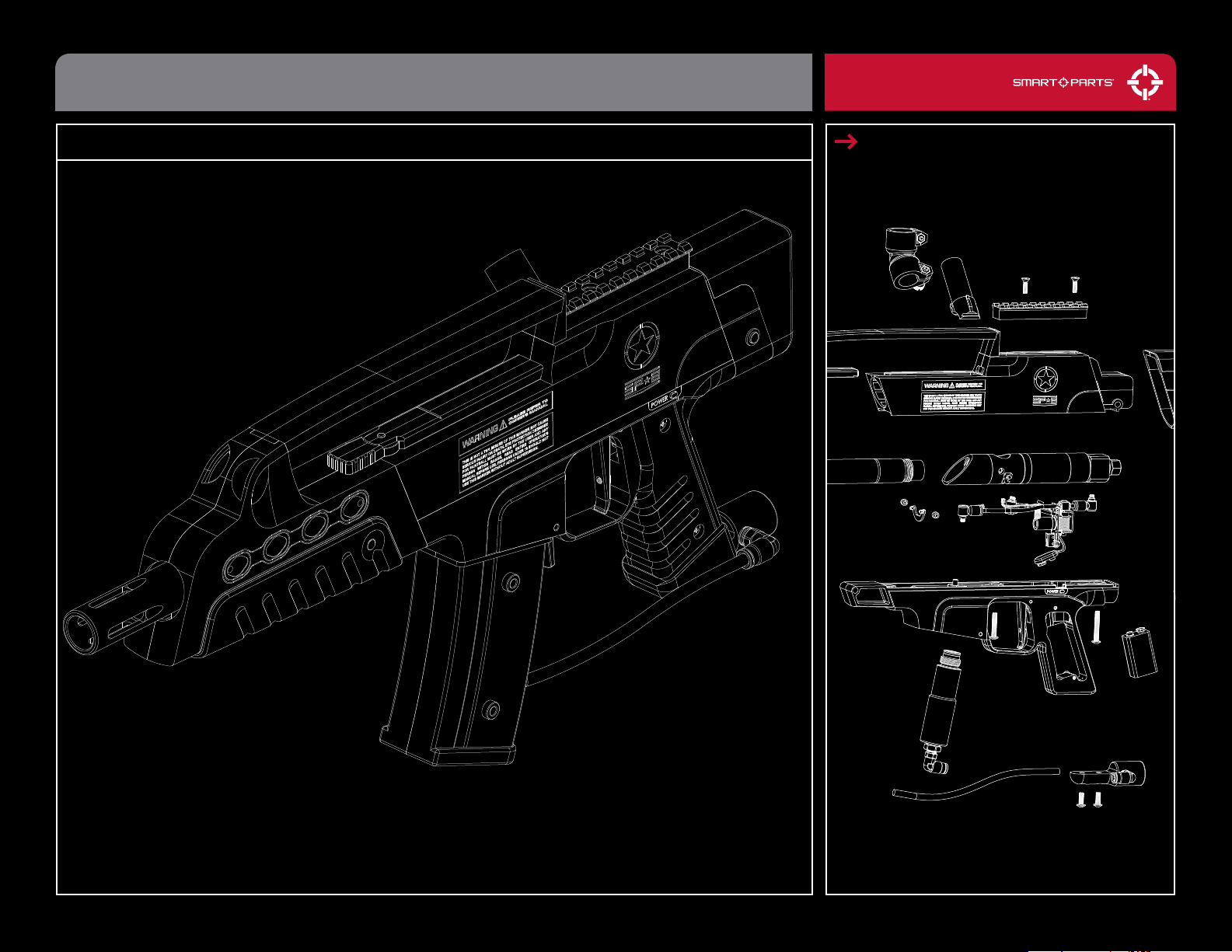

Smart Parts SP 8 User Manual

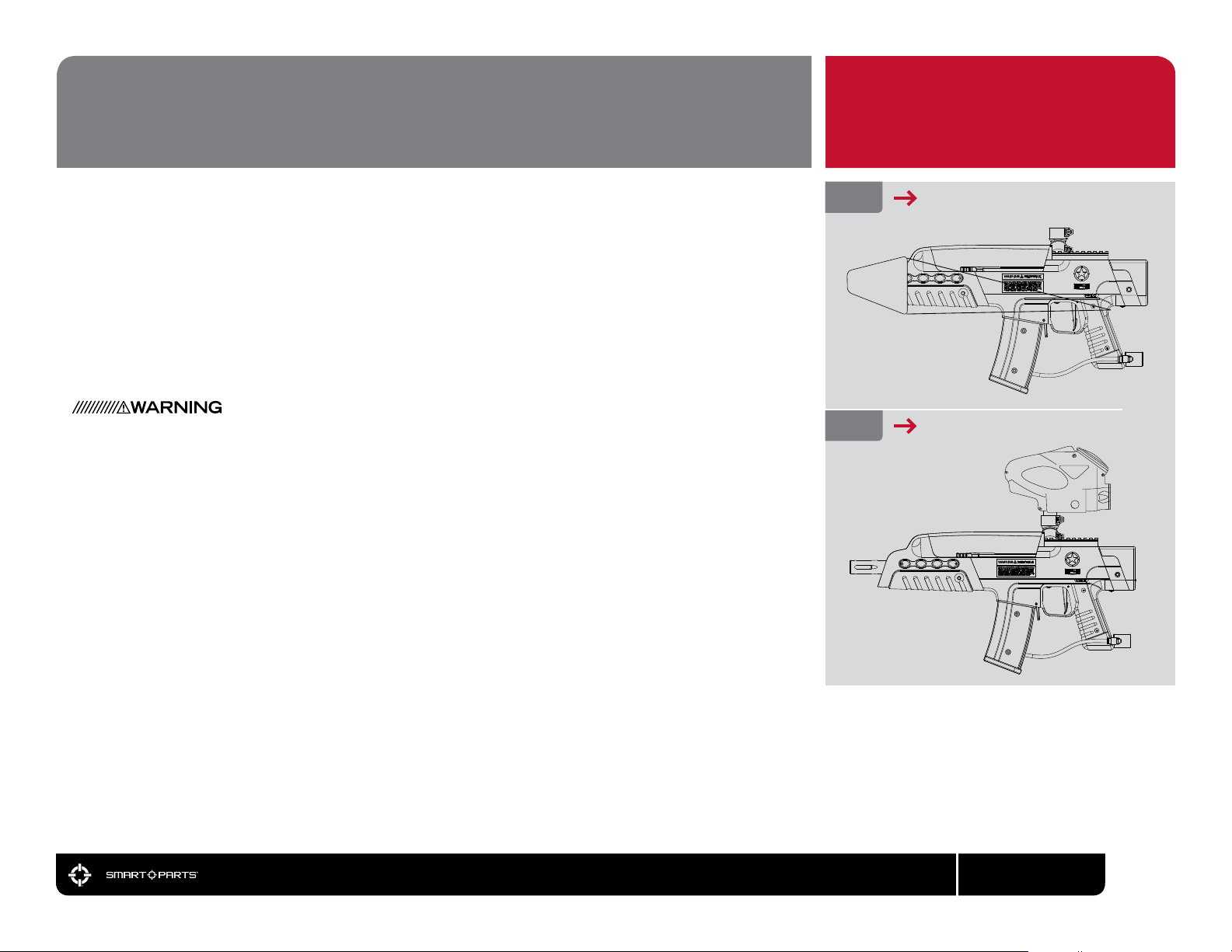

SP-8

Operation and adjustment instructions

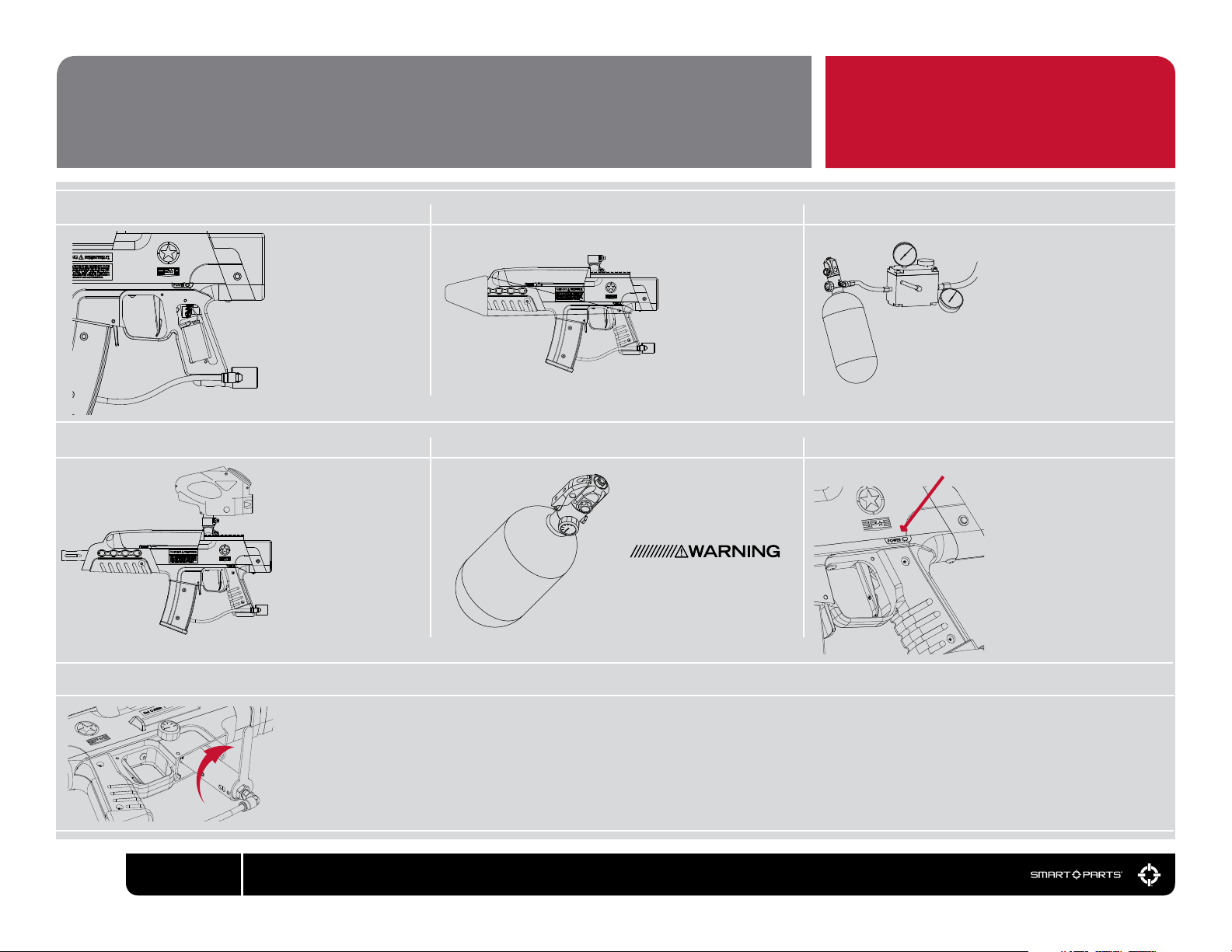

QUICK START

BATTERY BARREL BLOCKER FILL TANK

01 02

Using a #1 Phillips

Screwdriver, remove

the two screws from

the left side of the

rubber grip and lift the

panel open. Attach a

fresh 9-volt alkaline

battery to the battery

clip. Position the battery in the grip frame,

tucking the battery

wires into the space

above the battery.

