper insulation between

terminals, etc.). Damage may occur due to excess current flow

into a switch.

4. Do not wire with power lines or high voltage

lines.

Wire separately from power lines or high voltage lines,

avoiding parallel wiring or wiring in the same conduit with

these lines. Control circuits including auto switches may

malfunction due to noise from these other lines.

5. Do not allow short circuiting of loads.

<Reed switches>

If the power is turned on with a load in a short circuited

condition, the switch will be instantly damaged because of

excess current flow into the switch.

<Solid state switches>

Model D-F9(Y)/F9W(V)/J51/G5NB and all models of PNP

output switches do not have built-in short circuit prevention

circuits. If loads are short circuited, the switches will be

instantly damaged.

Use caution to avoid reverse wiring with the brown [red] power

supply line and the black [white] output line on 3-wire type

switches.

6. Avoid incorrect wiring.

<Reed switches>

A 24 VDC switch with indicator light has polarity. The brown

lead wire or terminal no. 1 is (+), and the blue lead wire or

terminal no. 2 is (–).

[In the case of model D-97, the side without indicator is (+),

and the black line side is (–).]

1) If connections are reversed, a switch will operate, however,

the light emitting diode will not light up.

Also note that a current greater than the maximum

specified one will damage a light emitting diode and make it

inoperable.

Applicable models:

D-A73/A73H/A73C/C73/C73C/E73A/Z73/R73

D-97/93A/A93/A93V

D-A33/A34/A33A/A34A/A44/A44A

D-A53/A54/B53/B54

2) However, when using a two color indication auto switch, the

switch (D-A79W/A59W/B59W), be aware that the switch

will constantly remain ON if the connections are reversed.

<Solid state switches>

1) If connections are reversed on a 2-wire type switch, the

switch will not be damaged if protected by a protection

circuit, but the switch will always stay in an ON state.

However, it is still necessary to avoid reversed connections,

since the switch could be damaged by a load short circuit in

this condition.

2) If connections are reversed (power supply line (+) and

power supply line (–) on a 3-wire type switch, the switch will

be protected by a protection circuit. However, if the power

supply line (+) is connected to the blue (black) wire and the

power supply line (–) is connected to the black (white) wire,

the switch will be damaged.

∗ Lead wire color changes

Lead wire colors of SMC auto switches have been changed in

order to meet NECA Standard 0402 for production beginning

September, 1996 and thereafter. Please refer to the tables

provided.

2-wire 3-wire

Old

Red

Black

White

Yellow

New

Brown

Blue

New

Brown

Blue

Black

Orange

Power supply (+)

Power supply GND

Output

Solid State with

Latch Type Diagnostic Output

Power supply (+)

Power supply GND

Output

Latch type

diagnostic output

Old

Output (+)

Output (–)

Red

Black

Solid State

with Diagnostic Output

Power supply (+)

Power supply GND

Output

Diagnostic output

Old

Red

Black

White

Old

Red

Black

White

Yellow

New

Brown

Blue

Black

New

Brown

Blue

Black

Orange

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

12-13-3

Page 4

1. Never use in the presence of explosive gases.

The construction of our auto switches does not make them

explosion-proof. Never use them in the presence of an

explosive gas, as this may cause a serious explosion.

2. Do not use in an area where a magnetic field is

generated.

Auto switches will malfunction or magnets inside cylinders will

become demagnetized. (Please consult with SMC regarding

the availability of a magnetic field resistant auto switch.)

3. Do not use in environments where the auto

switches will be constantly exposed to water.

Although switches except D-A3/A44/G39/K39 satisfy the

IEC standard IP67 structure (JIS C 0920: anti-immersion

structure), do not use switches in applications where

continually exposed to water splash or spray. Poor insulation

or swelling of the potting resin inside switches may cause

malfunction.

4. Do not use in environments with oil or

chemicals.

Please consult with SMC if auto switches will be used in an

environment with coolants, cleaning solvents, various oils or

chemicals. If auto switches are used under these conditions

for even a short time, they may be adversely affected by

improper insulation, a malfunction due to swelling of the

potting resin, or hardening of the lead wires.

5. Do not use in an environment with temperature

cycles.

Please consult with SMC if switches are to be used where

there are temperature cycles other than normal temperature

changes, as they may be adversely affected internally.

6. Do not use in environments where there is

excessive impact shock.

<Reed switches>

When excessive impact (300 m/s

2

or more) is applied to a

reed switch during operation, the contact point may

malfunction and generate or cut off a signal momentarily (1 ms

or less). Please consult with SMC regarding the need to use a

solid state switch depending on the environment.

7. Do not use in locations where surges are

generated.

<Solid state switches>

When there are units (solenoid type lifters, high frequency

induction furnaces, motors, etc.) which generate a large

amount of surge in the area around cylinders with solid state

auto switches, this may cause deterioration or damage to the

switches. Avoid sources of surge generation and crossed lines.

8. Avoid accumulation of iron debris or close

contact with magnetic substances.

When a large amount of ferrous debris such as machining

chips or spatter is accumulated, or a magnetic substance

(something attracted by a magnet) is brought into close

proximity with an auto switch cylinder, it may cause the auto

switches to malfunction due to a loss of the magnetic force

inside the cylinder.

Operating Environment

1. Perform the following maintenance periodically

in order to prevent possible danger due to

unexpected auto switch malfunction.

1) Securely tighten switch mounting screws.

If screws become loose or the mounting position is

dislocated, retighten screws securely after readjusting the

mounting position.

2) Confirm that there is no damage to lead wires.

To prevent faulty insulation, replace switches or repair lead

wires if damage is discovered.

3) Confirm that the green light on the 2-color indicator type

switch lights up.

Confirm that the Green LED is ON when stopped at the set

position. If the Red LED is ON when stopped at the set

position, the mounting position is not appropriate. Readjust

the mounting position until the Green LED lights up.

Maintenance

1. Please consult with SMC concerning water

resistance, elasticity of lead wires, and use at

welding sites.

Other

Warning

Warning

Warning

Auto Switches

Precautions 3

Be sure to read before handling.

For detailed precautions on every series, refer to main text.

4

12-13-4

Page 5

Before Operation

Auto Switches Common Specifications

Precautions

Refer to “Auto Switches Precautions” on pages 12-13-2 to 12-13-4 before handling.

5

Auto Switches Common Specifications

Type

Leakage current

Operating time

Impact resistance

Insulation resistance

Withstand voltage

Ambient temperature

Enclosure

Reed switch

None

1.2 ms

2

300 m/s

50 MΩ or more at 500 M VDC (Between lead wire and case)

1500 VAC for 1 minute

(Between lead wire and case)

IEC529 Standard IP67, Immersible construction (JIS C 0920)

3-wire: 100 µA or less, 2-wire: 0.8 mA or less

(1)

–10 to 60°C

Solid state switch

1 ms or less

1000 m/s

1000 VAC for 1 minute

(Between lead wire and case)

Lead Wire Length

Lead wire length indication

(Example)

D-A73

L

Lead wire length

Nil

0.5 m

L

3 m

∗ Applicable for the connector

(Example)

type (D-

C) only.

D-F8PL-

5 m

Z

∗

None

N

Flexible lead wire

specifications

(D-Y59, D-Y69, D-Y7 and D-M9/M9V

series use flexible lead wire as srandard. )

Part No. of Lead Wires

with Connectors

(Applicable only for connector type)

Model

D-LC05

D-LC30

D-LC50

Lead wire length

0.5 m

3 m

5 m

•

61

•

Note 1)

Applicable auto switch with 5

m lead wire (“Z”)

Reed switch: D-B53/B54, DC73(C)/C80C, D-A73(C)(H)/

A80C, D-A53/A54, D-Z73, D90/97/90A/93A

Solid state switch:

Manufactured upon receipt of

order as standard.

The standard lead wire length

Note 2)

of solid state switches with

timer, water resistant 2-color

indication type, wide range

detection type or heat

resistant 2-color indication

type is 3 meters in length.

