Non-contact infrared

thermometer Instruction manual

+

Model: AR882

-09-

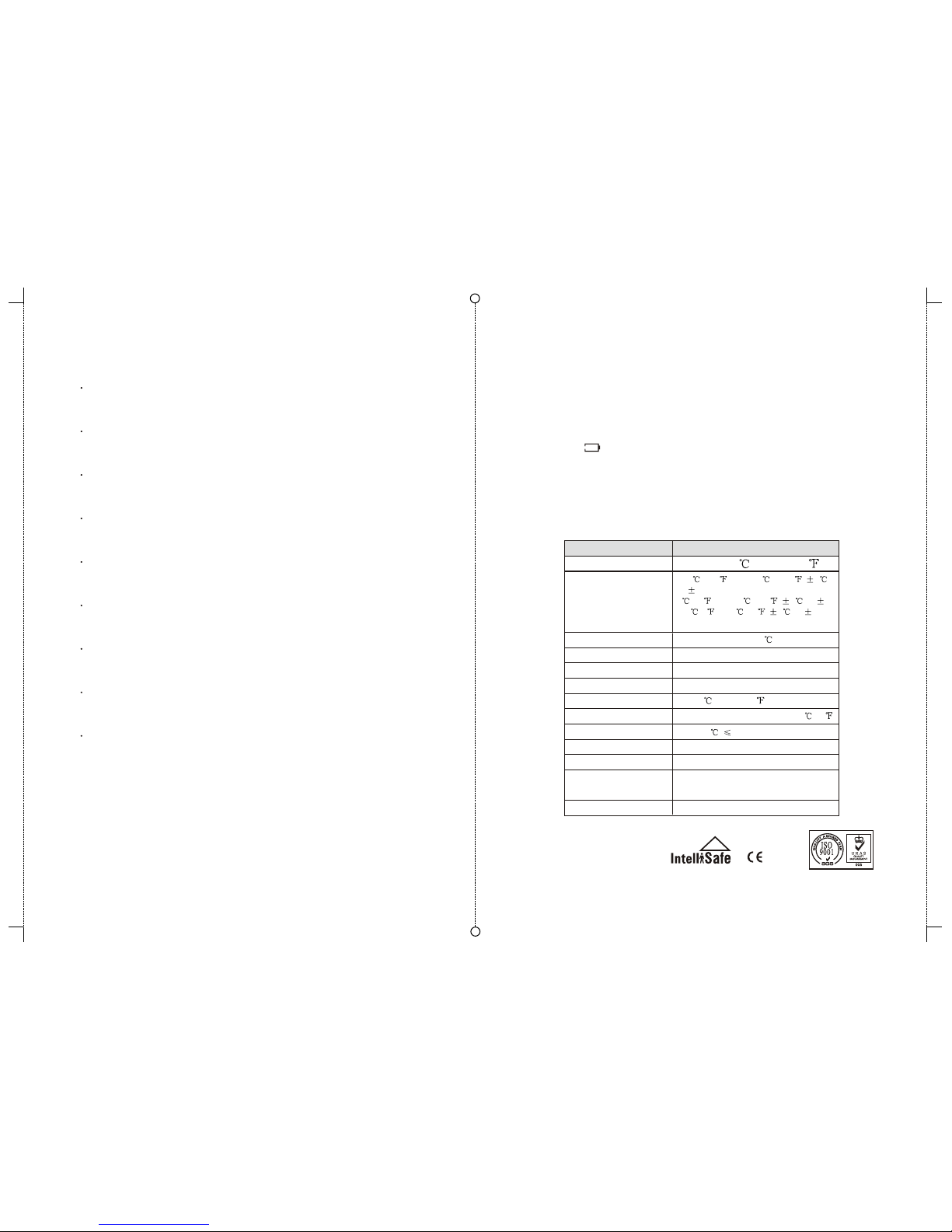

9.Specifications

1 Introduction----------------------------------------------(01)

2 How it works--------------------------------------------- (01)

3 Cautions--------------------------------------------------(02)

4 Operation Instruction---------------------------------- (02)

5 Quick Start Instruction---------------------------------(05)

6 ----------------------- (07)

7 Maintenance---------------------------------------------(08)

8 Note-------------------------------------------------------(09)

9 Specifications----------------------------------------- (09)

RS-232&DC IN PUT Interface

CONTENTS

8. Note:

8.1 Do not use solvent to clean lens.

8.2 Do not submerge the unit in water.

8.3 Do not use/place the unit in high temperature or moist

environment, that might inflect the units performance.

