TigerChassis 10/100/1000

14-Slot Multilayer Chassis Switch

◆ IP routing with RIP and OSPF support

◆ Optional blades include 10BASE-T/100BASE-TX, 100BASE-FX, 1000BASE-SX/LX, 10/

100/1000BASE-T, GBIC

◆ 12 slots available for media expansion

◆ 24 Gbps switch fabric for non-blocking switching performance

◆ Security features to prevent intruder access and ensure a safe network

environment

◆ Full support for IEEE 802.1Q VLANs with GVRP

◆ QoS support for IEEE 802.1p priority

◆ IGMP and DVMRP multicast support

◆ Optional redundant power, fan, and switch fabric failover support

◆ Manageable via console, web, SNMP/RMON

◆ Supports CIDR, multinetting

Installation and Maintenance Guide

SMC9712G

TigerChassis 10/100/1000

Installation and Maintenance Guide

From SMC’s Chassis line of feature-rich workgroup LAN solutions

38 Tesla

Irvine, CA 92618

Phone: (949) 679-8000

January 2002

Pub. # 150200008900A R01

Information furnished by SMC Networks, Inc. (SMC) is believed to be accurate and reliable. However, no responsibility is assumed by SMC for its

use, nor for any infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of SMC. SMC reserves the right to change specifications at any time without notice.

Copyright © 2002 by

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

All rights reserved. Printed in Taiwan

Trademarks:

SMC is a registered trademark; and TigerChassis is a trademark of SMC Networks, Inc. Other product and company names are trademarks or registered trademarks

of their respective holders.

L

IMITED

Limited Warranty Statement: SMC Networks, Inc. (“SMC”) warrants its products to be free from defects in workmanship and materials, under

normal use and service, for the applicable warranty term. All SMC products carry a standard 90-day limited warranty from the date of purchase

from SMC or its Authorized Reseller. SMC may, at its own discretion, repair or replace any product not operating as warranted with a similar or

functionally equivalent product, during the applicable warranty term. SMC will endeavor to repair or replace any product returned under warranty

within 30 days of receipt of the product.

The standard limited warranty can be upgraded to a Limited Lifetime* warranty by registering new products within 30 days of purchase from

SMC or its Authorized Reseller. Registration can be accomplished via the enclosed product registration card or online via the SMC web site.

Failure to register will not affect the standard limited warranty. The Limited Lifetime warranty covers a product during the Life of that Product,

which is defined as the period of time during which the product is an “Active” SMC product. A product is considered to be “Active” while it is

listed on the current SMC price list. As new technologies emerge, older technologies become obsolete and SMC will, at its discretion, replace an

older product in its product line with one that incorporates these newer technologies. At that point, the obsolete product is discontinued and is no

longer an “Active” SMC product. A list of discontinued products with their respective dates of discontinuance can be found at:

http://www.smc.com/index.cfm?action=customer_service_warranty.

All products that are replaced become the property of SMC. Replacement products may be either new or reconditioned. Any replaced or repaired

product carries either a 30-day limited warranty or the remainder of the initial warranty, whichever is longer. SMC is not responsible for any

custom software or firmware, configuration information, or memory data of Customer contained in, stored on, or integrated with any products

returned to SMC pursuant to any warranty. Products returned to SMC should have any customer-installed accessory or add-on components, such

as expansion modules, removed prior to returning the product for replacement. SMC is not responsible for these items if they are returned with

the product.

Customers must contact SMC for a Return Material Authorization number prior to returning any product to SMC. Proof of purchase may be

required. Any product returned to SMC without a valid Return Material Authorization (RMA) number clearly marked on the outside of the

package will be returned to customers at customer’s expense. For warranty claims within North America, please call our toll-free customer

support number at (800) 762-4968. Customers are responsible for all shipping charges from their facility to SMC. SMC is responsible for return

shipping charges from SMC to customer.

WARRANTIES EXCLUSIVE: IF AN SMC PRODUCT DOES NOT OPERATE AS WARRANTED ABOVE, CUSTOMER’S SOLE

REMEDY SHALL BE REPAIR OR REPLACEMENT OF THE PRODUCT IN QUESTION, AT SMC’S OPTION. THE FOREGOING

WARRANTIES AND REMEDIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER WARRANTIES OR CONDITIONS,

EXPRESS OR IMPLIED, EITHER IN FACT OR BY OPERATION OF LAW, STATUTORY OR OTHERWISE, INCLUDING

WARRANTIES OR CONDITIONS OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SMC NEITHER

ASSUMES NOR AUTHORIZES ANY OTHER PERSON TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH

THE SALE, INSTALLATION, MAINTENANCE OR USE OF ITS PRODUCTS. SMC SHALL NOT BE LIABLE UNDER THIS

WARRANTY IF ITS TESTING AND EXAMINATION DISCLOSE THE ALLEGED DEFECT IN THE PRODUCT DOES NOT EXIST

OR WAS CAUSED BY CUSTOMER’S OR ANY THIRD PERSON’S MISUSE, NEGLECT, IMPROPER INSTALLATION OR TESTING,

UNAUTHORIZED ATTEMPTS TO REPAIR, OR ANY OTHER CAUSE BEYOND THE RANGE OF THE INTENDED USE, OR BY

ACCIDENT, FIRE, LIGHTNING, OR OTHER HAZARD.

LIMITATION OF LIABILITY: IN NO EVENT, WHETHER BASED IN CONTRACT OR TORT (INCLUDING NEGLIGENCE),

SHALL SMC BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, OR PUNITIVE DAMAGES OF ANY KIND,

OR FOR LOSS OF REVENUE, LOSS OF BUSINESS, OR OTHER FINANCIAL LOSS ARISING OUT OF OR IN CONNECTION

WITH THE SALE, INSTALLATION, MAINTENANCE, USE, PERFORMANCE, FAILURE, OR INTERRUPTION OF ITS PRODUCTS,

EVEN IF SMC OR ITS AUTHORIZED RESELLER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES OR THE LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR CONSUMER PRODUCTS, SO THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT

APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

NOTHING IN THIS WARRANTY SHALL BE TAKEN TO AFFECT YOUR STATUTORY RIGHTS.

* SMC will provide warranty service for one year following discontinuance from the active SMC price list. Under the limited lifetime warranty,

internal and external power supplies, fans, and cables are covered by a standard one-year warranty from date of purchase.

W

ARRANTY

SMC Networks, Inc.

38 Tesla

Irvine, CA 92618

i

L

IMITED WARRANTY

ii

CONTENTS

ABOUT THIS GUIDE

Audience Definition 11

Conventions 11

Related Documentation 12

1 SETTING UP YOUR SMC9712G

2 OVERVIEW OF THE SMC9712G

Product Overview 15

Physical Description 15

Minimum Requirements for Normal Operation 16

Module Slots in the Chassis 16

Building a System 17

Servicing a System 17

Switch Backplane Architecture 18

3 SITE REQUIREMENTS AND PRODUCT SPECIFICATIONS

Physical Specifications 19

Environmental Specifications 20

Ventilation Requirements 20

Location Requirements 20

Precautionary Guidelines 21

Power Requirements 22

Power Cords 22

Safety Information 22

Laser Warning 23

FDA Class 1 Laser Device 23

LED Warning 23

Regulatory Compliance 24

4 SMC9712G CHASSIS

Overview 25

Preinstallation Guidelines 26

Safety Precautions 26

Rack Installation Guidelines 27

Chassis PreInstallation Guidelines 27

Cable Management Device Preinstallation Guidelines 27

Rack Installation 28

Table or Shelf Installation 30

Installing the Cable Management Device 31

5 SMC9712G POWER SUPPLIES

Power Supply Features 33

Normal Operating Requirements 34

Power Supply Slot Covers 34

AC and DC LEDs 35

No ON/OFF Switch 35

Power Cords 35

Autosensing Capability 35

How Two Supplies Operate 35

Maintenance 35

If Failure Occurs 35

Hot Swap 35

Installing a Power Supply 36

Removing a Power Supply 38

Troubleshooting a Power Supply 39

Diagnosing Switch Indicators 39

Intermittent Operation 39

Power Supply Failure 39

6 SMC9712G FAN TRAYS

Fan Tray Description 41

Normal Operation 42

Maintenance 42

If Failure Occurs 42

Hot Swap 42

Removing a Fan Tray 43

Installing a Fan Tray 44

Troubleshooting a Fan Tray 46

7 NETWORK MANAGEMENT MODULES AND INTERFACE MODULES

Network Management Module Overview 48

Network Functions 48

Management Functions 48

High Availability Operation 51

Installation 52

The Relationship Between Two Management Modules 52

The Failover Process 52

Connectivity Rules 52

Interface Module Overview 53

Feature Configuration Process 53

Traffic Handling 53

Hot Swap 53

Fast Ethernet Interface Modules 53

8-port 10/100BASE-TX Fast Ethernet Module 53

8-port 100BASE-FX Fast Ethernet Module 54

Gigabit Ethernet Interface Modules 57

1000BASE-SX Gigabit Ethernet Modules 57

1000BASE-T Gigabit Ethernet Modules 57

GBIC Gigabit Ethernet Modules 58

Installing a Module 61

Safety Precautions 61

ESD Safety Information 62

Handling Precautions 62

Installation Prerequisites 62

Slot Restrictions 62

Installation and Removal Consequences 63

Module Installation Procedure 64

Removing a Module 66

GBIC Transceivers 67

Compatible Transceivers 67

1000BASE-LX GBIC Transceiver 67

1000BASE-SX GBIC Transceiver 67

Attaching and Removing GBIC Transceivers 68

Troubleshooting Modules 69

Interface Modules 69

Network Management Modules 69

A TECHNICAL SUPPORT

Online Technical Services 71

World Wide Web Site 71

Support from Your Network Supplier 71

Support from SMC 71

GLOSSARY

INDEX

ABOUT THIS GUIDE

This SMC9712G Installation and Maintenance Guide provides a description of

SMC9712G components, installation and removal procedures, site requirements,

and important safety information for SMC9712G components.

