SMC Networks ATV50, ATV100 Service Manual

SERVICE MANUAL

CF5/UR5/UR0

ATV 50/100 ATV with F/N/R

3 in 1 engine

Standard Motor Corporation

1-

01-01-01-01-01-0

1.

Thi

s

not

iackcha

1-

0

Sy

m

is

nand

1. Sym

b

2. Gene

r

3. Servi

c

4. Spec

i

5. Torq

u

6. Trou

b

General

chapter

o

ce, cautio

n

nowledge

pters.

1. Sym

b

bols an

d

eeded. In

marks,

e

Warni

n

Cauti

o

Engine

Greas

Gear

o

Oil se

a

Rene

w

Brake fl

Special t

o

ols and

al Safe

t

e Prec

a

fication

s

e Value

s

les Dia

g

Informa

ffer you t

h

and the

t

and skills

ols and

marks a

r

case su

p

xplanatio

g

Mfon M

oil

Li

oi

li

m

e C

il

G

r

e

l

Ap

R

uid U

ols S

p

S

MC

Marks

y

utions

nosis

tion

e general

ools tong

u

before sta

Marks

e used in

plement

a

ns will b

e

eans that

llowed.

eans that

mits to us

l. Warrant

ited engi

n

hassis gr

e

ear oil s

e

commend

ply with li

eplace wit

se recom

m

ecial tool

s

ATV5

0

informati

o

e setting,

rt to do an

this man

l informa

t

added to

serious i

n

equipmen

t

SAE #

2

will not

c

e oil.

ase is rec

o

rials are

ed )

thium-soa

a new p

a

ended br

a

/10

0

Se

n of SMC

please re

a

y repair/in

s

ual to ind

ion of pr

o

the text i

jury or e

v

damage

s

0 or JAS

O

over the

mmende

d

recomm

e

p base lu

b

rt before

i

ke fluid

D

rvice

M

1

2

3

10

12

14

ATV 50/1

0

d carefull

y

pection j

o

cate wha

t

cedures

i

stead of

en death

may resu

FC clas

s

damage t

h

.

nded. (

G

ricant.

nstallatio

n

OT4.

anua

l

Chapt

e

0 with 2

s

and mak

bs as me

n

and wh

e

s needed

using th

e

may resul

t

lt if proce

d

or simila

at cause

d

ear oil

S

.

er 1 Gen

troke eng

i

e sure yo

u

tioned at

re the sp

e

for thes

e

symbols

t if proce

d

ures are

n

r class 2

s

by not a

AE #40

-

ral Infor

m

ne, safety

have wel

furthering

cial serv

i

symbols

or marks

ures are

n

ot followe

d

troke eng

pply with

t

or above

1 -

ation

l

ce

.

ot

.

ine

he

is

1-

0

Bel

o

Ca

r

If y

o

are

ause

Ex

h

Ga

Ga

sspa

Ga

s

chil

Us

e

Pro

ver

iKee

Ho

Co

mThe

ser

v

Ba

t

Gene

r

w is som

e

bon mo

n

u must ru

. Run yo

u

an extrac

Cautio

n

aust cont

a

oline

oline is a

rk should

Cautio

n

oline is hi

ren.

d trans

m

Cautio

n

longed co

n

fied. We r

e

p the use

d

compo

n

Cautio

n

ponents

o

y remain

v

ice work

o

tery

Cautio

n

Batte

r

when

Batte

r

not b

e

imme

d

water

If you

veget

a

Keep

al infor

m

of the g

e

oxide

n your en

g

r engine i

n

tor.

ins toxic

g

low ignitio

n

be allowe

d

ghly flam

m

mission

tact with

u

commen

d

oil beyo

n

nents

f the eng

i

ery hot e

v

n these p

y emits e

x

charging

t

y contain

s

spray on

iately wit

h

and then

g

swallow it

ble oil an

electrolyt

e

S

MC

ation r

e

neral info

r

ine, ensu

r

an open

as which

point an

d

in the w

o

able, and

oil

sed tran

s

that you

w

d reach o

f

ne and e

x

en after t

h

arts, wear

plosive g

a

he battery

sulfuric a

c

your eyes

water. If

y

o to hos

p

by mistak

d then im

m

beyond r

e

ATV5

0

fer to y

mation to

e the pla

c

area, if yo

may caus

e

explosiv

e

rk place o

r

may expl

o

mission oi

ash you

r

children.

haust sys

t

e engine

h

insulated

ses; Flam

.

id (electr

o

or skin. If

ou get b

a

ital to see

e, drink a

l

ediately

g

ach of ch

/10

0

Se

our ow

n

your own

s

e is well v

e

u have to

one to lo

material.

where g

a

de under

l may cau

s

hands wi

t

em can b

e

as been

s

gloves an

d

e is strictl

y

lyte) whi

c

you get b

a

ttery acid

an ophth

a

ot of wate

o to see

a

ildren.

rvice

M

safety

afety duri

ntilated.

N

run your e

se consci

o

Work in a

soline is

b

some con

d

e skin ca

n

h soap an

come ext

r

topped fo

wait until

prohibite

d

h can cau

s

ttery acid

in your ey

e

lmologist.

r or milk,

a

doctor.

anua

l

Chapt

e

ng the rep

ever run

y

gine in a

usness a

n

well-ventil

eing store

itions, ke

e

cer altho

u

d water ri

g

emely hot

r some ti

m

cooling o

f

. Keeps t

h

e serious

on your s

k

s, flush it

nd take s

o

er 1 Gen

air/servic

e

your engi

n

closed ar

e

d even re

ated plac

e

d.

ep it awa

y

gh it mig

h

ht after c

o

after engi

e. When

p

f.

e place

w

burns so

b

in, flush i

t

off immed

me laxati

v

-

ral Infor

m

time.

e in a clo

s

a, be sur

e

sult in de

a

, no flam

e

from

t not be

ntacting.

ne runnin

g

erforming

ell ventila

t

e careful

off

iately with

e such a

s

2 -

ation

ed

to

th.

or

.

ed

do

Br

a

Do

cle

a

Inh

a

Br

a

Spi

l

cle

a

the

1-

0

1.

A

2.

3.

W

v

4.

5.

W

ke pad/

s

not use a

n

ner or th

e

Cautio

n

ling brake

ke fluid

Cautio

n

ling brake

n towel o

n

brake flui

d

3. Servi

c

lways us

Using n

o

ATV an

d

Special to

o

compone

n

Using wro

hen ser

v

interchan

g

ehicle.

Clean the

deposit a

c

cause da

m

ash and

dry with c

o

seals bec

a

on them.

hoe

air hose

o

equivale

n

shoe or pa

d

fluid on p

a

the abo

v

beyond r

e Preca

e with SM

C

n-genuin

e

out of S

M

ls are de

s

ts without

ng tools

m

icing this

A

eable wit

h

outside of

cumulate

d

age.

clean par

t

mpresse

d

use most

S

MC

r a dry br

t to avoid

ash may

c

inted, pla

e-mention

each of c

h

utions

genuine

parts for

S

C warran

t

igned for

damagin

g

ay result i

n

TV, use

o

the Engli

s

the parts

o

on the p

a

s with hig

h

air. Pay

s

cleaning

a

ATV5

0

sh to cle

a

dust flying

ause diso

r

stic, or ru

b

ed parts f

o

ildren.

parts and

MC ATV

y service.

remove a

n

the parts

parts da

m

nly metri

c

h system

,

r the cov

e

rt's surfac

e

ignition

p

pecial att

e

gents ha

v

/10

0

Se

n compo

n

.

ders and c

a

ber parts

r protecti

o

recomme

may dam

a

d install o

being wor

aged.

tools. M

e

, using wr

o

r before r

e

e may fall

oint solve

n

ntion to

O

e an adve

rvice

M

ents of th

e

ncer of th

e

ay caus

e

n when s

e

nded oils.

ge the

f

ked on.

tric bolts,

n

ng tools

a

moving it

into the e

n

t, and blo

-rings or

o

rse effect

anua

l

Chapt

e

brake sy

s

breathing

damage

t

rvicing th

e

uts, and

s

nd fasten

e

rom the

A

gine, cha

s

il

SMC

G

er 1 Gen

stem; use

system

to the par

t

brake sy

s

crews ar

e

rs may d

a

TV. Other

w

sis, or br

a

enuine Par

t

-

ral Infor

m

a vacuum

s. Place a

tem. Kee

not

mage thi

s

ise, dirt

a

ke syste

m

s

3 -

ation

p

nd

to

6.

7.

8.

W

9.

10.

11.

12.

13.

w

Never be

n

and prem

a

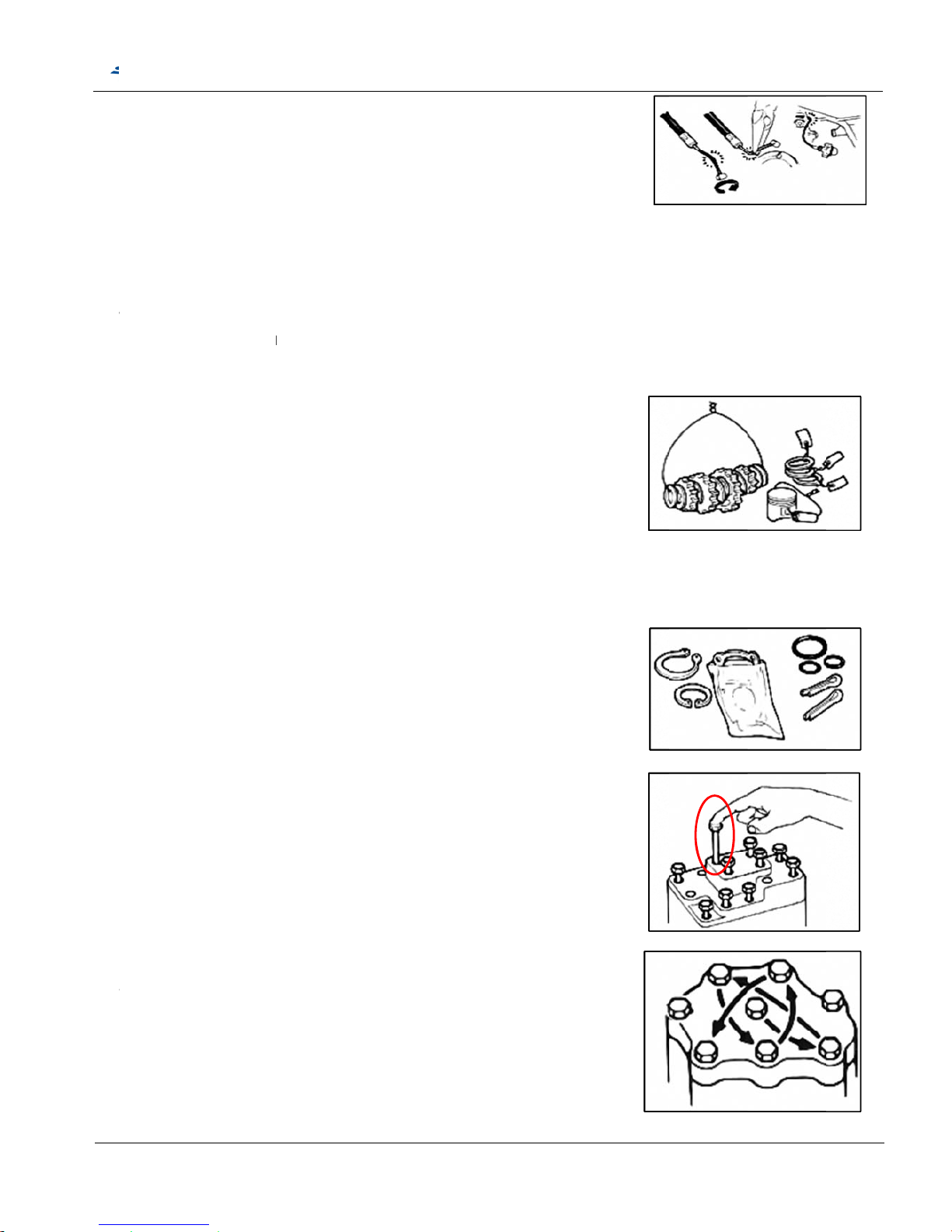

Rubber p

a

Check the

necessar

y

hen loo

s

pattern an

loosen fir

s

Store com

proper as

s

of installat

number ta

Note the r

e

ensure th

e

Compone

n

disassem

b

snap ring

s

he lengt

h

boxes is d

installed. I

compare i

t

he same

w

assembly

ighten a

s

ighten al

l

ith speci

a

important

c

appropriat

Bolts and

f

o the thre

d or twist

a

ture worn

rts may b

e

se parts b

e

.

ening a c

o

d work fro

m

t, small fa

s

plex com

p

emble or

d

ion later o

r

b for the s

assembl

e

y will be r

e

ts not to

b

led includ

, and split

of bolts

a

ifferent fro

n case of

c

s length

w

ith other

should ha

v

semblies

w

the faste

n

l tool first

ompone

n

e increme

n

asteners

s

ads.

