SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

SMART MAX GEOSYSTEMS

DE2A & DE2A-L Theodolite Manual

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

Precaution

1) If the instrument has not been used for a long time, check it

regularly(3 monthes).

2) Avoid shocking or bumping.

3) No using in high dusty, not well ventilated, and easy burning

environment.

4) No dismount and mount the instrument by yourselves.

5) Prohibit to see the sun with telescope.

6) Cover with umbrella in burning sun or rainy day.

7) Cover the instrument with rainy cover.

8) Power off before taking off battery, or the data will be lost.

9) Place instrument the case and avoid humidity.

10) Prohibit move the instrument with tripod.

11) It will cause measuring result is not correct if there is leaves

and obstacle between the target and the instrument.

12) Place the instrument like the picture below:

13) Contact me if you got any problem.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

Contents

1. Description of All Parts………………………………1

1.1 Name of Parts ……………………………………………1

1.2 Display …………………………………………………3

1.3 Operation Key ………………………………………… 4

1.4 RS 232 ……………………………………………………6

2. Battery……………………………………………………6

2.1 Battery Replacement……………………………………6

2.2 Battery Recharging ………………………………………7

3. Measurement Preparation …………………………7

3.1 Instrument Setting Up……………………………………7

3.2 Instrument Leveling………………………………………7

3.3 Centering with Optical Plummet…………………………9

3.4 Eyepiece Adjustment and Object Sighting………………9

3.5 Power on ………………………………………………10

3.6 Power off………………………………………………10

4. Angle Measurement …………………………………11

4.1 Measuring Horizontal Angle Right and Vertical Angle …11

4.2 Switching Horizontal Angle Right/Left …………………12

4.3 Setting Horizontal Angle ……………………………13

4.4 Vertical Angle Percent Grade (%) Mode ………………14

4.5 Compasses (vertical angle) ……………………………15

4.6 Remeasuring Horizontal Angle…………………………15

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

5. Distance Measurement………………………………17

6. Distance Measurement through the crossline in

the telescope………………………………………… 19

7. Laser Measurement…………………………………20

7.1 Orientation Measurement ……………………………… 20

7.2 Angle Designment……………………………………20

7.3 Zeith Measurement ……………………………………21

7.4 Level Measurement ……………………………………21

8. Parameter Setting Up………………………………22

8.1 Enter into Setting up Parameter ………………………22

8.2 Setting up Parameter ……………………………………23

9. Check & Adjustment………………………………24

9.1 Check & Adjustment of Plate Vial………………………24

9.2 Check & Adjustment of Circular Vial …………………26

9.3 Check & Adjustment of Optical Plummet………………26