Audience Definition This guide is intended for network administrators who are responsible for

installing and managing the network hardware and who are considered to be

trained service personnel. This guide assumes that the network administrator has a

working knowledge of local area network (LAN) operations, but it does not

assume prior knowledge of SMC9712G high performance networking equipment.

Furthermore, this guide assumes that the network administrator has obtained the

appropriate technical training and experience to perform tasks in service access

areas of network equipment, to be aware of electrical hazards or other hazards

that exist in performing these tasks, and to take steps that minimize the danger to

themselves or other persons.

Conventions Table 1 and Table 2 list conventions that are used throughout this guide.

Table 1 Notice Icons

Icon Notice Type Description

Information note Information that describes important features or instructions

Caution Information that alerts you to potential loss of data or potential

damage to an application, system, or device

Warning Information that alerts you to potential personal injury

Table 2 Text Conventions

Convention Description

Words in italics Italics are used to:

■ Emphasize a point.

■ Denote a new term at the place where it is defined in the text.

12 ABOUT THIS GUIDE

Related Documentation The SMC9712G documentation set includes the following documents:

■ SMC9712G Installation and Maintenance Guide (this guide)

■ SMC9712G Key Information Guide

■ SMC9712G Software Configuration Guide

■ SMC9712G Release Notes

To read a brief description of each document, to understand how each document

is distributed, or to learn how to order additional paper copies or download

electronic copies, see the SMC9712G Key Information Guide, which is included in

the shipping box of every item in the SMC9712G product set.

1

SETTING UP YOUR SMC9712G

To install your SMC9712G safely and efficiently so that you can connect it to your

network, follow these tasks:

1 Read Chapter 2 in this guide for a quick review of basic facts about the Switch.

2 Ensure that your installation environment meets the site requirements described in

Chapter 3.

3 Unpack and inspect the SMC9712G components for visible damage, if you have

not already done so.

For unpacking procedures and information on how to proceed if damage exists,

see the SMC9712G Key Information Guide.

See Chapter 5 for the installation procedure.

4 Install the chassis.

5 (Optional) Install a second power supply (for redundancy) into the chassis before

you install it on a table, shelf, or in a rack.

See Chapter 4 for the installation procedure.

SMC recommends that you do not connect the SMC9712G to a power source

until all components are installed. This way, you can focus your attention on all

module LEDs simultaneously.

6 (If required) Install Fast Ethernet and Gigabit Ethernet Interface Modules.

If you need to install additional modules, see Chapter 7 for the information about

their physical attributes and module installation procedure.

All chassis ship from the manufacturing center with a Network Management

Module (NMM) preinstalled, thus you do not have to install one. However, you can

install a second (redundant) NMM to provide standby management support.

At your option, you may connect network cabling to your SMC9712G interface

modules prior to powering on the Switch. However, once the Switch is powered

on, be aware that features such as the Spanning Tree Protocol’s root bridge

election process may affect your network operations. If you are unfamiliar with the

SMC9712G, SMC recommends that you power up the Switch without cabling

attached so that you can first spend a few minutes studying the management

interface.

7 Power on the system by connecting the power cables to the sockets on the

SMC9712G power supplies and then to the dedicated power outlets.

There is no ON/OFF button on the SMC9712G. The system is powered on as long

as the mains power source is connected to the Switch. If you need to cycle power

to the SMC9712G, you can either unplug and replug the power cord, or you can

do it through a command on the SMC9712G management interface.

14 CHAPTER 1: SETTING UP YOUR SMC9712G

If you installed a second, redundant power supply, SMC recommends that you

connect it to a dedicated power source.

After power is supplied to the SMC9712G, power supplies begin operating, fans

start rotating, all modules begin power-on verification processes and

self-diagnostic processes, and the NMM begins its software boot cycle. The

module LEDs will flash in different colors and sequences during this time.

8 Wait for the chassis to finish its start-up sequence of diagnostic tests.

This could take up to five minutes (approximately).

For information about module LEDs, see Table 5, Table 6, Table 11, and Table 13 in

Chapter 7.

The SMC9712G is not ready for operation until its initialization processes finish.

This process may last up to 5 minutes.

If no problems exist at the completion of the module initialization process, you

should see the following:

■ All four fans are rotating continuously.

■ The AC and DC LEDs on each installed power supply are lighted.

■ The Power LED on the NMM module is Green.

■ The Diagnostic LED on all modules is Green.

■ The Port Link and Mode LEDs on all interface modules remain off until you

attach cabling and functioning network links are created.

If a Module Diagnostic LED is off after the diagnostics run, that module has failed.

If you observe error conditions with the following hardware components, see the

referenced chapter:

■ power supplies, see “Troubleshooting a Power Supply” in Chapter 5.

■ fans, see “Troubleshooting a Fan Tray” in Chapter 6.

■ modules, see“Troubleshooting Modules” in Chapter 7.

9 To view or modify the default software configuration, use a standard null modem

cable to connect a terminal or PC with terminal emulation software (such as

®

HyperTerm that is included with Windows

) to the console port on the NMM.

At this point, the menu-driven command line interface (CLI) that is built into the

software becomes visible to you.

See the SMC9712G Software Configuration Guide to view or modify the default

settings in the software as well as to learn about other management interface

options.

10 When you are ready to join the SMC9712G to the rest of your network, attach

GBIC transceivers (if applicable) and network cabling to the ports on the interface

modules.

OVERVIEW OF THE SMC9712G

2

This chapter provides an introduction to the design of the SMC9712G. The topics

in this chapter include:

■ Product Overview

■ Switch Backplane Architecture

Product Overview The SMC9712G is a feature-rich, 14-slot, modular routing switch that can be

configured with up to 24 Gigabit Ethernet ports or up to 96 Fast Ethernet ports

with currently available modules. The SMC9712G currently supports redundant

power supplies, redundant Network Management Modules, and a variety of Fast

Ethernet and Gigabit Ethernet Interface Modules. Combining the speed and low

cost of a Layer 2 switch with Layer 3 routing capabilities, the SMC9712G currently

routes the IP protocol and offers many other advanced features to provide the

high performance that you need to aggregate wiring closets in your network.

Physical Description A SMC9712G chassis can contain:

■ Two fa n tray s.

Each fan tray contains two fans (four fans total). Both fan trays are required for

normal operation.

■ Two 300 Watt AC power supplies

Only one power supply is required for normal operation. If installed, a second

power supply provides load-sharing and redundancy.

■ Two Network Management Modules (NMMs)

Only one NMM is required for normal operation. If the NMM is removed from a

powered up chassis that is functioning in a network, chassis operations will

cease. However, if a backup NMM is installed in the chassis, and the primary

NMM is removed or fails, the backup NMM will take over operations.

The NMM has two elements: a central Network, which manages the layer 3

routing functions of the system such as routing table updates and layer 3

configuration changes, and the management of the system, which includes

SNMP, command line interface (CLI), and Web client activities.

■ Up to Twelve Fast Ethernet or Gigabit Ethernet Interface Modules

You install the number and type of interface modules that are appropriate to

your cabling infrastructure and bandwidth requirements. When the source and

destination ports are located on the same interface module, the interface

module performs local switching. If the destination port resides on a different

interface module, the interface module forwards the packet to the NMM.

16 CHAPTER 2: OVERVIEW OF THE SMC9712G

Minimum Requirements

for Normal Operation

Module Slots in the

Chassis

The following minimum components are required for normal operation of the

SMC9712G:

■ Two fan trays (four fans total)

■ One 300 Watt AC power supply

■ One Network Management Module (NMM) operating with system software

■ The number and type of interface modules that are appropriate for your

network connectivity needs

■ Blank faceplates that cover all empty module slots and the second power

supply bay (if a second power supply is not installed).

You insert modules vertically into the chassis slots so that the slot number shows

through a hole in the module faceplate. As shown in Figure 1, the slots for

interface modules are numbered from left to right, starting with number 1 and

continuing to 12. The two center slots are numbered M1 and M2 because they

exist solely to contain Network Management Modules (NMMs). An NMM can be

placed in either of these slots.

