Page 1

DOCUMENT No.: CE*-OMG0104-F

Brake Position Determination System’s

User Guide

PRODUCT NAME :

MONOSASHI-KUN WITH BRAKE

MODEL :

CE2:MONOSASHI-KUN WITH BRAKE

CEU2:CONTROLLER

○ Read this operation manual carefully to

understand before installation and operation.

○ Pay extra attention on the clause concerning the

safety.

○ Keep this operation manual available whenever

necessary.

SMC CORPORATION

Page 2

Contents

Read Before Use ··············································································· 1

1. General ························································································ 7

1-1. Features

1-2. Position Control

1-3. Positioning at Stroke End

2. System Configuration ······································································ 8

2-1. System Checking Flow Chart

2-2. System Configuration

2-3. Recommended Circuit Design

3. Specifications ··············································································· 13

3-1. Cylinder Specifications

3-2. Controller Specifications

3-3. Sensor Specifications

4. Model ·························································································· 15

4-1. Cylinder

4-2. Controller

4-3. Extension Cable

5. External Dimension Drawing ···························································· 17

5-1. Monosashi-kun with Brake

5-2. Controller

5-3. Extension Cable

6. Part Identification ·········································································· 21

6-1. Monosashi-kun with brake

6-2. Controller

7. Installation & Wiring ······································································· 22

7-1. Installation

7-1-1 Installation of Cylinder

7-1-2 Installation of Controller

7-2. Wiring

7-2-1 The connection of Power Supply

7-2-2 The connection of Extension Cable

7-3. Input Signal’s Wiring

7-3-1 Input Signal Wiring Diagram

7-3-2 Input Signal Content

7-3-3 Input Signal Wiring

7-3-4 OUTPUT Signal Wiring

7-3-5 Solenoid Valve Wiring

7-3-6 Sequencer

8. Timing Chart ················································································· 28

9. Data Setting ················································································· 36

9-1. Preset Data Setting

9-1-1 Data Classification & Content

9-1-2 Input Method

9-1-3 Confirmation of Set Data

Page 3

9-2. Program Setting

9-2-1 Input Method

9-2-2 Confirmation of Input Data

9-3. Selection of Dip Switch

10. Driving ······················································································· 44

10-1. Setting of Origin Direction

10-2. Adjustment of Air Balance

11. Error Messages & Countermeasures ··············································· 45

11-1. Controller

11-2. Brake Unit’s Life Span

12. Appendix ···················································································· 49

12-1. Data Sheet

Specifications are subject to change without prior notice

Page 4

Read before Use

These safety instructions are intended to prevent a hazardous situation and/or equipment damage.

These instructions indicate the level of potential hazard by label of “Caution”, ”Warning”, or ”Danger”.

To ensure safety, follow the instructions below as well as ISO/IEC, JIS

*1)

and other safety laws

*2)

.

Caution

Operator error could result in injury or equipment damage.

Warning

Operator error could result in serious injury or loss of life.

Danger

In extreme conditions, there is a possible result of serious injury or

loss of life.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems

ISO 10218-1: 2006: Robots for industrial environments - Safety requirements - Part 1: Robot

IEC 60204-1: Safety of machinery - Electrical equipment of machines - Part 1:General

requirements

JIS B 8370: General Rules for Pneumatic systems

JIS B 9960-1: Safety of machinery - Electrical equipment of machines - Part 1: General

requirements

JIS B 8433-1:2007: Robots for industrial environments - Safety requirements - Part 1: Robot

*2) Labor Safety and Sanitation Law etc.

Warning

1. The compatibility of pneumatic equipment is the responsibility of the person who designs the

pneumatic system or decides its specifications.

Since the products specified here are used in various operating conditions, their compatibility for

the specific pneumatic system must be based on specifications or after analysis and/or tests to

meet your specific requirements. Ensuring the initial performance and safety are the responsibility

of the person who decides the compatibility of the pneumatic system. Pneumatic systems should

be constructed after full review of the details of the products other than specifications and

possibilities of failures by checking the latest product information.

2. Only trained personnel should operate poneumaticallly operated machinery and equipment.

Assembly, handling, or repair of pneumatic systems should be performed by trained and

experienced operators.

3. Do not service machinery/equipment or attempt to remove component until safety is confirmed.

a. Inspection and maintenance of machinery/equipment should only be performed after

confirmation of safe locked-out control positions.

b. When equipment is to be removed, confirm the safety process as mentioned above. Cut the

supply pressure for this equipment and exhaust all residual compressed air in the system.

c. Before machinery/equipment is re-started, take measure to prevent shooting-out of cylinder

piston rod etc.

4. Contact SMC and take necessary safety measures if the products are to be used in any of the

following conditions:

a. Conditions and environments beyond the given specifications, or if products are used outdoors.

b. Installation on equipment in conjunction with atomic energy, railway, air navigation, vehicles,

medical equipment, food and beverages, recreation equipment, emergency stop circuits, press

applications, or safety equipment.

c. An application which has the possibility of having negative effects on people, property, or animals,

requiring special safety analysis.

d. When used in an interlock circuit, dual interlock such as mechanical protection is necessary in

case of accident. Periodical inspection is also necessary to confirm proper operation.

!

!

!

!

Page 5

Operating and Storage Environments

Warning

1. Envionments to avoid

Avoid using or storing the products in the

following environments which may cause

failures.

If the products need to be used or stored in

those environments, take necessary measures.

a. Place where ambient temperature exceeds

the range of 0℃ to 60℃.

b. Place where ambient humidity exceeds the

range of 25% to 85% RH.

c. Place where condensation occurs due to

sudden temperature change.

d. Place where atmosphere containing corrosive

gas, flammable gas or organic solvent.

e. Place where atmosphere containing

con-ductive powder such as dust and iron

chips, oil mist, salt, or organic solvent, or

splashing cutting chips, dust and cutting oil

(water , liquid) over the products.

f. Place where the products are exposed to

direct sunlight or radiated heat.

g. Place where strong electromagnetic noise is

generated (place where strong electric field,

strong magnetic field or surge is generated).

h. Place where static electricity is discharged or

condition that the products have electrostatic

discharge.

i. Place where strong high frequency is

gene-rated.

j. Place where damages of thunder are

expected.

k. Place where vibration or impact is directly

given to the products.

l. Condition that the products are deformed by

force or weight applied.

2. Do not close any objects which are affected

by magnets.

Since magnets are built in cylinders, do not close

magnetic disks, magnetic cards or magnetic

tapes. The data may be destroyed.

Precaution on Design

Warning

1. There is a possibility of dangerous sudden

action by cylinders if sliding parts of

machi-nery are twisted due to external forces,

etc.

In such cases, human injury may occur; e. g., by

catching hands or feet in the machinery, or

damage to the machinery itself may occur.

2. Provide a cover to minimize the risk of

human injury.

When a driven object or moving parts of a

cylinder may cause the risk of human injury,

design a structure to avoid contact with human

body.

3. Securely tighten all stationary parts and

connected parts of cylinders so that they will

not become loose.

Tighten cylinders securely especially when they

are used in high frequency or in locations where

direct vibration or impact shock, etc. will be

applied to the body of the cylinder.

4. Deceleration circuits or shock absorbers are

needed in some cases.

If a driven object travels at a high speed or is

heavy, impact will not be sufficiently absorbed

only with the cylinder cushion. In such cases,

use a circuit to decelerate the cylinder speed

before the cushion becomes effective or use

external shock absorbers to reduce impact. At

this time, take the rigidity of machinery into

account.

5. Consider possible drop of pressure in circuit

due to power outage.

For cylinders used in clamping mechanism, a

work may become loose due to less clamping

force by pressure drop in circuit at the time of

power outage. Install safety devices to prevent

human injury and machinery damage. Measures

should be taken to prevent drop of hanging or

lifing equipment.

6. Consider possible loss of power sources.

Measures should be taken to protect against

human injury and machinery damage in the

event that there is a loss of air pressure,

electricity or hydraulic power.

7. Design circuit to prevent shooting out of a

driven object.

A driven object is quickly shot out when pressure

is supplied from one side of the piston after air in

the cylinder is exhausted in such cases that

cylinder is actuated by exhaust center type of

directional control valve or started after residual

air is exhausted from the circuit. At this time,

human injury may occur; e.g., by catching hands

or feet in the machinery, or damage to the

machinery itself may occur. Therefore, the

machine should be designed and constructed to

prevent shooting out.

!

!

Page 6

3

8. Consider emergency stops.

Design the machinery so that human injury

and/or damage to machinery and equipment will

not be caused when machinery is stopped by a

safety device under abnormal conditions, a

power outage or a manual emergency stop.

9. Consider actions when operation is restarted

after an emergency stop or abnormal stop.

Design the machinery so that human injury or

equipment damage will not occur upon restart of

operation. When the cylinder is required to return

to the initial position, provide the equipment with

a safe override.

10.Construct the machinery so that moving

objects and the moving parts of the cylinder

with brake do not come into direct contact with

the human body.

11.Use a balanced circuit in which lurching of the

cylinder is prevented. When operation is locked

in specified intermediate positions of the stroke,

and air pressure is applied to only one side of

the cylinder, the piston will lurch when the lock

is released. This might cause injury or damage

to machinery.

Selection

Warning

1. Confirm the specifications.

The product in this manual is designed to be

used only in industrial compressed air system.

The product should not be used with pressures

or temperatures outside the range of the

specifications, as this may cause damage or

malfunction, etc.

2. Intermediate stop

When cylinder piston is stopped intermediately

by 3-position closed center type of directional

control valve, intermediate stop positions may

not be as precise and exact as hydraulic

operation due to compressibility of air. Valves

and cylinders are not guaranteed for zero air

leakage, and stop position may not be held in a

long period of time. Consult SMC for long term

holding of stop positions.

3. When a cylinder is in a no-load and locked state,

the holding force (maximum static load) is the

lock’s ability to hold a static load that does not

involve vibrations or shocks. To ensure braking

force, the maximum load must be set as described

below.

①For constant static loads, such as for drop

prevention:

35% or less of holding force (Maximum static

load)

Note) For applications such as drop prevention,

consider situations in which the air source

is shut off, and make selections based on

the holding force of the spring locked

state. Do not use the pneumatic lock for

drop prevention purposes.

②When kinetic energy acts upon the cylinder,

such as when effecting an intermediate stop,

there are constraints in terms of the allowable

kinetic energy that can be applied to the

cylinder in a locked state. Refer to the

allowable kinetic energy of the respective

series. Furthermore, during locking, the

mechanism must sustain the thrust of the

cylinder itself, in addition to absorbing the

kinetic energy. Therefore, even within a given

allowable kinetic energy level, there is an

upper limit to the amount of the load that can

be sustained.

- Maximum load for horizontal mounting: 70%

or less of the holding force (Maximum static

load) for spring lock

- Maximum load for vertical mounting: 35% or

less of the holding force (Maximum static

load) for spring lock

③In a locked state, do not apply impact, strong

vibrations or rotational forces. Any impact,

strong vibrations or rotational forces from

external sources could damage or shorten

the life of the lock unit.

