A.C. MODULAR

GENERATOR SYSTEM

OWNERS MANUAL

MODEL#: ER-6.2, ER-8, ER-10 and ER-110

For Compartment or Top Mounting

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 1 of 52

Table of Contents

Section Page

Disclaimer .......................................................................................................................... 5

Description of Product ...................................................................................................... 6

System Specifications ...................................................................................................... 9

Pre-Installation Guide ..................................................................................................... 11

Installation Guide ............................................................................................................ 16

Hose Installation Guidelines .......................................................................................... 18

Operation ......................................................................................................................... 26

Special Operating Instructions ...................................................................................... 32

Maintenance Instructions ............................................................................................... 33

Troubleshooting Guide ................................................................................................... 36

SPS Model Matrix ............................................................................................................ 43

Component Part Number Lists ...................................................................................... 44

ER-6.2, ER-8, ER-10 AND ER-110 Assembly drawing .................................................. 45

Pump Adjustment ............................................................................................................ 47

Manufacturers Limited Warranty ................................................................................... 51

Doc. 9991031 Rev. H

ECO #15696

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 2 of 52

WARNING:

Do not install or operate the A.C. modular generator system without reading this entire

manual.

The A.C. modular generator system will generate enough voltage to produce a fatal

electrical shock. Do not perform any wiring installations or modifications while the system

is operating. Never touch any live connections while the system is operating. Never

operate the system with the generator wiring enclosure open. Install and secure cover

before operating.

The installation of the Smart Power® A.C. modular generator system is to be done in

accordance with applicable sections in the National Fire Protection Association’s

document NFPA 1901, National Electrical Code

®

, and/or other applicable, recognized

electrical codes and by a certified electrician.

Never directly expose the generator to any liquids, especially water, oil, or solvents.

Electrical shock, fire and/or damage to the generator can occur and will void the system’s

warranty.

Smart Power hydraulic generators, as well as all generators, must be sufficiently protected

from the environment to prevent damage to the stator. Smart Power stators go through a

very important double-dip coating process prior to generator assembly, however, exposure

to direct water sprays can cause the stator to electrically short. Generator damage and

electrical shock can occur.

Caution should be taken during truck pressure washing, since water damage to the

generator can occur if directly sprayed with high water pressure. Though Smart Power

generators are enclosed as much as possible, direct spray through the cooler, fan or open

lid can still cause such damage.

Excessive road spray/salt can also cause an electrical short of the stator in the generator

and can also shorten the generator’s operating life. To prevent this type of damage, do not

mount the system where it will be exposed to road spray.

Evidence of water damage, road spray/salt infiltration, and improper mounting will void the

generator warranty.

Avoid physical contact with any of the components of the A.C. modular generator system

during its operation or immediately after its use. The components of this system will get

hot enough to cause burns and could ignite combustible materials.

Do not mount or locate anything inside of the framework. System overheating could result

and void the system’s warranty.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 3 of 52

Never operate the system with leaks of any type. Clean up any hydraulic fluid that is

spilled or has leaked out of the system. Hydraulic fluid is combustible, and ignition may

occur.

With the exception of oil filter periodic replacement, never modify or remove any of the

components within the tray assembly.

Never modify or remove any of the components within the pump or the controls mounted

to the pump. This includes all fittings and tubing that are originally provided with the A.C.

modular generator system.

Never make any adjustments to the pump other than for flow control. If it appears the

pump needs to be adjusted, contact Smart Power® Systems at (231) 832-5525 before

proceeding. Damage to the generator from improper pump adjustment will void the

system’s warranty.

Never attempt any adjustments or repairs to the A.C. modular generator system (other

than pump flow control) while the vehicle engine is running and the PTO is engaged.

Never operate the system with the hydraulic fluid exceeding 175F. Above this

temperature, hydraulic fluid can rapidly oxidize and deteriorate causing generator

performance problems. Operating the system while the hydraulic fluid is above 175F will

void the system’s warranty.

Hydraulic fluid is combustible and toxic. In the event of human contact with hydraulic fluid,

generously flush body part (eyes, skin, etc.) with running water. Avoid inhalation of any oil

mist or vapor. Do not ingest hydraulic fluid. In case of fire, use foam, dry chemical or

carbon dioxide to extinguish flame.

Do not exceed the wattage rating of the generator. The generator may be permanently

damaged and the generator and hydraulic components may reach temperatures that could

cause severe burns upon human contact with the components. Operating the generator

system at wattages above the system’s rating will void the system’s warranty.

Disengage the system immediately if a hydraulic fluid leak is detected. Operation of the

A.C. modular generator system with low fluid level will result in permanent damage to the

hydraulic components in the system and will void the system’s warranty.

Do not attempt to operate the generator with the tray assembly top lid open. Do not

tamper with the top lid interlock switch or the hydraulic fluid level sensor.

Never attempt to operate the system without hydraulic fluid. Always maintain a fluid level

between ½ to ¾ full in the sight gage. When installing the system, fill the pump case with

1 pint of hydraulic fluid (Dexron III) before engaging the system. Failing to do so will void

the system’s warranty.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 4 of 52

Operating the A.C. modular generator system in the presence of flammable vapors may

result in an explosion.

Use only hoses that meet or exceed the minimum requirements specified in this manual.

A ruptured hose can cause personal injury and/or damage to the generator system.

Do not operate the system under electrical load with air in the hydraulic fluid (the system

will make a growling sound). Do not allow anything to contact the hydraulic hoses that will

cause a kink, pinch or chaffing. The A.C. modular hydraulic system generates hydraulic

pressures approaching 3600 psi. A ruptured hose may result from abrasion, discharging

hot, high-pressure hydraulic fluid, which can cause serious personal injury, fire, and/or

damage to the system.

Never remove the guards on the generator to expose the rotating fan or motor coupling.

Personal injury will result if fingers, hair or loose clothing come in contact with rotating

components.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 5 of 52

Disclaimer

Although SPS has taken all reasonable care to ensure that the information contained in

this installation manual (including without limitation, references, databases, resources,

specifications, illustrations and instructions) was accurate in all material respects at the

time of publication, SPS PROVIDES NO ASSURANCE, REPRESENTATION,

WARRANTY OR GUARANTEE, expressed or implied (including third party liability), with

regard to this manual, including without limiting the generality of the foregoing, with regard

to its accuracy, reliability or completeness. The entire information contained in this

installation manual is provided by SPS “AS IS” and without warranty of any kind, express

or implied, including (but not limited to) any implied warranties or merchantability, fitness

for any particular purpose, or non-infringement. Accordingly, by using the SPS unit and

this information, you agree that, to the greatest extent permitted by law, SPS (including,

without limitation, its subsidiaries, affiliates, agents, officers, directors, employees and

insurers) is not and will not be liable for losses or damages resulting from this installation

manual, its use, any information contained therein or the installation of the SPS unit.

This installation manual contains references to certain database and resources. As SPS

has no control over these database and resources, you acknowledge and agree that SPS

is not responsible or liable for any content, advertising, products, information or other

materials on or available from such database or resources. You further acknowledge and

agree that SPS shall not be responsible or liable, directly or indirectly, for any damage or

loss caused or alleged to be caused by or in connection with use of or reliance on any

such content, information goods or services available on or through any such database or

resources. All product illustrations and specifications are based upon current information

at the time of publication. Although descriptions are believed correct, complete accuracy

cannot be guaranteed. SPS reserves the right to make changes of any kind at any time,

without notice or obligation, in the information contained on this installation manual. All

data and information of any kind are subject to change without notice and SPS assumes

no obligation to update or correct information in this manual.

As some states do not allow the exclusion or limitation of liability for consequential or

incidental damages, the limitation contained herein may not apply to you. In such states,

SPS’ liability is limited to the greatest extent liability limitation is permitted by applicable

law.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 6 of 52

Description of Product

Hydraulic Generator Applications:

This heavy-duty electronically controlled generator system has been designed to meet the

most demanding mobile applications. It provides 120/240 volt AC @ 60 Hz from no-load to

full load, handling electrical loads of 6200, 8000 and 10000 watts, depending on model.

How our System works:

A generator driven by a hydraulic motor delivers the electrical power. The motor turns at

3600 RPM as controlled by the flow of hydraulic fluid through an electrically controlled

proportional valve. The proportional valve is directly driven by the system controller. The

piston pump delivers fluid to the proportional valve through installer-supplied PTO

mounted to the vehicle’s transmission.

Heat generated in the hydraulic fluid as it passes through the various components in the

system is cooled by a heat exchanger and fan. A filter removes impurities in the fluid. A

venturi boost assembly monitors the volume of oil in the hydraulic circuit and feeds the

system from the reservoir as needed.

Essentially, the only system maintenance required is periodic replacement of the hydraulic

fluid filter and adding hydraulic fluid to maintain the fluid level (when the hydraulic fluid is

between 70 and 80 F, it should be at the ¾ mark on the sight gauge).

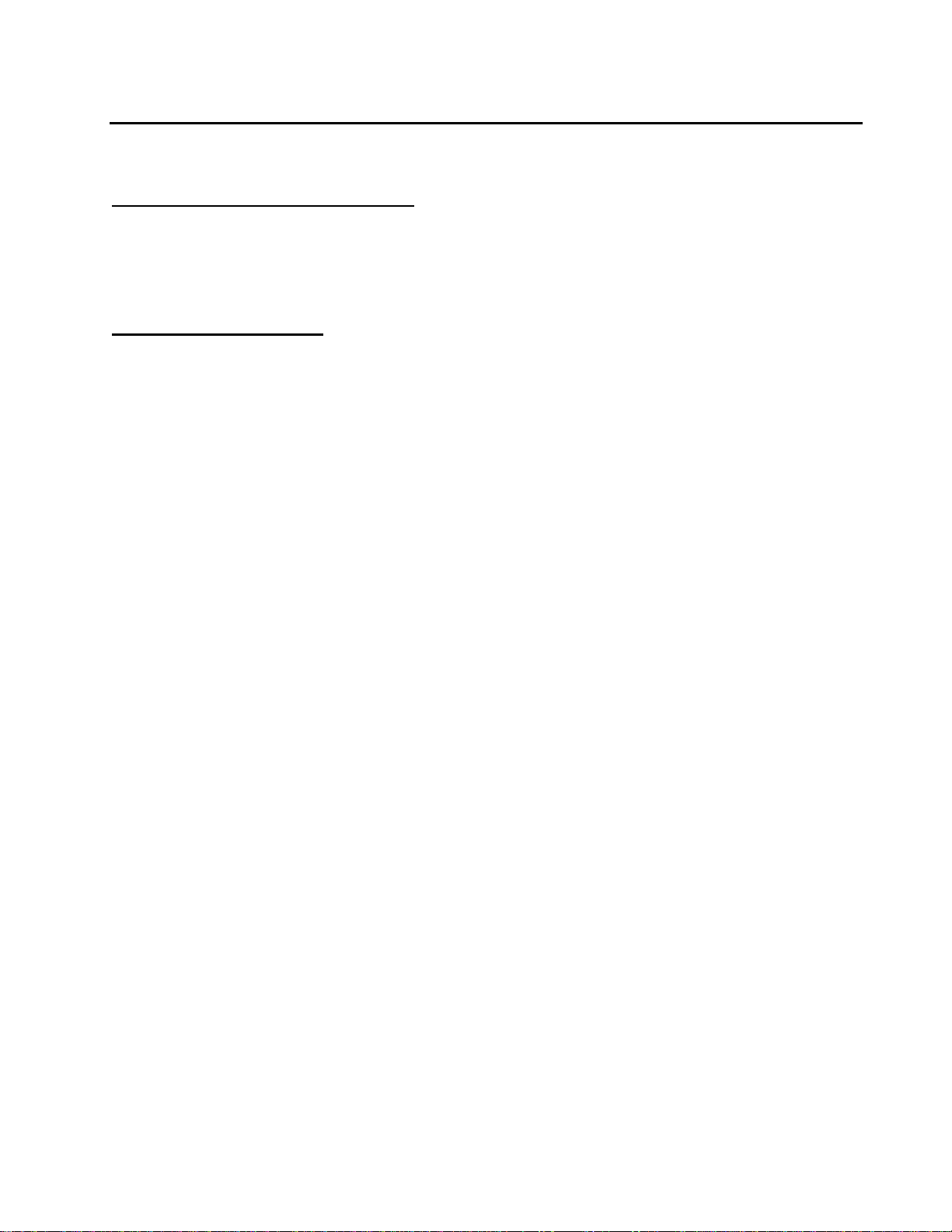

Generator hydraulic and electrical schematics: see Figure 1, and Figure 2.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 7 of 52