Close the grip and

reinstall the screws.

LOADER TURN ON AIR TURN ON SP-8

04 05 06

Install the supplied elbow

onto the SP-8’s feedneck

and mount your loader in

the elbow. Due to the high

rates of fi re that the SP-8

can achieve, we recommend the use of a modern

high-performance loader

(see the Hopper section.)

Put the supplied barrel

blocker over the end of

the barrel, securing its

cord as far back on the

SP-8 body as possible,

and cinching it tight.

Gently gas up the marker

by slowly turning on the air

system or ASA’s on/off valve,

or slowly screwing the CO

compressed air system into

the ASA.

A gentle rise in pressure is

important, as a sudden blast

may reduce the service life of

the SP-8’s internals.

2 or

03

POWER BUTTON

PLEASE READ CAREFULLY

Have your compressed air (HPA)

2 tank fi lled by a person

or CO

who is properly trained to do so.

If using an HPA system with an

on/off valve, such as the Max-Flo

or Max-Flo Micro, make sure it is

in the OFF position.

Turn on the marker by holding the power button down for

approximately 2 seconds. The

marker will turn on with Vision

mode activated. The light will blink

slowly if there is no paintball in

the breech, or rapidly if there is.

To de-activate Vision mode, press

the power button briefl y and it will

blink in a double-tap sequence.

Press it briefl y again to re-activate

Vision mode. Press and hold the

power button for approximately 2

seconds to turn the SP-8 off.

ADJUST VELOCITY

07

00

800.922.2147 www.smartparts.com

Fill the loader with paint and turn it on. While wearing ASTM compliant paintball goggles, in an area where all bystanders are protected, remove the barrel blocker and fi re over

a chronograph to measure the velocity. Expose the SP-8’s vertical reglator by removing the magazine. Using a 5/8-inch open-end wrench or adjustable wrench on the fl ats at

the bottom of the vertical regulator, turn clockwise to increase velocity/pressure, and counter-clockwise to decrease. Take three or four shots after every adjustment to allow the

gas pressure inside the SP-8 to stabilize. Adjust until the marker is fi ring consistently within the limits for the fi eld where you are playing (for safety reasons, never adjust the SP-8

to fi re at greater than 300 feet per second.) As you adjust, check the marker’s pressure gauge to be certain you stay below the SP-8’s operating limit of 200 psi. Depending on

what modes of fi re are allowed at the fi eld where you are playing (semi-automatic, rebound, etc.) you may need to adjust the SP-8’s fi ring mode. See the Electronic Adjustment

section for more information. Shoot out the competition, hang the fl ag and win the game.

TABLE OF CONTENTS

Quick Start

Getting Familiar

Barrel Blocker/Hopper

Gases

Gas System Mounting

Paint/Velocity

Vision/Degassing

Electronic Adjustment

Dwell

ROF Delay/Fire Modes

Trigger [ DISASSEMBLY/REASSEMBLY ]

SP-8 Parts

Disassembly

Reassembly

Solenoid

Regulator

Ball Detents

Troubleshooting

Warranty/Tech Support

CPS Table

00

02

03

04-05

06

07

08

09

10

11

12

13

14

15-16

18

19

20

21-24

24

25

While every effort has been made to ensure that the information contained in this guide is accurate and complete, no liability can be accepted for

errors or omissions. Smart Parts, Inc. reserves the right to change the specifi cations of the SP-8 at any time without prior notice. The latest version of

this manual may be downloaded free of charge at www.SmartParts.com.

– THE SP-8 IS NOT A TOY

– MISUSE OF THE SP-8 MAY RESULT IN SERIOUS

INJURY OR DEATH.

– EYE PROTECTION SPECIFICALLY DESIGNED FOR PAINT BALL USE MUST BE IN COMPLIANCE WITH ASTM SPECI FICATION F1776 AND MUST BE USED BY THE USER AND

ANYONE WITHIN RANGE OF THE SP-8.

– SMART PARTS RECOMMENDS THAT THE SP-8 ONLY

BE SOLD TO PERSONS 18 AND OLDER.

– THOROUGHLY READ THE SP-8 OPERATION AND

INSTRUCTION MANUAL BEFORE OPERATING.

– TREAT EVERY PAINTBALL MARKER AS IF IT WERE

LOADED.

– NEVER LOOK DOWN THE BARREL OF A PAINTBALL

MARKER.

– KEEP YOUR FINGER OFF THE TRIGGER UNTIL READY TO

SHOOT.

– NEVER POINT THE SP-8 AT ANYTHING YOU DON’T

WISH TO SHOOT.

– KEEP THE SP-8 ON SAFE (POWER OFF) UNTIL

READY TO SHOOT. (SEE QUICK START)

– KEEP THE BARREL BLOCKING DEVICE ON THE

SP-8’S MUZZLE WHEN NOT SHOOTING.