④Although the cylinder can be locked in both

directions, be aware that its holding force is

smaller in one of the directions. Holding

force at piston rod extended side is approx.

15% less.

Caution

1. Mount speed controller and adjust cylinder

operation speed gradually from low speed to

a desired speed.

Air Supply

Warning

1. Do not use the product out of the specified

ranges for pressure and temperature to

pre-vent equipment damage and

mal-function.

!

!

!

Page 7

4

①Operating pressure:

Actuating part: 0.1 – 1.0MPa

Braking part

: 0.3 – 0.5MPa

②Fluid & ambient temperature: 0 to 60C

2. Use clean air.

Do not use the product with compressed air

includes chemicals, synthetic materials

(including organic solvents), salinity, corrosive

gases, etc., as this may cause damage or

malfunction.

Caution

1. Install air filter.

Install air filter before and in vicinity of valve. The

filter should be able to collect particles of 5

microns or smaller. A large quantity of drain may

cause malfunction of pneumatic components.

2. Install after cooler, air dryer, auto drain, etc.

Compressed air that includes excessive

condensate may cause malfunction of valve and

other pneumatic equipment. To prevent this,

install after cooler, air dryer, auto drain, etc.

Pneumatic circuit

Warning

1. Be certain to use a pneumatic circuit which will

apply balanced pressure to both sides of the

piston when in a locked stop. (Refer to Chapter 6

for recommended pneumatic circuit.)

In order to prevent the cylinder lurching after a

locked stop, use a circuit which applies balanced

pressure to both sides of the piston when restarting

or when manually releasing the lock, thereby

canceling the force generated by the load in the

direction of piston movement.

2. Use a solenoid valve for unlocking which has a

larger effective area, as a rule 50% or more of

the effective area of the cylinder drive solenoid

valve. (Refer to Chapter 6 for recommended

pneumatic components.)

The larger the effective area is, the shorter the

locking time will be, and stopping accuracy will

be improved.

3. Place the solenoid for unlocking close to the

cylinder, and no farther than the cylinder drive

solenoid valve.

The shorter the distance from the cylinder, the

shorter the overrun amount will be, and stopping

accuracy will be improved.

4. Allow at least 0.5 seconds from a locked stop

(intermediate stop of the cylinder) until release of

the lock.

When the locked stop time is too short, the

piston rod may lurch at a speed greater than the

control speed of the speed controller.

5. When restarting, control the switching signal for

the unlocking solenoid valve so that it acts before

or at the same time as the cylinder drive solenoid

valve.

If the signal is delayed, the piston rod may lurch at

a speed greater than the control speed of the

speed controller.

Installation

Warning

1. Connect the rod end and the load with the lock

released.

2. Ensure that the equipment operates properly

before the use.

3. Operation manual

Do not install the products unless the safety

instruction have been read and understood.

Keep this operation manual on file for future

reference.

Caution

1. Maintenance space

When installing the products, allow space for

maintenance.

2. Installation of jigs

When hardware and nuts are screwed into the

piston rod end, the piston rod should be fully

retracted.

Use double nuts to fix a work since Precision

MONOSASHI-KUN (Scale Reading Cylinder)

does not have any parallel parts at the rod.

3. Do not give strong impact and/or excessive

moment when work is mounted.

External force other than allowable moment may

cause rattle at guide part and/or increase in

sliding resistance.

4. Use the product in such a condition that load

is always applied in the axial direction of the

piston rod.

When load is applied in other directions than

cylinder axial direction, regulate the load itself

by the guide.

Perform a complete centering when cylinder is

mounted.

5. Be careful to avoid scratches or dents, etc. on

the sliding sections of the piston rod.

! ! !

!

Page 8

5

Wiring

Warning

1. Preparation for wiring

Shut off the power before wiring (including

insertion and removal of connectors). Mount a

protective cover on the terminal block after

wiring.

2. Check the power

Make sure the power has sufficient capacity and

voltages are within the specified range before

wiring.

3. Grounding

Ground terminal block F.G. (Frame Ground).

Do not ground it with devices generating strong

electromagnetic noise.

4. Check wiring

Incorrect wiring may cause damage or

malfunction of the products. Make sure the

wiring is correct before operation.

Caution

1. Separation of signal wires from power wire

Avoid common or parallel wiring of signal and

power wires to prevent malfunction due to noise.

2. Wiring arrangement and fixation

Avoid bending cables sharply at connector part

or electrical entry in wiring arrangement.

Inproper arrangement may cause disconnection

which in turn causes malfunction. Fix cables

close enough not to give excessive force to the

connector.

Piping

Caution

1. Before piping

Remove cutting chips, cutting oil, dust, etc. in

piping by flushing or cleaning before piping.

Care should be taken especially that any cutting

chips, cutting oil, dust, etc. do not exist after a

filter.

2. At piping

①Foreign matter should not enter. Entering of

foreign matter will cause malfunction.

②Cutting chips and sealing materials at piping

threads should not enter valves when piping

and fittings are screwed in. Leave 1.5 to 2

threads when seal tape is used.

Lubrication

Caution

1. Lubrication of cylinder

①This cylinder is pre-lubricated and can be used

without lubrication.

②In case of lubrication, use a equivalent of the

turbine oil type 1 ISO VG32. Once lubrication

is performed, it should be continued since the

initial lubricant flows out causing malfunction.

Adjustment

Caution

1. The locks are manually disengaged when the

cylinder is shipped from the factory. Be sure to

change them to the locked state before using

the cylinder.

2. Adjust the cylinder’s air balance. In the state in

which a load is attached to the cylinder,

disengage the lock and adjust the air pressure

on the rod side and the head side of the cylinder

to obtain a load balance. By maintaining a

proper air balance, the piston rod can be

prevented from lurching when the lock is

disengaged.

3. Adjust the mounting position of detection

devices such as autoswitches.

Sensor unit

Caution

1. Do not remove the sensor unit.

The position and sensitivity of the sensor is

adjusted properly before shipment.

Removing or replacing the sensor may cause

malfunction.

2. Operate the system with an external magnetic

field of 14.5mT or less.

Strong magnetic field in the vicinity may cause

malfunction, since CE2 sensor is magnetic type.

This is equivalent to a magnetic field of

approximately 18cm in radius from a welding area

using a welding current of almost 15,000 amperes.

To use the system in a magnetic field that exceeds

this value, use a magnetic material to shield the

sensor unit

!

! ! ! ! !

Page 9

6

3. Do not pull sensor cable strongly.

Such action may cause failure.

4. Water shall be kept away from the sensor unit to

avoid failure. (IP65 Protection)

5. Power supply line

Do not mount any switch or relay to power

supply line (12 VDC to 24 VDC).

Measurement

Caution

SMC products are not intended for use as

instruments for legal metrology.

Measurement instruments that SMC manufactures

or sells have not been qualified by type approval

tests relevant to the metrology (measurement) laws

of each country. Therefore, SMC products cannot

be used for business or certification ordained by the

metrology (measurement) laws of each country.

Maintenance and Check

Warning

1. Performing regular check

Check regularly that the products do not operate

with failures unsolved. Check should be done

by trained and experienced operators.

2. Dismantling of product and supply/exhaust

of compressed air.

Before dismantling, ensure that drop preventing

and runaway preventing treatments are properly

provided, shut the power source of air supplied,

and exhausts compressed air in the system.

When starting operation again, operate the

product with care after ensuring that a treatment

for preventing extrusion is properly provided.

3. Prohibition of disassembly and modification

To prevent accidents such as failures and

electric shocks, do not remove the cover to

perform disassembly or modification. If the

cover has to be removed, shut off the power

before removal.

4. Disposal

Request a special agent for handling industrial

waste to dispose the products.

!

Operating

range

Welding machine

!

Page 10

7

1.General

1-1 Features

Controller (CEU2) is a special controller designed for Monosashi-kun with Brake. Upon the input, controller

will stop the cylinder, smoothly and precisely at position as inputted.

Stopping positions of Monosashi-kun with Brake are stored into “Step”, ranging from step 1 to 32. Steps will

be grouped together and form as “Program”. CEU2 allows maximum storage of 16 programs.

Following are CEU2’s special feature: -

1. Predictive Control & Learning Function

(Allow High Repeatability and Precision, ±0.5mm)

With learning function, after every execution, brake point will be amended, according to the deviation of

stopping position from setting position.

2.Equipped Function with Retries→If stopping position deviates from setting position’s tolerance, retries

function will execute to revise the brake point.

Program

P1

P2

P3

・・・・・

P16

Step

S1

S1

S1 S1 S2

S2

S2 S2

・

・

・

・

・

・

・

・

・

・

・

・

S32

S32

S32

S32

Brake Point Setting Point Stopping Position

First Move

Deviation

Predictive of OverRun with taking into the consideration of bore size, cylinder speed and load rate.

Brake Point

Stopping Position

Second Move or above

With reference to previous deviation, brake point was shifted.

Brake point Setting point

停止位置

Stopping Position

Tolerance

Deviation

Retract position

of cylinder

about 30mm Cylinder will retract 30mm

and re-determine position.

Brake point

Stopping Position

Position , falling within the tolerance range, is determined.

Page 11

8

3. Error Detector

When System is found faulty, error detector will take action, detect and analyze error. Finally, error

messages will be displayed. Thus, ease of debugging time.

4. DIN Rail installation is possible.

1-2 Position Control

1. With controller, valve outputs to achieve precise positioning.

2. For the situation whereby cylinder stopping position does not fall into the tolerance range, retries will

be performed. First, it will retract (30mm), and then extend to achieve setting position.

3. With learning ability, brake point will be recognized and thus lead to precise positioning with taking

into the consideration of factors like loading & pressure condition, momentum & impact when

stopping.

4. Stopping method applied is through air balance and brake to lock the movement. While brake applies

the combination of spring and pneumatic locking method.

5. Position is determined when positioning falls on the setting tolerance range.

6. Position determination will follow the sequence of selected program’s steps.

7. Only programs are available for selection. Program steps are not selectable.

1-3 Positioning at Cylinder Rod End

Do not use cylinder with cushion, if determined position falls at cylinder rod’s end (front or back). This is

due to drastical change of speed occurring at the stroke end will lead to imprecision and easy occuring

of learning error (Err 6).