9.4 Check & Adjustment of Inclination of Reticle…………28

9.5 Check & Adjustment of discrepancy between twice

collimation errors(C)………………………………… 29

9.6 Check & Adjustment of Vertical Index(i angle) ………30

9.7 Check & Adjustment of the laser confocal and coaxial… 31

10. Technical Index………………………………………33

11. Packing List …………………………………………35

12. Erorr Code Instruction ……………………………36

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

1

1. Description of All Parts

1.1 Name of Parts

1.Telescope 2.Main body 3.Left Side Cover

4.Series No. 5.Optical Plummet 6.Circular Vail

7.Leveling Screw 8.Tribrach

9.Connection Knob on Tribrach 10.Soft Key

11.Display 12.Function Key 13.Plate Vial

14.Vertical Tangent Screw 15.Vertical Clamp Screw

16.Objective Lens

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

2

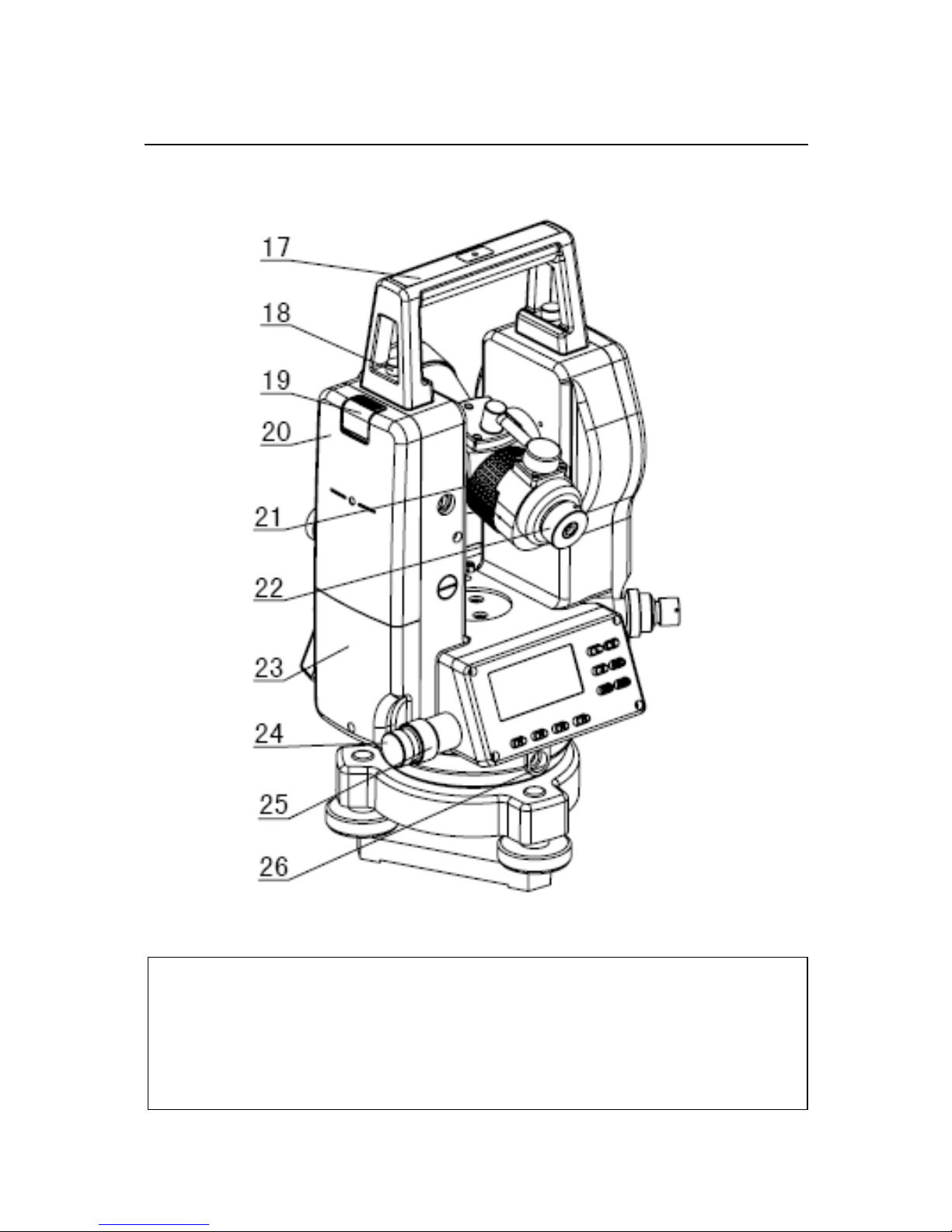

17. Handle 18.Handle Screw 19. Battery locking Lever

20. Battery 21. Grip 22. Eyepiece

23.Right Side Cover 24. Horizontal Tangent crew

25. Horizontal Clamp Screw 26.RS232 Port

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

3

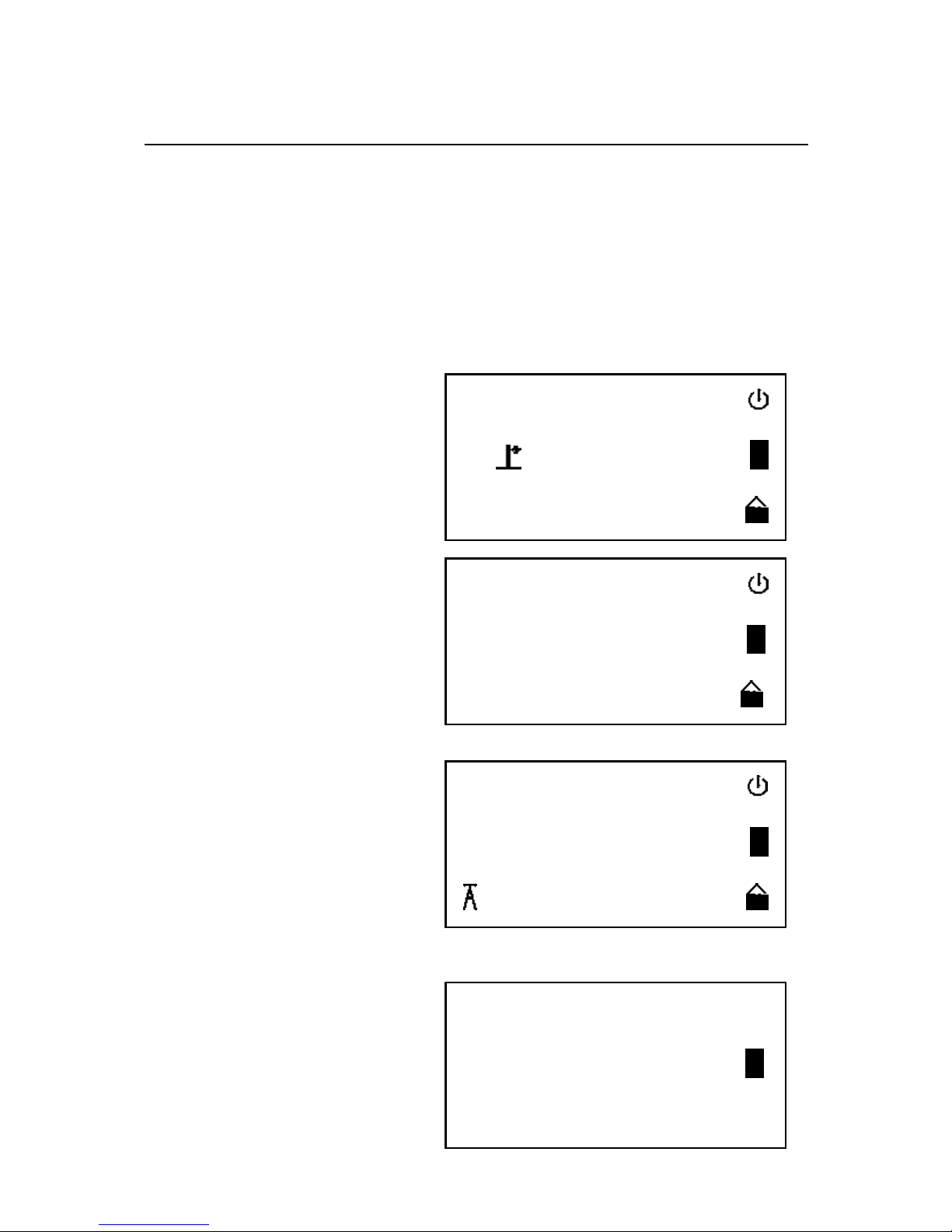

1.2Display

The figure LCD can display angle,characters,date and time,etc.

There are two modes on display:Measurement Mode & Menu

Mode.

Display(example):

