SMC Networks AC40-A, AC40-06-A, AC10A-A, AC20A-A, AC30A-A Operation Manual

...

Doc. No. AC-OMQ0008-C

PRODUCT NAME

AIR COMBINATION

MODEL/ Series

AC10(A,B)-※ -A

AC20(A,B,C,D)-※ -A

AC25(B,C)-※ -A

AC30(A,B,C,D)-※ -A

AC40(A,B,C,D)-※ -A

Contents

PAGE

1. PRECAUTION FOR SAFETY 1~8

2. APPLICATION 9

3. SPECIFICATIONS. . . 9

4. SERIESMAP AND COMBINATION OF EQUIPMENT. . . 10

5. HOW TO ORDER 11~15

6. ATTACHMENTS / ACCESSORIES(OPTIONS)PART NUMBER 16

7. TROUBLE SHOOTING 16

8. SPARE PARTS LIST 16

9. HOW TO REPLACE 17

10. DISASSEMBLY DRAWING . 18~19

11. DIMENSIONS . 20~24

1

AIR COMBINATION

Safety Instructions

These safety instructions are intended to prevent hazardous situations and/or equipment damage.

These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC),

Japan Industrial Standards (JIS)

1)

and other safety regulations

2)

.

1) ISO 4414: Pneumatic fluid power -- General rules relating to systems

ISO 4413: Hydraulic fluid power -- General rules relating to systems

IEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)

ISO 10218-1992: Manipulating industrial robots -- Safety

JIS B 8370: General rules for pneumatic equipment.

JIS B 8361: General rules for hydraulic equipment.

JIS B 9960-1: Safety of machinery – Electrical equipment for machines. (Part 1: General requirements)

JIS B 8433-1993: Manipulating industrial robots - Safety. etc.

2) Labor Safety and Sanitation Law, etc.

Caution

Operator error could result in injury or equipment damage.

Warning

Operator error could result in serious injury or loss of life.

Danger

In extreme conditions, there is a possibility of serious injury or loss of life.

Warning

1. The compatibility of the product is the responsibility of the person who designs the equipment or

decides its specifications.

Since the product specified here is used under various operating conditions, its compatibility with specific

equipment must be decided by the person who designs the equipment or decides its specifications based on

necessary analysis and test results.

The expected performance and safety assurance of the equipment will be the responsibility of the person who

has determined its compatibility with the product.

This person should also continuously review all specifications of the product referring to its latest catalog

information, with a view to giving due consideration to any possibility of equipment failure when configuring the

equipment.

2. Only personnel with appropriate training should operate machinery and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment including our products must be

performed by an operator who is appropriately trained and experienced.

3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.

The inspection and maintenance of machinery/equipment should only be performed after measures to prevent

falling or runaway of the driven objects have been confirmed.

When the product is to be removed, confirm that the safety measures as mentioned above are implemented

and the power from any appropriate source is cut, and read and understand the specific product precautions

of all relevant products carefully.

Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.

4. Contact SMC beforehand and take special consideration of safety measures if the product is to

be used in any of the following conditions.

1) Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to

direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping,

vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other

applications unsuitable for the standard specifications described in the product catalog.

3) An application which could have negative effects on people, property, or animals requiring special safety

analysis.

4) Use in an interlock circuit, which requires the provision of double interlock for possible failure by using a

mechanical protective function, and periodical checks to confirm proper operation.

2

AIR COMBINATION

Safety Instructions

Caution

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in manufacturing industries.

If considering using the product in other industries, consult SMC beforehand and exchange specifications

or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

Limited warranty and Disclaimer / Compliance Requirements

The product used is subject to the following “Limited warranty and Disclaimer” and “Compliance

Requirements”.

Read and accept them before using the product.

Limited warranty and Disclaimer

The warranty period of the product is 1 year in service or 1.5 years after the product is delivered,

whichever is first.

Also, the product may have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

For any failure or damage reported within the warranty period which is clearly our responsibility, a

replacement product or necessary parts will be provided.

This limited warranty applies only to our product independently, and not to any other damage

incurred due to the failure of the product.

Prior to using SMC products, please read and understand the warranty terms and disclaimers noted

in the specified catalog for the particular products.