BOOST BLOCK

FILTER

CASE DRAIN

Hydraulic schematic for ER-6.2, ER-8, ER-10 and ER-110

COOLER

CHECK

VALVE

MOTOR

VENTURI BOOST

x

y

BP

REG

PROPORTIONAL

VALVE

IN

generator system

Figure 1

PUMP

RESERVOIR

CASE DRAIN

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 8 of 52

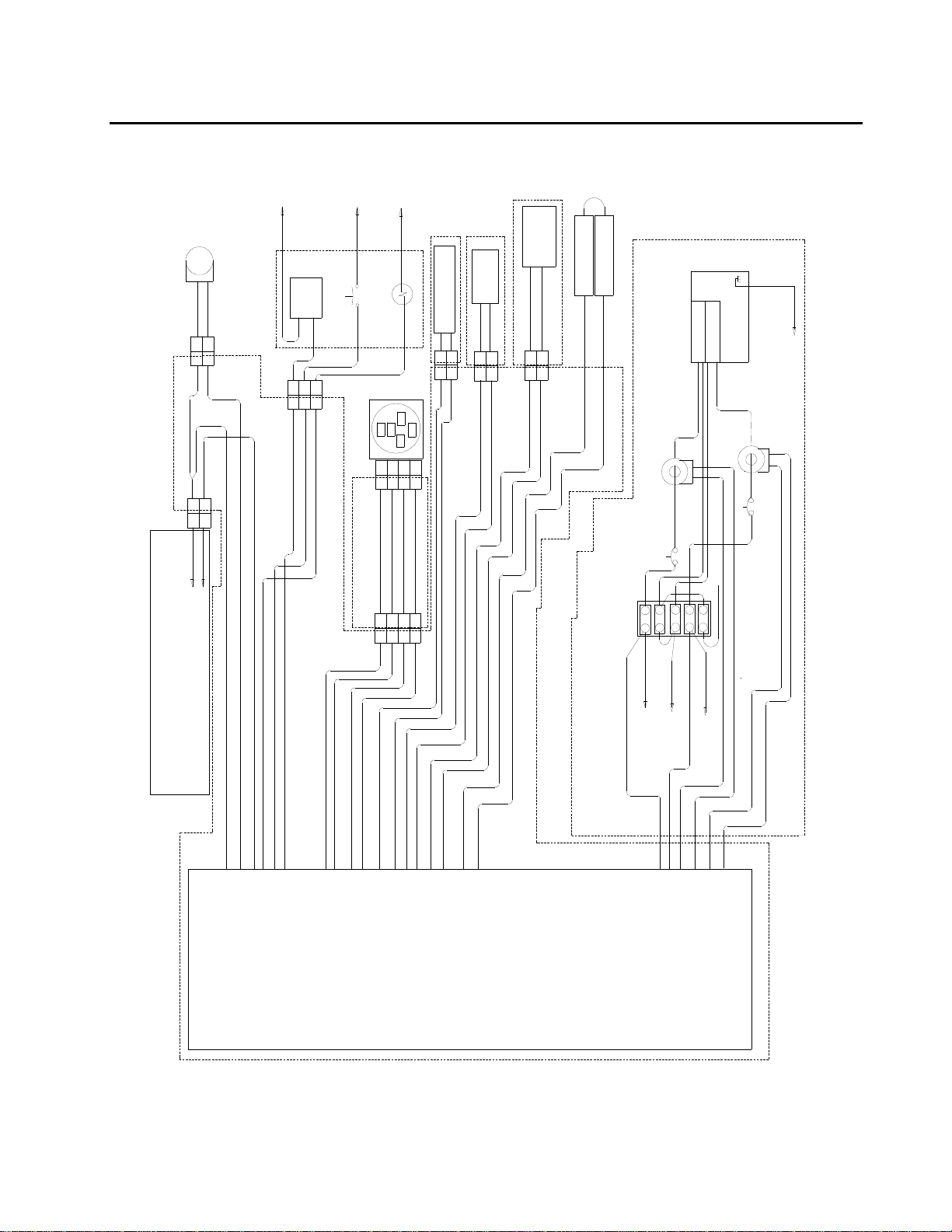

YELL

VEHICLE

CONN 5

+12V SUPPLY

BUZZER

3

2

11

3

2

GRY

ORG

BRN/WHT

Fan Motor

-

+

11

2

2

CONN 1

RING OR SPLICE

CONN 6

2

1

2

1

VEHICLE

VEHICLE

+12V SUPPLY

+12V SUPPLY

SENSOR

P/N 3310736

ASM, OIL TEMP.

NOT PROVIDED

A MOMENTARY SWITCH)

REMOTE ENB. SW (MUST BE

CENTER

P/N 1500047

1

COMMAND & CONTROL

1

2

P/N 3320106

INDICATOR BULB

ASM, OIL LEVEL SE N SOR

2

1

2

11

CONN 5

432

4

3

CONN 3

1

22

CONN 4

VALVE

P/N 8594452

PROP. CONTROL

22

11

P/N 8594019

P/N 3310775

LID SWITCH

PRESSURE SWITCH

GRN

WINDING B

GENERATOR

WINDING A

GENERATOR

OUTPUT

P/N 1500035

CURRENT TRANS.

P/N 1500035

CURRENT TRANS.

PURP

P/N 3722004

YELLOW

BLK/WHT

GRN/WHT

1

2

SPS DISPLAY WIRE HARNESS

4

3

2

211

4

VEHICLE GND

VEHICLE +12V SUPPLY

BLK

RED

ORG

WARNING:

12 VOLTS DC MUST BE DIRECTLY APPLIED TO THE GENERATOR SYSTEM

CONTROLLER WHENEVER THE HYDRAULIC PUMP IS ENGAGED.

FAILURE TO DO SO MAY CAUSE EXCESSIVE FLUID TEMPERATURE,

DAMAGING THE SYSTEM COMPONENTS AND WILL VOID THE WARRANTY.

PURP

YELLOW

BLK/WHT

3

YELL

BLK

CONN 2

GRN

BLK/YELL

YELLOW

GRN/WHT

SYSTEM CONTROLLER

PURP/YELL

PINK

BLU

3

BLK

WHT

GENERATOR

OUTPUT

GENERATOR

WHT/BLU

WHT/RED

CHASSIS

4

RED

GENERATOR

OUTPUT

OUTPUT

RED/WHT

PURP/WHT

ORG/WHT

BLU/WHT

P/N 8505028 (ER-6.2, ER-8, ER-10, ER-110)

Electrical schematic for ER-6.2, ER-8, ER-10

and ER-110 generator systems

MODEL OF

GENERATOR

Generator

Type

Speed

Frequency

Voltage

Amperage

Output

Power

Hydraulic

Motor

Maximum

Speed

Motor Shaft

Size

Port Size

Hydraulic

Pump

Operating

Speed

Standard Shaft

Optional Shaft

Mounting

Flange

Displacement

Continuous

Pressure (Max)

Peak Pressure

Standard

Rotation

Dry Weight

ER-6.2 ER-8 ER-10 ER-110

AC Inductive

3600 RPM

60 Hz

240 VAC or

120/240 VAC

52A @ 120 VAC or

26A @ 240 VAC

6.2 KW continuous

7.5 KW peak

Gear Type, 8cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Piston w/pressure

compensated control

880-3120 RPM

continuous duty

SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Figure 2

System Specifications

AC Inductive

3600 RPM

60 Hz

240 VAC or

120/240 VAC

66A @ 120 VAC or

33A @ 240 VAC

8 KW continuous

9 KW peak

Gear Type, 8cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Piston w/pressure

compensated control

880-3120 RPM

continuous duty

Spline, SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

AC Inductive

3600 RPM

60 Hz

240 VAC or

120/240 VAC

83A @ 120 VAC or

42A @ 240 VAC

10 KW continuous

12 KW peak

Gear Type, 11cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Piston w/pressure

compensated control

1100-3120 RPM

continuous duty

Spline, SAE B 7/8”-13

Tooth Spline

SAE 1” parallel with key

SAE B-2 bolt mount

45cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand

rotation (opposite

engine rotation

available upon request)

46 lbs

Page 9 of 52

AC Inductive

3600 RPM

60 Hz

240 VAC or

120/240 VAC

83A @ 120 VAC or

42A @ 240 VAC

10 KW continuous

12 KW peak

Gear Type, 11cc

4000 RPM

0.626 inches

9 tooth spline

7/8” – 14 SAE

7/8” – 14 SAE

Piston w/pressure

compensated control

850-3240 RPM

continuous duty

SAE B-B 1” 15

Tooth Spline

SAE 1¼” parallel with key

SAE B-2 bolt mount

60cc per revolution

3500 psi (250 bar)

4600 psi (315 bar)

Engine right-hand rotation

(opposite engine rotation

available upon request)

51 lbs

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Table 1

MODEL OF

GENERATOR

Oil Cooler

Dimensions (Core)

Fan

Voltage

Amperage

Filter 10 Micron 10 Micron

Hydraulic Oil

(recommended)

(alternate)

Maximum Viscosity

Op. Temp. range

(deg. F.)

Hoses

Motor Inlet

All Others

ER-6.2, ER-8 ER-10, ER-110

2.25”D x 12.5” W x 10.3” H

12 Inch Pusher

12 Volts DC

22 Amps

Dexron III

ISO Approved Hydraulic Fluid

4600 SUS (1000mm2/S)

60 SUS (10mm2/S)

-13° F to 195° F

JIC STD

3600 psi, SAE

1250 psi, SAE

Page 10 of 52

2.25”D x 22.6” W x 11” H

12 Inch Pusher

12 Volts DC

22 Amps

Dexron III

ISO Approved Hydraulic Fluid

4600 SUS (1000mm2/S)

60 SUS (10mm2/S)

-13° F to 195° F

JIC STD

3600 psi, SAE

1250 psi, SAE

Fittings SAE SAE

Dry Weight

(without pump)

Dimension of Tray Asm.

Ambient Operating

Temperature Range

ER-6.2 165 lbs

ER-8 185 lbs

33 ¾” L x 15 ¾” W x 13 ¾” H

(Including Reservoir)

0F to 120F 0F to 120F

ER-10 220 lbs

ER-110 220 lbs

33 ¾” L x 15 ¾” W x 13 ¾” H

(Including Reservoir)

Table 1 (cont.)

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 11 of 52

Pre-Installation Guide

Pre-Installation Check List

1. Verify that the Power Take Off (PTO) and the pump rotations match.

To identify the pump rotation, check the pump part number found on the metal tag

attached to side of the pump. A right hand rotating pump (the standard pump

offered by Smart Power® Systems), will have the letter “R” in its part number.

Example: A10VO (45 or 60) DFR-1/52 R PUC.

A left hand rotating pump will have the letter “L” in its part number.

Example: A10VO (45 or 60) DRF-1/52 L PUC.

Depending on genset model, a 45cc or 60cc pump is supplied. To determine the

PTO rotation, check the PTO manufacturer’s specification or observe the PTO when

it is engaged with the vehicle’s engine running.

A right hand rotating pump requires a PTO that turns counter-clockwise when looking

at the free end of the PTO shaft. A left hand rotating pump requires a PTO that turns

clockwise when looking at the free end of the PTO shaft.

WARNING:

Operating the pump with reverse rotation will damage the pump and void the

system’s warranty.

2. Verify that the PTO ratio is properly sized to provide adequate speed to the

hydraulic pump during normal operation of the generator system. The PTO speed

must be between in the range specified in Table 1 for your model generator.

Example: For an ER-8 System that is to operate at 600 RPM:

PTO Ratio = 850 RPM ÷ 600 RPM = 1.42 or 142%

WARNING:

Never exceed the maximum pump shaft speed. Pump failure or premature pump

wear will result. Doing so will void the system’s warranty.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 12 of 52

3. Verify the combined weight of the pump and hoses filled with hydraulic fluid do not

exceed the PTO manufacturer’s weight restriction. If the pump weight does exceed

this restriction, the installer has two options: A) a bracket to support the pump can

be implemented, or B) the pump can be mounted to the vehicle chassis, connected

to the PTO with a drive shaft.

4. Verify that the pump shaft will mount to the PTO. Pumps supplied by Smart Power®

Systems have an SAE B 2 bolt flange. The standard pumps supplied by Smart

Power® Systems have either a SAE B 7/8” 13 tooth spline for Models ER-6.2, ER-8

and ER-10; OR a SAE B-B 1” 15 tooth spline on the ER-110 model.

Upon special order, a 1” keyed shaft is available on Models ER-6.2, ER-8 and ER-

10. A 1 ¼” keyed shaft is available on the ER-110 Model. Check the PTO

manufacturer’s specification to verify that the pump supplied with the system will

mount to the PTO installed on the vehicle.

Note: In some cases it may be necessary to mount the pump remote from the PTO

and drive it with a drive shaft. Contact the PTO manufacturer for information on the

proper mounting configuration under these conditions.

WARNING:

The installer must provide guarding to prevent damage to the pump seals from road

debris if the pump is remotely located. Also, properly sized and installed vibration

isolators must be used if the pump is mounted to the chassis. Failure to do either

will void the system’s warranty.

Never use an unbalanced drive shaft to drive a remotely located pump. An

unbalanced drive shaft will cause premature wear of the pump and will void the

system’s warranty.

Do not approach a running A.C. modular generator when wearing long, loose items

such as hair, jewelry, ties, clothing, etc. Direct contact with a rotating drive shaft

can cause serious personal injury and/or damage to the system.

5. Obtain the following hoses of the necessary length for the installation:

a) Pump inlet hose: 1” SAE 100R1AT-16 hose (use Parker hose ends P/N 10643-

16-16). Note: Maximum hose length is 20’.

b) Pump outlet hose: 1/2” SAE 100R9AT-8 rated to 4000 PSI (use Parker hose

ends, part number 10643-8-8). Note: Maximum hose length is 20’.

c) Pump case drain hose: 5/8” SAE 100R1AT-10 (use Parker hose ends, part

number 10643-10-10). Note: Maximum hose length is 20’.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 13 of 52

WARNING:

Do not install hose ends until proper hose length has been determined.

