Smart Parts shocker 4x4 User Manual

Shocker Sport

TM

Manual

Includes: Shocker Sport 4X4TM and Shocker Sport Turbo

TM

2

WARNING! The Shocker Sport

TM

Paintball Marker is not a toy. Misuse or

careless use may cause serious injury or death. The user and any person within

range must wear eye protection designed for paintball use. Recommended at

least 18 years old to purchase, 14 years old to use with adult supervision, or 10

years old to use on paintball fields meeting ASTM standard F1777-97. Read operation

manual before using. Always use barrel plugs when not involved in actual play. When

gassing and de-gassing the marker’s system, never aim the gun at another person. Always

point the barrel towards the ground. Never use over-filled CO2 bottles as this will “spike” the

system causing the hoses to burst.

Shocker Sport™ Limited Warranty

Smart Parts warrants for 1 year to initial retail purchaser that the Shocker

Sport™ paintball marker and regulator are free from defects in materials and

workmanship. Disposable parts (batteries, o-rings, seals, etc) are not warranted. The

fill poppet and firing piston are warranted for six months. The solenoids and

electronics on your Shocker Sport™ are unconditionally warranted for six months,

plus an additional warranty of six months for electronic parts only (installation and

labor are not included.) This warranty does not cover surface damages (scratches and

nicks,) misuse, or improper disassembly and re-assembly, or attempts made to drill

holes or remove metal from the external surfaces, which could result in degrading the

performance and reducing pressure safety factors. Do not use Teflon tape on any part

of this marker--the tape can break off and plug the solenoids. Instead, use Loctite 271.

Do not make changes to the basic marker parts without written approval. The only

authorized lubricant for the gun is DOW 33 Lubricant. Use of any other lubricant could

result in voiding your warranty. Use only those “on/off” switches purchased from

Smart Parts. Unauthorized “on/off” switches will void this warranty. This warranty is

limited to repair or replacement of defective parts with the customers to pay shipping

costs. This warranty is effective only if the customer returns the warranty registration

card enclosed with the marker.

Thank you for purchasing the Shocker Sport. The Shocker Sport is the culmination of

years of research and testing. Engineers at Smart Parts, building on their experience with

the original Shocker, have given the Shocker Sport a complete overhaul to keep up with the

demands of today’s players and the quality you expect from Smart Parts, Inc. We’ve made

the Shocker Sport smaller, lighter and faster than the original Shocker while keeping the

low pressure, accuracy and extremely low ball breakage! In addition, we’ve upgraded the

electronics, wiring and grounding to make the marker more reliable. The Shocker Sport

now incorporates a digital circuit board, redesigned bolt assembly, new solenoid valves and

an optional integrated air assist port.

THE BASICS

The Shocker Sport 4x4 and Turbo consist of three main assemblies: the Body, the Solenoid

Housing, and the Grip Frame.

Body

The Body is two interlinked systems, the Bolt and the Firing System. It also includes an air

transfer port and air assist fitting port.

The Bolt is contained in the upper chamber and should only be removed when the gun is

degassed. The Bolt is operated by the rearmost solenoid controlling the air going to the front and

rear of the bolt piston in order to make it travel back and forth. The bolt’s function is to load the

paintballs into the breach of the gun and to transfer the air from the firing system to the ball in order

to propel it.

The firing system contains three main moving parts: the firing piston, the fire rod and the fill

poppet. The firing system is controlled by the foremost solenoid valve which when activated starts

the firing cycle. The firing piston and fill poppet are contained in their respective housings. NOTE:

The firing piston also contains a glide ring that is split to facilitate assembly.

The air transfer port distributes air to the entire gun and has 1/8" N.P.T. ports at the front

and rear of the gun. This also contains a gun filter. Clean the filter every six (6) months with

alcohol.

The air assist fitting port is where the 10-32 air fitting is screwed into for the optional air

assist elbow. It is located on the right-hand side of the gun.

Solenoid Housing

The solenoid housing serves three functions. First it encloses and protects the solenoids,

secondly it holds the circuit board and third it connects the body and the grip frame. The solenoid

housing is held to the body using four 10-32 Phillips head cap screws. It is important not to over

tighten these screws as thread damage may occur. The circuit board is mounted to the solenoid

housing using screws and should not be removed or adjusted. The circuit board is coated with a

water-repellent coating to prevent problems in wet playing conditions. The timing of the gun is

preset at the factory.

A small green LED is located on the side of the solenoid housing. This is the battery life

indicator. It will light up continuously when the battery needs replaced. In front of the LED light is

the on/off battery switch. This switch acts as the gun’s safety.

If you have purchased a Shocker Sport Turbo, your solenoid housing will have a 3-way

switch protruding from the front of it. This is the Selective Mode switch. It allows you to select

between Semi-Automatic and Turbo. With the switch in the center position the gun is in Semi-

Automatic mode, the gun shoots once per trigger pull. Moving the switch to the left or right position

when you are facing the back of the gun sets Turbo mode.

Two switch covers are provided with the Shocker Sport , the tournament cover does not

allow the modes to be changed during play. The recreational cap is exposes the switch to allow

changing modes during play.