(0.5 m is not available.)

Note 3)

Lead wire lengths of 3 m and

5 m are standard for magnetic

field resistant 2-color indicator

type solid state switches. (0.5

m is not available.)

Add “-61” at th end of the part

Note 4)

number for the flexible lead

wire except D-Y59, D-Y69, DY7 and D-M9/M9V type

auto switches.

Auto Switch Hysteresis

Hysteresis is the distance between the position at which piston movement

operates an auto switch to the position at which reverse movement turns

the switch off. This hysteresis is included in part of the operating range

(one side).

Auto switch

Note 1)

Electrical entry: Connector type (A73C/A80C/C73C/C80C)

and D-9/9

(4)

(3)

2

Note 2)

Note 3)

Note 4)

(2)

Contact Protection Box:

1

<Applicable switch types>

D-A7/A8, D-A7H/A80H, D-A73C/A80C, D-C7/C8, D-C73C/C080C, DE7A/E80A, D-Z7/Z8, D-9/9A, D-A9/A9V, and D-A79W type

The above auto switches do not have internal contact protection circuits.

1. Operating load is an inductive load.

2. The length of wiring to the load is 5 m or more.

3. The load voltage is 100 or 200 VAC.

A contact protection box should be used in any of the above

conditions, Unless using a contact protection box, the contact life may

be shortened. (Due to permanent energizing conditions.)

D-A72(H) must be used with the contact protection box regardless

of load styles and lead wire length.

2

Please contact SMC when using built-in contact protection circuit style (DA34[A][C], D-A44[A][C], D-A54/A64, D-B54/B64, D-A59W, D-B59W) in the

following conditions: 1. The wiring length to load is more than 30 m; 2.

When using PLC with large flow current.

A/A9/A9V type: 1000 VAC/min. (Between

lead wire and the case)

The following switches, Terminal conduit type (DA3/A3

A/A3C/G39/G39A/G39C/K39/K39A/K39C), DIN

terminal type (D-A44/A44A/A44C) and Heat resistant auto

switch (D-F7NJL) meet the IEC529 standard.

IP63, JIS C 0920 Rainproof construction

Except solid state switch with timer (D-M5

G5NTL/F7NTL/F5NTL) and magnetic resistant 2-color indication type solid state switch (D-P5DWL). D-J51: 5 ms or

less

Except D-J51 (1 mA or less at 100 VAC, 1.5 mA or less at

200 VAC), D-M5NW/M5PW/M5BW, D-F9BAL, D-P5DWL (1

mA or less at 24 VDC).

TL,

CD-P11, CD-P12

Contact Protection Box Specifications

Part no.

Load voltage

Max. load current

∗ Lead wire length — Switch connection side 0.5 m

CD-P11

100 VAC or less

25 mA

Load connection side 0.5 m

200 VAC

12.5 mA

CD-P12

24 VDC

50 mA

Contact Protection Box Internal Circuit

CD-P11

CD-P12

Surge absorber

Zener diode

Choke

coil

Choke

coil

OUT Brown

~

OUT Blue

OUT (+) Brown

OUT (–) Blue

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

Switch

operating

position

(ON)

Switch

operating

position

(OFF)

Note) Hysteresis may fluctuate due to the operating environment.

Please contact SMC if hysteresis causes an operational problem.

Hysteresis

Reed switch: 2 mm or less

Solid state switch: 1 mm or less

Contact Protection Box/Dimensions

Note)

Contact Protection Box Connection

To connect a switch unit to a contact protection box, connect the lead wire

from the side of the contact protection box marked SWITCH to the lead

wire coming out of the switch unit. Keep the switch as close as possible to

the contact protection box, with a lead wire length of no more than 1

meter.

12-13-5

Page 6

Before Operation

Auto Switches Connection and Example

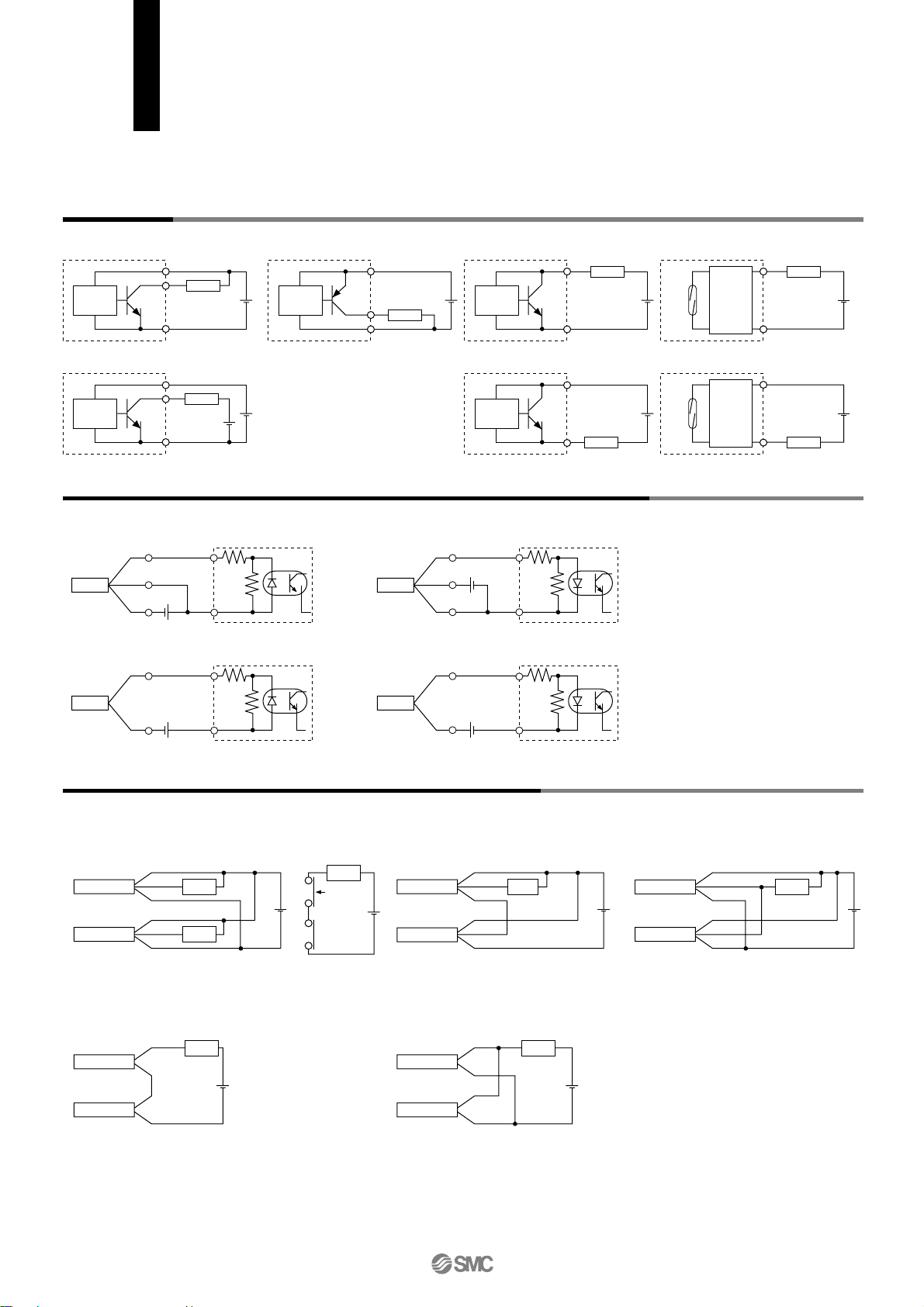

Basic Wiring

Example of Connection with PLC (Programmable Logic Controller)

Example of AND (Series) and OR (Parallel) Connection

Solid state 3-wire, NPN Solid state 2-wireSolid state 3-wire, PNP

Main

curcuit

of switch

Brown

Black

Blue

Brown

Black

Blue

Brown

Blue

Brown

Blue

Reed switch 2-wire

Indicator

protection

circuit,

etc.

