Smartrise F220 Equipment Installation Manual

EQUIPMENTINSTALLATIONMANUAL

HydraulicControllers

ACTractionControllers

Thismanualcontainsinformationforsoftwareversion3

www.smartrise.us|2601FairOaksBlvd,Sacramento,CA95864|916.457.5129

Version3.16

Smartrise Engineering offers several options for customer training:

30 Minute phone introductory training for new customers

4 or 8 hour personal training classes at customer’s office or jobsite

4 hour regional training classes held throughout the U.S.A. & Canada

Online training videos to supplement regional training courses

To accommodate the busy work schedules of our customers all regional training

classes are 4–hours each and are held in one day from 8am to 5pm.

Training classes can also be performed at the customer’s site in place of the

universal 4 or 8-hour training.

Smartrise Training is recognized by the NAEC for CET credits for up to 8 hours.

For more information, contact the main office at (916) 457-5129 or send an email

to: Training@smartrise.us

1

WARRANTY

Products sold by Smartrise Engineering (Smartrise) are warranted to be free from defects in

workmanship and material for a period of fifteen (15) months from the date of shipment. Any

products defective in workmanship or material shall, at the discretion of Smartrise, be repaired

or replaced at no charge to the Buyer. Determination as to whether a product is defective and

eligible for an authorized return rests with Smartrise. The obligation of Smartrise shall be limited

solely to that of repairing or replacing of defective products returned to Smartrise by the Buyer.

It is the obligation of the Buyer to return defective products to Smartrise with all parts and

documentation. A return merchandise authorization (RMA) number must be obtained from

Smartrise prior to returning products.

Smartrise makes no warranty as to the fitness of its products for any application not specified in

writing by Smartrise. Use of Smartrise products in any unauthorized manner will void this

warranty and may cause damage to the product and/or injury.

This warranty is exclusive and in lieu of all other warranties, expressed or implied, including, but

not limited to, any warranty of merchantability or of fitness for a particular purpose and

therefore, the Buyer hereby waives any and all claims.

LIMITATIONS OF LIABILITY

In no event shall Smartrise Engineering be liable for loss of profit, indirect, consequential, or

incidental damages whether arising out of warranty, breach of contract or tort. Failure to

understand the elevator control system could result in damage to the system and possibly even

danger to the passengers. Only properly trained and qualified personnel should attempt to work

on the system.

CODE COMPLIANCE

Smartrise controllers are certified by ASME A17/CSA B44 and the State of California. Depending

on the jurisdiction where the controller is operating, it will be configured per the specific local

code requirements as specified by the buyer.

2

PERSONAL SAFETY: PERSONAL INJURY

AND/OR DEATH MAY OCCUR

Smartrise Engineering controllers should only be installed by qualified, licensed, trained elevator

personnel familiar with the operation of microprocessor-based elevator controls. All safety

devices, known as electronic protective devices (limits, governors, hoistway locks, car gate, etc.)

shall be tested to be fully functional prior to attempting to run the elevator. Never operate the

system with any safety device rendered inoperative in any way. The User is responsible for

compliance with the current National Electrical Code with respect to the overall installation of

the equipment, and proper sizing of electrical conductors connected to the controls. The User is

responsible for understanding and applying all current Local, State, Provincial, and Federal Codes

which govern practices such as controller placement, applicability, wiring protection,

disconnections, over current protection, and grounding procedures. To prevent the risk of

personal shock, all equipment should be securely grounded to earth ground as outlined in the

National Electrical Code. Failure to obtain an actual earth ground source may result in electrical

shock to personnel.

EQUIPMENT SAFETY

All equipment chassis should be securely grounded to earth ground as outlined in the National

Electrical Code. Improper grounding is the most common cause of electrical component failures

and electrically noise-induced problems. All component replacement must be done with the

main line power off. Unauthorized modifications to circuits or components should not be

attempted without Smartrise Engineering authorization to ensure all safety features are

maintained. Care should be taken when using test leads and jumpers to avoid applying high

voltage or ground to low voltage microprocessor circuits.

3

CONTROLLER GROUNDING REQUIREMENTS

NOTE – For the controller to function properly it is very important to

provide proper building ground connections to the controller.

Examples of a proper building-to-controller ground connection is

to attach the ground cable to:

The street side of the incoming water main.

To a grounding rod that has been driven into the pit flooring.

The controller has a common ground bus terminal connection.

All grounds need to land at this common point including building,

motor, transformer, and filter grounds. This prevents ground loops,

and will limit the impedance between the grounds and noise will

be channeled back to building ground.

Providing a proper ground is mandatory and will improve the

performance of the controller.

4

TABLE OF CONTENTS

CONTROLLER GROUNDING REQUIREMENTS ................................................................................................ 4

GENERAL INFORMATION .............................................................................................................................. 9

Bypass Term Limits ................................................................................................................................. 19

HYDRO INSTALLATION ................................................................................................................................ 21

Main Power Setup ................................................................................................................................... 22

Motor Wiring – 3/9 Lead Motor Wiring .................................................................................................. 23

Motor Wiring – 6/12 Lead Motor Wiring ................................................................................................ 24

Valve Wiring ............................................................................................................................................ 25

Soft Start setup – Sprecher + Schuh ....................................................................................................... 26

Soft Start setup – Siemens ...................................................................................................................... 30

AC TRACTION INSTALLATION ...................................................................................................................... 36

Main Power Setup ................................................................................................................................... 37

Motor & Brake Wiring ............................................................................................................................. 38

Encoder Wiring (Instructions per Manufacturer Drive Type) ..................................................................... 39

MAGNETEK HPV900-S2 DRIVE ................................................................................................................ 46

INDUCTION MOTOR SETUP ................................................................................................................. 46

PERMANENT MAGNET SETUP ............................................................................................................. 51

MAGNETEK L1000A DRIVE ...................................................................................................................... 58

INDUCTION MOTOR SETUP ................................................................................................................. 58

PERMANENT MAGNET SETUP ............................................................................................................. 64

KEB DRIVE................................................................................................................................................ 71

INDUCTION MOTOR SETUP ................................................................................................................. 71

PM MOTOR SETUP .............................................................................................................................. 80

Brake Board Adjusting & Replacing Procedure ........................................................................................... 90

Brake Board Replacement ...................................................................................................................... 91

Brake Board Adjustment ......................................................................................................................... 92

STEEL TAPE LANDING SYSTEM .................................................................................................................... 96

IP8300 SELECTOR, TAPE AND MAGNETS ................................................................................................ 97

DOOR ZONE MAGNET INSTALLATION – TAPE ....................................................................................... 100

TRACTION DZ1/DZ2 MAGNET PLACEMENT – ALL LANDINGS ........................................................... 101

HYDRO DZ1/DZ2 MAGNET PLACEMENT – TOP TERMINAL LANDING ............................................... 102

HYDRO DZ1/DZ2 MAGNET PLACEMENT – INTERMEDIATE LANDINGS ............................................. 103

5

HYDRO DZ1/DZ2 MAGNET PLACEMENT – BOTTOM TERMINAL LANDING ....................................... 104

UT1/DT1 MAGNET DESCRIPTION – TAPE .............................................................................................. 105

UT1/DT1 MAGNET ALIGNMENT – TAPE ............................................................................................... 106

UET/DET MAGNET PLACEMENT – TAPE ................................................................................................ 107

HOISTWAY SWITCH POSITIONING TABLE – NTS ............................................................................... 108

TAPELESS LANDING SYSTEM ..................................................................................................................... 109

GOVERNOR ENCODER LANDING SYSTEM INSTALLATION ..................................................................... 113

UET/DET MAGNET PLACEMENT – RAIL ................................................................................................. 121

NTS MAGNET PLACEMENT – RAIL ......................................................................................................... 122

SLIDE DISTANCE DETERMINATION PROCEDURE FOR ETS MAGNET PLACEMENT .................................... 123

MANUAL ETS and FINAL LIMIT SWITCHES ................................................................................................ 130

FINAL SWITCH PLACEMENT - TAPE ....................................................................................................... 131

FINAL SWITCH PLACEMENT – RAIL ....................................................................................................... 132

SMOKE SENSORS, SHUNT, & LOAD WEIGHING ........................................................................................ 133

Smoke Sensor Setup ............................................................................................................................. 134

SMOKE SENSOR SETUP ILLUSTRATION – LOWER LEVEL MACHINE ROOM ....................................... 138

Shunt Operation .................................................................................................................................... 139

Load Weighing ...................................................................................................................................... 140

EMERGENCY POWER & SAFETY STRING ................................................................................................... 141

Emergency Power ................................................................................................................................. 142

SAFETY STRING DESCRIPTION ............................................................................................................... 143

SAFETY STRING TROUBLESHOOTING ................................................................................................ 143

DOOR OPERATOR GENERAL ...................................................................................................................... 144

INSTALLATION ........................................................................................................................................... 144

MOVFR DOOR OPERATOR ..................................................................................................................... 145

MOVFR DOOR OPERATOR – G.A.L. CERTIFIED PHE ........................................................................... 146

IPC DOOR OPERATOR CONTROL MODEL D3000 ................................................................................... 147

Adjusting Door Dwell Times .................................................................................................................. 152

Battery Lowering Device ........................................................................................................................... 153

Reynolds & Reynolds Battery Lowering Device – “BLD” ....................................................................... 154

BLD / MOVFR Door Operator Voltage Issues ........................................................................................ 156

Learning the Hoistway .............................................................................................................................. 157

Adjusting Car Speeds ................................................................................................................................ 161

Car Speed Profiles Overview ................................................................................................................. 162

Adjusting Floor Levels ............................................................................................................................... 166

