Page 1

Page 2

19" Rack-mount

12-Slot Standalone

Media Converter Chassis

User's Manual

December 2003

Page 3

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Terms/Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . 3

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Outlook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Affixing brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Rack Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

LEDs Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Technical Specifications . . . . . . . . . . . . . . . . . . . 19

Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Legal Information and Contacts . . . . . . . . . . . . . . v

i

Page 4

About This Guide

Welcome

INTRODUCTION

Thank you for choosing the 19" Rack-mount 12-slot Standalone

Media Converter Chassis. This device provides power and

protection for media converters in one reliable package.

Purpose

This guide discusses how to setup and install your 19"

Rack-mount 12-slot Standalone Media Converter Chassis.

Terms/Usage

In this guide, the term "Chassis" (first letter upper case) refers

to your 19" Rack-mount 12-slot Standalone Media Converter

Chassis, and "chassis" (first letter lower case) refers to other

chassis.

Features

• Supports two load sharing, hot swappable power supplies.

• Three high volume cooling fans ensure perfect operating

environment.

• Status panel with fan and slot power status LEDs.

• Supports slot power isolation – ensures each slot

is electrically isolated from the next.

• Supports 10/100/1000Base, Copper, Fiber.

• Single/Multi-mode, ST, SC, connectors.

1

Page 5

Introduction

• Avoids network downtime and protects your converter

investments.

• Ideal for mission critical networks such as Large Office

Complex, Banks, Military etc.

• High quality 19" Rack-mount Chassis.

• Supports up to 12 media converters.

Package Contents

• One 12-slot Media Converter Chassis.

• One power supply.

• One power supply cable.

• 19" rack mounting kit.

• 12 blank panels (fitted).

• 24 Converter mounting panels.

• Four self-adhesive pads.

• Spare screws.

• Spare fuses.

• One user's manual.

2

Page 6

HARDWARE DESCRIPTION

Product Overview

The Converters Chassis offers the user a dedicated and secure

environment for multiple media conversion applications. It also

allows the user to utilize existing and new media converters

either in the rack or in a stand-alone installation.

Flexibility

The Chassis supports up to 12 media converters covering

10Base-T, 10Base-FL, 100Base-TX and 100Base-FX, Gigabit

1000Base-T, Gigabit SX/LX, conversion. In addition, both Multimode and Single Mode options are supported too.

Reliability

The Chassis also supports two high quality hot swappable power

supplies. Either power unit can be removed without disturbing

the Chassis' operation – offering total efficiency, maximum

redundancy and minimum down time. Each converter is supplied

from a common shared power bus – but as an added precaution,

each is individually protected in the event of a problem on the

or from the power supply. Each converter can also be changed

without powering down.

bus

Functionality

The Chassis was carefully designed to offer a lifetime of operation

Incorporated into the Chassis are three long-life cooling fans to

ensure a cool operating environment. The Chassis also features

an LED status panel. Each fans and converter is monitored and

connected to the LED status panel. This indicates that power

is supplied to each converter and that the Fans are functioning

correctly. The power supplies also feature a "trigger guard" to

prevent the supply from being accidentally switched off.

.