Compliance Requirements

The use of SMC products with production equipment for the manufacture of weapons of mass

destruction(WMD) or any other weapon is strictly prohibited.

The exports of SMC products or technology from one country to another are govemed by the relevant

security laws and regulation of the countries involved in the transaction. Prior to the shipment of a SMC

product to another country, assure that all local rules goveming that export are known and followed.

当社の製品は、製造業向けとして提供していま

す。

ここに掲載されている当社の製品は、主に製

造業を目的とした平和利用向けに提供してい

ます。

製造業以外でのご使用を検討される場合には、

当社にご相談いただき必要に応じて仕様書の

取り交わし、

契約などを行ってください。

当社の製品は、製造業向けとして提供していま

す。

ここに掲載されている当社の製品は、主に製

造業を目的とした平和利用向けに提供してい

ます。

製造業以外でのご使用を検討される場合には、

当社にご相談いただき必要に応じて仕様書の

取り交わし、

契約などを行ってください。

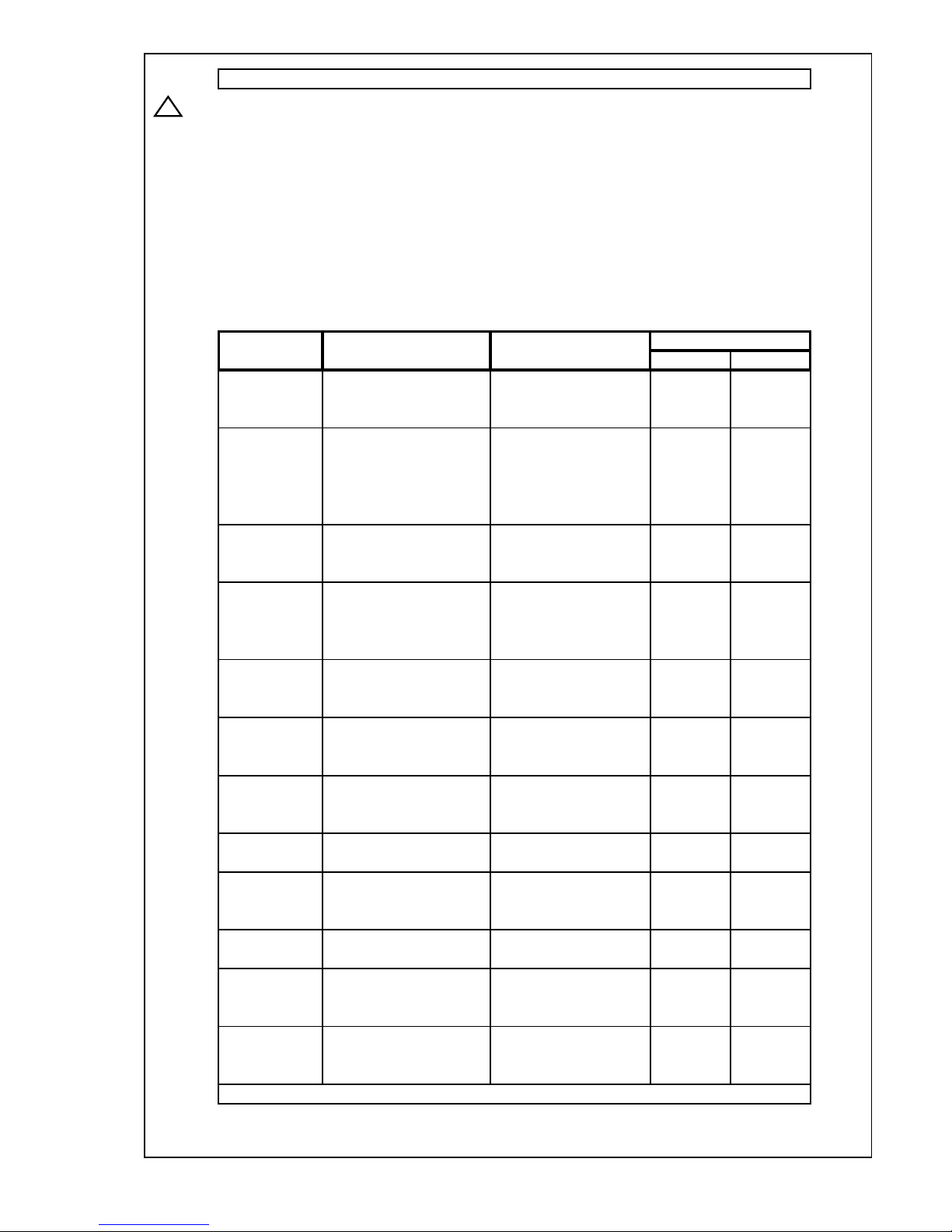

! WARNING

○ Air combination

①

②

Polycarbonate

Nylon

Hydrochloric acid

△

×

Chromic acid

Potash

×

○

Ammonia water

Carbonate of soda

Sodium sulphide

Sulphate of potash ×

△

Sulphate of soda

Carbon tetrachloride

Chloroform

△

Ethylene chloride

Methylene chloride

Benzene

Toluene

△

Paint thinner

Acetone Photographic film

Methyl ethyl ketone Dry cleaning × ×

Cyclohexane Textile industries

Ethyl alcohol

IPA

△

×

Methyl alcohol

Gasoline

Kerosene

Phthalic acid dim ethyl

Phthalic acid diethyl ×

○

Acetic acid

Methyl ether

Ethyl ether

Cutting oil

Brake oil additives × ×

Rubber accelerator

Thread -lock fluid

Seawater ×

△

Leak tester

When the above factors are present, or there is some doubt, use a metal case for safety.

③

External parts including the bonnet (material: polyacetal), bowl, sight dome (material:

polycarbonate) are made of resin. Organic solvents including synthetic fluid, chemicals

including acetone, alcohol, ethylene chloride, sulphuric acid, nitrate, hydrochrolic acid,

cutting oil, kerosene, gasoline, lock material of screw are harmful. Do not use the products

where containing those.

Effects organic solvents and chemicals, and where these elements are

likely to adhere to the equipment.

Chemical data for substances causing degradation (Reference)

Acid washing liquid

for metals

Sulphuric acid, Phosphoric acid