6

Adjustment Too High/Too Low method ............................................................................................... 167

Adjusting up/down Stop Points method............................................................................................... 169

Testing Procedures for Hydro Controllers ................................................................................................ 172

Emergency Power Testing ..................................................................................................................... 173

Normal Limit Testing Setup ................................................................................................................... 174

Normal / NTS Stopping test .................................................................................................................. 175

ETS Slowdown Test ............................................................................................................................... 176

Normal/Directional limits Test .............................................................................................................. 177

Re-leveling with In-Car Stop switch (Hydraulic System): ...................................................................... 177

Redundancy test ................................................................................................................................... 178

Battery Lowering Test ........................................................................................................................... 178

Buffer Test ............................................................................................................................................. 179

Stop Ring Test – Low Speed .................................................................................................................. 180

Low Oil / Low Pressure Test .................................................................................................................. 180

Leveling Speed Test (v2.35e or newer only) ......................................................................................... 181

Leveling Zone Test................................................................................................................................. 181

Pressure Test (Hydraulic System): ........................................................................................................ 182

Hydro Rupture setup............................................................................................................................. 182

Testing Procedures for Traction Controllers ............................................................................................. 183

Normal Limit Testing Setup ................................................................................................................... 184

NTS SWITCH DRIVE SETUP .................................................................................................................... 185

NTS SWITCH POSITION SETUP ............................................................................................................ 189

NTS SWITCH TESTING PROCEDURE .................................................................................................... 191

EMERGENCY TERMINAL STOPPING DEVICE (ETS) ............................................................................. 191

NORMAL/DIRECTIONAL LIMITS............................................................................................................. 193

REDUNDANCY TEST ............................................................................................................................... 194

MANUAL BRAKE RELEASE TEST ............................................................................................................. 194

BATTERY LOWERING TEST .................................................................................................................... 194

BUFFER TEST ........................................................................................................................................ 195

PRESSURE TEST (HYDRAULIC SYSTEM): ............................................................................................. 196

RE-LEVELING WITH IN-CAR STOP SWITCH (HYDRAULIC SYSTEM): ....................................................... 196

STOP RING TEST – LOW SPEED ............................................................................................................. 197

OVERSPEED AND GOVERNOR TEST – MAGNETEK DRIVE ..................................................................... 198

OVERSPEED AND GOVERNOR TEST – L1000A ....................................................................................... 199

EARTHQUAKE COUNTERWEIGHT TEST ................................................................................................. 201

7

LEVELING ZONE TEST ............................................................................................................................ 201

UNINTENDED MOVEMENT ................................................................................................................... 202

RACK AND PINION DROP TEST .............................................................................................................. 203

LOSS OF TRACTION TEST (2010 code compliance only) ....................................................................... 204

OTHER ADJUSTMENTS .............................................................................................................................. 205

ACCESS TOP/BOTTOM LIMITS: .............................................................................................................. 205

POSITION INDICATOR VIA CE: ............................................................................................................... 205

RESYNCHING - HYDROS ......................................................................................................................... 205

SIMPLEX PARKING SETUP ...................................................................................................................... 205

HYDRO RUPTURE SETUP ....................................................................................................................... 205

SMARTRISE MENU DEFINITIONS ............................................................................................................... 206

FAULTS & ALARMS .................................................................................................................................... 214

Common Fault Clearing Procedures ..................................................................................................... 217

ALARM DESCRIPTION INDEX ..................................................................................................................... 249

SRU INPUT / OUTPUT PROGRAMMING TUTORIAL ................................................................................... 253

APPENDIX A – SMARTRISE BOARDS .......................................................................................................... 256

APPENDIX B – MAKING CAT5 CABLES ....................................................................................................... 258

APPENDIX C – REPLACING RELAYS ............................................................................................................ 259

ADDENDUM I – REPLACING AND PROGRAMMING A DEFECTIVE SRU BOARD ......................................... 262

ADDENDUM II – ENCODER WIRING TABLES ............................................................................................. 269

ADDENDUM III – TRACTION BRAKE PICK OPERATION .............................................................................. 270

ADDENDUM IV – PARAMETER ADJUSTMENTS ......................................................................................... 271

ADDENDUM V – SECURITY ........................................................................................................................ 274

ADDENDUM VI – SCREEN LOCKOUT FEATURE .......................................................................................... 276

ADDENDUM VII – PI CONVERSION TABLE ................................................................................................. 277

8

GENERAL INFORMATION

THE JOB BINDER

The job binder is a 2.5” white binder that contains specific information about the job

you are installing. The cover contains the job name and job number that is required

for technical support with Smartrise Engineering. This binder should be kept at the

jobsite at all times for future reference and troubleshooting.

COMPONENTS

The following components are included in each job binder.

1. Software

a. The binder contains a 256meg USB flash drive that contains all the software,

drawings and programs needed for each specific job.

2. Drawings or Prints

a. There are anywhere from 13 to 17 sheets of drawings that pertain to that

specific controller. These prints include an index indicating the job specifics,

tables that show correct dip switch settings, jumper settings for individual

boards, and factory and field wiring diagrams and generic wiring references.

i. The solid lines on the prints show factory installed wiring.

ii. The dashed lines show installer wiring.

b. If the voltages or wiring for your job does not match the Job Specification table

on the ‘Sheet 01: Getting Started’ page of the drawings, contact Smartrise

Engineering for clarification before powering up.

3. Manual

a. The Equipment Installation Manual contains useful information for installation,

testing, adjusting, troubleshooting, menu navigation and much more.

For the most recent version of our installation manual go to

www.smartrise.us, click on Support and download a pdf copy of our latest

release.

4. IO Sheets

a. All binders include an IO sheet that shows each board’s input & output

programming. This is very useful when locating a specific IO for installation

and/or troubleshooting and for recording changes in the SRU IOs.

5. Drive, Door Operator, and other operating manuals (optional)

9

Common Installation Issues & Procedures

CARTOP COMMUNICATION ISSUES

Make sure to connect the shield of the CN+/CN- shielded pair to reference (REF) on

both ends. This communication cable part of the traveler located between the

machine room and car top board. Make sure the CN+ & CN- wires are connected to

the same terminals in the machine room as well as the cartop DIN rails.

Special Note on 2-Board Systems – Make sure the software on the COP SRU

says “Prewire CT” and NOT “Prewire COP”. Prewire COP software WILL NOT

communicate with the machine room SRU board.

HALL BOARD COMMUNICATION TESTING

To test communication on any hall board turn on Dip Switch 8. The two green LEDs

on the hall board blink indicating it is transmitting and receiving communication

from the machine room. This is a test dip switch only. Do this one floor at a time

when installing the hall boards; it will confirm that the wiring and board are good.

Always do this before moving onto the next floor.

JUMPING OUT UNUSED INPUTS

If the drawings show a normally closed contact for an Input your system does not

require, apply a jumper from 24vdc to the specified Input terminal. All Smartrise

boards Receive 24vdc inputs ONLY and provide 24vdc reference via programmed

outputs.

Entering Car Calls

You can enter a car call from the Machine Room or Cartop SRU by going to MAIN

MENU | DEBUG | ENTER CAR CALLS and using the Up/Down arrow keys to select

a floor to go to. Press the Enter button to latch that floor.

NOTE: There will be a noticeable delay between the time a call is latched and

the time the car actually initiates the call. This is normal because the call is

initiated through the software and not the physical car call button.