(SEE BARREL BLOCKER SECTION).

– ALWAYS REMOVE PAINTBALLS AND DEGAS THE

SP-8 BEFORE DISASSEMBLY. (SEE DEGAS-

SING SECTION.)

– STORE AND TRANSPORT THE SP-8 UN-

LOADED AND DEGASSED IN A SECURE PLACE.

– FOLLOW ALL MANUFACTURER’S WARNINGS AND

INSTRUCTIONS FOR PROPELLANT SOURCE HANDLING,

STORAGE, AND FILLING.

– DO NOT SHOOT FRAGILE OBJECTS SUCH AS WINDOWS.

– ALWAYS MEASURE THE VELOCITY OF PAINTBALLS FIRED

BY THE SP-8 BEFORE USE, AND NEVER ADJUST TO

FIRE ABOVE 300FPS (91.44 M/S.)

800.922.2147 www.smartparts.com

01

GETTING FAMILIAR

PLEASE READ CAREFULLY

STATISTICS

LENGTH/HEIGHT/WEIGHT:

OPERATING PRESSURE:

PAINTBALLS:

POWER SOURCE:

PROPELLANT:

RATE OF FIRE:

OPERATION:

MODES OF FIRE:

ANTI CHOP SYSTEM:

BARREL THREAD:

GAS EFFICIENCY:

LUBRICANT:

21 Inches with stock 12” / 4lbs, 4oz (marker only)

Approx. 180 psi, 200 psi max

.68 caliber –Compliant to ASTM F1979 Specifi cation

9-volt alkaline battery

2 or Nitrogen/Compressed air

CO

17 bps maximum –higher with optional Blackheart board

Low pressure electropneumatic

Full Auto, 3-shot burst, Semi automatic and Rebound

Break Beam Vision

Smart Parts (Impulse/Ion)

1200 shots (68ci, 4500psi tank), 800 shots (20oz. ANTI-SIPHON tank) – Effi ciency will vary with paint,

barrel and setting combinations.

For proper and consistent operation, the SP-8 should only be lubricated with SL33K lubricating grease.

MAINTENANCE

The SP-8 has been designed to handle the rigors of scenario style paintball while providing tournament

level performance. It has a minimal number of moving parts and seals so that you can maintain the marker

with little effort. This DOES NOT mean that you should neglect your marker. If you take care of it off the

fi eld, your SP-8 will take care of you on the fi eld. For best performance, clean and grease your SP-8 frequently. Many players clean their marker after every use. While this may seem a bit extreme, being vigilant

in the upkeep of your marker will extend its useful life considerably. Playing in the rain will not damage

your SP-8, but you should NEVER immerse it in water. If your marker should become waterlogged, remove

the barrel, body cover and rubber grips and allow them to dry out, then follow the disassembly instructions for full cleaning. Clean out mud and paint with a damp cloth and alcohol. Grease the SP-8 ONLY

with SL33K pneumatic grease. For best performance, use high quality paintballs.