Grip Frame

The Grip Frame contains the trigger and battery. It is held to the solenoid housing with two

1/4"-20 screws. The front screw can be replaced with a 1/4"-20 stud and a handle. The batteries

are replaceable and can be purchased through Smart Parts or any Smart Parts Authorized

dealers. NOTE: It is highly recommended that you turn off your on/off switch after each day of

play. This will greatly extend the life of the battery—if you do not turn off your battery the power

will slowly drain. With normal care and usage the batteries should last at least 100,000 shots.

There are holes on the bottom of the grip frame for a standard bottomline fitting.

4

General Cleaning and Lubrication

The body of the gun should be cleaned off with a damp cloth. In the unlikely event of a ball

break, the bolt can be removed when the gun is degassed and a squeegee can be run through the

entire upper chamber to clean out the paint residue. DO NOT run the gun under water to clean out

broken paint.

If you should ever lose or damage an o-ring or seal in your Shocker or your Shocker

regulator you may purchase o-ring kits from Smart Parts. They are available in partial and

complete kits for both the Shocker regulator and the Shocker.

Your Shocker will need to be disassembled and re-lubricated with a LIGHT coat of Dow

Corning 33 silicon grease after each day of play! The main parts that need greased are the bolt,

the firing piston and the fill poppet. Proper lubrication is vital to the performance of your

Shocker. If it is not lubricated thoroughly it will not perform at its optimum level! This may

also result in premature failure of the o-rings.

To lubricate the bolt you must unscrew it from the gun. Then using your finger work a small

amount of grease into the holes in the body of the bolt, onto the bolt shaft and on the O-rings

around the outside of the bolt cylinder body. After this is done work the bolt head back and forth to

distribute the grease throughout the assembly.

To lubricate the firing piston (10), first remove the firing cylinder (9) from the gun using a

large flat headed screwdriver. (Note: The firing cylinder is located underneath the barrel on the

front of the gun.) Next using a small pair of needle nosed pliers remove the firing piston from the

firing cylinder. After it is removed spread a light coating of grease on all the o-rings and on the

firing piston guide (11). After this is done replace the firing piston and the firing cylinder.

To lubricate the fill poppet (13) first remove the fill poppet seat (12) from the rear of the gun

using an adjustable wrench. The fill poppet seat is located below the bolt. Once the seat is

removed you must remove the fill poppet guide (14) using a flat bladed screwdriver while holding

the housing with an adjustable wrench. Once the cap is removed you should see the end of the fill

poppet and the fill poppet bearing (19). Remove these items with a pair of needle nosed pliers.

Once you have removed the poppet, spread a light coating of grease on the poppet and the poppet

bearing and reassemble the poppet housing. Finally reinstall the poppet housing into the gun.

Anti-siphon Information

An anti-siphon tube is a tube that is installed in a CO2 tank’s valve in order to help prevent

liquid CO2 from entering the system. The tube is screwed into the back of the valve and bent so

that the end of the tube will be pointing up when the tank is screwed into the gun. When the valve

is completely screwed into the gun mark an “ X” on the outside of the valve (or on the outside of the

tank) near the neck to indicate the up position of the tube inside the tank and to also show that

the tank is an Anti-Siphon Tank. NOTE: Tanks with anti-siphon tubes should only be used on the

cradle or fitting that it was set-up for. If you use an anti-siphon tank on a different bottle adapter,

there is a good possibility that the tube will be oriented incorrectly and draw liquid CO2. Anti-siphon

equipped tanks should never be used on remote systems.

Anti-siphon tubes should only be installed by QUALIFIED AIRSMITHS. Please do not

attempt to install an anti-siphon tube on your tank, have a professional install it for you. If you

need more information regarding this matter please feel free to contact your local paintball field or

Smart Parts at (724) 539-2660.