3

Page 7

Hardware Description

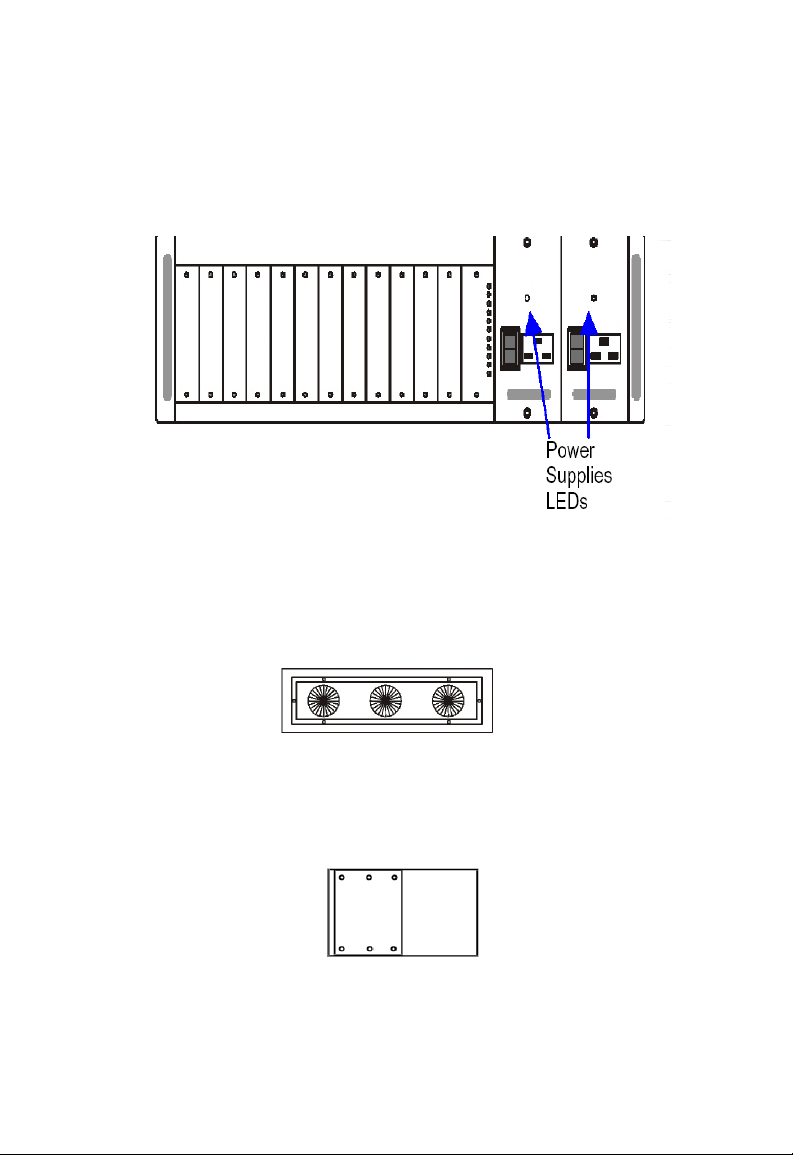

Product Outlook

Front View with 12 blank slots and two power supplies

Rear View showing 3 cooling fans

Side View with rack-mount assembly fitted

4

Page 8

INSTALLATION

In this chapter, we will take a look at how to install converters into

the Chassis and the different options available for placement of the

Chassis system within its operating environment. First, it is important

to unpack the Chassis and ensure that all the components listed

on page 2 "Package Contents" are present. In some cases, the

Chassis may come complete with certain converters already

installed. You can either install the converters first and then

the Chassis, or you can install the Chassis first and then the

converters. We recommend that you do the latter as it is more

convenient.

Installing the brackets

All the converters are made using a standard case. This allows it

to fit into the Chassis with ease. The converters can be mounted

directly into the Chassis without using the supplied brackets but

we strongly advise against this. We have supplied special brackets

that easily attaches to the converters. This allows for the secure

placement of the converters into the Chassis. The bracket also

seals off the front of the Chassis and allows it's cooling system

to function correctly.

5

Page 9

Installation

Affixing brackets

Step 1. Using a Phillips screwdriver, remove two screws

from the side panels on the converter.

Step 2. Place the converter and brackets on a flat horizontal

surface as illustrated above. Secure the brackets by

replacing the screws

.

Ensure that the rails are flush-mounted with the underside

of the converter. The converter is now ready for loading into

the Chassis.

6

Page 10

Installing the converter

Installing the converter

Once the converters have been attached to the brackets, it can be

installed into the Chassis. The converters can go into the Chassis

in any order and can be placed in any available slot. Special care

must be taken to ensure the correct mating of the power connector.