Brown

Blue

~

~

Brown

Blue

Indicator

protection

circuit,

etc.

• Sink input specifications

3-wire, NPN

• Source input specifications

3-wire, PNP

2-wire

Switch

Input

Black

COM

Brown

Blue

2-wire

Switch

Input

Black

PLC internal circuit

COM

Brown

Blue

PLC internal circuit

PLC internal circuit

Switch

Input

Blue

COM

Brown

PLC internal circuit

Switch

Input

Blue

COM

Brown

• 3-wire

OR connection for NPN output

2-wire with 2-switch AND connection 2-wire with 2-switch OR connection

Load voltage at ON = Power supply voltage – Residual voltage x 2 pcs.

= 24 V – 4 V x 2 pcs.

= 16 V

Example: Power supply is 24 VDC

Internal voltage drop in switch is 4 V.

Load voltage at OFF = Leakage current x 2 pcs. x Load impedance

= 1 mA x 2 pcs. x 3 kΩ

= 6 V

Example: Load impedance is 3 kΩ.

Leakage current from switch is 1 mA.

Switch 2

Switch 1

Load

Brown

Black

Blue

Brown

Black

Blue

Switch 1

Brown

Switch 2

Black

Blue

Relay

Relay

Brown

Black

Blue

Load

Relay

contact

Switch 1

Switch 2

Brown

Blue

Brown

Blue

Load

Switch 1

Switch 2

Brown

Blue

Brown

Blue

Load

AND connection for NPN output

(Using relays)

• 2-wire

Switch 1

Brown

Switch 2

Black

Blue

Load

Brown

Black

Blue

AND connection for NPN output

(Performed with switches only)

The indicator lights will light up when

both switches are turned ON.

When two switches are

connected in series, a load

may malfunction because

the load voltage will decline

when in the ON state.

The indicator lights will light

up when both of the

switches are in the ON

state.

(Solid state switch)

When two switches are

connected in parallel,

malfunction may occur

because the load voltage

will increase when in the

OFF state.

(Reed switch)

Because there is no

current leakage, the load

voltage will not increase

when turned OFF.

However, depending on

the number of switches in

the ON state, the

indicator lights may

sometimes grow dim or

not light up, due to the

dispersion and reduction

of the current flowing to

the switches.

Brown

Black

Blue

Main

curcuit

of switch

Main

curcuit

of switch

Main

curcuit

of switch

Main

curcuit

of switch

Connect according to the applicable PLC

input specifications, as the connection

method will vary depending on the PLC

input specifications.

(Power supply for switch and load are separate)

Load

Load

Load

Load

Load

Load

Load

6

12-13-6

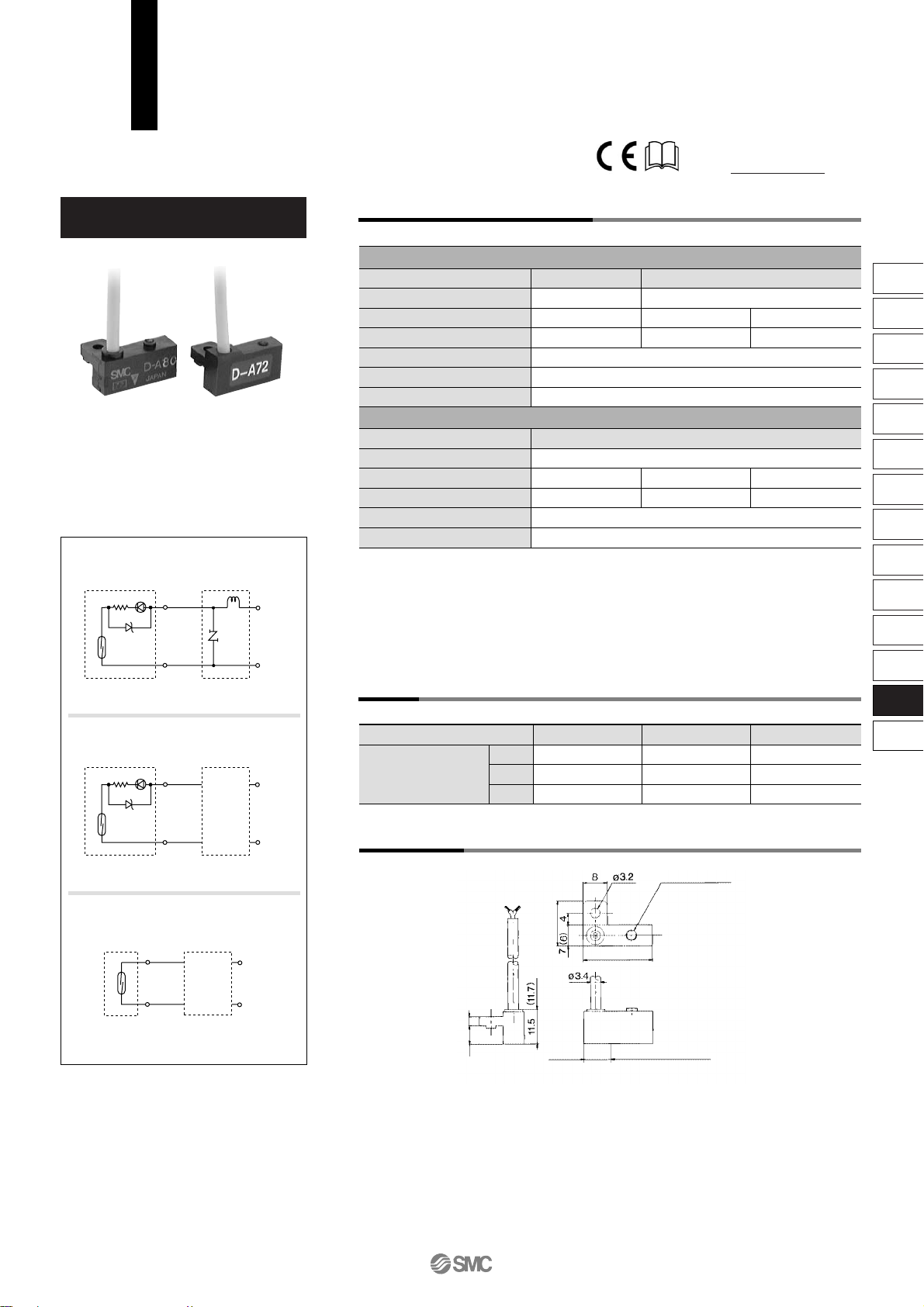

Page 7

Reed Switch

Band Mounting Style

D-A72/D-A73/D-A80

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

7

Grommet

Electrical entry: Perpendicular

Auto Switch Internal Circuit

D-A72

Contact protection box

LED

Resistor

Zener diode

Reed switch

Brown

Blue

CD-P11

Choke

coil

Surge

absorber

OUT

Brown

앑

OUT

Blue

D-A73

LED

Resistor

Zener diode

Reed switch

Brown

Blue

Contact

protection

box

CD-P11

CD-P12

OUT (

Brown

앑

OUT (–)

Blue

D-A80

OUT (±)

Brown

앑

OUT ( )

Blue

±

Reed switch

Contact

protection

box

CD-P11

CD-P12

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-A7 (With indicator light)

Auto switch model

Applicable load

Load voltage

Load current range

Contact protection circuit

Internal voltage drop

Indicator light

(3)

D-A8 (Without indicator light)

Auto switch model

Applicable load

Load voltage

Maximum load current

Contact protection circuit

Internal resistance

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm

Note 1) Regarding the common specifications of the reed switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Note 3) Under 5 mA, the strength of the indicator light is poor. In some cases, visibility of the

indicator light will not be possible where the output signal is less than 2.5 mA. However,

there is no problem in terms of contact output, when an output signal exceeds 1 mA or

more.

D-A72

Relay, PLC

200 VAC

5 to 10 mA

24 VDC

5 to 40 mA

None

2.4 V or less

Red LED lights when ON.