① Angle

Measurement Mode

② Distance

Measurement Mode

③Remeasurement Mode

④Menu Mode

ANG 08-01-02 12:00

V : 81°54′21″

HR : 157°33′58″

08-01-02 12:00

n - 0 T-0

HR : 57°33′58″

08-01-02 12:00

S.E.T.-1

OFF

DIST 08-01-02 12:00

0.000 m

HR : 157°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

4

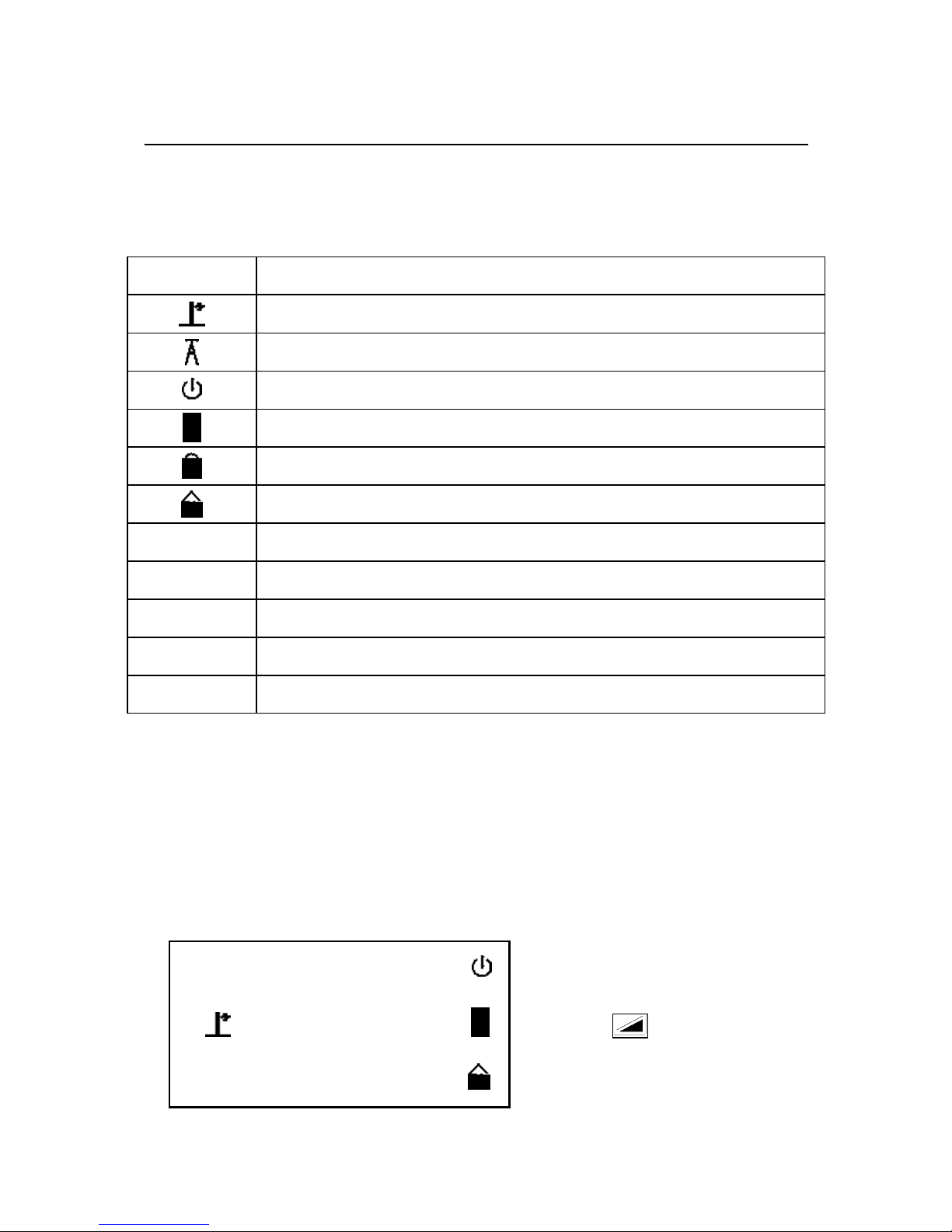

Symbol

Contents

Vertical compensation

Horizontal remeansure

Automatic Power off

Battery

Horizontal locked

Special Function,press ¤ twice,it will be disappeared

%

Gradient Display

b-OUT

Vertical angle is over the compensation

OUT

Slope is over ±100%

m

Meter unit

°′″

Set 360°as angle unit

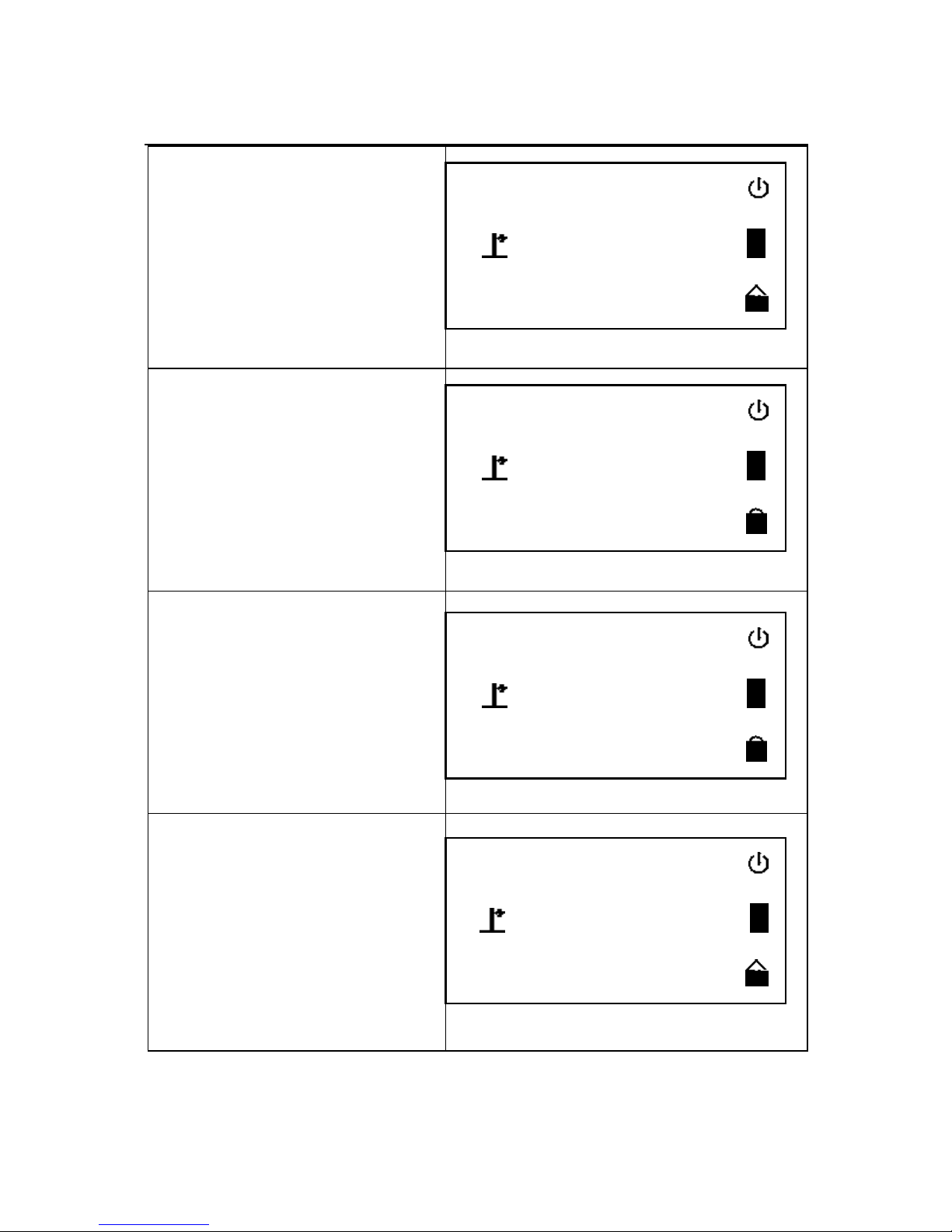

1.3 Operation Key

The function of the soft key is different in different

measurement mode.

①Angle Measurement Mode

REP▲ Power

◆ ¤

ANG 08-01-02 12:00

V : 81°54′21″

HR :157°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

5

ANG▼ ENT

L/R HOLD % 0SET

Soft Key

Function

L/R

Switches R/L rotation of horizontal angle

HOLD

Hold the horizontal angle

%

Vertical angle percent grade(%) mode

0SET

Set horizontal angle as 0°00′00″

②Distance Measurement Mode

REP▲ Power

◆ ¤

ANG▼ ENT

SD HD VD TR

Soft Key

Function

SD

Enter into SD Measurement

HD

Enter into HD Measurement

VD

Enter into VD Measurement

TR

Enter into TR Measurement

DIST 08-01-02 12:00

0.000 m

HR : 157°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

6

③Special function Measurement mode(This will be valid only

in the Angle Measurement Mode)

Soft Key

Function

First press ¤, when it

display , press▲

Turn on /off laser alignment

First press ¤, when it

display , press▼

Turn on /off laser plummet

First press ¤, when it

display , press◆

Turn on /off LCD

First press ¤, when it

display , press ENT

Enter into Menu mode,press ENT

one more time will save and exit

1.4 RS232

RS232 is used to connect the Theodolite with computer or PC to

transfer measured data to computer or PC.

2. Battery

2.1 Battery Replacement

1. Battery Insert

Insert battery correctly. Check and

insert battery holder true to side into

the housing.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

7

2. Battery Removement

Remove battery and replace.

2.2 Battery Recharging

1. Insert recharger into battery’s hole.

2. Insert the plug of the recharger into 220V AC power supply. It

shows green light after finishing recharging.

3. Cut the power supply of the recharger and drew the battery out

from the recharger.

3. Measurement Preparation

3.1 Instrument Setting Up

1. Setting up the tripod.Pull out to

required length and tighten screws.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

8

2. Place the INSTRUMENT onto

the tripod head. Tighten central fixing

screw of tripod.