*** Note: Before getting started, take a few minutes learning to

navigate the LCD reader of the Smartrise board. The board and the

menu options are the same for all locations (MR, CT or COP) and all

menu items are located in Appendix A – Smartrise Menu Definitions ***

10

SRU BOARD REVISION 8 LAYOUT

J24

DIP SWITCH A

POWER

LCD SCREEN

LCD NAVIGATION

BUTTONS

JTAG

PORTS

Outputs

Outputs

Inputs

Inputs

Inputs

Inputs

Outputs

Inputs

Inputs

Inputs

Dip Switch 1

DIP SWITCH B

Revision 8 Board

PROGRAMMING

11

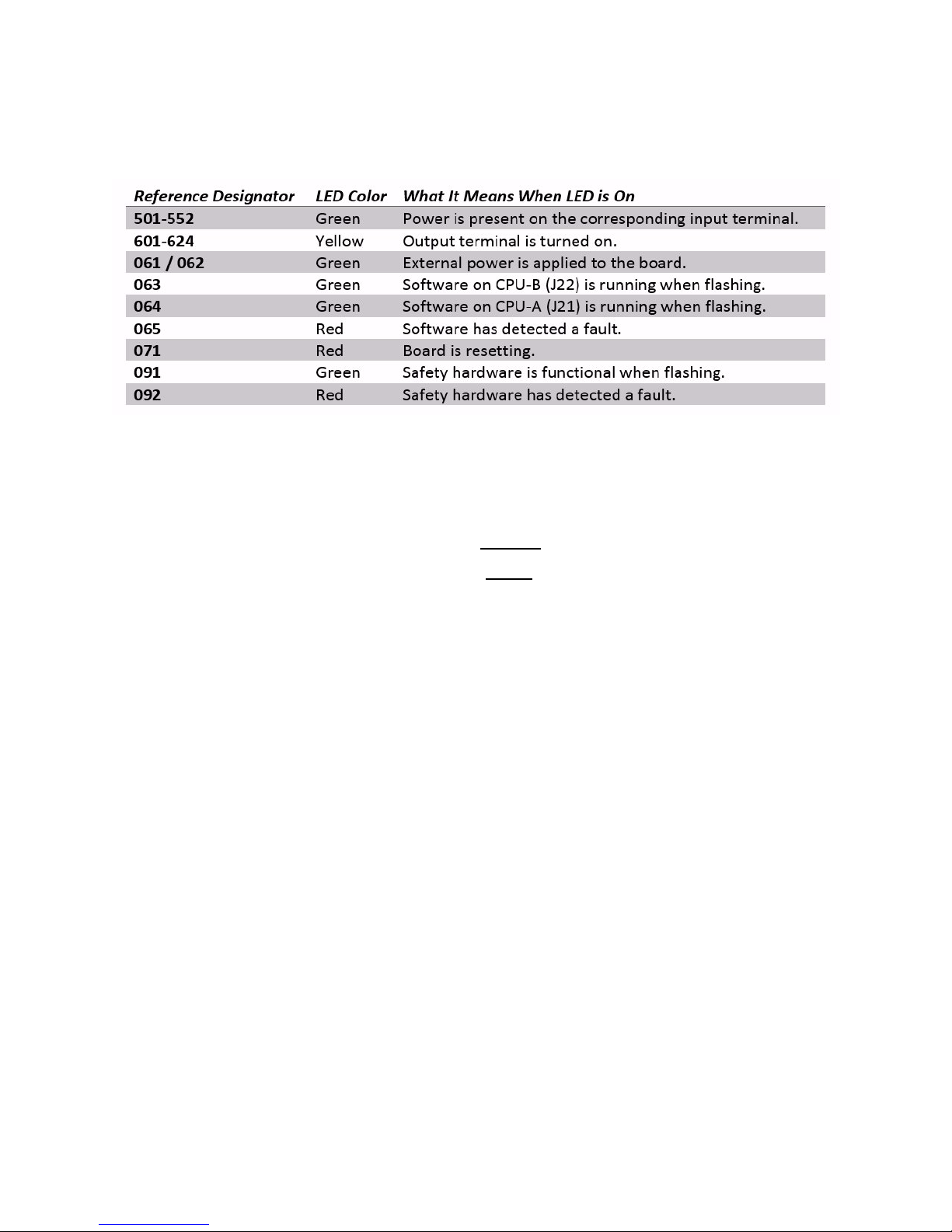

SRU LED Indicator Table

Each LED on the SRU board has a reference designator next to it. The table below

explains the function of each LED.

You will notice that the LEDs come in three colors: red, yellow, and green.

Red indicates a problem. Either a fault has been detected or the board is

resetting.

Yellow is used to indicate an active output terminal.

Green is used to show power on an input terminal, power to the board, and

as a “heartbeat” to show the software is running on the two processors.

The heartbeat is displayed by the CPU LEDs (063 and 064) which flash when

the board is functioning.

Inputs

The input terminals are labeled 501 through 548. Each terminal has a green LED

next to it which indicates when there is power present on the input. Inputs are

designed for DC current only. Putting AC current on an input will damage it.

Outputs

The yellow LED indicates the output transistor is on and current can flow

through the output terminal. The output terminal provides a reference (REF)

signal which means it will always connect to the negative side of the load. The

positive side of the load should be connected to a +24vDC power source.

** Never connect +24vDC directly to the output terminal. Without a load to

limit the current, the output transistor may be damaged. **

When the yellow LED is off, it means the output transistor is also off which

means any load connected to it will not be actuated.

12

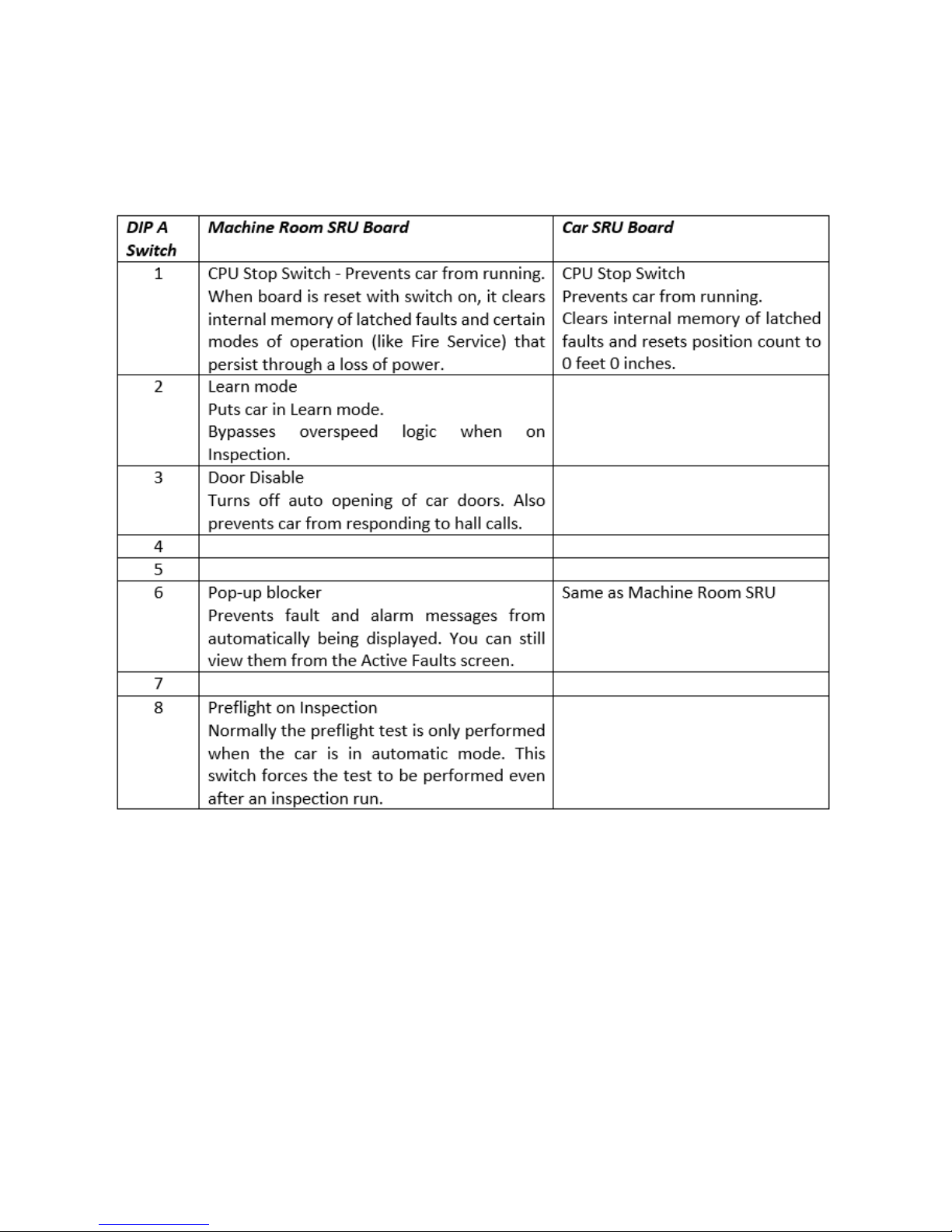

DIP Switches and Jumpers (Rev 8 bds.)

The Revision 8 SRU board has two sets of DIP switches, each containing eight

switches. The sets are labeled A and B and are located in the lower right area of

the board. The table below explains their functions.