S

MC

control

c

out.

come det

e

fore inst

a

mponent

inside o

teners m

a

onents su

er and tie

you can l

equence t

o

position

o

assembl

e

e reused

ing gaske

t

pins.

nd screw

s

m one an

o

onfusion,

ith other

b

bolts, it is

e the sa

m

ith differ

e

ers with fi

diagonall

y

ts should

ts to avoi

hould be

ATV5

0

able to pr

e

riorated

w

llation to

m

which has

ut. Loose

n

y receive

ch as tran

s

them tog

e

abel the a

s

avoid th

e

f the imp

o

d in corre

c

should be

s, metal s

e

for asse

m

ther, be s

Insert the

olts, if its l

a correct

b

e length.

nt dimen

s

ngers, the

from insi

d

e tighten

e

d warp un

l

kept clean

/10

0

Se

vent uns

m

hen old,

a

ake sure

different

s

the small

too much

mission

p

ther with

a

ssembly p

mistake.

rtant com

ct dimensi

replaced

w

al rings,

O

blies, cov

ure they a

bolt into t

h

ength out

s

olt. Bolts

f

ion fasten

n tighten t

e toward

d 2 to 3 ti

ess other

w

and dry.

D

rvice

M

ooth con

t

nd prone

t

that they

a

ized faste

fasteners

stress.

arts in th

e

wire for

e

arts by Ar

a

ponents b

e

ons (dept

h

hen

-rings, oil

er plates

o

e correctl

y

e hole to

ide the h

o

or the sa

m

ers as foll

o

he big on

e

outside,

mes with

ise indic

a

o not ap

p

anua

l

Chapt

e

rol

o be dam

a

re in goo

d

ners, ope

r

first. If th

e

ase

bic

fore disa

s

, distance

seals,

r

le is

e

ws:

s

ted.

ly oil

er 1 Gen

ged by s

o

conditio

n

ate with a

bigger o

n

sembling

or positio

n

-

ral Infor

m

lvent and

, replace i

f

diagonal

es are

them to

).

4 -

ation

oil.

14.

15.

16.

17.

18.

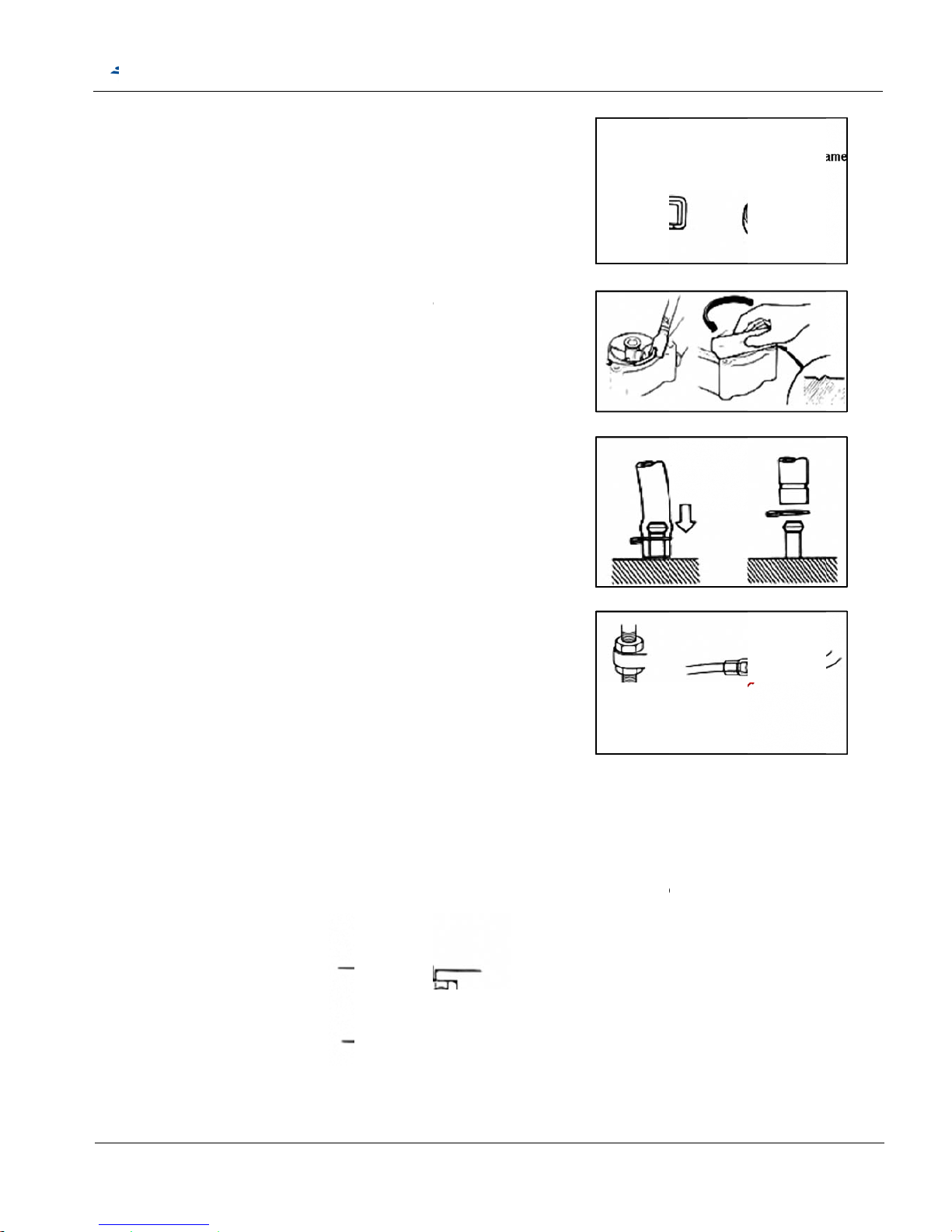

When oil

he oil se

a

outside, a

n

installed f

o

oil seal.

Remove r

e

reinstallati

has any d

a

he ends

o

should be

so that th

e

ightening

Rubber a

n

he origin

a

he beari

n

removing

a

inner race

bearing, u

s

seal is in

s

l with the

n

d check t

h

r smooth

n

sidues of

on, grind

w

mage.

f rubber

h

pushed a

s

re is eno

u

the clamp

d plastic

b

l correct

p

g tool sh

o

ball bea

r

or outer r

a

e equal f

o

(B

o

S

MC

talled, fill t

ame of th

e shaft o

n

ess and f

o

the old g

a

ith a grin

d

oses (for

far as th

e

gh room

b

s.

oots shou

ositions a

s

uld be pr

e

ing. Dam

a

ce). In thi

rce on b

o

th of the

s

ATV5

0

he groove

e manufa

c

which th

e

r burrs th

a

sket or se

a

stone if t

h

uel, vacu

u

y can go

t

elow the

e

ld be prop

designe

d

ssed agai

n

ge may r

e

s case, th

e

th races.

e exampl

e

/10

0

Se

with grea

s

turer faci

n

oil seal i

s

t may da

m

alant befo

r

e contact

m, or co

o

o their co

n

nlarged e

n

erly reinst

a

.

st two (in

sult if the

t

bearing

s

s can re

s

rvice

M

e, install

g

to be

age the

e

surface

lant)

nections

ds for

lled to

ner and o

u

ool is pre

s

hould be

r

ult in bea

r

anua

l

Chapt

e

ter) beari

n

sed again

eplaced.

T

ing dama

g

er 1 Gen

g races

w

st only on

e

o avoid d

ge)

-

ral Infor

m

hen

race (eit

h

amaging t

h

5 -

ation

er

e

he rotatio

n

points be

f

sitions a

n

service s

a

parts fall

d

oval/inst

a

attery re

m

(-) cabl

e

ith body

t

vice com

p

. Battery p

install the

two pole

s

re that th

e

.

Voltage

rate expl

o

stic sulfu

r

tective ey

e

atteries in

teries aw

a

).

SMOKE

w

S

MC

ball face

ore asse

m

d operati

o

fety for e

a

own.

llation.

oval oper

a

firstly. T

o

o prevent

leted, ma

k

ositive (+)

battery c

o

ide of bat

t

battery p

o

and cond

sive hydr

o

ic acid. T

h

gear wh

e

a well-ve

n

y from fir

e

hen char

g

ATV5

0

with spec

i

bling.

n for inst

a

ch other

w

tion, it ha

s

ols like o

p

from shor

t

e sure all

cable sho

rd. .

ery have t

o

st caps a

r

tion of c

h

gen gas

a

erefore,

a

n handlin

g

tilated a

r

e

, sparks o

r

ing or ha

n

/10

0

Se

fied lubric

a

lled parts

hen con

d

to remo

v

en-end w

r

-circuit an

connectio

uld be co

n

be grea

s

re located

arge in b

a

nd contai

lways foll

o

or worki

n

a.

open fla

m

dling batt

e

rvice

M

nt on the

is in corre

c

ucting by

e the batt

e

ench do n

o

create s

p

n points is

nected fir

s

ed after c

o

in properl

y

ttery

n electrol

y

w these p

g near b

a

es (e.g.,

w

ries.

anua

l

Chapt

e

t and

wo perso

n

ry

t

ark.

tly

nnected

t

after the

e which i

s

reventive

m

tteries.

elding e

q

er 1 Gen

s.

he cables

.

battery p

o

made of

p

easures:

uipment, l

-

ral Infor

m

sts had b

e

oisonous

ighted

6 -

ation

en

FI

REXT

IN

T

24.

25.

