Page 1

S0700-TFS56

Instruction Manual

Manifold 56-SS0750-##SDA#

Solenoid Valve 56-S07#0#-5-#

The intended use of this manifold is to control pneumatically operated

equipment in ATEX Zone 2 (3G) areas. The valves in the manifold are

controlled via the 56-EX260 Serial Transmission System.

This manual should be read in conjunction with the manual for the 56EX260 (56-EX260-TFT07).

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of potential

hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition to

International Standards (ISO/IEC)

1)

, and other safety regulations.

1)

ISO 4414: Pneumatic fluid power - - General rules relating to systems.

ISO 4413: Hydraulic fluid power - - General rules relating to systems.

IEC 60204-1: Safety of machinery - -Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Manipulating industrial robots -Safety.etc.

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

1 Safety Instructions (continued)

Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

Keep this manual in a safe place for future reference.

To ensure safety of personnel and equipment the safety instructions in

this manual must be observed, along with other relevant safety

practices.

Caution

Caution indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Warning

Warning indicates a hazard with a medium level

of risk which, if not avoided, could result in death

or serious injury.

Danger

Danger indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

1.1 Safety instructions

Warning

The compatibility of the product is the responsibility of the person

who designs the equipment or decides its specifications.

Since the product specified here is used under various operating

conditions, its compatibility with specific equipment must be decided by

the person who designs the equipment or decides its specifications

based on necessary analysis and test results. The expected

performance and safety assurance of the equipment will be the

responsibility of the person who has determined its compatibility with the

product. This person should also continuously review all specifications of

the product referring to its latest catalogue information, with a view to

giving due consideration to any possibility of equipment failure when

configuring the equipment.

Only personnel with appropriate training should operate machinery

and equipment.

The product specified here may become unsafe if handled incorrectly.

The assembly, operation and maintenance of machines or equipment

including our products must be performed by an operator who is

appropriately trained and experienced.

Do not service or attempt to remove product and

machinery/equipment until safety is confirmed.

1) The inspection and maintenance of machinery/equipment should only

be performed after measures to prevent falling or runaway of the driven

objects have been confirmed.

2) When the product is to be removed, confirm that the safety measures

as mentioned above are implemented and the power from any

appropriate source is cut, and read and understand the specific product

precautions of all relevant products carefully.

3) Before machinery/equipment is restarted, take measures to prevent

unexpected operation and malfunction.

Contact SMC beforehand and take special consideration of safety

measures if the product is to be used in any of the following

conditions.

1) Conditions and environments outside of the given specifications, or

use outdoors or in a place exposed to direct sunlight.

2) Installation on equipment in conjunction with atomic energy, railways,

air navigation, space, shipping, vehicles, military, medical treatment,

combustions and recreation, or equipment in contact with food and

beverages, emergency stop circuits, clutch and brake circuits in press

applications, safety equipment or other applications unsuitable for the

standard specification described in the product catalogue.

3) An application which could have negative effects on people, property,

or animals requiring special safety analysis.

4) Use in an interlock circuit, which requires the provision of double

interlock for possible failure by using a mechanical protective function,

and periodical checks to confirm proper operation.

Always ensure compliance with relevant safety laws and standards.

All electrical work must be carried out in a safe manner by a qualified

person in compliance with applicable national regulations.

1 Safety Instructions (continued)

1.2 Special conditions of use

Warning

Protect from impacts using an ATEX compliant enclosure.

Do not separate manifold components when energised.

The manifold is suitable for use in ATEX Zone 2 applications only.

Ensure that the hazardous gas does not enter the pneumatic circuit.

The manifold must be installed in an enclosure of at least IP54.

The manifold is suitable for areas of maximum pollution degree 2 only.

To maintain the IP rating, do not separate manifold parts.

To avoid static charge build up, use only a damp cloth to clean the

manifold.

Ensure that the product does not become electrostatically charged.

Protect the unit from sources of heat which can generate surface

temperatures higher than the temperature classification.

Use only ATEX approved M12 connectors and use only shielded

cable to provide grounding.

Only 56-S07#0#-5-# valves to be used in this manifold.

If energising 5 or more adjacent stations for an extended period the ON

time must be less than the OFF time in any 24 hour period.

Caution

Ensure that the air supply system is filtered to 5 microns.