Never install a hose in a location where it will rub against another surface or

abrasion member.

Do not position hoses with tight bend radii. Consult the hose manufacturer’s

installation guidelines. Tight bends may kink and cause serious damage to the

system and will void the system’s warranty.

Use caution when tightening the hose ends to prevent the hose from becoming

twisted.

Never install a 90° fitting at the pump inlet or outlet. Avoid the use of flow

restricting fittings.

Do not form loops in the hose that may collect air or kink. Run hoses as straight as

possible (but not taut) between connections.

Do not exceed hose lengths of 20 feet.

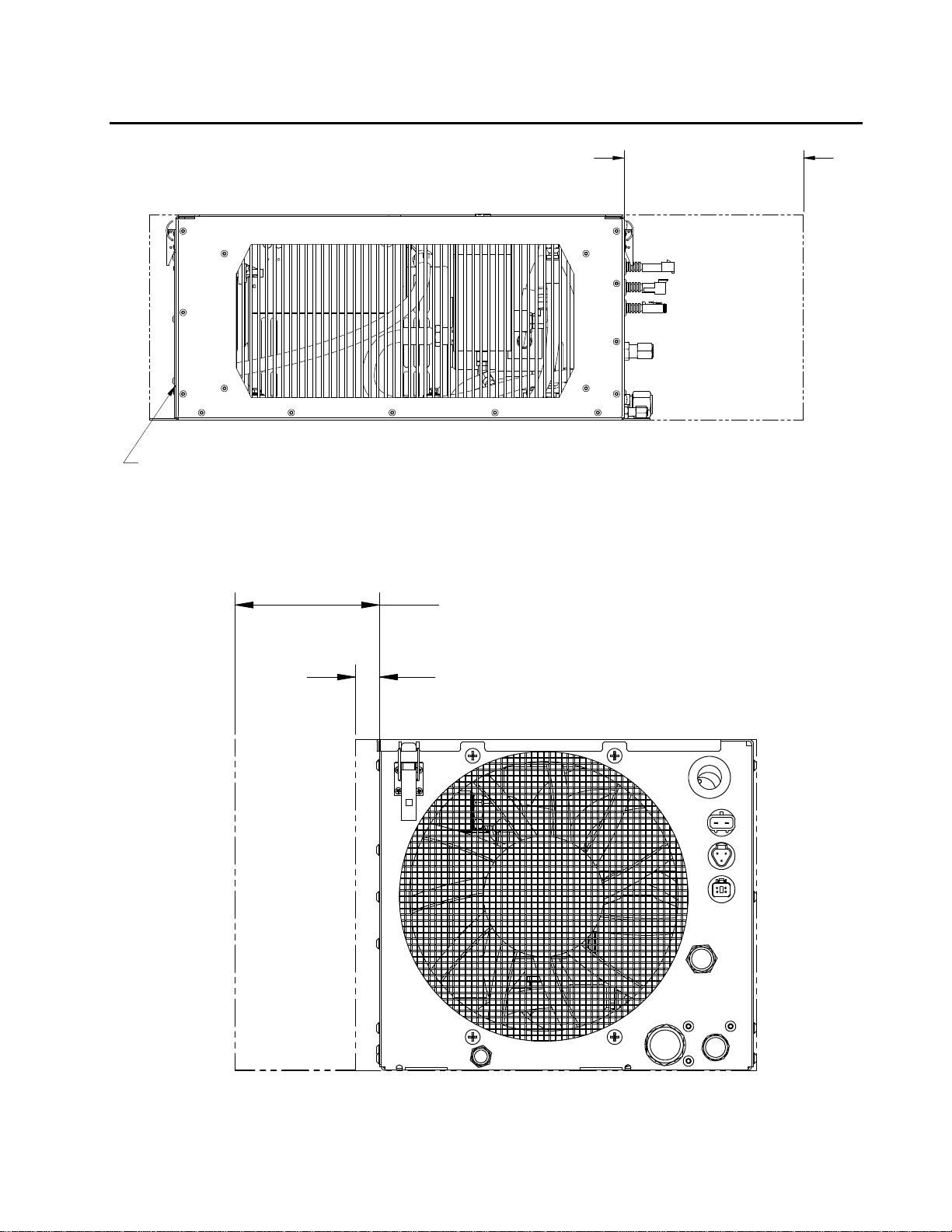

6. SPS models ER-6.2, ER-8, ER-10 and ER- 110 can be mounted on top of a vehicle,

in the open, without requiring any additional coverings. Reference Error!

Reference source not found., Error! Reference source not found., Figure 3,

and Figure 4 for the minimum clearances around the perimeter of the generator’s

tray assemble. Also, do not position any obstructions directly in front of the

system’s oil cooler. If the system cannot be installed without maintaining the

minimum clearances as indicated, or if you have any questions relative to the

®

installation of these systems, contact Smart Power

Systems at (231) 832-5525.

OIL FILTE R

ACCESS PANEL

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 14 of 52

12" MINIMUM OBSTRUCTION

FREE CLEARANCE

Front view of ER-6.2, ER-8, ER-10 and ER-110 tray assemblies

showing minimum clearance for proper ventilation

Figure 3

6" MINIMUM OBSTRUCTION

FREE CLEARANCE

1" MAXIMUM SETBACK FROM

FRONT OF COMPARTMENT

Side view of ER-6.2, ER-8, ER-10 and ER-110 tray assemblies

showing minimum clearance for proper ventilation

Figure 4

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 15 of 52

WARNING:

Do not mount the hydraulic pump or tray assembly in any location that is not well

ventilated. External heat sources elevating the hydraulic fluid and/or the generator

temperature will result in premature wear and degraded system performance and

void the system’s warranty.

7. The tray assembly must be mounted in a position that is higher than the pump. If

the pump inlet hose is 10’ in length or less, the tray and reservoir assemblies must

be a minimum of 12” higher than the pump. If the pump inlet hose is longer than

10’, elevate the tray and reservoir assemblies an additional 12” for every additional

10’ of pump inlet hose length. See below for examples of minimum tray assembly

elevations above the pump:

Pump inlet hose length

Minimum tray and reservoir elevation

(above pump)

0 – 10 ft. 12 inches

15 ft. 18 inches

20 ft. 24 inches

8. Locate a p osition to mount the SPS Com mand & Control Cente r. The ideal location

for the Command & Control Center will be in an area that is easily seen and

accessed by the generator operator. When the generator system is in use, the

Command & Control Center will continuously show the status of the generator,

including faults (warnings) if they occur. The Command & Control Center can also

be used to engage and disengage the generator. The Command & Control Center

is water sealed, and operates on low voltages so pump house mounting is

permissible. A 15 ft. water sealed harness is provided to connect the Command &

Control Center to the system controller mounted within the generator tray assembly.

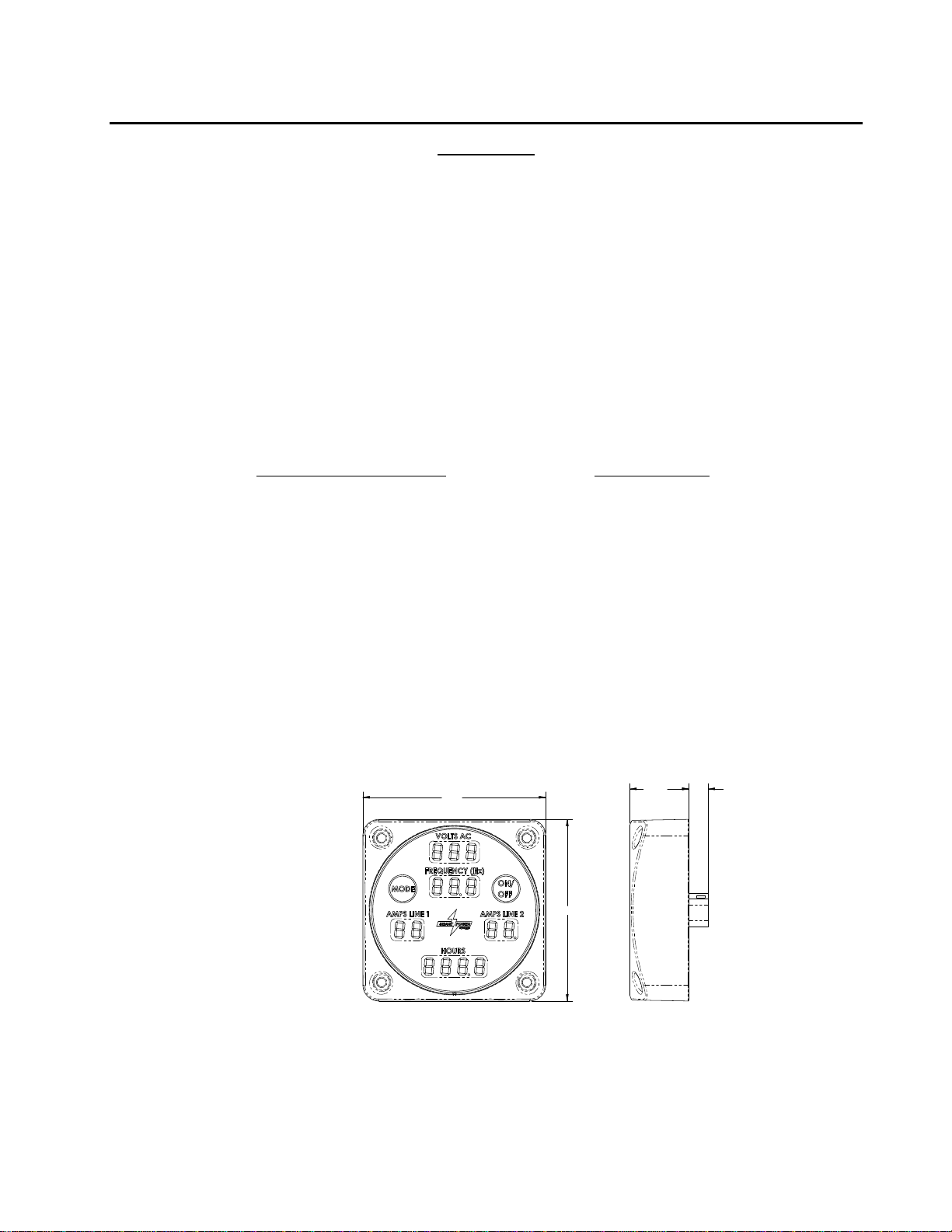

See Figure 5 for the dimensions of the Command & Control Center.

4.25

1.375 .45

4.25

Command & Control Center, P/N 1500047

Figure 5

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 16 of 52

Installation Guide

1. Mount the pump securely to the Power Take-Off (PTO). This may require attaching

a mounting bracket to the PTO housing prior to mounting the pump.

WARNING:

Always mount the hydraulic pump in a position with the pump controls up.

Mounting the pump in any other orientation will not allow hydraulic fluid in the

pump to reach the correct level before starting, causing premature wear of the

pump, thus voiding the system’s warranty. The pump and undercarriage

components will corrode if they are left unprotected. It is advisable to paint them

before completing the installation.

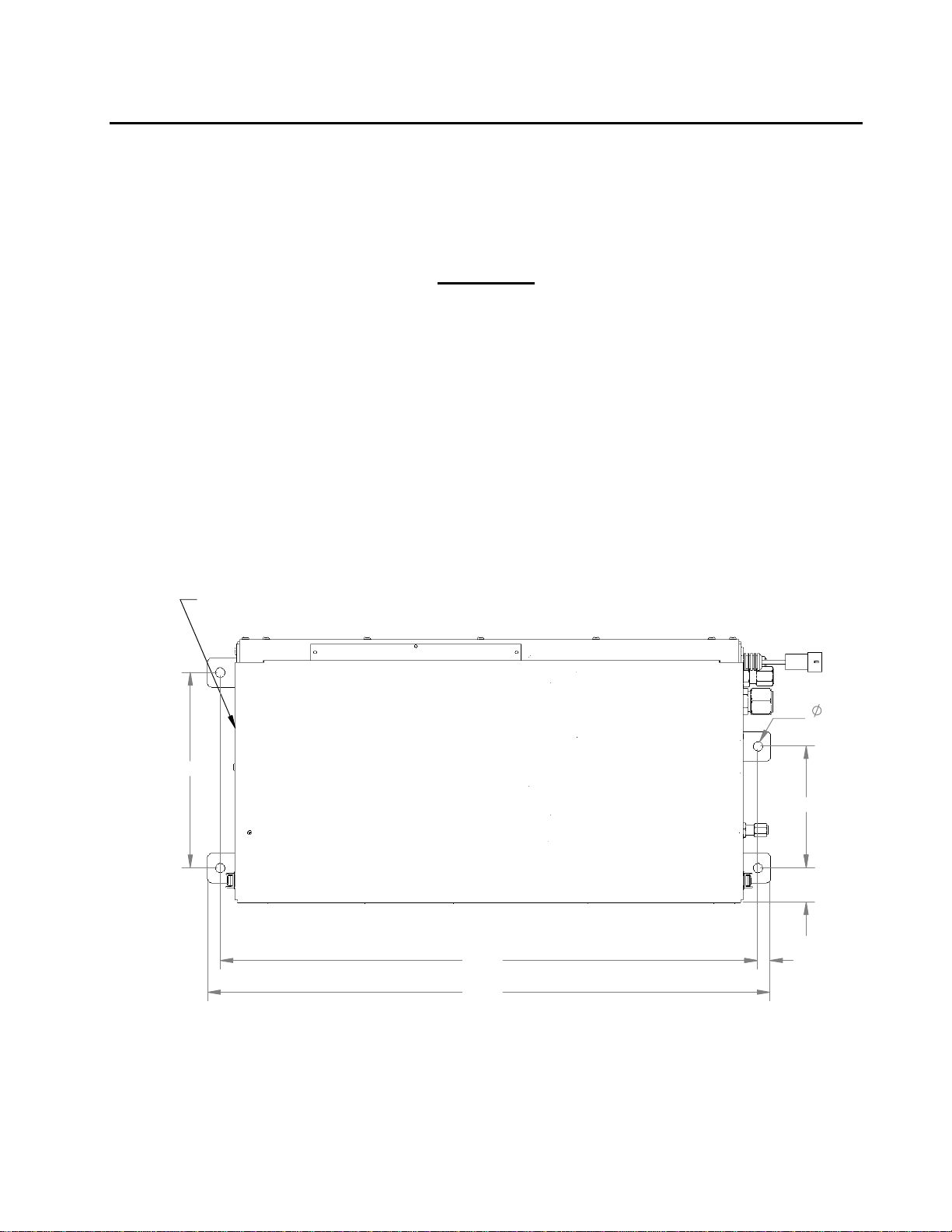

2. Locate and bore mounting holes for generator tray assembly as shown in Figure 6.

Maintain minimum clearances as indicated in Error! Reference source not found.,

Error! Reference source not found., Figure 3, and Figure 4.