Choose an available slot and align the converter so that it fits

between the upper and lower guide rails.

Warning

Always ensure that the converter's power socket

is positioned at the base of the Chassis.

Warning

Never force the converter into the Chassis – check

power socket position and alignment.

12-slot Media Converter Chassis

If necessary, you may gently move the converter up & down

or left & right to ensure that the plug and socket align correctly.

7

Page 11

Installation

Installing the Chassis

The Chassis is made from a combination of steel and aluminum

and is very sturdy in design. This allows the Chassis to be installed

in the following ways.

Rack-mount

The Chassis is built to established EIA Standards and as such will

fit into any 19" EIA designed rack. Refer to the section "Rack Kit".

Wall-Mount

The Chassis can be mounted separately on a wall with the use of

a shelf. This should be securely mounted on a suitable structure

and must be able to hold at least 15 kg. The shelf should also be

big enough to accommodate the Chassis whilst still offering space

for adequate ventilation.

8

Page 12

Installing the converter

Desktop

The Chassis can be situated on any suitable desktop. Simply

attach the adhesive pads to the base of the Chassis and position

where suitable, again, keep adequate space for ventilation.

9

Page 13

POWER SUPPLY

The Chassis is normally supplied with one redundant, hot –

swappable power supply as shown below. The design of the power

system is based around flexibility and maximum redundancy. For

normal operation, one power supply is sufficient to operate with

12 converters fully loaded simultaneously. However, for critical

applications, installing two power supplies is recommended.

During 2-power operation, both power supplies will be switched

on and will share the currant load between them. In the event

that a power supply should fail, the other supply will take 100%

of the load. This will happen instantaneously and will have no

adverse effects on the operation of the Chassis. Similarly, if a

power supply is removed for servicing, it can be switched off and

removed while the Chassis continues to function normally.

The Chassis shown as supplied with one Hot-swappable,

Redundant 75Watt Power Supply

11

Page 14

Power Supply

The Chassis shown as supplied with two Hot-swappable,

Redundant 75 Watt Power Supplies

To remove the Power Supplies from the Chassis, simply undo

the securing screws, and then pull the power supply unit out

from the Chassis by the handles.

Warning

Always exercise Caution when removing supplies.

Always switch Power Supply off before removing.

Always remove Power Cable from Supplies before removing.

Do not touch Power Supply components after removal

they may hold residual electrical charges.

12

–

Page 15

RACK KIT

The Chassis comes with a 19" Rack Mounting Kit. This basically

comprises of two brackets and a set of screws. The brackets are

fitted to the Chassis via six screws. It is strongly recommended

that you use all six screws supplied with the Chassis. This will

ensure that stress is not unnecessary endured by the Chassis or

the brackets. Each bracket has EIA standard mounting holes and

is symmetrical so that either bracket can be used on either side

of the Chassis.

13

Page 16

LEDS INDICATORS

To enable the MIS personnel to establish the operational status of

the Chassis, a simple LED display panel is installed. Its simplicity

hides the fact that the Chassis employs a sophisticated power

distribution system. All converters are supplied from the one hotswappable Power Supply. However, this is where their common

connection stops. Each slot has its own protection system that

isolates each converter from any problems that might occur with

either the power supplies or another faulty converter. This offers

the best possible protection to your investment in the various

media converters.

Fan Indicator LED's

These should illuminate under

normal operating conditions.

Slot Power LED's

These will illuminate when converters

are loaded into the Chassis' slot. The

LEDs will extinguish if converters are

not installed or if there is a problem

with the power supply.

15

Page 17

COOLING

The Chassis holds up to two power supplies and twelve media

converters, so it needs to have reliable form of cooling. This

Chassis has three fans located at the rear of the Chassis, and

draws air into the Chassis. Each fan is connected to the Status

Monitoring Panel on the front of the Chassis. Even with only one

fan working, the Chassis is capable of operating under normal

operating temperatures. For the purpose of cleaning, the Fan

panel assembly can be removed for periodic maintenance. Switch

both power supplies off, and remove the six securing screws.