Figure 1 Front View of a SMC9712G Chassis Without Interface Modules Installed

Interface

module slots

Management

module slots

Powe r

supply

(in slot 1)

Powe r

supply

slot 2

Product Overview 17

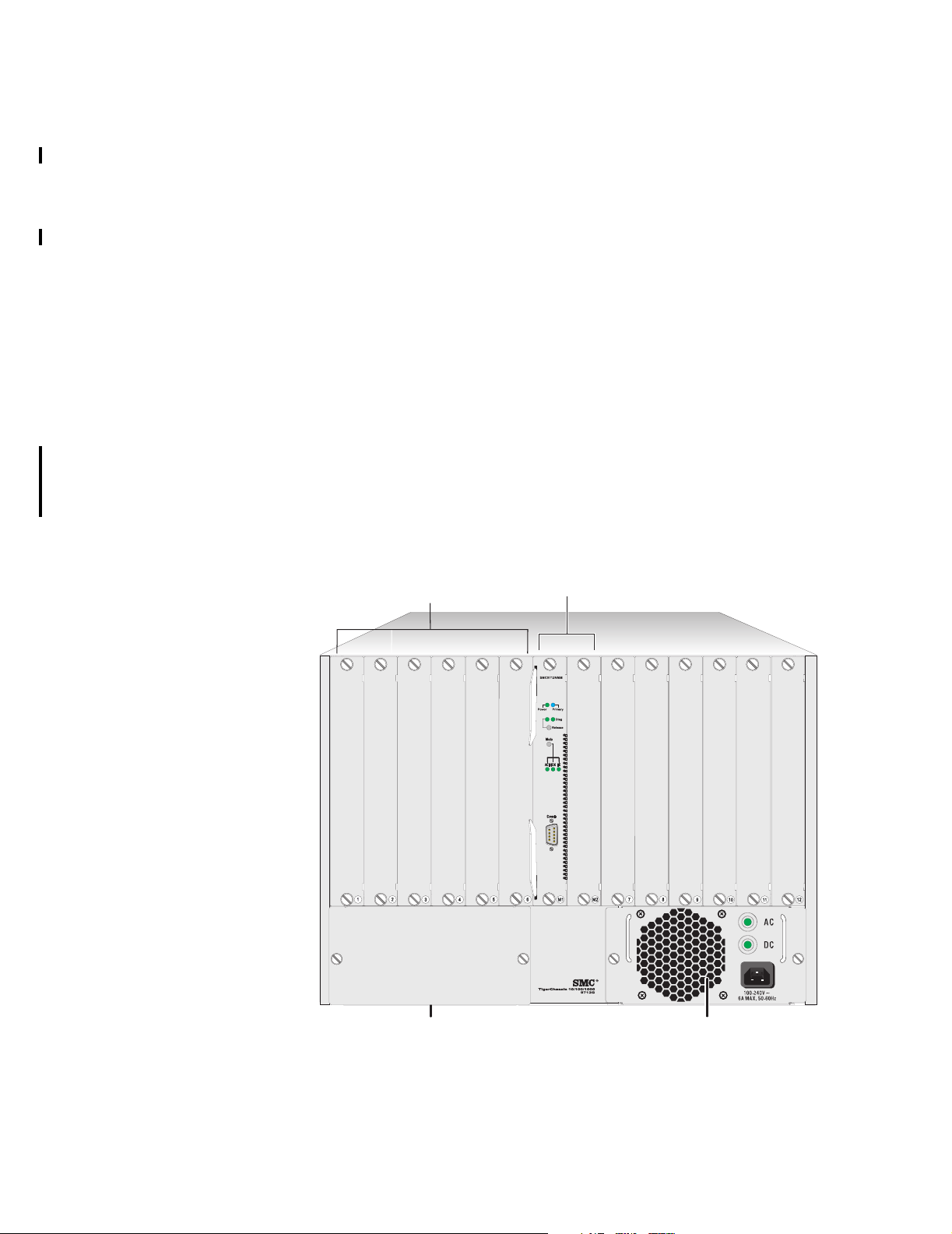

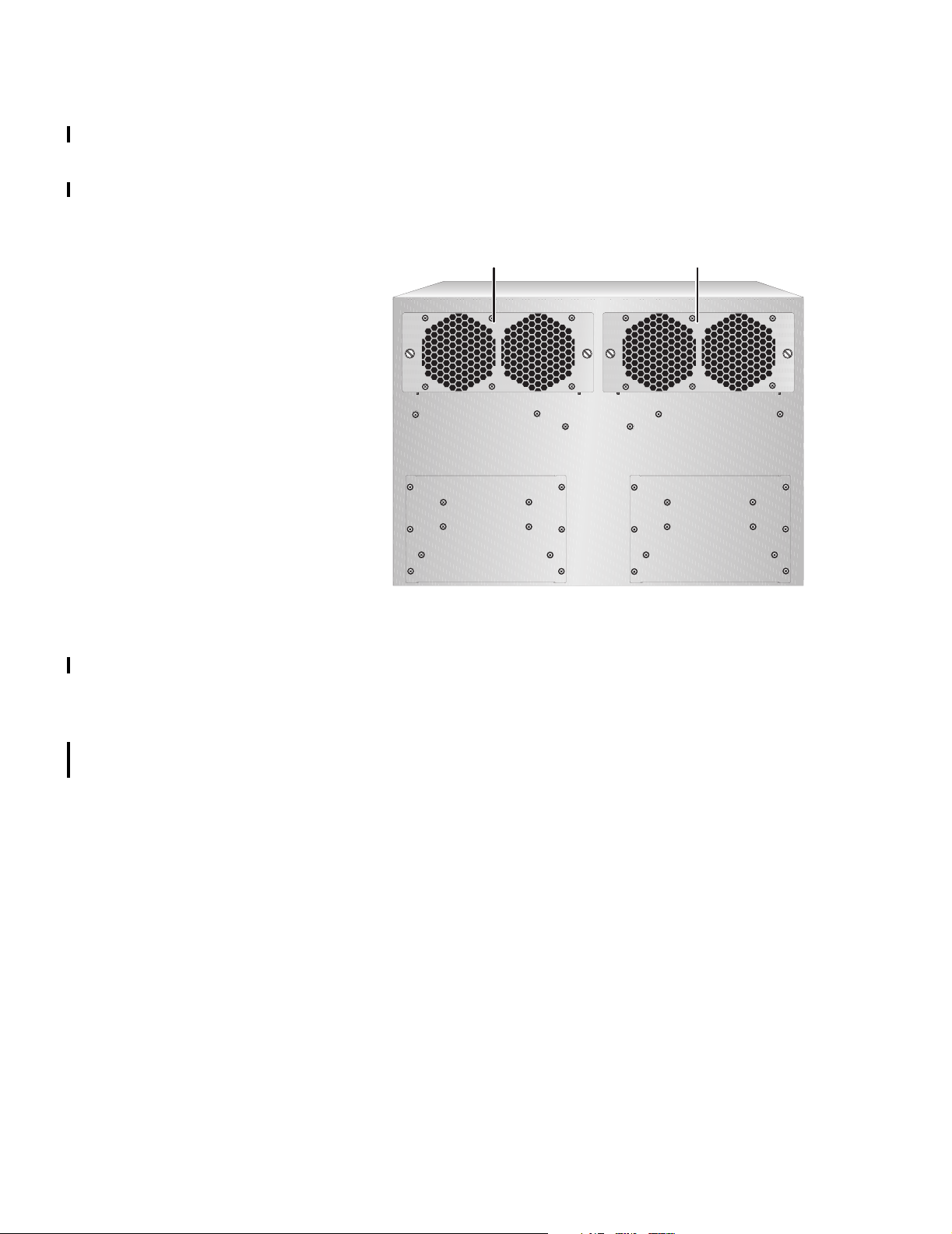

Figure 2 shows the rear view of a standard SMC9712G chassis in the minimum

configuration.

Figure 2 Rear View of a standard SMC9712G Chassis

Fan tray

(in slot 1)

Fan tray

(in slot 2)

Building a System You can build a complete system from component items that are ordered

separately.

Servicing a System For service spares purposes, all component items such as fan trays, power supplies,

and modules can be purchased separately at any time. Check with your network

supplier to see if they stock spare components, provide service, or resell SMC

service agreements.

