Page 1

We will be pleased to help you with further questions:

smb Seilspielgeräte GmbH Berlin in Hoppegarten Fon. +49 (0) 3342 50837-20 info@smb.berlin

Technikerstraße 6/8 Fax. +49 (0) 3342 50837-80 www.smb.berlin

DE-15366 Hoppegarten

05.06.2018

Page 1 of 4

Installation instructions EN 1176-1 tuev-sued.de/

Maintenance instructions EN 1176-1 ps-zert

Content

1 General 2

2 Ground Composition 2

3 Provided Tools for Installation: 2

4 Assembly 3

5 Jumping Mat Installation/Removal 3

6 Maintenance Instructions EN 1176-1 4

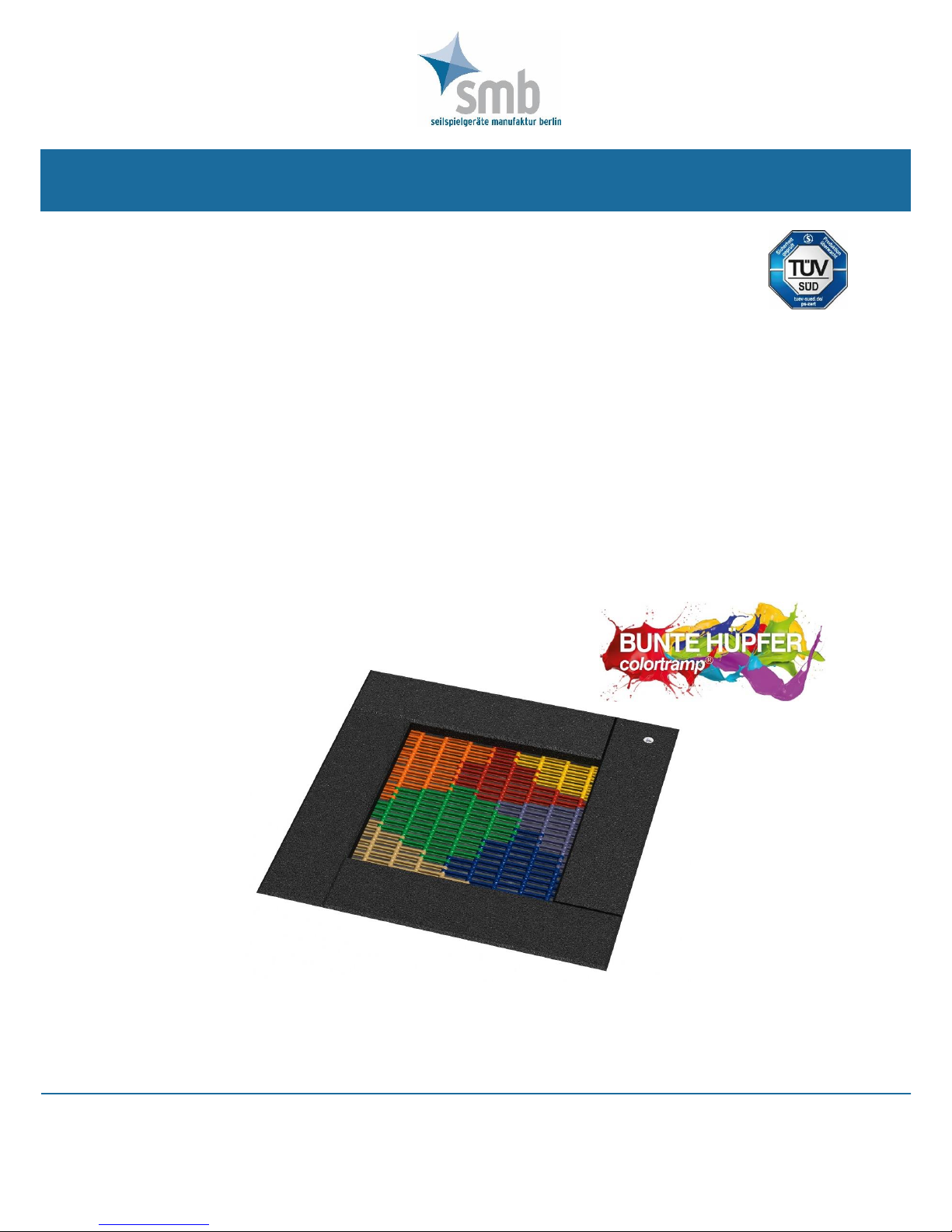

Fig. 1 - TRAMPOLINE „S“ EXAMPLE – MULTICOLOR art.no.:7240032

No. 7210001

Technical Information – TRAMPOLINE „S“

Page 2

TECHNICAL INFORMATION

TRAMPOLINE „S“

We will be pleased to help you with further questions:

smb Seilspielgeräte GmbH Berlin in Hoppegarten Fon. +49 (0) 3342 50837-20 info@smb.berlin

Technikerstraße 6/8 Fax. +49 (0) 3342 50837-80 www.smb.berlin

DE-15366 Hoppegarten

05.06.2018

Page 2 of 4

1 General

The work described must be carried out by qualified personnel.