Material

Precautions for design

Acid

×

×

×

×

-

Sodium hydroxide (Caustic soda)

Calcium hydroxide (Slack lime)

Consult SMC if no leakage is allowed due to the environment, or operating fluid is not air.

Alcohol

Antifreeze

Adhesives

Degreasing of metals

Industrial salts

Water-soluble cutting

oil

Coatings

Dry cleaning

Cleaning liquid for

metals

Printing ink

Dilution

Inorganic

salts

Chlorine

solvents

Aromatic

series

Ketone

Alkaline

Other

Oil

Methyl amino

Brake oil additives

Synthetic oil

Anti-rust additives

-

Ester

Ether

Amino

○:Essentially safe. △:Some effects may occur. ×:Effects will occur.

○

○

3

Type

Chemical name

Application examples

-

Protect from ultra violet ray and radiation heat by shield.

○ Air filter, Lubricator, Filter-regulator and Mist separator

①

Avoid the application where charge and discharge of pressure to bowl is switched frequently.

This may damage the bowl. A metal bowl is recommended in these cases.

○ Regulator and Filter-regulator

①

! CAUTION

○ Air filter, Filter-regulator and Mist separator

①

○ Regulator and Filter-regulator

①

Air consumption from release port is 0.1L/min(ANR) or less.

! WARNING

○ Air combination

①

○ Air filter, Filter-regulator and Mist separator

①

Output of compressor: 0.75kW or more.

Discharged flow rate: 100L/ min (ANR) or more.

Operating pressure: 0.1MPa or more at min..

②

○ Regulator and Filter-regulator

①

②

③

④

⑤

○ Lubricator

①

②

③

④

⑤

Selection

A safety device needs to be installed if output pressure is exceeding the set pressure, otherwise this

can cause the breakage of outlet device and equipment or malfunction.

AD17-A and AD27-A with auto drain may leak during exhaust of pressure. (This leakage is allowed

in their constructions and not failure.) Be sure to connect piping for drain.

Mineral grease used on internal surfaces and packing may leak to the outlet. Please contact SMC if

this is a problem.

Operating pressure: 0.1MPa or more at min. for AD17-A and AD27-A, 0.15MPa or more at min. for

AD37-A and AD47-A.

Consult SMC if using this product for purposes other than its primary use of lubricating air line

equipment.