2. System Configuration

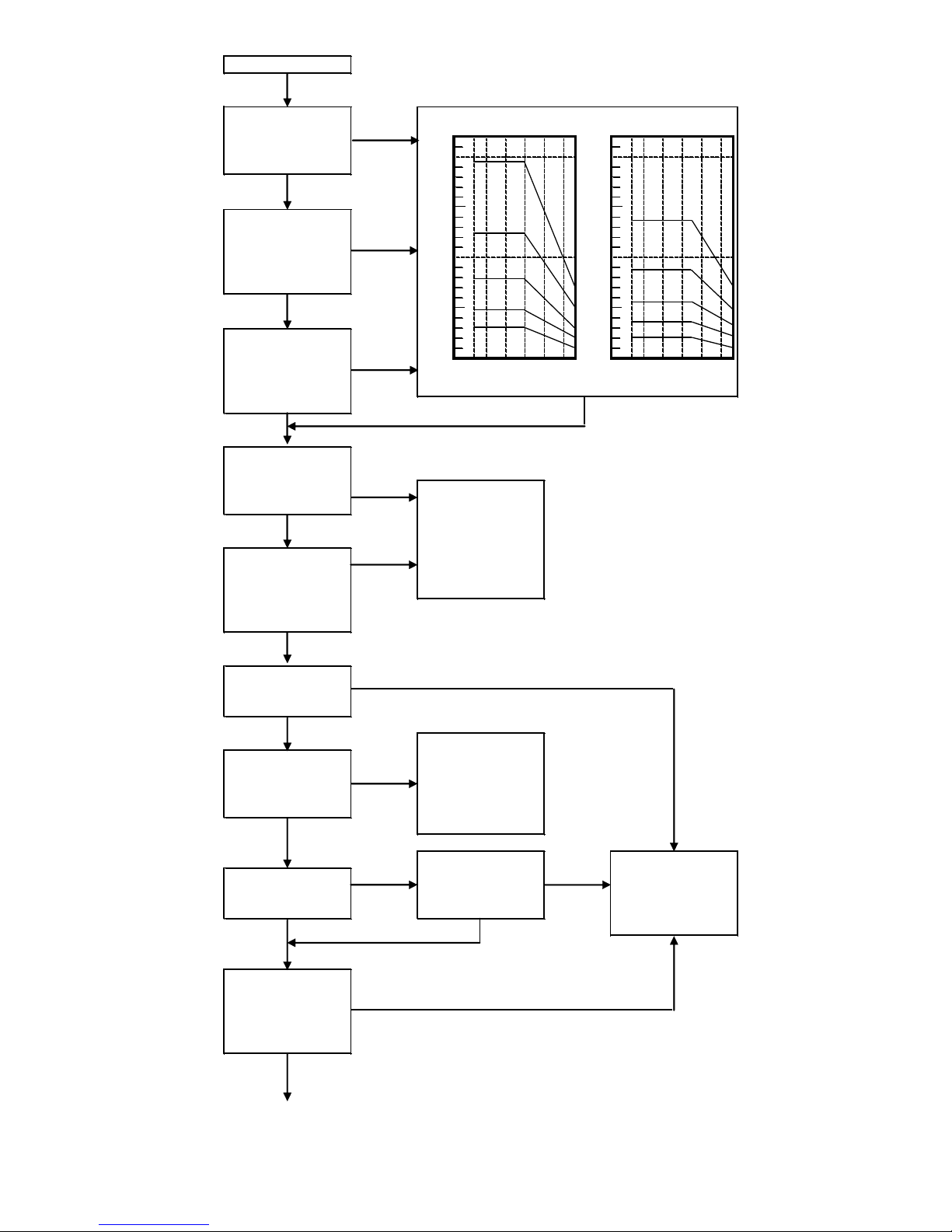

2-1 System Checking Flow Chart

《CE2 (Monosashi - kun with brake) + CEU2 (Controller)》

Refer to check Flow, showing at next page, to determine brake position, so as to reduce the

possibility of occurring errors, which are mostly due to the stopping precision, caused by brake

position.

Page 12

9

NO

NO

OK

YES

NO

NO

NO

YES

Install driving and

brake valve

seperately.

NO

Continue on page 4

YES

Where there is

pressure & speed

changes during

simultaneous action.

YES

Due to the effect on

pressure, loading

and speed, do not

use the cylinder.

YES

Whether there is

changes on

pressure and

NO

If learning function's

problem arises and

affects the stopping

precision, please

reminded not to use

the cylinder.

Whether there is

impact or

momentum occur

during position

YES

Whether there is

other cylinder

working at the same

YES

Whether retries

function is still

workable, without

any problem.

NO

If retries problem

arises, please

reminded, not to use

the cylinder.

YES

NO

Whether determined

position matches the

inputted value.

YES

Whether cylinder

speed is within

speed level as

shown in allowable

kinetic energy graph.

YES

Whether loading is

under specific load

as shown in graph.

Start

Allowable Kinetic Energy Graph

Refer to graph for selection.

Whether selected

bore size's loading is

within allowable

kinetic energy level.

NO

Piston Speed (mm/s)

Horizontal Mounting

Piston Speed (mm/s)

Vertical Mounting

Load(kgf)

Load(kgf)

100

200

100

200

300

400

500

φ40

φ50

φ63

φ80

φ100

100

200

100

200

300

400

500

φ40

φ50

φ63

φ80

φ100

Page 13

10

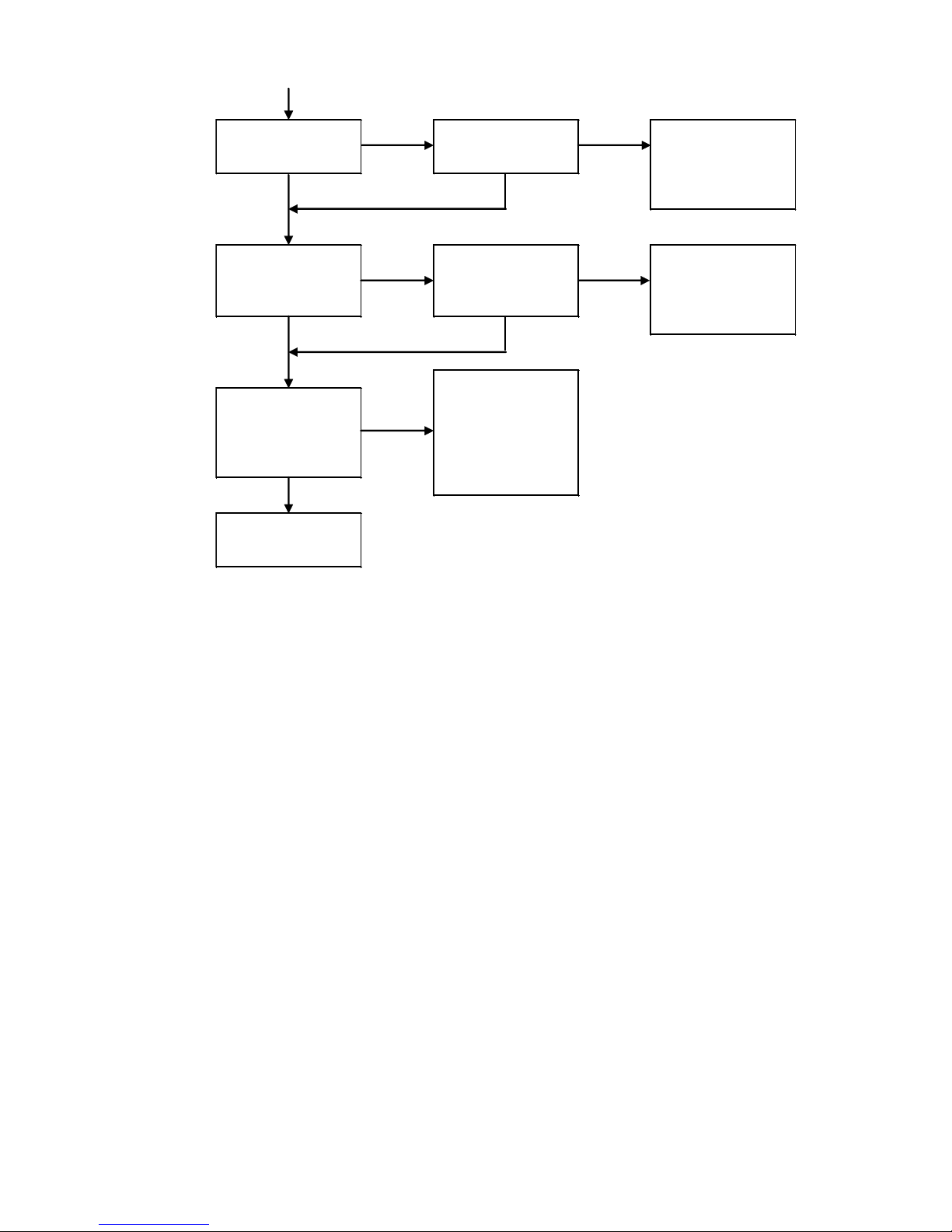

YES NO

YES

YES

YES

NO

Use With No

Problem.

NO

Due to pulsation

output signal is earily

affected by noise,

operation error may

occur and lead to

failure.

Whether cable used

separates from other

power line.

YES

Whether there is

coolant, oil, air, dust

or others.

Whether there is

protection, such as

cover, for cylinder.

NO

Wear or damage on

sensor, packing, etc.

will lead to failure of

cylinder.

YES

Whether magnetic

field affects the

results.

Whether it is

operated at

environment which

Count will

mulfunction and

control will be out

Thus, lead to failure

of operation.