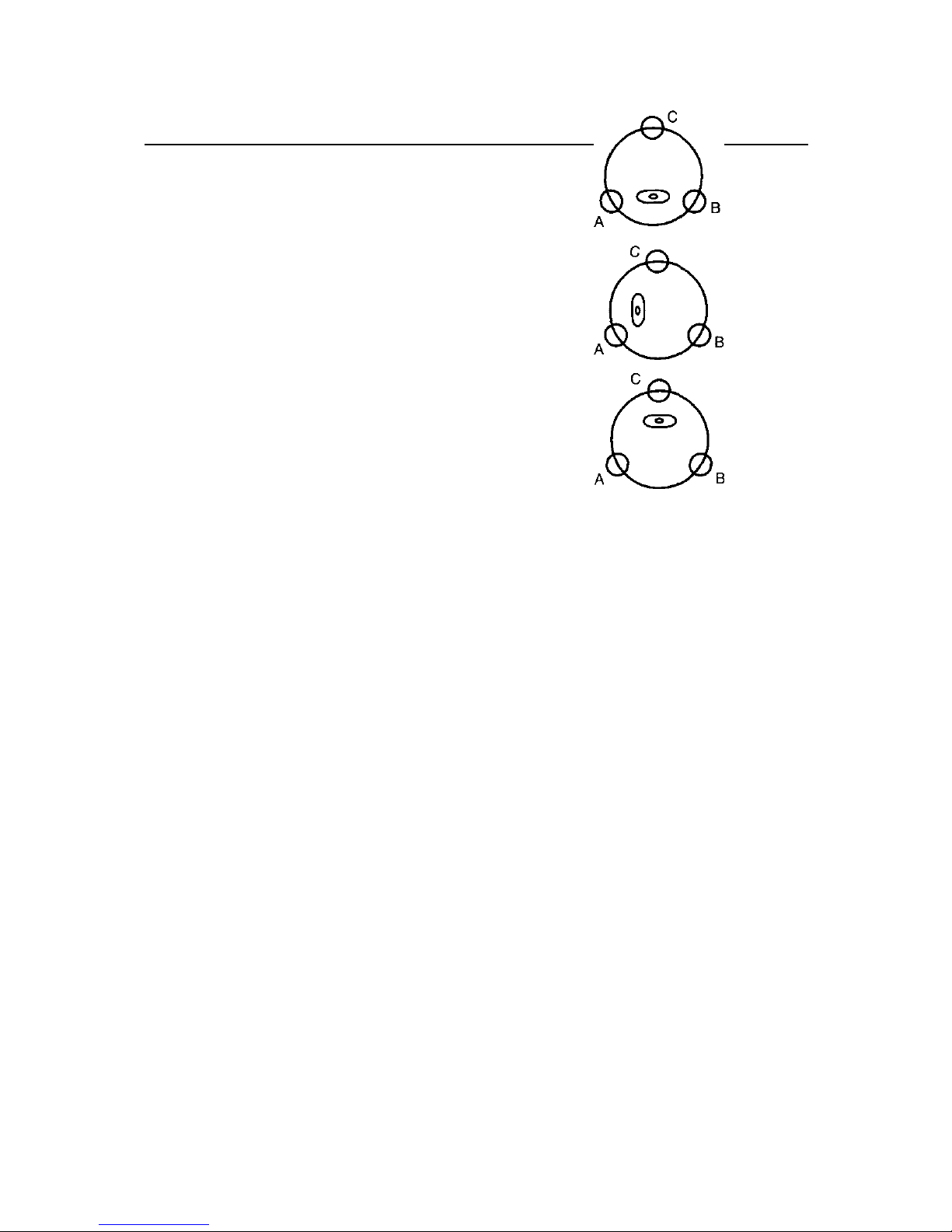

3.2 Instrument leveling

1.Level the instrument with circular vial

a. Turn the leveling screw A and B

to move the bubble in the circular vail.

The bubble is now located on a line

perpendicular to a line running through

the centers of the two leveling screw

being adjusted.

b. Turn the leveling screw C to bring

the bubble to the center of the circular

vail.

