SMC Networks 56-VQC1000 Series,56-VQC4000 Series,56-VQC2000 Series Installation And Maintenance Manual

56-VV5QC*1-TFL33-C

Installation and Maintenance Manual

5 Port Solenoid Valve

Series 56-VQC1000/2000/4000

Marking description

Manifold 56-VV5QC#1…

II 3G Ex nA IIB T5 Gc X -10ºC ≤ Ta

≤

+50ºC

II 3D Ex tc IIIC T85°C Dc X IP67

Manifold with Serial Transmission System (56-EX500 or 56-EX250)

Also refer to separate applicable documentation

Group II

Category 3

Suitable for Gas and Dust environment

Type of Protection “non-sparking apparatus”

Special condition X “Protect from impacts” see Section 3

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution

Indicates a hazard with a low level of risk, which if

not avoided, could result in minor or moderate

injury.

Warning

Indicates a hazard with a medium level of risk,

which if not avoided, could result in death or

serious injury.

Danger

Indicates a hazard with a high level of risk, which

if not avoided, will result in death or serious

injury.

• The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed

by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

1 Safety Instructions (continued)

3) Before machinery/equipment is re-started, ensure all safety measures to

prevent sudden movement of cylinders etc. (Supply air into the system

gradually to create back pressure, i.e. incorporate a soft-start valve).

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if the

product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air navigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

1.1 Specific recommendations:

• Protect from impacts using an ATEX enclosure suitable for impacts.

• Not suitable for Zones 0/20 and Zones 1/21. Only suitable for Zones

2/22.

• This product has components made of aluminium alloy. W hen mounting

this product, it must be installed such that, even in the event of rare

incidents, ignition sources due to impact and friction sparks are

excluded.

• Do not brush or wipe this product to avoid static charge build up. Static

charge can cause a spark or ignition source.

• Ensure that the air supply system is filtered to 5 microns.

1.2 Conforming to Standards

This product is certified to and complies to the following standards:

Electrical Apparatus for Explosive Gas

Atmospheres

EN 60079-0 : 2009,

EN 60079-15 : 2010

Electrical Apparatus for use in the presence of

Combustible Dust

EN 60079-31 : 2009

2 Specifications

2.1 General Specifications

Series 56-VQC1000, 2000, 4000

Valve configuration Metal seal Rubber seal

Fluid Air/Inert gas

Maximum operating

pressure

0.7 MPa

Single 0.1 MPa 0.15 MPa

Double 0.1 MPa

3-position 0.1 MPa 0.2 MPa

56-VQC1000

56-VQC2000

Minimum

operating

pressure

4-position - 0.15 MPa

Maximum operating

pressure

1.0 MPa

Single 0.15 MPa 0.2 MPa

Double 0.15 MPa

56-

VQC4000

Minimum

operating

pressure

3-position 0.15 MPa 0.2 MPa

Proof pressure 1.5 MPa

Fluid temperature -10°C to 50°C

Lubrication Not required

Manual override Locking type (tool required)

Locking type (finger/thumb operation)

Slide locking type (56-VQC1000/2000)

Impact/Vibration resistance 150/30 m/s

2 (Note 1)

Enclosure IP67

Rated coil voltage 24VDC

Allowable voltage fluctuation ±10% of rated voltage

Coil insulation Equivalent to B type

Power consumption (current)

at 24VDC

1W (42mA), inrush

(Note 2)

0.35W (15mA), holding

2 Specifications (continued)

Note 1) Impact resistance: There should be no malfunction of the valve

after testing, using a drop impact tester, along the valve axis and

at right-angles to the valve and armature. Carry out each test with

the valve energised and de-energised (Value at the initial stage).

Vibration resistance; There should be no malfunction of the valve

after testing, using a 8.3 to 2000 Hz sweep along the valve axis

and at right-angles to the valve and armature. Carry out each test

with the valve energised and de-energised (Value at the initial

stage).

Note 2) The power saving circuit is included in the manifold.

2.2 Batch codes and Construction month:

2012 2013 2014 ….. 2021 2022 2023 ….. Year

Month

Q R S ….. Z A B …..

Jan o Qo Ro So ….. Zo A o Bo …..

Feb P QP RP SP ….. ZP AP BP …..

Mar Q QQ RQ SQ ….. ZQ AQ BQ …..