The product is provided for use in manufacturing industries.

The product herein described is basically provided for peaceful use in

manufacturing industries.

If considering using the product in other industries, consult SMC

beforehand and exchange specifications or a contract if necessary.

If anything is unclear, contact your nearest sales branch.

1.3 Conformity to Standards

This product conforms to the following ATEX standards

Electrical Apparatus for Explosive

Gas Atmospheres

EN 60079-0:2012+A11:2013

EN 60079-15:2010

2 Specifications

2.1 General specifications

56-S07#0#-5-# Solenoid valve

Valve specification

Valve construction

Rubber seal

Fluid

Air/Inert gas

Maximum operating pressure

0.7MPa [1.0MPa]

Minimum operating pressure

0.2MPa [0.3MPa]

Ambient temperature °C

–10 to 50°C

(Note 1)

Maximum operating frequency

5Hz

Pilot valve exhaust method

Common exhaust

Pilot valve manual override

Push type

Lubrication

Not required

Impact/Vibration resistance

(Note 2)

30/100 m/s2

Enclosure

See notes 3, 4

Electrical

specification

Coil rated voltage

24 VDC

Allowable voltage variation

±10% of rated voltage

Coil insulation type

Class B or equivalent

Power consumption (current)

DC

0.35W [0.5W]

Value in [ ] shown for K option

Note 1) Use dry air to prevent condensation when operating at low

temperatures.

Note 2) Impact resistance: No malfunction occurred when it is tested

with a drop tested in the axial direction and at right angles to the main

valve and armature in both energised and de-energised states.

Vibration resistance: No malfunction occurred in a one-sweep

test between 8.3 and 2000 Hz. Test was performed in both energised and

de-energised states in the axial direction and at right angles to the main

valve and armature.

2 Specifications (continued)

Note 3) The manifold must be installed in an enclosure of at least IP54,

and only used in an area of maximum pollution degree 2.

Note 4) Protect from impacts using an ATEX compliant enclosure.

Note 5) For 56-EX260 specifications, see manual 56-EX260-TFT07.

2.2 Batch codes and construction month:

2.3 Piping

56-SS0750-##SDA# (56-EX260)

3 Installation

3.1 Installation

Warning

Do not install the product unless the safety instructions in section 1 have

been read and understood.

Protect from impacts using an ATEX compliant enclosure.

To maintain the IP rating, do not separate manifold parts.

This manual should be read in conjunction with the manual for the 56-

EX260 (56-EX260-TFT07).

3.2 Environment

Warning

Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

Do not expose to direct sunlight. Use a suitable protective cover.

Do not install in a location subject to vibration or impact. Check the

product specifications.

Do not mount in a location exposed to radiant heat.

The manifold is suitable for use in ATEX Zone 2 applications only.

Ensure that the hazardous gas does not enter the pneumatic circuit.

The manifold must be installed in an enclosure of at least IP54.

The manifold is suitable for areas of maximum pollution degree 2 only.

Ensure that the product does not become electrostatically charged.

3.3 Lubrication

Caution

SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

If a lubricant is used in the system, use turbine oil Class 1 (no additive),

ISO VG32. Once lubricant is used in the system, lubrication must be

continued because the original lubricant applied during manufacturing

will be washed away.

Contact SMC for OIL FREE specification.

Year

Month

2012

2013

2014

….

2021

2022

2033

…. Q R S …. Z A B ….

Jan O Qo

Ro

So

….

Zo

Ao

Bo

….

Feb P QP

RP

SP

….

ZP

AP

BP

….

Mar Q QQ

RQ

SQ

….

ZQ

AQ

BQ

….

Apr R QR

RR

SR

….

ZR

AR

BR

….

May S QS

RS

SS

….

ZS

AS

BS

….

Jun T QT

RT

ST

….

ZT

AT

BT

….

Jul U QU

RU

SU

….

ZU

AU

BU

….

Aug V QV

RV

SV

….

ZV

AV

BV

….

Sep W QW

RW

SW

….

ZW

AW

BW

….

Oct X QX X SX

….

ZX

AX

BX

….

Nov Y Qy

RQy

Sy

….

Zy

Ay

By

….

Dec Z QZ

RZ

SZ

….

ZZ

AZ

BZ

….

