Page 1

文書 No.JCRB-OM00003

Model name

ROTARY ACTUATOR

Standard Type

Part number / Series

C

RB10

to

40-

Page 2

INDEX

Precautions for Safety Front matter

1. Product Description 1

How to order 1

Specifications 1

Effective Torque 2

Chamfer Position and Rotation Range 3

2. Internal Construction and Description of Individual Parts 4

Standard Type (Size 10, 15) 4

Standard Type (Size 20, 30, 40) 5

With Auto Switch 6

Auto Switch Proper Mounting Position 7

Operating Angle and Hysteresis Angle 7

3. Basic Circuit 8

Circuit Configuration 8

Preferred Components 8

4. Setting 8

Shaft Load Limit 9

Use of Shaft Coupling 9

How to Mount Loads 10

Mounting 10

Adjusting the rotating angle 11

Operating environment 12

5. Setting of Rotation Time 13

Moment of Inertia 13

Kinetic Energy 15

Eternal Stopper 16

6. Maintenance and Inspection 17

Standard Type (Size 10, 15) 17

Standard Type (Size 20, 30, 40) 18

With Auto Switch (Size 20, 30, 40) 19

7. Troubleshooting 20

Notice on Trouble and Troubleshooting 21

Page 3

前付 1

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/ or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger”.

They are all important notes for safety and must be followed in addition to International Standards (ISO/ IEC)

Japan Industrial Standards (JIS)

*1)

and other safety regulations.

*1)

ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

etc.

Caution

Operator error could result in injury or equipment damage.

Warning

Operator error could result in serious injury or loss of life.

Danger

In extreme conditions, there is a possibility of serious injury or loss of life.

Page 4

前付 2

Warning

1. The compatibility of the product is the responsibility of the person who designs the

equipment or decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with

specific equipment must be decided by the person who designs the equipment or decides its

specifications based on necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of

the person who has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest

catalog information, with a view to giving due consideration to any possibility of equipment failure

when configuring the equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products

must be performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is

confirmed.

1) The inspection and maintenance of machinery/equipment should only be performed after

measures to prevent falling or runaway of the driven objects have been confirmed.

2) When the product is to be removed, confirm that the safety measures as mentioned above

are implemented and the power from any appropriate source is cut, and read and understand

the specific product precautions of all relevant products carefully.

3) Before machinery/equipment is restarted, take measures to prevent unexpected operation

and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product

is to be used in any of the following conditions.

1) Conditions and environments outside of the given specifications, or use outdoors or in a place

exposed to direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways, air navigation, space,

shipping, vehicles, military, medical treatment, combustion and recreation, or equipment in

contact with food and beverages, emergency stop circuits, clutch and brake circuits in press

applications, safety equipment or other applications unsuitable for the standard specifications

described in the product catalog.

3) An application which could have negative effects on people, property, or animals requiring

special safety analysis.

4) Use in an interlock circuit, which requires the provision of double interlock for possible failure

by using a mechanical protective function, and periodical checks to confirm proper operation.

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange

specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Page 5

前付 3

Limited warranty and Disclaimer / Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and

“Compliance Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

1. The warranty period of the product is 1 year in service or 1.5 years after the product is

delivered, whichever is first.

*2)

Also, the product may have specified durability, running distance or replacement parts.

Please consult your nearest sales branch.

2. For any failure or damage reported within the warranty period which is clearly our

responsibility, a replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other

damage incurred due to the failure of the product.

3. Prior to using SMC products, please read and understand the warranty terms and

disclaimers noted in the specified catalog for the particular products.

*

2)

Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.

Also, even within the warranty period, the wear of a product due to the use of the vacuum pad or failure due

to the deterioration of rubber material are not covered by the limited warranty.

Compliance Requirements

When the product is exported, strictly follow the laws required by the Ministry of Economy,

Trade and Industry (Foreign Exchange and Foreign Trade Control Law).

Page 6

前付 4

Design / Selection

(1) Confirm the specifications.

Products represented in this catalog are designed only for use in compressed air systems.

Do not operate at pressures or temperatures, etc., beyond the range of specifications, as this can cause

damage or malfunction. (Refer to the specifications.)

Please contact SMC when using a fluid other than compressed air.

We do not guarantee against any damage if the product is used outside of the specification range.

(2) If the operation involves load fluctuations, ascending/descending movements, or changes in friction

resistance, make sure to provide safety measures.

Failure to provide such measures could accelerate the movement, which may be hazardous

to humans, machinery, and other equipment.

(3) If there is a chance that the product will pose a hazard to humans, install a protective cover.

If the moving portion of the product will pose a hazard to humans or will damage machinery or equipment,

provide a construction that prevents direct contact with those areas.

(4) Make sure that the secured portions will not loosen.

Be sure to adopt a reliable connecting method if the rotary table is used very frequently or if it is used in a

location that is exposed to a large amount of vibrations.

(5) There may be cases in which a speed reduction circuit or a shock absorber is required.

If the driven object moves at high speeds or is heavy, it will be unfeasible for only the rotary actuator cushion

to absorb the shock. Therefore, provide a speed-reduction circuit to reduce the rotary actuator speed before

the thrust is applied to the cushion, or an external shock absorber to dampen the shock. If these

countermeasures are taken, make sure to take the rigidity of the mechanical equipment into consideration.

(6) Consider the possibility of a reduction in the circuit air pressure caused by a power failure.

When an actuator is used as clamping mechanism, there is a danger of workpiece dropping if there is a

decrease in clamping force, due to a drop in circuit pressure caused by a power failure. Therefore, safety

equipment should be installed to prevent damage to machinery and bodily injury.

(7) Consider the possibility of power source related malfunctions that could occur.

For equipment that relies on power sources such as compressed air, electricity, or hydraulic pressure, adopt

countermeasures to prevent the equipment from causing a hazard to humans or damage to the equipment in

the event of malfunction.

(8) If a speed controller is provided in the exhaust restrictor, implement a safety design taking the residual

pressure into consideration.

If air pressure is applied to the air supply side without residual pressure in the exhaust side, the rotary actuator

will operate at abnormally high speeds, which could pose a hazard to humans and damage the machinery and

equipment.

(9) Consider the behavior of the rotary actuator in the event of an emergency stop.

Devise a safe system so that if a person engages the emergency stop, or if a safety device is tripped during a

system malfunction such as a power failure, the movement of the rotary actuator will not cause a hazard to

humans or damage the equipment.

(10) Consider the action of the rotary actuator when restarting after an emergency stop.

Devise a safe design so that the restarting of the rotary actuator will not pose a hazard to humans or damage

the equipment. Install manually controlled equipment for safety when the actuator has to be reset to the starting

position.

(11) Do not use the product as a shock absorber.

If an abnormal pressure or air leakage occurs, the rotary actuator speed reduction capability could become

severely affected, which could pose a hazard to humans and damage the machinery and equipment.

Warning

Page 7

前付 5

(12) Select a speed within the product’s allowable energy value.