Apr R QR RR SR ….. ZR AR BR …..

May S QS RS SS ….. ZS AS BS …..

Jun T QT RT ST ….. ZT AT BT …..

Jul U QU RU SU ….. ZU AU BU …..

Aug V QV RV SV ….. ZV AV BV …..

Sep W QW RW SW ….. ZW AW BW …..

Oct X QX X SX ….. ZX AX BX …..

Nov y Qy RQ y Sy ….. Zy Ay By …..

Dec Z QZ RZ SZ ….. ZZ AZ BZ …..

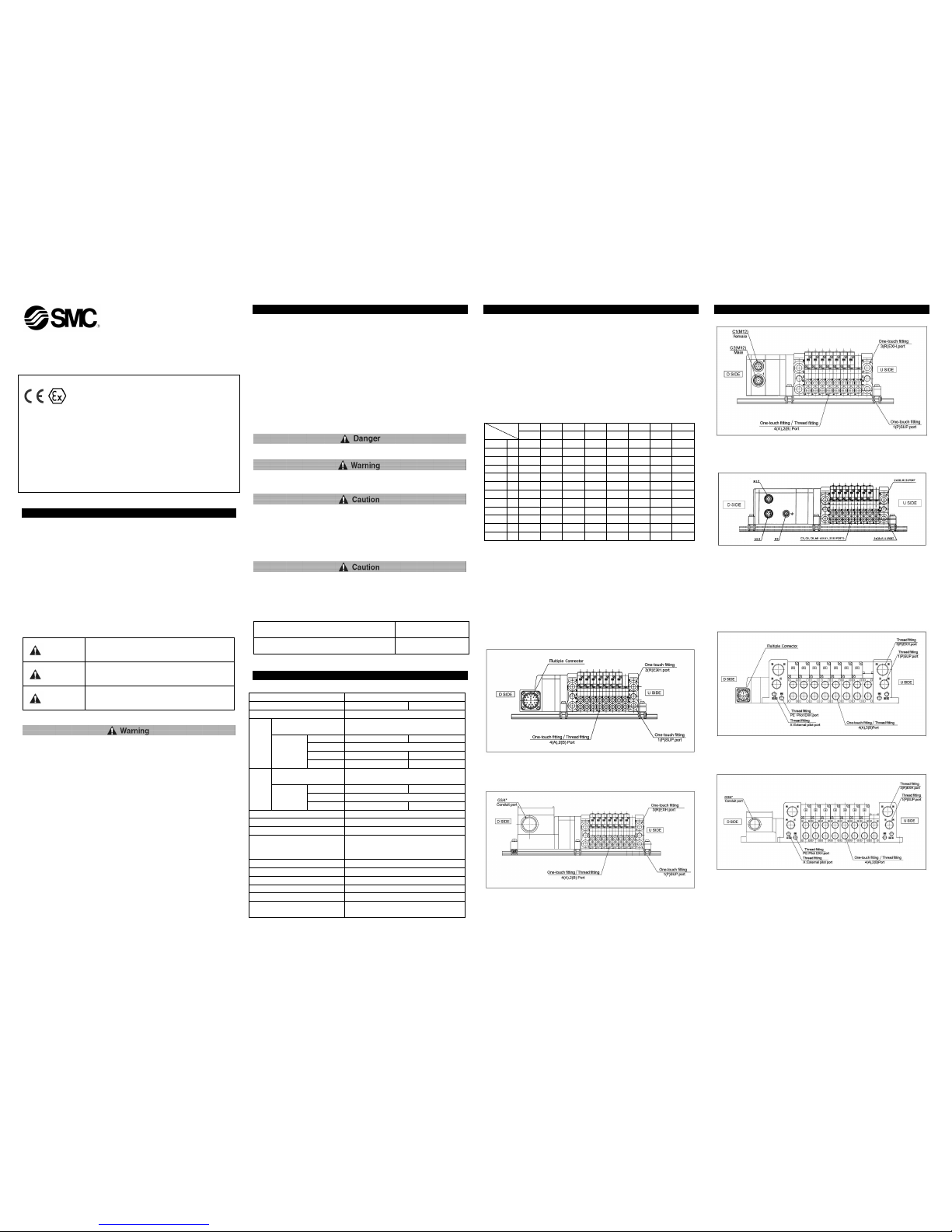

2.3 Piping

56-VQC1000/2000 (M-Kit)