D-A73

Relay, PLC

D-A80

AC

24 V or less

DC

50 mA 20 mA

1 Ω or less (Including lead wire length of 3 m)

Relay, IC circuit, PLC

AC

48 V

DC

40 mA

None

2

, 2 cores (Brown, Blue), 0.5 m

100 VAC

5 to 20 mA

AC

100 V

DC

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

Weight

D-

(g)

Auto switch model

Lead wire length

+)

(m)

0.5

3

5

D-A72

10

47

—

D-A73 D-A80

10

47

77

10

47

—

20-

Dimensions

Indicator light

D-A80 without

indicator light

15 (14)

23 (22)

Note 1) Operating load is an induction load.

Note 2) Wiring to the load is 5 m or longer.

Note 3) Load voltage is 100 VAC.

Use the contact protection box in any of the

above listed situations. The contact point life

may decrease. (Refer to page 12-13-5 for

contact protection box.)

6 (6.2) 3

9 (8.5)

( ) values for D-A72

Most sensitive position

12-13-7

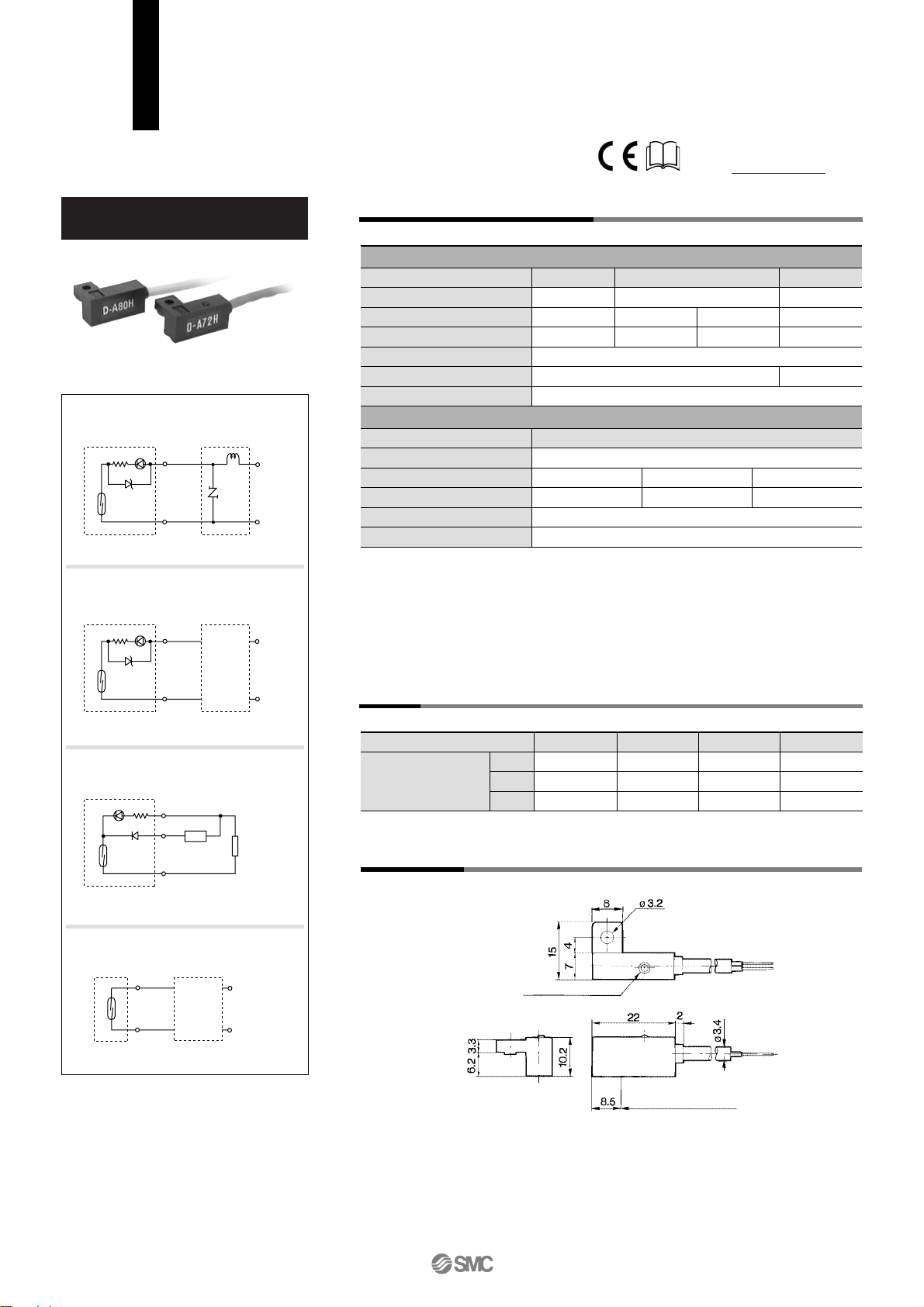

Page 8

Indicator light

D-A80H without

indicator light

Most sensitive position

Auto Switch Internal Circuit

D-A72H

D-A73H

D-A76H

D-A80H

Auto Switch Specifications

Dimensions

Auto switch model

0.5

3

5

10

47

—

10

47

—

11

52

—

10

47

77

D-A72H D-A73H D-A76H

D-A80H

D-A7H, D-A80H

Grommet

Electrical entry: In-line

Lead wire length

(m)

PLC: Abbreviation of Programmable Logic Controller

D-A7H (With indicator light)

Auto switch model

Applicable load

Load voltage

Max. load voltage/Load current range

(3)

Contact protection circuit

Internal voltage drop

Indicator light

24 VDC

5 to 40 mA

2.4 V or less

100 VAC

5 to 20 mA

D-A72H

Relay, PLC

200 VAC

5 to 10 mA

D-A76H

IC circuit

4 to 8 VDC

20 mA

0.8 V or less

D-A73H

Relay, PLC

None

Red LED lights when ON.

D-A80H

Relay, IC circuit, PLC

40 mA

None

1 Ω or less (Including lead wire length of 3 m)

D-A80H (Without indicator light)

Auto switch model

Applicable load

Load voltage

Maximum load current

Contact protection circuit

Internal resistance

50 mA 20 mA

24 V or less

AC

DC

48 V

AC

DC

100 V

AC

DC

LED

Reed switch

Resistor

Zener diode

Brown

Blue

OUT

(+)

Brown

앑

OUT (–)

Blue

LED

Reed switch

Resistor

Reverse

current

prevention

diode

OUT

Black

DC

(+)

Brown

DC

(–)

Blue

Load

(+)

(

–)

DC power

supply

Blue

LED

Reed switch

Resistor

Zener diode

Brown

OUT

Blue

OUT

Brown

Choke

coil

Contact protection box

CD-P11

Surge

absorber

앑

Reed switch

OUT (±)

Brown

앑

Note 1) Operating load is an induction load.

Note 2) In the case the wiring length to load is

more than 5 m.

Note 3) Wiring to the load is 5 m or longer.

Use the contact protection box in any of the

above listed situations. The contact point life

may decrease. Especially in the case of

D-A72H, be sure to use the contact

protection box. (Refer to page 12-13-5 for

contact protection box.)

• Lead wire — Oil resistant vinyl heavy-duty cord, 0.2 mm2, 2 cores (Brown, Blue), 3 cores (Brown,

Black, Blue), 0.5 m

Note 1) Regarding the common specifications of the reed switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Note 3) Under 5 mA, the strength of the indicator light is poor. In some cases, visibility of the

indicator light will not be possible where the output signal is less than 2.5 mA. However,

there is no problem in terms of contact output, when an output signal exceeds 1 mA or

more.