18 CHAPTER 2: OVERVIEW OF THE SMC9712G

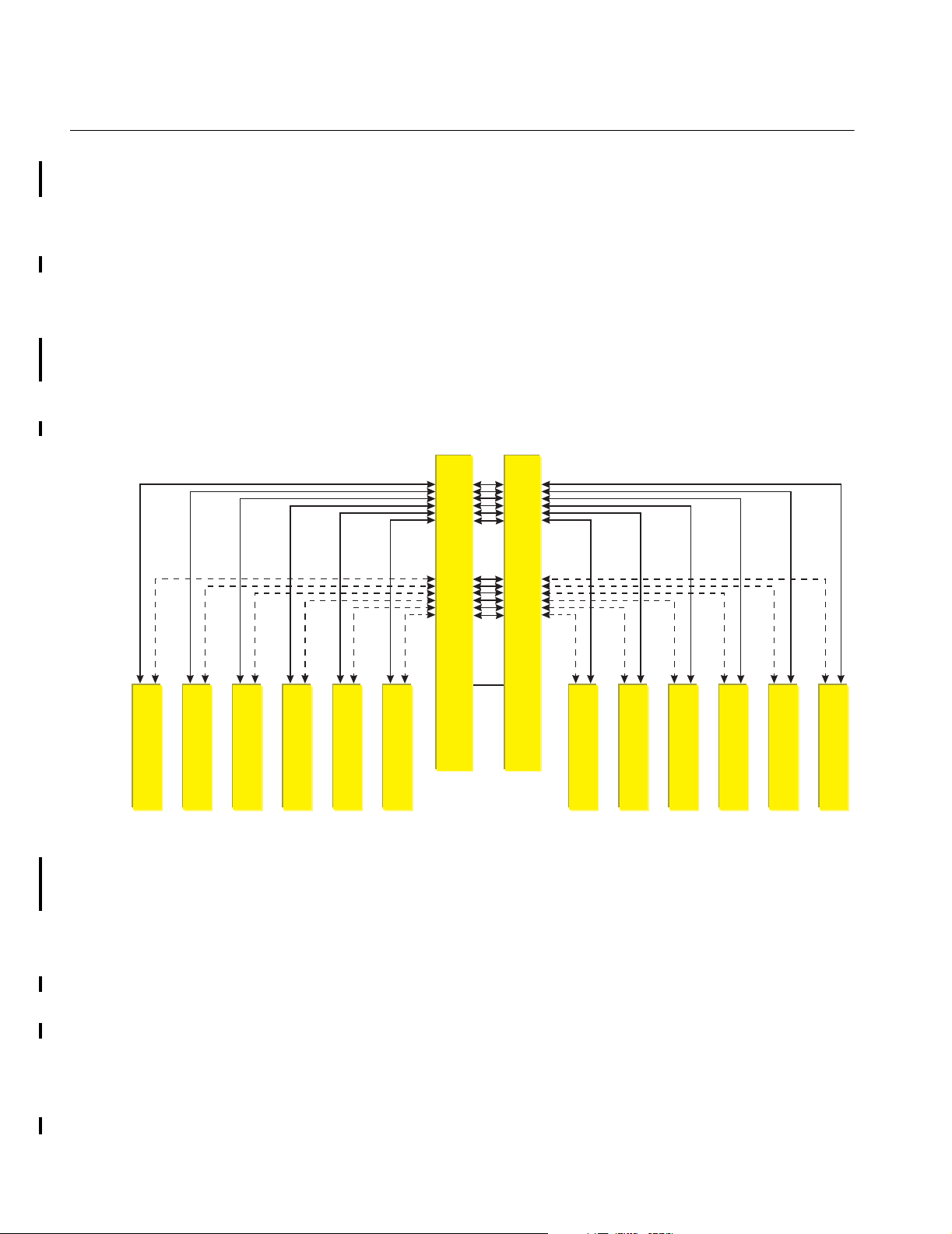

Switch Backplane Architecture

Gigabit

Data

Traces

UART

Control

Traces

A star-wired scheme of traces inside the chassis, which is called the backplane, is

used to connect each interface module slot to the Network Management Module

(NMM) slots. A module, fan tray, or power supply connects to the backplane when

it is inserted into a slot and its connectors engage the connectors that are inside

the chassis.

As shown in Figure 3, the SMC9712G backplane design offers:

■ 12 Gbps of non-blocking bandwidth capacity

■ Passive design, meaning that there are no active components that can fail

■ Support for dual, redundant Network Management Modules (NMMs)

■ Support for system communication between the NMM and interface modules

for control signals, detection, and other management activities.

Figure 3 Backplane Architecture of the SMC9712G

Swithc Fabric & Management Slot M1

Swithc Fabric & Management Slot M2

SCI

Interface Slot 1

Interface Slot 2

Interface Slot 3

Interface Slot 4

Interface Slot 5

Interface Slot 6

Interface Slot 7

Interface Slot 8

Interface Slot 9

Interface Slot 10

Interface Slot 11

Interface Slot 12

The backplane connector on each module provides easy access to all the services

from the SMC9712G backplane:

■ a data channel for network traffic between the NMM and interface modules

■ a control channel that passes signals for module detection

■ module diagnostics

■ LED operation between the NMM and interface modules

■ a Serial Communication Interface (SCI) communications channel that operates

between two NMMs (if installed) to keep their configurations synchronized

Traffic between ports on the same interface module does not enter the backplane;

that is, the interface modules provide layer 2 and layer 3 switching when the

packet’s destination is a locally attached node. Interface modules send packets

that have non-local destination addresses across the backplane to the NMM which

then switches the packets to the appropriate interface module.

SITE REQUIREMENTS AND PRODUCT

3

PECIFICATIONS

S

This chapter describes the site requirements and product specifications for your

SMC9712G. The major sections are titled as follows:

■ Physical Specifications

■ Environmental Specifications

■ Ventilation Requirements

■ Location Requirements

■ Power Requirements

■ Safety Information

■ Regulatory Compliance

Physical Specifications The physical specifications for the SMC9712G chassis are shown in Table 1.

Tabl e 1 Chassis Physical Specifications

Height

Width

Depth

Weight

Mounting

Network

Interfaces

Management

Access Ports

31.06 cm 12.22 inches (5 Rack Units)

48.3 cm

43.94 cm

29.77 cm 11.72 inches

12.42 kg

20.62 kg

Tabletop, shelf, or standard 19-inch rack

10/100BASE-TX, 100BASE-FX, 1000BASE-SX, 1000BASE-T, GBIC

Any Ethernet port on the interface modules

RS-232 (DB-9) serial port on the Network Management Module

19 inches (including rack-mount flanges)

17.3 inches (not including rack-mount flanges)

27.38 pounds (chassis, backplane, power supply, fans)

45.46 pounds (fully loaded)

20 CHAPTER 3: SITE REQUIREMENTS AND PRODUCT SPECIFICATIONS

Environmental Specifications

Ventilation Requirements

The site for the SMC9712G should meet the environmental requirements shown in

Tab le 2:

Tab le 2 Environmental Specifications

Operating temperature

Operating humidity 10% to 90%, noncondensing

Storage temperature -40 °C to 66 °C

Storage humidity 10% to 90%, noncondensing

1

Switch operating temperature is the temperature of the environment in which the switch is installed.

2

Ambient air is room air (more specifically, the air drawn into the switch by installed fans to cool

installed switch components).

1

0 °C to 50 °C ambient

(32 °F to 122 °F)

(-40 °F to 151 °F)

2

The chassis operates with two fan trays. Each fan tray contains two fans. These

fans pull ambient air into the chassis from vents in the module faceplates and

expel hot air through vents in the back of the fan tray.

Although the fan trays provide the majority of the cooling, the power supplies also

contain fans. Each power supply pulls in ambient air through side vents in the

adjacent chassis wall and expels hot air through its vents in the back.

If a power supply overheats, it shuts itself off.

Location Requirements

To ensure that adequate ventilation exists for the SMC9712G:

■ Maintain at least 7 cm (2.76 in.) between the sides of the chassis and the

nearest wall or other vertical surface.

■ Maintain at least 8 cm (3 in.) between the front of the chassis and another

vertical surface (such as a rack door).

■ Maintain at least 91.4 cm (36 in.) at the back of the chassis.

CAUTION: Operate a SMC9712G chassis with all four fans running. If one fan in a

fan tray fails, replace the fan tray as soon as possible.

Install the SMC9712G in an area that meets the following location requirements:

■ The surface on which you want to place the SMC9712G chassis is level.

■ The power source is within approximately 2 meters (6.6 feet) of the location

where you plan to install the SMC9712G.

■ Each of the power supplies is connected to its own dedicated circuit. Do not

connect the power supplies to a single power strip.

■ There is a sufficient amount of space on each side of the SMC9712G chassis to

accommodate any cables along the side of the chassis.

■ There is at least 91.4 cm (36 in.) at the back of the chassis to service power

supplies and fans.

■ If the chassis is the first device in your rack, then mount it about 10.2 cm (4 in.)

above the floor.

Location Requirements 21

■ The following list shows the amount of rack space that is needed to install a

SMC9712G chassis in a Telco rack or a Metric rack:

■ Height — 31.06 cm / 12.15 in.

The height of the chassis, allowing for some extension beyond the location

of the upper and lower unit dividing lines.

■ Telco Rack Unit — 7.2 RU

The unit of measure is 1 Rack Unit (1.75 in. or 4.45 cm).

■ Metric Rack Unit — 14.4 SU

The unit of measure is 1 System Unit (25 millimeters).

■ Front clearance — 8 cm / 3 in.

This is the recommended minimum space required between the front of the

chassis and another vertical surface (such as a rack door). Your cabling may

require that you leave the rack door open.

Precautionary

Guidelines

■ Safety regulations stipulate that the table, shelf, or rack on which the

SMC9712G rests can support at least 61.8 kg (136.5 lb), which is three times

the weight of a fully loaded SMC9712G chassis.

■ To reduce the possibility of personal injury or serious damage to the chassis, use

at least two people to install the chassis. This is especially important for rack

installations, because you must hold the chassis in place while you secure it to

the rack.

■ If you are installing the SMC9712G in a rack, first ensure that the rack is

installed properly according to the manufacturer’s instructions, which may

include steps such as:

■ Ground the rack in accordance with the rack manufacturer’s instructions.

■ Bolt the rack to the floor.

■ Make certain that the rack is properly aligned and squared. Use a framing

tool to ensure that the rack is squared.

■ Use the following guidelines to tighten screws to Torque Specification:

■ Module faceplate screws — 1.3 in/lb (inch-pounds)

■ Power supplies and fan trays to the chassis — 1.3 in/lb

■ #10 screws for holding the chassis onto a rack — 22-25 in/lb

To ensure that you tighten screws to Torque Specification, use a torque

screwdriver.

22 CHAPTER 3: SITE REQUIREMENTS AND PRODUCT SPECIFICATIONS

Power Requirements This section outlines the power requirements for the SMC9712G 300-watt AC

power supply (Model Number SMC9712P). Table 3 lists power specifications for

the chassis.