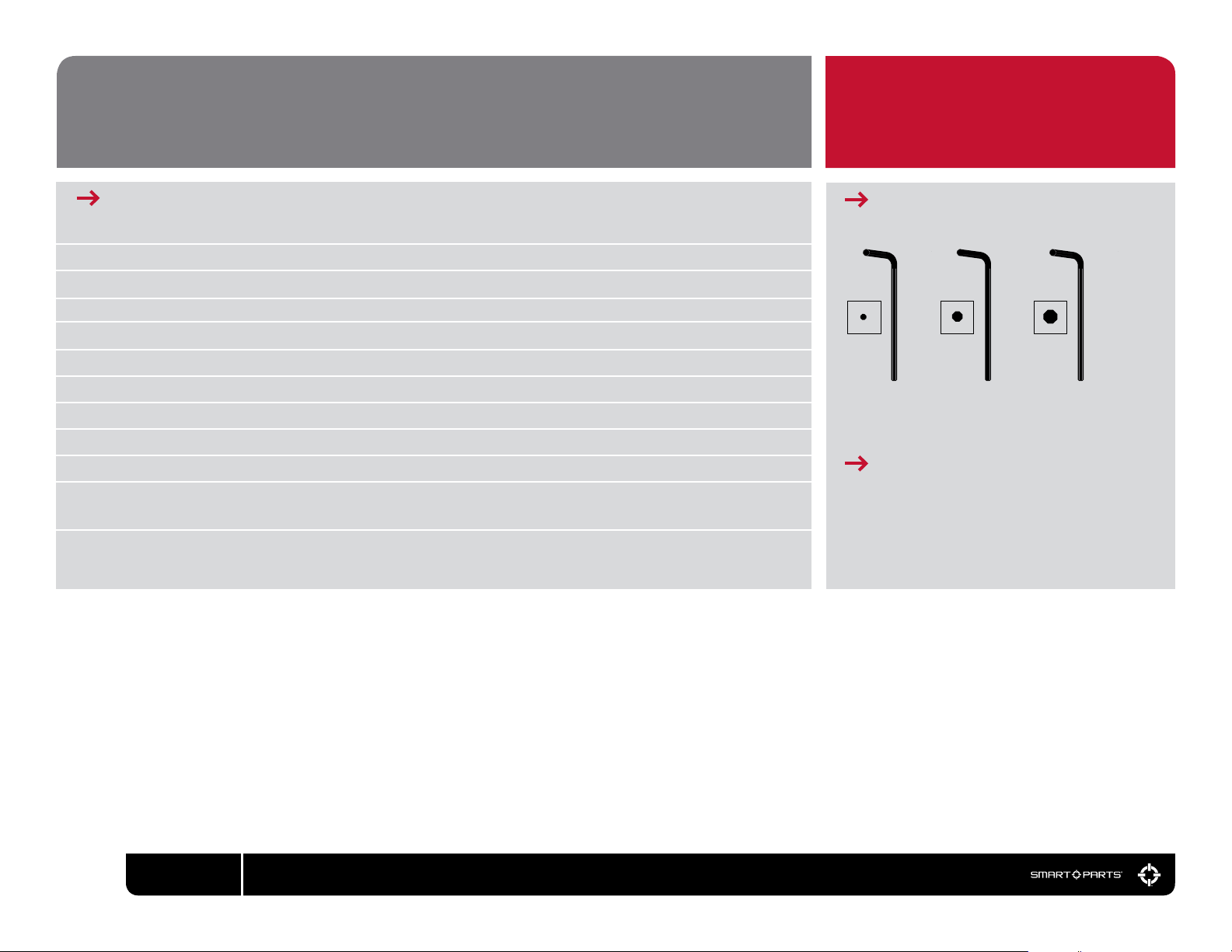

REQUIRED ALLEN WRENCHES

.050” 3/32” 1/8”

ADDITIONAL REQUIRED ITEMS

· 5/8” OPEN OR ADJUSTABLE END WRENCH

· 9/16” DEEP WALL SOCKET AND WRENCH

· #1 PHILLIPS SCREWDRIVER

02

800.922.2147 www.smartparts.com

BARREL BLOCKER/HOPPER

PLEASE READ CAREFULLY

BARREL BLOCKER

The Barrel Blocking Device is a critical piece of paintball safety equipment - nearly as important as

paintball goggles. The Barrel Blocker serves to protect against accidental discharge of a paintball by

catching it before it can cause harm. A Barrel Blocker is included with the SP-8, and must be used

every time the marker is handled in an area where people or property are not properly protected by

paintball goggles or paintball fi eld netting. To use the Barrel Blocker simply slip it over the end of the

barrel and stretch its cord back over the back of the marker or the rearmost part over which it can

be securely looped. Use the strap’s adjuster to cinch the strap tight, so that the Barrel Blocker can

provide protection against accidental discharge of a paintball.

The Barrel Blocker should only be removed when the marker is on a “live” paintball fi eld and all persons involved are wearing proper paintball protection.

HOPPER

The SP-8 is a high performance scenario paintball marker capable of high rates of fi re. The breakbeam Vision system means that you won’t need to worry about chopping paint because your trigger

fi nger is faster than your hopper. However, if you want to realize the marker’s maximum fi repower

potential, you will need to use a high performance loader. High performance loaders, especially those

which provide force-feeding, will yield the best results with the SP-8.

Included with the SP-8 is a 45-degree elbow for attaching standard paintball hoppers. Slide the

narrow end of the elbow onto the SP-8’s feedneck and secure it in place by tightening its wing-nut.

Place your hopper in the top of the elbow and secure it similarly.