A

KEEP B

A

A

void bo

d

ST AID I

N

ERNAL

Skin —

W

Eyes —

F

ERNAL

Drink lar

g

vegetabl

e

If fuse bur

capacity f

u

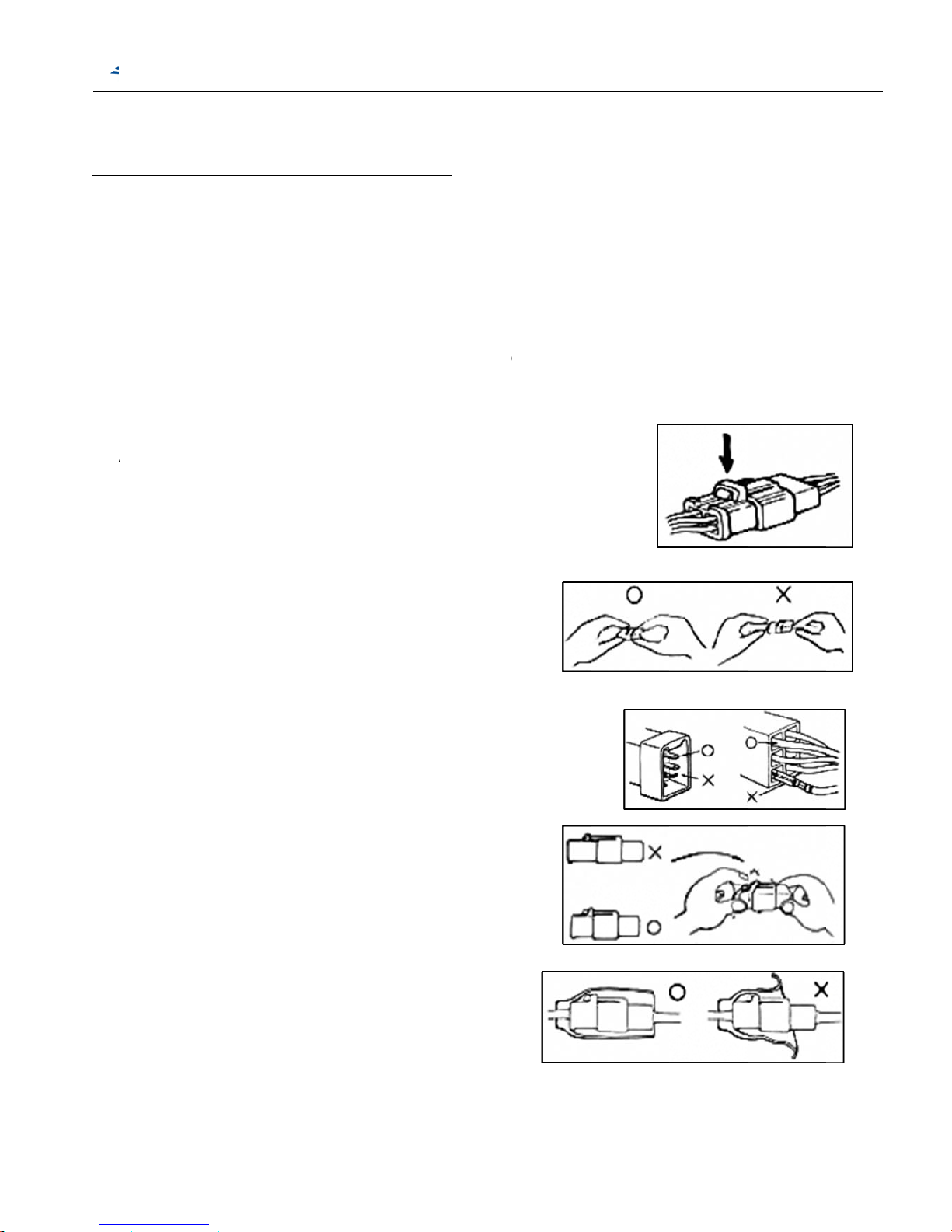

Connecto

r

. When

s

compl

e

B. Do not

wires.

H

C. Make

s

D. Insert

t

locker

s

locker

s

loose.

E. Check

conne

c

TTERIES

ily conta

c

CASE O

F

ash with

w

lush with

e quantiti

e

oil. Get i

m

ned, it ha

s

se.

unlock/in

s

eparatin

g

tely, unlo

c

pull the w

old the c

o

ure if the

c

he conne

c

on two c

o

are locke

if the con

n

tor boot c

o

S

MC

AND EL

E

t with ele

c

BODILY

ater.

water for

1

s of wate

mediate

to find ou

ert

a connec

t

ked it firs

t

ires as re

m

nnector

b

onnector

tor compl

e

nnector s

i

d in prope

ector is c

o

mpletely

ATV5

0

CTROLY

T

trolyte as

CONTAC

5 minute

s

or milk f

o

medical a

t

the caus

e

or, it lock

e

.

oving a c

o

ody.

pins are b

e

tely. If th

e

des, mak

e

rly. Check

vered by

t

and secur

e

/10

0

Se

E OUT O

it can cau

s

T:

and get i

m

llowed wit

tention.

and solv

e

r has to I

n

onnector

o

nt, extru

d

re are tw

o

sure the

if any wir

e

he twin

d properl

y

rvice

M

F REACH

e severe

b

mediate

h milk of

m

d it. And

t

sert the t

e

r

ed or loo

s

.

anua

l

Chapt

e

OF CHIL

D

urns or p

e

medical a

t

agnesia,

b

hen repla

c

rminal

en.

er 1 Gen

REN.

rmanent

e

tention.

beaten eg

g

e with sp

e

-

ral Infor

m

ye injury.

or

cified

7 -

ation

26.

27.

W

28.

29.

30.

31.

F. Before

termin

a

Secure wi

r

locations.

harnesse

s

ire ban

d

properly.

Do not sq

u

Do not let

compone

n

Keep wire

Route wir

e

corners a

n

and scre

w

terminal

c

l is loose.

es and wi

Tighten th

.

and wire

eeze wir

e

the wire h

a

ts as routi

harnesse

s

harness

e

d also av

o

s.

S

MC

onnection

re harnes

s

e bands s

o

harness

h

s against

t

rness co

n

ng the ha

r

far away

s to avoid

id the pro

j

ATV5

0

check if t

es to the

f

that only

ave to b

e

he weld o

tact with

r

ness.

from the

h

sharp ed

g

ected en

d

/10

0

Se

he boot is

rame with

the insul

a

clamped

r its clam

p

otating, m

ot parts.

es or

s of bolts

rvice

M

crack or t

h

respectiv

e

ted surfac

secured

.

oving or v

i

anua

l

Chapt

e

e

wire ban

d

s contact

brating

er 1 Gen

s at the

d

the wires

-

ral Infor

m

esignated

or wire

8 -

ation

32.

33.

34.

35.

36.

37.

38.

W

39.

40.

W

f

Route har

n

slack.

Protect w

contact a

tape is to

Secure th

e

Never us

e

broken.

W

replace th

e

Never cla

m

compone

n

Do not let

ire harn

e

slack, be

r

Before op

e

instrumen

t

ith sand

ound. An

d

esses so

ires or wir

e

sharp ed

g

be applie

d

rubber b

o

wires or

h

rap electri

m.

p or squ

e

ts.

the wire h

a

sses rout

ubbed ag

a

rating a t

e

. And the

n

paper to

c

then con

S

MC

that they

n

harness

e

e or corn

e

.

ot firmly

a

arnesses

cal tape a

r

eze the

w

rness be

e

ed along t

h

inst or int

e

st instru

m

, conduct

lean rust

o

duct conn

e

ATV5

0

either pul

s with ele

c

r. Thorou

g

s applyin

g

which ins

u

ound the

d

ire harnes

n twisted

e handle

b

rfere with

ent, oper

a

test in ac

c

n connec

t

ction ope

/10

0

Se

l too tight

n

trical tap

e

hly clean

it on wir

e

lation ha

s

amaged

p

s as instal

as install

a

ar should

adjacent

o

tor shoul

d

ordance

w

or pins/te

r

ration late

r

rvice

M

or have

e

or tube i

f

he surfac

e

harness.

been

arts or

ling other

tion.

not be pu

r surroun

read the

o

ith the in

s

minals if

.

anua

l

Chapt

e

xcessive

they

where

led too tig

ding parts

peration

m

truction.

er 1 Gen

ht or have

in all stee

anual of

-

ral Infor

m

excessiv

e

ring positi

o

the

9 -

ation

n.

1-

0

1.

Di

mSeaWhe

Gro

Wei

En

g

Cyli

Bor

e

Dis

p

Co

m

Lub

Car

Sp

a

Sta

r

Igni

tGen

Bat

tEngEng

Air-

F

Tra

nGea

Fin

a

Fin

a

Ge

a

Ge

aFue

Fu

e

Ch

a

Fro

nRea

Bra

k

Bra

k

F.

B

R.

B

Tir

e

Fro

n

He

aRea

Fla

s

4 Speci

f

SMC CF5

ension (Lx

W

t height

el base

und Cleara

ght

ine

nde

r

* Stroke

lacement:

pression

R

ricant :

bureto

r

rk

ting

ion

erator

ery :

ine Oil

ine Oil

ilter

smission (

r Shifting :

l ratio

:

l Drive :

r box oil

:

r Ratio :

l : Unl

e

l tank: 8.1

L

ssis : Ste

e

t Suspens

r Suspensi

e (F/R)

e (F/R)

rake oper

a

rake oper

a

: Tubeles

s

t/Rear: (F

)

(

R

d Light (ty

p

r Light: 12

V

her Light :

ication

s

series A

T

xH): 165

5

: 845mm

: 1080mm

nce : 23

5

: Un-laden

: 2 Stroke,

A

: Single, H

o

: 40 x 39.2

m

49.3 cc

atio : 7.8:1

mixed with

: Mikuni V

M

: NGK BP

R

: Electrical

: C.D.I.

:

A

CG Fly

W

MF type,

F

: 2Stroke

E

: 1.1L

: Wet type

e

F-R): C.V.

T

F- R (shift

s

1.59(35/2

2

Chain Dri

v

SAE #40,

Forward:

4

aded gas

o

l tube fra

m

ion: Doubl

e

on: Single

s

: Front dua

: Front dua

tion: Front

tion: Front

pedal for

i

AT 21x7-1

) AT 21x1

0

e 1): 12V

3

5W* 1 (L

E

12V 10W*

4

S

MC

50, CV

T

mm/1028

m

mm

Mass = 14

2ir

Cooled

rizontal

m

fuel by oil

p

16 (18m

m

7HS x 1

starte

r

/Kic

k

heel Mag

n

actory def

a

ngine Oil,

S

lement

Automati

c

elector fu

n

T)

e, 428*88

0.12L

1.15~17.3

7

line

e

A-arm; sh

o

wing Arm;

l hydraulic

d

l drum bra

k

RH side ha

LH side h

a

ntegrate fr

o

0 or others

-8 or othe

r

5W/35W*1

D)

ATV5

0

with rev

e

m/1025m

m

kg; with fu

e

ump

), MJ:#65,

Starter

eto 90W

ult: YUAS

A

AE #20 or

with centri

f

ction in re

v

; Reverse:

ck absorb

e

shock abs

o

isc / Rear

e / Rear si

n

ndle brake

ndle brake

nt and rea

s

(Hi/Low-B

e

/10

0

Se

rse gear,

l Mass =

1

PJ:#17.5,

N

/GS Batte

r

JASO FC

c

ugal clutc

h

erse with

p

34.86- 14.

: 72 mm

t

rber: 63m

m

single hydr

gle drum

b

lever for fr

o

lever for r

e

r wheeler

a

am)

rvice

M

Chain dri

48 kg

J:E-1(#42

6

y YTX4L-B

lass or ab

o

.

edal brake

)

71

ravel, 5-Se

travel, 5-

S

ulic disc (

O

rake (optio

nt wheele

r

ar wheeler

/

t the same

anua

l

Chapt

e

e.

)

/GTX4L-

B

ve.

tion adjus

t

ection adj

u

ption 1)

2)

parking br

a

time

er 1 Gen

S

able pre-lo

ustable pre

ke; R side

-

ral Infor

m

aded

-loaded

footrest br

a

10 -

ation

ke

2.

Di

mSeaWhe

Gro

Wei

En

g

Cyli

Bor

e

Dis

pCom

Lub

Car

Sp

a

Sta

r

Igni

tGen

Bat

tEngEng

Air-

F

Tra

nGea

Fin

a

Fin

aGeaGeaFue

Fu

eCha

Fro

nRea

Bra

k

Bra

k

F.

B

R.

B

Tir

e

Fro

n

He

a

Re

a

Fla

s

SMC CF0

ension (Lx

W

t height

el base

und Cleara

ght

ine

nde

r

* Stroke

lacement:

pression

R

ricant :

bureto

r

rk

ting

ion

erator

ery :

ine Oil

ine Oil

ilter

smission

r Shifting :

l ratio

:

l Drive :

r box oil

:

r Ratio :

l : Unl

e

l tank: 8.1

L

ssis : Ste

e

t Suspens

r Suspensi

e (F/R)

e (F/R)

rake oper

a

rake oper

a

: Tubeles

s

t/Rear: (F

)

(

R

d Light (ty

p

r Light: 12

V

her Light:

1

series A

T

xH): 165

5

: 845mm

: 1080mm

nce : 23

5

: Un-laden

: 2 Stroke,

A

: Single, H

o

: 52 x 45m

m

95.2 cm3

atio : 5.8:1

mixed with

: Mikuni V

M

: NGK BP

R

: Electrical

: C.D.I.