13

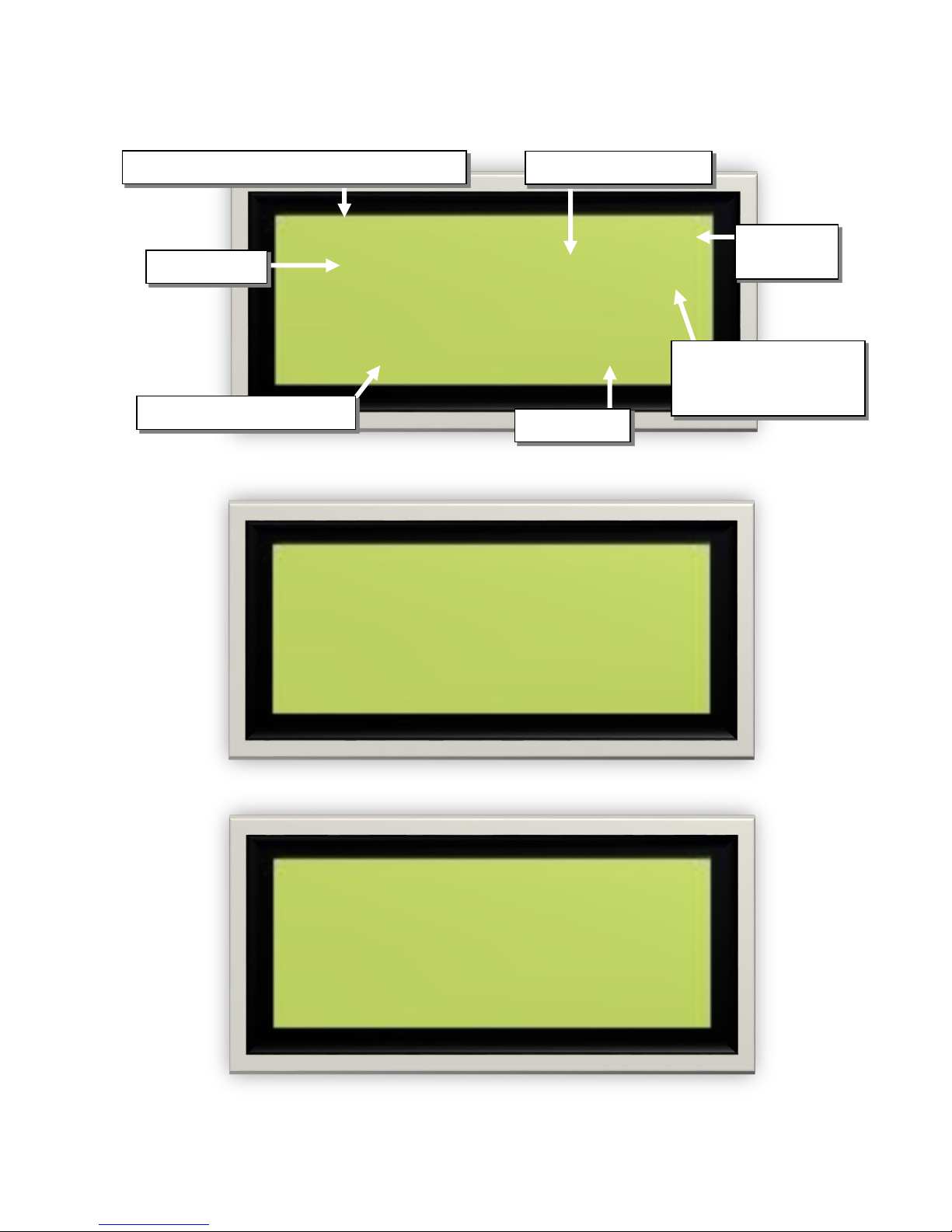

SMARTRISE SRU LCD SCREEN VIEWS

Main Me nu

*St a tus

Fa u lts

Se t up

N o r mal DZ

.. [ | ] P I : 1 T- 14

658 0 ’ 03. 3 7 ”

C M D : 0 F P M : 0

Door Zone

indicator

Current Mode (Normal, Inspection, Fire, etc)

Floor Position Indicator

Current FPM

Door Zone Step value:

T – ## (down direction)

Controller Command speed

Door position

UP [ | ] PI: 1 T- 14

GSW DCL DOL DO DC ND

DCB DOB PHE SE DPM

CAM RES RUN HVY

Normal View Screen

B + ## (up direction)

MAIN MENU SCREEN

CAR DOOR DATA SCREEN (SEE NEXT PAGE)

14

---CAR DOOR DATA---DN [ | ] PI:25 T-14

GSW DCL ... .. .. ..

... ... ... .. DPM

---CAR DOOR DATA---DN [ | ] PI:25 T-14

... ... DOL .. .. ..

... ... ... .. ...

Car Door Data Screen

Inspection (CT) DZ

These screens show the status of the door operator signals.

When the letters are visible the flag is being made.

Below are two examples of the car door status screen when Open and Closed:

Car Door Closed Car Door Open

--- CAR DOOR DATA ----

FIRST LINE

1. UP / DN – Direction of travel

2. [ | ] – Door status

3. PI: – Position Indicator

4. T-# / B+# – Magnet steps (only in door zone)

SECOND LINE

1. GSW – Gate Switch

2. DCL – Door Close Limit

3. DOL – Door Open Limit

4. DO – Door Open

5. DC – Door Close

6. ND – Nudge

THIRD LINE

1. DCB – Door Close Button

2. DOB – Door Open Button

3. PHE – Photo Eye

4. SE – Safety Edge

5. DPM – Door Position Monitor

FOURTH LINE

1. CAM – Door Cam

2. RES – Door Restrictor

3. RUN – Providing low current output to doors during travel

4. HVY – Used for heavy car/hall doors

DN [ | ] PI:25 T-14

16385 246’00.18”

CMD:-LEV FPM:-10

---CAR DOOR DATA---DN [ | ] PI:25 T-14

GSW DCL DOL DO DC ND

DCB DOB PHE SE DPM

CAM RES RUN HVY

---HALL DOOR DATA--DN [ | ] PI:25 T-14

BL BC ML MC TL TC

15

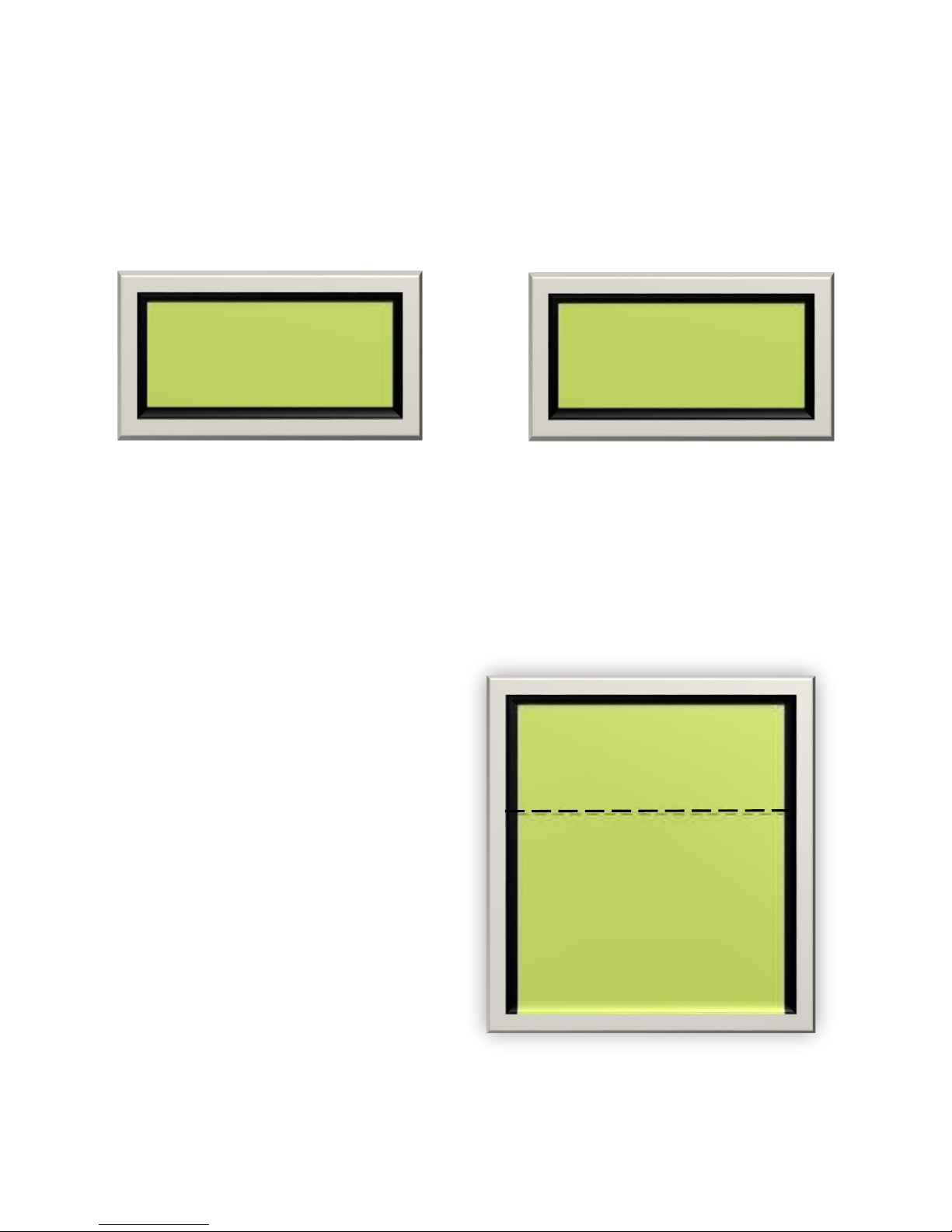

Hall Door Data Screen

DOOR ICON

MEANING

[ | ]

Doors are fully closed

[ < > ]

Doors are opening

[ ]

Doors are fully open

[ > < ]

Doors are closing or nudging

[ < | > ]

Doors are opening but gate switch is still made

< >

Doors are fully open but the Door Open output is still on

[ | | ]