Reed Switch

Rail Mounting Style

D-A7

H/D-A80H

OUT ( )

Blue

±

Contact

protection

box

CD-P11

CD-P12

Contact

protection

box

CD-P11

CD-P12

Weight

(g)

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

8

12-13-8

Page 9

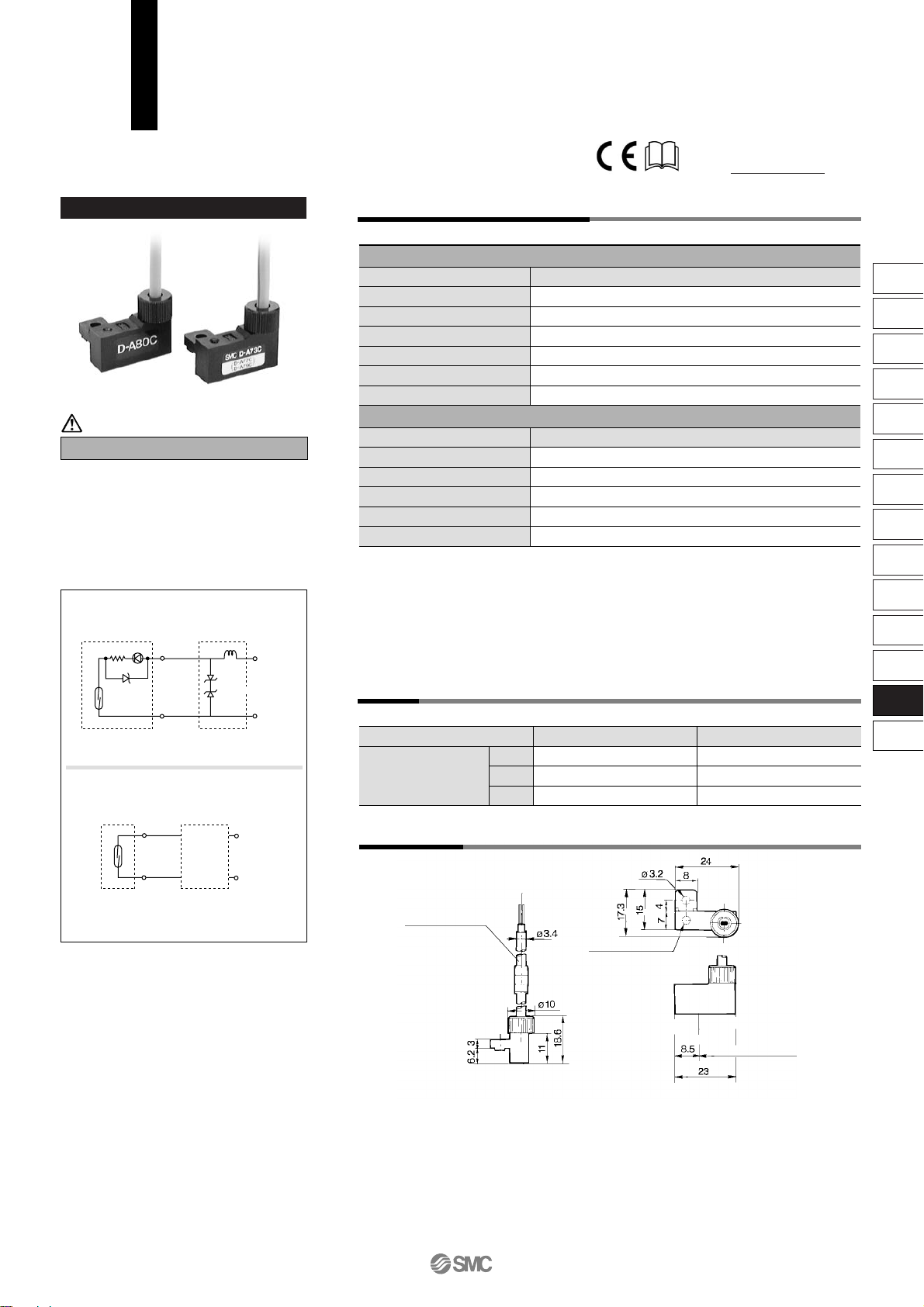

Reed Switch

Rail Mounting Style

D-A73C/D-A80C

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

9

Connector

Caution

Precautions

1. Confirm that the connector is appropriately

tightened. If tightened insufficiently, the

waterproof performance will deteriorate.

2. Refer to Best Pneumatics Vol. 6/7/8/9/10

for the details.

Auto Switch Internal Circuit

D-A73C

LED

Resistor

Zener diode

Reed switch

D-A80C

Contact protection box

CD-P12

Brown

Blue

Choke coil

Zener

diode

OUT (+)

Brown

(–)

OUT

Blue

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-A73C (With indicator light)

Auto switch model

Applicable load

Load voltage

Load current range

Contact protection circuit

Internal voltage drop

Indicator light

(4)

D-A73C

Relay, PLC

24 VDC

5 to 40 mA

None

2.4 V or less

Red LED lights when ON.

D-A80C (Without indicator light)

Auto switch model

Applicable load

Load voltage

Maximum load current

Contact protection circuit

Internal resistance

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the reed switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Note 3) Lead wire with connector may be shipped with switch.

Note 4) Under 5 mA, the strength of the indicator light is poor. In some cases, visibility of the

indicator light will not be possible where the output signal is less than 2.5 mA. However,

there is no problem in terms of contact output, when an output signal exceeds 1 mA or

more.

1 Ω or less (Including lead wire length of 3 m)

D-A80C

Relay, IC circuit, PLC

24 V

50 mA

None

AC

DC

Weight

(g)

Auto switch model

Lead wire length

(m)

0.5

3

5

D-A73C

12

54

84

D-A80C

12

54

84

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

Contact

protection

box

CD-P11

Reed switch

Note 1) Operating load is an induction load.

Note 2) Wiring to the load is 5 m or longer.

Use the contact protection box in any of the

above listed situations. The contact point life

may decrease. (Refer to page 12-13-5 for

contact protection box.)

CD-P12

(±)

OUT

Brown

앑

OUT ( )

Blue

±

Dimensions

Lead wire

with connector

Indicator light

D-A80C without

indicator light

Most sensitive position

12-13-9

Page 10

( ): dimensions for D-A93.

D-A90V, D-A93V, D-A96V

Auto Switch Specifications

Grommet

Electrical entry: In-line

PLC: Abbreviation of Programmable Logic Controller

D-A90, D-A90V (Without indicator light)

Auto switch model

Applicable load

Load voltage

Maximum load current

Contact protection circuit

Internal resistance

D-A93, D-A93V, D-A96, D-A96V (With indicator light)

Auto switch model

Applicable load

Load voltage

Load current range and

Maximum load current

Contact protection circuit

Internal voltage drop

Indicator light

D-A90, D-A90V

IC circuit, Relay, PLC

24 V or less

50 mA

None

1 Ω or less (Including lead wire length of 3 m)

48 V or less

40 mA

100 V or less

20 mA

D-A93, D-A93V

Relay, PLC

24 VDC

5 to 40 mA

None

D-A93 —— 2.4 V or less (up to 20 mA)/3 V or less (up to 40 mA)

D-A93V —— 2.7 V or less

Red LED lights when ON.

100 VAC

5 to 20 mA

D-A96, D-A96V

IC circuit

4 to 8 VDC

20 mA

0.8 V or less

AC

DC

AC

DC

AC

DC

Note 1) Operating load is an induction load.

Note 2) Wiring to the load is 5 m or longer.

Note 3) Load voltage is 100 VAC.

Use the contact protection box in any of the

above listed situations. The contact point life may

decrease. (Refer to page 12-13-5 for contact

protection box.)

1. Fix the switch with appropriate screw

installed on the switch body. If using other

screws, switch may be damaged.

Model

Lead wire length: 0.5 m

Lead wire length: 3 m

D-A90

6

30

D-A90V

6

30

D-A93

6

30

D-A93V

6

30

D-A96

8

41

D-A96V

8

41

(g)

Weight

Auto Switch Internal Circuit

Colors of lead wire inside ( ) are the

ones before conformed to IEC standard.

