Page 1

PROGRAMMING INSTRUCTIONS

for

SRU Boards

www.smartrise.us | 1235 N. Union Bower Rd, Irving, TX 75061 | 916.457.5129

Page 2

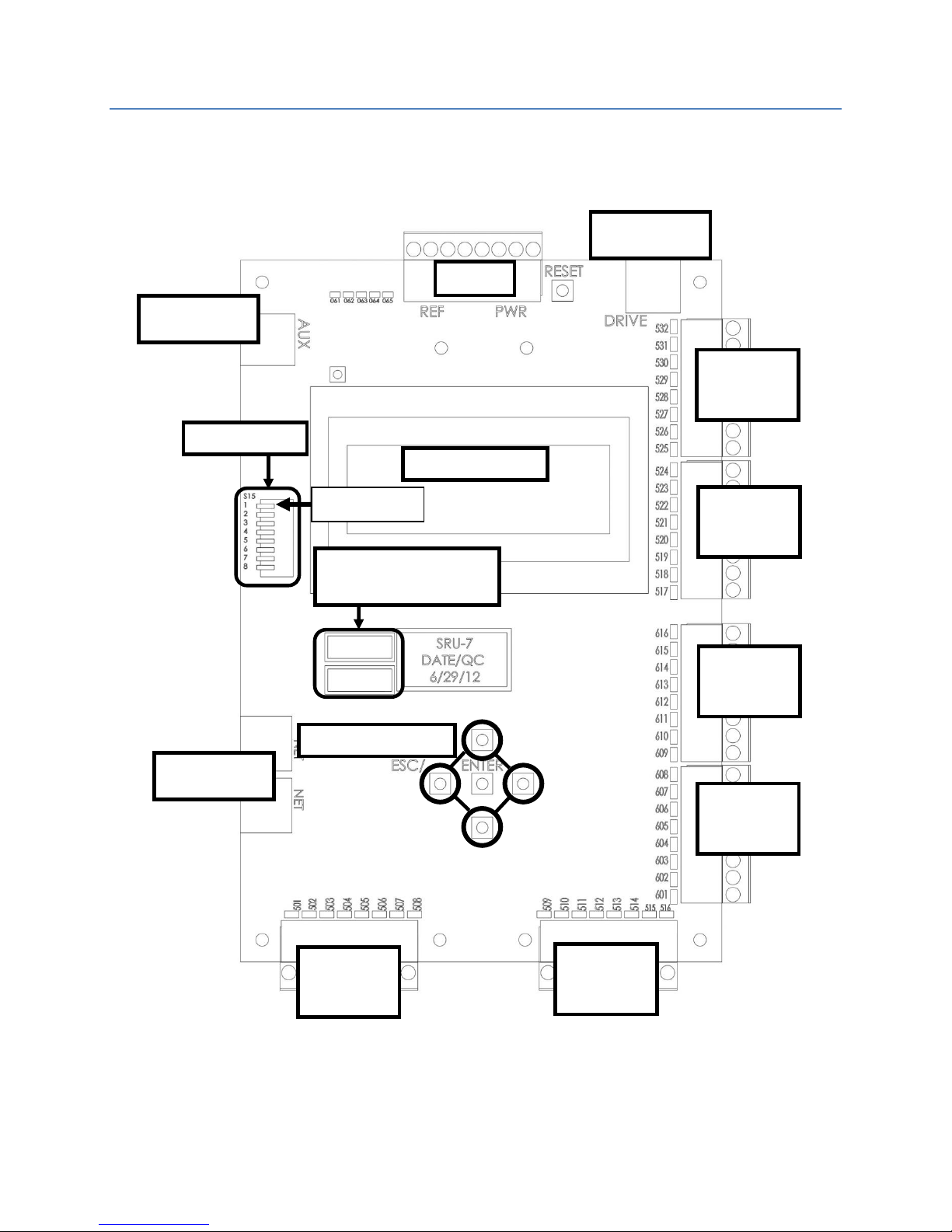

SRU Board Revision Layouts

POWER

DIP SWITCH

Inputs

525-532

Inputs

517-524

Inputs

501-508

Inputs

509-516

Outputs

601-608

Outputs

601-608

LCD SCREEN

Drive Port

AUX Port

NET Ports

JTAG PROGRAMMING

PORTS

LCD NAVIGATION

Dip Switch 1

Revision 5-7 Board

1

Page 3

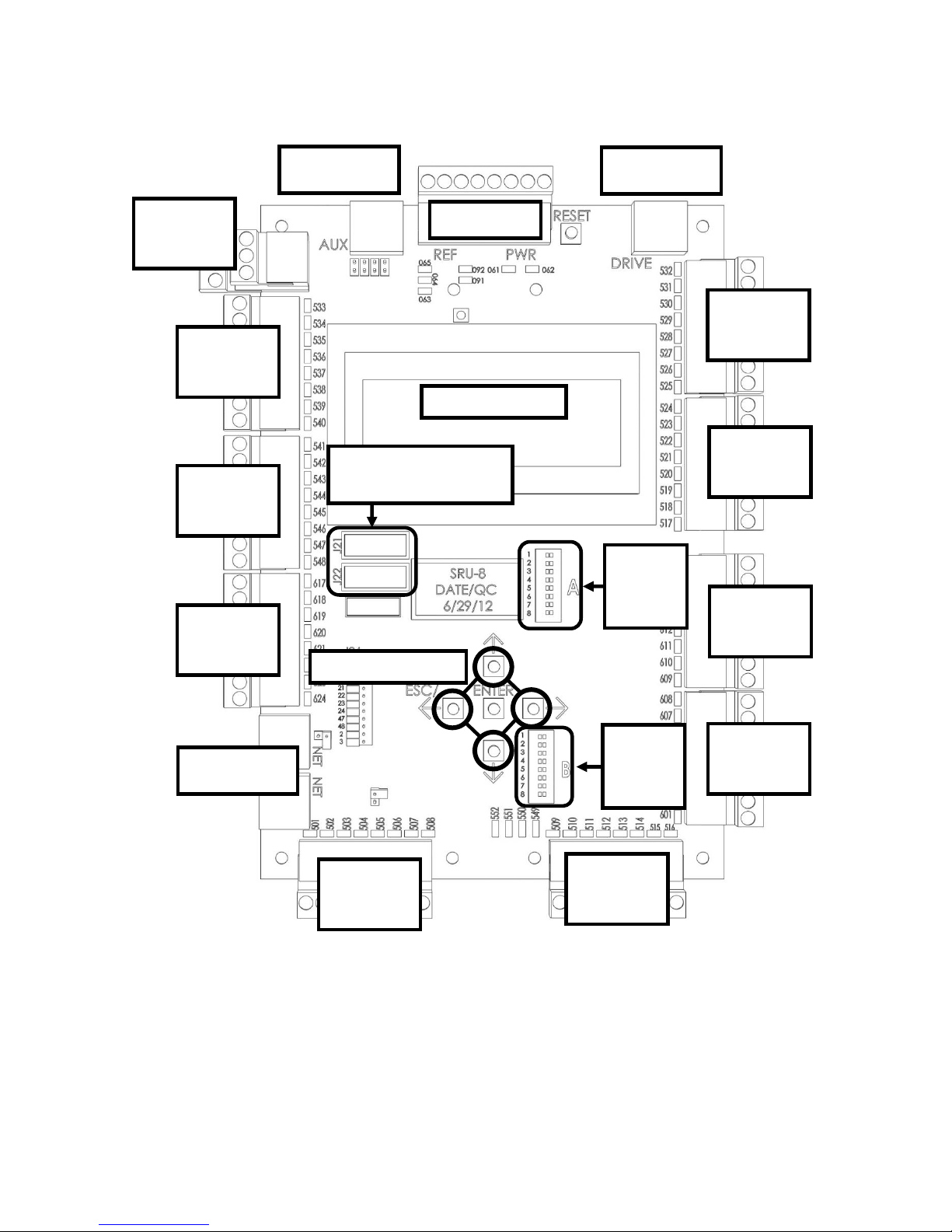

DIP

SWITCH

A

POWER

LCD SCREEN

JTAG PROGRAMMING

PORTS

Inputs

525-532

Drive Port

AUX Port

NET Ports

Inputs

517-524

Inputs

533-540

Inputs

501-508

Inputs

509-516

Inputs

549-552

Outputs

601-608

Outputs

601-608

DIP

SWITCH

B

Inputs

541-548

Outputs

617-624

LCD NAVIGATION

Revision 8 Board

2

Page 4

Access Code

Enter Access Code

Enter

“xFFFF”

Some software versions required an access code to be inputted when powering up a SRU board

for the first time. The access code is “xFFFF” and when prompted, press and hold the UP arrow

button on the SRU board until the display reads “xFFFF”, then press the enter key.