Doors are ajar or not flagging properly – Unknown status

Bottom Hall Door Open –

BL / BC not flagging

---HALL DOOR DATA---

--- HALL DOOR DATA ---

FIRST LINE – SAME AS CAR DOOR DATA

SECOND LINE

1. BL / BC – Bottom Hall Lock / Bottom Close Switch

2. ML / MC – Middle Hall Lock / Middle Close Switch

3. TL / TC – Top Hall Lock / Top Close Switch

.. .. ML MC TL TC

Door Status Descriptions

16

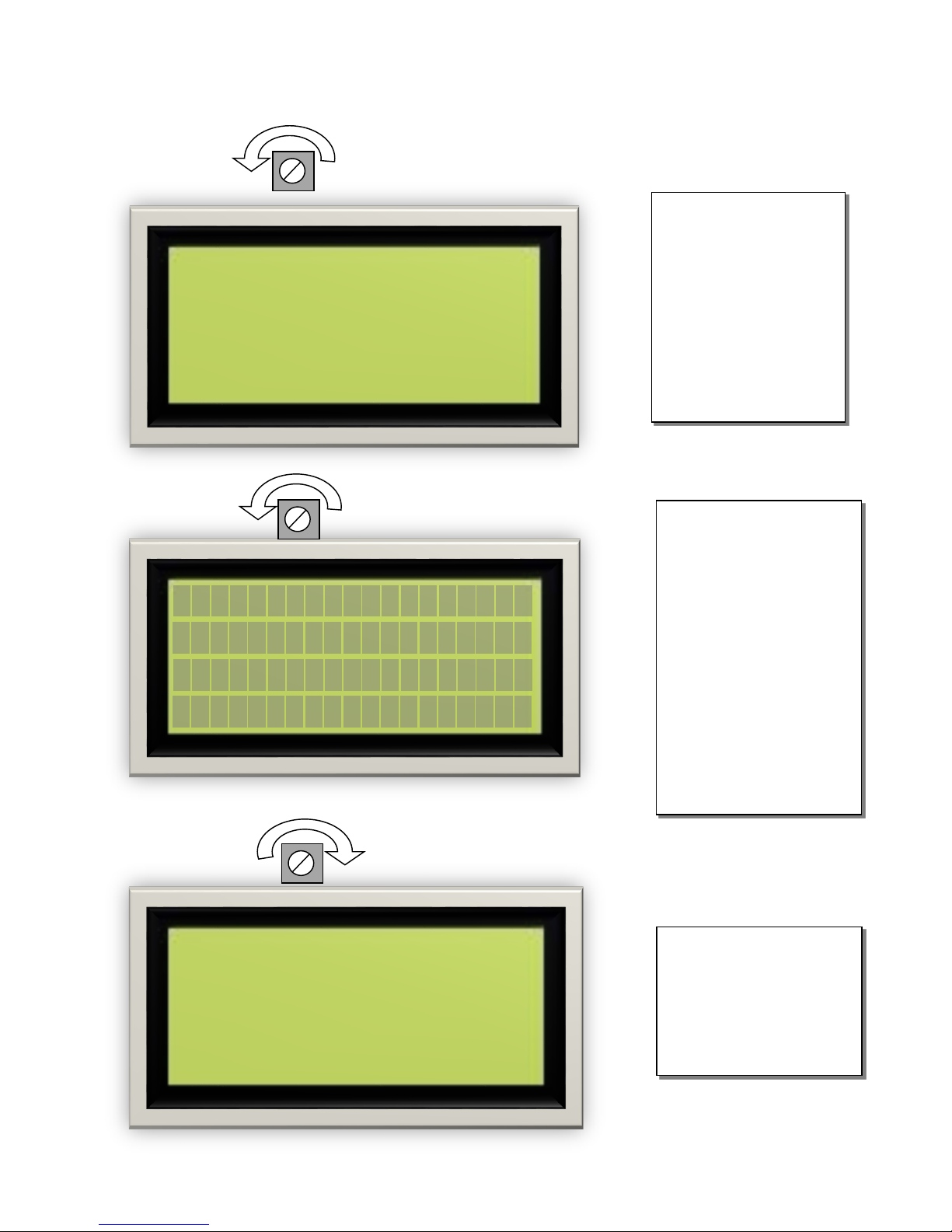

Smartrise SRU LCD Screen Adjustment

If the LCD screen is

blank but the LEDs on

the SRU board are lit

then adjust

Potentiometer R249

(located above the

LCD screen) counterclockwise.

Keep turning

Potentiometer R249

counter-clockwise until

the display comes on.

Caution: Turning

Potentiometer R249

too far will cause dark

boxes to appear around

the letters and may

burn out the LCD

screen prematurely.

N o r mal DZ

.. [ | ] P I: 1 T- 14

658 0 ’ 03. 3 7 ”

C M D : 0 F P M : 0

Turn Potentiometer

R249 clockwise until

the dark boxes

disappear but you can

still read the screen.

N o r mal D Z

.. [ | ] P I : 1 T - 14

658 0’ 03 . 3 7 ”

C M D : 0 F P M : 0

17

GENERAL INSTALLATION

While Smartrise takes every measure to provide the

customer with an out of box installation, sometimes

incomplete information leads to default values being

set on equipment and voltage settings. This is done

to protect your equipment from overvoltage issues.

[For example, the door operator for your job might

operate on 240vac but Smartrise wasn’t supplied with

that information when the job was developed,

therefore, the DR breaker (door operator voltage

supply) will be set to 120vac for safety reasons.]

Please take a moment to verify that all required

voltages for the existing equipment matches the

voltages set by Smartrise PRIOR TO POWERING UP

THE CONTROLLER. You can verify this with the

drawings provided in your job binder.