NO

Page 14

11

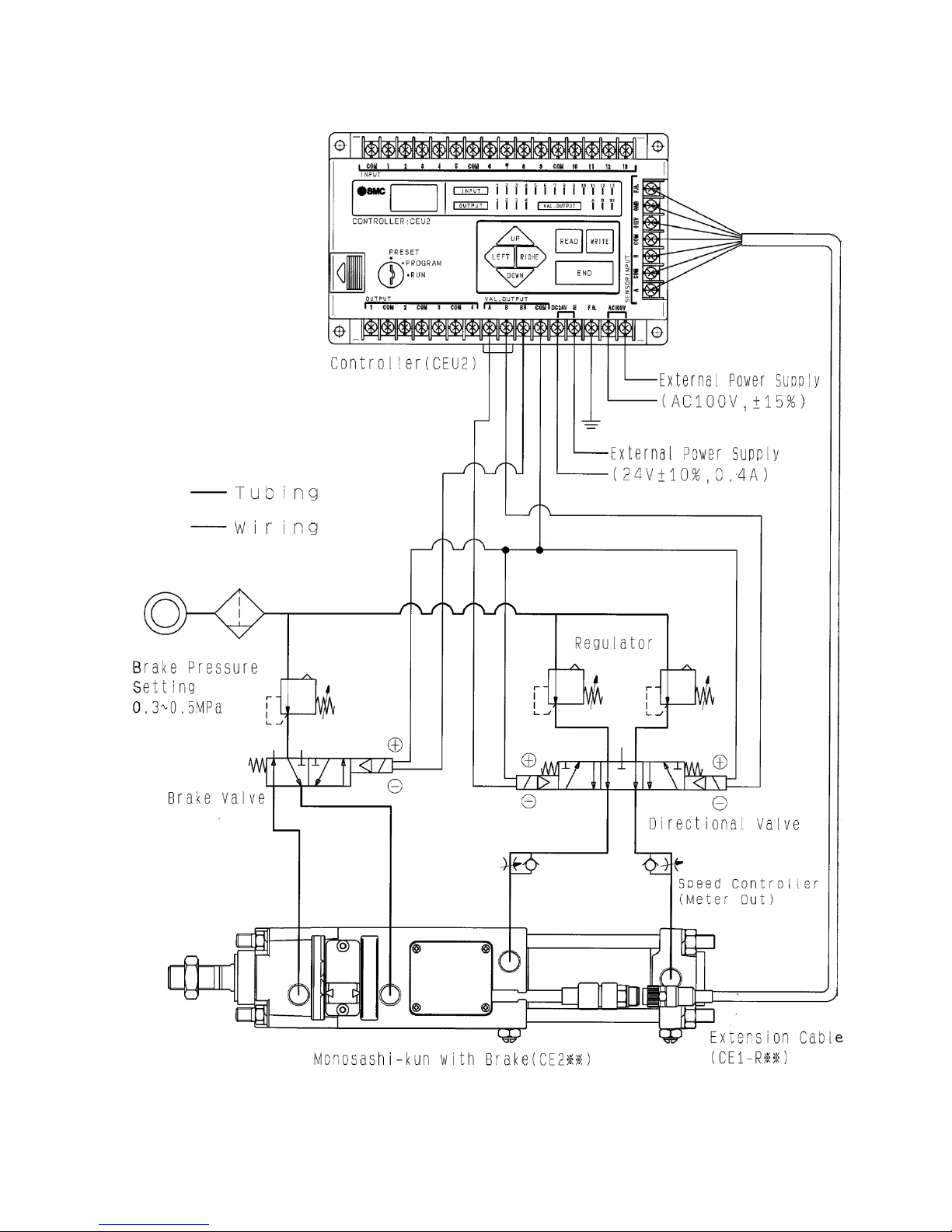

2-2 System Configuration

Page 15

12

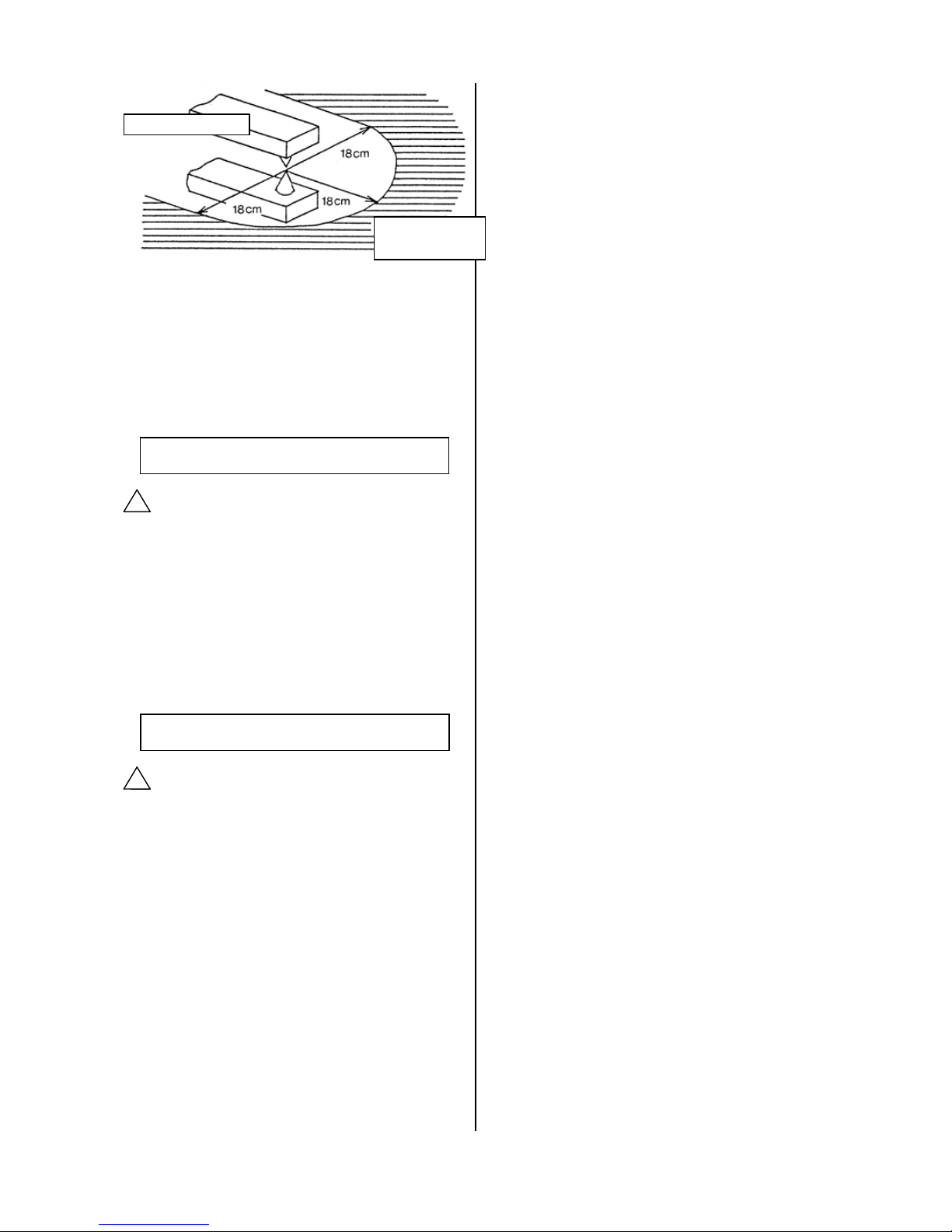

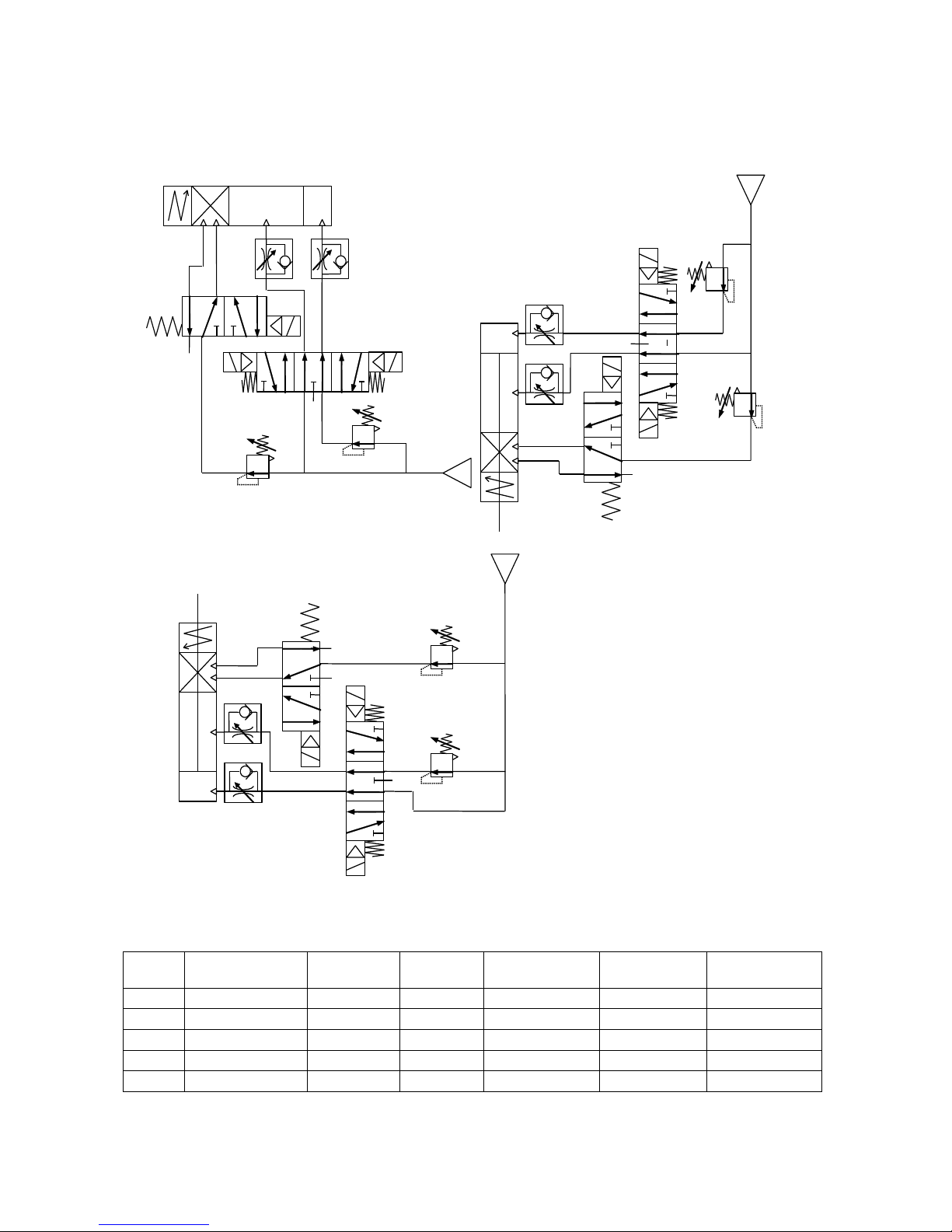

2-3 Recommended Circuit Design

Horizontal Mounting

Downward Mounting

Upward Mounting

<Air Circuit Diagram>

Recommended Pneumatic Equipment

Bore

Directional

valve

Brake

valve

Regulator

Tubing

Silencer

Speed

Controller

φ40

VFS24□0R

VFS21□0

AR425

Nylon φ8/6

AN200-02

AS4000-02

φ50

VFS24□0R

VFS21□0

AR425

Nylon φ10/7.5

AN200-02

AS4000-02

φ63

VFS34□0R

VFS21□0

AR425

Nylon φ12/9

AN300-03

AS4000-03

φ80

VFS44□0R

VFS31□0

AR425

Nylon φ12/9

AN300-03

AS420-03

φ100

VFS44□0R

VFS31□0

AR425

Nylon φ12/9

AN400-04

AS420-04

*Please install the silencer responding to it necessary.

Page 16

13

3. SPECIFICATIONS

3-1 Cylinder Specifications

Bore Size

φ40

φ50

φ63

φ80

φ100

Operating Fluid

Air (Non-Lubricated)

Proof Pressure

Drive Pressure : 1.5MPa Brake Pressure : 0.75MPa

Max. Operating Pressure

Drive Pressure : 1.0MPa Brake Pressure : 0.5MPa

Min. Operating Pressure

Drive Pressure : 0.1MPa Brake Pressure : 0.3MPa

Piston Speed

50~500mm/s

Ambient Temperature

0~60℃

Maximum Stroke (Standard)

850mm

800mm

800mm

750mm

750mm

Brake Type

Integrated Pneumatic and Spring

Sensor Cord Length & Type

φ7-500mm & Oil Resistant

Hardware

JIS B0209

3-2 Controller Specifications

Type

CEU2

CEU2P

Model Nomenclature

Controller

Mounting

Surface Mounting (Din Rail or Screw)

Operating Modes

PRESET・PROGRAM・RUN

Display

Back lighted Display

Position Setting Capacity

1-16 Programs, Each Program 1-32 steps

Position Control Method

PTP(Point To Point)

Control Axes

One Axis

Position Setting Method

Key Input to Controller

Position Setting Range

9999.9mm

Min. Setting Range

0.1mm

Memory

8kbyte Static RAM (5-Year Battery Backup)

Min. Setting Interval

5mm and above

Input Signal

START, GOHOME, PROGRAM#, PAUSE, EMERG, STOP, SETHOME

RESET, AUTO/MANUAL, IN/OUT(Manual mode only)

Output Signal

Move Completed, At Home, Program End, Error

Controlled Output

NPN Open Collector

(DC30V, 50mA)

PNP Open Collector

(DC30V,50mA)

Power Supply

AC100V±15%, 50Hz/60Hz & DC24V±10%, 0.4A

Operating Temp. Range

0℃~50℃

Operating Humidity Range

25%~85%

Shock Resistance

10~55Hz, Amplitude 0.75mm Each Axis for 2 hours

Noise Resistance

Square Wave (1μs Pulse Width)

±1500V at Power Terminal, 600V at Input Terminal

Impact Resistance

10G, 3 times at each axis

Proof Voltage

AC1500V, 1Min(less than 3mA) , between Case & AC Line

AC500V, 1Min(less than 3mA) , between Case & 12VDC

Current Consumption

Below 1.0A

Insulation Resistance

DC500V with Above 50MΩ, between Case & AC Line

Mass

690g

Page 17

14

3-3 Sensor Specifications

Cable

φ7, 6 Core Twisted Pair Shielded Wire

(Oil, heat and flame resistance cable)

(Connector : R03-R8M, Tajima Musen Denki Company)

Max. Transmission Distance

20m (6 core twisted pair shielded wire)

Position Detection Method

Magnetive Scaled Piston Rod & Detection Head

(50cm Cable, Incremental Type)

Magnetive Field Resistance

14.5mT

Power Supply

DC12V~24V±10% (ripple less than 1%)

Current Consumption

50mA(MAX.)