2. Level the instrument with plate vial

a. Rotate the instrument horizontally

by loosening the Horizontal Clamp

Screw and place the plate vial parallel with the line connecting

leveling screw A and B, and then bring the bubble to the center of

the plate vial by turning the leveling screws A and B.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

9

b. Rotate the instrument 90º (100g) around its vertical axis and

turn the remaining leveling screw or leveling C to center the

bubble once more.

c. Repeat the procedures 1& 2 for each 90º (100g) rotation of the

instrument and check the whether the bubble is correctly centered

for all four points.

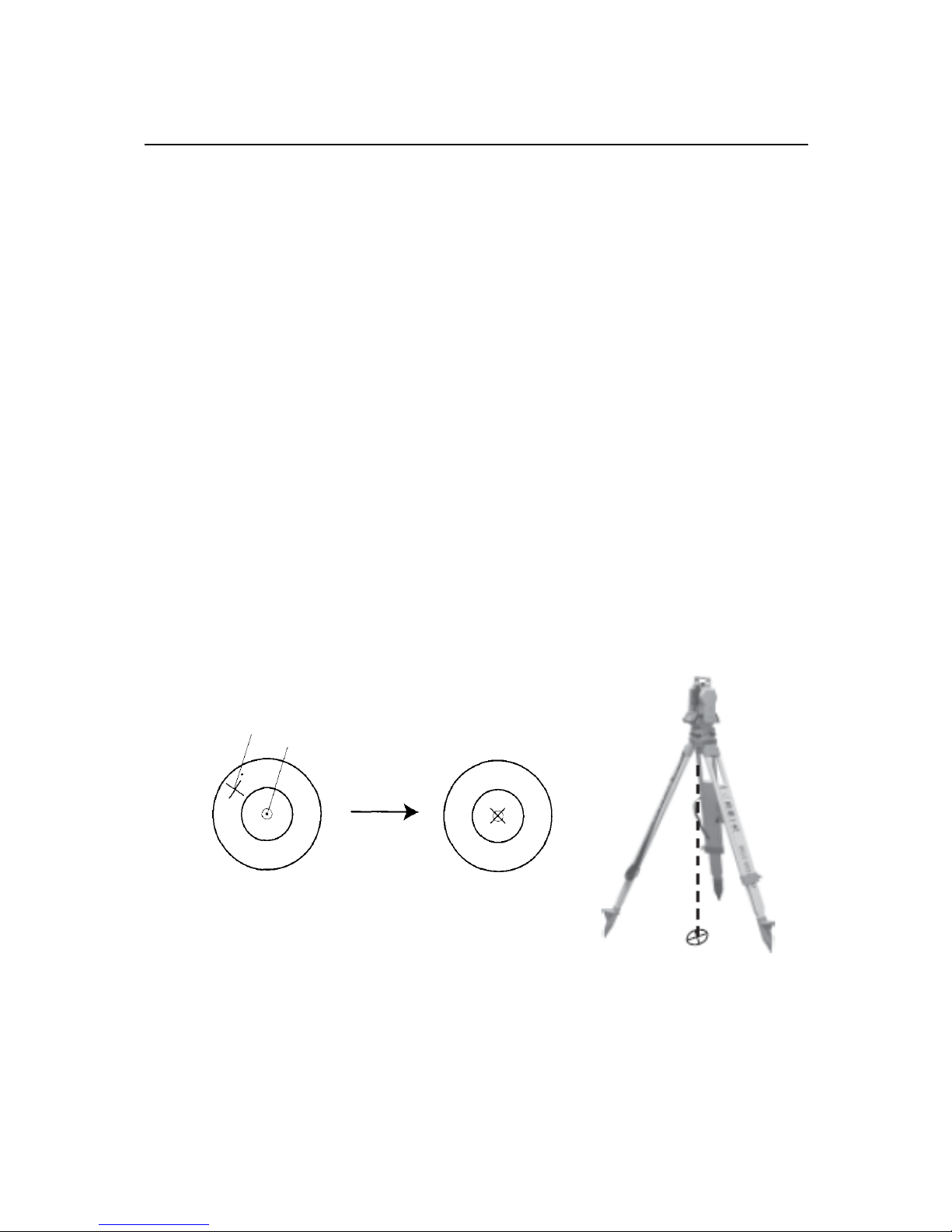

3.3 Centering by optical plummet

Adjust the eyepiece of the optical plummet telescope to your

eyesight. Slide the instrument by loosening the tripod screw,

place the point on the center mark of the optical plummet. Sliding

the instrument carefully not to rotate that allows you to get the

least dislocation of the bubble.