18

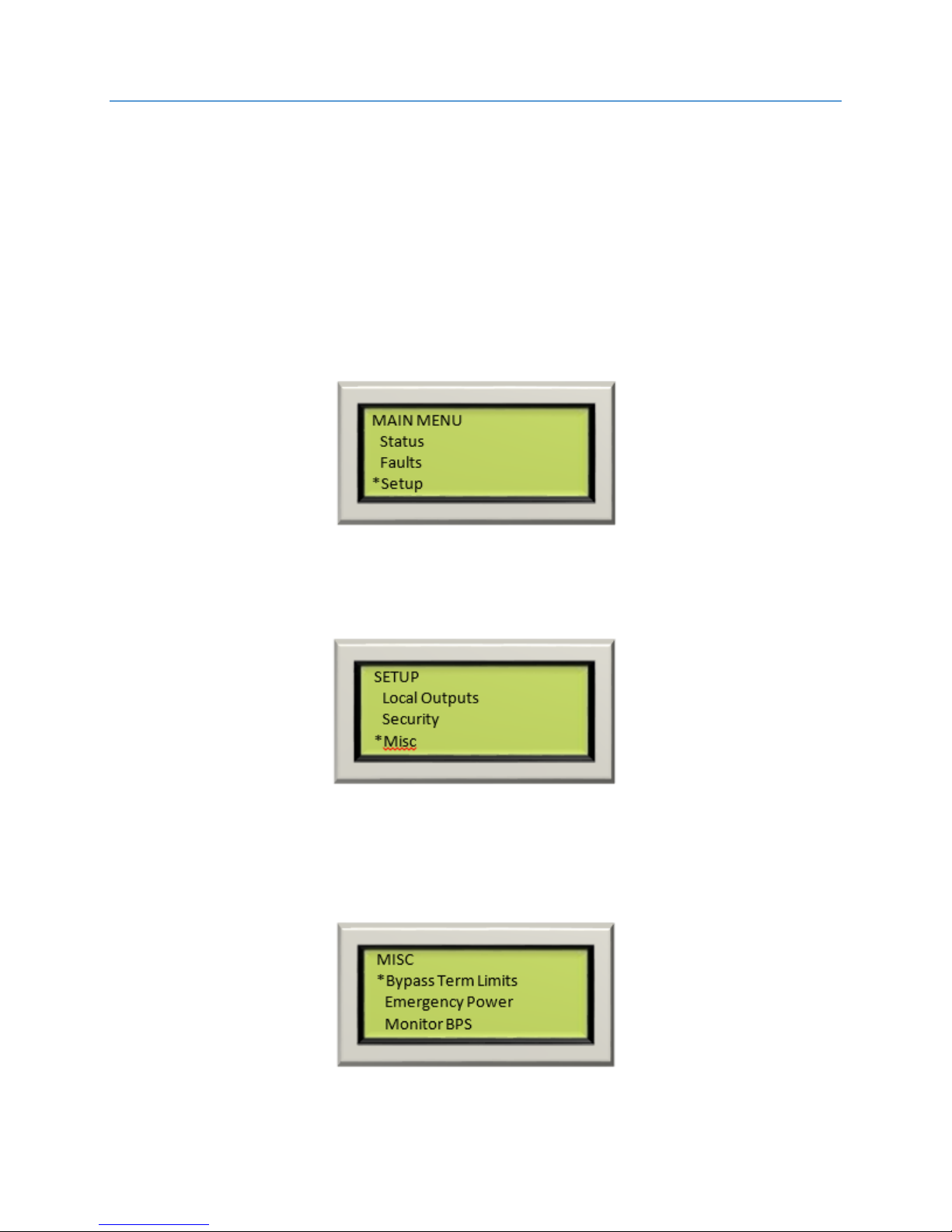

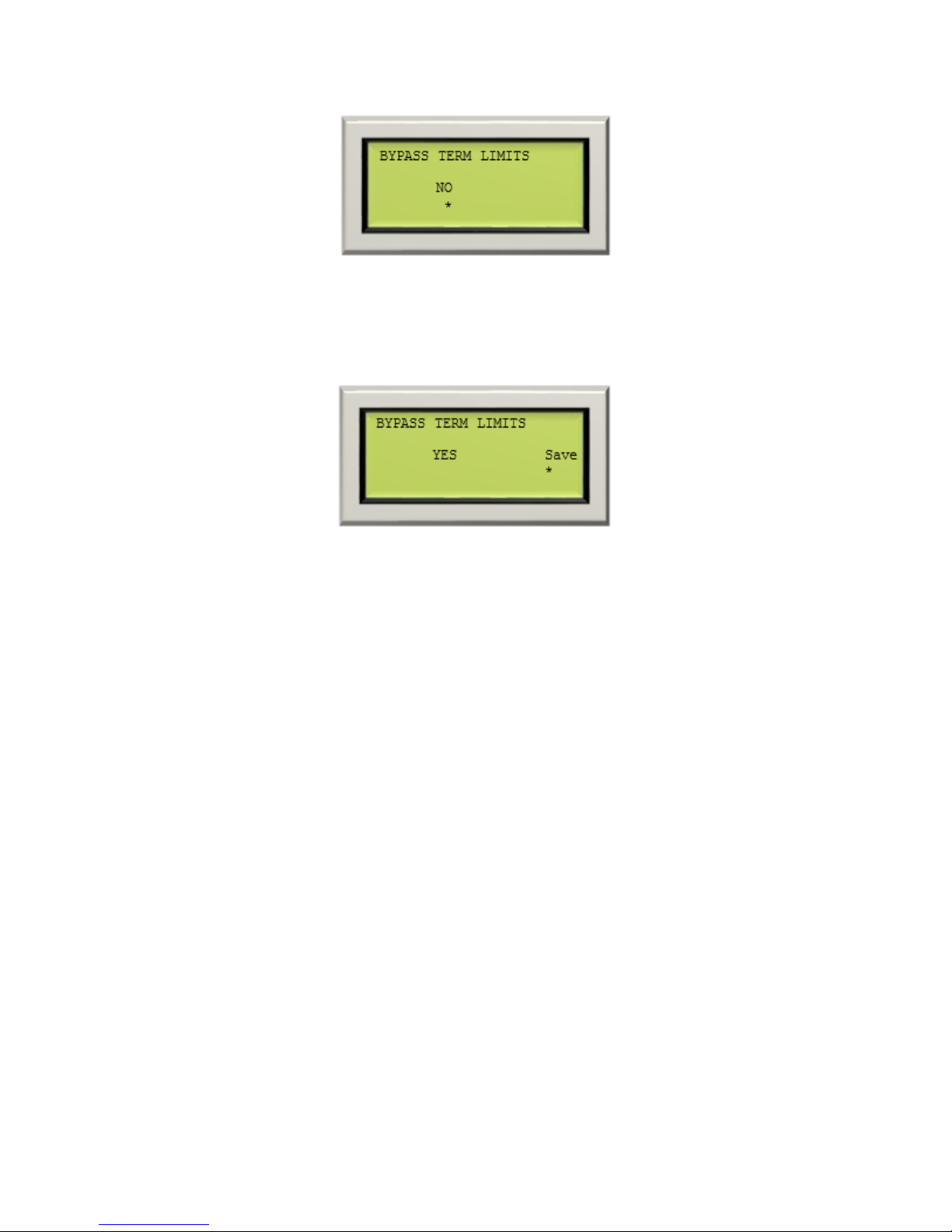

BYPASS TERM LIMITS

(Check off box when complete)

Toggle the Inspection/Normal switch to the “INSP” position.

Set BYPASS TERM LIMITS to YES:

On the Smartrise Machine Room controller board, press the Left

Arrow (ESC) button several times to get to the MAIN SCREEN.

Press the Right Arrow to go to MAIN MENU. Use the Up / Down

Arrow keys and move the asterisk to SETUP and press the enter

key.

o

Use the Up / Down Arrow keys and move the asterisk to MISC

and press the enter key.

BYPASS TERM LIMITS should be the first item listed. If it’s not, use

the Up / Down Arrow keys and move the asterisk to BYPASS

TERM LIMITS and press the enter key.

19

Use the Up / Down Arrow keys to change the word “NO” to “YES”.

Use the RIGHT Arrow key and move the asterisk under the

word “SAVE” and press enter.

Hit the LEFT Arrow (ESC) button several times to get to the MAIN

SCREEN.

Verify the LCD displays “Construction” Mode on the MAIN SCREEN.

Verify that the drive is not showing a fault on its display.

20

HYDRO INSTALLATION

QUICK START MANUAL

Smartrise now sends a quick start manual inside the

controller cabinet. These manuals allow the technician

to get the controller running in Construction Mode. If

the manual for the controller is missing it can be

downloaded at:

http://www.smartrise.us/support/

21

MAIN POWER SETUP

Green in Window

OFF

Red in Window

ON

Up = OFF

White showing

Down = ON

showing

Main Disconnect

Verify that main disconnect is turned off prior to installing wiring on

controller

Push Button Breakers

Verify that all green push button breakers are in the up position (OFF).

Do this for all 120vac, 240vac and 24vdc breakers.

Controller Main L1/L2 Breaker

Verify that the L1/L2 breaker is in the OFF position (green shows in

windows)

NO White

22

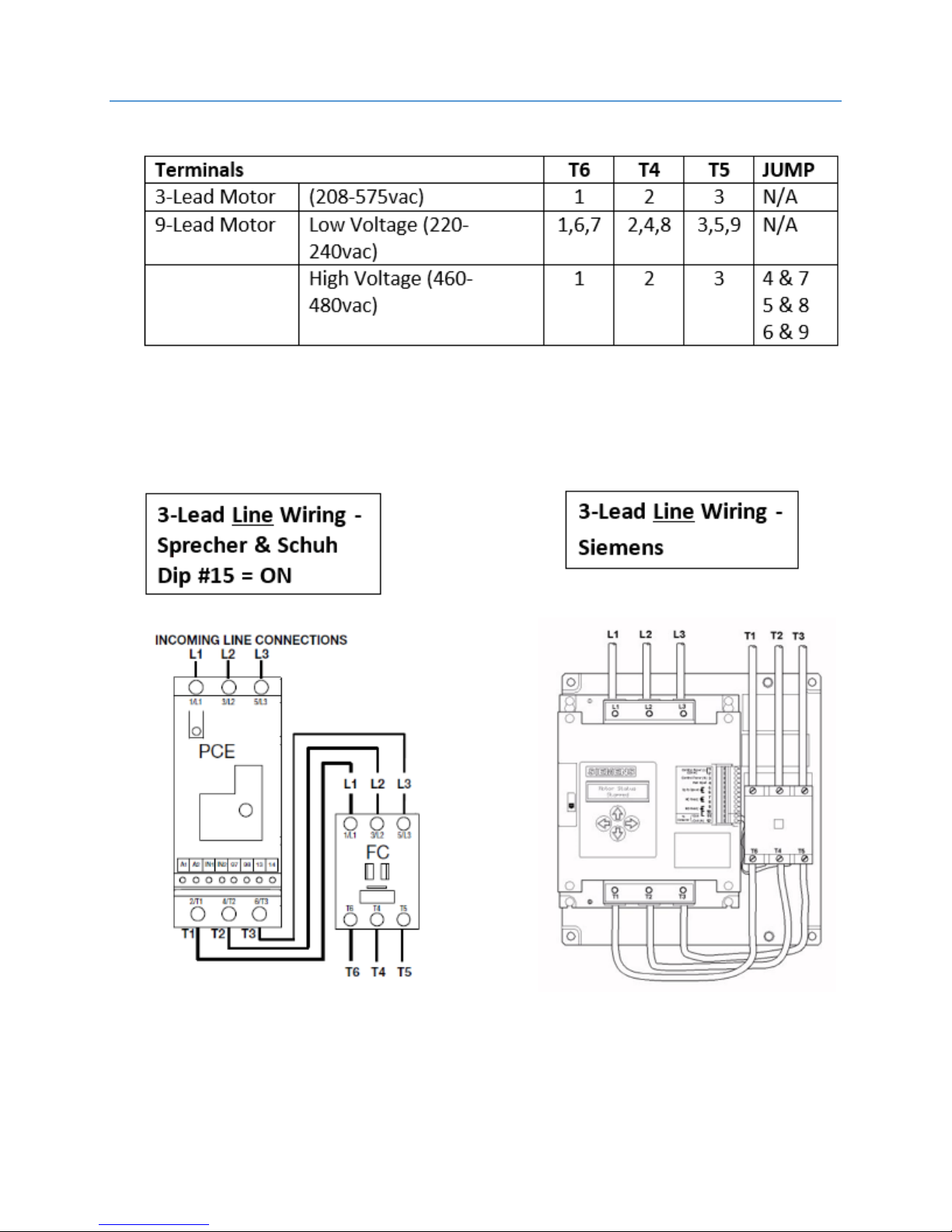

MOTOR WIRING – 3/9 LEAD MOTOR WIRING

Connect motor leads to the terminals T1/T2/T3 on the fault contactor.