Resolution

0.1mm/pulse

Accuracy

±0.2mm

Output Type

Open Collector (26.4V, 35mA)

Output signal

Phase A & B with Differential Output

Max. Response Speed

500mm/s (Sensor : 1500mm/s)

Proof Voltage

AC500V, 1 min (Case to 12E)

Insulation Resistance

DC500V, above 50MΩ (Case to 12E)

Shock Resistance

33.3Hz6.8G, 2hours at X, Y and 4 hours at Z

JIS D1061 as standard

Impact Resistance

30G, 3 times at each axis

Moisture Resistance

IP-65<IEC STD>

Extension Cable

(Option)

5m, 10m, 15m, 20m

(Connector : R03-P8F, Tajima Musen Denki Company)

Page 18

15

4. MODEL

4-1 Monosahi-kun with Brake

CE2 B 40 100 J

4-2 Controller

CEU2

B Standard

L Plate

F Rod Flange

G Head Frange

C Single Clevis

D Double Clevis

T Center Trunnion

Mounting

40 40mm

50 50mm

63 63mm

80 80mm

100 100mm

Tube Bore

Without Gaiter With Gaiter Without Gaiter With Gaiter

40

25~850 25~700

1200 950

50

25~800 25~650

1150 900

63

25~800 25~650

1150 900

80

25~750 25~600

1100 900

100

25~750 25~600

1100 850

Range of manufacturable stroke

Standard stroke (mm)

Tube Bore(mm)

Standard Stroke

J Nylon Tarpaulin

K Neoprene

None Both Sides

N None

R Cushion at Rod side

H Cushion at Head side

None With connector

Z None

Gaiter

Cushion

Connector

Auto switch’s Type

(Refer to Catalog)

Cylinder Accessories

None 2

s 1

n n

No. of Auto switch

None NPN Open Collector

P PNP Open Collector

Output Method

Page 19

16

4-3 Extension Cable

CE1-R

Length of Cable

Postscript

Connector’s Connection

05 5m

10 10m

15 15m

20 20m

None Extension Cable

C

Symbol Core Wire Color

A White

B Yellow

C , D Brown, Blue

E Red

F Black

G (Shield)

Page 20

17

5. External Dimension Drawing

5-1 Monosashi-kun with Brake

Page 21

18

Page 22

19

5-2 Controller

Page 23

20

5-3 Extension Cable

Page 24

21

6. Part Identification

6-1 Monosashi-kun with Brake

①Piston Rod

②Cover

③Pin Guide

④Rod Cover

⑤Sensor Cover

⑥Cylinder Tube

⑦Tie Rod

⑧Head Cover

⑨Cushion Valve

⑩Connector

⑪Cable

①External Input Terminal

②Sensor Input Terminal

③AC Power Supply Input Terminal

④Earth Terminal

⑤DC Input Terminal

⑥Valve Output Terminal

⑦External Output Terminal

⑧Mode Switch

⑨Dip Switch for Condition Setting

⑩LCD Display

⑪Input Signal Monitor

⑫Input Data Key

1

3 4 7 5 2 6 10

11

8

9

1 2 3 4 5 6 7 8 9

10

11

12

Page 25

22

7. Installation & Wiring

7-1 Installation

7-1-1 Installation of Cylinder

1. During installation of metal fitting onto the end (screw thread) of piston rod, prevent from the

induction of impact and unbalance loading acting upon it.

2. During mounting of cylinder and load, care should be taken not to give misalignment non twist.

Please attach floating joint between the connection.

3. Make sure that pushing force of cylinder act on the centre of load.

4. Do not disassemble cylinder and dismantle sensor from cylinder.

5. Flushing of pipe should be done. Prevent dust & dirt entering into cylinder. Moreover, mist separator

should be used to get rid of water vapor, oil and dirt from the utilized comprised air.

6. When oil is needed to be fed in, use turbine oil class 1 (ISO, VG32).

7. If there is a lot of dust at working environment, use gaiter. Besides that , please take note that

operating temperature should be kept between 0 to 60℃.

8. The total length of air piping (from cylinder to solenoid valve) should be kept below 1m.

7-1-2 Installation of Controller

1. During installation of controller, use M4 bolt and DIN rail.

2. Prevent from direct shining of sun, high or low temperature’s environment.

[Operating temperature range : 0℃~50℃]

3. Do not utilize it at high humidity’s environment.

[Operating humidity range : 25%~85%]

4. Keep it within noise protection material and away from high voltage and power supply wire.

5. Prevent it from mounting in environment containing a lot of dust, salinity, ferrous, or flammable,

corrosive gas.

6. Do not mount it at high vibration and impact environment.

[Proof Vibration : 10~55Hz, range 0.75mm, x, y, z each axis for 2 hours]

7-2 Wiring

7-2-1 The Connection of Power Supply

Power Supply Specification : AC100V±15% (AC85V~AC115V), 50/60Hz

DC24V±10%, 0.4A

Use wire with 0.75mm2 or more in the diameter of wire sectional area and twist it.

FG is meant for preventing lightening strike, use wire, 0.75mm2 or more in the diameter of wire

sectional area, to connect to earth.

If FG is not connected to earth, controller’s noise filter will not be able to function properly. Hence, noise

will be generated and lead to misreading / disoperation of cylinder.

7-2-2 The Connection of Extension Cable

Use specified (SMC) extension cable. Cable length, 5m~20m, with interval of 5m. For distance more

than 20m, use specified transmitter・Receiver box (Model : CE1-H0374)

* Example on cable Connection

Above 20m

Extension Cable

(CE1-R※※)

Page 26

23

* Note

1. Clamp and fix the connector and sensor connection to reduce tension acting on them.

2. Separate cable with power line to prevent from the occurring of noise.

3. When cable is necessary to have U bend, set the bending radius to be above 25mm.

Bending Ability: According to drawing shown below, life span 4 million cycles or more can be achieved.

R25

200m

Reciprocating with

Bending Speed, 100 times/sec

Page 27

24

7-3 Input Signal Wiring

7-3-1 Input Signal Wiring Diagram

Page 28

25

7-3-2 Input Signal Content

Start・・・・・・・・・・・Once started, setting position will be inputted. One step of movement per one shot

(above 50msec).

Note: Start signal (above 50msec’s signal) will be received and activated to carry out

subsequence step, only if homing has been performed and origin signal has been fed

back to controller.

Homing・・・・・・・・When cylinder rod returns to origin, signal above 50msec will be inputted.

Auto / Man’l・・・・When the terminal and COM are in open state, auto mode is on. Vise versa (short circuit),

manual mode is on.

Auto mode・・・・・・When start signal is inputted. Motion will be executed step by step.

Hand mode・・・・・Man’l 1 (terminal 11) or Man’l 2 (terminal 12) and COM is short circuit to

control either moving forward or backward.

Motion direction depends on tubing and wiring.

Pause・・・・・・・・・・・・・During positioning, motion is stopped by this command. When the command is

cancelled, positioning will be resumed from the stopped position.

Note: Please note that Err5 (operating error) will arise, if the stopping position after

pausing is less than 5mm away from setting point.

Emergency Stop・・・・・During positioning, the input of this command will force immediate stoppage of

executing motion. After signal inputs, controller will show error message, Err10.

Note: After emergency stop, homing will perform

Program selection 1,2,3 & 4・・・・・Select program according to following table (Binary Cord): -

Program No.

N Terminal No.

6 7 8 9 1

0 0 0

0

2

1 0 0 0 3

0 1 0

0

4

1 1 0 0 5

0 0 1 0 6

1 0 1

0

7

0 1 1

0

8

1 1 1

0

9

0 0 0 1 10

1 0 0 1 11

0 1 0

1

12

1 1 0

1

13

0 0 1 1 14

1 0 1 1 15

0 1 1 1 16

1 1 1

1

0…Open between IN6~9 and COM

1…Short Circuit between IN6~9 and COM

Set Home・・・・・ When dip switch No.1 is set ON, origin’s signal is inputted. If dip switch No.1 is set to OFF,

auto switch signal input is not required.

・・・・・・・Used at Manual Mode. When signal is inputted, cylinder rod either moves forward or

backward.

External Reset…The input of signal above 50msec will lead to reset of the system. When error occurs,

execute RESET.

Man’l 1

Man’l 2

Page 29

26

7-3-3 INPUT’s Wiring

Input signal consists of 13 signals. With +24V input, +5V is isolated by photo-coupler.

Signal’s name: Start, Homing, Man’l / Auto, Pause, Emergency Stop, Program selection #1,

Program selection #2, Program selection #3, Program selection #4, Set Home,

Man’l 1, Man’l 2 and External Reset.

Input internal circuit is shown below:

7-3-4 OUTPUT’s Wiring

Output signal consists of 4 signals. Together with +5V, photo-coupler is insulated from the 4 output.

Signal’s name: Position Detected, Origin Calculated, Program End, Error

Maximum terminal Voltage: DC +30V

Maximum Current: 50mA (0℃~50℃)

Output Internal’s Circuit

+24V

IN

+5V

10mA

COM

Use current of more than 10mA as input signal.

Model

CEU2

CEU2P

Connection Method

OUT

COM

Load

Controller: CEU2

NPN Output Transistor

Max

DC +30V , 50mA

COM

Load

OUT

PNP Output Transistor

Max

DC +30V , 50mA

Controller: CEU2P

Page 30

27

7-3-5 Solenoid valve’s wiring

Solenoid valve Driving Output consists of 3 signals.

+5v together with photo-coupler is in isolation state.

Signal’s name: Brake, Driving A & B

Maximum terminal’s Voltage +24V DC

Maximum current 80mA (0℃~50℃)

Solenoid Output’s internal Circuit is shown below.