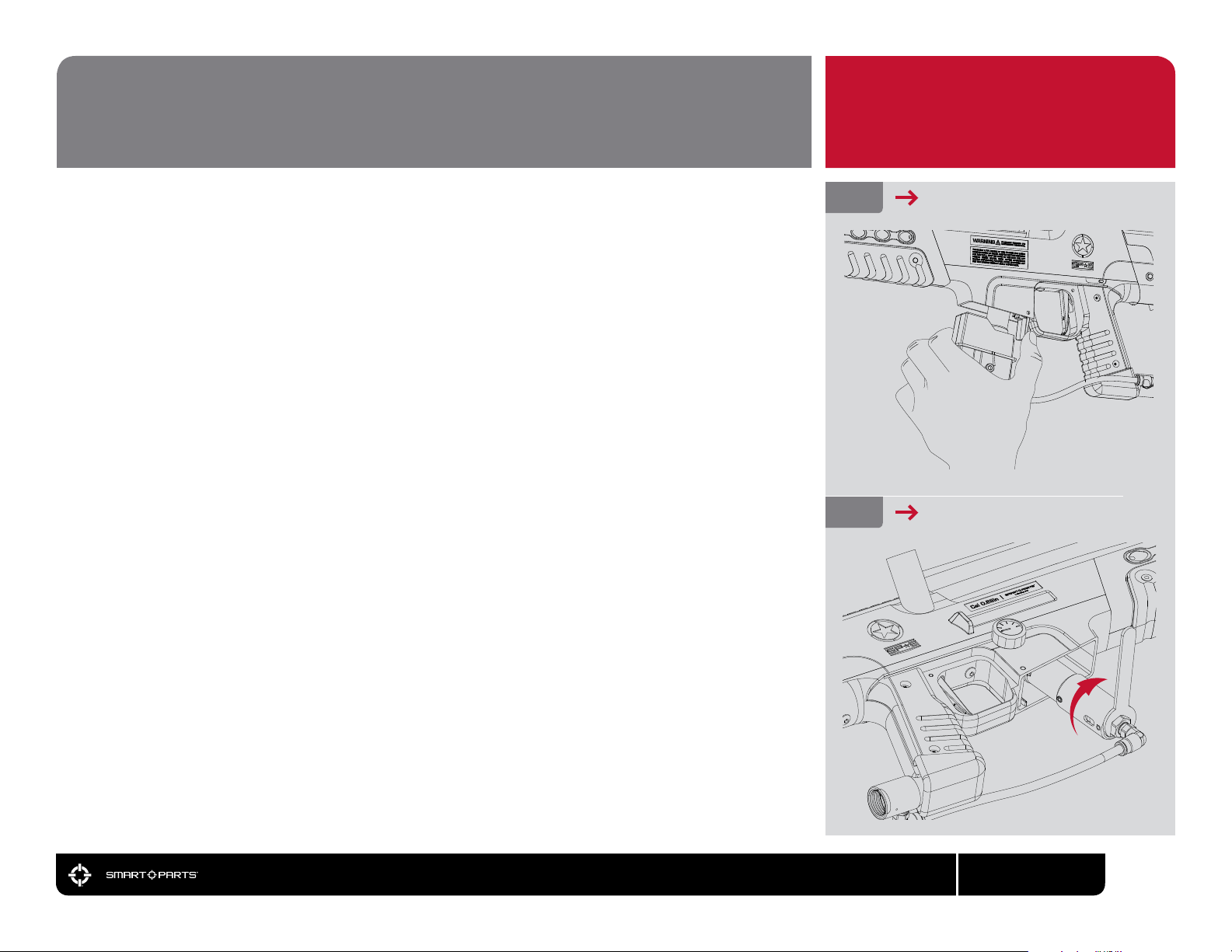

FIG. 1

FIG. 2

BARREL BLOCKER IN USE

USE HIGH PERFORMANCE LOADER

800.922.2147 www.smartparts.com

03

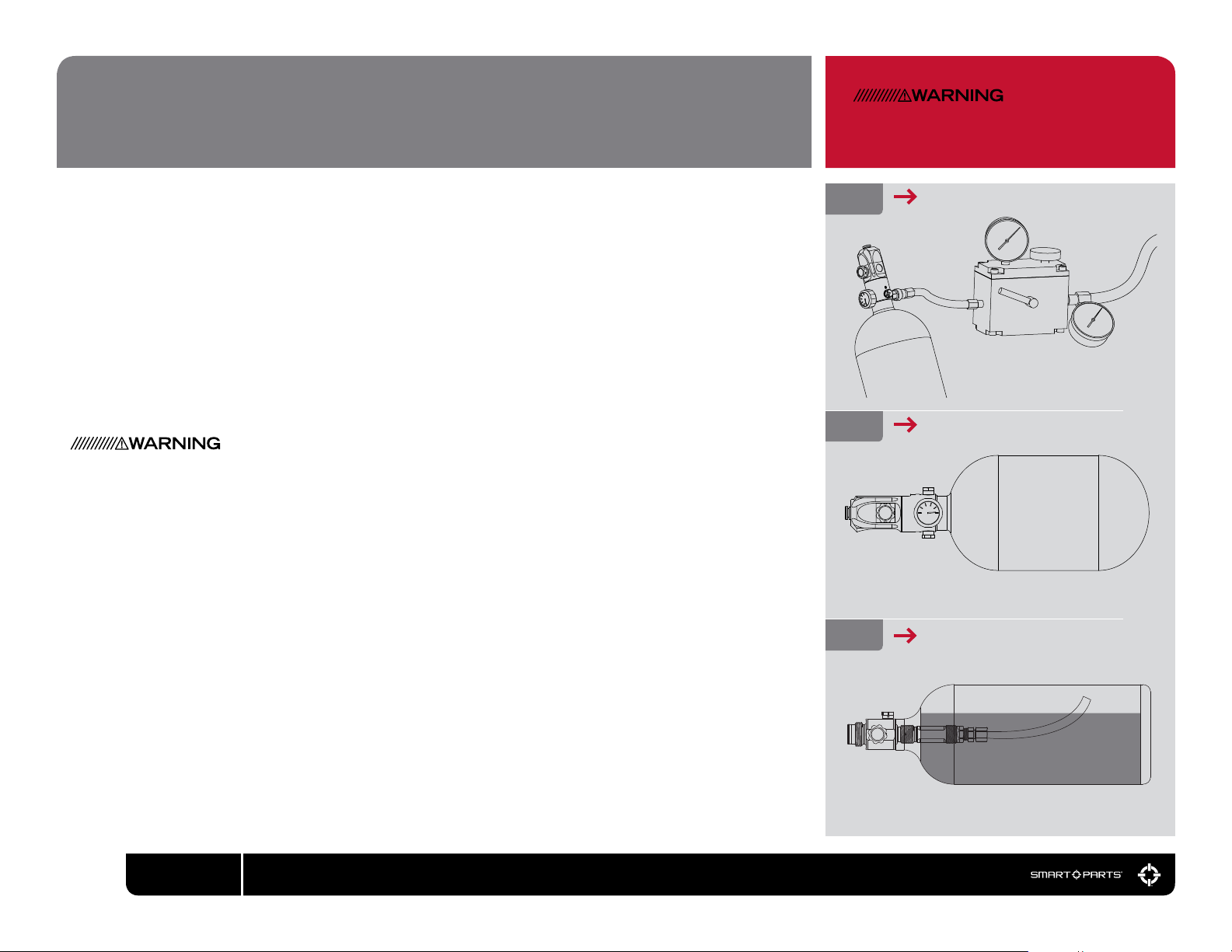

GASES

Never put oil in a compressed air regulator or tank—only

apply manufacturer specifi ed lubricants.

The SP-8 is a low-pressure paintgun. It operates optimally at 180 psi, which means it can function well

with either compressed air or CO2 as a power source. Proper set up of your gas system will help you

obtain the best possible performance.