23

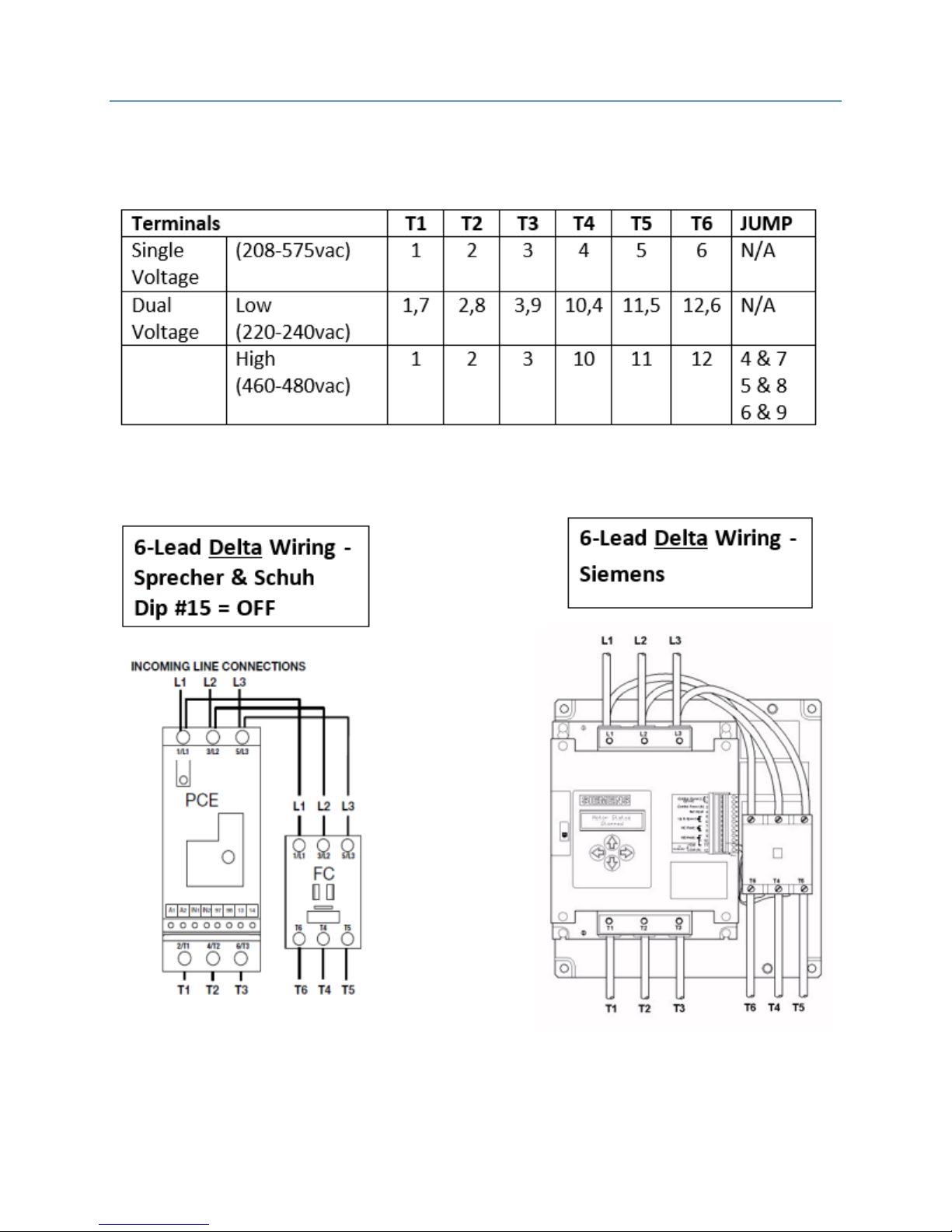

MOTOR WIRING – 6/12 LEAD MOTOR WIRING

Connect motor leads to terminals T1/T2/T3 on the softstart and

T6/T4/T5 on the fault contactor.

24

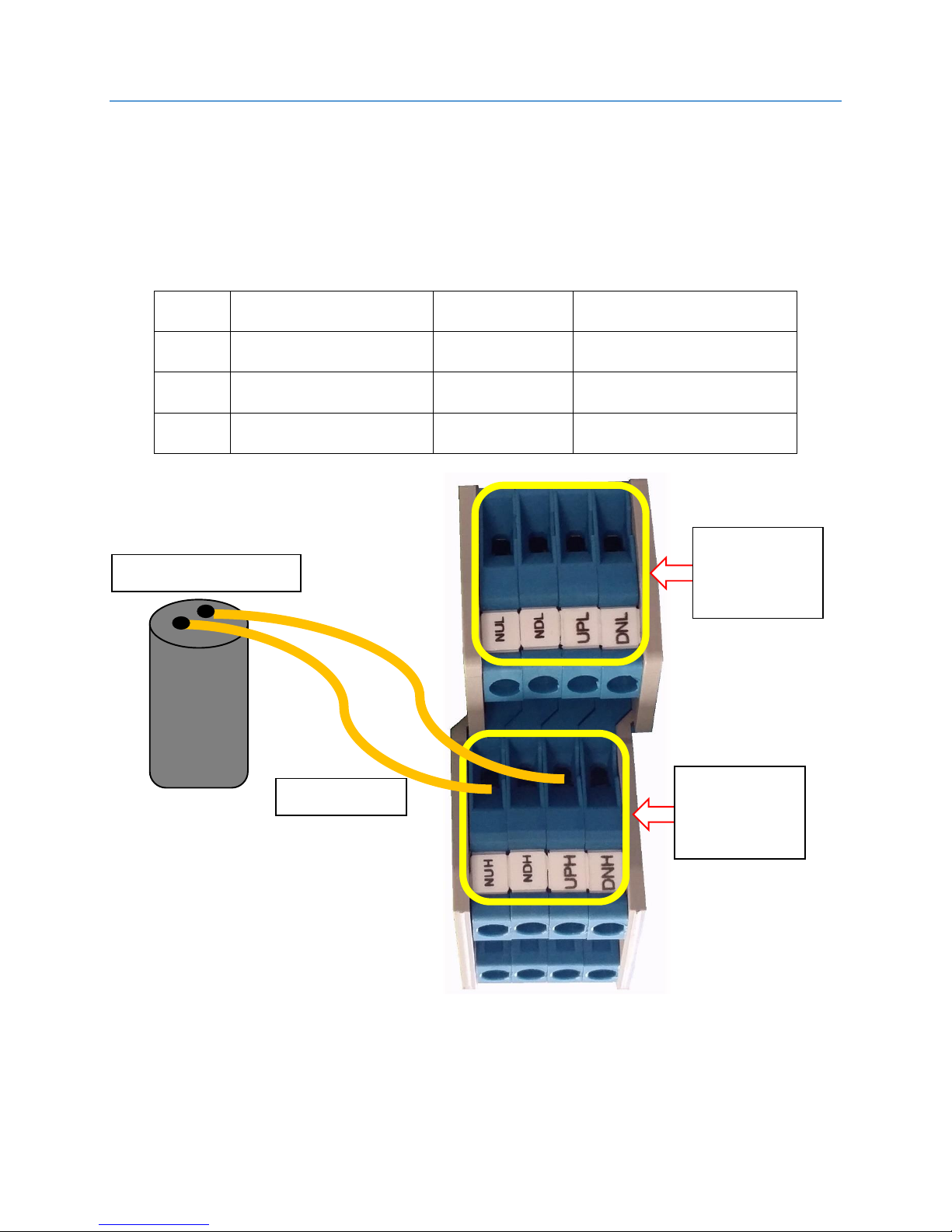

VALVE WIRING

UPH

Up High valve coil

NUH

Neutral Up High

UPL

Up Low valve coil

NUL

Neutral Up Low

DNH

Down High valve coil

NDH

Neutral Down High

DNL

Down Low valve coil

NDL

Neutral Down Low

Valve Leads

DNH / NDH

Valve Leads

DNL / NDL

Valve Leads

UP High Valve Coil

Wire the valve solenoids to the Machine Room DIN Rail terminals.

One lead of each valve solenoid goes to the “N” UP/DN (Neutral) DIN

Rail terminals and the other lead goes to the corresponding High/Low

UP/DN DIN rail terminals. See drawings for connection reference.

Refer to “Sheet 4 – Drive and Motor” for voltage requirements.

UPL / NUL

UPH / NUH

25

SOFT START SETUP – SPRECHER + SCHUH

SETUP

Verify the motor line or delta configuration and ensure that DIP switch 15 on

the Soft Starter reflects this configuration.

If the Soft Start faults out upon initial up run command, check for a red-

blinking LED on the Soft Start and count the number of times it illuminates

sequentially before a brief pause.

o The most likely cause is a line rotation issue which can be resolved by

switching T1 & T2 motor leads or change DIP switch 9 on the soft starter

to its alternate position (refer to “Sprecher + Schuh PCE Soft Start Dip

Switch Settings”).

o After changing the position of this switch, press the Reset Button adjacent

to the DIP switch group.

A noisy pump motor usually indicates a motor wiring issue. Check the pump

motor wiring and make sure it’s connected per the manufacturers

specifications.

If problems persist, refer to the Sprecher + Schuh manual for all faults

associated with the light.

26

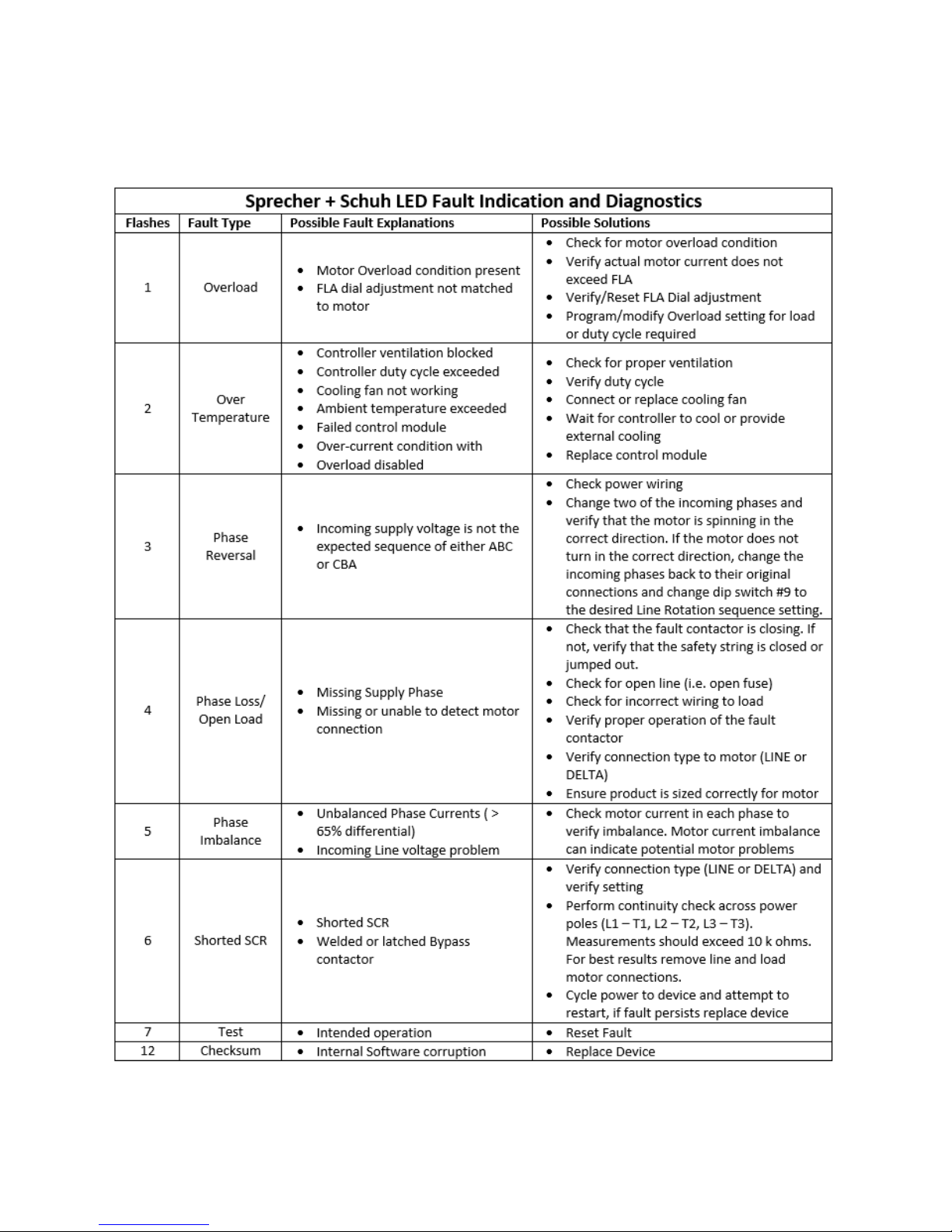

Troubleshooting

If the Smartrise controller indicates a “Drive Fault” and the softstart has the fault

LED flashing, refer to the following table for troubleshooting:

27

1) If the pump is too noisy or the motor is running in the wrong direction, it can

usually be fixed by swapping any two main lines.