Long absence of operation or operation with outlet circuit sealed or balance circuit may cause

pressure fluctuation in outlet set pressure. Please consult SMC if this is a problem.

Set pressure of outlet pressure shall be 85% or less of inlet pressure. Pressure over 85% makes

operation susceptible to flow and inlet pressure which lead to cause unstable operation.

N.O type auto drain should be used under the following requirements to avoid operating failure.

N.C. type auto drain should be used under the following requirements to avoid operating failure.

4

If multiple auto drains are used, confirm used compressor has capacity over the result of multiplying

the above capacity and the number of used auto drains.

{For example, in case of two auto drain, the compressor need the capacity over 1.5kW [200L/ min

(ANR)].}

Maximum set pressure range in the spec. has margin. Pressure set may be higher than the

maximum value.

If regulator is used with circuit which requires high exhaust sensitivity or set precision, please

consult SMC.

The use at high frequency such as the use in press machine may damage internal components and

cause operating failure of the equipment installed to secondary side. Contact SMC for such a use.

Small air consumption may prevent the oil from dropping. Confirm air flow necessary to produce the

drops required for the correct amount of oil.

Do not supply the air from secondary side (reverse air flow). Otherwise, internal components may be

damaged.

If piping is branched at inlet side, the oil may flow back. Avoid the reverse flow by installing a check

valve (AKM series) to inlet side.

It is possible to exhaust the residual pressure to the inlet when releasing the inlet pressure, but the

exhaust can fail at a set pressure of 0.15MPa or less.

When the backflow function is necessary at 0.15MPa or less, a regulator with backflow function is

recommended.

! WARNING

○ Air combination

①

②

! CAUTION

○ Air combination

①

②

③

○ Air filter, Filter-regulator and Mist separator

①

○ Lubricator

①

! WARNING

○ Regulator and Filter-regulator

①

②

Operate the pressure adjusting handle manually. Tools may break the handle.

○ Lubricator

①

②

③

! CAUTION

○ Regulator and Filter-regulator

①

Check inlet pressure before setting up.

