SMART MAX GEOSYSTEMS DE Series Repair Manual

0

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

Theodolite Repair Manual

INDEX

INDEX ........................................................................................................................... 0

1. Preface ....................................................................................................................... 1

2. Precautions ................................................................................................................. 2

3. Product Instruction ..................................................................................................... 3

3.1 External Components ........................................................................................ 3

3.2 Display And Keypad ......................................................................................... 4

4. Specifications Check And Adjustment ...................................................................... 5

4.1 Plat Vial ...................................................................................................................... 5

4.2 Circular Vial .............................................................................................................. 7

4.3 Laser Plummet .................................................................................................. 8

4.4 Inclination Of Telescope Reticle ..................................................................... 10

4.5 Laser Alignment Component .......................................................................... 11

4.6 Perpendicularity Between Line Of Sight And Horizontal Axis (C) ................ 13

4.7 Check of 2C .................................................................................................... 14

4.8 Vertical Index Difference (I) ........................................................................... 15

4.9 Vertical Index Difference Compensation ........................................................ 16

5. Disassemble the Inatrument ..................................................................................... 19

6. Circuit Section Check .............................................................................................. 25

6.1. Adjusting Tools ...................................................................................................... 25

6.2. Adjusting Method .......................................................................................... 25

6.2 Mainboard ....................................................................................................... 26

7. Failure Maintenance ................................................................................................ 27

7.1 Common Failure ............................................................................................. 27

7.2 Error Code And Failure Maintenance ............................................................. 29

1

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

1. Preface

The DE Series electronic theodolite uses the incremental grating and absolute

encoder system for angle measurement. Microcomputer technology is employed to

realize measurement, calculation, display, storage and other functions. Horizontal or

vertical angle and other measurement results can be displayed at the same time. There

is variety of modes to survey the angle, slope, etc.

The DE Series can be widely applied to the class 3/4 triangle survey. It can also be

used in various engineering surveys, such as railway, highway, bridge, water

conservancy, mine, etc. and the installation of buildings and large equipments, as well

as cadastral and topographic surveying.

This manual is applicable to DE2A, DE2A-L, DE2B, DE5A, DE5B, DE10A,

DE10B and other DE Series electronic theodolite. The numbers 2, 5, 10 means the

precision of angle measurement; A means with compensator; B means without

compensator.

2

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

2. Precautions

1. When failure occurs, please follow the instruction of this manual and debug as the

photos guidance. If the instrument damage is caused by personal behavior going against

service manual, the responsibility is definitely belongs to individual.

2. If the instrument failures involving some main components, such as mainboard,

grating disk, reading terminal, telescope LCD, etc., please replace the whole component.

Do not repair it.

3. When replacing components, please strictly according to the service manual. Do not

disassemble the instrument unauthorized if the repairing method is not involved in this

manual. In this case, please send it back to our company for repair.

4. After replacing components, you should calibrate the overall specifications. Before

using the instrument, please confirm all the specifications eligible.

5. Electronic theodolite is a precision instrument. If you don’t have professional

maintenance skills or equipment, do not repair the total station unauthorized to avoid

damaging it.

6. This service manual is only for the DE Series of Smart Max Geosystems CO.,Ltd.

Anything unclear during maintenance, please contact us.

3

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

3. Product Instruction

3.1 External Components

4

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

3.2 Display And Keypad

a. Display

The adopted LCD can display angle, words, date, time or other information. There

are ten buttons on display. The red button is a power switch button. Under angle

measurement mode, other functions are illustrated as follow:

L/R: switch left/ right of horizontal angle measuring direction

HOLD: lock horizontal angle measurement result

%: switch vertical angle/ slope percent

OSET: set horizontal angle as 0°00′00″

¤-▲: turn on/ off directing laser

¤-▼: turn on/ off laser plummet

¤-◆: turn on/ off background light of LCD

¤-ENT: enter main menu

¤-ENT-ENT: save and exit

b. Illustration Of Symbols On Screen

: automatic shutdown symbol

: battery power symbol

: special function symbol;