Figure 1

56-VQC1000/2000 (T-Kit)

Figure 2

2 Specifications (continued)

56-VQC1000/2000 (56-EX500)

Figure 3

56-VQC1000/2000 (56-EX250)

Figure 4

56-VQC4000 (M-Kit)

Figure 5

56-VQC4000 (T-Kit)

Figure 6

56-VV5QC*1-TFL33-C

2 Specifications (continued)

56-VQC4000 (56-EX500)

Figure 7

56-VQC4000 (56-EX250)

Figure 8

3 Installation

3.1 Installation

• Do not install the product unless the safety instructions have been read

and understood.

• Protect from impacts using an ATEX enclosure suitable for

impacts.

3.2 Environment

• Do not use in an environment where the product is directly exposed to

corrosive gases, chemicals, salt water, water or steam.

• Do not use in an explosive atmosphere, except Zone 2/22.

• The product should not be exposed to prolonged sunlight. Use a

protective cover.

• Do not mount the product in a location where it is subject to excessive

vibrations and/or impacts.

• Do not mount the product in a location exposed to radiant heat.

• Remove emissive heat.

• Employ suitable protective measures in locations where there is contact

with water droplets, oil or welding splatter, etc.

• When the solenoid valve is mounted in a control panel or is energised for

a long time, make s ure the ambient temperature is within the valve

specification range.

3.3 Piping

• Before piping make sure to clean up chips, cutting oil, dust etc.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1.5 to 2 threads exposed on

the end of the pipe/fitting.

• Install piping s o that it does not apply pulling, pressing, bending or other

forces on the valve body.

3 Installation (continued)

• Tighten fittings to the specified tightening torque shown in Table 1.

Thread Tightening Torque N•m

M5 By hand + 1/6 turn with a wrench (1/4 turn for miniature fittings)

Rc 1/8 7 to 9

Rc 1/4 12 to 1 4

Rc 3/8 22 to 2 4

Rc 1/2 28 to 3 0

Rc 3/4 28 to 3 0

Table 1

3.4 Electrical Connection

• The manifold has negative common (-COM).

• Avoid mis-wiring, as this can cause malfunction, damage and

combustion to the product.

• Use voltage that is within ±10% of the rated voltage. Application of

incorrect voltage may cause malfunction or damage.

• To prevent noise and surge in signal lines, keep all wiring separate from

power lines and high voltage lines. Otherwise this can cause

malfunction.

• Use electrical circuits that do not generate chattering in their contacts.

• Do not bend or pull cables repeatedly.