If the kinetic energy of the load exceeds the allowable value, it could damage the product, and cause a

hazard to humans and damage the machinery and equipment.

(13) Provide a shock absorber if the kinetic energy that is applied to the product exceeds the

allowable value.

If the product’s kinetic energy exceeds the allowable value, it could damage the product, and cause a hazard

to humans and damage the machinery or equipment.

(14) Do not stop or hold the product at midpoint by keeping air pressure in the product.

For a product without an external stopping mechanism, if a directional control valve is closed to keep the air

pressure in the product, in an attempt to stop the product at midpoint, it might not be possible to maintain

that stopped position due to an air leakage. As a result, it could pose a hazard to humans and cause

damage to machinery and/or equipment.

(15) Do not use two or more rotary actuator with the aim of synchronized movement.

One of the actuators may bear the load of operation, making synchronized movement impossible, and

possibly leading to deformation of the equipment.

(16) Do not use in a location where external leakage of lubricant could have an adverse effect.

The lubricant coating the interior of the product may leak to the outside of the product from connecting parts

of the rotary body, cover, etc.

(17) Do not disassemble the product or make any modifications, including additional machining.

This may cause human injury and/or an accident.

(18) Refer to the Auto Switches Precautions when using with an auto switch.

Selection

(1) Do not use below the adjustment range specified for the product.

If the product is used below the specified speed adjustment range, it could cause the product to stick, slip, or

the movement to stop.

(2) Do not apply external torque to the product that exceeds the rated output.

If an external force that exceeds the product’s rated output is applied to the product, it could damage the

product.

(3) If it is necessary to provide repeatability of the rotation angle, directly stop the load externally.

Even with a product that is equipped with an angle adjuster, there are times when the initial rotation angle

could change.

(4) Do not use the product under hydraulic pressure.

The product will be damaged if it is used by applying hydraulic pressure.

(5) Do not use in a location where there are many temperature fluctuations.

When using in lower temperature applications, take care not to allow frost inside the cylinder.

Operation may be unstable.

(6) Perform speed adjustment in the environment in which the product is to be used.

Speed adjustments may be necessary if the environmental conditions vary.

Caution

Page 8

前付 6

Mounting

(1) Operation manual

Install the product and operate it only after reading the operation manual carefully and understanding its

contents. Also, keep the manual in a location where it can be referred to as necessary.

(2) Ensure sufficient space for maintenance activities.

When installing the products, allow access for maintenance.

(3) Tighten threads with the proper tightening torque.

When installing the products, follow the listed torque specifications.

(4) Before adjusting the angle by supplying air pressure, take appropriate measures to prevent the

equipment from rotating unnecessarily.

When an adjustment is performed under air pressure, the equipment could rotate and fall during the adjustment,

depending on the mounted posture of the equipment. As a result, it could pose a hazard to humans and damage

the machinery and equipment.

(5) Do not place a magnetic object near the product.

The auto switch is a magnetic sensing type. If a magnetic object is placed close to it, the rotary actuator could

operate suddenly, which could pose a hazard to humans and damage the machinery and equipment.

(6) Do not perform additional machining to the product.

Additional machining to the product can result in insufficient strength and cause damage to the product.

This can lead to possible human injury and damage to the surrounding equipment.

(7) Do not enlarge the fixed throttle by modifying the pipe connectors.

If the hole diameter is enlarged, the product’s rotation speed will increase, causing the shock force to increase

and damage to the product. As a result, it could pose a hazard to humans and damage the machinery and

equipment.

(8) If shaft couplings are to be used, use those with angular freedom.

If shaft couplings that lack angular freedom are used, they could scrape due to eccentricity, leading to

equipment malfunction and product damage. As a result, it could pose a hazard to humans and damage the

machinery and equipment.

(9) Do not apply a load that exceeds the values given in the catalog.

If a load that exceeds the allowable values is applied to the product, it could lead to equipment malfunction, a

hazard to humans, and damage to the machinery and equipment.

(10) Place an external stopper in a position away from the rotating shaft.

If the stopper is placed near the rotating shaft, the torque that is generated by the product itself will cause the

reaction force which is directed to the stopper to be redirected and applied to the rotating shaft. This will lead

to the breakage of the rotating shaft and bearing. As a result, it could pose a hazard to humans and damage

the machinery and equipment.

Precautions when using external stoppers

Be sure to install external stoppers in the proper places. Installation in the wrong place can result in equipment

breakage, which could damage other equipment or cause human injury.