D-A90V

D-A93V

D-A96V

Reed switch

OUT(±)

Brown

앑

OUT (±)

Blue

Blue (Black)

LED

Reed switch

Resistor

Zener diode

Brown (Red)

OUT (+)

Brown

앑

OUT (–)

Blue

LED

Reed switch

Resistor

Reverse

current

prevention

diode

OUT

Black

DC (+)

Brown

DC (

–)

Blue

Load

(+)

(

–)

DC

power supply

Dimensions

D-A90, D-A93, D-A96

(3)

• Lead wire

D-A90(V)/D-A93(V)—Oil resistant vinyl heavy-duty cord, ø2.7, 0.18 mm2 x 2 cores (Brown, Blue), 0.5 m

D-A96(V)—

Oil resistant vinyl heavy-duty cord, ø2.7, 0.15 mm2 x 3 cores (Brown, Black, Blue), 0.5 m

Note 1) Regarding the common specifications of the reed switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Note 3)

Under 5 mA, the strength of the indicator light is poor. In some cases, visibility of the indicator

light will not be possible where the output signal is less than 2.5 mA. However, there is no

problem in terms of contact output, when an output signal exceeds 1 mA or more.

M2.5 x 4

l

Slotted set screw

Indicator light

D-A90 without indicator light

Indicator light

D-A90V without indicator light

M2.5 x 4l Slotted set screw

Most sensitive position

Reed Switch

Direct Mounting Style

D-A90(V)/D-A93(V)/D-A96(V

)

Contact

protection

box

CD-P11

CD-P12

Contact

protection

box

CD-P11

CD-P12

Most sensitive

position

Precautions

Caution

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

10

12-13-10

Page 11

2-color Indication Type Reed Switch

Rail Mounting Style

D-A79W

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

11

Grommet

The optimum operating position

can be determined by the color

of the light.

(Red → Green ← Red)

Auto Switch Internal Circuit

D-A79W

(+)

OUT

Reed switch

of switch

Main circuit

LED

Brown

Reverse flow

prevent diode

OUT (–)

Blue

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-A79W (With indicator light)

Auto switch model

Applicable load

Load voltage

Load current range

Contact protection circuit

Internal voltage drop

Indicator light

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the reed switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Note 3) Under 5 mA, the strength of the indicator light is poor. In some cases, visibility of the

indicator light will not be possible where the output signal is less than 2.5 mA. However,

there is no problem in terms of contact output, when an output signal exceeds 1 mA or

more.

(3)

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

D-A79W

Relay, PLC

24 VDC

5 to 40 mA

None

4 V or less

Weight

(g)

Auto switch model

Lead wire length

(m)

0.5

3

5

D-A79W

11

53

—

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

Indicator light/Display method

Operating range

Indication

Green

Red Red

Optimum operating position

Note 1) Operating load is an induction load.

Note 2) Wiring to the load is 5 m or longer.

Use the contact protection box in any of the

above listed situations. The contact point life

may decrease. (Refer to page 12-13-5 for

contact protection box.)

D-

Dimensions

20-

Most sensitive position

12-13-11

Page 12

Auto Switch Internal Circuit

D-F79

D-J79

D-F7P

Auto Switch Specifications

Weight

Dimensions

Auto switch model

0.5

3

5

D-F79

D-F7P D-J79

Grommet

Lead wire length

(m)

D-F7, D-J79 (With indicator light)

PLC: Abbreviation of Programmable Logic Controller

Auto switch model

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-F79

NPN

28 VDC or less

40 mA or less

1.5 V or less

(0.8 V or less

at 10 mA load current)

D-F7P

PNP

—

80 mA or less

0.8 V or less

Red LED lights when ON.

3-wire

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 VDC)

10 mA or less

100 µA or less at 24 VDC

D-J79

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

13

57

92

11

50

81

13

57

92

• Lead wire — Oil resistant vinyl heavy-duty cord,

ø3.4, 0.2 mm

2

, 3 cores (Brown, Black, Blue),

2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Indicator light

Most sensitive position

ø3.5 mounting hole

(g)

Solid State Switch

Rail Mounting Style

D-F79/D-F7P/D-J79

Main circuit

of switch

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT (

+)

Brown

OUT (–)

Blue

Main circuit

of switch

Main circuit

of switch

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

12

12-13-12

Page 13

Solid State Switch

Rail Mounting Style

D-F7NV/D-F7PV/D-F7BV

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

13

Grommet

Electrical entry: Perpendicular

Auto Switch Internal Circuit

D-F7NV

DC (

+)

Brown

OUT

of switch

Main circuit

Black

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-F7V (With indicator light)

Auto switch model

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 3 cores (Brown, Black, Blue),

2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

D-F7NV

NPN

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 VDC)

10 mA or less

28 VDC or less

40 mA or less

1.5 V or less

(0.8 V or less

at 10 mA load current)

100 µA or less at 24 VDC

D-F7PV

3-wire

PNP

—

80 mA or less

0.8 V or less

Red LED lights when ON.

D-F7BV

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

Weight

Auto switch model

Lead wire length

(m)

0.5

3

5

D-F7NV

13

57

92

D-F7PV D-F7BV

13

57

92

11

50

81

(g)

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

D-F7PV

D-F7BV

of switch

Main circuit

of switch

Main circuit

DC (

–)

Blue

DC (

Brown

OUT

Black

DC (

–)

Blue

OUT (

Brown

OUT (–)

Blue

Dimensions

ø3.5 mounting hole

Indicator light

+)

+)

Most sensitive position

12-13-13

Page 14

Auto Switch Internal Circuit

D-J79C

Auto switch model

0.5

3

5

13

52

83

D-J79C

Connector

Lead wire length

(m)

D-J79C

Auto switch model

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-J79C

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

Red LED lights when ON.

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

Weight

(g)

Dimensions

1. Confirm that the connector is appropriately

tightened. If tightened insufficiently, the

waterproof performance will deteriorate.

2. Refer to Best Pneumatics Vol. 6/7/8/9/10

for the details.

Precautions

Solid State Switch

Rail Mounting Style

D-J79C

Main circuit

of switch

OUT (+)

Brown

OUT (–)

Blue

ø3.2 mounting hole

Indicator light

Most sensitive position

Caution

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

14

12-13-14

Page 15

Solid State Switch

Direct Mounting Style

D-F8N/D-F8P/D-F8B

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

15

Grommet

Caution

Precautions

Fix the switch with appropriate screw installed

on the switch body. If using other screws, switch

may be damaged.

Auto Switch Internal Circuit

D-F8N

+)

DC (

Brown

OUT

of switch

Main circuit

Black

DC (

Blue

–)

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

I

nternal voltage drop

Leakage current

Indicator light

• Lead wire ——— Oil resistant vinyl heavy-duty cord, ø2.7, 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

D-F8N, D-F8P 0.15 mm

D-F8B

D-F8N

Perpendicular

NPN

IC circuit, 24 VDC Relay, PLC

5, 12, 24 VDC (4.5 to 28 VDC)

10 mA or less

28 VDC or less

40 mA or less

1.5 V or less

(0.8 V or less

at 10 mA load current)

100 µA or less at 24 VDC

2

0.18 mm

2

x 2 cores (Brown, Blue)

D-F8P

Perpendicular

3-wire

PNP

—

80 mA or less

0.8 V or less

Red LED lights when ON.

x 3 cores (Brown, Black, Blue)

D-F8B

Perpendicular

2-wire

—

24 VDC relay, PLC

—

—

24 VDC (10 to 28 VDC)

2.5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

Weight

Auto switch model

Lead wire length

(m)

0.5

3

5

D-F8N

7

32

52

D-F8P

7

32

52

D-F8B

7

32

52

Dimensions

(g)

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

20-

D-F8P

D-F8B

of switch

Main circuit

of switch

Main circuit

DC (

Brown

OUT

Black

DC (

–)

Blue

OUT (

Brown

OUT (–)

Blue

D-F8N, D-F8P, D-F8B

+)

10.9 3

+)

3.1

4.3

2

ø2.7

2.8

4

Mounting screw M2.5 x 4l

Indicator light

10

4.6

Most sensitive position

8

Slotted set screw

12-13-15

Page 16

Auto Switch Internal Circuit

D-M9N, D-M9NV

D-M9B, D-M9BV

D-M9P, D-M9PV

Auto switch model

0.5

3

5

D-M9N(V)

8

41

68

D-M9P(V)

8

41

68

D-M9B(V)

7

38

63

Lead wire length

(m)

• Lower load current

• Lead free solder

• Using UL certified (style

2844) lead wire

Grommet

D-M9, D-M9V (With indicator light)

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-M9N

In-line

3-wire

NPN

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 V)

28 VDC or less

D-M9NV

Perpendicular

D-M9BV

Perpendicular

D-M9PV

Perpendicular

D-M9B

In-line

2-wire

—

24 VDC relay, PLC

—

—

24 VDC (10 to 28 VDC)

2.5 to 40 mA

4 V or less

0.8 mA or less

D-M9P

In-line

PNP

10 mA or less

Red LED lights when ON.