Due to the heavy weight of the completed trampoline, no further anchorage is necessary.

The trampoline is designed to be built level with the ground.

Dimensions

Overall size 1.25 x 1.25 m

Minimum space 3.75 x 3.75 m

Jumping area 0.75 x 0.75m

Clearance 1.50 m

Max. free drop height: 0.90 m

Age suitability

3 years and older

Number of users

1 person

2 Ground Composition

Please refer to DIN EN 1176-1 for ground conditions in the play area.

We recommend a floor surfacing with shock-absorbing qualities like grass or synthetic surfaces. Loose

material like sand, bark mulch or wood chips is not optimal, as the pieces can fall into the trampoline and

thereby reduce play value.

3 Provided Tools for Installation:

4 pieces Carrying Iron

1 piece Rope with Hook: Tool to assemble and/or remove jumping mats

Page 3

TECHNICAL INFORMATION

TRAMPOLINE „S“

We will be pleased to help you with further questions:

smb Seilspielgeräte GmbH Berlin in Hoppegarten Fon. +49 (0) 3342 50837-20 info@smb.berlin

Technikerstraße 6/8 Fax. +49 (0) 3342 50837-80 www.smb.berlin

DE-15366 Hoppegarten

05.06.2018

Page 3 of 4

4 Assembly

The trampoline is placed after the ground has been

excavated (450 mm deep, size according to

number of trampolines) and a level horizontal

surface has been created.

If bad soil conditions prevail (e.g. loamy soil), it

is favourable to insert a drainage layer.

The frame features boreholes which are sealed

with caps. Carrying irons can be inserted into these

holes.

It must be ensured that the framework is lying

snugly and does not wobble. This can be checked

simply by standing on it. After placement, the play

level around the trampoline has to be refilled

appropriately.

5 Jumping Mat Installation/Removal

The trampoline is supplied with a jumping mat, which is suspended in the frame. The jumping mat must only

be removed in case of damage or when cleaning the trampoline.

Reaching from the top and using the provided tool, the springs can be loosened from the suspended mat (Fig.

3). To do this, the hook has to be inserted into the spring eye and then pulled carefully, gripping the rope, until

the connection opens. The same procedure has to be repeated for all springs.

Fig. 3

Fig. 2

Page 4

TECHNICAL INFORMATION

TRAMPOLINE „S“

We will be pleased to help you with further questions:

smb Seilspielgeräte GmbH Berlin in Hoppegarten Fon. +49 (0) 3342 50837-20 info@smb.berlin

Technikerstraße 6/8 Fax. +49 (0) 3342 50837-80 www.smb.berlin

DE-15366 Hoppegarten

05.06.2018

Page 4 of 4

Jumping Mat Orientation

The jumping mat flanks which are equipped with chain links (see Fig. 2) have to face the frame’s sides which

feature boreholes (see Fig. 2).

Brief Instruction: Jumping Mat Installation

• Tighten the spring (using the provided tool)

• Clip the spring into the corresponding link

• Release the spring

6 Maintenance Instructions EN 1176-1

Routine Visual Inspection

The frequency of this inspection depends on local conditions (high/low usage, vandalism, weather influence).

Operational Inspection (Every 6 Months)

• Check unit for general damage or wear and tear.

• Check condition of the jumping mat, spring suspensions and protective panels.

Main Inspection

The trampoline framework consists of galvanised sheets, 3 mm thick. Due to this fact, a main inspection,

which then includes checking the framework for corrosion, only needs to be carried out every two years.

Type Plate Location

The type plate is located in one of the rubber tiles, which are glued on the trampoline steel frame. On the type

plate you will find details to the manufacturer, the DIN-Norm, a serial number and also a QR-Code for

furthermore information.

Tighten the spring

(using the provided tool)

Clip the spring into the

corresponding link

Release the spring

Loading...

Loading...