5

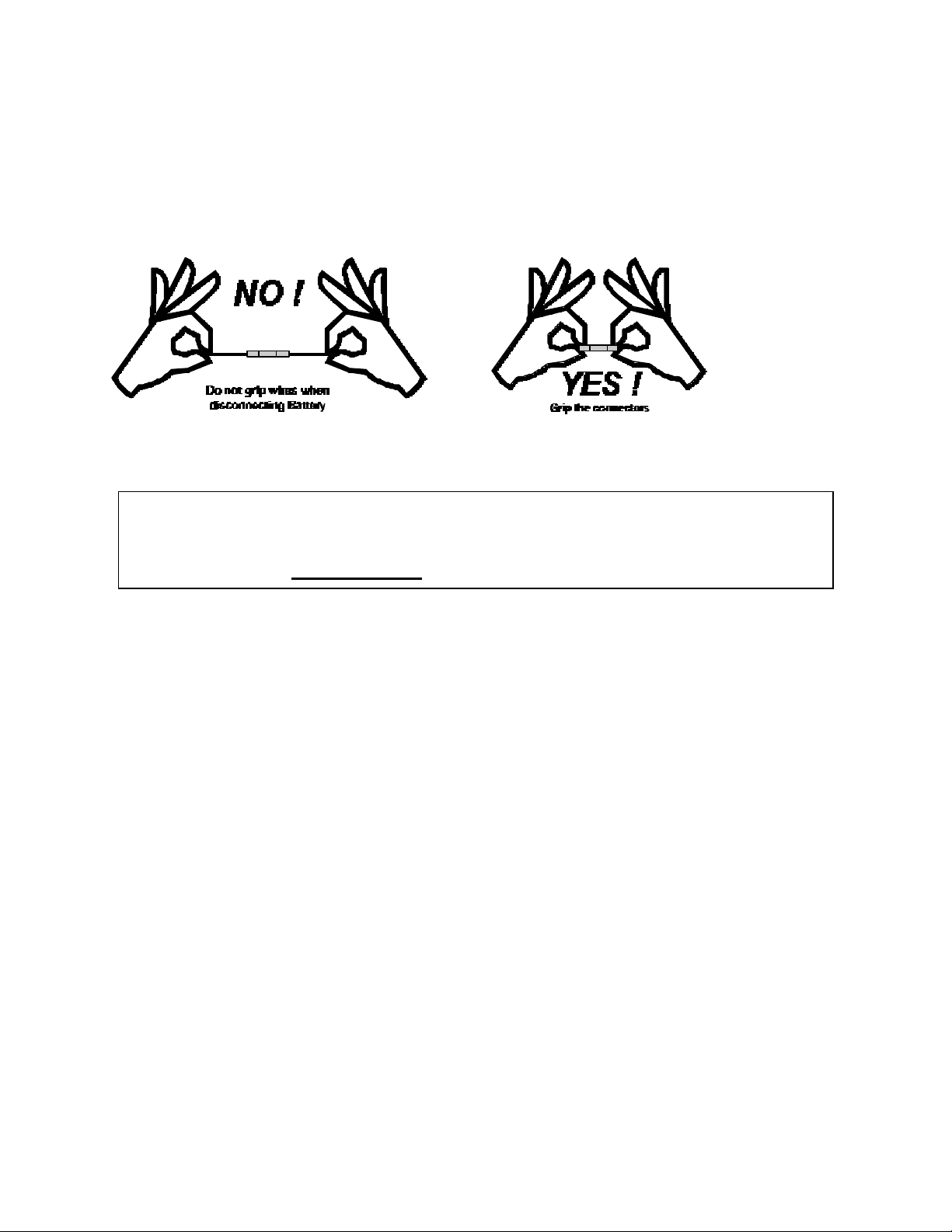

Battery Pack Removal and Replacement

The battery pack is located in the grip frame and can be replaced easily. In order to change

the battery pack one side of the grip must be removed. To do this you must use a Phillips head

screwdriver and remove the two screws in the side of the grip frame holding the grip on. Once this

is done you can pull the grip back and see the battery pack. Disconnect the battery pack by simply

unplugging the connector-plug. Note: It is important that the on/off switch be turned off after each

day of play. Replacement battery packs are available through Smart Parts and their distributors.

Disassembly of the Shocker Sport

Before attempting any disassembling of the Shocker Sport : remove all

sources of paint and air, remove the barrel, and disconnect the battery pack.

Failure to follow these precautions may result in damage to the gun and/or

NN grievous injury NN to operator or bystanders.

The disassembly of the Shocker Sport into its three main parts is easy. Usually it is not

necessary to remove the grip frame and the solenoid housing from the body to do normal

maintenance of the components in the body. If you need to access the body or firing chamber skip

down to the second paragraph in this section.

The first step is to remove the grip frame from the solenoid housing. This is done using a

5/32” Allen wrench to loosen and remove the two screws holding the two parts together. If you

have a front handle it takes the place of the front frame screw. Note: Use caution when separating

the grip frame from the solenoid housing. The spring détente in the safety may come out. The

battery pack must also be disconnected from the circuit board. The next step is to separate the

solenoid housing from the main body. The four body screws must be loosened and removed using

a Phillips screwdriver. Once this is done the solenoids must be disconnected from the circuit

board. Disconnecting the solenoids is accomplished by unplugging the connector from the board

itself. Now you have separated the gun into its three main parts.

The body of the gun is the only part that can really be disassembled any further. The first

and easiest part to remove is the bolt. To remove the bolt, simply grasp the knurled end and

unscrew. A schematic of the bolt and its replacement seals is shown on page 13, figure 1.

The next step is to remove all the parts to the firing chamber. The first part of this is the

firing piston housing. This is located beneath the barrel in the front of the gun. The firing piston

housing is removed using a flat head screwdriver, once the threads are out the part can be

removed by simply pulling on it. Note: Once this part is remove the firing rod may fall out of the

gun. Inside the housing is the firing piston. To remove the piston grasp the end of it using a pair

of needle nosed pliers. The firing piston housing is shown on page 13, figure 2.

The poppet housing is the next part that can be remove from the marker body. To remove

this use a 7/8” open-ended wrench and turn counter clockwise. Again once the threads are out the

part can be removed by simply pulling on it. To access the poppet, the poppet guide cap must be

Loading...

Loading...