Disconnect the three power cables supplying DC to the fans. The

fans can then be cleaned with a dry cloth. Replace the fan panel

by reversing the above procedure.

17

Page 18

TECHNICAL SPECIFICATIONS

Chassis Specs

Capacity: 12 slots – up to 12 converters

Chassis: Aluminium, Steel

Power: Up to two load sharing, hot swappable power supplies

LEDs: 3 Red for fan status,

12 Green for slot power status,

1 Red for each power supply.

Cooling: Three 42.5 cfm rear-mounted fans

Dimension: 440 x 290 x 133 mm (L x W x H)

(EIA 3U)

Weight: 7.6 kg (with one power supply)

13 kg (loaded with 12 standalone converters)

Power Supply Specs for AC

AC input: 100 ~ 240V AC @ 47 ~ 63Hz

DC Output: Norm. +12V, Min. +11.88V, Max +12.12V, 75Watts

Load: Min. OA, Full. 6.4A

Total Reg.: +/- 1.0%, Rip. 120mV, Load 2.0%, Line 0.5%

Overload Protection: All outputs protected against short circuit

conditions, automatic recovery

Over volts Protection: Output level exceeding + 13.2V causes

shutdown – automatic recovery

19

Page 19

Technical Specifications

Temperature: Operating: 0×C ~ 50×C,

Storage: -55×C ~ 85×C

EMI: FCC Part 15 Class A

Safety: UL / cUL / TUV Approved

Power Supply Specs for DC -48V

DC input: -48V ±10%

DC Output: Norm. +12V, Min. +11.76V, Max +12.24V, 75Watts

Load: Min. OA, Full. 6.4A

Total Reg.: +/- 2.0%, Rip. 120mV, Load 2.0%, Line 1.0%

Overload Protection: Output protected against short circuit

conditions, automatic recovery

Over volts Protection: Output level exceeding + 13.2V

causes shutdown – automatic recovery

Temperature: Operation: 0×C ~ 50×C,

Storage: -55×C ~ 85×C

Fans Specs

Speed: 2510 rpm +/- 250, Delivery 42.5ft3 Per Min.

Noise Level: 36.5dB(A) (each fan)

Temperature: Operation: 10×C ~ 50×C

Storage: 40×C ~ 70×C

Bearing: Precise Ball Bearing

Safety: UL / cUL / TUV Approved

20

Page 20

COMPLIANCES

FCC – Class A

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with instructions, may cause harmful interference to radio

communications. However, there is no guarantee that the interference

will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

• Reorient the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help

EC Conformance Declaration – Class A

SMC contact for these products in Europe is:

SMC Networks Europe,

Edificio Conata II,

Calle Fructuós Gelabert 6-8, 2o, 4a,

08970 - Sant Joan Despí,

Barcelona, Spain.

This information technology equipment complies with the requirements

of theCouncil Directive 89/336/EEC on the Approximation of the laws

of the MemberStates relating Electromagnetic Compatibility and 73/23/

EEC for electricalequipment used within certain voltage limits and the

Amendment Directive 93/68/EEC. For the evaluation of the compliance

with these Directives, the following standards were applied:

RFI Emission:

• EN 55022:1994/5/7 Class A

• Limit class A for harmonic current emission according to

N 61000-3-2/1995

i

Page 21

Compliances

• Limitation of voltage fluctuation and flicker in low-voltage supply

system according to EN 61000-3-3/1995

Immunity:

• Product family standard according to EN 55024:1998

• Electrostatic Discharge according to EN 61000-4-2:2001

(Contact Discharge: ±4 kV, Air Discharge: ±8 kV)