shows when press ¤ button and disappears after another press

%: slope percent

b-OUT: vertical angle over compensated

OUT: slope over ±100%

m: unit in meters

°, ′, ″: unit of angle

5

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

4. Specifications Check And Adjustment

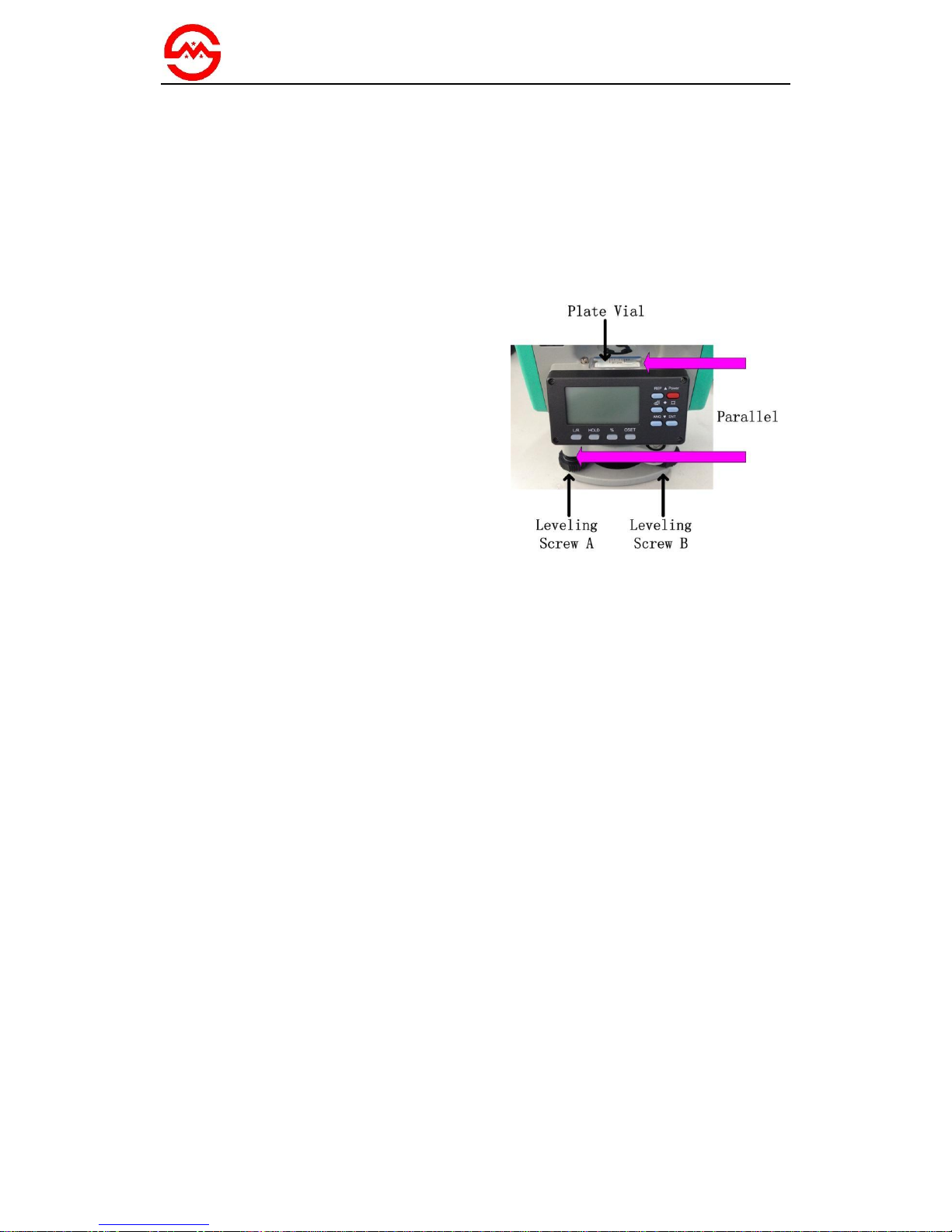

4.1 Plat Vial

a. Check

(1) Place the instrument on a stable

device (a tripod or calibration table) and

fix it.

(2) Parallel the plate vial and the line

between two out of three leveling screws.

Adjust the two screws to keep the bubble

in the middle of plate vial.

(3) Rotate the instrument around the

vertical axis and observe the offset of

bubble. If the bubble remains in the middle,

no adjustment is necessary. Otherwise, the

following adjustment is required.

Picture A

6

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

b. Adjust

(1) Place the instrument on a stable

device.

(2) Rotate the instrument to parallel plate

vial and the line connecting two leveling

screws A, B. Adjust screws A and B inside

or outside simultaneously to make plate

bubble in the middle.

(3) Rotate the instrument 90° to plumb

plate vial and the line between two

leveling screws A, B. Then adjust screw C

to make plate bubble in the middle. Repeat

step (2) and (3) until the bubble remains in

the middle in these two directions.

(4) Rotate the instrument 180°. When the

bubble is not stop in the middle, tweak

adjusting screw with a adjusting pin to

make plate bubble move half of the offset

back.

(5) Repeat step (2) (3) (4) until the bubble

keeps in the middle of vial in all directions.

Tweak the adjusting screw

with an adjusting pin

Picture B

Adjusting Process

7

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

4.2 Circular Vial

a. Check

(1) Place the instrument on a stable

device.

(2) Check and adjust the plate vial.

(3) Observe the bubble in circular vial. If

the bubble remains in the center, no

adjustment is necessary. Otherwise, the

following adjustment is required.

b. Adjust

(1) Place the instrument on a stable

device.

(2) Check and adjust the plate vial.

(3) Tweak two adjusting screws with a

correction pin to keep the bubble centered

in the vial: loosen the screw (one or two)

opposite with bubble deflective direction;

tighten the screw on the direction

accordant deflective until circular bubble

is centered.

Note: Be gentle while using adjusting pin

to calibrate screws. The force power fixing

two adjusting screws must be consistent

when circular level is centered at last.

Picture C

8

Smart Max Geosystems CO.,Ltd

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

4.3 Laser Plummet

a. Check

(1) Place the instrument on a tripod and

fix it.

(2) Put a piece of paper with two

crisscross lines on it right below the

instrument.

(3) Turn on the laser plummet and adjust

the laser luminance to a proper level.

(4) Adjust 3 leveling screws to make the

laser spot coincides with the intersection

point of the paper.

(5) Rotate the instrument around the

vertical axis. If the laser spot always

coincides with the intersection point, no

adjustment is necessary. Otherwise, the

following adjustment is required.

b. Adjust

(1) Adjust 3 leveling screws to make the

laser spot coincide with the intersection

point.

(2) Rotate the instrument 180°and

remove the cover of laser plummet. Adjust

4 screws to make the laser spot moves half

of the offset back.

(3) Repeat step (1) and (2) until the laser

spot coincides with the intersection point

in all directions.

Picture D (a)

Loading...

Loading...