7-3-6 Sequencer

Due to wiring between controller and sequencer, setting of pulse width to be 50msec in program does

not ensure the output pulse width will take the same value, Hence, set the pulse width accordingly, so

as to obtain pulse width of above 50msec, measured from controller.

U

24E

+24V

COM

Valve

driving Output

VAL.OUT

(A、B、BR)

(+)

Valve

(-)

External

Supply

24V DC

24E

Page 31

28

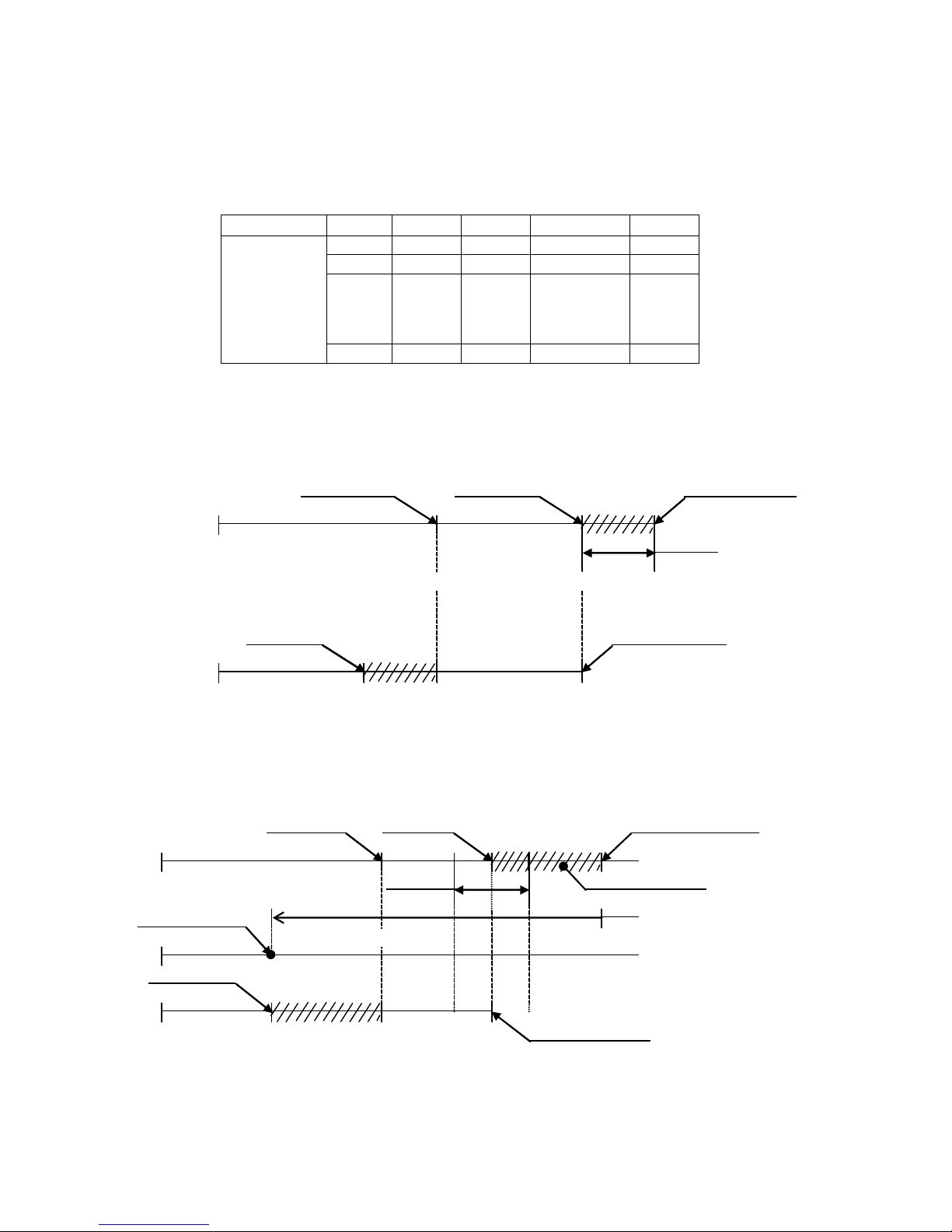

8. Timing Chart

Homing Timing Chart

Note: Homing will be executed only on RUN mode and during automatic executing.

(*1)After resetting and re-supplying power, controller will need 2.0 sec (max) to resume operation.

(*2)Timing from stopping till output is the preset timing t1 (preset data P7).

(*3)Refer to P.27 7-3-6 Sequencer.

(Input)

Reset

Homing

(*3)

SetHome

Man'l / Auto

Start

Program Selection

Man'l (+)

Man'l (-)

(Output)

Driving(+)

Driving(-)

Brake

(*1)

Origin Determined

(*2)

(*2)

Program END

(*1)

Error

Origin

POWER ON

I

N

I

T

I

A

L

I

Z

E

D

MIN50msec

Page 32

29

Automatic Executing’s Timing Chart

Note: After starting, program selection is not valid until program END.

Perform program selection before inputting START signal.

(*1)Timing from stopping till output is 0.2sec (max).

(*2)Refer to P.27 7-3-6 Sequencer.

(Input)

Reset

Homing

SetHome

Man'l / Auto

Start

Program Selection

Man'l (+)

Man'l (-)

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1) (*1)

Program END

(*1)

Error

Origin

MIN50msec(*2)

Page 33

30

Automatic Execution Timing Chart (Activation of Manual mode during motion)

Note: If Manual mode or Run Mode is activated during Auto Mode, motion will stop.

(*1)Timing from stopping till output is 0.2sec (max).

(*2)Refer to P.27 7-3-6 Sequencer.

(Input)

Reset

Homing

SetHome

Man'l / Auto

Start

Program Selection

Man'l (+)

Man'l (-)

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1) (*1)

Program END

(*1)

Error

Origin

MIN50msec(*2)

Page 34

31

Manual Executing Timing Chart

Note: During manual operation, Start signal is not effective.

Pressing Man’l (+) and Man’l (-) together will not take effect too.

Despite software determines origin, manual operation will be executed.

(*1) Timing from stopping till output is 0.2sec (max).

(Input)

Reset

Homing

SetHome

Man'l / Auto

Start

Program Selection

Man'l (+)

Man'l (-)

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1) (*1)

Program END

Error

Origin

Page 35

32

Pause during homing Timing Chart

Note: Homing will be executed, only on RUN mode and during automatic executing.

(*1) Timing from stopping till output is the preset timing t1 (preset data P7).

(*2) Refer to P.27 7-3-6 Sequencer.

(Input)

Reset

Homing

SetHome

Man'l / Auto

Start

Man'l (+)

Man'l (-)

Pause

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1)

(*1)

Program END

Error

Origin

POWER ON

I

N

I

T

I

A

L

I

Z

E

D

MIN50msec(*2)

Page 36

33

Pause during Automatic Execution Timing Chart

Note: During manual operation, Pause is effective less.

(*1)Timing from stopping till output is 0.2sec (max).

(Input)

Homing

SetHome

Man'l / Auto

Start

Program Selection

Man'l (+)

Man'l (-)

Pause

(Output)

Driving (+)

Driving (-)

Brake

Origin Determined

(*1) (*1)

Program END

(*1)

Error

Origin

Page 37

34

Emergency Stop (Automatic Execution) Timing Chart

Note: When Emergency Stop is set to be ON, error will be also set ON. Vice versa.

Therefore, the display of error does not really show that error output.

Emergency Stop is also effective at Manual mode.

(*1) Timing from stopping till output is the preset timing t1 (preset data P7).

(*2) Timing from stopping till output is 0.2sec (max).

(Input)

Homing

SetHome

Man'l /Auto

Start

Program Selection

Man'l (+)

Man'l (-)

Pause

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1)

(*1)

Program END

(*1)

Error

(*2)

Origin

Page 38

35

Data Error (Program free of error) Timing Chart

Note: When LCD displays error ON, press ON to clear the error.

Therefore, it is quite different from error output.

Data error will be recognized while the first step is executed.

(*1)Timing from stopping till output is 0.2sec (max).

(*2)Refer to P.27 7-3-6 Sequencer

(Input)

Reset

Homing

SetHome

Man'l / Auto

Start

Program Selection

Program No1 Program No2

Man'l (+)

Man'l (-)

(Output)

Driving(+)

Driving(-)

Brake

Origin Determined

(*1)

Program END

Error

Origin

LCD displays error ON LCD displays error OFF

MIN50msec(*2)

Program No.1 Data Error (or no)

Program No.2 Data Normal (or error)

Page 39

36

9. Data Setting

9-1 Data Presetting

9-1-1 Data Classification & Content

P1―Cylinder Stroke Input stroke.

P2―Tolerance Input positioning tolerance range. Retries will assure the positioning

within the tolerance range.

P3―Retries Input no. of retries. Maximum retries will be 9. Since Err9 (positioning

error) will appear and the system will stop when positioning is not

able to be set within the range, it is advisable to set the max. retries

no.

P4―Bore Size Input cylinder bore size.

P5―Load Rate Input the load rate (the amount of correction for load against the

movement of cylinder rod). Use formula as shown below: -

<Eg.> Bore size: 40(⇒0.04m) Load: 200N (Allowable kinetic Energy)

Operating Pressure: 0.5MPa(⇒5×105Pa)

200 ÷

0.04×0.04×3.14×5×105

× 100 = 31.8 = 30%

4

P6―No. of Brake operation

P7―Origin Detection Time Set the Origin Detection time (t1).

(10ms as 1 unit, maximum will be 9.99s)

After inputting the homing (returning to origin)‘s signal, if sensor does

not receive any signal within t1 (situation whereby the cylinder stops),

this reflects homing is achieved.

Setting of response time should take into consideration of load,

mounting condition, tubing length, etc. The response time should be

re-calibrated. If the operating conditions change.

When controller dip switch No.1, is set at ON, homing will be

confirmed in addition that the auto switch is ON.

P8―Err12 (Operating Error) confirmation time, t2.

*Input Err12’s decision time.

*10msec as 1 unit. Max. will be 9.99sec.

*Within the time frame, if there is no signal feedback by sensor

(cylinder stops) after inputting of start’s signal. Err12 will be reported.

*Setting of the detection time should take into the consideration of

load, mounting condition, tubing length, etc. If the operating

conditions change, re-calibrate the detection time.

9-1-2 Input Method

Turn the controller switching mode to RESET.

P1 will blink.

Load(N) ÷

Bore size(m) × D2 × π × Operating Pressure(Pa)

4

Round-off

PRG

STEP P1

″

″

″

〟

1000.0

Blinking

Page 40

37

Press either READ or WRITE to proceed to the input

condition for cylinder stroke setting. The first decimal

point will start to blink.

Use LEFT and RIGHT buttons to select digit to be

changed and set the digit to the desired setting through

UP and DOWN buttons. With that, input desired cylinder

stroke.

After setting of cylinder stroke, press WRITE to switch

to the next input condition. The display will indicate

PRG STEP P2 and the current tolerance setting. At the

same time, the first decimal point will start blinking.

Next, enter the desired tolerance value as in above

mentioned method.

The maximum possible input value is 9.9mm.