ORIGINAL INSTRUCTIONS

Refer to Declaration of

Conformity for relevant

Directives

ATEX Marking Description

II 3G Ex nA IIC T3 Gc X Ta -10 to 50°C

Equipment Group II

Category 3

Gas (G) environment

Ex European standards apply

nA Non- sparking apparatus

IIC For all types of gas

T3 Temperature classification

Gc Equipment Protection Level (EPL)

X Special conditions apply, see section 1.2

Ta Ambient temperature range

Communication

(M12)

Power (M12)

Ground

terminal

Page 1 of 2

Page 2

S0700-TFS56

4 Settings

4.1 Manual override

Warning

The manual override is used for switching the main valve.

Push style (tool needed)

Push down on the manual override button with a small screwdriver until it

stops.

4.2 56-EX260-###-X## Serial Transmission System

For 56-EX260 specifications, see manual 56-EX260-TFT07.

5 How to Order

Contact SMC for relevant assembly drawing.

6 Outline Dimensions (mm)

56-SS0750-##SDA# (Dimensions shown for a 12 station manifold)

7 Maintenance

7.1 General Maintenance

Caution

Not following proper maintenance procedures could cause the product to

malfunction and lead to equipment damage.

If handled improperly, compressed air can be dangerous. Maintenance

of pneumatic systems should be performed only by qualified personnel.

Before performing maintenance, turn off the power supply and be sure to

cut off the supply pressure. Confirm that the air is released to

atmosphere.

After installation and maintenance, apply operating pressure and power

to the equipment and perform appropriate functional and leakage tests to

make sure the equipment is installed correctly.

If any electrical connections are disturbed during maintenance, ensure

they are reconnected correctly and safety checks are carried out as

required to ensure continued compliance with applicable national

regulations.

Do not make any modification to the product.

Do not disassemble the product, unless required by installation or

maintenance instructions.

7.2 Safety

Warning

Ensure that the Safety Instructions in section 1 of this document have

been read and understood before carrying out maintenance procedures.

Do not separate manifold components when energised.

To avoid static charge build up, use only a damp cloth to clean the

manifold.

7.3 Replacing the A/B port one-touch fittings

Warning

The A/B port fittings are cassette type so they can be easily replaced. The

fittings are held in place by a clip inserted from the top of the manifold, so

this clip should be removed with a flat bladed screwdriver before replacing

the fittings.

To replace, after inserting the fitting assembly into position, replace the clip

in its correct position.

This part number is for one fitting assembly.

Please order in units of 10.

7Maintenance (continued)