X0000

Tips to Preserve Your Settings During Board Replacement

The Machine Room (MR) board sends all settings and parameters to the Cartop (CT) and Car

Operating Panel (COP) boards. These settings are stored in each board. If the Machine Room SRU

goes out then the only way to save your jobs settings (Slowdowns, Floor Levels, Parameters, etc.)

is to replace it and reprogram it with either the COP board or the CT board. Follow these steps:

1. Replace the MR board with either the CT or COP board

2. Reprogram it as the MR board.

** DO NOT USE “DIP SWITCH 1” + “DEFAULT ALL” AFTER PROGRAMMING **

3. Install the new board as the CT or COP board and program it as such.

The previous settings in the reprogrammed MR board will then transfer to the new board and

the car should operate as before with all the original settings.

You can replace either the CT or COP board anytime as they will retrieve the settings from the

MR board when powered up.

USB Debug Adapter

To program an SRU board you will need:

Smartrise Programming Pod (USB Debug Adapter).

A fully charged laptop with either of the following operating

systems: Windows XP, Vista, 7, or 8.

The software for your specific job is provided by Smartrise in two ways: a Smartrise CD

included in the job binder OR by online download. Contact Smartrise if you don’t have

the software for your particular jobsite.

3

Page 5

Step 1 - Software Extraction to Laptop

Software provided by online download link

If an update was made to the job OR the CDs are missing, Smartrise can send an e-mail with a

link to a downloadable zip file for the software. For example:

http://smartrise.info/Software_packages/Smartrise_Job_(111112-001).zip

1. Click on the link and choose “Save As” to save the zip file to your laptop, preferably to

your desktop.

There are several ways to open a zip file. Your laptop should have the capability to extract

the file to a location of your choosing. If not you will need to download a free program

from the internet to process this file.

2. Navigate to the location you saved the file and double click on it to show the contents.

3. Some laptops won’t allow the Smartrise programmer to run directly from a zip file. To

resolve this you need to copy all the contents of the zip file to a folder on your laptop.

This will allow you to access all the folders necessary for installation (i.e. software,

Smartrise Programmer, etc.).

4. Now that the files are extracted to your laptop’s hard drive you can proceed with the

installation of the programmer (if not installed already) and the software.

4

Page 6

Step 2 - Installing the Smartrise Programmer

Special considerations need to be made when installing the software:

Do you have the Smartrise Programmer Application to install the software?

- If not, install the application by doing the following:

1. Open the (5) New Smartrise Programmer Folder in your software package

2. Open the 1 – Programmer Installer Folder

3. Install the Smartrise Programmer

4. Once the Smartrise Programmer is installed go back to the index of folders (shown below)

and open the:

(1) Controller Software folder with the JCF Software file inside shown below:

5

Page 7

5. Open the Software Folder, in this example the version is 2.20h, the version will vary on

how recent the job is.

6. Open the JCF file by double clicking on it. If it doesn’t open then the Smartrise

Programmer might not be correctly installed. Please see previous page for installation

instructions.

The Smartrise Programmer interface

Note: All the controller software is located on this interface except the group software.

6

Page 8

Software provided by CD

Revision 8 Board

Revision 5-7 Board

Ports J21 and J22

correspond to the JTAG

ports located on the

controller board.

Every Smartrise job is provided with a binder that consists of two CD’s containing software for

the specific job. Smartrise controllers are shipped initially with the software already installed on

the controller; these CD’s are provided as back-ups.

1. Insert the supplied CD into the CD ROM drive. Usually a menu similar to the one shown

below will appear. If no menu appears then open “My Computer” and click on the CD

ROM drive.

2. Click on the “Open folder to view files” option to explore the Smartrise CD folders. A list

of folders with the software will appear. The software is located in the “(1) – Controller

Software” folder.

It is imperative that you install the correct software onto the correct JTAG port.

To do this, first connect your Smartrise programmer to your laptop via USB, and then connect

the other end to the JTAG port on the controller.

7

Page 9

Step 3 - Installing the SRU Software

Warning: Your laptop needs to be fully charged for this process, plugging in your laptop to an

AC source while installing software could result in damage to the SRU Board. Also, do not

disconnect the programmer pod from the SRU board while the controller is being programmed.

Identify which controller you are installing, Machine room, Car-Top, COP.