Warning

Page 9

前付 7

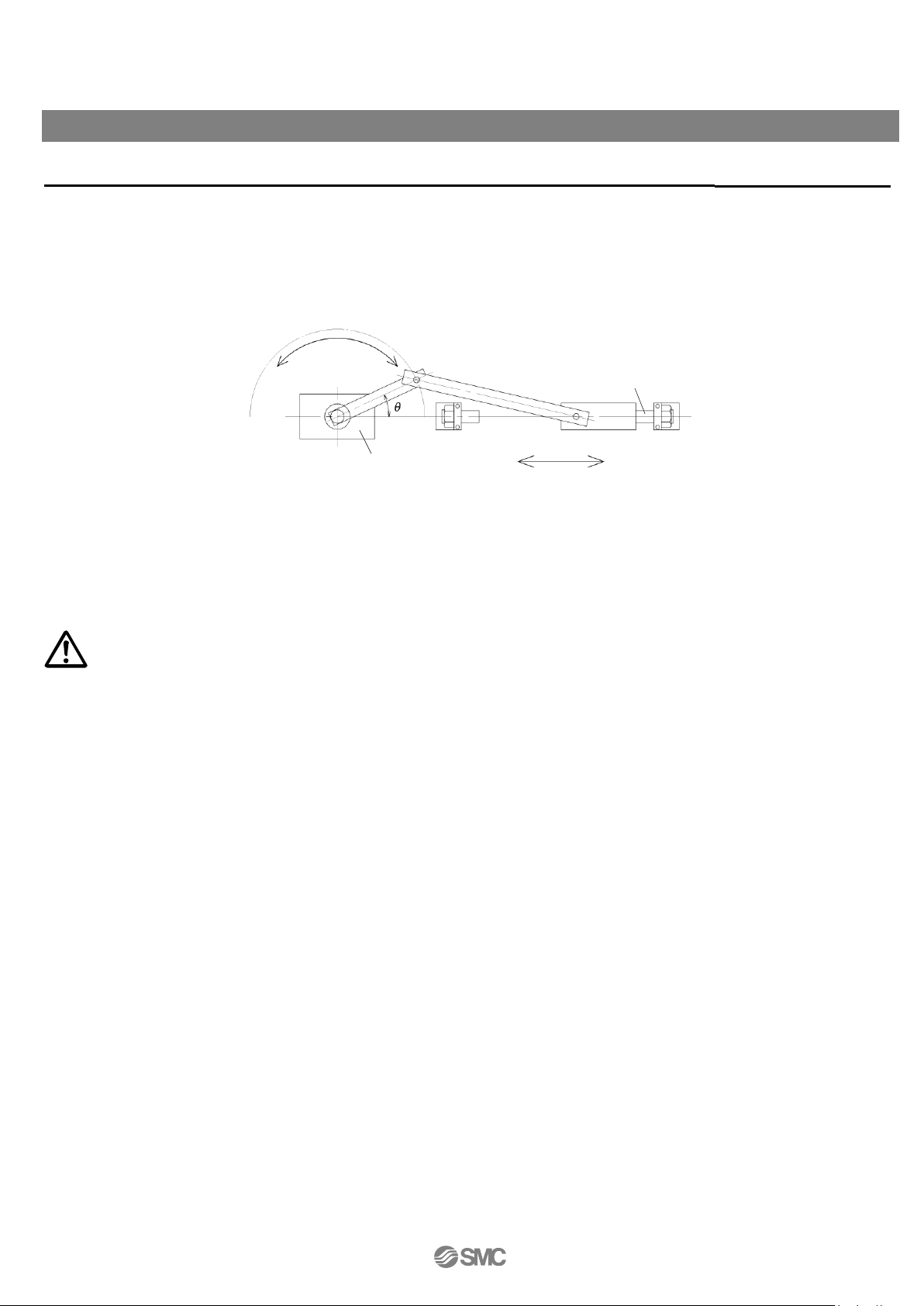

Precautions when Converting Rotational Motion to Linear Motion

When using a link mechanism, etc., to convert rotational motion to linear motion, and determining the operation

end using the stopper on the linear motion end (see below), a small value for θ at the operation end may result in

the torque of the rotary actuator causing excessive radial load to act on the output axle, and equipment breakage

may occur.

Install a stopper on the rotation motion side, or increase the value of θ at the operation end, to make sure the load

generated does not exceed the allowable value for the product.

(11) Do not use springs, etc., to add force in the rotational movement direction.

When rotational force from an external spring, etc., acts and generates negative pressure on the product’s

interior, breakage of the internal seal or acceleration of abrasion may occur.

(1) Do not use organic solvent to wipe the area of the name plate that shows the model.

It will erase what is indicated on the name plate.

(2) Do not hit the output shaft by securing the body or hit the body by securing the output shaft.

These actions could cause the table to bend or damage the bearing. When a load must be coupled to the output

shaft, secure the output shaft.

(3) Do not step directly onto the table or on the equipment that is coupled to the table.

Standing directly on the output shaft could cause the output shaft or the bearing to become damaged.

(4) If a product is equipped with an angle adjustment function, use it within the specified adjustment range.

If the product is used outside the specified adjustment range, it could lead to equipment malfunction or product

damage. Refer to the product specifications for details on the adjustment range of the products.

ストッパ

Rotary table

Stopper

Caution

Page 10

前付 8

Piping

(1) Refer to the Fittings and Tubing Precautions (Best Pneumatics No.6) for handling one touch fittings.

(2) Preparation before piping

Before piping is connected, it should be thoroughly blown out with air (flushing) or washed to remove chips,

cutting oil and other debris from inside the pipe.

(3) Wrapping of pipe tape

When screwing piping or fittings into ports, ensure that chips from the pipe threads or sealing material do not

enter the piping. Also, if pipe tape is used, leave 1.5 to 2 thread ridges exposed at the end of the threads.

Speed and cushion adjustment

(1) To make a speed adjustment, gradually adjust starting from the low speed end.

If the speed adjustment is performed from the high speed end, it could damage the product.

As a result, it could pose a hazard to humans and damage the machinery and equipment.

For products with shock absorbers, when the shock absorber stops moving before reaching the stroke

end by using a stopper mechanism with the objective of shortening tact time, be sure the shock

absorber is stopped in a position where it has adequately absorbed the kinetic energy.

Failure to do so can result in damage to equipment.

Lubrication

(1) This product should be used without lubrication. Although it will operate even if it is lubricated, it could

lead to sticking or slipping.

Pipe tape

Leave approx.

2 threads exposed

Winding

direction

Caution

Warning

Warning

Page 11

前付 9

Air Supply

(1) Type of fluids

Please consult with SMC when using the product in applications other than compressed air.

(2) When there is a large amount of moisture

Compressed air containing a large amount of moisture can cause malfunction of pneumatic equipment. An air

dryer or water separator should be installed upstream from filters.

(3) Drain flushing

If condensation in the drain bowl is not emptied on a regular basis, the bowl will overflow and allow the

condensation to enter the compressed air lines. This may cause malfunction of pneumatic equipment.

If the drain bowl is difficult to check and remove, installation of a drain bowl with an auto drain option is

recommended.

(1) When extremely dry air is used as the fluid, degradation of the lubrication properties inside the

equipment may occur, resulting in reduced reliability (or reduced service life) of the equipment. Please

consult with SMC.

(2) Install an air filter.

Install an air filter upstream near the valve. Select an air filter with a filtration size of 5μm or smaller.

(3) Take measures to ensure air quality, such as by installing an aftercooler, air dryer, or water separator.

Compressed air that contains a large amount of moisture can cause malfunction of pneumatic equipment such

as rotary actuator. Therefore, take appropriate measures to ensure air quality, such as by providing an

aftercooler, air dryer, or water separator.

(4) Ensure that the fluid and ambient temperature are within the specified range.

If the fluid temperature is 5°C or less, the moisture in the circuit could freeze, causing damage to the seals and

equipment malfunction. Therefore, take appropriate measures to prevent freezing.

Operating Environment

(1) Do not use in an atmosphere containing corrosive gases, chemicals, sea water, water, steam, or where

there is direct contact with any of these.

Refer to the construction diagram for information on the materials used in the rotary actuator.

(2) Do not expose the product to direct sunlight for an extended period of time.

(3) Do not use in a place subject to heavy vibration and/or shock.

(4) Do not mount the product in locations where it is exposed to radiant heat.

(5) Do not use in dusty locations or where water oil, etc., splash on the equipment.

Warning

Caution

Warning

Page 12

前付 10

Maintenance

(1) Perform maintenance inspection according to the procedures indicated in the operation manual.

If handled improperly, malfunction and damage of machinery or equipment may occur.

(2) Maintenance work

If handled improperly, compressed air can be dangerous. Assembly, handling, repair and element replacement

of pneumatic systems should be performed by a knowledgeable and experienced person.

(3) Drain flushing

Remove drainage moisture from air filters regularly.

(4) Removal of equipment, and supply/exhaust of compressed air

When components are removed, first confirm that measures are in place to prevent workpieces from dropping,

run-away equipment, etc. Then, cut off the supply pressure and electric power, and exhaust all compressed air

from the system using the residual pressure release function.

When machinery is restarted, proceed with caution after confirming that appropriate measures are in place to

prevent cylinders from sudden movement.

(1) For lubrication, use the designated grease for each specific product.