8.4 Do not change circuity of the unit, that possibly will

destruct the unit / endanger.

8.5 When icon display, means low battery power.

Please replace new battery to prevent inaccurate

measuring.

8.6 If unit not being use for long period, please unload the

battery.

Repeatability

1% of reading or 0.1

Response time

500 mSec, 95% response

Spectral response

8-14 um

Emissivity 0.10 to 1.00 adjustable (pre-set 0.95)

Ambient operating range

0 to 40 (32 to 104 )

Relative humidity

10-95% RH noncondensing, @ upto 30 (86 )

Storage temperature

-20 to 60 , 85%RH, without battery

Weight/Dimensions

480g ;220*134*60mm

Power

9v Alkaline or NiCd battery

Battery life (Alkaline)

Laser Models:12 hrs

Distance to Spot Size

50:1

Specifications

-18 to 1650 (0 to 3002 )

Temperature range

Accuracy

100 (212 ) to1650 (3002 ) 2

or 2%

0 (32 ) to 100 (212 ) 2 or 2%

-18 (0 ) to 0 (32 ) 3 or 3%

whichever is greater

-08-

1.Introduction

Compact, rugged and easy to use. Just aim and push

the button, read current surface temperature in less than

a second. Safely measure surface temperature of hot,

hazardous or hard-to-reach objects without contact.

2.How it works

Infrared thermometer measures the surface temper ature of an object. The unit's optics sense emitted, ref lected, and transmitted energy which is collect and fo cused onto a detector. The unit's electronics translate

the information into a temperature reading which is dis played on the unit.

For increased ease and accuracy the laser pointer

makes aiming even more precise.

Computer software disc 1pcs

RS232 /USB Input interface 1pcs

Main Parts 1pcs

English Manual 1pcs

Warranty card 1pcs

9V battery 1pcs

PP packing box 1pcs

----------------------

-------------------

----------------------------------

-----------------------------

-------------------------------

----------------------------------

------------------------------

-01-

RS232

9V

DC IN

(Figure5)

RS232 socket

Standard DC socketIN

6.1 For software installation and intructions, please

read the User Guide on CD.

6.2 Software function:

Check the data store off-line record curve graph.

6.3 DC : For saving battery consumption, please

use 9V 500mA adapter on long period measurement.

(Polarity show on socket label)

7M aintenance

7.1 Lens cleaning: Blow off lose particles using clean

compressed air. Gently brush remaining debris away

with a moist cotton cloth.

input

.

7.2 Case cleaning: Clean the case with a damp sponge

cloth and mild soap.

-07--02-

3.2Warning

-- Do not point laser directly at eye or indirectly off reflective

surfaces.

-- The unit cannot measure through transparent surfaces

such as glass or plastic. It will measure the surface

temperature of these materials instead.

-- Steam, dust, smoke, or other particles can prevent

accurate measurement by obstructing by the units optics.

4.1 When take measurement, point thermometer toward

the object to be measured and hold the yellow trigger.

The object under test should be larger than the spot size

calculated by the field of view diagram.

4.2 Distance & spot size: As the distance from the object

increase, the spot size of measuring area becomes larger.

4 Operation Instructions

3.Cautions

3.1Infrared thermometer should be protected for the following:

--EMF (electro-magnetic fields) from arc welders, induction heaters.

--Thermal shock (cause by large or abrupt ambient temperature

changes allow 30 minutes for unit to stabilize

before use).

--Do not leave the unit on or near objects of high temperature.

--Static electricity.

(8) LCD(see 5.1)

(9) Battery door clip

(10) Battery door: When replace battery, please press

battery door clip, pull down and forward the battery

door. Then install 9v battery correctly.

(11) Clesius / Fahrenheit switch: Please open battery

and push the slide switch for convertsion

6.R S-232&DC IN PUT interface

When connected AR882A+ with PC, DATA willd isplay

on LCD.D uring taking realt ime measurment, AUT

willb link on LCD.

h. PLY: Data reall function , press ,which can

recall the stored data .

i. CLR: Clear the Memory press the button of REC/CLR

two seconds can clear all stored data

j. Emissivity : Measuring Range 0.1-1.0 Adjustable

(6) Data Store press : REC/CLR

1.Storeage:

a.Press REC/CLR can store 1 unit data when in testing

model , Maximum data 4000units.

b.Press REC/CLR one seconds can Continuous record

the sampling data( press REC/CLR button on lock

status can finish store function ).