:

A

CG Fly

W

MF type,

F

: 2 Stroke

E

: 1.1L

: Wet type

e

: C.V.T A

u

F-N- R (sh

i

1.59(35/2

2

Chain Dri

v

SAE #40,

Forward:

4

aded gas

o

l tube fra

m

ion: Doubl

e

on: Single

s

: Front dua

: Front dua

tion: Front

tion: Front

pedal for

i

AT 21x7-1

) AT 21x1

0

e 1): 12V

3

5W* 1 (L

E

2V 10W*

4

S

MC

100, CV

mm/1028

m

mm

Mass = 14

4ir

Cooled

rizontal

fuel by oil

p

16 (18m

m

7HS x 1

starte

r

/Kic

k

heel Mag

n

actory def

a

ngine Oil,

lement

tomatic wit

ft selector

f

T)

e, 428*88

0.12L

1.15~17.3

7

line

e

A-arm; sh

o

wing Arm;

l hydraulic

d

l drum bra

k

RH side ha

LH side h

a

ntegrate fr

o

0 or others

-8 or othe

r

5W/35W*1

D)

ATV5

0

with re

v

m/1025m

m

kg; with fu

e

ump

), MJ:#77.

5

Starter(op

t

eto 90W

ult: YUAS

A

AE #20 o

r

h centrifug

a

unction in

r

; Reverse:

ck absorb

e

shock abs

o

isc / Rear

e / Rear si

n

ndle brake

ndle brake

nt and rea

s

(Hi/Low-B

e

/10

0

Se

erse gea

r

l Mass =

1

, PJ:#17.5

ional)

/GS Batte

r

JASO FC

l clutch.

everse wit

h

34.86- 14.

: 72 mm

t

rber: 63m

m

single hydr

gle drum

b

lever for fr

o

lever for r

e

r wheeler

a

am)

rvice

M

, Chain d

r

50 kg

, NJ:E-1(#

4

y YTX5L-B

class or ab

pedal bra

k

71

ravel, 5-Se

travel, 5-

S

ulic disc (

O

rake (optio

nt wheele

r

ar wheeler

/

t the same

anua

l

Chapt

e

ive.

26)

/GTX5L-

B

ove.

e)

tion adjus

t

ection adj

u

ption 1)

2)

parking br

a

time

er 1 Gen

S

able pre-lo

ustable pre

ke; R side

-

ral Infor

m

aded

-loaded

footrest br

a

11 -

ation

ke

1-

0

Th

e

val

u

A.

5m

6m

8m

10

m12m

B.

Sp

a

Cyl

Cyl

A

ir

A

ir

Fa

n

Oil

Ca

rCar

A

ir

Int

a

Oil

Oil

Ge

a

Cr

a

ca

sL.R

Kic

Idl

eOne

Cl

uCluExhMufPro A.C

Ma

Ge

a

5. Tool

T

torque v

a

es for not

Standard

Ite

m

m Bolt, N

u

m Bolt, N

u

m Bolt, N

u

m Bolt,

N

m Bolt,

N

Engine T

o

rk Plug

inder hea

d

inder hea

d

Shroud

Shroud c

o

Bolt

pump bolt

buretor u

p

buretor fl

o

cleaner fi

x

ke bolt (r

e

plug cap

drop bolt

(

r box bol

t

nkcase c

o

e)

Crankca

s

k Nut

gear plat

e

way clut

c

tch

tch carrie

r

aust Pipe

fler bolt

tector, m

u

. Generat

o

gnet (A.C.

r shifting

orque

v

lues listed

listed in t

h

Toque V

a

t

t

t

ut

ut

rque

Item

/cylinder

s

nut

ver

per bolt

at bolt

ing bolt

ed valve)

drain bolt

)

ver bolt (t

r

e bolt

bolt

h bolt

(cylinder

s

ffler

r nut (fly

w

G. coil) sc

lever nut

S

MC

alue se

t

in table a

r

e table.

lue

Torqu

00135

tud bolt

ansmissi

o

ide)

heel/roto

r

rew

ATV5

0

ting

e for mor

e

e Value (

k

.45~0.60

.80~1.20

.80~2.00

.00~4.00

.00~6.00

Q

’

n

)

1443142242411

6161211122212

1

/10

0

Se

importan

t

g-m)

5m

6m

6m

8m

10

m

ty

Thr

e

(

m

1

1

4070706060504040606

1

4

0

806

1

1

0

6

0

6

0

6101028060806100606

rvice

M

tighten to

Item

m Screw

m Screw

m Screw

m Screw

m Screw

ad Dia.

m)

*1.22

*1.00

*1.00

*1.00

6.0

*1.00

*0.8

*0.7

*0.7

*1.00

*1.00

*1.50

*1.25

*1.00

*1.00

*1.00

*1.00

*1.00

*1.25

*1.00

*1.00

*1.00

*1.25

*1.00

*1.25

*1.00

*1.00

anua

l

Chapt

e

rque valu

e

T

o

Torqu

e

(kg

1.5

~

1.4

~

1.3

~

0.5

~

0.1

~

0.5

~

0.3

~

0.15

~

0

0.7

~

0.7

~

0.2

~

1.5

~

0.7

~

0.7

~

0.7

~

0.7

~

0.6

~

2.5

~

3.5

~

5

0.7

~

2.2

~

0.7

~

3.8

~

1.0

~

1

er 1 Gen

s. Please

rque Val

u

0.45~

0

1.00~

1

0.70~

1

2.00~

3

3.50~

4

Value

-m)

2.0

2.0

1.5

0.8

0.2

0.8

0.5

0.25

.2

1.0

1.0

0.4

2.0

1.0

1.0

1.0

1.0

1.0

3.5

4.5

.0

1.0

3.0

1.0

4.2

1.6

.0

-

ral Infor

m

see stand

a

e (kg-m)

.60

.40

.10

.00

.50

sugges

2.0

1.0

1.4

0.7

0.2

0.7

0.4

0.2

0.2

0.9

1.1

0.3

1.8

1.2

1.2

1.2

0.9

0.8

4.0

3.0

0.9

2.6

0.9

3.8

0.8

12 -

ation

rd

t

C.

Ste

Ste

Fro

Fro

Ste

Tie

-

Tie

-

Fro

Fro

Re

aRea

Fro

Re

a

En

g

F.e

n

Sw

iUndChaFooReaRea

Re

aRea

Fo

oFoo

Ex

hHan

Chassis

P

ering colu

m

ering colu

m

nt Shock

a

nt Arm (U

p

ering Knu

c

rod (lock

n

rod end a

nt hub

nt Wheel

r collar w

h

r Wheel

nt shield

b

r shield b

o

ine Moun

t

gine and

ng-Arm

er guard

in suppor

t

trest L&R

r Shock

A

r axles h

e

r axles h

e

r Brake H

t brake b

o

t brake b

o

aust Pipe

dlebar H

o

arts Tor

q

Item

n holder

n holder

bsorber (

u

per-Fram

kle and u

p

ut)

nd steerin

g

eel

olt

lt

ing

frame

er

bsorber (

u

xagon nu

t

xagon nu

t

ub Bolt

lt

lt

holder (fr

a

lder

S

MC

ue Value

and fram

e

and handl

pper & lo

w

e)

per arm

column

pper) bolt

(IN)

(EX)

me)

ATV5

0

Q

e bar

er)

2142244

2828411144411

1

4

1

2

2

2

/10

0

Se

’ty

Thr

e

(

1

1

1

1

1

1

1

1

0

810101010101014

1

0

1

410080810140810081028

2

810

1

008

0

808

rvice

M

ad Dia.

mm)

*1.25

*1.25

*1.25

*1.25

*1.25

*1.25

*1.25

*1.50

*1.25

*1.50

*1.25

*1.25

*1.25

*1.25

*1.50

*1.25

*1.25

*1.25

*1.25

*1.50

*1.50

*1.25

*1.25

*1.25

*1.25

*1.25

anua

l

Chapt

e

Torqu

(k

g

1.

82.24.0

34.023

7

4

1

42248

21.8

22.010

1

0

5

4.

01.0

1.

81.0

er 1 Gen

e Value

-m)

/2.3

/3.5

/3.0

.0

/6.0

.5

.0

.0

.5

2.0

.5

.6

.6

.5

.5

.3

/2.8

.6

/3.0

/16

/16

.0

/6.0

/1.6

/2.8

/1.5

-

ral Infor

m

Rema

r

13 -

ation

ks

1-

0

A.