The use of a non-designated lubricant could damage the seals.

Warning

Caution

Page 13

前付 11

Auto Switches Precautions

Design / Selection

(1) Confirm the specifications.

Read the specifications carefully and use this product appropriately. The product may be damaged or

malfunction if it is used outside the range of specifications of current load, voltage, temperature or impact.

We do not guarantee against any damage if the product is used outside of the specification range.

(2) Cautions for use in an interlock circuit

When an auto switch is used for an interlock signal requiring high reliability, devise a double interlock system

to avoid trouble by providing a mechanical protection function, or by also using another switch (sensor) together

with the auto switch.

Also, perform regular maintenance and confirm proper operation.

(3) Do not make any modifications (including exchanging the printed circuit boards) to the product.

This may cause human injuries and accidents.

(1) Pay attention to the length of time when a switch is ON at an intermediate stroke position.

When an auto switch is placed at an intermediate position of the stroke and a load is driven, at the time the

piston passes the auto switch will operate, but if the speed is too great the operating time will be shortened and

the load may not operate properly.

The maximum piston speed is:

V ( mm / s ) = ×1000

(2) Keep wiring as short as possible.

<Reed>

As the length of the wiring to a load gets longer, the rush current at switching ON becomes greater, and this

may shorten the product’s life. (The switch will stay ON all the time.)

1) Use a contact protection box when the wire length is 5m or longer.

2) Even if an auto switch has a built-in contact protection circuit, when the wiring is more than 30m long, it is

not able to adequately absorb the rush current and its life may be reduced.

It is again necessary to connect a contact protection box in order to extend its life. Please consult SMC in

this case.

<Solid state>

3) Although wire length should not affect switch function, use a wire 100m or shorter.

Even if the length is less than 100m, longer wiring makes it more likely to be affected by noise.

When the wire length is long, we recommended a ferrite core should be attached to both ends of the cable

to prevent excess noise.

A contact protection box is not necessary for solid state switches due to the nature of the product construction.

Auto switch operating range (mm)

Load applied time (ms)

Warning

Caution

Page 14

前付 12

(3) Do not use a load that generates surge voltage. If a surge voltage is generated,

discharge may be generated at the contact, possibly reducing the product life.

If driving a load such as a relay that generates a surge voltage.

<Reed>

Use an auto switch with built-in contact protection circuit or use a contact protection box.

<Solid state>

Use a built-in surge absorbing element type device.

(4) Take precautions when multiple rotary actuator are used close together.

When multiple auto switch rotary actuator are used in close proximity, magnetic field interference may cause

the auto switches to malfunction. Maintain a minimum separation of 40mm between rotary actuator.

The auto switches may malfunction due to the interference from the magnetic fields.

Use of a magnetic screen plate (MU-S025) or commercially available magnetic screening tape can reduce the

interference of magnetic force.

(5) Pay attention to the internal voltage drop of the auto switch.

<Reed>

1) Auto switch with an indicator light

● If auto switches are connected in series as shown below, note that there will be a large voltage drop because

of internal resistance in the LED. (Refer to the internal voltage drop in the auto switch specifications.)

[The voltage drop will be “n” times larger when “n” auto switches are connected.]

Even though an auto switch operates normally, the load may not operate.

● In the same way, when operating under a specified voltage, although an auto switch may operate normally,

the load may not operate. Therefore, the formula below should be satisfied after confirming the minimum

operating voltage of the load.

Supply Internal voltage Minimum operating

voltage drop of auto switch voltage of load

2) If the internal resistance of an LED causes a problem, select an auto switch without an indicator light.

<Solid state / 2-wire type>

3) Generally, the internal voltage drop will be greater with a 2-wire solid state auto switch than with a reed auto

switch. Take the same precautions as in 1).

Also, take note that a 12VDC relay is not applicable.

(6) Pay attention to leakage current.

<Solid state / 2-wire type>

Current (leakage current) flows to the load to operate the internal circuit even when in the OFF state.

Operating current of load (OFF condition) > Leakage current

If the criteria given in the above formula are not met, it will not reset correctly (stays ON).

Use a 3-wire switch if this specification will not be satisfied.

Moreover, leakage current flow to the load will be “n” times larger when “n” auto switches are connected in

parallel.

(7) Ensure sufficient clearance for maintenance activities.

When designing an application, be certain to allow sufficient clearance for maintenance.

(8) Use the rotary actuator and auto switch in proper combination.

The auto switch is pre-adjusted to operate properly for an auto-switch-capable SMC rotary actuator.

If the auto switch is mounted improperly, used for another brand of rotary actuator or used after changing the

machine installation, the auto switch may not operate properly.

Load

>

Page 15

前付 13

Mounting / Adjustment

(1) Do not drop or bump.

Do not drop, bump or apply excessive impacts (300m/s2 or more for reed auto switches and 1000m/s2 or more

for solid state auto switches) while handling. Although the body of the auto switch may not be damaged, the

inside of the auto switch could be damaged and cause malfunction.

(2) Observe the proper tightening torque for mounting an auto switch.

When an auto switch is tightened beyond the range of tightening torque, auto switch mounting screws, auto

switch mounting brackets or auto switch may be damaged.

On the other hand, tightening below the range of tightening torque may allow the auto switch to slip out of

position.

(3) Do not carry a rotary actuator by the auto switch lead wires.

Never carry a rotary actuator by its lead wires. This may not only cause broken lead wires, but it may cause

internal elements of the auto switch to be damaged by the stress.

(4) Fix the auto switch using the appropriate screws on the switch body. If other screws are used, the auto

switch may be damaged.

Wiring

(1) Confirm proper insulation of wiring.

Be certain that there is no faulty wiring insulation (contact with other circuits, ground fault, improper insulation

between terminals, etc.). Damage may occur due to excess current flow into the auto switch.

(2) Do not wire with power lines or high voltage lines.

Wire separately from power lines or high voltage lines, avoiding parallel wiring or wiring in the same conduit

with these lines. Control circuits containing auto switches may malfunction due to noise from these other lines.

(3) Avoid repeatedly bending or stretching lead wires.

Broken lead wires will result from repeatedly applying bending stress or stretching forces to the lead wires.

Stress and tensile force applied to the connection between the cable and auto switch increases the possibility

of disconnection.

Fix the cable in the middle so that it is not movable in the area where it connects with the auto switch.

(4) Be certain to connect the load before power is applied.

<2-wire type>

If the power is turned ON when an auto switch is not connected to a load, the auto switch will be instantly

damaged because of excess current (Short circuit).

It is the same as when the 2-wire brown lead wire (+, output) is directly connected to the (+) power supply

terminal.

(5) Do not allow short-circuit of loads.

<Reed>

If the power is turned ON with a load in a short circuit condition, the switch will be instantly damaged because

of excess current flow into the switch.

<Solid state>

PNP output type auto switches do not have built-in short circuit prevention circuits.

If a load is short circuited, the auto switch will be instantly damaged as in the case of reed auto switches.