2) If the car doesn’t move verify that the valve relays are turning on when a

direction is given (i.e. UPL and SM for Up direction, DNL for Down direction).

If they are then check the wiring and voltages to the valves.

3) At this point the car should be able to run using Construction Mode. Use this

mode to adjust your valves, install the traveler, tape, and the permanent

safety string.

4) Adjust your valves as required to get proper starts, stops, and run speeds.

There are two parameters that affect the pump motor during starts and

stops.

a. MAIN MENU | SETUP | TIMERS | UP TO SPEED DELAY

i. This parameter allows the pump motor to run for a specified amount

of time at the start of a run before opening the UP valves.

b. MAIN MENU | SETUP | TIMERS | PUMP OFF DELAY

i. This parameter allows the pump motor to continue running for a

specified amount of time at the end of a run after closing the UP

valves.

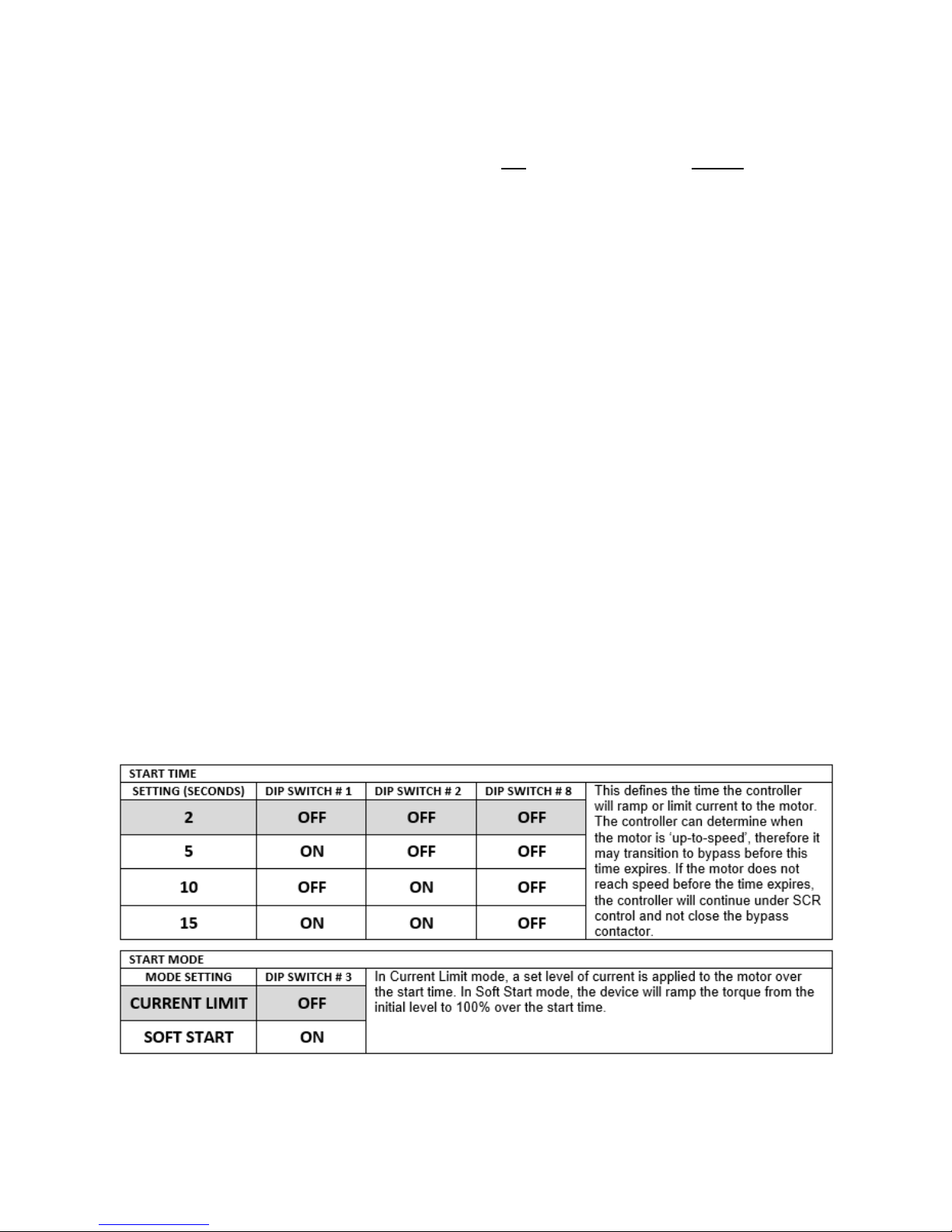

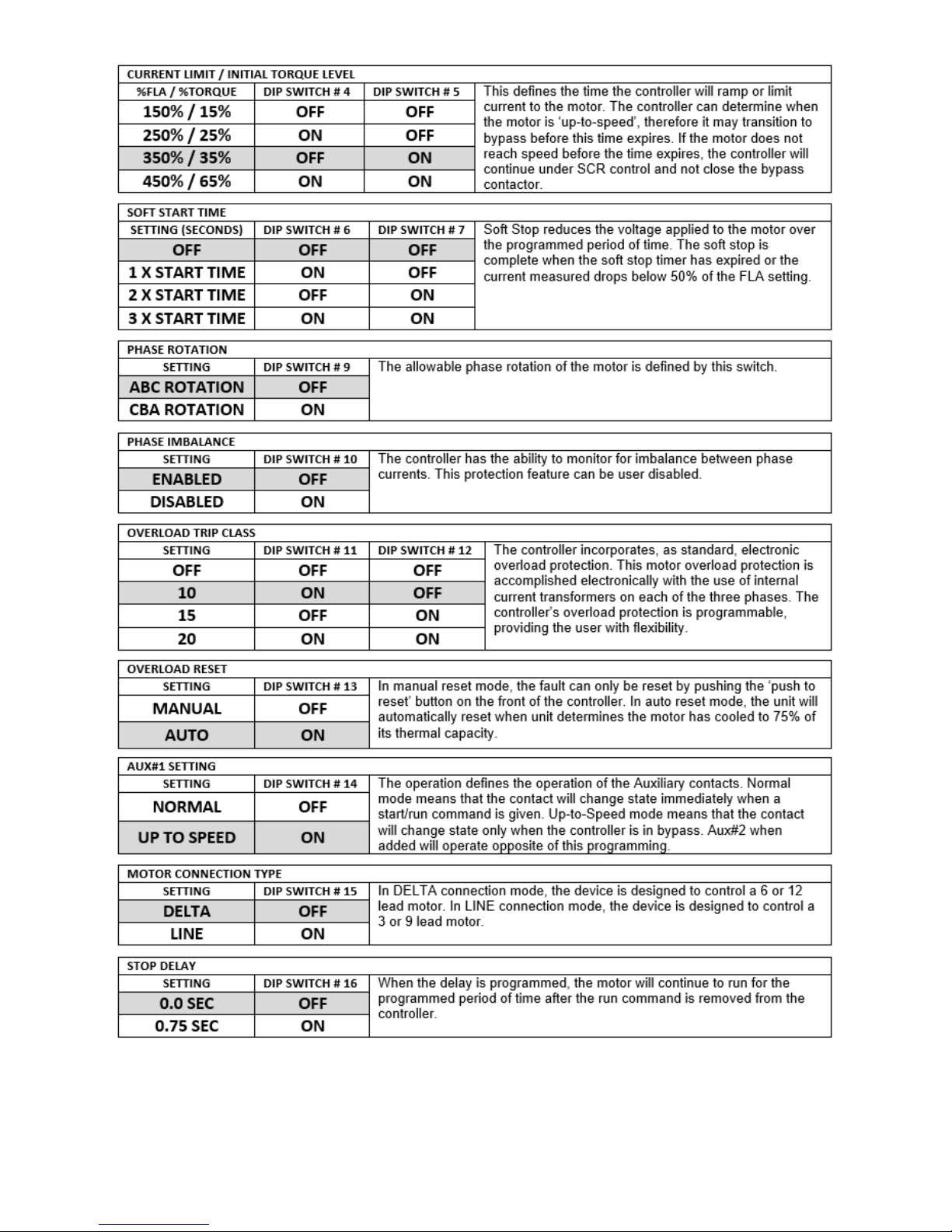

Sprecher + Schuh PCE Soft Start Dip Switch Settings

The PCE elevator controller is programmed through dipswitches located on

the front of the controller. Default settings are indicated by the shaded

areas.

28

29

Loading...

Loading...