2.Checkup:

a.On PLY model , press ,can playback the

sampling data.

B.Press Set button , and can quick view it , and

connect the PC readout the data.

3. Clear:

On CLR model ,Press REC/CLR two seconds Can

clear record data

(7)Lock and Unlock function, Press the trigger on measuring

status ,press the set button will display the lock and

unlock icon .Lock Function---Means continuous

measuring,press mode button can unlock it( lock,

unlock)

-06- -03-

4.3 Field of view: Make sure the target is larger than the

unit's spot size. The smaller target the closer measure

distance. When accuracy is critical, make sure the target is

at least twice as large as the spot size.

4.4 Emissivity: Most organic materials and painted or

oxidized surfaces have an emissivity of 0.95 (pre-set in

the unit). Inaccurate readings will result from measuring

shiny or polished metal surfaces. To compensate for this,

adjust the units emissivity reading (see table below and

5.3 settings) or cover the surface to be measured with

masking tape or flat black paint. Measure the tape or

painted surface when the tape or painted reach the same

temperature as the material underneath.

4.5 Table of approximate emissivity

(Figure4)

1

8

(Figure3)

9

9V

DC IN

(2) Laser / back light button: when back light turn on ,any

operations will remain back light for 10 sec. LCD

indicate on/off status.

(3) (5) key functions: press 3 key, LCD subdisplay

MAX-MIN-AVG -HAL-LAL-SGN-PLY-CLR-EMS

display means normal

press 4 key to enter.

a. MAX: measuring maximum temperature

b. MIN: measuring minimum temperature

c. AVG: measuring average temperature

d

e. HAL: high temperature alarm--when selected

press 5 keys to set high temperature alarm

dconfirmed by pressing 4 key. When

trigger, LCD display HI icon with

f. LAL: low temperature alarm--when selected

press 5 keys to set low temperature alarm

blinks

-DIF

segment (only main measuring

mode)

. DIF: Basic on the reading before press 4 key,

compute the difference of current reading.

HAL,

trigger

an reading

over BiBi audio

sounds.

LAL,

trigger

and confirmed by pressing 4 key. When reading

over trigger, LCD display LOW icon with BiBi audio

sounds

g. SGN: data storage--when selected STO, lock &

DATA & 1---indicator will shown when press 4 key.

After temperature read out press 6 key to store,

then 2---memory unit will be shown.

REC/CLR

LASER

BACKLIT

MODE

SET

7

5

MODE

SET

REC/CLR

4

3

6

2

RS232

9V

DC IN

10-11

19mm@

300mm

18mm@

900mm

42mm@

1500mm

0.8”@ 0.7”@

36"

1.7”@

60"

D:S=50:1

12"

-05--04-

(Figure1)

A

B

C

D

E

F

G

H

I

J

K

5.2 Locating a hot/cold spot: To find a hot/cold spot, aim

the thermometer outside the area of interest, then

scan across with up and down motion until you locate

the hot/cold spot.

(Figure2)

9V

DC IN

5.Quick start instruction

5.1 LCD display: B measuring unit

A measuring reading D back light on icon

C laser on icon F scanning icon

E battery power icon G data hold icon

H mode/emissivity indicator I data storge / read icon

J low temperature alarm icon

K high temperature alarm icon

5.3 Diagram description

(1) Trigger: When turn on LCD display VERXX software

version for 1 sec. And turn to display reading with

SCAN icon. Release the trigger, display reading

with HOLD icon. Built in auto power off in 30sec.

RS232

9V

DC IN

0.30

0.95

0.95

0.70

0.50

0.90

0.85

0.95

0.95

0.95

0.94

0.90

0.93

0.85

0.98

0.70

0.50

0.98

0.94

0.93

0.95

0.95

0.95

0.90

0.98

0.90

0.80

0.94

0.93

0.94

Emissivity

Emissivity

Marterial

Marterial

Aluminum

Asbestos

Asphalt

Basalt

Brass

Brick

Carbon

Ceramic

Concrete

Copper

Dirt

Frozen food

Hot food

Glass(plate)

Ice

Iron

Lead

Limestone

Oil

Paint

Paper

Plastic

Rubber

Sand

Skin

Snow

Steel

Textiles

Water

Wood

Loading...

Loading...