Take special care to avoid reverse wiring with the brown power supply line and the black output line on 3-wire

type auto switches.

Caution

Caution

Page 16

前付 14

(6) Avoid incorrect wiring.

<Reed>

A 24 VDC auto switch with indicator light has polarity. The brown lead wire or terminal No.1 is (+), and the blue

lead wire or terminal No.2 is (-).

1) If connections are reversed, the auto switch will operate, however, the LED will not light up.

Also, take note that a current greater than that specified will damage the LED and it will no longer operate.

Applicable models: D-93, A93V

<Solid state>

1) If connections are reversed on a 2-wire type auto switch, the auto switch will not be damaged if protected by

a protection circuit, but the auto switch will always stay in an ON state. However, it is still necessary to avoid

reversed connections, since the auto switch could be damaged by a load short circuit in this condition.

2) If connections are reversed (power supply line + and power supply line-) on a 3-wire type auto switch, the

auto switch will be protected by a protection circuit. However, if the power supply line (+) is connected to the

blue wire and the power supply line (-) is connected to the black wire, the auto switch will be damaged.

When the cable sheath is stripped, confirm the stripping direction. The insulator may be split or damaged

depending on the direction. (D-M9□ only)

Operation Environment

(1) Never use in an atmosphere with explosive gases.

Auto switches are not designed with explosion-proof construction. Never use in an atmosphere containing

explosive gas since this may cause a serious explosion.

Please contact SMC concerting ATEX compliant products.

(1) Do not use in an area where a magnetic field is generated.

Auto switches will malfunction or magnets inside rotary actuator will become demagnetized. (Please consult

with SMC if a magnetic field resistant auto switch can be used.)

(2) Do not use in an environment where the auto switch will be continually exposed to water.

Although auto switches satisfy IEC standard IP67 construction (JIS C 0920: watertight construction), do not

use auto switches in applications where continually exposed to water splash or spray. Poor insulation or

swelling of the potting resin inside auto switches may cause malfunction.

Recommended Tool

Description

Model

Wire stripper

D-M9N-SWY

* Stripper for a round cable (

2.0) can

be used for a 2-wire type cable.

Warning

Caution

Page 17

前付 15

(3) Do not use in an environment with oil or chemicals.

Please consult with SMC if auto switches will be used in an environment with coolant, cleaning solvent, various

oils or chemicals. If auto switches are used under these conditions for even a short time, they may be adversely

affected by improper insulation, malfunction due to swelling of the potting resin, or hardening of the lead wires.

(4) Do not use in an environment with temperature cycles.

Please consult with SMC if switches are used where there are temperature cycles other than normal

temperature changes, as there may be adverse effects inside the auto switches.

(5) Do not use in an environment where there is excessive impact shock.

<Reed>

When excessive impact (300m/s2 or more) is applied to a reed auto switch during operation, the contacts may

malfunction and generate or cut off a signal momentarily (1ms or less). Please consult with SMC if a solid

state auto switch can be used according to the environment.

(6) Do not use in an area where surges are generated.

<Solid state>

When there are units (solenoid lifter, high frequency induction furnace, motor, radio equipment etc.) which

generate a large amount of surge in the area around the rotary actuator with solid state auto switches, this

may cause deterioration or damage to the auto switch’s internal circuit elements. Avoid sources of surge

generation and crossed lines.

(7) Avoid accumulation of iron debris or close contact with magnetic substances.

When a large amount of iron debris such as machining chips or spatter is accumulated, or a magnetic substance

(something attracted by a magnet) is brought into close proximity with a rotary actuator with auto switches, or

a rotary actuator, it may cause the auto switch to malfunction due to a loss of the magnetic force inside the

rotary actuator.

(8) Please contact SMC concerning water resistance, elasticity of lead wires, usage at welding sites, etc.

(9) Do not use in direct sunlight.

(10) Do not mount the product in locations where it is exposed to radiant heat.

Maintenance

(1) Removal of equipment, and supply/exhaust of compressed air.

Before any machinery or equipment is removed, first ensure that the appropriate measures are in place to

prevent the fall or erratic movement of driven objects and equipment, then cut off the electric power and reduce

the pressure in the system to zero. Only then should you proceed with the removal of any machinery and

equipment.

When machinery is restarted, proceed with caution after confirming that appropriate measures are in place to

prevent actuators from moving suddenly.

(1) Perform the following maintenance periodically in order to prevent possible danger due to unexpected

auto switch malfunction.

1) Secure and tighten auto switch mounting screws.

If screws become loose or the mounting, position is dislocated, retighten them after readjusting the mounting

position.

2) Confirm that there is no damage to lead wires.

To prevent faulty insulation, replace auto switches or repair lead wires, etc., if damage is discovered.

3) Confirm the lighting of the green light on the 2-color indicator type auto switch.

Confirm that the green LED is on when stopped at the established position. If the red LED is on, the mounting

position is not appropriate. Readjust the mounting position until the green LED lights up.

Warning

Caution

Page 18

1

1. Product Description

This manual describes the operation of the vane type compact rotary actuator,

CRB Series.

Confirm the operating conditions such as load size (inertial moment), rotating time, and the product

specifications before using this product.

How to Order

Specifications

Size

10

15

20

30

40

Rotating angle range

90°

+5°/0

180°

+5°/0

90°

+4°/0

180°

+4°/0

90°

±10°

180°

±10°

Fluid

Air (Non-lube)

Proof pressure [MPa]

1.05

1.5

Fluid temperature [

o

C]

5 to 60

o

C

Max. operating pressure [MPa]

0.7

1.0

Min. operating pressure [MPa]

0.2

Speed adjustable range [s / 90o]

(Note 2)

0.03 to 0.5

Note1)

0.04 to 0.5

0.07 to 0.5

Allowable kinetic energy [J]

0.00015

0.001

0.003

0.02

0.04

Shaft load

N

Radial

15

15

25

30

60

Thrust

10

10

20

25

40

Port size

M5 × 0.8

Note1)

Size 10 requires at least 0.35 MPa of operating pressure to reach the minimum rotation time (0.03 s/90°).

Note2)

Operate within the speed adjustable range.

Operation at a low speed outside of the speed adjustable limit may cause stick slip or operation failure.

It is difficult to make adjustments during use if rotation time is changed to 0.5 s/90° or lower.

C RB S 30 -90

CDRB S 30 -90-M9B L S

With auto switch

①

② ③ ④ ⑤ ⑥

⑦

① Built-in auto switch magnet

② Shaft type

S

Single shaft with single flat

(Sizes: 10 to 30)

Single shaft end key (Size: 40)

W

Double shaft with single flat

(Sizes: 10 to 30)

Long shaft end key, Short shaft with

single flat (Size: 40)

③ Size

10

15

20

30

40

④ Rotating angle

90

90°

180

180°

⑤ Auto switch

Nil

Without auto switch (Built-in magnet)

*For applicable auto switches, refer to the table below.