100 µA or less at 24 VDC

D-M9V

D-M9

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

Weight

(g)

Dimensions

•

Lead wire — Oil resistant vinyl heavy-duty cord, ø2.7 x 3.2 ellipse 0.15 mm2, 2 cores (D-M9B), 3

cores (D-M9N, D-M9P)

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Solid State Switch

Direct Mounting Style

D-M9N(V)/D-M9P(V)/D-M9B(V

)

Main circuit

of switch

Main circuit

of switch

Main circuit

of switch

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT (

+)

Brown

OUT (–)

Blue

—

40 mA or less

0.8 V or less

Precautions

During installation, secure the rod cover and tighte

• Over-current protection is not equipped with this product series. When it is

wired incorrectly or a load is short-circuited, a switch may be damaged or

burned.

• In the event of stripping cable sheath, use caution for the stripping direction.

Its insulation may be torn or damaged, depending on the direction.

• Below is given as the recommended tool.

∗ As for 2-wire, a stripper for round shape cord (ø2.0) is usable.

• Fix the switch with appropriate screw installed on the switch body. If using

other screws, switch may be damaged.

Caution on Handling

Caution

Be sure to read before handling. Please contact SMC when using

beyond specifications.

Maker

Product’s name

Part no.

VESSEL Co., Inc.

Tokyo Ideal Co., Ltd.

Wirestripper

Stripmaster

No 3000G

45-089

Operating range shortened, compared to conventional

types.

When replacing conventional types, dependant upon

application, the shortened operating range may cause auto

switch imperceptive.

• When the range of stroke is wider than the operating

range. Example) Stamping, press-fitting, clamping, etc.

• When used to detect intermediate position. (Detection

output time is shortened.)

Note) Please consult with SMC regarding details of

operation range by each actuator.

Since short circuit protection circuit is not built-in, the auto

switch will be immediately damaged when the load is shortcircuited. Be careful not to exchange the power cable

(brown) with the output cable (black).

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

2.6

4

2.8

M2.5 x 4l slotted set screw

Indicator light

2.7

22

500 (3000)

2.6

4

9.5

500 (3000) (5000)

2.7

4.6

2

20

M2.5 x 4l

Slotted set screw

2.8

8

3.2

4

6

Indicator light

Most sensitive position

3.2

22

500 (3000)

6

Most sensitive position

16

12-13-16

Page 17

Solid State Switch

Direct Mounting Style

A

D-Y59 /D-Y69 /D-Y7P(V

B

A

B

)

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

17

Grommet

Auto Switch Internal Circuit

D-Y59A, D-Y69A

DC (

Brown

OUT

of switch

Main circuit

Black

DC (

Blue

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-Y5, D-Y6, D-Y7P, D-Y7PV (With indicator light)

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.15 mm

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

D-Y59A

In-line

28 VDC or less

at 10 mA load current)

2 cores (Brown, Blue), 0.5 m

D-Y69A

Perpendicular

3-wire

NPN

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 V)

10 mA or less

40 mA or less

1.5 V or less

(0.8 V or less

100 µA or less at 24 VDC

D-Y7P

In-line

Red LED lights when ON.

D-Y7PV

Perpendicular

PNP

—

80 mA or less

0.8 V or less

2

, 3 cores (Brown, Black, Blue),

D-Y59B

In-line

24 VDC relay, PLC

24 VDC (10 to 28 VDC)

0.8 mA or less at 24 VDC

D-Y69B

Perpendicular

2-wire

—

—

—

5 to 40 mA

4 V or less

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

+)

Weight

Auto switch model

Lead wire length

(m)

–)

D-Y59B D-Y69B

0.5

3

5

9

50

83

D-Y59A D-Y69A

10

53

87

D-Y7P(V)

10

53

87

MRHQ

(g)

Misc.

D-

20-

D-Y7P, D-Y7PV

of switch

Main circuit

D-Y59B, D-Y69B

of switch

Main circuit

+)

DC (

Brown

OUT

Black

–)

DC (

Blue

OUT (+)

Brown

OUT (–)

Blue

Dimensions

D-Y59A, D-Y7P, D-Y59B D-Y69A, D-Y7PV, D-Y69B

Mounting screw M2.5 x 4

Slotted set screw

SMCSMC

27.3

Most sensitive position

12.5

Indicator light

ø3.4

8.5

2.5

6.2

5

Mounting screw M2.5 x 4l

Slotted set screw

Indicator light

SMC

29

Most sensitive position

12.5

2.5

6.2

ø3.4

5

l

12-13-17

Page 18

Auto switch model

0.5

3

5

13

57

92

13

57

92

11

50

81

D-F79W

D-F7PW D-J79W

Lead wire length

(m)

Auto Switch Internal Circuit

D-F79W

D-J79W

Indicator light/Display method

D-F7PW

Grommet

D-F7W, D-J79W

Auto switch model

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-F79W

3-wire

NPN

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 VDC)

10 mA or less

28 VDC or less

40 mA or less

100 µA or less at 24 VDC

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

D-J79W

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

D-F7PW

PNP

—

80 mA

0.8 V or less

1.5 V or less

(0.8 V or less

at 10 mA load current)

• Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 3 cores (Brown, Black, Blue),

2 cores (Brown, Blue), 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

The optimum operating position

can be determined by the color

of the light.

(Red → Green ← Red)

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

Weight

(g)

Dimensions

Operating range

Indication

GreenRed Red

Optimum operating position

ø3.2 mounting hole

Indicator light

Most sensitive position

2-color Indication Type Solid State Switch

Rail Mounting Style

D-F79W/D-F7PW/D-J79W

Main circuit

of switch

Main circuit

of switch

Main circuit

of switch

OUT (+)

Brown

OUT (–)

Blue

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

18

12-13-18

Page 19

2-color Indication Type Solid State Switch

Direct Mounting Style

19

D-Y7NW(V)/D-Y7PW(V)/D-Y7BW(V

Grommet

The optimum operating position

can be determined by the color

of the light.

Auto Switch Internal Circuit

D-Y7NW, D-Y7NWV

D-Y7PW, D-Y7PWV

(Red → Green ← Red)

of switch

Main circuit

DC (

Brown

OUT

Black

DC (

Blue

+)

–)

DC (

Brown

+)

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-Y7W, D-Y7WV (With indicator light)

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

• Lead wire —

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

D-Y7NW

In-line

at 10 mA load current)

Oil resistant, flexible vinyl heavy-duty cord, ø3.4, 0.15 mm2, 3 cores (Brown, Black, Blue),

2 cores (Brown, Blue), 0.5

D-Y7NWV

Perpendicular

NPN

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 VDC)

10 mA or less

28 VDC or less

40 mA or less

1.5 V or less

(0.8 V or less

100 µA or less at 24 VDC

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

D-Y7PW

In-line

3-wire

m

D-Y7PWV

Perpendicular

PNP

—

80 mA or less

0.8 V or less

D-Y7BW

In-line

24 VDC relay, PLC

24 VDC (10 to 28 VDC)

0.8 mA or less at 24 VDC

D-Y7BWV

Perpendicular

2-wire

—

—

—

5 to 40 mA

4 V or less

Weight

Auto switch model

Lead wire length

(m)

0.5

3

5

D-Y7NW(V)

11

54

88

D-Y7PW(V)

11

54

88

D-Y7BW(V)

11

54

88

)

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

(g)

Misc.