• Radio-frequency electromagnetic field according to EN 61000-4-3:1996

(80 - 1000 MHz with 1 kHz AM 80% Modulation: 3 V/m)

• Electrical fast transient/burst according to EN 61000-4-4:1996

(AC/DC power supply: ±1 kV, Data/Signal lines: ±0.5 kV)

• Surge immunity test according to EN 61000-4-5:1996

(AC/DC Line to Line: ±1 kV, AC/DC Line to Earth: ±2 kV)

• Immunity to conducted disturbances, Induced by radio-frequency

fields: EN 61000-4-6:1996 (0.15 - 80 MHz with 1 kHz AM 80%

Modulation: 3 V/m)

• Power frequency magnetic field immunity test according to

EN 61000-4-8:1993 (1 A/m at frequency 50 Hz)

• Voltage dips, short interruptions and voltage variations immunity

test according to EN 61000-4-11:1994 (>95% Reduction @10 ms,

30% Reduction @500 ms, >95% Reduction @5000 ms)

LV D:

• EN 60950 (A1/1992; A2/1993; A3/1993; A4/1995; A11/1997)

MDD:

• IEC 60601-1

Industry Canada – Class B

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus as set out in the interference-causing

equipment standard entitled "Digital Apparatus" ICES-003 of the

Department of Communications. Cet appareil numérique respecte les

limites de bruits radioélectriques applicables aux appareils numériques

de Classe B prescrites dans la norme sur le matériel brouilleur:

« Appareils Numériques » NMB-003 édictée par le ministère des

Communications.

ii

Page 22

Compliances

Safety Compliance

CSA/NRTL (C22.2.950, UL 1950)

EN60950, (IEC 950)

Wichtige Sicherheitshinweise (Germany)

1. Bitte lesen Sie diese Hinweise sorgfältig durch.

2. Heben Sie diese Anleitung für den späteren Gebrauch auf.

3. Vor jedem Reinigen ist das Gerät vom Stromnetz zu trennen.

Verwenden Sie keine Flüssigoder Aerosolreiniger. Am besten

eignet sich ein angefeuchtetes Tuch zur Reinigung.

4. Die Netzanschlu ßsteckdose soll nahe dem Gerät angebracht

und leicht zugänglich sein.

5. Das Gerät ist vor Feuchtigkeit zu schützen.

6. Bei der Aufstellung des Gerätes ist auf sicheren Stand zu achten.

Ein Kippen oder Fallen könnte Beschädigungen hervorrufen.

7. Die Belüftungsöffnungen dienen der Luftzirkulation, die das Gerät vor

Überhitzung schützt. Sorgen Sie dafür, daß diese Öffnungen nicht

abgedeckt werden.

8. Beachten Sie beim Anschluß an das Stromnetz die Anschlußwerte.

Verlegen Sie die Netzanschlußleitung so, daß niemand darüber fallen

9.

Es sollte auch nichts auf der Leitung abgestellt werden.

kann.

10. Alle Hinweise und Warnungen, die sich am Gerät befinden,

sind zu beachten.

11. Wird das Gerät über einen längeren Zeitraum nicht benutzt,

sollten Sie es vom Stromnetz trennen. Somit wird im Falle einer

Überspannung eine Beschädigung vermieden.

12. Durch die Lüftungsöffnungen dürfen niemals Gegenstände oder

Flüssigkeiten in das Gerät gelangen. Dies könnte einen Brand bzw.

elektrischen Schlag auslösen.

Öffnen sie niemals das Gerät. Das Gerät darf aus Gründen der

13.

elektrischen Sicherheit nur von authorisiertem Servicepersonal

geöffnet werden

14. Wenn folgende Situationen auftreten ist das Gerät vom Stromnetz

zu trennenund von einer qualifizierten Servicestelle zu überprüfen:

a. Netzkabel oder Netzstecker sind beschädigt.