⑦ Number of auto switches

Nil 2 S

1

⑥ Lead wire length

Nil

Grommet / Lead wire: 0.5 m

M

Grommet/Lead wire: 1 m

L

Grommet/Lead wire: 3 m

Z*

Grommet/Lead wire: 5 m

* The 5 m lead wire is produced upon

receipt of order.

Page 19

2

Effective torque

Page 20

3

Chamfered Position and Rotation Range: Top View from Long Shaft Side

Chamfered positions shown below illustrate the conditions of actuators

when B port is pressurized.

Note)

The angle adjusting screw (adjustment bolt) is set at random within the adjustable rotating range.

Therefore, it must be re-adjusted to obtain the angle that suits your application. (Refer to page 11.)

For size 40 actuators, a parallel key will be used instead of chamfer.

Size

Recommended tightening torque for hexagon

nut to fix the adjustment bolt

20

1.5N・m

30,40

3.0 N・m

Page 21

4

部 Construction: Standard Type

Size:10,15

For 90

o

For 180o

Component Parts

No.

Description

Material

Note

1

Body (A)

Aluminum alloy

Painted

2

Body (B)

Aluminum alloy

Painted

3

Vane shaft

Stainless steel

4

Stopper

Resin

5

Stopper for 90

o

Resin

For 90

o

6

Holding rubber

NBR

For 90

o

7

Stopper seal

NBR

Special seal

8

Back-up ring

Stainless steel

9

Bearing

Bearing steel

10

O-ring

NBR

11

Hexagon socket head cap screw

Chrome molybdenum steel

Special screw

Page 22

5

Size:20,30,40

For 90

o

For 180o

Component Parts

No.

Description

Material

Note

1

Body (A)

Aluminum alloy

Painted

2

Body (B)

Aluminum alloy

Painted

3

Vane shaft

Stainless steel *

4

Stopper

Resin

5

Stopper for 90

o

Resin

For 90

o

6

Holding rubber

NBR

For 90

o

7

Stopper seal

NBR

Special seal

8

Back-up ring

Stainless steel

9

Bearing

Bearing steel

10

O-ring

NBR

11

Seal washer

NBR

12

Adjustment bolt

Chrome molybdenum steel

13

Hexagon nut

Steel wire

14

Hexagon socket head cap screw

Chrome molybdenum steel

Special screw

* The material is chrome molybdenum steel for sizes 30 and 40.

Page 23

6

Construction: Standard Type (With Auto Switch)

Size:10,15 Size:20,30,40

Component Parts

No.

Description

Material

1

Cover

Resin

2

Magnet holder

Resin

3

Magnet

Magnetic material

4

Body C

Resin

5

Switch plate

Aluminum alloy

6

Spring pin

Stainless steel

7

Cross recessed round head screw

Chrome molybdenum steel *

8

Cross recessed round head screw

Chrome molybdenum steel

* The material is stainless steel for sizes 10 and 15.

Page 24

7

Auto Switch Proper Mounting Position (at Rotation End Detection)

Operating Angle and Hysteresis Angle

Size

Solid state auto switch

D-M9□

A

10 6 15 6 20 6 30 6 40

6

Size

Solid state auto switch

D-M9□

Operating angle (θm)

Hysteresis angle

10

36

o

5

o

15

36

o

5o

20

20

o

5o

30

20

o

5o

40

20

o

5o

Note) Since the figures in the table on the left are

provided as a guideline only, they cannot

be guaranteed. Adjust the auto switch after

confirming the operating conditions in the

actual setting.

Proper tightening torque: 0.05 to 0.15 [N·m]

(mm)

Page 25

8

2. Basic circuit

Circuit Configuration

The standard circuit for operating a rotary actuator with an air filter, regulator, solenoid valve

and speed controller is shown in Fig. 1 below.

Fig.1

Recommended models

Recommended models for the standard circuit in Fig. 1 are shown in Table 1 below.

Table 1

Model

Solenoid valve (CV)

Speed Controller

Tubing

CRB10

CRB15

0.05

AS-M5

4/ 2.5

6/ 4

CRB20

CRB30

CRB40

0.1 to 0.2

AS-M5

4/ 2.5

6/ 4

Note) The speed controllers must be used in a meter-out control.

(Do not use a speed controller for slow speed.)

エアフ

ィルタ

ミスト

セパレータ

レギュ

レータ

ロータリ・

アクチュ

エータ

電磁弁

スピード・

コントローラ

Page 26

9

3. Setting

Limit load to the shaft

(1) Although static loads shown in Table 1 are allowable, avoid applying load directly to the shaft.

Table 1 Allowable shaft load

Note) Application point of force "Fr" is at the center of longitudinal dimension of the key.

(2) For better operating conditions it is recommended to use the method shown in the figure below

to avoid applying direct load to the shaft.

Shaft fitting

As shown in Fig. 4, when the rotary actuator is used with an extended shaft, align the center of the shaft

of the rotary actuator and the counterpart. If they are off-centered, the load factor becomes partially large

and an excessive bending moment may be applied to the shaft.

In such a condition, the assembly may not perform a stable operation and the shaft may be damaged.

In this case, use Flexible Fitting ("flexible joint" defined in JIS).

Fig.1

Model

Load direction

Fs[N]

Fr[N]

M[N-m]

CRB10

9.8

14.7

0.13

CRB15

9.8

14.7

0.17

CRB20

19.6

24.5

0.33

CRB30

24.5

29.4

0.42

CRB40

40

60

1.02

Fig.4

Fig.2

Fig.3

Fr

Fs

M

Warning

Warning

Page 27

10

Screw

How to Mount Loads

How to connect a load directly to a single flat shaft.

To secure the load, select a bolt of an appropriate size from those listed in tables 2 and 3

by taking the shaft’s single flat bearing stress strength into consideration.

Table 2 Directly Fixed with Bolts (Refer to Fig. 5.)

Size

Shaft dia.

Bolt size

10

4

M4 or larger

15

5

M5 or larger

20 6 30

8

M6 or larger

Table 3 Fixed with a Holding Block (Refer to Fig. 6.)

Size

Shaft dia.

Bolt size

Plate thickness (t)

10

4

M3 or larger

2 or wider

15

5

2.3 or wider

20

6

M4 or larger

3.6 or wider

30

8

M5 or larger

4 or wider

The plate thickness (t) in the table above indicates a reference

value when a carbon steel is used.

Besides, we do not manufacture a holding block.

Mounting

Mounting 1

Using the tapped holes on the output shaft side of body (Refer to Fig.7)

Table 4 Bolt,Tightening torque

Size

Bolt

Recommended tightening torque

10

M3

0.63 N・m

15

20

M4

1.50 N・m

30

M5

3.00 N・m

40

Mounting 2

Using a plate with tapped holes (Refer to Fig. 8).

L dimension when the unit is used as a flange is shown in the table below.