D-

20-

OUT

of switch

Main circuit

Black

DC (

Blue

–)

D-Y7BW, D-Y7BWV

+)

OUT (

Brown

of switch

Main circuit

OUT (–)

Blue

Indicator light/Display method

Operating range

Indication

Green

Red Red

Optimum operating position

Dimensions

D-Y7W

D-Y7WV

2.5

2.5

6.2

5

6.2

5

Mounting screw M2.5 x 4l

Slotted set screw

Indicator light

SMC

29

Most sensitive position

12.5

Mounting screw M2.5 x 4l

Slotted set screw

Indicator light

SMC

27.3

12.5

Most sensitive position

ø3.4

ø3.4

8.5

12-13-19

Page 20

Auto Switch Internal Circuit

D-F9NW, D-F9NWV

D-F9BW, D-F9BWV

D-F9PW, D-F9PWV

Grommet

D-F9W, D-F9WV (With indicator light)

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-F9NW

In-line

D-F9NWV

Perpendicular

D-F9PW

In-line

D-F9PWV

Perpendicular

D-F9BW

In-line

D-F9BWV

Perpendicular

3-wire

IC circuit, Relay, PLC

5, 12, 24 VDC (4.5 to 28 V)

10 mA or less

100 µA or less at 24 VDC

NPN

28 VDC or less

40 mA or less

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less

—

80 mA or less

0.8 V or less

PNP

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

1.5 V or less

(0.8 V or less

at 10 mA load current)

Mounting screw M2.5 x 4l

Slotted set screw

2

2.8

22

ø2.7

Indicator light

2.6

4

Most sensitive position

6

Mounting screw M2.5 x 4

l

Slotted set screw

Indicator light

4.3

2

3.8

3.1

6.2

4

ø2.7

Most sensitive position

6

4.6

2.8

20

D-F9WV

D-F9W

Indicator light/Display method

Auto switch model

0.5

3

5

D-F9NW(V)

7

34

56

D-F9PW(V)

7

34

56

D-F9BW(V)

7

32

52

Lead wire length

(m)

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

• Lead wire — Oil resistant vinyl heavy-duty cord: ø2.7, 3 cores (Brown, Black, Blue), 0.15 mm

2

2 cores (Brown, Blue) 0.18 mm

2

, 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Weight

(g)

Dimensions

Operating range

Indication

Green

Red Red

Optimum operating position

2-color Indication Type Solid State Switch

Direct Mounting Style

D-F9NW(V)/D-F9PW(V)/D-F9BW(V

)

Main circuit

of switch

Main circuit

of switch

Main circuit

of switch

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT

Black

DC (

+)

Brown

DC (

–)

Blue

OUT (

+)

Brown

OUT (–)

Blue

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

20

12-13-20

Page 21

21

2-color Indication Type with Diagnostic Output Solid State Switch: Rail Mounting Style

D-F79F

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

Grommet

Since the output signal can be

detected in an unsteady detecting

area, the difference of detecting

position can be confirmed by the

side of PLC (Programmable Logic

Controller).

Auto Switch Internal Circuit

+)

DC (

Brown

OUT (Normal output)

Black

Diagnosis OUT

(Diagnostic output)

of switch

Main circuit

Orange

DC (

Blue

–)

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-F79F (With indicator light)

Auto switch model

Wiring

Output

Diagnostic output

Applicable load

Power voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Current leakage

Indicator light

•

Lead wire

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

— Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 4 cores (Brown, Black, Orange, Blue), 0.5 m

50 mA or less at the total amount of normal output and diagnostic output

Optimum operating position······Green LED lights when ON.

5, 12, 24 VDC (4.5 to 28 VDC)

1.5 V or less (0.8 V or less at 5 mA)

Operating position······Red LED lights when ON.

D-F79F

4-wire

NPN

Normal operation

IC circuit, Relay, PLC

10 mA or less

28 VDC or less

100 µA or less at 24 VDC

Weight

Auto switch model

Lead wire length

(m)

0.5

3

5

D-F79F

13

56

90

Diagnostic Output Operation

The diagnostic signal is

output within unsteady

detecting area (where

indicator light is Red), and

the diagnostic output

becomes OFF when the

detecting position remains

within the optimum

operating position (where

indicator is Green). When

the detecting position is not

adjusted, the diagnostic

output becomes ON.

Indicator light

OUT

(Normal output)

Diagnosis OUT

(Diagnostic output)

OFF OFF

ON

Red Green Red

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

(g)

MRHQ

Misc.

D-

20-

Red

Dimensions

ø3.2 mounting hole

Indicator light

ø3.4

Most sensitive position

12-13-21

Page 22

Auto Switch Internal Circuit

Dimensions

Grommet

Water (coolant) resistant type

Please consult with SMC if using coolant liquid

other than water based solution.

Indicator light/Display method

D-F7BA(V)L (With indicator light)

Auto switch model

Electrical entry direction

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

D-F7BAL

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 40 mA

4 V or less

0.8 mA or less at 24 VDC

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

D-F7BAVL

Perpendicular

8.5

15

6.2 3.2

11

23

SMC

8

15

7

15

ø3.4

D-F7BAL

D-F7BAVL

Auto switch model

0.5

3

5

D-F7BA

—

50

81

D-F7BAV

—

50

81

Lead wire length

(m)

In-line

•

Lead wire — Oil resistant vinyl heavy-duty cord, ø3.4, 0.2 mm2, 2 cores (Brown, Blue), 3 m (Standard)

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

Weight

(g)

ø3.2 mounting hole

Most sensitive position

Indicator light

ø3.2 mounting hole

Most sensitive position

Indicator light

Precautions

Operating range

Indication

GreenRed Red

Optimum operating position

Water Resistant 2-color Indication Type

Solid State Switch: Rail Mounting Style

D-F7BA(V)L

Main circuit

of switch

Caution

OUT (+)

Brown

OUT (–)

Blue

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

22

12-13-22

Page 23

Water Resistant 2-color Indication Type

Solid State Switch: Direct Mounting Style

D-F9BAL

For details about certified products

conforming to international standards,

visit us at www.smcworld.com.

23

Grommet

Water (coolant) resistant type

Caution

Precautions

Please consult with SMC if using coolant

liquid other than water based solution.

Auto Switch Internal Circuit

Auto Switch Specifications

PLC: Abbreviation of Programmable Logic Controller

D-F9BAL (With indicator light)

Auto switch model

Wiring type

Output type

Applicable load

Power supply voltage

Current consumption

Load voltage

Load current

Internal voltage drop

Leakage current

Indicator light

• Lead wire — Oil resistant vinyl heavy-duty cord, ø2.7, 2 cores (Brown, Blue), 0.18 mm2, 0.5 m

Note 1) Regarding the common specifications of the solid state switches, refer to page 12-13-5.

Note 2) Regarding the lead wire length, refer to page 12-13-5.

Operating position······Red LED lights when ON.

Optimum operating position······Green LED lights when ON.

D-F9BAL

2-wire

—

24 VDC Relay, PLC

—

—

24 VDC (10 to 28 VDC)

5 to 30 mA

5 V or less

1 mA or less at 24 VDC

Weight

Auto switch modelAuto switch model

Lead wire length

(m)

0.5

3

5

D-F9BA

—

37

57

(g)

MHZ

MHF

MHL

MHR

MHK

MHS

MHC

MHT

MHY

MHW

MRHQ

Misc.

D-

OUT (+)

Brown

of switch

Main circuit

OUT (–)

Blue