E

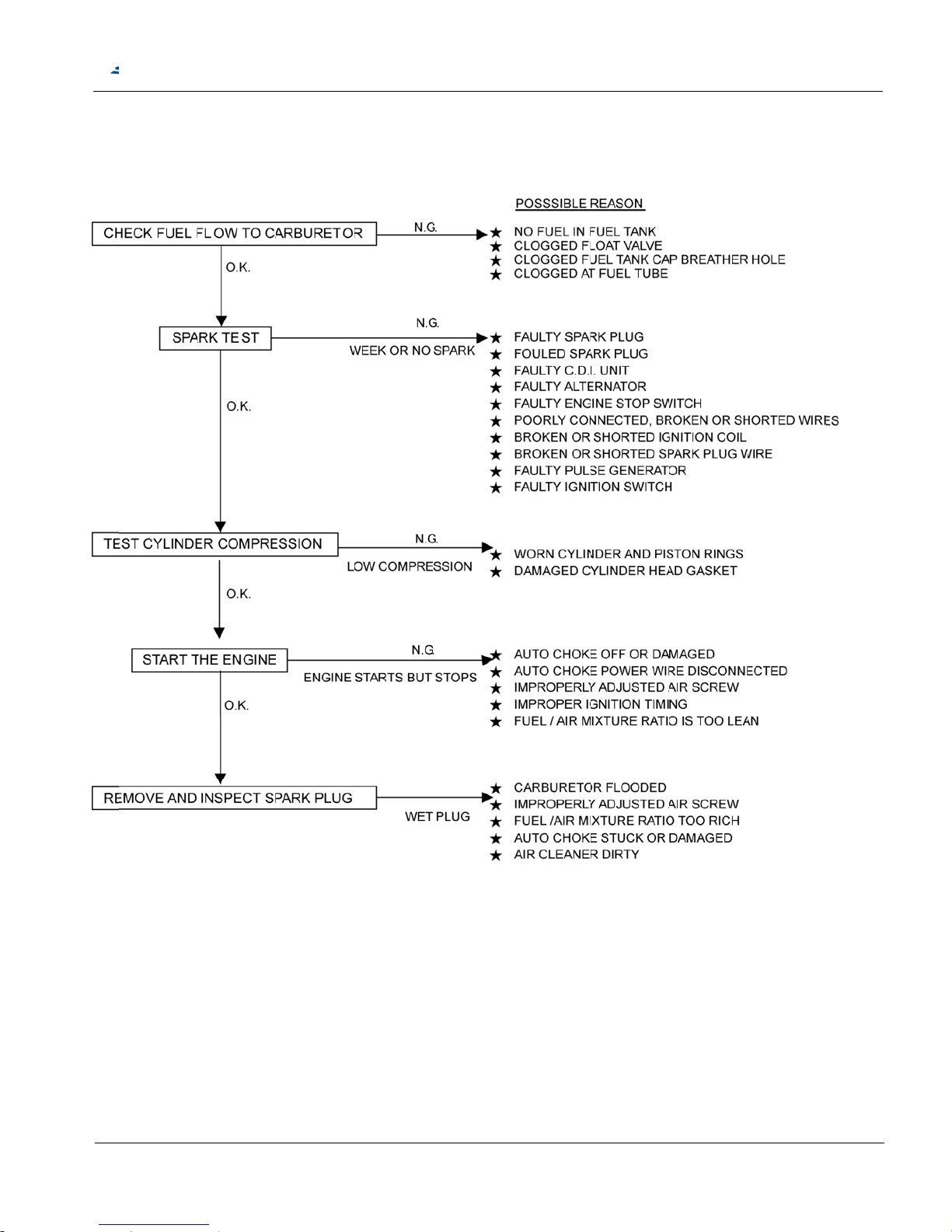

6.Trou

b

ngine d

o

les Diag

es not st

a

S

MC

nosis

rt

ATV50/10

0

Se

rvice Manua

l

Chapteer 1 Gen- ral Infor

m

14 -

ation

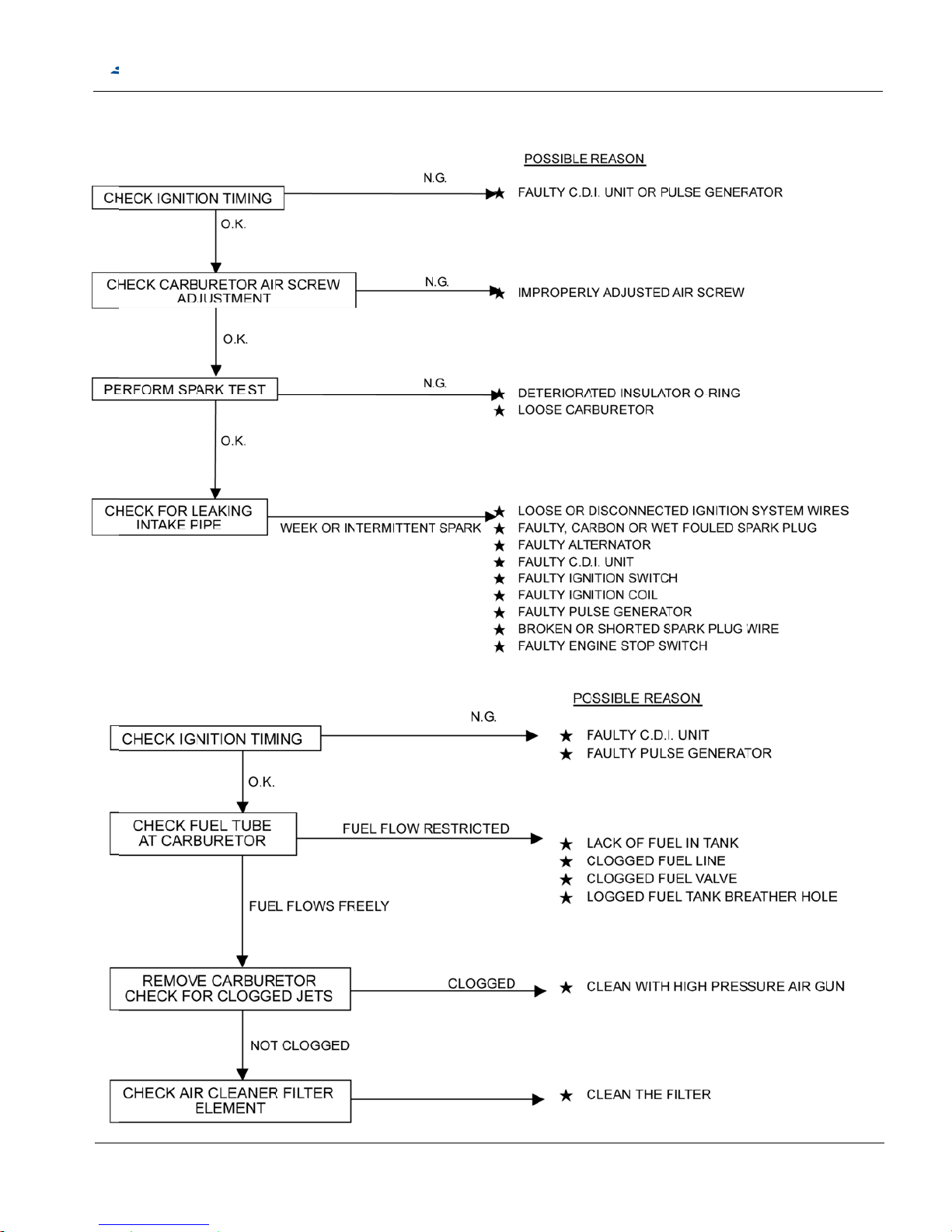

B.

E

C.

E

ngine p

o

ngine p

o

or perfor

m

or perfor

m

S

MC

ance at

ance at

ATV5

0

ow and i

d

igh spe

e

/10

0

Se

le speed

d

rvice Manua

l

Chapteer 1 Gen- ral Infor

m

15 -

ation

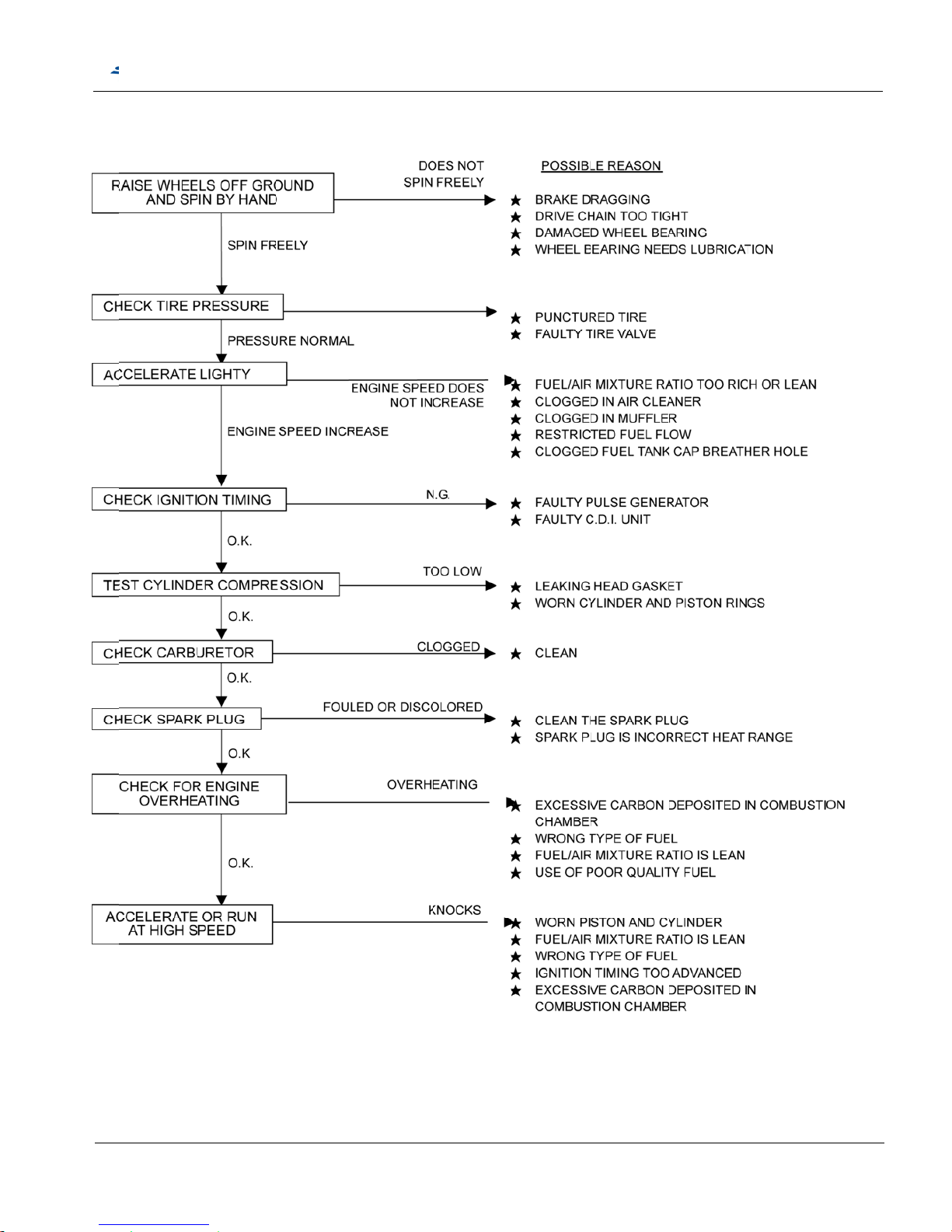

D.

P

oor Performance

S

MC

ATV50/10

0

Se

rvice Manua

l

Chapteer 1 Gen- ral Infor

m

16 -

ation

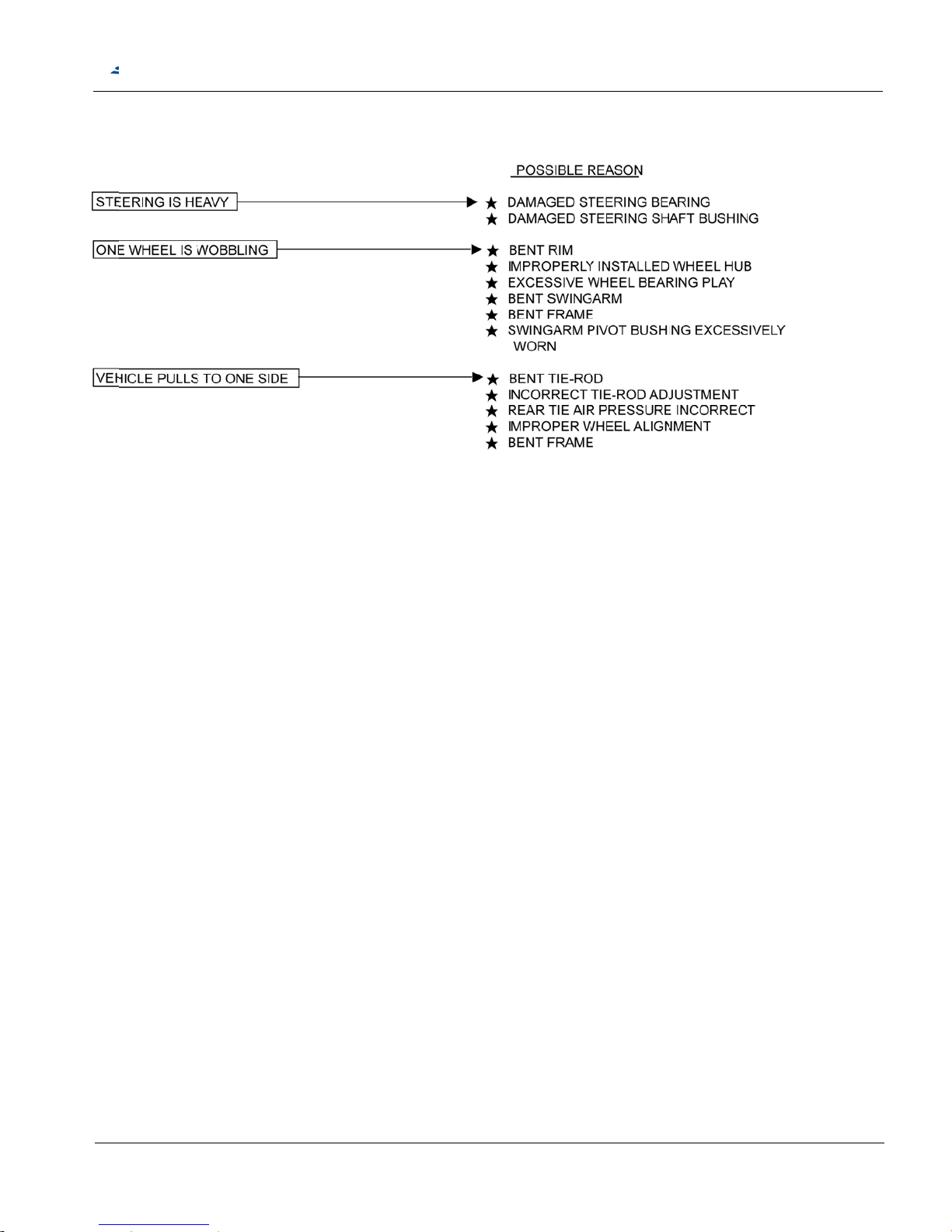

A.