High Pressure Air systems (HPA) are the most common power source used with the SP-8, as they are

unaffected by temperature fl uctuations and do not have the potential for liquid problems. HPA systems

consist of a tank and a regulator, and are typically rated to store air or nitrogen (while pure nitrogen is

almost never used in paintball, many players call compressed air “nitro” as air is made of more than 70%

nitrogen) at pressures of 3,000 or 4,500 psi.

There are two main types of HPA systems, those on which the output pressure is adjustable, and those

for which their regulator is pre-set to a fi xed output pressure. HPA systems designed to screw into an

ASA are usually pre-set to deliver either 400 psi (low pressure output) or 800 psi (high pressure output.)

Never use oil or any petroleum based cleaner or lubricant in a compressed air regulator or tank. Exposure to pressurized air increases oil’s fl ammability and can cause a serious safety hazard. Only use

manufacturer recommended lubricants with compressed air systems, and follow the manufacturer’s

maintenance and operation instructions explicitly.

If you are using your SP-8 with an adjustable output compressed air system, it should be adjusted to

deliver about 650 psi to the marker’s vertical regulator. The SP-8’s regulator can accommodate a wide

range of input pressures, so exact adjustment of the air system is not critical, and either low output, or

high output pre-set HPA systems may be used as well.

While CO2 can also be used, it is less popular, since its pressure fl uctuates with temperature and use.

The important thing to remember when using CO2 is that liquid CO2 must not be delivered to the marker.

If liquid CO2 were to make it past the vertical regulator, it could expand into gas form inside the paintgun,

raising the pressure levels high enough to cause damage to internal seals, hoses or the solenoid valve.

Because liquid CO2 is heavier than CO2 gas, it is easily blocked through the use of gravity.

FIG. 3

FIG. 4

FIG. 5

HPA TANK BEING FILLED

COMPRESSED AIR

CO

2 WITH ANTI-SIPHON [CUTAWAY VIEW]

04

800.922.2147 www.smartparts.com

GASES

PLEASE READ CAREFULLY

Two easy ways to properly use CO2 with the SP-8 are an anti-siphon tank or a remote line.

Anti-siphon tanks have a J shaped tube professionally installed inside. When the tank is screwed into a

bottom line ASA, such as the one that is standard on the SP-8, the tube delivers gas only. The anti-si-

phon tube works like a diver’s snorkel, repositioning the gas intake from the valve to the top side of the

tank. When an anti-siphon tube is installed in a tank, the airsmith will usually mark the valve, to indicate

the position of the tube. When the tank is screwed into a marker, this mark must be oriented to the top.

A remote hose allows a standard (non-siphoned) CO2 tank to be carried in a player’s pack. Not only does

this reduce the total weight of the marker, but it also allows the tank to be placed vertically, so that its

valve is at the top while gravity holds the liquid CO2 at the bottom. It is important to note that lying down

on the fi eld or crawling while using a remote can cause liquid CO2 to be fed to the paintgun as the tank is

turned on its side. Remote hoses offer an additional advantage, like straight-rails and drop-forwards they

move the CO2 or HPA tank to allow use of the optional SP-8 Adjustable Stock.

Whether using compressed air or CO2 it is important that the marker is not exposed to sudden “pops”

of pressure. If using a standard ASA with a screw in HPA system or CO2 tank, screw the tank in slowly,

so that the valve opens slowly and the pressure rises gently. If using an ASA with a built in on/off valve,

screw in the tank fully, then open the valve slowly. If using an HPA system or CO2 tank with its own on/off

valve, open that valve slowly. Be gentle to the internals of your marker and they will reward you with

a long service life.

IMPORTANT

CO2 can also be used with remote hose

with-out Anti-Siphon. [Not Shown]