Tab le 3 SMC9712G Chassis Power Specifications

Total power consumption

Output voltage

Input voltage range

Inrush current

Input frequency

300 watts, 1023 BTU/hour

+5 V @ 53A,

+12 V @ 3A

United States — 100 to 120 VAC

International — 200 to 240 VAC

6 A

50-60 Hz

The power supplies are autosensing; that is, a power supply can automatically

sense the type of input voltage to which it is being connected at the electrical

outlet.

If a power supply overheats, it shuts itself off.

Power Cords One power cord per power supply is required. If you have two power supplies

installed in the chassis, SMC recommends that you connect them to separate,

dedicated power outlets. The power cord that you require depends on your

country location. The correct power cord should be in your chassis shipping box.

If you do not have the correct power cord, contact your supplier.

Safety Information This section lists warning notices to read before you install the SMC9712G and its

components.

WARNING: The SMC9712G chassis and its components must be installed,

maintained, or replaced only by trained service personnel. This guide assumes that

the network administrator has a working knowledge of local area network (LAN)

operations. Furthermore, this guide assumes that the network administrator has

obtained appropriate technical training and experience to perform tasks in service

access areas of network equipment, to be aware of electrical hazards that exist in

performing these tasks, and to take steps that minimize the danger to themselves

or other persons. If you have questions on installation tasks, contact your network

supplier or SMC technical support. For contact information, see Appendix A.

WARNING: To maintain proper cooling in the chassis and maintain safety

compliance, make certain that blank faceplates cover any empty module slots or

power supply slots.

WARNING: Hazardous energy levels exist inside of the Switch. Do not place hands

or objects into the switch or touch components on an inserted module.

WARNING: Safety regulations state that the selected table, shelf, or rack must be

able to support at least three times the weight of a fully loaded Switch. A fully

loaded SMC9712G chassis weighs approximately 20.6 kg (45.5 lb). Therefore, the

selected table or shelf must support at least 61.8 kg (136.5 lb).

Safety Information 23

Laser Warning

The following warning is required when you install fiber-optic communication

modules into the SMC9712G:

WARNING: To ensure optical safety when you install a fiber-optic interface

module, comply with the following precaution:

Although the data communication LEDs and Lasers used in this product meet the

regulatory requirements for casual exposure to the eye, as with any source of

bright light, SMC recommends that you do not look into the light source.

Laser Safety Information: IEC 825 and EN60825, Class 1 Laser Device. For

connection only to Class 1 Laser Devices.

CLASS 1

LASER PRODUCT

FDA Class 1 Laser Device

This product complies with U.S. Department of Health and Human Services Rules

21 CFR Subchapter J applicable at date of manufacture.

LED Warning

The following warning is required when you install fiber-optic communication

modules into the SMC9712G:

WARNING: To ensure optical safety when you install a fiber-optic interface

module, comply with the following precaution:

Although the data communication LEDs that are used in this product meet the

regulatory requirements for casual exposure to the eye, as with any source of

bright light, SMC recommends that you do not look into the light source.

LED Safety Information: IEC 825, Class 1 LED Device. For connection only to

Class 1 LED Devices.

CLASS 1

LED PRODUCT

24 CHAPTER 3: SITE REQUIREMENTS AND PRODUCT SPECIFICATIONS

Regulatory Compliance

Table 4 lists the regulatory standards that the SMC9712G complies with.

Regional or country compliance information is also listed in the SMC9712G

Key Information Guide, which is included in the shipping box of every item in the

product set.

Tab le 4 Regulatory Compliance for the SMC9712G

Safety

Low Voltage Directive

EMC Directive*

*EMC Directive Compliance

This equipment was tested and found to conform to the Council Directive 72/23/EEC for safety of

electrical equipment. Conformity with this directive is based upon compliance with the following

harmonized standards:

EN55022-Limits and Methods of Measurement of Radio Interference

EN50082-1 Electromagnetic Compatibility Generic Immunity Standard: Residential, Commercial, and

Light Industry

CSA 22.2 No. 950

UL1950

TUV GS mark

IEC950, CB Certificate

EN60950, with amendments

For products declaring LVD compliance on the Declaration of

Conformity

This equipment was tested and found to conform to the Council

Directive 72/23/EEC for safety of electrical equipment.

Conformity with this directive is based upon compliance with the

safety standard.

Emissions:

■ EMC EN55022

■ EN61000-3, 2

Immunity:

■ EN50082-1

SMC9712G CHASSIS

4

This chapter describes how to install the SMC9712G chassis. The main sections in

this chapter are as follows:

■ Overview

■ Preinstallation Guidelines

■ Installing the Chassis

■ Installing the Cable Management Device

Overview The basic steps that comprise a chassis installation are as follows:

1 Confirm that the installation area (rack, table, or shelf) is ready to receive the

chassis, in terms of the site requirements and safety information provided in

Chapter 3.

2 Read the pre installation guidelines, cautions, and warnings in this chapter before

you begin the installation procedure.

3 (Rack installation only) Attach the flanges to the chassis. These are included in the

chassis shipping box.

4 Use at least two people to install the chassis and follow the appropriate

procedures in this chapter.

5 (Optional, rack installation only) Attach the cable management device, which is

included in the chassis shipping box, to the rack.

WARNING: The SMC9712G chassis and its components must be installed,

maintained, or replaced only by trained service personnel. This guide assumes that

the network administrator has a working knowledge of local area network (LAN)

operations. Furthermore, this guide assumes that the network administrator has

obtained appropriate technical training and experience to perform tasks in service

access areas of network equipment, to be aware of electrical hazards that exist in

performing these tasks, and to take steps that minimize the danger to themselves

or other persons. If you have questions on installation tasks, contact your network

supplier or SMC technical support. See Appendix A for contact information.

WARNING: You can install the SMC9712G chassis on a table or a shelf or into a

rack. To minimize the risk of personal injury or equipment damage, SMC

recommends that at least two people perform a chassis installation.

26 CHAPTER 4: SMC9712G CHASSIS

Preinstallation Guidelines

Safety Precautions Read this section before you begin to install the SMC9712G chassis.

This section provides safety precautions and various installation guidelines to

prepare you to install the SMC9712G chassis in a safe and efficient manner.

WARNING: The installation requires at least two people. Do not attempt to install

the chassis alone.

WARNING: The chassis shipping box contents include two rack-mount brackets

called flanges, each of which has one stationary flange pin (see Figure 4). After the

flanges are attached to the chassis, use the flange pins only to help position the

chassis on the rack. Do not use these pins to support the full weight of the chassis.

Figure 4 Rack-Mount Flange Pin and Rack Slots

Metric rack

closed slot

Preinstalled

flange pin

Telco rack

open slot

WARNING: When the SMC9712G chassis is fully loaded with modules, fans and

power supplies, the chassis weighs approximately 20.6 kg (45.5 lb). To reduce the

weight that you have to lift or support, you may consider installing your chassis

before you install additional modules or power supplies.

WARNING: Safety regulations state that the selected table, rack or shelf must be

able to support at least 61.8 kg (136.5 lb), which is three times the weight of a

fully loaded chassis.

WARNING: If you are installing the chassis in a rack, at least one person should

support the weight of the chassis until another person has securely installed it

according to the procedures in this chapter. If you release the weight of the chassis

before it is secured to the rack, the chassis may drop off the rack. Personal injury

or serious damage to the chassis may result.

Preinstallation Guidelines 27

Rack Installation

Guidelines

Review the following guidelines before you install the chassis in a rack to ensure

your safety and the optimal performance of the SMC9712G:

WARNING: To ensure mechanical stability and to avoid circuit overloading and

improper grounding, follow the rack manufacturer’s instructions for rack

installation. If the instructions are unclear, consult a qualified electrician.

■ Clip nuts are not included in the SMC9712G chassis hardware kit. Clip nuts are

not required for all rack types. Consult your rack manufacturer’s

documentation.

■ If you are going to use clip nuts, position them on the rack before you install

the chassis. You must position the clip nuts according to the rack type:

■ For Metric racks, install clip nuts and screws in the closed slots of the chassis

flanges (see Figure 4 on page 26).

■ For Telco racks, install clip nuts and screws in the open slots of the flanges

(see Figure 4 on page 26).

■ Because the equipment rack environment can cause increased ambient

temperatures and reduced air flow, review the “Environmental Specifications”

on page 20 and “Ventilation Requirements” on page 20.

■ Review the section “Precautionary Guidelines” on page 21.

■ Review the section “Safety Information” on page 22.

Chassis PreInstallation

Guidelines

Cable Management

Device Preinstallation

Guidelines

■ Review the section “Safety Precautions” on page 26.

■ Before you attempt to mount the chassis in a rack, select a rack that can

support at least 61.8 kg (136.5 lb), which is three times the weight of a fully

loaded chassis.

■ If you install more than one chassis in a rack, install the bottom chassis first.

Before you install the chassis:

■ Move the SMC9712G shipping box to a location near where you plan to install

the chassis. Leave the chassis in its packaging until you are ready to install it.

■ For a rack installation, make certain that you have a Phillips screwdriver, a

flat-blade screwdriver, and the hardware kit available. For table or shelf

installation, have the rubber feet from the hardware kit available.

■ Attach the flanges (L-shaped brackets) to the sides of the chassis before you

attempt to lift and install the chassis in a rack.