P

oor Steering

S

MC

ATV50/10

0

Se

rvice Manua

l

Chapteer 1 Gen- ral Infor

m

17 -

ation

2-

02-02-02-02-02-02-02-02-0

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-

0

1. Tech

n

2. Perio

d

3. Fuel

H

4. Throt

t

5. Air C

l

6. Spar

k

7. Idle

S

8. Drivi

n

9. Brak

e

0. Brak

e

1. Brak

e

2. Clutc

h

3. Susp

e

4. Steer

i

5. Whe

e

6. Nuts,

7. Toe-I

n

8. Gear

1 Tech

n

Cl

e

Spar

k

“

F

Tire

d

ical Da

t

ical Ma

oses

le Cabl

e

eaner

Plug

peed A

d

g Chai

n

Syste

m

Syste

m

Light S

Wear

nsion

ng Han

d

l/Tire

Bolts Ti

Oil

ical Dat

a

Fuel Tank

2T Eng

i

Gea

r

arance of

t

plug

Brake leve

r

” Mark in

s

Idling

s

imension

Tire pr

e

Batt

e

SMC

a

intenan

c

justme

n

(drum

b

(Disk

B

witch/St

le

ghtness

of Oil

&

Capacity

ne Oil

Oil

hrottle val

v

T

y

G

a

free play

tatic timing

peed

F

R

ssure

ry

ATV 5

0

e Sche

d

t

rake)

rake)

arting I

n

Pressu

r

e

pe

p

ront

ear

/10

0

S

ule

hibitor

S

e Capa

c

50 CC: 1

2

YT

100CC: 1

2

Y

T

ervice

M

C

witch

ity

1.

10.1NG0B

18

AT21

x

AT21

x

12 p

s

V3Ah (typ

e

4L-BS or

V4Ah (typ

e

X5L-BS or

anua

l

hapter 2

8.1L.

L, SAE 2

0

2L, SAE 4

0

4~6 mm

K BPR7H

S

.6~0.7 mm

3~5 mm

TDC 18º

0±100 rp

m

7-10 / or o

t

10-8 / or o

t

i (0.81 kgf/c

m

: MF batt

e

GS Battery

: MF batt

e

GS Batter

y

Maintena

n

15

16

18

18

18

19

19

20

21

22

24

24

24

25

25

25

26

26

hers

hers

2)

ry, default:

GTX4L-B

S

ry, default:

GTX5L-B

S

-

1

ce Inform

a

YUASA

)

YUASA

)

5-

tion

2-

0

Ha

v

A

ut

sch

It

1

2

3

4

5

6

7

8

9

1

1

1

1

1

4

1

1

1

1

1

2

2

2

2

2

4

2

2 Perio

d

e your A

T

horized D

e

edule is e

s

em

Ch

e

Ite

m

*

*

*

A

*

A

*

*

0 *

1 *

*

3 *

*

5 *

6 *

7 *

W

8 *

W

9 *

0 *

1 *

*

3 *

*

5

ical Ma

V checke

d

aler to m

a

tablished

ck

s

Ma

Kil

o

Ma

Engine oil (

2

Gear Oil

Engine idle

s

Fuel Filter(f

u

Spark plug

ir cleaner

e

ir Cleaner

t

Carburetor

Throttle ope

limiter

Fuel lines (c

cracks/dam

a

Upper and l

o

Steering Sh

a

in check)

Front and R

e

absorber ch

e

Front /Rear

check

Front / Rear

shoe/pad w

e

Front and R

e

Level/Leaka

Wheel rim c

h

Wheel Hub

B

looseness/d

a

Tire (Wear/

P

Nuts, Bolt,

B

check and l

u

Fr. & Rr. St

e

pivot

CVT driving

CVT driving

Driving Cha

i

Battery Volt

a

SMC

intenan

c

, adjuste

d

intain the

by taking

t

intenance

meter

intenance In

stroke)

peed

el cup)

lement (Re

m

ube

ration /Spee

heck or

ge)

Fram

ew A

-Arm

ft (lubricant

ar shock

ck

brake free p

l

brake or

ar

ar Brake Fl

ge Check

eck for da

m

earing

mage

ressure)

ush, fasten

e

bricant.

ering Knuc

k

belt/weight

r

Clutch

n

ge

ATV 5

0

e Sche

d

, and rec

o

ATV at th

e

he hours

o

30

0

terval 20

hEngFue

ark)

C

/Steering/S

u

, Toe

ay

uid

age

r

le

T

ollers

/10

0

S

ule

rded mai

n

optimum

r kilomet

e

KM

r

ine mainten

a

A

dd 2 strok

R

I

l and air sy

s

lean or repl

a

(more of

t

I

spension/B

r

I

Replac

e

I

I

ransmissio

ervice

M

C

tenance d

condition

.

rs as a re

Every 3

M

1000 KM

60 hr

nce

e oil into oil

t

I

tem

ce if neces

s

en when in

w

I

I

I

I

ake/ Wheel

L

I/

L

I

I

whenever

w

I

I

I

I

I

L

n

I/

L

I

anua

l

hapter 2

ata period

The abo

v

erence w

h

on. Ev

20

0120

ank, when

o

ary for Eve

r

et or dusty

& Tires

orn to the li

Maintena

n

ically by y

o

e mainten

ichever c

o

ery 6 Mon.

00 KM

0 hr

il warning l

a

R

I

I

I

y 1000 KM

areas)

I

I

I

I

L

I/L

I

I

mited

I

I

I

I

I

L

I

I

I/L

I

-

1

ce Inform

a

ur SMC

ance

mes first.

Remark

s

mp is “on”

6-

tion

2

2

2

Co

d

Re

m

1.

Are

2.

Man

3.

C

4.

P

a

b

- C

A

the

ma

i

pro

d

6 *

7 *

8 *

e: I ~ I

n

C ~

c

*Sh

o

arks:

ir cleane

r

placemen

aintenan

c

d after th

e

heck batt

e

reventive

. Ignition

s

after-bur

n

. Carbon

d

system w

h

UTION:

T

time, or h

a

ntenance

uct warr

a

Dashboard/

s

Lights /elect

Front and r

e

spection

,

leaning

(

uld be p

e

needs to

t after ridi

n

e should

ATV ha

s

ry before

maintena

n

ystem: pe

r

or overh

e

eposit re

m

en powe

r

he user

m

ve SMC

d

of your ve

h

nty.

SMC

peedomete

r

rical equipm

ar brake sw

i

cleanin

g

replaced

rform an

d

be clean

g on (1)

d

be perfor

m

accumul

a

riding AT

V

ce

form mai

n

ating occ

u

oval: re

m

is obviou

s

ust perfor

ealer for

a

icle will l

e

ATV 5

0

El

e

nt

tch

, and adj

u

if necess

a

settle b

y

very 100

0

usty rain

d

ed more

ted a high

. Re-cha

r

tenance

a

rs.

ove carb

lower th

a

m the peri

o

periodic

m

ad to poo

r

/10

0

S

ectrical Syst

I

I

I

stment

ry)

local de

a

0 KM driv

e

ays (2) s

a

often if th

e

er mileag

e

ge battery

nd check

w

on deposi

n ever.

d check

&

aintena

n

perform

a

ervice

M

C

em

I

I

I

R ~ Repl

a

L ~ Lubri

c

ler or se

r

and req

u

nd area (

3

ATV is f

r

.

or replac

e

hen con

t

ts in cylin

d

service

a

ce progra

m

nce, brok

e

anua

l

hapter 2

cement

ation

vice stati

o

ires mor

e

) snow d

a

equently

o

a new b

a

inuous ab

n

er head,

nd keep t

h

. Failure

n of your

v

Maintena

n

I

I

I

n

frequentl

y

ys.

perated i

n

ttery, if it

n

normal ig

n

piston he

a

e service

to follow t

h

ehicle an

d

-

1

ce Inform

a

cleaning

high sp

e

ecessary.

ition, misf

i

ds, exha

u

records a

l

e periodi

c

out of

7-

tion

or

ed

re,

st

l

2-

.

W

G

a

of

2-

Fr

e

2-

03 Fuel

/

Check fu

e

any dete

r

leaking.

R

necessa

r

Check th

e

tank to th

damage,

replace

w

arning

soline is

a

fire is stri

c

04 Thro

t

Have a

w

handle in

back orig

Check h

a

Lubricat

e

smooth.

Check th

e

cable/oil

p

Replace

i

damage

d

Measure

flange p

a

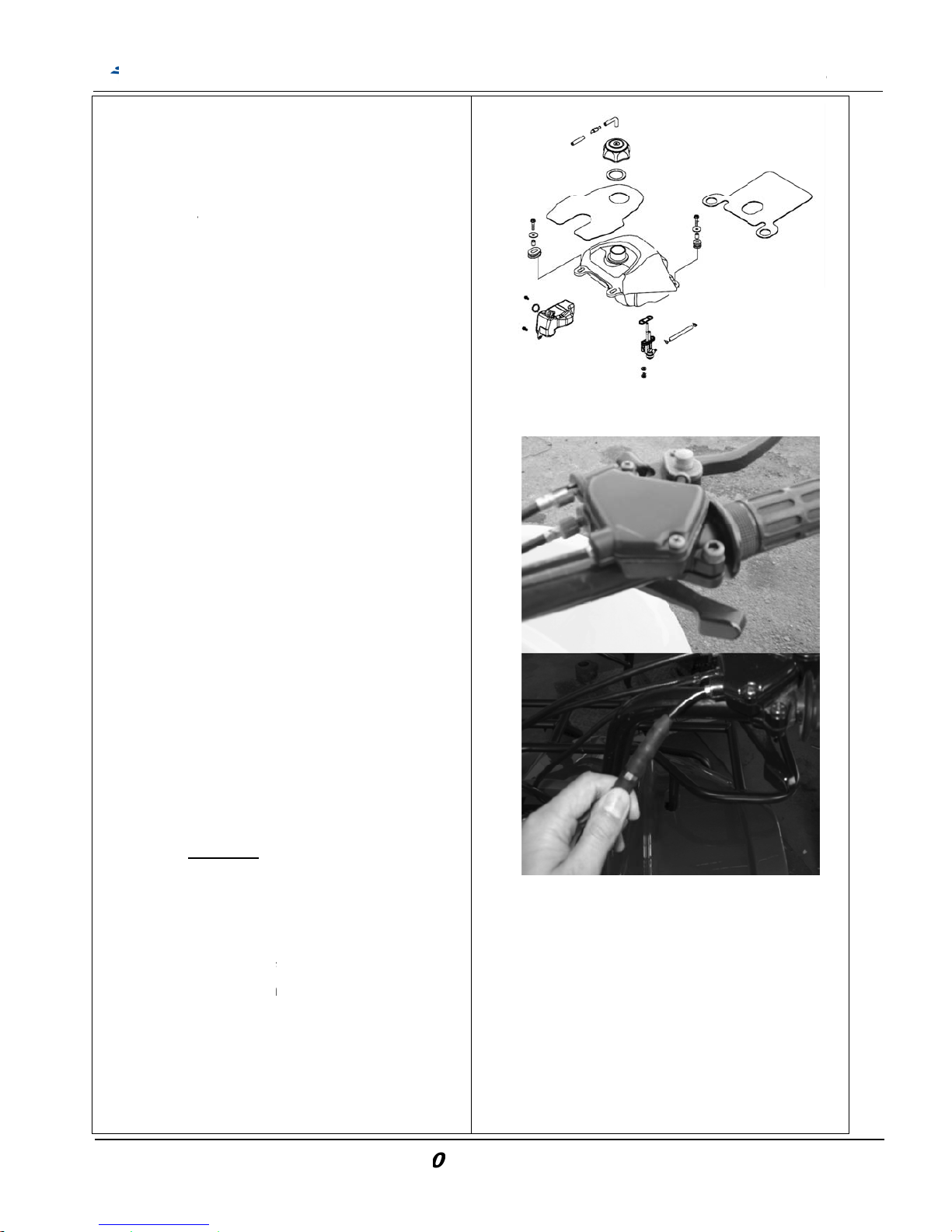

a. Rem

o

and t

h

adjus

t

b. Tight

e

accel

e

e play: 4

05. Air

C

Remove

t

with full

s

Remove

3

cover an

d

Clean th

e

high-flas

h

for dry.