②

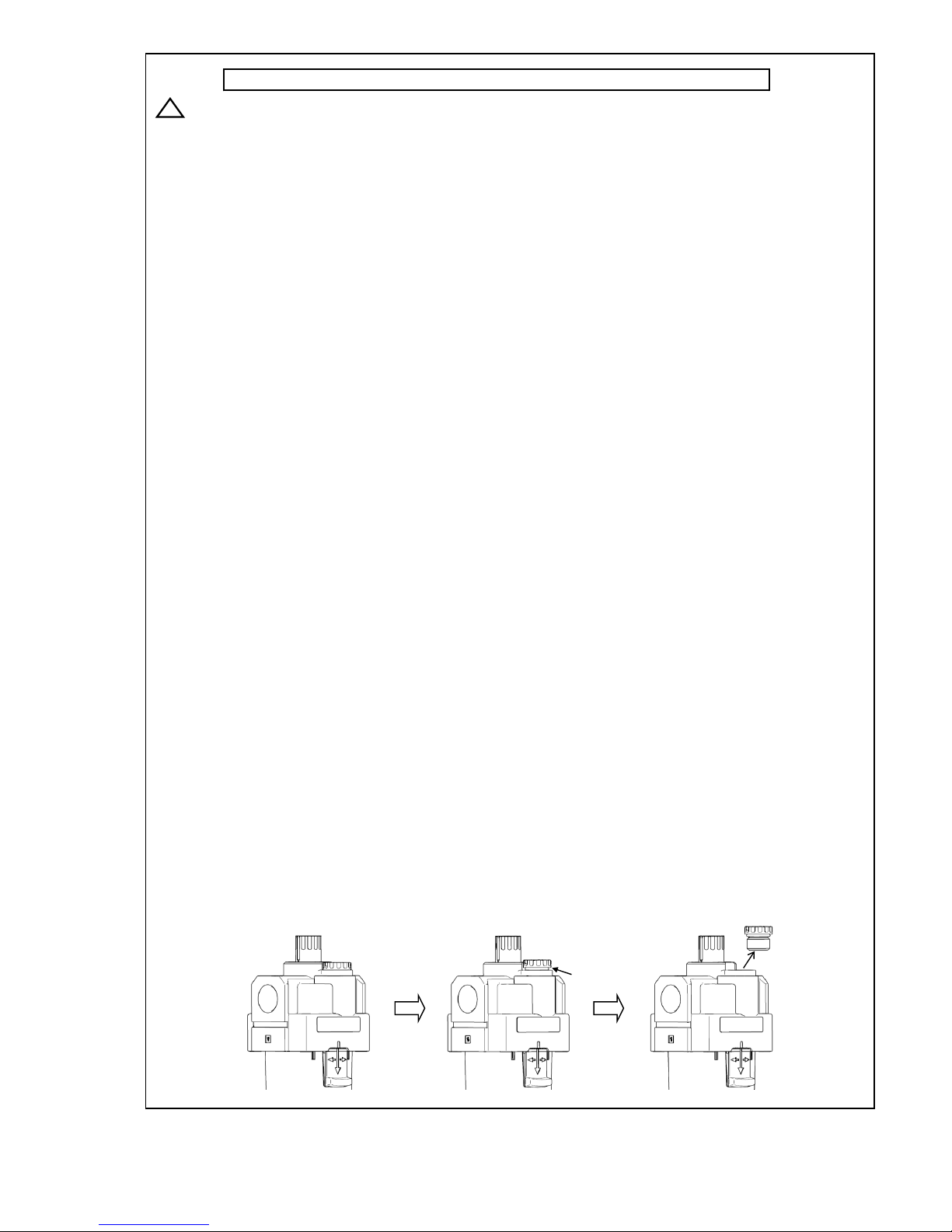

・Pull the pressure regulator handle to unlock. (You can visually verity this with the "orange

mark" that appears in the gap.)

③

④

⑤

Installation

Adjustment

Adjust the pressure adjusting handle ensuring correct inlet pressure and outlet pressure.

Excessive rotation may cause damage to internal parts.

Adjustment of the oil adjustment valve should be carried out manually. The use of tools, etc. can

result in damage to the unit. (AL20-A to AL40-A)

Install the bowl vertically with bowl facing down. If it is inclined, dripping may not be confirmed.

Turning the oil adjustment valve counterclockwise increases the dripping amount, and turning it

clockwise reduces the dripping amount. From the fully closed position, three rotations will bring it

to the fully open position. Please do not rotate it any further than this.

Note that the numbered scale markings are guidelines for adjusting the position, and not

indicators of the dripping amount. (AL20-A to AL40-A)

Connect the product ensuring the direction of " " (IN) and " " (OUT) for air direction or an

arrow. Wrong connection may cause malfunction.

Install with enough space around each assembly component to perform regular maintenance and

operation. The required space is shown on 「11. Dimensions」 (P20 to 24).

Do not drop or apply impact during transportation or installation. It will cause damage to the

product or operation failure.

Do not install in areas of high humidity or high temperature. The product cannot be used in the

horizontal or upward directions outside of the specifications.

Install vertically so that outlet of drain would turned downward. Use with the outlet of drain turned

horizontal or upward causes malfunction.

When using a hexagon socket head cap screw to wall mount an air combination, we recommend

using a ballpoint screwdriver.

On AL10-A, some dripping may occur even when needle is fully opened.

djust pressure incrementally. Pressure may become lower than set pressure if adjusted by

decreasing the value. Rotate the handle clockwise to raise the set pressure. Counterclockwise to

reduce the pressure. Moreover, please lock the handle after setting pressure.

Outlet pressure may rise if eliminate the inlet pressure after pressure setting and supply pressure

again. The pressure becomes close to the set pressure after air is consumed in outlet.

Be sure to unlock the handle before adjusting the pressure and lock it after setting the pressure.

Failure to follow this procedure can damage the handle and the outlet pressure may fluctuate.

5

For the regulator with the pressure gauge, do not apply pressure exceeding the maximum scale

of the pressure gauge in order to protect the gauge.

・Push the pressure regulator handle to lock. When the handle is not easily locked, turn it

left and right a little and then push it. (When the handle is locked, the "orange mark", i.e.,

the gap will disappear.)