(Only for standard CRB without auto switch)

Table 5 Bolt,Tightening torque

Size

L

Bolt

Recommended tightening torque

10

11.5

M2.5

0.36 N・m

15

16

20

24.5

M3

0.63 N・m

30

35

M4

1.50 N・m

40

40

Fig.7

Fig.8

Fig.6

Fig.5

Warning

Page 28

11

Adjusting the rotating angle

Do not apply a load when adjusting the rotating angle.

For size 20, 30 and 40, the rotation range can be set as shown in Fig.9 and 10 by adjusting

the adjustment bolt whilst supplying air to the opposite port.

Example 1) For 90 degrees

Fig.9

Example 2) For 180 degrees

Fig.10

(1) Set the adjustment bolt B while supplying

pressure from the A port.

(2) Set the adjustment bolt A while supplying

pressure from the B port.

A port

Adjustment bolt B

Chamfer

Adjustment range

Adjustment bolt A

B port

Adjustment range

Chamfer

(1) Set the adjustment bolt B while supplying

pressure from the A port.

(2) Set the adjustment bolt A while supplying

pressure from the B port.

Warning

Page 29

12

Operating environment

Do not use in environments where there is a danger of corrosion.

Refer to "Internal Construction and Components" on pages 4 to 6 for materials used for

the rotary actuator.

Never use this product in dusty locations or where water, oil, etc., splash on the equipment.

Air Supply

(1) The air supplied to the rotary actuator shall be filtered by an SMC air filter and regulated

to the specified set pressure by an SMC AR series regulator.

(2) This is a non-lube type actuator. Never supply lubricant oil.

(3) If lubricant is supplied to the actuator, the grease inside the actuator will be washed away,

and this may cause operation failure.

Compressed air containing a large amount of condensate may cause malfunction of

rotary actuator.

Therefore, take appropriate measures to ensure air quality, such as by providing an after cooler,

air dryer, or water separator.

Warning

Caution

Page 30

13

4. Setting of Rotation Time

Even if the torque - required by the load in the rotation movement is small, the shaft and/or internal parts

could become damaged depending on the inertia of the load. Therefore, select an appropriate model for

your application by taking the load’s moment of inertia, kinetic energy, and rotation time into consideration.

Moment of inertia

(1) Moment of inertia is the tendency of a stationery object to resist rotation, or, conversely, the tendency

of a rotating object to resist stopping.

When the actuator moves an object (load), inertia (kinetic energy) is generated in the object.

The actuator stops at the rotation end, but due to inertia, a large shock (kinetic energy) is applied to the rotary

actuator.

The kinetic energy can be calculated using the formula below.

E = 1/2 x I x ω2

E:Kinetic energy (J)

I:Moment of inertia (kg/m2)

ω:Angular speed (rad/s)

(2) There is a threshold of kinetic energy that a rotary actuator allows. Therefore, by finding the moment

of inertia, it is possible to find the threshold value of the rotation time.

The basic formula for finding the moment of inertia is shown below.

Moment of inertia can be found with the basic formula shown below.

I = m x r

2

m::Weight (kg)

This represents the moment of inertia for a shaft with mass M, which is located at distance r

from the shaft.

Page 31

14

(3) Moment of inertia of each style can be found with the calculation formula shown below.

How to read Graph 1.

Example 1) When there are constraints for the moment of inertia of load and rotation time.

From “Graph 1”, to operate at the load moment of inertia 1 x 10–4 kg·m2 and

at the rotation time setting of 0.3 S/ 90°, the model will be CRB□30.

Example 2) When there are constraints for the moment of inertia of load, but not for rotation time.

From “Graph 1”, to operate at the load moment of inertia 1 x 10–5 kg·m2

CRB15 will be 0.22 to 0.5 sec/ 90

o

CRB20 will be 0.13 to 0.5 sec/ 90o.

[Remarks] As for the rotation times in “Graph 1”, the lines in the graph indicate the adjustable

speed ranges.

If the speed is adjusted towards the low-speed end beyond the range of the line, it could

cause the actuator to stick, or, in the case of the vane type, it could stop its operation.

Graph 1

Page 32

15

Kinetic energy

Allowable kinetic energy is shown in Table 1.

Since the rotary actuator reaches the rotation end in the middle of acceleration, terminal acceleration

"ω" can be found with the calculation shown below:

ω = 2θ / t θ::Rotating angle (rad)

t::Rotation time (s)

Kinetic energy E can be found with the formula below:

E = 1 / 2・I・ω

2

Therefore, rotation time "t" of the rotary actuator is as shown below.

t =

E

I2

2

E:Kinetic energy (J)

I :Moment of inertia (kg / m

2

)

θ::Rotating angle (rad) 180o = 3.14 rad

During uniform acceleration, angular speed ω after t seconds and

displacement angle θ can be found as shown below.

ω =

x t (1)

θ = ∫

t d t = 1 / 2

t

2

+ C (2)

C is integration constant.

When t = 0, rotation angle θ = 0, so the integration constant is C = 0.

θ = 1 / 2

t2 = 1 / 2 ω t

Therefore,

ω = 2 θ / t

Table 1 Unit (J)

Model

Allowable kinetic energy

CRB10

0.00015

CRB15

0.001

CRB20

0.003

CRB30

0.02

CRB40

0.04

Page 33

16

External stopper

If the kinetic energy - generated by the load exceeds the actuator’s threshold value, an external

dampening function must be provided to absorb the energy.

The figure below shows the correct installation of external stopper.

As a rotary actuator itself has a slight angular error due to the construction, use an external stopper

when accurate positioning is required.

Angle controlled by the

external stopper

Rotating angle of the actuator

without an external stopper

External stopper

External stopper

Secure a margin

Secure a margin

A port

B port

Correct position

External stopper

Incorrect position

Incorrect position

External stopper

The external stopper works

as a fulcrum, resulting in the

load’s inertia force being

applied to the shaft as a

bending moment.

External stopper

If an external stopper is

installed to the shaft on the

opposite side of the load,

the inertia force generated

by the load is applied

directly to the shaft.

When buffer such as

Shock Absorber is used,

or when load is within

allowable energy range,

single rod can be used.

Page 34

17

5. Maintenance and Inspection

[Precautions]

a. Disassembling the product will void SMC’s warranty. If disassembly is really necessary it is

recommended to fully understand the internal construction before disassembling the products.

b. Do not damage the seals when reassembling the product.

Be sure to add grease to all the seals and sliding surfaces of the bodies and vane shaft.

c. Use caution to prevent any damage to the sliding surfaces of the bodies (A) and (B) and vane shaft.

d. As the rubber of the vane shaft is baked to adhere to the vane, it cannot be removed.

e. If locking adhesive is applied to the bolts or screws, apply locking adhesive again during re-assembly.

Standard Type (For CRB10, 15)

●Be sure to install an air filter to clean the supply air.