Replace

w

Oil Hos

e

l tank, fu

e

ioration, d

eplace it

w

y.

oil tank,

e oil pum

p

bend or o

i

ith new o

n

low igniti

o

tly prohibi

t

tle Cabl

ide open

o

any positi

inal (full C

ndle if its

o

the cable

throttle

c

ump cabl

t if deterio

.

the throttl

e

rt.

ve rubber

en adjust

ment scre

n the fixin

ration op

e

~6 mm.

leaner

he LH fo

o

ize type.

screws

f

then re

m

element

w

point sol

v

ith new

o

SMC

s

l cock, an

amage, b

e

ith new

o

oil hose b

e

if any de

t

l leaking.

C

e if nece

s

n materi

a

ed as de

a

e

f throttle

v

on and rel

losed) po

s

peration

i

if operati

o

able/carb

u

e if functi

o

rated, twi

s

lever fre

e

boot, loos

it by turni

n

w.

g nut, and

ration co

n

trest guar

d

rom the ai

ove the c

o

ith non-fl

a

ent and t

h

ne if nece

ATV 5

0

d fuel hos

e

nd or fuel

ne if

tween oil

erioration,

orrect it

a

sary.

l so any ki

ling it.

alve as

ease it to l

ition.

s smooth.

n is not

retor

n correctl

y

ted or

play in it

s

en fixing n

g the

check

dition.

(if equip

p

cleaner

ver.

mmable

o

en squee

z

ssary

/10

0

S

if

nd

nd

et

.

ut,

ed

e it

ervice

M

C

anua

l

hapter 2 Maintena

n

-

1

ce Inform

a

8-

tion

C

a

N

e

to

S

othethecle

2-

R

eabcd

S

p

ef.g

Ti

g

2-

C

a

1.

2.

S

p

18

ution

ver use g

a

clean the

e

ap the el

e

n squeez

e

element

s

aner cov

e

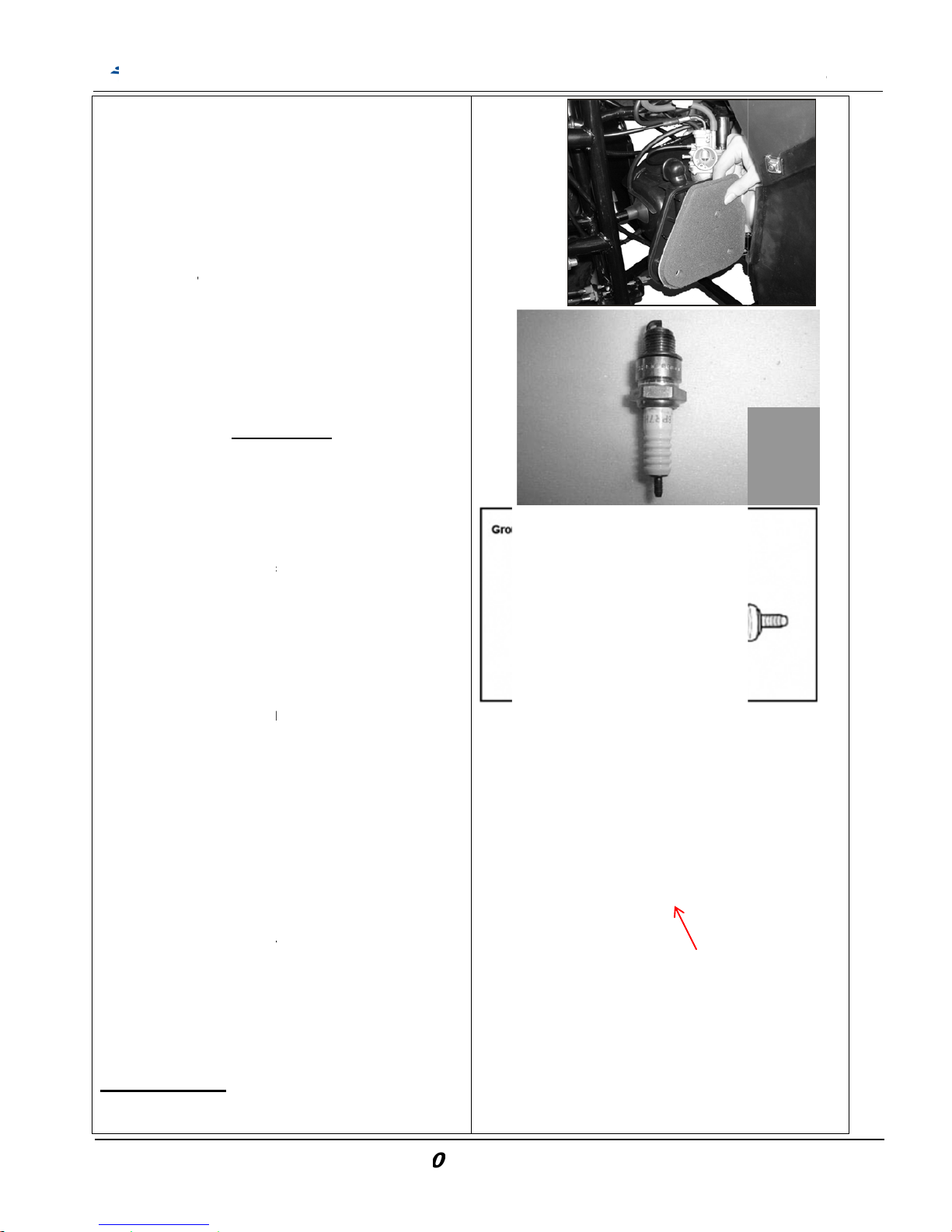

06. Spa

r

commen

d

. Remove

. Clean di

r

. Remove

. Measur

e

ark plug

g

. Carefull

y

plug to

a

Hold sp

a

spark pl

u

. Tighten

t

with plu

g

hten tor

q

07. Idle

S

ution

Inspectio

have to

b

engine th

adjusted.

Idle spee

be done

a

is enoug

h

running f

o

Warm up

Turn the

in) to

g

clockwis

e

Start the

screw un

t

ecified id

00 ± 100

r

soline or

lement.

ment into

it out. In

s

eat and t

h

r.

k Plug

ed spark

p

spark plu

g

t around t

spark plu

g

spark plu

ap 0.6 ~

0

bend gro

u

djust the

g

rk plug w

a

g by scre

w

he plug b

y

socket a

ft

ue: 2.0 k

g

peed A

n & adjust

m

e perform

e

at needed

d check a

n

fter engi

n

that oper

r 10 min

u

the engin

e

Idle adju

s

et highe

r

(Turn ou

t

engine an

d

il around

1

le speed:

pm

SMC

acid orga

n

cleaning

e

tall the el

e

en install

lug : NG

K

cap.

he spark

p

.

g gap.

.7 mm

nd electr

o

ap if nec

e

sher and

ing it.

turning 1

/

er install

e

-m / 20N

-

djustm

e

ent for i

d

d after all

adjustme

n

d adjust

m

e is being

ates engi

n

tes.)

.

t screw c

l

Idle sp

e

) to get lo

w

adjust th

,750~18

5

ATV 5

0

ized solv

e

ngine oil

a

ment ont

o

the air

- BPR7H

S

lug hole.

de of the

ssary.

nstall the

2 turn mo

d.

m

nt

le speed

parts in

t have b

e

ent have

t

warm up.

e from sto

ockwise (

t

ed. Cou

n

er Idle sp

e throttle

s

0 rpm.

/10

0

S

nt

nd

re

en

o

(It

p to

urn

nter

eed

top

ervice

M

C

anua

l

hapter 2 Maintena

n

Adjust Scr

e

-

1

ce Inform

a

w

9-

tion

2-

a.

b.

1.

2.

c.

In

s

ex

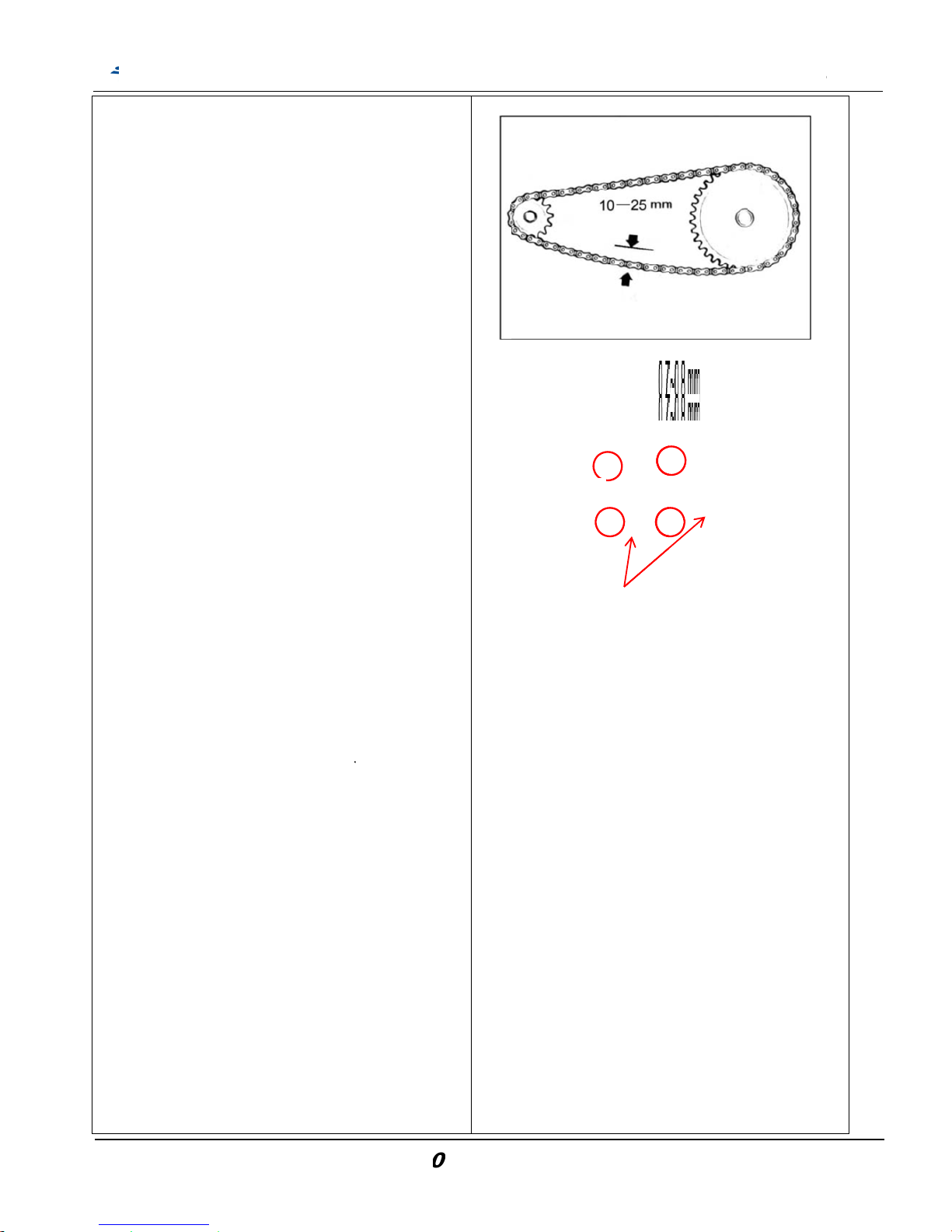

08. Driv

i

Inspect t

h

The st

a

A

djust th

e

Loose th

e

connecti

o

rear hub,

by turn t

h

After adj

u

four lock

Clean th

e

When t

h

it shoul

d

lubricat

e

Using c

o

lubricat

e

Clean t

h

wipe it

d

Inspect

t

or dam

a

Replac

e

or dam

a

pect the

d

cessive w

e

ng Chai

e chain sl

ndard is

1

chain sl

a

lock bolt

s

n betwee

n

then adju

s

e adjustin

g

st to the s

bolts.

Driving

C

e drive ch

be remo

v

d by spe

c

mmercial

the drive

e drive ch

ry.

he drive

c

ge.

the chain

ged.

rive spro

c

ar or da

m

SMC

n

ack.