OIL FILTER

ACCESS PANEL

11.64

7.25

2.06

32.00

33.50

.75

Hole pattern for mounting ER-6.2, ER-8, ER-10and ER-110 tray assemblies

Figure 6

.56

4 PL.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 17 of 52

3. Mount the tray assembly as high as possible within the structure of the vehicl e. The

ideal location for the generator is at the top of the truck in the dunnage area. The

manufacturer must also take sufficient precautions to ensure that the generator is

not mounted in the path of the deck gun/water cannon.

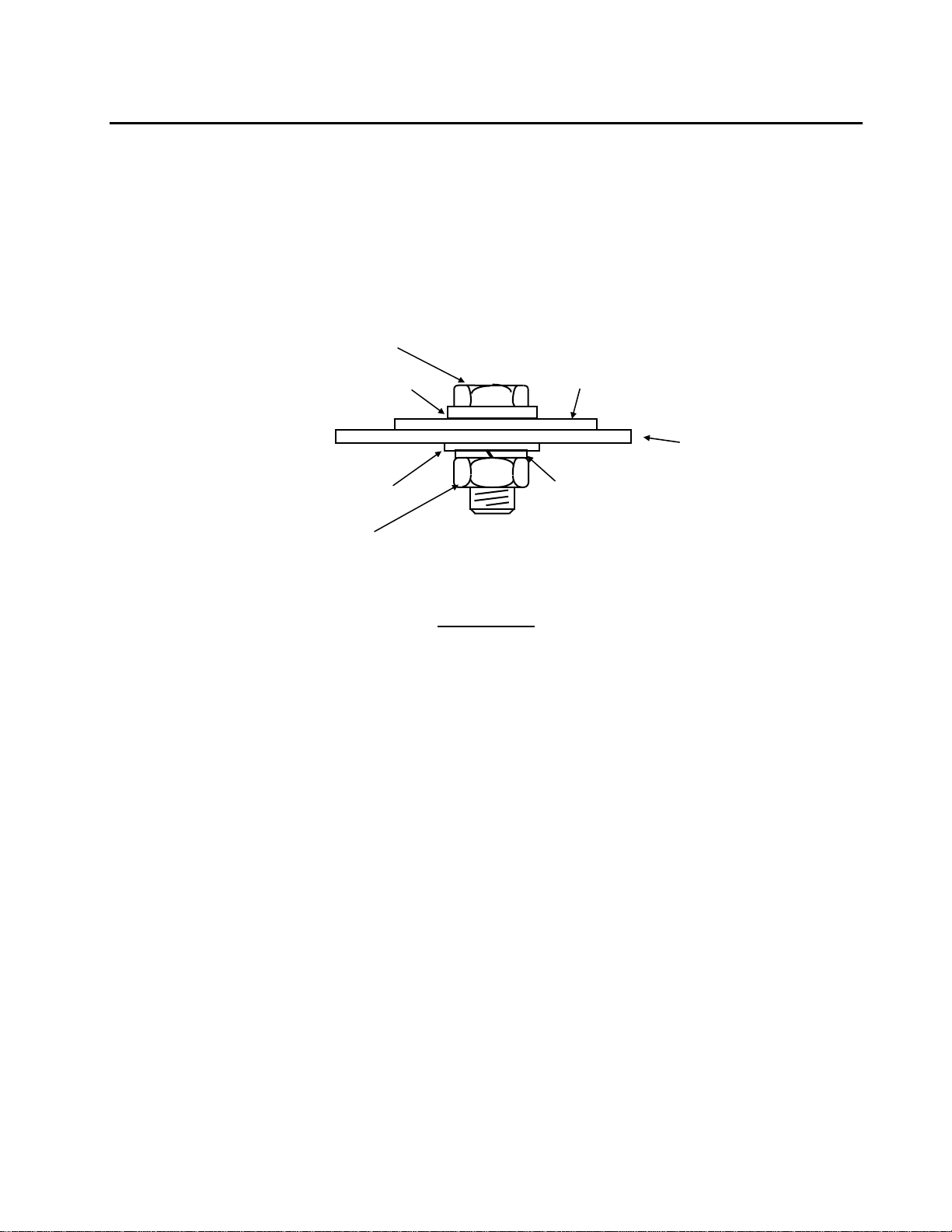

4. Mount the hydraulic generator tray securely to vehicle. Secure the generator to the

floor of the enclosure using mounting hardware (not included), as shown in Figure

7.

1/2-13UNC Screw

1/2” Flat Washer Generator Tray

Dunnage Area

Floor

1/2” Flat Washer 1/2” Lock Washer

1/2-13UNC Nut

Figure 7

WARNING:

Never mount the Generator on its side or upside down. Always mount the generator

upright with its base horizontal. Improper mounting will lead to poor performance

and damage to the system and will void the system’s warranty.

Never operate an AC modular generator system that is not secured in place;

damage will result.

Do not mount the hydraulic pump or tray assembly in any location that is not well

ventilated. External heat sources elevating the hydraulic fluid and/or the generator

temperature will result in premature wear and degraded system performance and

void the system’s warranty.

5. Mount Command & Control Center:

a. Create hole pattern as shown in Figure 8.

b. Mount Command & Control Center to vehicle using #10 stainless steel

fasteners.

c. Connect Command & Control Center to system controller unit using p/n

3722004 harness.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 18 of 52

3.375

1.688

1.688

3.375

.208

CLEARANCE HOLE

FOR #10 SCREW

4 PL.

2.000

Hole pattern for Command & Control Center

Figure 8

6. Flush the hoses with fresh hydraulic fluid (Dexron III). Install hoses and tighten hose

ends, using the Hose Installation Guidelines. See Figure 27 and Figure 31 for

connection locations

WARNING:

Never operate the system with the pump case drain plugged. Damage to the pump

seals will result. To do so will void the system’s warranty.

Lubricate hose fitting o-rings with clean hydraulic fluid (Dexron III) before

installation to prevent damage to them.

Hose Installation Guidelines

Never install a hose without first flushing it with clean hydraulic fluid to remove any

debris.

Never install a hose in a location where it will rub against an abrasive surface or

sharp edge or corner.

Do not position hoses with tight bend radii. Tight bends may kink and cause

serious damage to the system. Consult the hose manufacturer’s guidelines when

installing hoses.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 19 of 52

Use caution when tightening the hose ends to prevent the hose from becoming

twisted.

Never install a 90° fitting at the pump outlet or inlet.

Never use an inlet line fitting less than 1”.

Never install a hose tightly between connections. Leave length for the hoses to

expand.

Do not form loops in the hose that may collect air or cause kinking. Run hose as

straight as possible (but not taut) between connections.

To keep debris out of hoses while being positioned, cover the ends.

Do not bundle installed hoses tightly together with banding. Hoses must have

freedom to expand.

Do not operate the system with external stresses applied to the hydraulic hoses.

The A.C. modular hydraulic system generates hydraulic pressure approaching 3500

psi. A ruptured hose may result, causing personal injury or damage to the system.

Do not put any substance into the reservoir other than clean, fresh Dexron III

hydraulic fluid. Doing so will void the system’s warranty.

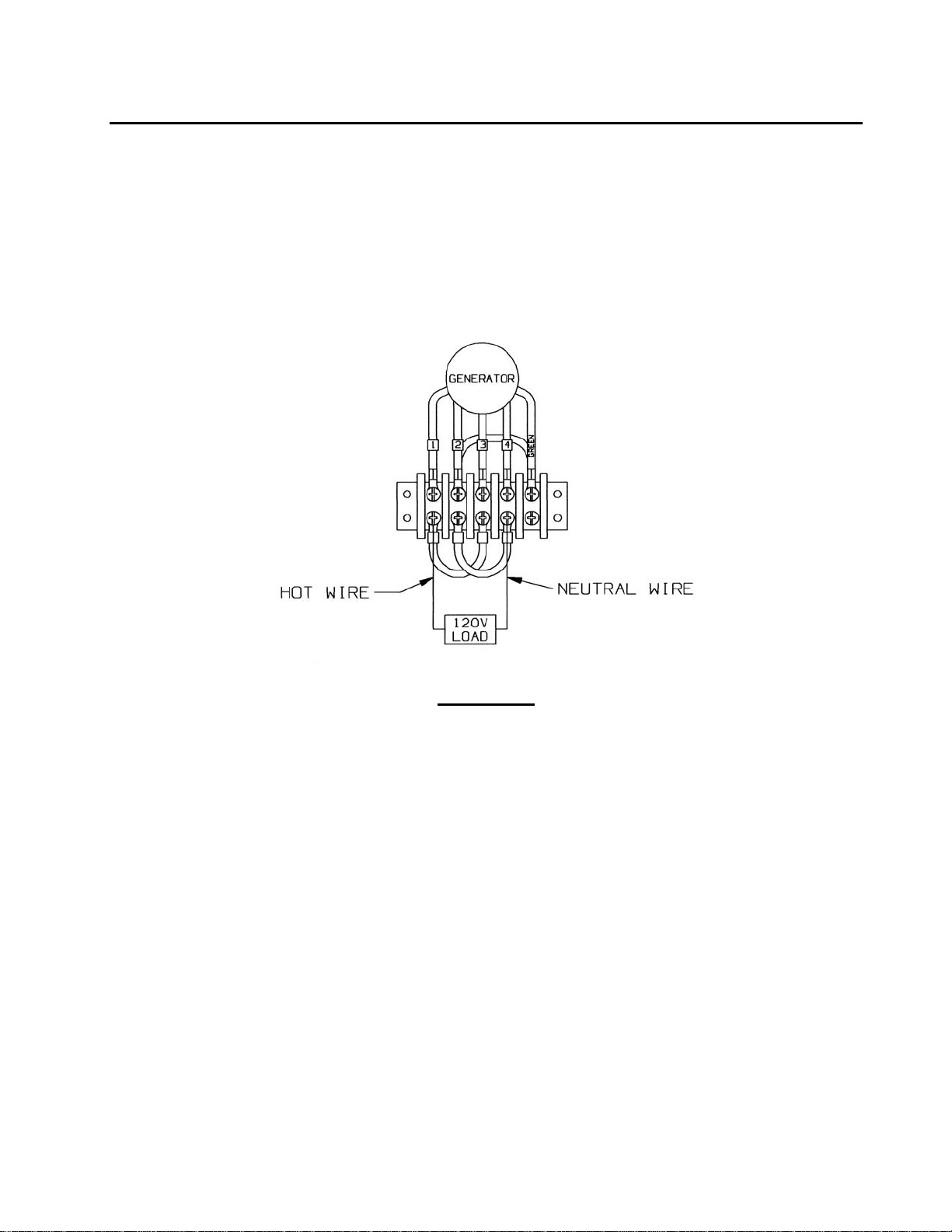

7. Connect the vehicle’s breaker panel to the generator output. The generator is prewired to supply 120/240 VAC, with the generator frame bonded to ground. Route

the generator output conduit/wiring to the breaker panel, and carefully cut the

conduit to length without cutting the wire insulation. A conduit connector has been

provided to connect the conduit to the breaker panel. Connect the (4) four

generator output wires to the breaker panel as follows (see Figure 2 for electrical

schematic and wiring diagram):

Phase A: Black wire (120 VAC)

Phase B: Red wire (120 VAC)

Neutral: White wire

Ground: Green wire

To completely utiliz e the generator’s output capabilities, the 120 VAC loads must be

equally divided between the generator’s two main windings. Before wiring the

vehicle, calculate the wattage of each 120 VAC load that will be connected to the

generator. Next, create two groups of loads based on total wattage (add the

individual wattage of each load together). Exchange loads between the two groups

until the total wattage of the two groups is as close as possible to being equal. Wire

the system with one group connected to Phase A (BLACK) and neutral, with the

other group connected to Phase B (RED) and neutral.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 20 of 52

ALTERNATE CONFIGURATION: 120 VAC only: If the application requires 120

VAC only, the generator terminal strip should be configured as depicted below. This

method ensures balanced loading of the generator, fully optimizing the system’s

capabilities. Make the following wire connections at the terminal strip:

a) place one jumper between wire 1 and wire 3.

b) place the second jumper between wire 2 and wire 4.

c) connect the phase wire from the breaker box to either wire 1 or wire 3.

d) connect the neutral wire from the breaker box to either wire 2 or wire 4.

e) connect the ground wire from the breaker box to the green wire.