⑥

⑦

! WARNING

○ Air combination

①

②

③

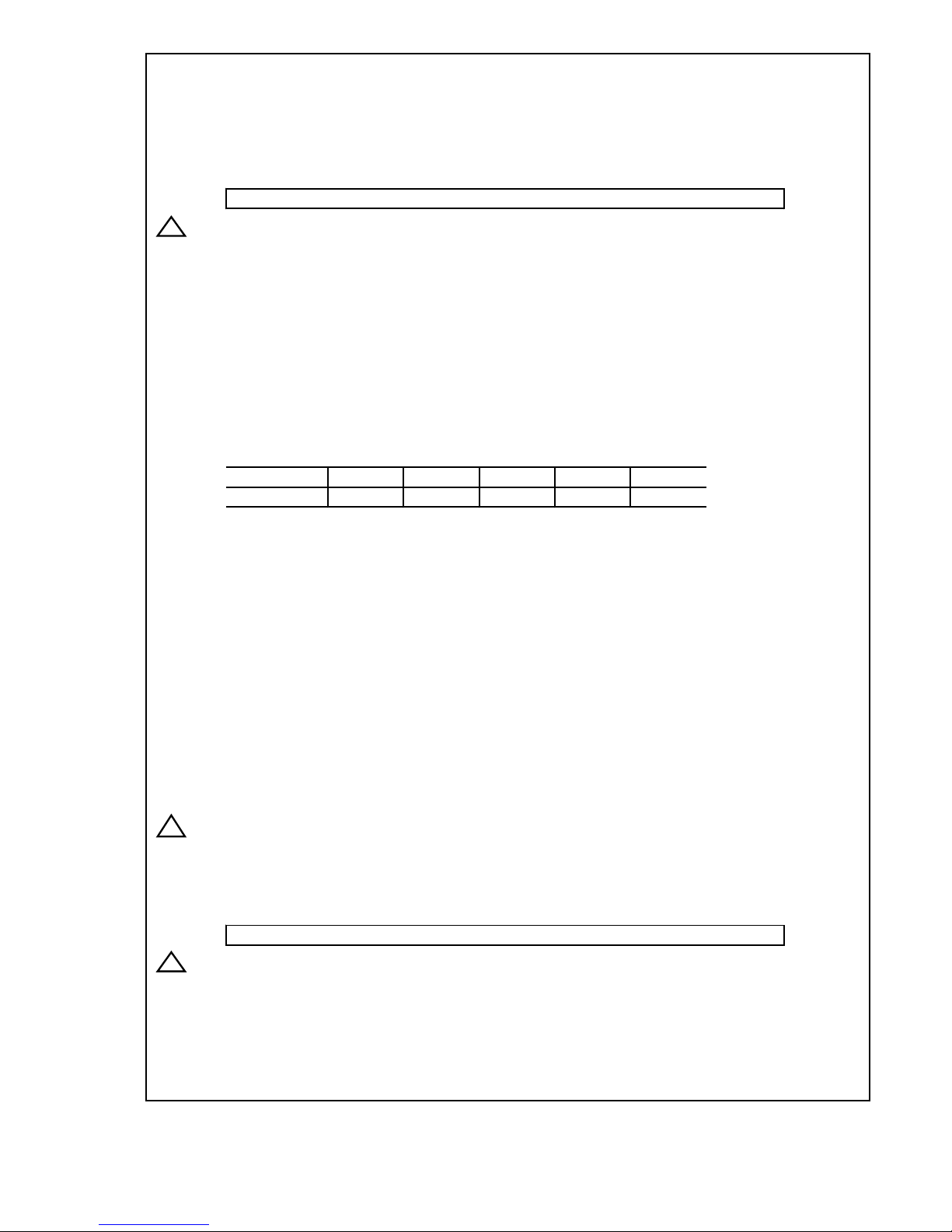

Recommended torque unit: N・m

Screw 1/8 1/4 3/8 1/2 3/4

Torque

3~5 8~12 15~20 20~25 28~30

*For port size M5: After tightening fitting, tighten approx. 1/6 more by using tool.

④

○ Air filter, Filter-regulator and Mist separator

①

②

AD17, 27-A: I.D. f2.5 (f3/32") at min., Length 5m (200") at max.

AD37, 47(N)-A: I.D. f4 (f3/16") at min., Length 5m (200") at max.

AD38, 48(N)-A: I.D. f6.5 (f1/4") at min., Length 5m (200") at max.