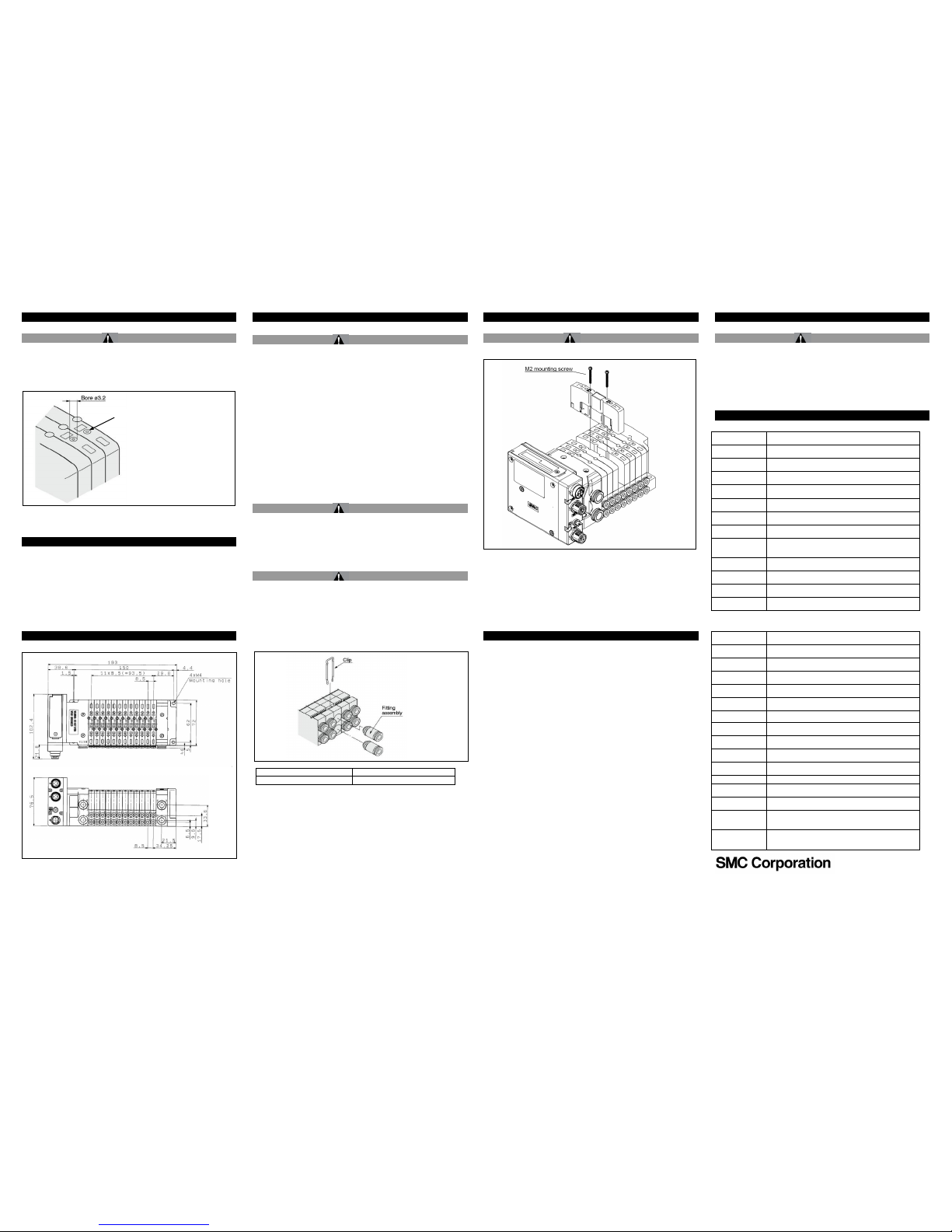

7.3 Mounting of valves

Warning

Valve mounting method

Tighten mounting screws to a torque of 0.17–0.23 N.m to clamp the gasket

securely.

8 Limitations of Use

8.1 Limited warranty and Disclaimer/Compliance Requirements

The product used is subject to the following “Limited warranty and

Disclaimer” and “Compliance Requirements”. Read and accept

them before using the product.

Limited warranty and Disclaimer

1) The warranty period of the product is 1 year in service or 1.5 years

after the product is delivered, whichever is first

(1)

. Also, the product may

have specified durability, running distance or replacement parts. Please

consult your nearest sales branch.

2) For any failure or damage reported within the warranty period which is

clearly our responsibility, a replacement product or necessary parts will

be provided.

This limited warranty applies only to our product independently, and not

to any other damage incurred due to the failure of the product.

3) Prior to using SMC products, please read and understand the

warranty terms and disclaimers noted in the specified catalogue for the

particular products.

(1)

Vacuum pads are excluded from this 1 year warranty.

A vacuum pad is a consumable part, so it is warranted for a year after it

is delivered. Also, even within the warranty period, the wear of a product

due to the use of the vacuum pad or failure due to the deterioration of

rubber material are not covered by the limited warranty.

Compliance Requirements

1) The use of SMC products with production equipment for the

manufacture of weapons of mass destruction (WMD) or any other

weapon is strictly prohibited.

2) The exports of SMC products or technology from one country to

another are governed by the relevant security laws and regulations of

the countries involved in the transaction. Prior to the shipment of a SMC

product to another country, assure that all local rules governing that

export are known and followed.

8Limitations of use (continued)

Caution

SMC products are not intended for use as instruments for legal

metrology.

Measurement instruments that SMC manufactures or sells have not

been qualified by type approval tests relevant to the metrology

(measurement) laws of each country.

Therefore, SMC products cannot be used for business or certification

ordained by the metrology (measurement) laws of each country.