WARNING:

To ensure proper voltage regulation, during the operation of generator system, the

load difference between Phase A and Phase B must never exceed 20%. Damage to

generator system caused by operating it with an unbalance load will void the

system’s warranty.

Wiring of the A.C. modular generator system and electrical distribution throughout

the vehicle must be done in accordance with applicable sections in the National Fire

®

Protection Association’s document NFPA 1901, the National Electrical Code

and/or

other applicable, recognized electrical code and by a certified electrician.

Smart Power® Systems’ A.C. modular generators are supplied with the neutral

bonded to ground. Refer to National Fire Protection Association’s document NFPA

1901, National Electrical Code, and/or other applicable recognized electrical codes

before wiring an SPS A.C. modular generator system.

Never wire any loads to the generator’s output without a circuit breaker in series

with the load. Damage to the generator, to the components within that circuit,

electrical shock, or fire may result if a short occurs in an unprotected circuit. Run

all 120 VAC and 240 VAC electrical connections between the generator and the

distribution panel in conduit. Bypassing the SPS factory installed breaker will void

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 21 of 52

the system’s warranty. Replacement breakers must be obtained from Smart Power®

Systems approved sources only.

Do not perform any wiring installations or modifications while the system is

operating. The A.C. modular generator system will generate enough voltage to

produce a fatal shock.

Never touch any live connections while the system is operating.

Never operate the system with the generator cover removed.

8. Connect 12 VDC (vehicle battery positive) to the generator’s system controller input

(reference Figure 2). Connect the RED wire from the system controller, marked

“Vehicle +12V supply” to the vehicle’s ignition circuit through a 30 amp fuse.

Connect the BLACK wire to the vehicle’s ground (vehicle battery negative).

WARNING:

12 volts DC must be directly applied to the generator system controller whenever

the hydraulic pump is engaged. Failure to do so may cause excessive fluid

temperature, damaging the system components and will void the warranty.

Never come near a running fan with loose items such as long hair, clothing, jewelry,

ties, items that can fall out of pockets, etc.

Do not attempt to operate the generator with the tray assembly top lid open.

Serious personal injury may result if clothing, fingers or other body parts come in

contact with rotating fan blades.

Never operate the system with fan disabled or removed. System over-heating will

result and this will void the system’s warranty.

Improper wiring of the generator system to the vehicle may discharge the vehicle

battery, cause a fire, or cause improper operation of the generator system.

9. Bleed air from the hydraulic system:

a. Turn off the generator’s main power breaker. See Figure 9.

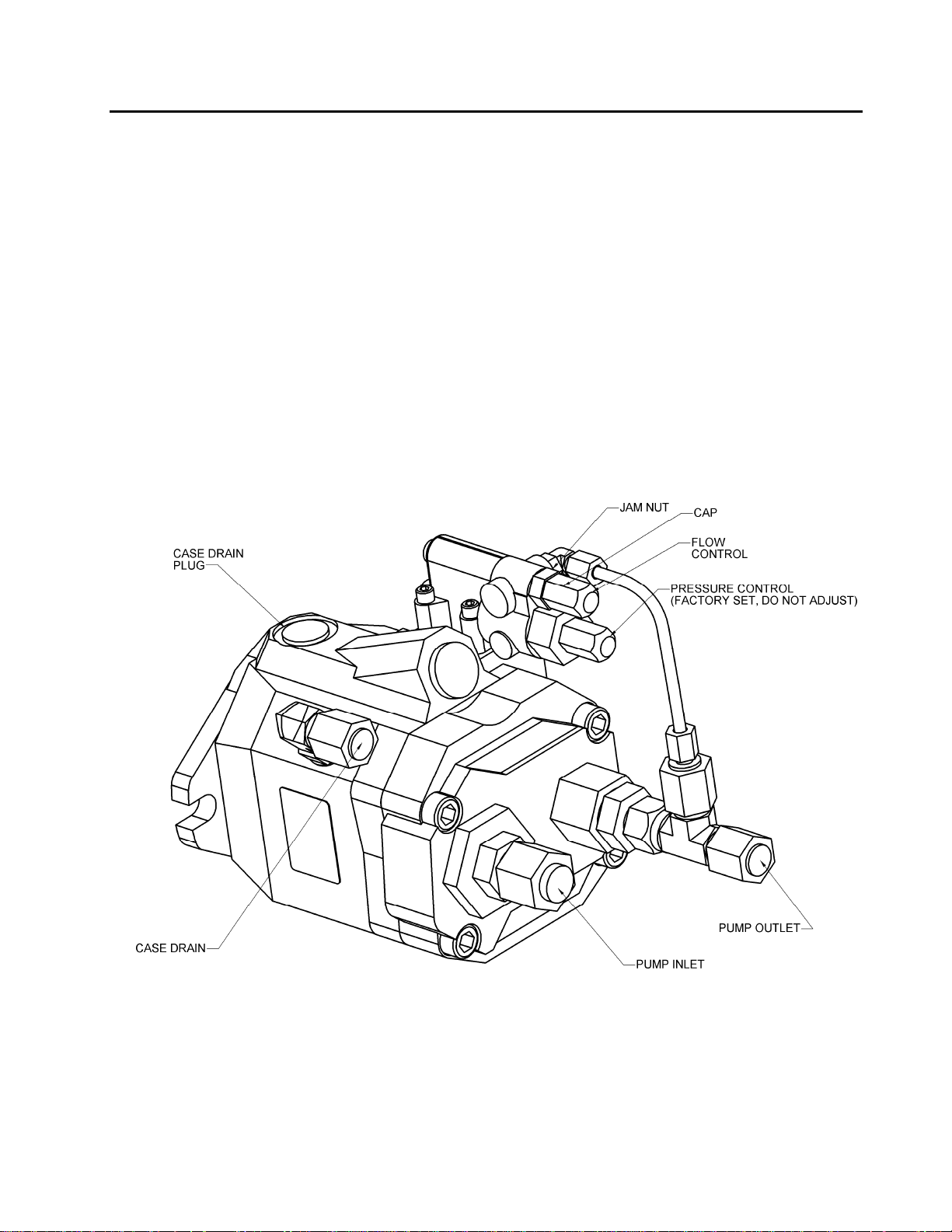

b. Open the case drain hole on the pump by removing the plug (see Figure 31).

c. Fill the Gen-set reservoir with fresh Dexron III hydraulic fluid until the sight

gauge is full. As hydraulic fluid begins to fill the hoses, maintain the level of fluid

in the reservoir until hydraulic fluid begins to flow from the case drain hole on the

pump. Replace the case drain hole plug.

d. Start the vehicle and allow the engine to idle.

e. Ensure the generator purge option is enabled.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 22 of 52

Note: The generator is shipped from the factory with the purge option enabled.

The system controller has been designed to provide a purge option. With this

option applied, the generator will turn at a reduced speed to minimize wear to

the system’s hydraulic components while purging air from the system. Once

enabled, the purge option will remain set until automatically reset by the system

controller. The system controller will reset the option once the following two

conditions are met:

1. The hydraulic system has been purged for a total of at least 30 minutes.

2. Of those 30 minutes, at least 20 occurred with the generator on.

Main power breaker

Figure 9

WARNING:

Never operate the system without the filler/breather plug installed. Contaminants

may enter the hydraulic fluid through the filler opening, causing premature wear on

the hydraulic components and void the system’s warranty.

Never apply a load to the generator while there is air trapped in the hydraulic fluid.

Damage to the system’s hydraulic components, as well as ruptured hoses, may

result and void the system’s warranty.

Always run the purge cycle after installation, after replacing the hydraulic fluid and

the filter, or after making any other repairs that may allow air into the hydraulic

system. Failure to do so will void the system’s warranty.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 23 of 52

Enabling System Purge Option

The purge option can also be set by performing the following steps:

Step 3: Hold Mode

until Amps Line 1

Blinks 88. Release

switch so

appears.

0Pt

Step 5: Press On/Off

y

until

appears.

Step 4: Press mode to

PvrG

make

appear.

Figure 10

1. If the Command & Control Center is dark, press the Mode switch to put the

display into Normal mode.

2. If the Display looks like Figure 11, The purge option is enabled.

3. Otherwise, press and hold the Mode switch until the Amps Line 1 field begins

blinking 88 (more than 10 seconds). Release the switch so 0Pt appears.

Reference Figure 10.

4. Press (and release) the Mode switch until PvrG appears.

5. Press the On/Off switch until a y appears, indicating Purge option is Active.

6. Return to system purge display by pressing the Mode switch repeatedly until the

screen shown in Figure 11 is displayed. Purge will still be active.

Indicates whether the

generator is 0n or

0ff

Example of display with purge option set

Figure 11

f. Engage the Power Take-Off (PTO). (Note: Pump may sound rough for a few

minutes due to entrapped air.) Make sure the Command & Control Center

displays the string “0FF” as shown in Figure 11, press the On/Off switch to turn

the generator off, if needed.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 24 of 52

g. Check for hydraulic fluid leaks, all hose connections must be tight. Monitor the

hydraulic fluid level, adding fluid as needed to keep the level in the sight

gauge full.

h. After 10 minutes, the system controller will automatically switch the generator to

“0N”. Check to see that the generator is turning (The frequency display should

indicate 0n). If it is not, press the On/Off switch on the Command & Control

Center to start the generator.

i. After the generator has been operated for 20 minutes with the generator on, the

system controller will automatically disable the purge option.

Verify that the generator’s output frequency is 59-62 Hz. If the frequency is not

within that range, contact Smart Power Systems at (231) 832-5525 for more

information.

10. Prior to applying full load, and after the oil temperature is above 120°F verify proper

operation of the cooler fan by feeling for airflow being pulled into the cooler and

pushed out by the fan. If the air is not being pulled through the cooler face contact

Smart Power® Systems at (231) 832-5525 for more information. Also verify that the

air passing through the cooler and the fan is not restricted.

WARNING:

The SPS Model ER-6.2, ER-8, ER-10 and ER-110 have been pre-set at the factory to

provide correct frequency and voltage. No pump adjustment is required. If it

appears the pump needs to be adjusted, contact Smart Power® Systems at (231)

832-5525 before proceeding. Damage to generator from improper pump adjustment

will void the system’s warranty.

Improper ventilation will result in system overheating, reduced performance and

possible damage to the system and/or cause personal injury. If the system is

installed such that improper ventilation exists, the system’s warranty will be voided.

11. Set “auto-start” option.

If the auto-start option is enabled, the generator will begin generating electricity

whenever the PTO is engaged. If the auto-start option is disabled, the generator

will not output electricity after PTO engagement until the “on/off” switch is pressed.

Select the auto-start function by performing the following steps:

Smart Power® Systems

pp

A. C. MODULAR GENERATOR SYSTEM

Page 25 of 52

Step b: Hold Mode until

Amps Line 1 Blinks 88.

Release sw itch so

AStr

and

appear.

0Pt

Step c: Press On/Off

until the des ir e d value

a

ears

Figure 12

Enabling Auto-Start Option

a. If the Command & Control Center is dark, press the Mode switch to put the

Command & Control Center into Normal mode.

b. Press and hold the Mode switch until the Amps Line 1 field begins blinking 88

(more than 10 seconds). Release the switch so 0Pt and AStr appear.