<Reference>

With input of tolerance, 1.0, any point fall between the

set point ±1.0 will be accepted. If the attempt falls

outside the range, retries will perform to get into the

required range.

If the required position is not achieved within the

maximum retries, positioning error (Err9) will be shown.

After setting of tolerance range, press WRITE to switch

to the next input condition. The display will indicate

PRG STEP P3 and the current maximum retries.

Next, enter desired maximum retries.

The maximum possible input value is 9.

PRG

STEP P1

″

″

″

〟

1000.0

Blinking

PRG

STEP P2

″

″

″

〟

1.0

Blinking

PRG

STEP P3

″

″

″

〟

9

Blinking

Setting Point

Tolerance

-1.0

+1.0

1000.0

2

1

9

8

UP

DOWN

RIGHT

LEFT

Page 41

38

During initial setup, predictive control is executing.

Hence, it is suggested to set the maximum retries to

5 or above.

After setting of maximum retries, press WRITE to

switch to the next input condition. The display will

indicate PRG STEP P4 and the current cylinder bore

size, which is blinking.

Next, enter appropriate cylinder bore size.

Setting value will vary as shown below.

Note:

Monosashi-kun with Brake (CE2)’s bore size setting

range from φ40 to φ100.

After setting of cylinder bore size, press WRITE to

switch to the next input condition. The display will

indicate PRG STEP P5 and the current load rate,

which is blinking.

Next, enter correct load rate.

<Calculation>

Load ÷ Cylinder Pushing Force × 100

Setting value will vary as shown below.

After the above setting, press WRITE to switch to the

next input condition.

The display will indicate PRG STEP P6 and the

current number of brake operation

The display number shows the operation number of

brake assembly that had been activated. 1 unit

represents 10,000.

Setting is not required.

PRG

STEP P4

″

″

″

〟

40

Blinking

DOWN

UP

638010025324050

PRG

STEP P5

″

″

″

〟

0

Blinking

DOWN

UP

405001020

30

PRG

STEP P6

0.0

No blinking.

Note:

Change the brake assembly, when

the counter reaches 300.0.

(refer to P.41 11-2)

Page 42

39

After reviewing of number of brake operation, press

WRITE to switch to next input operation. The display

will indicate PRG STEP P7 and present origin

detection time.

Next, enter desired origin detection time. The setting

range is 0~9.99sec (1 unit as 10msec). Set the date

with taking into the consideration of cylinder

operating conditions.

After the above setting, press WRITE to switch to

next input operation. The display will indicate PRG

STEP P8 and present operating error detection time.

Next, enter desired operating error detection time.

The setting range is 0~9.99sec (1 unit as 10msec).

Set the data with taking into the consideration of

cylinder operating conditions.

After the above setting, press WRITE to end the

whole preset operation.

9-1-3 Confirmation of Set Data

Turn the controller switching mode to PRESET.

PRG

STEP P7

″

″

″

〟

200

Blinking

PRG

STEP P8

″

″

″

〟

Blinking

200

PRG

STEP P1

″

″

″

〟

1000.0

″

″

″

〟

UP

DOWN

P1P2P3P4P8P5P6

P7

When P1 is blinking, use UP & DOWN key to

reconfirm each and individual preset value.

When the input value is blinking, press READ

once to shift the operation back to P1.

Page 43

40

9-2 Program Setting

Input desired cylinder positions.

9-2-1 Input Method

Turn the controller switching mode to PROGRAM.

Note:

Step 0 for every program is END.

Program no. “1” will start blinking.

Set the program no. through UP & DOWN buttons.

Program No.

, 1 , 2 , ・・・・・・・・・・・, 15 , 16

After above setting, press WRITE to end the

operation. Step “0” starts to blink.

Next, press either READ or WRITE to proceed to

next stage.

The display “End” will be replaced by “0000.0”,

leading to the input STEP 1.

Input first setting position into STEP 1.

Then, press WRITE to proceed to STEP 2.

Set the following setting positions.

STEP by STEP.

After inputting the last data into last STEP, press

WRITE, and then END to end the program setting.

Note:

Controller will show Err7 during operation, if END is

not inputted at the end of program.

With above mentioned inputting steps,

input program shown below: -

PRG 1

STEP 0

End

″

″

″

〟

Blinking

PRG 1

STEP 1

″

″

″

〟

0000.0

Blinking

PRG 1

STEP 2

″

″

″

〟

0000.0

Blinking

PRG 1

STEP 0

End

″

″

″ 〟 点滅

UP

DOWN

Page 44

41

<Input example>

Turn the controller switching mode to PROGRAM.

Press WRITE 2 times.

The display “End” will be replaced by “0000.0”,

leading to the input STEP 1.

Press LEFT 2 times.

Blinking is shifted to “0”, the first decimal point.

Press UP 5 times to set value of 5.

Press WRITE one time.

Press LEFT 3 times to shift the blinking cursor.

Press UP 3 times to set the value of 3.

Program

Step

S1 50.0 68.0

S2 300.0 30.5

S3 30.0

S0 End End

P1

P8

PRG 1

STEP 0

End

″

″

″

〟

Blinking

PRG 1

STEP 1

″

″

″

〟

0000.0

Blinking

PRG 1

STEP 1

″

″

″

〟

0050.0

Blinking

PRG 1

STEP 2

″

″

″

〟

0000.0

Blinking

PRG 1

STEP 2

″

″

″

〟

0300.0

Blinking

Page 45

42

Press WRITE one time.

Press LEFT 2 times to shift the blinking cursor.

Press UP 3 times to set the value of 3.

Press WRITE one time to enter into program STEP

4, which is the end of program 1.

Press END to end the program setting for program

1.

Program 1’s programming ends.

Set the program no. to 8 through UP to PRG “8”.

Press WRITE 2 times.

The display “End” will be replaced by “0000.0”,

leading to input STEP 1.

PRG 1

STEP 3

″

″

″

〟

0000.0

Blinking

PRG 1

STEP 3

″

″

″

〟

0030.0

Blinking

PRG 1

STEP 1

0050.0

″

″

″

〟

Blinking

PRG 1

STEP 4

″

″

″

〟

Blinking

0000.0

PRG 1

STEP 1

0050.0

″

″

″

〟

Blinking

PRG 8

STEP 0

End

″

″

″

〟

Blinking

PRG 8

STEP 1

″

″

″

〟

0000.0

Blinking

Page 46

43

First, press LEFT one time.

Next, use DOWN to set the value of “8”.

Press LEFT one time.

Then, use DOWN to set the value of “6”.

Press WRITE one time.

Press UP 5 times to set the value of “5”.

Press LEFT 2 times.

Press UP 3 times to set the value of “3”.

Press WRITE to enter input STEP 3, which is the

end of program 8.

Press END to the program setting for program 8.

Program 8’s programming ends.

9-2-2 Confirmation of Input Data

Turn the controller switching mode to PROGRAM.

When PRG “1” is blinking, use UP & DOWN to

select desired program to be checked.

Next, press READ to proceed to the specified

program’s STEP “1”.

Then, use UP & DOWN to check and confirm every

step.

PRG 8

STEP 1

″

″

″

〟

0068.0

Blinking

PRG 8

STEP 2

″

″

″

〟

0000.0

Blinking

PRG 8

STEP 2

″

″

″

〟

0030.5

Blinking

PRG 8

STEP 3

″

″

″

〟

0000.0

Blinking

PRG 8

STEP 1

0068.0

″

″

″

〟

Blinking

PRG 1

STEP 1

0050.0

″

″

″

〟

Blinking

Page 47

44

9-3 Selection of Dip Switch

No.1・・・The Identification of Origin

OFF・・・・When cylinder stops, if there is no signal feedback from sensor within t1 (Preset data,P7),

counter value will be reseted to “0” and origin is obtained / recognized.

Generally, origin will be at the stroke end.

If origin is set within the stroke, install stopper with respect to the origin.

ON・・・・・When the cylinder stops at origin, situated at the location where auto switch or limit switch

is, and sensor signal is not feedback within t1, counter value will be reset to “0.0” and

origin is obtained.

Install the origin wire to terminal 10.

No.2・・・The Setting of Braking System

OFF・・・・In this state, ON means brake is activated. OFF means brake is in releasing state.

If power supply of controller is cut off, the brake will be in releasing state.

If cylinder is mounted horizontally and the air balance is not achieved, when power is cut

off, the cylinder may keep moving in and out.

If cylinder is mounted vertically, when power is cut off, cylinder rod will fall to the bottom

end, due to its own weight.

ON・・・・・In this state, OFF means brake is activated, ON means brake is in releasing state.

If power supply of controller is cut off, the brake will be in clamping state.

Note: Please take note at piping, which may lead to opposite setting.

No.3・・・The Change of Counter Direction

OFF・・・・The extend direction will be an increment on counter.

The origin is set to be at the retract end.

ON・・・・・The retract direction will be an increment on counter.

The origin is set to be at the extend end.

Note: Please take note at wiring as it may result to opposite

setting.

No.4・・・Delection of Memory: Delete all the input data, back to the initial state.

Generally, set the state to OFF. If input data is required to be deleted, set the state to ON. Next,

reset the power supply through terminal 13. After achieving the initial state, set the state back to

OFF.

10. Driving

10-1 Setting of Origin Direction

Location’s detection method used by Monosashi-kun with brake cylinder is incremental method. Please

set the origin and reference accordingly.

Cylinder stroke end, either extend end or retract end, will be the origin. When dealing with cylinder with

cushion, please do not over monitoring the cushion effect.

When stopper is used, please use shock absorber to prevent from the occurrence of impact and “spring

back” effect.

Retract End

Extend

Extend End

Retract

Page 48

45

10-2 Adjustment of Air Balance

Due to the stoppage precision, the rate of occurring of abnormal operation, etc. Will be greatly affected

by the stability of air flow. Please monitor closely to achieve air balancing of cylinder.

Adjustment

1

Manually operate the controller or directional valve & brake valve to shift the piston rod to the center of

stroke.

2

Release the brake and carry out adjustment through pressure reducing valve. Remember, piston rod

should not move during adjustment. Release the brake through brake valve or controller dip switch

No.2.

3

After completion of the adjustment, manually operate brake valve to release and lock the brake system

for a few times. If piston rod is moving during operation, redo the adjustment.

4

Lastly, check it with testing the attainment of desired location.

If piston rod moves to the extreme end or with extraordinarily speed, redo the above adjustment.

Note: If the braking assembly unit has been changed, reset the controller.

11. Error Messages & Countermeasures

11-1 Controller

Err1: Sub-CPU’s ROM, RAM Error

Content

: During power supply to sub-CPU is on, ROM or RAM is found faulty.

Solution

: Reset & Retry.

Countermeasure

: After resetting, if error occurs again, ROM. RAM may have faulty. Change

ROM.RAM.

Err2: Main-CPU’s ROM, RAM Error

Content

: During power supply to sub-CPU is on, ROM or RAM is found faulty.

Solution

: Reset & Retry.

Countermeasure

: After resetting, if error occurs again, ROM. RAM may have faulty. Change

ROM.RAM.

Err3: Battery Error

Content

: During initial checkout, battery voltage less than 3.2V.

Input data can only be retained within 2 hours after the error detection.