800.922.2147 www.smartparts.com

05

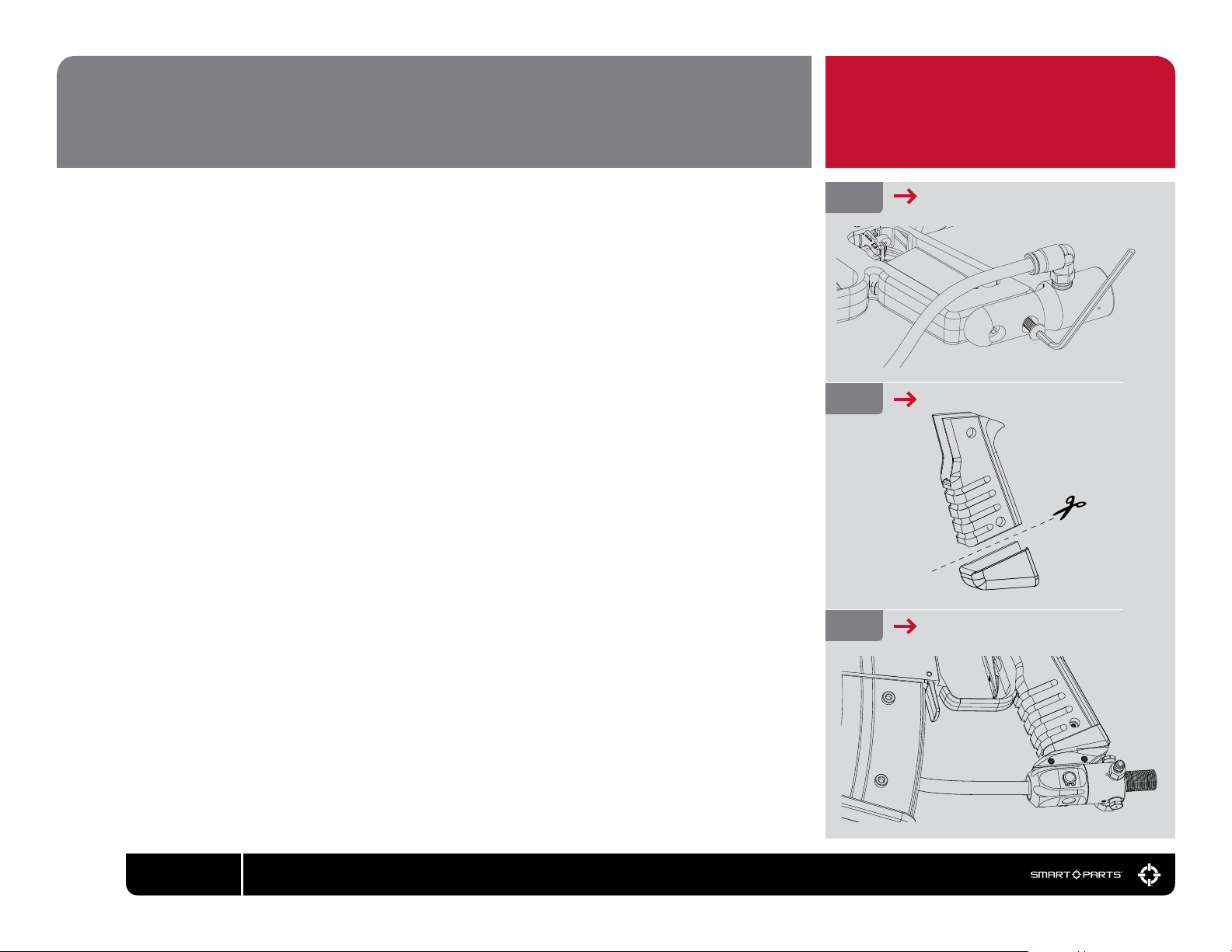

GAS SYSTEM MOUNTING

PLEASE READ CAREFULLY

The SP-8 uses paintball industry standard gas system mounting. At the bottom of the grip frame, it has

a pair of 10-32 screw holes.

The SP-8 is preconfi gured with a standard duckbill style ASA mounted on bottom of the grip frame. To

remove this ASA, degas and unload the marker. Use a #1 Phillips Screwdriver to remove the four grip

screws and the rubber grip. Use a 1/8” allen wrench to remove the two ASA mount screws.

The ASA can be replaced with a mounting rail or drop forward to place the gas source in a position that

is most comfortable for you. The stock SP-8 rubber grip is not compatible with all ASAs, or most dropforwards, without modifi cation.

If the rubber grip will not fi t correctly with your new custom set-up, carefully cut off the lower cup portion with a set of heavy-duty kitchen shears, following the existing cut-lines. Carefully lubricating the

utility scisors with SL33K minimize binding for a smoother cut.

FIG. 6

FIG. 7

FIG. 8

REMOVING BOTTOMLINE ASA

TRIM GRIP ON CUT LINES

MAX-FLO MICRO ON S-RAIL MOUNT

06

800.922.2147 www.smartparts.com

PAINT / VELOCITY

PLEASE READ CAREFULLY

PAINT

Even the best quality paintballs will vary in size from one batch to the next and as weather conditions

change. While your marker will work well even with a poor paint to barrel fi t, optimal performance will be

achieved with a proper fi t. Paintgun barrels are available in a variety of bore sizes to allow the user to select

the best possible fi t, and barrel kits like The Freak allow for easy adjustment to paint of different diameters.

The ideal fi t between the paintball and the barrel is when the ball is inserted in the bore (the end that

screws into the marker) and does not slip or roll through to the muzzle (the business end) on its own. The

ball should sit in place, even when the barrel is pointed straight down. If the paintball can roll out on its

own, the fi t is too loose. The ball should be able to be expelled from the barrel by blowing it out like a

blowgun, using a minimal amount of breath. If the ball is diffi cult to blow through, the fi t is too tight, which

can lead to ball breakage.

VELOCITY

The velocity, or speed at which a marker fi res a paintball, must be measured and adjusted to below the

paintball fi eld’s velocity limit immediately before each day of play. This is required for player safety. If CO2

is used, velocity should be checked and adjusted multiple times during the day. To access the verticcal

regulator for velocity adjustment, press down on the magazine release lever and pull the magazine down.

While wearing proper paintball specifi c goggles and protective equipment, and in an area in which all

persons and property are properly protected, fi re three or four shots over a chronograph and if necessary

change the velocity by adjusting the vertical regulator with a 5/8-inch open-end or adjustable wrench.

Turn clockwise to increase velocity/pressure, and counter-clockwise to decrease. Take three or four shots

after every adjustment to allow the gas pressure inside the marker to stabilize. Adjust until the marker is

fi ring consistently within the limits for the fi eld where you are playing. For safety reasons, never adjust the

marker to fi re at greater than 300 feet per second. As you adjust, check the pressure gauge to be certain

you stay within the SP-8’s operating pressure range of 160 to 200 psi. Optimal pressure is 180 psi.

Replace the magazine after velocity adjustment has been completed.

FIG. 9

FIG. 10

REMOVING MAGAZINE

INCREASING VELOCITY

800.922.2147 www.smartparts.com

07

Loading...

Loading...