●Do not disassemble the actuator. When disassembling it for an unavoidable reason, follow the

procedures below, and prevent dust and/or foreign matter from entering the product. (As operation

failure is caused by an increase in the internal leakage in most of the cases, the speed controller needs

to be readjusted. It is recommended to operate the product in the stable speed adjustable range (see

"Speed adjustable range" on page 1)

For CRB10, 15-90

<Disassembly>

1. Remove the hexagon socket head cap screws (11).

2. Hold either body A (1) or body B (2), and separate the body A and B by pushing the vane shaft (3) out.

3. Take out the vane shaft (3), stoppers (4) and (5).

<Reassembly>

1. Mount the vane shaft (3) into the body B (2).

2. Mount the stopper seals (7) into the stopper (4).

3. Mount the stoppers (4) and (5) into the body B (2).

(Note) The stopper has the specified position for mounting.

4. Insert the vane shaft (3) into the body A (1).

5. Tighten the body A (1) and body B (2) with the hexagon socket head cap screws (11).

(Refer to table 1.)

90° specification

180° specification

Applicable grease package

part number

GR-L-005 (inner capacity: 5g)

Page 35

18

Standard Type (For CRB20, 30, 40)

●Be sure to install an air filter to clean the supply air.

●Do not disassemble the actuator. When disassembling it for an unavoidable reason, follow the

procedures below, and prevent dust and/or foreign matter from entering the product. (As operation

failure is caused by an increase in the internal leakage in most of the cases, the speed controller needs

to be readjusted. It is recommended to operate the product in the stable speed adjustable range (see

"Speed adjustable range" on page 1)

For CRB20, 30, 40-90

<Disassembly>

1. Remove the parallel key. (For size 40.)

2. Remove the hexagon socket head cap screw (14).

3. Hold either body A (1) or body B (2), and separate the body A and B by pushing the vane shaft (3) out.

4. Take out the vane shaft (3), stoppers (4) and (5).

<Reassembly>

1. Mount the vane shaft (3) into the body B (2).

2. Mount the stopper seals (7) into the stopper (4).

3. Mount the stoppers (4) and (5) into the body B (2).

(Note) The stopper has the specified position for mounting.

4. Insert the vane shaft (3) into the body A (1).

5. Tighten the body A (1) and body B (2) with the hexagon socket head cap screws (14).

6. Mount the parallel key (For size 40).

90° specification

180° specification

Page 36

19

With Auto Switch (For CDRB20, 30, 40)

For CDRB20, 30, 40-90

<Disassembly>

1. Remove the parallel key. (For size 40.)

2. Remove the cross recessed round head screw (18).

3. Remove the cover (14) and magnet holder (15).

4. Remove the hexagon socket head cap screw (19).

5. Hold either body A (1) or body B (2), and separate the body A and B by pushing the vane shaft (3) out.

6. Take out the vane shaft (3), stoppers (4) and (5).

<Reassembly>

1. Mount the vane shaft (3) into the body B (2).

2. Mount the stopper seals (7) into the stoppers (4).

3. Mount the stoppers (4) and (5) into the body B (2).

(Note) The stopper has the specified position for mounting.

4. Insert the vane shaft (3) into the body A (1).

5. Tighten the body A (1) and body B (2) with the hexagon socket head cap screws (19).

(Refer to table 1.)

6. Mount magnet holder (15) and cover (14).

(Note) Align the rotating angle indicator of the magnet holder and the chamfered position of the shaft.

7. Tighten with cross recessed round head screws (18). Tightening torque: 0.6 to 0.7 Nm.

(Note) Apply locking adhesive.

8. Mount the parallel key (For size 40).

* The CRB with switch (size 10 and 15) cannot be disassembled.

180° specification

90° specification

Table 1.Hexagon socket head cap screws tightening torque

Model

Bolt

Tightening Torque (N・m)

CRB10, CRB15

M3

0.8 to 1.2

CRB20

M4

2.0 to 3.4

CRB30, CRB40

M5

4.0 to 6.0

Page 37

20

6. Troubleshooting

Failure

Possible causes

Countermeasures

No operation

The product is not used at a speed within the

range of the stable speed adjustable range.

Use the product within the specified speed

adjustable range shown in the catalog or

operation manual.

Increase in the internal leakage due to damage

to the internal seal with foreign matter, drainage,

etc.

Replace the vane shaft and stopper seals with

new ones.

(The whole product needs to be replaced as a

rule.)

Sealing failure of the internal seal or increase in

the internal resistance due to operation outside

of the operating temperature(Including

freezing).

Operate the product within the operating

temperature range.

(For sealing failure, replace the vane shaft and

stopper seals with new ones.)

Malfunction of the peripheral equipment.

a. The speed controller is not adjusted properly.

b. Operation failure of the solenoid valve.

c. Air is not supplied sufficiently due to clogging

of the air filter.

d. Air pressure is reduced due to operation

failure of the regulator.

Use the countermeasure peripherals.

(Including circuit problems)

Broken shaft

Load energy is too large.

a. Load weight is too large.

b. Operating speed is too fast.

c. Radius of rotation is too large.

Replace the shaft.

a. Use the product with the energy within the

allowable range.

b. Absorb the impact energy.

Mount the cushion and external stopper

correctly.

External force other than load is applied to the

shaft.

Replace the shaft.

Avoid excessive external force being applied to

the shaft.

Eccentric load due to misalignment.

Replace the shaft with a new one.

Operation without the

specified rotation angle

Joint of the rotating shaft or internal stopper is

damaged.

Replace the joint or replace the whole product

with a new one.

Damage to the

bearing

Excessive load

(Loads in thrust and radial directions are too

large.)

Replace the bearing with a new one.

Operate with the radial load and thrust load

which is within the allowable range.

Eccentric load due to misalignment.

Replace the bearing for correct alignment.

Too much vibration is applied to the product.

Replace the bearing to reduce the vibration.

External leakage

Sealing failure with the O-ring due to damage to

the bearing or bending of the shaft.

Replace the bearing or the shaft with a new

one.

Reduce the external force.

Damage to the O-rings due to foreign matter

and/or drainage.

Replace the O-rings with new ones.

Prevent foreign matter or drainage from

entering the product.

Internal leakage

Damage to the seals due to foreign matter

or drainage.

Replace the vane shaft and stopper seals.

(The whole product needs to be replaced

as a rule.)

Prevent any foreign matter and drainage

from entering the product.

Sealing failure due to operation outside of

the operating temperature range.

Replace the vane shaft and stopper seals

with new ones.

(Replace the whole product as a rule,

especially for the product used at a high

temperature.)

Operate the product within the operating

temperature range.

Page 38

21

Notes for the Troubleshooting shown above

1. Causes of the operation failure due to product life are not shown in the troubleshooting table.

2. For failures due to causes other than –those shown in the troubleshooting table and product life,

please contact SMC, as a disassembly investigation of the product may be required.

Page 39

Revision history

A: [Safety Instructions] Revision of sentences.

4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN

Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362

URL http://www.smcworld.com

Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

© 2012 SMC Corporation All Rights Reserved

0120-837-838

Loading...

Loading...