Before you install any cable management device in a rack, determine which rack

position is best by examining the:

■ Location in the rack where you plan to install the chassis

■ Depth of the rack in which you plan to install the chassis

■ Space required for proper ventilation of the chassis

■ Space required for module cables to bend

■ Proximity of other devices in the rack and their installation or environmental

requirements

28 CHAPTER 4: SMC9712G CHASSIS

Install the chassis before you install the cable management device, but plan ahead

so that there will be sufficient space for the cable management device on the rack.

NOTE: If your rack has a door, you may have to leave the door open to provide

space for the cable management device and the cabling.

Installing the Chassis This section describes how to install the chassis in a rack (with or without clip

nuts), on a table, or on a shelf. See the section that applies to your installation:

■ Rack Installation

■ Table or Shelf Installation

Rack Installation Using at least two people, follow these steps to mount the chassis in a rack:

Some steps in the next procedure mention clip nuts. All racks do not require the

use of clip nuts. Consult your rack documentation. (Note: Clip nuts are not

provided in the SMC9712G hardware kit.)

1 Read the previous section in this chapter titled “Preinstallation Guidelines” as well

as the all sections that discuss safety information.

2 Using eight of the smaller screws and the flanges from the hardware kit, attach

the flanges to the chassis (four screws per flange) as shown in Figure 5.

Figure 5 Attaching a Flange to the Chassis

Rack-mount

flange

3 Locate and mark the holes on the rack where you want to mount the chassis.

4 If applicable, position clip nuts on the rack. See Figure 6.

Installing the Chassis 29

Figure 6 Installing a Clip Nut on the Rack

Rack rail

10-32 inch screw

Be sure to thread the screw

through this nut to securely

attach each clip to the rack

Top view

5 Have two people lift the chassis through the front of the rack, until both flanges

on the chassis are flush against the front of the rack.

NOTE: You may require additional people to help balance the chassis or secure it

to the rack with screws.

6 Using the pre-installed flange pins for guidance, match the slots on the flange to

the marked area of the rack or to the clip nuts that you positioned on the rack.

Continue to support the back of the chassis.

7 Secure the chassis to the rack with four 10-32 inch screws (and clip nuts if

applicable):

a Install one screw in the bottom part of each flange.

b Install one screw in the top part of each flange.

WARNING: Continue to support the chassis until you have securely installed all

four screws (two screws per flange). If you release the weight of the chassis on

fewer than four fully inserted screws, the chassis may drop off the rack. Personal

injury or serious damage to the chassis may result.

c Tighten all screws completely.

NOTE: Tighten the screws that attach the chassis to the rack to a Torque

Specification of 22-25 in/lb (inch-pounds).

8 Ensure that the front, sides, and the front of the chassis are unobstructed and that

they are in compliance with ventilation requirements.

30 CHAPTER 4: SMC9712G CHASSIS

Table or Shelf

Installation

To install the chassis on a table or shelf, follow these steps:

1 Read the section titled “Preinstallation Guidelines” in this chapter as well as all

sections titled “Safety Information”.

2 Using two people, lift the chassis onto the table or shelf.

3 Remove the four rubber feet from the hardware kit.

4 Position the chassis on its side so that you can access the bottom of the chassis.

5 Remove the protective covering from the adhesive on the rubber feet, and attach

one foot at each corner within the scribed squares. See Figure 7.

Figure 7 Attaching Rubber Feet to the SMC9712G Chassis

6 Position the chassis so that it rests upright and level on its rubber feet.

7 Ensure that the front, sides, and the front of the chassis are unobstructed and that

they are in compliance with ventilation requirements.

Installing the Cable Management Device 31

Installing the Cable Management Device

An optional cable management device is included in the SMC9712G hardware kit.

The Cable Management Device helps to organize module cables from either the

top or the bottom of the chassis.

You may have other types of cable management devices at your site; if so, follow

the manufacturer’s suggested installation procedures.

To install the cable management device, follow these steps:

1 Read the section titled “Preinstallation Guidelines” in this chapter as well as all

sections titled “Safety Information.”

2 Place the cable management device flush up against the top or bottom of the

chassis as shown in Figure 8.

Figure 8 Position of the Cable Management Device

Flange

Cable

management

device

3 Using a Phillips screwdriver, secure the cable management device to the rack with

two screws (and with clip nuts if you are using these).

a If you use clip nuts, consider attaching nylon flat washers to the back of the

screws (to protect the face of the cable management device) and place the

clips nuts on the rack rail.

b Tighten the screws completely.

The SMC9712G accessories package includes fourteen plastic ties that can be

used to bundle the interface module cables into logical groups for easier

management.

32 CHAPTER 4: SMC9712G CHASSIS

5

SMC9712G POWER SUPPLIES

This chapter describes how to install and remove power supplies from the

SMC9712G chassis. The sections are titled as follows:

■ Power Supply Features

■ Installing a Power Supply

■ Removing a Power Supply

■ Troubleshooting a Power Supply

Power Supply Features

The SMC9712G can contain two 300-Watt, modular AC power supplies (Model

Number SMC9712P), but only one is required for normal operation of a fully

loaded chassis. The power supplies provide power to the management modules,

interface modules, fans, and backplane.

Power supplies are installed from the front of the SMC9712G chassis, as shown in

Figure 9.

Figure 9 SMC9712G with Minimum Front Configuration — 1 Power supply

34 CHAPTER 5: SMC9712G POWER SUPPLIES

Figure 10 and Figure 11 show the front and front views of a SMC9712G power

supply. The power supply connector shown in Figure 11 makes contact with a

connector inside the chassis.

Figure 10 External View of the SMC9712G Power Supply

Retainer

screw

Figure 11 Chassis Connector and Guide Pins on the SMC9712G Power Supply

Powe r

indicators

Power supply

handle

AC input

socket

Normal Operating

Requirements

Power Supply Slot

Covers

Power supply

guide pin

Power supply

connector

Only one power supply is required for normal operation of a chassis that contains

modules and fans in all slots.

However, to help to maintain high availability of your network, SMC recommends

that you install a second power supply in the chassis and connect it to a dedicated

power source.

All SMC9712G chassis have one power supply preinstalled at the manufacturing

center. If you want to configure your chassis for high availability, order a second

power supply and install it at your site. Save the blank faceplate that you remove

for future use.

If one of the power supply slots is empty, ensure that it is covered with a blank

faceplate to ensure proper airflow and cooling of the chassis.

Power Supply Features 35

AC and DC LEDs When the power supply, power cord, and power source are all functioning

normally, both LEDs on a power supply are lighted. If one or both LEDs are not

lighted, see the section “Troubleshooting a Power Supply” in this chapter.

No ON/OFF Switch There is no ON/OFF button on power supplies or anywhere on the SMC9712G

chassis. The mains power cord serves as the power disconnect. The power supply

receives power as soon as you connect the power cord to a mains outlet.

Power Cords The type of power cord that is used to connect a power supply to a mains outlet

depends on your country location. If you did not receive the correct type of power

cord in the shipping box, contact your supplier or SMC.

Autosensing Capability SMC9712G power supplies have autosensing capability. This means that each

power supply can automatically sense the type of input voltage to which it is being

connected at the electrical outlet. Thus, although countries around the world

differ in their standard input voltage, the same power supply can function

everywhere.

How Two Supplies

Operate

When two power supplies are installed, they operate in a load-sharing manner.

This means that each power supply provides an equal amount of the load current.

This is done so that if one power supply fails, the other power supply can

immediately provide all required power and network activity is not disrupted.

Maintenance Ensure that the immediate area around the SMC9712G is free from dust or small

debris and that the side and front vents are unobstructed. There are no

user-serviceable parts on a power supply.

If Failure Occurs If a power supply failure occurs and a second power supply is installed, Switch

activity is not disrupted. If a second power supply is not installed, then Switch

activity is immediately halted.

If a power supply fails, remove it as described in “Removing a Power Supply” in

this chapter and return the components to your supplier. Consult your purchase

records so that you can determine if the incident occurred during the warranty

period.

Hot Swap If you have two power supplies installed and at least one is operating normally,

you can remove and replace the other power supply while the chassis continues to

be powered on. This activity is called hot swap. It does not interfere with

operation.

For more information about power requirements for the chassis, see “Power

Requirements” on page 22.

36 CHAPTER 5: SMC9712G POWER SUPPLIES

Installing a Power Supply

To install a power supply into the SMC9712G chassis, follow these steps:

1 Read the following warnings and preparation guidelines:

WARNING: The SMC9712G chassis and its components (such as power supplies)

must be installed, maintained, or replaced only by trained service personnel. This

guide assumes that the network administrator has a working knowledge of local

area network (LAN) operations. Furthermore, this guide assumes that the network

administrator has obtained appropriate technical training and experience to

perform tasks in service access areas of network equipment, to be aware of

electrical hazards that exist in performing these tasks, and to take steps that

minimize the danger to themselves or other persons. If you have questions on

installation tasks, contact your network supplier or SMC technical support. See

Appendix A for contact information.

WARNING: Hazardous energy levels exist inside of the chassis. Do not place

hands or objects into the chassis or touch components on an inserted power

supply.

WARNING: To maintain proper cooling in the chassis and to maintain safety

compliance, make certain that a blank faceplate covers any empty power supply

slot.

WARNING: The power cord serves as the mains disconnect. Do not attach a

power cord to a mains outlet until the power supply is fully installed in the chassis.