Battery’s life is 5 years from the purchasing data.

Solution

: Press ON (UP & DOWN).

Countermeasure

: Change battery. After changing, verify input data. If data has been deleted,

re-input. After resetting, operation of cylinder is still possible.

However, during operation. LCD display will show that “PRG” is blinking. With

the power supply ON, data can be retained as long as 2 hours, after the error

massage appears. Therefore, do not cut off power supply, even during

interchanging of battery.

[Replacement in Japan]

The part No. of the replacement battery assembly is CEU2-H0125.

Please refer to the Battery assembly replacement procedure CE*-OMM0038-*

for replacement. Or please prepare a battery equivalent to the following

conditions and purchase a replacement battery holder assembly

(Part No.: CEU2-H0446) from SMC.Please refer to the Battery assembly

replacement procedure CE*-OMU0014-* for replacement.

[Replacement outside Japan]

Please prepare a battery equivalent to the following

conditions and purchase a replacement battery

holder assembly (Part No.: CEU2-H0446) from SMC.

Please refer to the Battery assembly replacement

procedure CE*-OMU0017-* for replacement.

Battery specifications

- Type: Lithium thionyl chloride battery

- Nominal voltage: 3.6 V - Capacity: 2600 mAh

- Size: Refer to the figure on the right.

<Example>

SAFT lithium battery part number LS14500

Page 49

46

Err4: Backup Error

Content

: After power supply is on or Reset signal is inputted, backup checking is

conducted, error is detected during output. Each and individual data is

checked through backup checking. Once, error is detected, clear the error and

at the same time, data will be deleted too.

Err41・・・Preset Data Error

When this error appears, input data will be deleted. Re-input is

required.

Err42・・・Program Data Error

When this error appears, input position’s data will be deleted.

Re-input is required.

Err43・・・Learning Data Error

When this error appears, learning data will be deleted and lead to

the operation of predictive control (retries will perform again).

When errors appear, re-entry of data is required.

Solution

: Press ON (UP or DOWN).

Countermeasure

: Check below 5 points and execute accordingly.

1

Check whether reset is executed during the execution of controller or during

motion.

Besides that, please verify wiring and sequence of the program.

2

Verify whether AC100V’s deviation is within the tolerance level,

±15% (AC85~115V).

3

Verify the power supply (AC100V) has been toggled within 20ms.

4

Check whether controller’s FG (frame ground) is being connected to earth.

5

Verify that there is no moving signal feedback from sensor while the power

is being cut off.

Err5: Data Error

Content

: 1

During presetting of data, over stating the cylinder’s stroke, or under

stating the moving distance of cylinder (less than 5mm), error will be

shown.

2

During operation, error will also appear, when moving distance is less

than 5mm. However, if the stop position is still within the tolerance of next

setting point, stop point will be determined and accepted.

<Example>

After inputting start, cylinder will stop at the position.

Solution

: During programming, press ON (UP or DOWN).

During moving state, press either ON or RESET.

Countermeasure

: If situation 1 and 2 occur, please change the program accordingly.

Err6: Learning Error

Content

: The stopping position is before the braking position.

50

Setting Point

Next Setting Point

57

Tolerance±4.0

Cylinder Stopping Position 53.1

Stop within the range

Tolerance±4.0

Page 50

47

There is no braking point within the moving distance.

Solution

: Reset or re-providing power supply.

Countermeasure

: Verify air balancing.

Verify whether there is any impact or momentum acting upon cylinder during

positioning. Verify that there is no entanglement or twisting.

Due to the momentum at the stroke end, setting of “0.0” as origin will lead to

high occurrence of errors.

Therefore, set the origin within “1.0~5.0”. Besides that, it is advisable to make

sure that cylinder rod should return to origin at the end of operation.

For cylinder with cushion, due to drastical change of speed within the stroke,

learning error may arise.

Therefore, for the case of stopping position within 30mm from stroke end is

required, it is advisable not to utilize cylinder with cushion.

Err7: No Program

Content

: There is no program being selected.

Program NO., which does not have any contents, is selected.

Solution

: Press ON or Reselect program.

Countermeasure

: Verify input.

Verify selected program, wiring or sequence of program inputted.

After the occurring of Err42, program will be deleted.

Please re-enter program.

Err8: Homing Error

Content

: When dip switch No.1 is set ON, error will show if homing is not performed.

When cylinder stops and limit switch at origin is still ON, homing will be

detected.

Solution

: Reset or Retry.

Countermeasure

: Ensure the origin detection switch is functioning (switch is on when cylinder

rod is at origin).

Ensure wiring is connected properly.

Ensure input signal sent by auto switch is fed to terminal 10 through input

monitor (red LED).

Ensure there is no twist at guide.

During the movement of cylinder rod, ensure that it will not stop within origin

detection time.

Err9: Positioning Error

Content

: Accurate positioning was not performed within specified preset retries (Preset

Data, P3) or preset tolerance (Preset Data, P2).

When Err9 occurs, there are 2 possibilies of errors.

First error due to Err9. Secondly, it may due to abnormal stoppage position.

Recognize the errors, so as to execute accurate remedy.

Stopping Point

Braking Point

Setting Point

Next Stopping Point

Braking Point

Stopping Point

Page 51

48

Solution

: Press either ON or RESET.

When ON is used to remedy situation, next program step will be executed.

However, Err5 will occur if the stopping position when Err9 occurs, is less than

5mm away from the next program step’s specified value. In this case, homing

should be done. Restart the program.

When RESET is used, homing will be performed and operation will go back to

initial state, program step No.1 and restart.

Countermeasure

: Ensure there is no variation on load or pressure.

Ensure air balance state. Ensure there is no twist at guide.

Ensure there is no momentum and impact acting on cylinder while positioning

is performed.

Err10: Emergency Stop

Content

: Display shows emergency stop.

Solution

: Disable the emergency stop signal.

Err11: Processing Error

Content

: Processing error by Sub-CPU is detected.

Solution

: Reset or Retry.

Countermeasure

: If error re-occurs, change the controller.

Err12: Operating Error

Solution

: Press either ON or RESET.

Countermeasure

: Ensure there is no twist at guide.

During the movement of cylinder rod, ensure that it will not stop within

operating error detection’s time. Re-adjust operating error detection’s time.

11-2 Brake Unit’s Life Span

Change the brake unit, when life span of 2 million cycles has been achieved. Check its life span

through the following method: -

a Check the lock pin’s check gap dimension.

b Check through controller preset data (P6), which records the brake’s operation cycle No.

*Check the lock pin. When check gap, L, is 1mm or less, change brake unit

*Check the controller. When the value of 200.0 is reached, change brake unit.

The 2 million cycle life span assumes following conditions:

a Piston speed : 300mm/sec

b 50% load or less when horizontally mounted.

c 35% or less when vertically mounted.

(Within allowable kinetic energy range.)

PRG

STEP P6

200.0

L

Pressure lock port

Lock release port

Page 52

49

12. Appendix

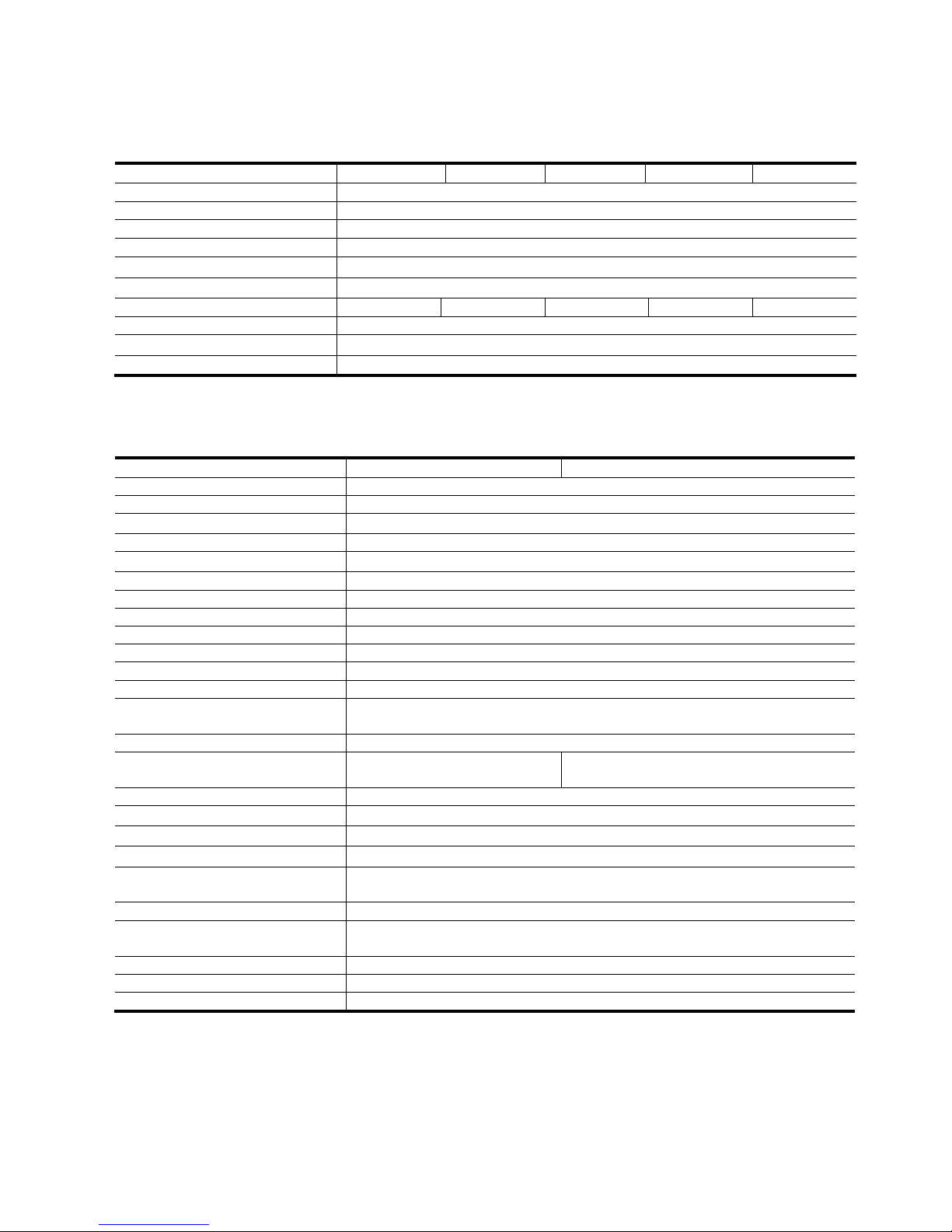

12-1 Data Sheet

●Parameter

Preset Data Dip Switch Setting

●Program Data (Determined Position Data)

No. Data Name

P1 Cylinder Stroke

P2 Tolerence

P3 Retries

P4 Bore Size

P5 Load Rate

P6

No. of Brake Operation

P7

Origin Confirmation Time

P8

Err12's Confirmation Time

No. Setting

No.1

OFF ON

No.2

OFF ON

No.3

OFF ON

No.4

OFF ON

Program

Step

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

5678123

4

Page 53

50

Program

Step

1

2

3