• Disconnect power supply before removing or making electrical

connections

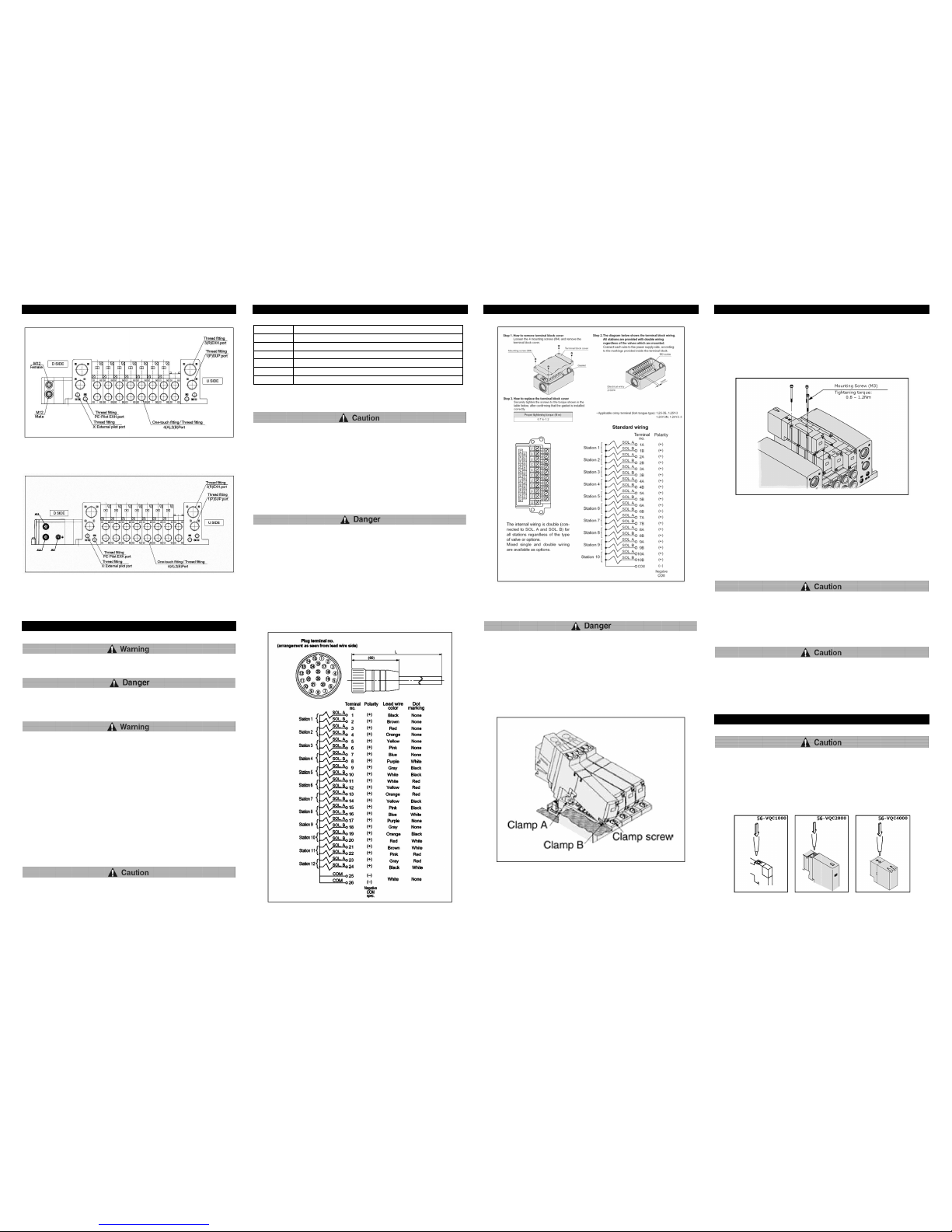

Multiple connector wiring (M-Kit)

Figure 9

3 Installation (continued)

Terminal block wiring (T-Kit)

Figure 10

3.5 Mounting

• Never remove a valve from the manifold when energised.

• Never remove terminal box cover when power is connected to the

manifold.

• Never disconnect or reconnect cables or connectors when power is

connected to the manifold.

• Install 56-VQC valves only.

• Install 56-VV5QC manifolds only, as it has an integrated power saving

circuit.

56-VQC1000/2000 Valve mounting:

Figure 11

Removal procedure:

• Loosen clamp screws until they turn freely (they do not come out).

• Remove the solenoid valve from Clamp B by lifting the coil side of the

valve, while pushing on the screw top.

3 Installation (continued)

Mounting procedure:

• Push the clamp screw. Clamp A now opens.

• Insert the end plate hook of the valve into Clamp B from an angle.

• Push the valve down into place (when the clamp screw is released,

Clamp A will lock).

56-VQC4000 Valve mounting:

Figure 12

Removal procedure:

• Loosen mounting screws until they turn freely.

• Remove the solenoid valve from Clamp B by lifting the coil side of the

valve first.

Mounting procedure:

• Push the coil side of the valve into the connector on the manifold.

• Tighten the mounting screws to torque 0.8 to 1.2 N•m.

• Ensure all gaskets are present before mounting valves.

• Do not l et foreign matter stick to gaskets or sealing fac es of the valve to

avoid air leaks

3.6 Lubrication

• SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

• If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32. Once lubricant is used in the system, lubrication must be

continued because the original lubricant applied during manufacturing

will be washed away.

4 Settings

4.1 Manual Override

• Since connected equipment will operate when the manual override is

activated, confirm that conditions are safe prior to activation.

Non-locking push type (tool required)

• Push down the manual override button with a small screwdriver, etc.

until it stops.

• The manual override will return when released.

Figure 13

Slotted locking push type (tool required)

• Push down the manual override button with a small flat head screwdriver

until it stops and turn 90° clockwise to lock.

Loading...

Loading...