9 Contacts

AUSTRIA

SMC PneumatikGmbH,Girakstrasse 8, AT-2100

Korneuburg, Austria

BELGIUM

SMC Pneumatics N.V. ⁄ S.A. Nijverheidsstraat 20, B-2160

Wommelgem, Belgium

BULGARIA

SMC Industrial Automation Bulgaria EOOD, Business

Park Sofia, Building 8-6th floor, BG-1715 Sofia, Bulgaria

CROATIA

SMC IndustrijskaAutomatikad.o.o. ZagrebačkaAvenija

104,10 000 Zagreb

CZECH REP.

SMC Industrial Automation CZ s.r.o. Hudcova 78a, CZ61200 Brno, Czech Republic

DENMARK

SMC Pneumatik A ⁄ S,Egeskovvej 1, DK-8700 Horsens,

Denmark

ESTONIA

SMC Pneumatics Estonia Oü,Laki 12, EE-10621 Tallinn,

Estonia

FINLAND

SMC Pneumatics Finland Oy, PL72, Tiistinniityntie 4, SF02031 Espoo, Finland

FRANCE

SMC Pneumatique SA.1, Boulevard de Strasbourg,

ParcGustave Eiffel, Bussy Saint Georges, F-77607 Marne

La ValleeCedex 3, France

GERMANY

SMC Pneumatik GmbH, Boschring 13-15, 63329

Egelsbach, Germany

GREECE

SMC Italia Hellas Branch, Anagenniseos 7-9-P.C. 14342

N.Philadelphia, Athens, Greece

HUNGARY

SMC Hungary IpariAutomatizálásiKft.Torbágy u. 19, HU2045 Törökbálint, Hungary

IRELAND

SMC Pneumatics (Ireland) Ltd.2002 Citywest Business

Campus, Naas Road, Saggart, Co. Dublin, Ireland

ITALY

SMC Italia S.p.A.Via Garibaldi 62, I-20061Carugate,

(Milano), Italy

LATVIA

SMC Pneumatics Latvia SIA, Dzelzavas str. 120g, Riga,

LV-1021, Latvia

LITHUANIA

UAB “SMC Pneumatics”, Oslo g. 1, LT-04123 Vilnius,

Lithuania

NETHERLANDS

SMC Pneumatics B.V.DeRuyterkade 120, NL-1011 AB

Amsterdam, the Netherlands

NORWAY

SMC Pneumatics Norway AS, Vollsveien 13 C,

GranfosNæringspark, N-1366 Lysaker, Norway

POLAND

SMC Industrial Automation Polska Sp. z o.o.ul.

Konstruktorska 11A, PL-02-673 Warszawa, Poland

PORTUGAL

SMC España S.A. Zuazobidea 14, 01015 Vitoria, Spain

ROMANIA

SMC Romania S.r.l. StrFrunzei 29, Sector 2, Bucharest,

Romania

RUSSIA

SMC Pneumatik LLC. Business centre, building 3, 15

Kondratjevskij prospect, St.Petersburg, Russia, 195197

SLOVAKIA

SMC PriemyselnáAutomatizáciaSpols.r.o. Fantranská

1223, Teplickanadvahom, 01301, Slovakia

SLOVENIA

SMC IndustrijskaAvtomatikad.o.o. Mirnskacesta 7, SLO8210 Trebnje, Slovenia

SPAIN

SMC España S.A. Zuazobidea 14, 01015 Vitoria, Spain

SWEDEN

SMC Pneumatics Sweden AB,Ekhagsvägen 29-31, SE141 71 Segeltorp, Sweden

SWITZERLAND

SMC PneumatikAG,Dorfstrasse 7, Postfach, 8484

Weisslingen, Switzerland

TURKEY

SMC PnömatikSanayiTicaretveServis A.Ş.

GülbaharCaddesi, Aydın Plaza, No: 9 ⁄ 4 Güneşli –

34212 , Istanbul

UK

SMC Pneumatics (U.K.) Ltd. Vincent Avenue, Crownhill,

Milton Keynes, Buckinghamshire MK8 0AN, United

Kingdom

URL :

http// www.smcworld.com (Global) http// www.smceu.com (Europe)

'SMC Corporation, Akihabara UDX15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101

0021

Specifications are subject to change without prior notice from the manufacturer.

© 2015 SMC Corporation All Rights Reserved.DKP50047-F-085B Feb. 2015

Tube diameter

One-touch fitting part number

Applicable tube ø4

VVQ0000-50A-C4

Manual override button

Page 2of 2

Loading...

Loading...