.

iii

Page 23

Compliances

b. Flüssigkeit ist in das Gerät eingedrungen.

c. Das Gerät war Feuchtigkeit ausgesetzt.

d. Wenn das Gerät nicht der Bedienungsanleitung

entsprechend funktioniert oder Sie mit Hilfe dieser

Anleitung keine Verbesserung erzielen.

e. Das Gerät ist gefallen und/oder das Gehäuse

ist beschädigt.

f. Wenn das Gerät deutliche Anzeichen eines Defektes

aufweist.

15. Stellen Sie sicher, daß die Stromversorgung dieses Gerätes nach der

EN 60950 geprüft ist. Ausgangswerte der Stromversorgung sollten

die Werte von AC 7.5-8 V, 50-60 Hz nicht über oder unterschreiten

sowie den minimalen Strom von 1 A nicht unterschreiten. Der

arbeitsplatzbezogene Schalldruckpegel nach DIN 45 635 Teil

1000 beträgt 70dB(A) oder weniger.

iv

Page 24

LEGAL INFORMATION

AND

SMC's Limited Warranty Statement

SMC Networks Europe ("SMC") warrants its products to be free from

defects in workmanship and materials, under normal use and service, for

the applicable warranty term. All SMC products carry a standard 2 year

limited warranty from the date of purchase from SMC or its Authorized

Reseller. SMC may, at its own discretion, repair or replace any product

not operating as warranted with a similar or functionally equivalent

product, during the applicable warranty term. SMC will endeavour to

repair or replace any product returned under warranty within 30 days of

receipt of the product. As new technologies emerge, older technologies

become obsolete and SMC will, at its discretion, replace an older product

in its product line with one that incorporates these newer technologies.

The standard limited warranty can be upgraded to a 5 year Limited

Lifetime * warranty by registering new products within 30 days of

purchase from SMC or its Authorized Reseller. Registration can be

accomplished via the enclosed product registration card or online via

the SMC web site. Failure to register will not affect the standard limited

warranty. The Limited Lifetime warranty covers a product during the Life

of that Product, which is defined as a period of 5 years from the date of

purchase of the product from SMC or its authorized reseller.

All products that are replaced become the property of SMC. Replacement

products may be either new or reconditioned. Any replaced or repaired

product carries, either a 30-day limited warranty or the remainder of the

initial warranty, whichever is longer. SMC is not responsible for any custom

software or firmware, configuration information, or memory data of

Customer contained in, stored on, or integrated with any products

returned to SMC pursuant to any warranty. Products returned to SMC

should have any customer-installed accessory or add-on components,

such as expansion modules, removed prior to returning the product for

replacement. SMC is not responsible for these items if they are returned

with the product.

CONTACTS

v

Page 25

Legal Information and Contacts

Customers must contact SMC for a Return Material Authorization

number prior to returning any product to SMC. Proof of purchase may

be required. Any product returned to SMC without a valid Return Material

Authorization (RMA) number clearly marked on the outside of the package

will be returned to customer at customer's expense. Customers are

responsible for all shipping charges from their facility to SMC. SMC

is responsible for return shipping charges from SMC to customer.