Reference Figure 12.

c. Press the On/Off switch until the desired value appears. A y means Auto-Start

is enabled, an n means Auto-Start is disabled.

d. Return to Normal mode by pressing Mode.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 26 of 52

Operation

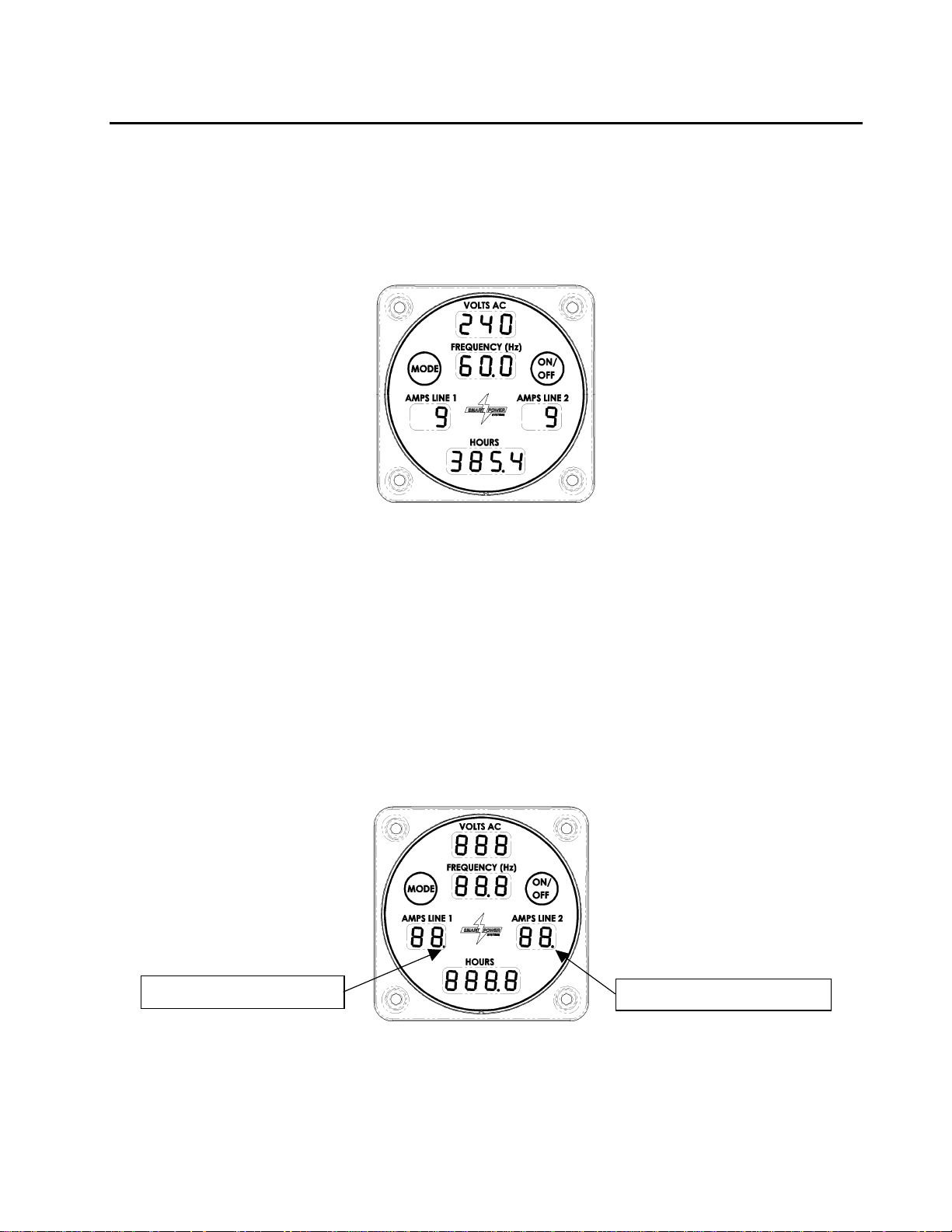

1. The Command & Control Center will show the generator’s output voltage,

frequency, current, and system run time whenever the Command & Control Center

is in the Normal mode. To access Normal mode, press the Mode switch repeatedly

until the correct information is displayed (reference Figure 13).

Example of Command & Control Center in normal mode

Figure 13

2. The PTO driving the SPS hydraulic pump must be engaged for the system to

generate electricity.

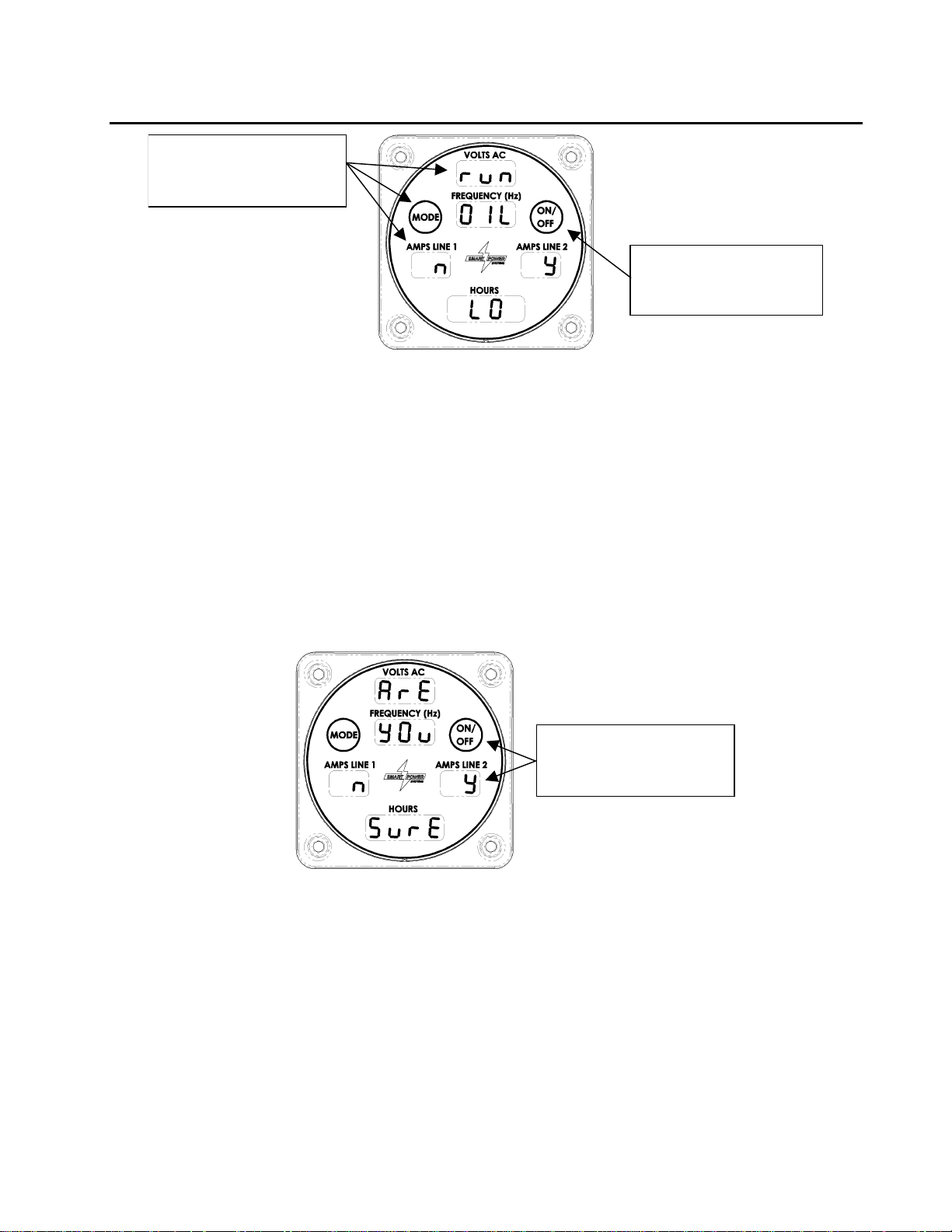

3. The Command & Control Center is equipped with two Smart Touch switches,

labeled “Mode” and “On/Off” respectively. These switches do not require pressure

to be activated, but instead sense the presence or absence of your fingertip. The

decimal points in the “Amps Line 1” and “Amps Line 2” fields of the Command &

Control Center are used to indicate the status of the Mode and On/Off switches

respectively (reference Figure 14).

Mode Switc h Status Li ght

On/Off Switch Status Light

Switch Status Lights

Figure 14

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 27 of 52

Normally, the status lights will be off. When a switch is pressed, the

corresponding light will be illuminated. When a status light is flashing,

the corresponding switch is calibrating, and the switch should not be

pressed. The system controller will ignore the switch while it is

calibrating.

4. If the system controller is powered on, but the generator is not running and no

buttons are pressed for 5 minutes, the system will enter Quiescent mode. In

Quiescent mode all displays are blank to conserve power. To return to Normal

mode from Quiescent mode, press the Mode switch.

5. Whenever the PTO is engaged and the system controller is in Normal or Quiescent

mode, the generator can be switched from an “off” state to an “on” state, and viseversa, by pressing the “on/off” switch on the Command & Control Center. If the

PTO is not engaged, the hydraulic pressure is too low, or the generator enclosure

cover is not closed when the “on/off” switch is pressed, the following two screens

will be displayed alternately (Reference Figure 15):

Example of low hydraulic pressure display

Figure 15

6. If the system controller has been set to “auto-start”, the generator will begin to

produce power whenever the PTO is engaged. See installation instructions for the

directions to select the “auto-start” options.

7. Additional Information provided by the Command & Control Center:

a. When the Command & Control Center is in Normal mode, pressing the Mode

switch once will display the oil temperature (reference Figure 16).

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 28 of 52

Displayed Oil

Temperature in degrees

Fahrenheit

Example of oil temperature display

Figure 16

b. When the Command & Control Center is in Normal mode, pressing the Mode

switch twice will cause the amount of time since the oil filter was last changed to

be displayed (reference Figure 17):

Time Since last Oil Filter

Change in Hours.

Example of oil filter run time display

Figure 17

c. When the Command & Control Center is in Normal mode, pressing the Mode

switch three times will cause the configuration of the generator system controller

to be displayed. The “En” indicates the controller is configured to run an

enclosed generator, and the number displayed corresponds to the maximum

power output of the generator in kilowatts (reference Figure 18).

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 29 of 52

The Er indicates the system

controller is configured to

operate an ER-series

Generator

The system controller is

configured to operate a generator

whose maximum output is this

number (in kW).

Example of configuration display

Figure 18

d. If there are no active faults, pressing the Mode switc h once more will return the

Command & Control Center to its normal mode. If there are active faults, they

will be displayed in succession, one each time you press the Mode switch.

See Diagnostics in the trouble shooting section for more information on faults.

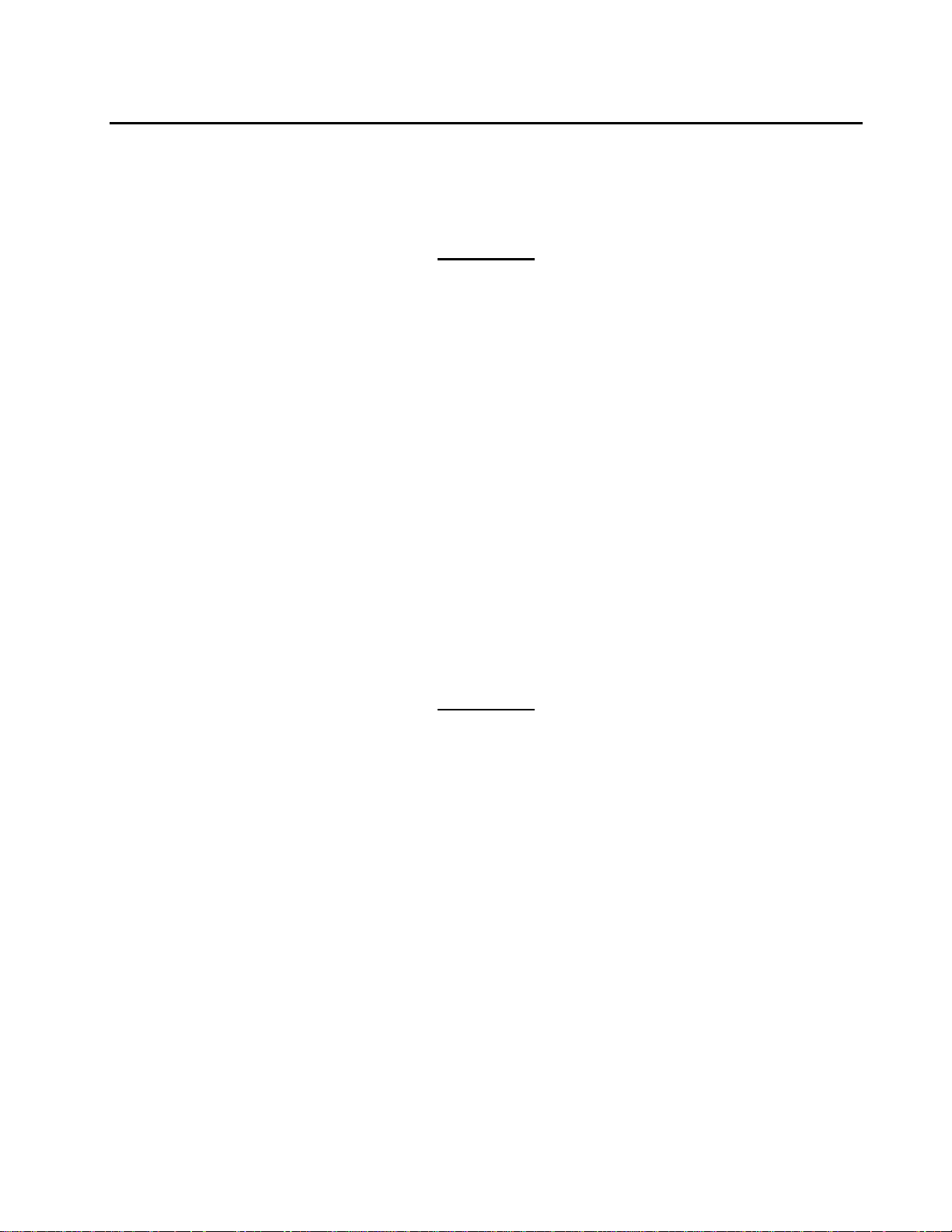

8. If the system measures a hydraulic oil temperature that exceeds 175F (79C), the

system will begin displaying an alarm. If the system measures a hydraulic oil

temperature that exceeds 180F (82C), the generator will automatically shut down

in 30 minutes unless the shutdown is overridden. If the temperature of the hydraulic

oil is measured at or above 220F, the system will immediately shut down unless

the high temperature oil warning is overridden. To override the shutdown, perform

the following steps:

Note: The system must measure a hydraulic oil temperature that exceeds 180F for

this procedure to work.