! CAUTION

○ Lubricator

①

! WARNING

○ Air combination

①

②

Outlet pressure may change if filter regulator is used for long periods. Please confirm set

pressure regularly.

When pressure difference between the inlet side and the outlet side is large, chattering

may occur. In that case, please reduce and use pressure difference between the inlet side

and the outlet side. Please consult SMC it chattering continues.

Blow out or clean piping before piping to eliminate swarf, cutting oil, solid foreign material.

Contamination of piping may cause damage or malfunction.

When installing piping, avoid chips and sealing materials from piping screws entering the

inside of equipment. Or malfunction may occur. When use sealing tapes, leave 1.5~2

threads of the end of thread exposed.

Hold the female screw side and screw in piping with recommended tightening torque.

Insufficient tightening torque lead to cause loose piping or sealing failure. Excessive

torque may lead to cause screw breakage. Tightening without holding female screw side

applies excessive force to the piping bracket which lead to cause breakage.

Use clean air. Compressed air containing chemicals, organic solvent, synthetic oil or

corrosive gas may lead to cause breakage of parts or malfunction.

Air containing too much moisture may cause malfunction. Install the air drier or the

aftercooler before the air combination.

6

Piping

Air Source

Do not apply any torsional moment, or bending moment except the weight of the filter

regulator itself. External piping needs to be supported separately. Hard piping like steel

tube is susceptible to excessive moment load or vibration. Insert the flexible tube to cancel

the influence.

Drain guide is not equipped with valve function. Be sure to connect piping for drain. No

piping for drain allows the drain and compressed air to exhaust freely. Also, the piping

should be performed with drain guide held by spanner to prevent breakage of bowl.

The piping for drain from auto drain should be connected under the following requirements

to avoid operating failure.

Avoid rising piping and piping branches on secondary side. Otherwise, lubricating failure

may be caused.

! WARNING

○ Air combination

①

○ Air filter, Lubricator, Filter-regulator and Mist separator

①

②

③

○ Air filter, Filter-regulator and Mist separator

①

② Drain the bowl by opening drain cock before the drain level in the bowl reaches baffle.

○ Regulator

①

○ Lubricator

①

②

③

Open and close drain cock manually. Open and close too much may damage the drain cock.

Use class 1 turbine oil (without additives) ISO VG32. Using other lubricant can cause damage

to devices and result in malfunction.

In AL10-A and AL20-A series, lubrication during pressurization is not possible.

Exhaust the inlet pressure and check that there is no pressure within the product. Supply oil

after removing the oil supply plug.

The AL30-A and AL40-A have a slight leak from the inside of the case to the oil supply orifice.

Loosen the oil supply plug one turn and wait a short time for pressure to release then remove

the oil supply plug. As there is a slight leak from inside the case to the oil supply orifice, set the

oil supply to “Max Level” slowly, while ensuring an oil film is not created over the oil supply

orifice.

When removing the oil supply plug, pressure within the case will be released, so ensure that

protective goggles are equipped.

After oil is supplied, after ensuring that it is correctly positioned, the oil supply “O” ring can be

returned to its previous state by gently screwing it in.

(For tightening torque, see Operation Manual of Lubricator)

Maintenance

7

Maintenance and checks should be done by following the procedure in the operation manual.

Incorrect handling of the product may cause breakage or malfunction of the equipment or

device.

Perform periodical check to find cracks, flaw or other deterioration on the resin parts such as

bowl or sight dome. If any of these are seen, a malfunction has occured, replace with new

parts. Investigate and review the operating conditions if necessary.

Check for dirt in resin bowl periodically. If any dirt is seen, replace with new bowl. And if

removing off the dirt by washing instead of using a replacement, never use washing material

other than neutral detergent. Otherwise, the bowl is damaged.

Replace the element before 2 years passed since purchase or pressure drop from initial outlet

pressure reaches 0.1MPa. Or the element is broken.

When using the regulator and filter regulator with backflow function between a solenoid valve

and an actuator, check the pressure gauge periodically.

Sudden pressure fluctuations may shorten the durability of the pressure gauge. A digital

pressure gauge is recommended for such situation or as deemed necessary.

exhaust

In Use

After removal

Internal case pressure

exhausted

Loading...

Loading...