WARNING: To ensure compliance with international safety standards, only use

the power cord that is supplied with the unit.

AVERTISSEMENT: Pour garantir le respect des normes internationales de sécurité,

utilisez uniquement l'adaptateur électrique remis avec cet appareil.

WARNHINWEIS: Aufgrund von internationalen Sicherheitsnormen darf das Gerät

nur mit dem mitgelieferten Netzadapter verwendet werden.

WARNING: The unit must be connected to an earthed (grounded) outlet to

comply with European safety standards and EMC standards.

AVERTISSEMENT: Vous devez raccorder ce groupe à une sortie mise à la terre

(mise à la masse) afin de respecter les normes européennes de sécurité.

WARNHINWEIS: Das Gerät muß an eine geerdete Steckdose angeschlossen

werden, die europäischen Sicherheitsvorschriften und den Vorschriften zur EMV

entspricht.

Before you begin the installation procedure, have ready a flathead torque

screwdriver.

2 If you need to:

a Install a power supply in a covered slot, go to step 3.

b Replace a power supply in your chassis, first follow the steps in “Removing a

Power Supply” on page 38 and then return here and proceed to step 4.

3 Using a flathead screwdriver, loosen the screws on the blank faceplate covering

power supply slot, and remove the faceplate.

Store the faceplate in a secure place for possible future use.

Installing a Power Supply 37

4 As shown in Figure 12, grasp either handle on the front of the power supply and

put your other hand beneath the power supply to support it. Then, face the front

of the chassis.

Figure 12 SMC9712G Chassis 300-watt AC Power Supply

Retainer

screw

Power

indicators

Power supply

handle

AC input

socket

5 Gently push the power supply inward, allowing the guide pins (see Figure 13) to

align the connector on the power supply with the connector that is inside the slot.

Figure 13 Connectors and Guide Pins on SMC9712G Chassis Power Supply

Power supply

guide pin

Power supply

connector

You will feel a slight resistance as the connectors engage.

CAUTION: If the resistance is too great, the power supply connectors and the

backplane connectors may not be aligned properly. Do not force the power supply

into the slot or you can damage the connectors. If necessary, remove and reinsert

the power supply, ensuring that the connectors are aligned.

6 To secure the power supply to the chassis, tighten the two retainer screws (see

Figure 12) to a torque specification of 1.5 kg-cm (1.3 in-lb).

CAUTION: Do not attach the power cord to the mains power outlet until the

power supply is fully secured in the chassis.

38 CHAPTER 5: SMC9712G POWER SUPPLIES

7 Before you apply power to the Switch, consult the setup procedure in Chapter 1.

If you are performing the initial installation of a SMC9712G, SMC recommends

that you install all modules and power supplies first, then power up the Switch.

This way, you can direct your full attention to the LEDs on the modules and power

supplies. If the SMC9712G is powered up while you install components, you must

finish securing them before you can concentrate on their LEDs.

8 If you are ready to apply power to the Switch, plug one end of the power cord into

the socket on the power supply and then plug the other end into the dedicated

electrical outlet.

If both the AC and DC LEDs are lighted, then the power supply is functioning

normally. If not, consult the section “Troubleshooting a Power Supply” in this

chapter.

If you have one power supply installed, it will assume the full load of the chassis. If

you have two power supplies installed, they will share the chassis load.

Removing a Power Supply

This section describes how to remove a 300-watt AC power supply from the

SMC9712G chassis.

WARNING: Before you attempt to remove a power supply from the chassis, be

sure to disconnect the power cord from the electrical outlet and then from the

SMC9712G power supply to avoid hazardous energy levels.

Before you begin, have ready a flathead screwdriver.

To remove a power supply, follow these steps:

1 Remove the power cord from the electrical outlet.

2 Remove the power cord from the AC input socket on the SMC9712G power

supply.

3 Remove the SMC9712G power supply:

a Using a flathead screwdriver, loosen the retainer screws that secure the power

supply to the front of the chassis. (See Figure 12 on page 37).

b Grasp the handles on the power supply with both hands.

c Begin to pull the power supply straight out, ensuring that you do not damage

the connector and guide pins on the front of the power supply or the

connector inside the chassis.

d Once the power supply is partially removed, put one hand beneath the power

supply to support it as you continue to remove it from the chassis.

CAUTION: To prevent damage to the guide pins and connectors, while you pull

the power supply straight out of the chassis, put one hand underneath the power

supply to support it.

4 If you are not going to install a replacement power supply in the empty slot, install

a blank faceplate over the empty slot to ensure proper cooling in the chassis.

Troubleshooting a Power Supply 39

Troubleshooting a Power Supply

Diagnosing Switch

Indicators

Intermittent Operation If the chassis powers off after running for a period of time, check for loose power

Power Supply Failure There are no user-serviceable parts on a power supply. Do not disassemble a

If a power supply failure occurs under any condition, a message or trap is sent to

the SNMP management application. If you see this trap, or experience any other

problems with the power supplies, please refer to the following sections and

contact technical support personnel.

If the AC LED on the power supply (see Figure 12 on page 37) does not light up

when the power cord is plugged in, you may have a defective power outlet, power

cord, or power supply. Check the power outlet by plugging in another device that

is functioning properly. Check the power cord with another device.

If the AC LED lights up but the DC LED does not light up when the power cord is

plugged in, you have a defective power supply.

If you need further assistance, contact your technical support provider or SMC for

assistance.

connections, power losses or surges at the power outlet, and verify that the fans

on the back of the chassis are unobstructed and operating prior to shutdown. If

you still cannot isolate the problem, then the power supply may be defective. In

this case, contact your technical support provider or SMC for assistance.

power supply and attempt to fix it. If a power supply fails, simply remove it as

described in this chapter and return the components to your supplier or SMC.

Consult your purchase records so that you can determine if the incident occurred

during the warranty period.

40 CHAPTER 5: SMC9712G POWER SUPPLIES

SMC9712G FAN TRAYS

6

This chapter describes how to remove and install a fan tray (Model Number

SMC972F) from the SMC9712G chassis. The main sections are titled as follows:

■ Fan Tray Description

■ Removing a Fan Tray

■ Installing a Fan Tray

■ Troubleshooting a Fan Tray

Fan Tray Description The SMC9712G chassis can contain two fan trays (Model Number SMC9712F),

which are installed from the rear of the chassis, as shown in Figure 14.

Figure 14 Fan Trays in the SMC9712G Chassis

Fan tray

(in slot 1)

Fan tray

(in slot 2)

Heat is produced while the SMC9712G is operating. To cool the chassis, the fan

trays pull in cooler ambient air from vents in the module faceplates and then expel

the hot air through vents in the rear of the fan trays.

The power supplies also contain small fans. Their fans pull air from side vents in

the chassis and expel hot air through vents in the rear of the power supplies.

Fan tray failure or ambient air that is too hot will eventually cause the SMC9712G

to power off. Ensure that your site meets the requirements described in Chapter 3.

The chassis does not contain temperature sensors. However, a trap is sent to the

management application when one or more fans in a fan tray is not operating

normally.

42 CHAPTER 6: SMC9712G FAN TRAYS

Normal Operation Two fan trays with a total of four functioning fans must be installed and operating

at all times. If one fan in a fan tray fails, replace the entire fan tray as soon as

possible.

CAUTION: All four fans must be operational when the SMC9712G is powered on

to ensure proper cooling of the chassis.

CAUTION: The SMC9712G chassis will continue to run if one fan fails. However,

replace the fan tray as soon as possible.

See the Ventilation Requirements and Environmental Specifications in Chapter 3.

All SMC9712G chassis have two fan trays preinstalled at the manufacturing

center. You do not need to install a fan tray until one of the original fan trays fails

or is operating intermittently.

Maintenance Ensure that the ambient environment for the Switch remains within the

specifications in Chapter 3. In addition, ensure that the immediate area around the

SMC9712G is free from dust or small debris and that the module and fan vents

are unobstructed. There are no user-serviceable parts on a fan tray.

If Failure Occurs If one or both of the fans in a fan tray fails or operates intermittently, remove and

reinsert the fan tray as described in sections “Removing a Fan Tray” and “Installing

a Fan Tray” in this chapter. If problems continue, remove the fan tray and replace it

with a new one. There are no user-serviceable parts in a fan tray. Do not attempt

to fix it. Consult your purchase records so that you can determine if the incident

occurred during the warranty period, and return the faulty fan tray to your

supplier or to SMC. The warranty terms are printed in the SMC9712G Key

Information Guide.

Hot Swap You can remove or install a fan tray while the Switch is powered on. This activity is

called hot swap.

Removing a Fan Tray 43

Removing a Fan Tray To remove a fan tray from the SMC9712G chassis, follow these steps:

WARNING: The SMC9712G chassis and its components (such as fan trays) must

be installed, maintained, or replaced only by trained service personnel. This guide

assumes that the network administrator has a working knowledge of local area

network (LAN) operations. Furthermore, this guide assumes that the network

administrator has obtained appropriate technical training and experience to

perform tasks in service access areas of network equipment, to be aware of

electrical hazards that exist in performing these tasks, and to take steps that

minimize the danger to themselves or other persons. If you have questions on

installation tasks, contact your network supplier or SMC technical support. See

Appendix A for contact information.

Before you begin, have ready a flathead screwdriver.