0-25mm.

ck.

(4 pcs) o

rear swi

n

t the driv

e

nut.

uitable sla

hain

ain beco

m

ed, clean

e

ify lubrica

t

chain lub

r

chain.

ain with k

e

hain for p

o

, if it is wo

r

ket teeth,

age, repl

a

ATV 5

0

n the

g arm an

d

chain sla

k, tighten

es very di

d and

or.

icant to

rosene a

n

ssible we

a

n excessi

v

f it is

ce it.

/10

0

S

ck

the

rty,

d

ar

ely

L

ervice

M

C

Adju

ock bolt

anua

l

hapter 2

st bolt

Maintena

n

-

2

ce Inform

a

0-

tion

2-

a.

M

e

en

pl

a

b.

M

ethemm

c.

M

ethe

09 Brak

e

Inspect t

h

excessiv

e

Replace

o

asure the

d of the b

r

y is 15-2

5

Inspect t

h

front /rea

excessiv

e

or repair

asure the

end of th

.

Inspect t

h

excessiv

e

or repair

asure the

end of th

Syste

m

e front br

a

free play

r repair if

free play

o

ake lever.

mm.

e integrat

r drum br

a

play or o

t

if necessa

free play

o

e lever. T

h

e rear br

a

play or o

t

if necessa

free play

o

e pedal.

SMC

(drum

b

ke lever

a

or other d

necessar

y

f the bra

k

The stan

d

e brake (f

o

ke and co

her dama

ry.

f the rear

e standar

d

ke pedal

a

her dama

ry.

f the rear

ATV 5

0

rake)

nd cable

f

amage.

.

e lever at

ard of fre

e

ot pedal)

f

trol cabl

e

ge. Repla

c

brake lev

e

is 10-20

nd cable

f

ge. Repla

c

brake lev

e

/10

0

S

or

the

or

for

e

r at

or

e

r at

ervice

M

C

anua

l

hapter 2

Maintena

n

-

2

ce Inform

a

1-

tion

\

2-

T

h

ac

co

th

e

co

a.

M

a

co

b.

C

hreslim

ch

le

v

C

a

In

in

un

D

o

ha

wi

lno

c.

abcde

f.

d.

Ad

R

e

(r

e

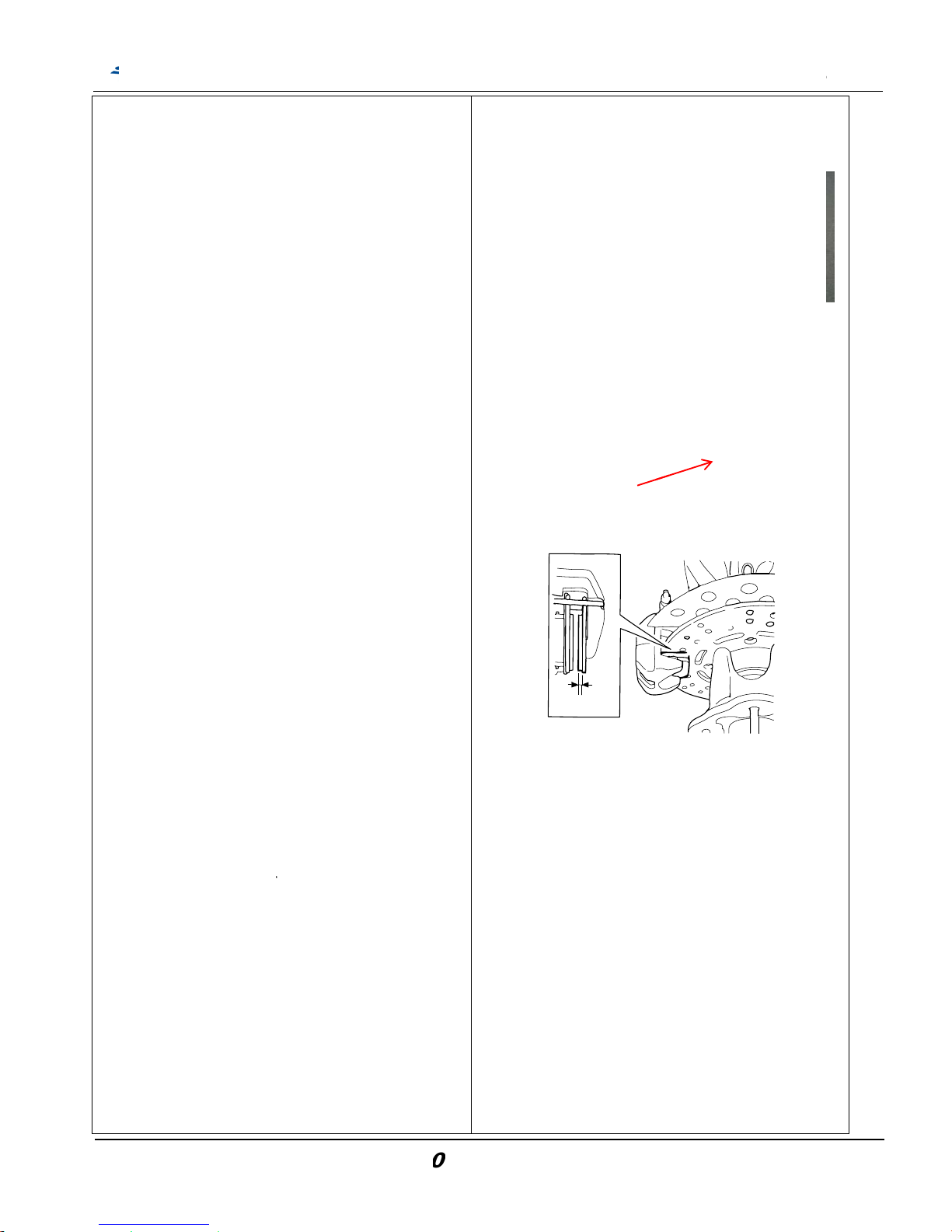

10. Bra

k

e Disk br

a

ive the th

r

mbine bra

right han

ntrolled b

y

Brake

S

ke sure t

h

rrosion or

Brake

F

eck brak

e

ervoir. If t

it, add br

a

eck brake

el found.

ution

order to

m

horizontal

til handle

s

not oper

a

d been re

m

l spread o

n-compati

Air Ble

e

Operati

. Open th

e

sufficient

bleed/oil

c

. Open th

e

the calip

e

. Connect

a

valve.

. Loose th

e

. Use a va

c

bubble/oi

fluid bec

o

Closed t

h

caliper.

Added

B

d brake fl

u

commen

d

commend

e Syste

m

ke versio

n

ee caliper

king syste

m

dle bar si

d

cable to t

ystem

H

e brake h

o

leaking oil

luid

fluid level

he level is

ke fluid to

system fo

r

aintain br

a

position,

d

top.

te the bra

oved. Ot

h

ut if opera

t

ble brake

f

d / Bra

k

on

brake flui

d

brake flui

d

hange.

rubber c

a

r.

transpar

drain val

v

uum dra

w

l brake flu

i

me clear

(

e drain v

a

rake Fl

id to UP

P

ed brake

f

) brake flu

SMC

(Disk

B

, apply by

(front 2 a

n

. The br

a

e is parki

n

he rear ca

ose

ses cont

a

.

in the bra

lower tha

n

UPPER li

leaking if

ke fluid in

o not rem

o

ke lever a

f

erwise, t

h

e the lev

e

luid toget

h

e fluid

C

reservoi

r

while doi

p of draini

ent hose t

o

e.

er to drai

n

d, until no

new).

lve on fro

n

uid

ER limit l

e

luid: DOT

3

id.

ATV 5

0

rake)

foot peda

d rear 1)

a

ke lever

o

g brake

liper side.

in no

ke fluid

the LO

W

it. Also

low brak

e

the reser

v

ve the c

a

ter the ca

p

e brake fl

u

r. Do not

m

er.

hange

cap. Add

ng the air

ng valve

o

draining

out the a

air bubbl

e

t/rear dis

k

vel.

or DOT4

/10

0

S

l, to

s a

n

ER

oir

p

id

ix

the

n

ir

or

ervice

M

C

anua

l

hapter 2

Maintena

n

-

2

ce Inform

a

2-

tion

C

a

N

efrobra

e.

B

r

T

hlimRema

C

a

T

ofro

It i

re

p

B

r

M

a

th

e

li

m

C

a

D

o

ca

pi

s

ba

on

ution

ver mix o

r

m damagi

ke perfor

m

Parking

b

A

pply th

then pu

s

release

brake.

To rele

a

lever ag

release.

Check t

h

parking

adjust t

h

side.

ake Lini

e indent

m

itation.

place the

rk closed

ution

check fro

nt wheel f

i

s not nec

e

lacing th

e

ake Pa

d

ke sure t

h

lining pa

d

itation gr

o

ution

not oper

a

liper bein

g

ton. In or

d

lance, the

e set.

use dirty

ng brake

s

ance.

rake

e right ha

n

h down t

h

the lever t

o

se the pa

r

ain and st

o

e brake f

o

brake. Adj

e adjustin

ng Wea

r

ark on br

a

brake lini

n

to the ed

g

nt brake li

n

rst.

ssary to r

e

brake lini

s Repla

c

e brake li

n

s if the b

r

ove close

te the bra

removed

er to mai

n

brake pa

d

SMC

brake flui

d

ystem or

r

d brake l

e

e button

s

activate

king brak

e

pper will

j

rce when

ust the br

a

g bolt on t

h

ke lining i

g pad if th

e of brak

e

ing must

move bra

ng.

ement

ing condi

t

ake lining

to the bra

k

ke pedal

a

to avoid p

tain brak

e

s must be

ATV 5

0

to preven

educing

ver and h

o

topper an

d

he parkin

g

, apply th

e

ump up a

n

set up th

e

ke force

b

e rear cal

s the wea

r

e wear li

m

disc.

e remov

e

ke hose w

ion. Repl

a

wear

e disc.

fter the

shing ou

t

power

replaced

b

/10

0

S

t

ld,

d

y

iper

it

hen

ce

y

ervice

M

C

A

dju

anua

l

hapter 2

st bolt

Maintena

n

-

2

ce Inform

a

3-

tion

2-

T

h

as

M

aop

2-

R

u

o

p

If

t

ch

2-

W

D

oLo

m

a

F

r

R

e

11. Bra

k

Inhibit

o

e brake li

g

brake pe

d

ke sure t

h

erated onl

12. Clut

c

n the AT

V

ening gra

d

he ATV is

eck clutch

13. Sus

p

arning

not ride t

h

oseness,

w

ke poor s

t

ont sus

p

Press d

o

several

t

Check i

f

bound

&

Replac

e

Tighten

ar sus

p

Press d

o

several

t

Check i

f

bound

&

Replac

e

e Light

S

r Switc

ht switch

i

al applied

at electri

c

y under b

r

h Wear

and incr

e

ually to c

h

in forwar

d

condition.

ension

e ATV wi

t

ear or d

a

ability an

d

ension

wn the fr

o

imes to c

h

it is dam

a

rebound)

relative p

all nuts a

n

ension

wn the re

imes to c

h

it is dam

a

rebound)

relative p

SMC

witch/

S

h

s to light

u

.

al starter

c

ake applyi

ase throttl

eck clutc

h

moving a

Replace i

h poor su

s

mage sus

drive-abi

l

nt suspe

n

eck its o

p

ged (oil le

arts if da

m

d bolts.

ar suspen

s

eck its o

p

ged (oil le

arts if da

m

ATV 5

0

tarting

p brake li

g

an be

ng.

e valve

operatio

n

d shakin

g

if need.

pension.

ension w

ity.

sion for

eration.

aking / ba

d

age foun

d

ion for

eration.

aking / ba

d

age foun

d

/10

0

S

ht

.

,

ill

.

.

ervice

M

C

anua

l

hapter 2

Adju

Maintena

n

st bolt

-

2

ce Inform

a

4-

tion

Loading...

Loading...