Instructions for Programming a NEW Machine Room Controller

1. A controller cannot be programmed if unpowered, ensure that you have 24V supplied to

the controller.

2. Turn on Dip Switch 1 (Dip A). When you activate Dip Switch 1 you should see a “F77: CPU

Stop Switch” fault on the controller. Do not be alarmed – this is normal.

3. Plug the programming pod’s ribbon cable connector into the J21 port first. Select the J21

checkbox on the Smartrise programming application show below.

4. Next, click the “Begin Programming” button on the bottom of the programming interface

to begin programming your board.

5. Notice the progress report bar, when programming is finished, you will see a

a. "Progress: Done” when programming is finished.

b. NOTE: You will also want to verify that the POWER and RUN LED’s on the

programming pod itself are off before disconnecting from a controller.

6. Next move your programming pod from port J21 to J22, then click on the J22 check box

and begin programming.

7. When programming is finished:

CYCLE POWER – ** DO NOT PRESS THE RESET BUTTON **

8. IF REPROGRAMMING AN EXISTING SRU BOARD – Don’t perform the DEFAULT ALL

procedure as this will erase all existing settings. Skip to Step #10.

9. IF PROGRAMMING A NEWLY INSTALLED MR SRU BOARD ONLY – Go to MAIN MENU |

SET UP | DEFAULT ALL | select “Yes” and press the center button. The controller will begin

defaulting all the factory parameters to original programming (This could take several

minutes).

10. Once this is finished, cycle power again.

11. When the controller is fully powered and finished loading, turn off Dip Switch 1.

12. Verify that the controller is programmed correctly. This is done by going to the MAIN

MENU | ABOUT screen. If all the information is correct, the Machine Room Controller

has been successfully programmed.

8

Page 10

123 California

(C) 2014

Type of Controller

Software Version

Job Name

MR SRU

Version 2.35h

Instructions for Programming a CT/COP Controller

Programming these boards is very similar to programming a machine room controller. When

programming these boards it is not necessary to activate dip switch 1 and DEFAULT ALL.

A controller cannot be programmed if unpowered, ensure that there is 24V supplied to

the controller.

Plug in the programming pod into the J21 port first. Select the correct J21 checkbox on

the Smartrise programming application for the corresponding controller.

Next, click the “Begin Programming” button on the bottom of the programming interface

to begin programming the board.

Notice the progress report bar, when programming is finished, the display will show

"Progress: Done”. NOTE: Verify that the POWER and RUN LED’s on the programming pod

itself are off before disconnecting from the controller.

Next move the programming pod from port J21 to J22, click on the J22 check box and then

“Begin Programming”.

When programming is finished:

CYCLE POWER – ** DO NOT PRESS THE RESET BUTTON **

When the controller is fully powered and finished loading, verify if the controller is

programmed correctly by going to the MAIN MENU | ABOUT

If all the information is correct, the controller software has been successfully installed.

9

Page 11

Instructions for Programming a Group Controller for Non-Simplex jobs

The group controller software will be located in the Controller Software folder.

Locate the folder with the group software in it. The folder will clearly be labeled “Group

Software.” After locating the folder, proceed below.

1. A controller cannot be programmed if unpowered, ensure that you have 24V supplied to

the controller.

2. Activate Dip Switch #1 on the group controller. (The group controller will not fault like

the machine room controller)

3. Plug in the programming pod into the J21 port first. Select the J21 checkbox on the

Smartrise programming application show below.

4. Next, click the “Begin Programming” button on the bottom of the programming interface

to begin programming the board.

5. Notice the progress report bar, when programming is finished, the LCD display will show

"Progress: Done”. NOTE: Verify that the POWER and RUN LED’s on the programming pod

itself are off before disconnecting it from a controller.

6. Next move the programming pod from port J21 to J22, click on the J22 check box and the

“Begin Programming” button.

7. When programming is finished:

CYCLE POWER – ** DO NOT PRESS THE RESET BUTTON **

8. Next, go to the MAIN MENU | SET UP | DEFAULT ALL | select “Yes” and press the center

button. The controller will begin to default all the factory parameters (This could take

several minutes).

9. Once this is finished, cycle power again.

10. When the controller is fully powered and finished loading, turn off Dip Switch 1.

11. Verify that the controller is programmed correctly. This is done by going to the MAIN

MENU | ABOUT. If all the information is correct, the controller software has been

successfully installed.

10

Loading...

Loading...