1 Face the back of the chassis and using a flathead screwdriver, loosen the two

retaining screws that attach the fan tray to the chassis (Figure 15).

2 Grasp the fan tray around the edges with both hands, and begin to pull the fan

tray towards you.

CAUTION: If the chassis is powered on, one or both of the fans in the fan tray

may be rotating prior to removal. Once the fan tray is partially removed, the fans

will lose power and begin to rotate more slowly. Before you completely remove

the fan tray from the chassis, wait until both fans in the fan tray stop rotating

completely.

Figure 15 Removing the Fan Tray

Retaining

screw

Fan tray

Retaining

screw

3 After the fans have stopped rotating, continue to pull the fan tray straight out

from the chassis.

4 Install a replacement fan tray as soon as possible. For procedures, see “Installing a

Fan Tray” next in this chapter.

44 CHAPTER 6: SMC9712G FAN TRAYS

Installing a Fan Tray To install a new fan tray in the SMC9712G chassis, follow these steps:

WARNING: The SMC9712G chassis and its components (such as fan trays) must

be installed, maintained, or replaced only by trained service personnel. This guide

assumes that the network administrator has a working knowledge of local area

network (LAN) operations. Furthermore, this guide assumes that the network

administrator has obtained appropriate technical training and experience to

perform tasks in service access areas of network equipment, to be aware of

electrical hazards that exist in performing these tasks, and to take steps that

minimize the danger to themselves or other persons. If you have questions on

installation tasks, contact your network supplier or SMC technical support. See

Appendix A for contact information.

Before you begin, have ready a flathead screwdriver.

1 Facing the back of the chassis, grasp the front panel of the fan tray around the

edges.

2 Slide the fan tray into the chassis, using the guides in the chassis slot.

Figure 16 Installing the Fan Tray

Retaining

screw

Fan tray

Retaining

screw

3 Gently push the fan tray inward until the connectors engage.

You will feel a slight resistance as the connectors engage.

CAUTION: If the resistance is too great, the fan tray connector and chassis

connector may not be aligned properly. Do not force the fan tray inward or you

can damage the connectors. If necessary, remove and reinsert the fan tray.

Figure 17 Rear View of a SMC9712G Fan Tray

Fan tray

connector

Installing a Fan Tray 45

Retaining

screw

4 Verify that the fan tray is flush with the back of the chassis; do not leave the fan

tray partially out of the slot. If the fan tray and the chassis are not properly aligned,

remove the fan tray and reseat it. Do not tighten the screws to seat the fan tray.

5 Secure the fan tray to the chassis by tightening the two external retaining screws

with a flathead screwdriver.

Tighten the screws to a Torque Specification of 1.5 kg-cm (1.3 in-lb).

NOTE: The fans begin rotating when you power on the chassis or when the

connector on a newly inserted fan tray makes contact with the backplane

connector in a powered-on chassis.

6 Visually inspect all installed fans to verify that each is turning continuously when

the chassis is powered up.

If one of the fans in a fan tray is not running at all or is running intermittently,

remove and reinsert the fan tray. If problems continue, replace the fan tray with a

different one.

46 CHAPTER 6: SMC9712G FAN TRAYS

Troubleshooting a Fan Tray

All four fans must rotate continuously for normal operation.

If one or both fans in a fan tray fail, a message or trap is sent to the SNMP

management application to alert you.

If one or both of the fans in a fan tray operate intermittently or fail, remove and

reinsert the fan tray and secure it as described in this chapter. From this, you can

determine if the problem was simply due to a loose connection or fan tray that

was not secured to the chassis.

If problems continue, remove and replace the fan tray with a new one.

There are no user-serviceable parts in a fan tray. Do not attempt to fix a faulty fan

tray. Return the faulty fan tray to your supplier or to SMC. Consult your purchase

records so that you can determine if the incident occurred during the warranty

period. The product warranty terms are printed in the SMC9712G Key Information

Guide.

7

NETWORK MANAGEMENT MODULES

AND INTERFACE MODULES

The front of the SMC9712G chassis has 14 slots that hold the following types of

modules:

■ Slots 1-12 can house any Fast Ethernet or Gigabit Ethernet Interface Module.

■ Slots M1 and M2 can house Network Management Modules.

This chapter describes the visible aspects of each currently available module or

related components and how to install or remove them. The major sections of this

chapter are as follows:

■ Network Management Module Overview

■ Interface Module Overview

■ Fast Ethernet Interface Modules

■ Gigabit Ethernet Interface Modules

■ Installing a Module

■ Removing a Module

■ GBIC Transceivers

■ Attaching and Removing GBIC Transceivers

■ Troubleshooting Modules

For information about the software features and the default software

configuration, see the SMC9712G Software Configuration Guide. A printed copy

of that guide is included in the shipping box of every standard chassis or you can

download a copy from the SMC Web site.

48 CHAPTER 7: NETWORK MANAGEMENT MODULES AND INTERFACE MODULES

Network Management Module Overview

The SMC9712G is required to have one Network Management Module (NMM)

installed in slot M1 or M2. These slots can only house this type of module.

CAUTION: All standard chassis leave the manufacturing center with one NMM

preinstalled in slot M1 or M2. The other M slot will be covered with a blank

faceplate and you must leave it in place until you are ready to install a redundant

NMM.

The NMM performs two critical functions in the chassis: (1) the central Network

and (2) the management entity.

Network Functions The Network Management Module includes a Network that serves as the central

backplane aggregator for the chassis. That is, if an interface module receives a

packet that is not destined for one of its local ports, it forwards it to the NMM for

processing. The NMM routes the packet to the correct interface module in the

chassis.

The system software resides on the NMM. Software is preinstalled on the NMM at

the manufacturing center so that the Switch is ready to operate in your network

after you physically install it. For information about the default settings on the

software features or how to modify them see the SMC9712G Software

Configuration Guide.

Management Functions The Network Management Module exchanges information with all modules

through the management bus. The module uses the management bus to send

commands to interface modules and to collect information from interface

modules.

The SMC9712G software includes a Web management interface and a

menu-based command line interface. You can access the Web management

interface through any Ethernet port from your PC using a Web browser. You can

access the command-line interface through the RS-232 console port on the NMM

by using terminal emulation software (such as HyperTerminal for Windows

®

remotely through any Ethernet port on the Switch from your PC by using a Telnet

utility.

The NMM also allows you to configure and monitor the SMC9712G chassis using

SNMP-based management software from a remote workstation. Two examples of

®

such software include Hewlett-Packard’s HP Openview

and SMC Network

Supervisor.

You can download SMC Network Supervisor from the SMC Web site.

For more information about management access, see the SMC9712G Software

Configuration Guide.

CAUTION: Do not install or remove any modules during the system power-on

process or while software is downloading to the Network Management Module.

), or

CAUTION: If only one Network Management Module (NMM) is installed in a

chassis, and you remove the NMM when it is operating normally or if the NMM

fails, all traffic processing on interface modules stops.

Network Management Module Overview 49

Figure 18 identifies the components on the front of the NMM.

Figure 18 Front faceplate of the Network Management Module

Retaining screw

Ejector handle

Port Mode

selection button

Port Mode

display option

Ejector handle

Model number

Module status LEDs

Release button

Display selection

ort Mode LEDs

for p

on interface modules

Console port

Retaining screw

Slot number window

The front panel of the NMM has the following features:

■ Ejector handles — You use these movable handles at the top and bottom of

the faceplate to insert and remove the module from the chassis. See the

procedures in “Installing a Module” and “Removing a Module” later in this

chapter.

■ Retaining screws — You use these screws to secure the module in the chassis

after you have closed the ejector handles. Do not use these screws to seat the

module, or you may damage the connectors on the rear of the module or

inside the chassis.

■ Release button and LED — You use this button and its LED as part of the

module removal procedure. See “Removing a Module” later in this chapter.

■ Slot window — After a module is installed, this hole in the module faceplate

allows you to see the number of the chassis slot that holds the module. An

NMM can be installed in either slot M1 or M2.

■ General status LEDs — These are the Diagnostics (D), Power (PWR),

Primary (P), and Release (R) LEDs. Table 5 explains their purposes.

50 CHAPTER 7: NETWORK MANAGEMENT MODULES AND INTERFACE MODULES

Tab le 5 Definitions of General Status LEDs

LED Name Condition Description

Diag

(Diagnostics)

Power Off

Primary Off

Release Flashing amber

■ Mode button and LEDs — You use this button on the NMM to set the Port

Flashing green

Green

Green

Blue

Amber

Mode LED display on all interface modules to one of three modes: Activity, Full

Duplex, or Flow Control. Table 6 defines each mode. You cannot have different

modes display on different modules.

Self-diagnostic process or software download is

occurring.

System has passed diagnostics or completed

software download.

Module is not receiving power.

Module is receiving power.

Module is in Standby mode.*

Module is in Primary mode and is functioning as the

central backplane aggregator and management

entity for the SMC9712G.

System is preparing for module removal.

Module is ready for removal.

Tab le 6 Definitions of Mode LEDs on the Network Management Module

LED Name Condition Description

ACT*

(Activity)

FDX*

(Full Duplex)

FC*

(Flow Control)

* Use the Mode button on the primary NMM to change the Port Mode LED display selection, which applies

to all ports on all interface modules.

■ Model Number — Use this number to order another NMM from your SMC

Green

Off

Green

Off

Green

Off