Step a: Press Mode to

rvn

cause

n

labels to appear.

and the

y

and

Step b: Press On/Off to

answer “yes” and make

the next screen appear.

Example of Command & Control Center in hot oil fault override

Figure 19

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 30 of 52

a. From the Normal mode display, press Mode, as if you wanted to display the oil

temperature. The screen shown in Figure 19 will be displayed instead, asking if

you want to “Run hot.” This screen will also be displayed if you attempt to start

the generator with the condition present.

b. Note the y and n labels below the Mode and On/Off switches. Press the On/Off

switch to answer “yes” and proceed to the next screen, or press Mode to answer

“no” and proceed to the oil temperature display.

Step c: Press On/Off to

answer “yes” and

override the shutdown.

Example of Command & Control Center

in hot oil fault override confirmation

Figure 20

c. If your answer was “yes” in the previous step, the confirmation screen shown in

Figure 20 will be displayed. Again note the y and n labels below the Mode and

On/Off switches. Press the On/Off switch to answer “yes” and override the

shutdown. Press Mode to answer “no” and proceed to the oil temperature

display.

Note: If you override the system and command it to operate at oil temperatures

above 175F, the system output power may degrade and you will void the

system’s warranty.

9. If the system detects an insufficient level of hydraulic fluid in the reservoir, it will

begin displaying an alarm. If the generator is started or was running when the fault

is detected, it will automatically be shut down in 30 minutes unless the shutdown is

overridden. To override the shutdown, perform the following steps:

Note: The oil level in the reservoir must be low for this procedure to work.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 31 of 52

Step a: Press Mode to

rvn

cause

n

labels to appear.

and the

y

and

Step b: Press On/Off to

answer “yes” and make

the next screen appear.

Example of Command & Control Center in low oil fault override

Figure 21

a. From the Normal mode display, press Mode, as if you wanted to display the oil

temperature. The screen shown in Figure 21 will be displayed instead, asking if

you want to “Run [with the] Oil Lo[w].” This screen will also be displayed if you

attempt to start the generator with the condition present.

b. Note the y and n labels below the Mode and On/Off switches. Press the On/Off

switch to answer “yes” and proceed to the next screen, or press Mode to answer

“no” and proceed to the oil temperature display.

Step c: Press On/Off to

answer “yes” and

override the shutdown.

Example of Command & Control Center

in low oil fault override confirmation

Figure 22

c. If your answer was “yes” in the previous step, the confirmation screen shown in

Figure 22 will be displayed. Again note the y and n labels below the Mode and

On/Off switches. Press the On/Off switch to answer “yes” and override the

shutdown. Press Mode to answer “no” and proceed to the oil temperature

display.

Note: If you override the system and command it to operate with insufficient

hydraulic fluid, the system output power may degrade and you will void the

system’s warranty.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 32 of 52

Special Operating Instructions

Cold Weather Procedure:

It is strongly recommended that the generator PTO be engaged prior to leaving a heated

garage or fire station in cold weather. The system will generate enough heat to keep its

hydraulic fluid viscosity low enough for proper operation, in all but the most extremes of

low ambient air temperatures.

If the generator system is “started” when the hydraulic oil temperature is below 40F, the

following message will be displayed on the Command & Control Center (reference Figure

23):

Message advising the

oil is cold (less than

40F)

Measured oil

temperature in

degrees fahrenheit

Example of Command & Control Center

when operating with cold hydraulic fluid

Figure 23

Operating Modes when the system START button is activated (or when the system is in

“autostart”):

When the meter displays hydraulic oil temperatures below 20F, the hydraulic

system will bypass the generator motor and the generator will not produce

power. This mode warms the hydraulic oil.

When the meter displays hydraulic oil temperatures between 20 and 40F, the

generator rotor will turn at a reduced RPM and the generator will not produce

power. This warms the hydraulic oil to 40F.

When the meter displays hydraulic oil temperatures that exceed 40F, the

system will then commence full power generating operations.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 33 of 52

Maintenance Instructions

WARNING:

Do not perform maintenance while system is running.

1. Perform regular, periodic checks to verify:

a. The cooler, the cooler fan and generator vents are not plugged by debris.

b. There are no fluid leaks within the framework of the generator, along the hoses,

or at the pump.

c. The hoses are not cut, chaffed, bulged or kinked.

d. That no electrical connections are loose.

e. That the hydraulic fluid level in the reservoir is between ½ to ¾ full in the sight

gage and the hydraulic fluid is clean and bright red in color.

f. That the bolts mounting the pump to the PTO are not loose.

g. If the hydraulic fluid appears dirty or black in the reservoir sight gage, replace

the fluid and filter immediately. Also, if the hydraulic fluid sustains a temperature

over 175° F, replace the fluid immediately. Oxidation can occur naturally over

time and can be accelerated with over temperature operation, affecting

generator output. Always change the filter when the hydraulic fluid is changed.

WARNING:

When adding or replacing hydraulic fluid, always use clean, new Dexron III fluid.

Do not power wash the generator. Doing so will void the system’s warranty.

Do not allow liquid to enter the generator.

If the outside of the generator requires cleaning, wipe surface with a damp cloth.

Clean the Command and Control Center using soap and water with a soft cloth only.

Improper cleaning, handling and use that may scratch, gouge, chip, fade or

otherwise damage the metallic coating and display surfaces are not covered under

the device warranty.

2. Replace the oil filter after every 250 hours of operation, or every three (3) years

(whichever comes first). Use Dexron III fluid and one of the following filters:

Hydac 0080 MA010 P

Puralator 20101

Fram P-1653-A (10 Micron 8 GPM)

WIX 51551 (10 Micron 8 GPM)

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 34 of 52

Lubricate the oil filter gasket with Dexron III before installation to permit

proper sealing of the filter.

WARNING:

Do not by-pass the filter or alter filtration plumbing in any way. Doing so will void

the system’s warranty.

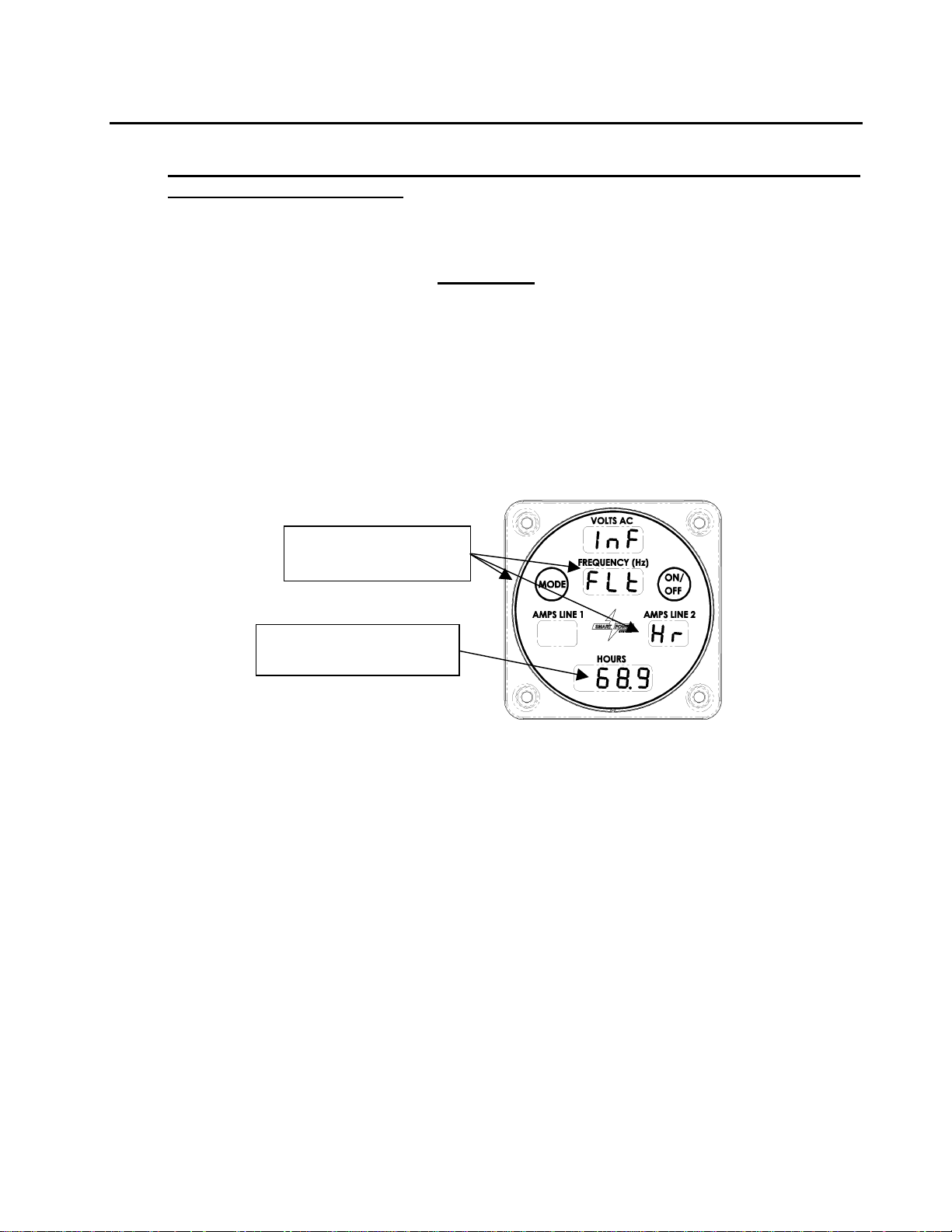

3. The system controller automatically records the time from the previous filter change.

The hours since the previous filter change can be accessed using the Command &

Control Center by pressing the Mode switch until the following screen appears

(reference Figure 24):

Press Mode until

Xr

and

Time Since last Oil Filter

Change in Hours.

are displayed

FLt

Example of oil filter run time display

Figure 24

4. The Command & Control Center will flash a fault when 250 hours have passed

since the previous filter change. After replacing the filter, this fault can be removed

from the Command & Control Center, and the filter run time can be reset by

performing the following steps:

Step a: Press Mode until InF,

0IL, and FILt appear.

Procedure will also work

in the Oil Filter Hours

Information display

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Step b: Hold Mode switch

down and press On/Off three

times in a row to clear the

fault.

Page 35 of 52

Example of oil filter service warning display

Figure 25

a. Press the Mode switch repeatedly until one of the screens shown in Figure 25

appears.

b. While holding the Mode switch down, press and release the On/Off switch three

times in succession, then release the Mode switch. The Oil Filter Fault display

will be removed and replaced by another screen. The fault has been cleared

and the timer reset.

c. When the fault has been cleared, the system automatically enters purge mode

to purge any entrapped air from the hydraulic lines (see Figure 11). The system

must be purged for 30 minutes, 20 of which must be with the generator ON.

Turn off the main power breaker during purge (see Figure 9). While purging, the

system will not produce usable electrical power.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 36 of 52

Troubleshooting Guide

Diagnostic:

The Command & Control Center will display certain faults that can assist a service

technician in trouble shooting a problem with the generator system. When these faults

occur, the fault message will periodically flash on the Command & Control Center,

interrupting the normal display. Reference Figure 26 for an example of an over-current

fault.

The faults can also be accessed by repeatedly pressing the mode switch. After displaying

the oil temperature, oil filter time, and configuration, the next display will be the first active

fault. Each time the Mode switch is pressed; the next fault will be displayed. When there

are no more faults to display, the Command & Control Center will return to Normal mode.

Example of high current in Line 1 fault display

Figure 26

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 37 of 52

Diagnostic Faults:

The following is a list of the diagnostic faults, with a brief explanation of each.

String Class Meaning

uLu CTrL

xI Cvrr

bAd (r 1

bAd (r 2

bAd uoLT

xoT <Temp> Alarm Oil temperature is getting too high (>175° F). Measured

xoT <Temp> Override Oil Temperature is too high (>180° F). Measured Temperature

Add 0il l0

xoT <Temp> Shutdown Oil Temperature dangerous (>220° F). Measured Temperature

bAd Ind

bAd tSnS

bAd Alrt

bAd dISP

LS FAn

0IL FILT

Alarm The control valve feedback is invalid, indicating the system is not

under control. Voltage and/or Frequency may be out of

specifications.

Alarm Overcurrent condition. The line in which the overcurrent

condition exists is indicated by the location of the “xI” string: If in

the “Amps Line 1” field, the overcurrent is in line 1; If in the

“Amps Line 2” field, the overcurrent is in line 2.

Alarm Current sensor fault on line 1. The indicated current may be

incorrect.

Alarm Current sensor fault on line 2. The indicated current may be

incorrect.

Alarm Voltage Sensor Fault. The indicated voltage may be incorrect.

Temperature in the “Hours” field

in the “Hours” field

Override Oil level in reservoir is low. Add oil to clear the error.

in the “Hours” field

Alarm Indicator Light Ground Fault. The indicator light may not

function properly.

Alarm Temperature Sensor Fault. The indicated oil temperature may

be incorrect.