WARRANTIES EXCLUSIVE: IF A SMC PRODUCT DOES NOT

OPERATE AS WARRANTED ABOVE, CUSTOMER'S SOLE REMEDY

SHALL BE REPAIR OR REPLACEMENT OF THE PRODUCT IN

QUESTION, AT SMC'S OPTION. THE FOREGOING WARRANTIES

AND REMEDIES ARE EXCLUSIVE AND ARE IN LIEU OF ALL OTHER

WARRANTIES OR CONDITIONS, EXPRESSED OR IMPLIED, EITHER

IN FACT OR BY OPERATION OF LAW, STATUTORY OR

OTHERWISE, INCLUDING WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

SMC NEITHER ASSUMES NOR AUTHORIZES ANY OTHER PERSON

TO ASSUME FOR IT ANY OTHER LIABILITY IN CONNECTION WITH

THE SALE, INSTALLATION, MAINTENANCE OR USE OF ITS

PRODUCTS. SMC SHALL NOT BE LIABLE UNDER THIS WARRANTY

IF ITS TESTING AND EXAMINATION DISCLOSE THE ALLEGED

DEFECT IN THE PRODUCT DOES NOT EXIST OR WAS CAUSED

BY CUSTOMER'S OR ANY THIRD PERSON'S MISUSE, NEGLECT,

IMPROPER INSTALLATION OR TESTING, UNAUTHORIZED ATTEMPTS

TO REPAIR, OR ANY OTHER CAUSE BEYOND THE RANGE OF THE

INTENDED USE, OR BY ACCIDENT, FIRE, LIGHTNING, OR OTHER

HAZARD.

LIMITATION OF LIABILITY: IN NO EVENT, WHETHER BASED IN

CONTRACT OR TORT (INCLUDING NEGLIGENCE), SHALL SMC BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL,

OR PUNITIVE DAMAGES OF ANY KIND, OR FOR LOSS OF REVENUE,

LOSS OF BUSINESS, OR OTHER FINANCIAL LOSS ARISING OUT

OF OR IN CONNECTION WITH THE SALE, INSTALLATION,

MAINTENANCE, USE, PERFORMANCE, FAILURE, OR INTERRUPTION

OF ITS PRODUCTS, EVEN IF SMC OR ITS AUTHORIZED RESELLER

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

vi

Page 26

Legal Information and Contacts

SOME COUNTRIES DO NOT ALLOW THE EXCLUSION OF

IMPLIED WARRANTIES OR THE LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES FOR CONSUMER PRODUCTS, SO

THE ABOVE LIMITATIONS AND EXCLUSIONS MAY NOT APPLY

TO YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

WHICH MAY VARY FROM COUNTRY TO COUNTRY. NOTHING IN

THIS WARRANTY SHALL BE TAKEN TO AFFECT YOUR

STATUTORY RIGHTS.

Under the limited lifetime warranty, internal and external power supplies,

*

fans, and cables are covered by a standard one-year warranty from date

of purchase.

Full Installation Manual

Full installation manuals are provided on the Installation CD-Rom.

Manuals in other languages than those included on the CD-Rom

are provided on www.smc-europe.com

Firmware and Drivers

For latest driver, technical information and bug-fixes please visit

www.smc-europe.com

(section support).

(section support).

Contact SMC

Contact details for your relevant countries are available on

www.smc-europe.com

and www.smc.com.

Statement of Conditions

In line with our continued efforts to improve internal design, operational

f

unction, and/or reliability, SMC reserves the right to make changes to

the product(s) described in this document without notice. SMC does not

assume any liability that may occur due to the use or application of the

product(s) described herein. In order to obtain the most accurate knowledge

of installation, bug-fixes and other product related information we advise

to visit the relevant product support page at www.smc-europe.com

before you start installing the equipment. All information is subject to

change without notice.

vii

Page 27

Legal Information and Contacts

Limitation of Liability

In no event, whether based in contract or tort (including negligence),

shall SMC be liable for incidental, consequential, indirect, special or

punitive damages of any kind, or for loss of revenue, loss of business

or other financial loss arising out of or in connection with the sale,

installation, maintenance, use, performance, failure

products, even if SMC or its authorized reseller has been adviced

possiblity of such damages.

Copyright

Information furnished by SMC Networks, Inc. (SMC) is believed to be

accurate and reliable. However, no responsibility is assumed by SMC for

its use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of SMC. SMC reserves the

right to change specifications at any time without notice.

Trademarks

SMC is a registered trademark and EZ Connect is a trademark of SMC

Networks, Inc. Other product and company names are trademarks or

registered trademarks of their respective holders.

or interruption of its

of the

viii

Page 28

Loading...

Loading...