Alarm Buzzer Ground Fault. The audible alert buzzer may not function

properly.

Alarm Display Ground Fault. The Command & Control Center may not

operate properly.

Alarm Low Side Fan Short. The Fan may not operate properly

Service

Warning

Service Warning: Change the Oil Filter

Table 2

Note: The fault “Classes” are defined in the table below:

Class Meaning

Service Warning

Alarm

Shutdown

Override

Normal maintenance needs to take place.

A condition requires the immediate attention of the operator.

A condition causes the immediate shutdown of the generator.

A condition that will cause the generator to be shut down in 30

minutes unless explicitly overridden by the operator.

Table 3

Hydraulic Problems:

1. Cavitation:

Cavitation is caused by trying to pump more fluid than is available at the

pump inlet due to system restrictions. Pump cavitation sounds like “marbles”

passing through the pump. Conditions frequently associated with cavitation are the

following:

a. Too many restrictive fittings such as elbows and reducers on the pump inlet

hose.

b. Tight bends or kinks in pump inlet hose and/or tubing.

c. Insufficient tray height above the pump, resulting in low head pressures.

d. Under sized pump inlet hose (minimum pump inlet hose size is 1”).

e. Excessive long inlet hose (may be corrected by using larger hose).

f. Cold hydraulic fluid.

Finding the cause and correcting it should stop cavitation.

Install a 0-25 psig gauge in line between inlet hose fitting and pump inlet port.

Engage PTO. Operate genset with no load for twenty minutes to purge air out of

the system. Observe the pressure reading. The pressure should always be

positive. If the pressure is not positive, system repair/rework is required.

2. Aeration:

Aeration results from air being drawn into the system through leak paths or a

low fluid condition. Aeration makes a “growling” sound and produces visible

bubbles in the fluid stream and/or reservoir. Conditions frequently associated with

aeration are the following:

a. Air leaks in the pump inlet flow path.

b. Low fluid level allowing air to be drawn into the system.

Verify there are no air bubbles in the fluid by viewing inside the reservoir. If there

are air bubbles, check fluid level, tighten all fittings, and look for cracked fittings or

hose leaks on the pump inlet line. Replace any suspect parts and adjust fluid level.

After correcting any problems, again operate the generator twenty minutes to purge

air out of the hydraulic fluid. Note that any bubbles seen in the reservoir indicate

leakage in the pump inlet line.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 38 of 52

A. C. MODULAR GENERATOR SYSTEM

3. Differential Pressure:

Differential pressure between the inlet pressure and the case pressure over 7

psig causes the piston shoes to lift off the swash plate. This occurs due to the

excessive lower pressure created on the fill (down) stroke of the piston. When the

swash plate begins its upstroke, with pump rotation, it comes back into contact with

the piston shoe, creating chatter.

NOTE: This is NOT NORMAL. The piston shoes should always remain in contact

with the swash plate. The causes of and correction for this problem are the same

as for cavitation above.

With the pressure gauge still installed in the suction line at the pump inlet port,

install a second gauge (0-50 psig pressure gauge) in the case drain line at the

pump case port. Next, engage the PTO and operate the genset with no load for

twenty minutes to purge air out of the fluid. Note both gauge readings. If the

differential pressure at the case is greater than 7 psig, the suction side plumbing will

require evaluation.

Note the following pressure measurements!

Inlet pressures: Should always be positive.

Outlet pressure: Approximately 500 psig with no load on the generator. Note: If

the gauge is fluctuating, record limits.

Case drain pressure to inlet pressure differential: The difference between

pump inlet pressure and case drain pressure should not exceed 7 psig. Pump inlet

pressure minus case drain pressure should never be less than 7 psig.

Verify the installation of the following hydraulic generator hose diameters:

a. Inlet hose (suction) on hydraulic pump (attaches to Port “S” on back of pump): 1

inch

b. Outlet hose (pressure) on hydraulic pump (attaches to Port “B” on back of

pump): 5/8 inch

c. Case drain to hydraulic pump (attaches to Port “L” top side, mid-length of pump):

5/8 inch

Note: The hose diameter appears in print along the length of the hose.

4. System Overheating:

System overheating may be caused by re-circulation of hot air through oil cooler,

dirty or obstructed oil cooler fins, restricted hydraulic fluid flow, excessive generator

load, restricted airflow, previously overheated (old) fluid, non-functional fan, or

improperly adjusted pump.

Smart Power® Systems

Page 39 of 52

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

a. Check the oil cooler fins for debris or damage. Clean and/or replace cooler.

b. Verify that the generator load is not excessive.

c. Verify that there is proper ventilation.

d. Verify that the DC fan motor is operating properly.

e. Verify that warm air from the fan outlet is not being re-circulated through the

cooler.

f. Check the hydraulic fluid to see if it is black or darkened. This indicates

overheating or aging. Drain and flush the system.

g. Fill with new, clean hydraulic fluid.

h. Adjust pump, if necessary, only after contacting Smart Power® Systems at (231)

832-5525.

5. Low Hydraulic Fluid Level In Reservoir:

Low hydraulic fluid level in reservoir can be caused by leaking fittings, hoses or

pipes.

a. Check all the fittings for leaks. Tighten any loose fittings that are found (but do

not over-tighten).

b. Replace defective fittings.

c. Check all tubing for leaks. Repair or replace as necessary.

Electrical Problems

1. No Output Voltage:

a. No output voltage may be caused by excessive current draw opening the circuit

breakers. (The circuit breakers can be found mounted on the generator wiring

enclosure.) Remove all electrical loads from the generator and reset breaker(s).

Re-engage electrical load in increments. If possible, monitor current draw with

the Command & Control Center to determine which portion of the load is

causing the breaker to open.

b. The PTO is faulty. Verify that the drive shaft that links the pump to the hydraulic

pump is spinning when the PTO is engaged. If the shaft is not turning, the

probable cause of the failure is a non-functional PTO. Contact the PTO

manufacture or qualified representative for further information.

c. The generator’s system controller has lost power (reference Figure 2). The

Command & Control Center would stay dark even after the mode and/or on/off

switch is pressed. Verify that the vehicle +12V supply has both +12 volts and

ground. If 12 volts is not available check the vehicle for a blown fuse or a

loose/open electrical connection.

Page 40 of 52

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 41 of 52

d. The stator field may be shorted or open. With a flashlight, check the generator

windings visible through the ventilation slots. If the windings appear burnt in any

area, the generator must be replaced. If the windings are not burnt, disconnect

wires 1, 2, 3, and 4 from the terminal strip located in the generator wiring

enclosure and make resistance measurement. The resistance between wires 1

and 2, and wires 3 and 4 should be between essentially 0 ohms. Contact Smart

Power® Systems at (231) 832-5525 if any problems are found.

WARNING:

Do not attempt to measure stator field resistance while the system is operating.

Electrical shock may occur.

e. The exciter field may be shorted or open. With a flashlight, check the generator

windings visible through the ventilation slots. If the windings appear burnt in any

area, the generator must be replaced. If the windings are not burnt, disconnect

the exciter field from the field capacitor. Measure the resistance of the exciter

field using an ohmmeter. The resistance of the exciter field should be between

.27 and .29 ohms. Contact Smart Power® Systems at (231) 832-5525 if the

resistance is outside this range.

WARNING:

Do not attempt to measure the exciter field resistance while the system is operating.

Electrical shock may occur.

f. Exciter field capacitor may be faulty. Disconnect the exciter field from the field

capacitor. Using a screwdriver, short leads of capacitor together to discharge

capacitor. Measure capacitance using a capacitance meter. Capacitor should

have capacitance between 47 and 53 microfarads.

WARNING:

Do not attempt to test the field capacitor with the system running. Electrical shock

may occur.

g. The generator drive motor or coupling is faulty. Observe the generator while the

system is engaged. If the coupling is not turning, or if it is turning but the

generator is not, one or more of the coupling components may be damaged and

must be replaced. Also, verify that the coupling halves are mating. If the

coupling halves are not mating, remove the hydraulic motor from the generator

to inspect coupling and the rubber insert between the coupling halves. Replace

components as necessary, reposition and tighten coupling setscrew so both

halves of the coupling are mating correctly.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 42 of 52

h. The pump is faulty. If no faults are found in steps a. through g., the problem is

likely to be a non-functional pump. Contact Smart Power® Systems at (231)

832-5525 for further instructions.

2. Output voltage exceeds 260 volts or falls below 220 volts AC on a 240 volt

line:

a. Verify that the hydraulic system is not overheating by viewing the temperature

as displayed by the Command & Control Center. The temperature should not

exceed 175° F. If the temperature is greater than 175° F, follow instructions for

system overheating (see hydraulic problems).

b. The hydraulic pump speed may be too low. Verify that the hydraulic pump

speed is in the required range (see Table 1). Pump speed can be calculated by

multiplying the engine RPM by the PTO ratio. Adjust the engine speed or PTO

ratio if necessary.

c. The generator speed may be incorrect. The generator output should be

between 59-61 Hz. If it is not, contact Smart Power® Systems at (231) 832-5525

for further instructions.

d. If the problem is not detected by performing steps a. through c., contact Smart

Power® Systems.

3. Generator Noise:

Generator noise can be caused by defective generator bearings or a faulty

generator/hydraulic motor coupling.

a. Contact Smart Power® Systems if bearings need replacement.

b. Check the generator/hydraulic motor coupling and replace it if necessary.

If problems occur other than those listed call Smart Power® Systems (231) 832-

5525 for additional assistance.

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 43 of 52

SPS Model Matrix

PARENT

P/N

DESCRIPTION

ASM

TRAY

P/N

P/N

PUMP ASM

RANGE

WR=WIDE

PUMP

RANGE

SHAFT

DISP. CC

D (STD)

S=SPLINE

K=KEYED

SHAFT

(STD),

R=CW

ROTATION

L=CCW

MOTOR

DISP. CC

1700006 GENERATOR, ER-6.2/45cc, R, SPL PUMP 8570006 8510010 WR 45 S R 8 6.2

1701006 GENERATOR, ER-6.2/45cc, R, KEY PUMP 8570006 8510013 WR 45 K R 8 6.2

1710006 GENERATOR, ER-6.2/45cc, L, SPL PUMP 8570006 8510004 WR 45 S L 8 6.2

1711006 GENERATOR, ER-6.2/45cc, L, KEY PUMP 8570006 8510018 WR 45 K L 8 6.2

1700008 GENERATOR, ER-8/45cc, R, SPL PUMP 8570008 8510010 WR 45 S R 8 8

1701008 GENERATOR, ER-8/45cc, R, KEY PUMP 8570008 8510013 WR 45 K R 8 8

1710008 GENERATOR, ER-8/45cc, L, SPL PUMP 8570008 8510004 WR 45 S L 8 8

1711008 GENERATOR, ER-/45cc, L, KEY PUMP 8570008 8510018 WR 45 K L 8 8

1700010 GERERATOR, ER-10, 45cc, R, SPL PUMP 8570010 8510001 Std. 45 S R 11 10

1701010 GENERATOR, ER-10, 45cc, R, KEY PUMP 8570010 8510016 Std. 45 K R 11 10

1710010 GENERATOR, ER-10, 45cc, L, SPL PUMP 8570010 8510002 Std. 45 S L 11 10

1711010 GENERATOR, ER-10, 45cc, L, KEY PUMP 8570010 8510017 Std. 45 K L 11 10

1700110 GENERATOR, ER-110/60cc, R, SPL PUMP 8570010 8510005 WR 60 S R 11 10

1701110 GENERATOR, ER-110/60cc, R, KEY PUMP 8570010 8510019 WR 60 K R 11 10

1710110 GENERATOR, ER-110/60cc, L, SPL PUMP 8570010 8510014 WR 60 S L 11 10

1711110 GENERATOR, ER-110/60cc, L, KEY PUMP 8570010 8510021 WR 60 K L 11 10

1711206 GENERATOR, ER-6.2, W/O PUMP 8570006 NONE N/A N/A N/A N/A 8 6.2

1711208 GENERATOR, ER-8, W/O PUMP 8570008 NONE N/A N/A N/A N/A 8 8

1711210 GENERATOR, ER-110, W/O PUMP 8570010 NONE N/A N/A N/A N/A 11 10

Table 4

POWER

OUTPUT

KILOWATT

S5

Smart Power® Systems

A. C. MODULAR GENERATOR SYSTEM

Page 44 of 52

Component Part Number Lists

(Reference Figure 27 and Figure 28)

ITEM NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

PARENT

1700006

GENER-

ATOR

1500088

OIL

COOLER

8591003 3401121 8590012 8594019 8573001 8590000 8574401

ASM,

FAN

ASM,

FILTER

PR. SW.,

FAN

CONT.

TRAY

FILTER

ELEMENT

HOUSING

BOOST

HYD.

MOTOR

8505009

GAUGE,

FLUID

LEVEL

8594660 8574404 8572003

BREATHER

PLUG

OIL RES.

ASM,

PUMP

8510010

ELEC.

CONT.

UNIT

8505028 8594463

PROP.

CONT.

VALVE

1701006

1710006

1711006

1700008

1701008

1710008

1711008

1700010

1701010

1710010

1711010

1700110

1701110

1710110

1711110

1711216

1711218

1711210

SHADED COLUMNS HAVE DIFFERING PART NUMBERS

1500088

1500088