Note:Centering by foot screw first and then leveled-up by

tripod.

T/S Point

center

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

10

3.4 Eyepiece Adjustment and Object Sighting

1. Sight the Telescope to the sky and rotate the eyepiece tube to

make the reticle clear.

2. Make the target image clear with the telescope focusing

screw. If there parallax when your eye move up, down or left,

right, that show the diopter of eyepiece lens or focus is not

adjusted well and accuracy will be influenced, so you should

adjust the eyepiece tube carefully to eliminate the parallax.

3.5 Power on

1.Leveling INSTRUMENT

2. Press the Power key (red

k

ey).

3. Turn telescope to

initial the INSTRUMENT.

Power

08-01-02 12:00

V 0 S.E.T.

ANG 08-01-02 12:00

V : 81°54′21″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

11

Confirm the battery is full,

if not so,please replace and

recharge the battery.

3.6 Power off

Press the Power key (red key).

4. Angle Measurement

4.1 Measuring Horizontal Angle Right and Vertical

Angle

Operation Procedure

Display

①Press ANG to enter into

Angle Measurement.

Aim at the first target A

测角 08-01-01 12:12 Φ

+垂直: 81°54′21″

水平右 : 157°33′58″

ANG 08-01-02 12:00

V : 81°54′21″

HR : 157°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

12

②Press 0SET to set

horizontal reading of target

A as 0°00′00″

③Aim at the second target

B. The required V/H angle

to target B will be

displayed.

★ Press ENT,the vertical and horizontal angle can be sent out

through RS232.

How to Collimate (Reference)

1. Point the telescope toward the light. Turn the diopter ring and

adjust the diopter so that the cross hairs are clearly observed.

(Turn the diopter toward you first and then backward to focus).

2. Aim the target at the peak of the triangle mark of the sighting

collimator. Allow a certain space between the sighting collimator

and yourself for collimating.

3. Focus the target with the focusing knob.If parallax is created

between the cross hairs and the target when viewing vertically or

horizontally while looking into the telescope, focusing is

incorrect or diopter adjustment is poor. This adversely affects

ANG 08-01-02 12:00

V : 81°54′21″

HR : 0°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HR : 57°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

13

precision in measurement or survey; eliminate the parallax by

carefully focusing and using diopter adjustment.

4.2 Switching Horizontal Angle Right/Left

Display

①Press ANG to enter into

Angle Measurement.

②Press L/R. The mode

Horizontal angle Right

(HR) Switches to (HL)

mode.

★ Press L/R to switch Right mode and Left mode.

★ Press ENT,the vertical and horizontal angle can be sent out

through RS232.

4.3 Setting Horizontal Angle

Setting by Holding the Angle

Operation Procedure

Display

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HL :260°00′00″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

14

①Press ANG to enter into

Angle Measurement.

②Set the required

horizontal angle, using

Horizontal tangent

screw.Then press HOLD.

③Aim at the target which

need to be set up the angle

④Press the ENT to finish

holding the horizontal

angle.The display returns

back to normal angle

measurement mode.

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

15

4.4 Vertical Angle Percent Grade (%) Mode

Operation Procedure

Display

①Press ANG to enter into

Angle Measurement.

②Press % to enter into

Slope Measurement.

★The display mode switches when pressing % key every time.

★While the measurement is carried out over ±45º(±100%)

from the horizontal,the display shows <OUT>.

4.5Compasses (vertical angle)(Refer to Parameter

Setting Up)

Vertical angle is displayed as shown below:

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 50 %

HR :100°00′00″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

16

4.6 Remeasuring Horizontal Angle

Operation Procedure

Display

①Press REP to get into the

mode of Horizontal Angle

Remeasurement

08-01-02 12:00

n - 0 T-0

HR :57°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

17

②Aim at the Target A

Press 0SET(one time)to

set the reading of A as:

0°00′00″

③Aim at the Target B by

Horizontal Tangent and

Clamp Screws.

Press ENT(one time)to

remain the horizontal angle

and it will be saved

④Aim at the Target A

again

Press 0SET (one time)to

set the reading of A

as:0°00′00″.(It begins the

first remeasurement.)

⑤Aim at the Target B

again by Horizontal

Tangent and Clamp Screws

Press ENT(one time)to

remain and save the

n-1:the beginning of the angle

n-0: the ending of the angle

T-0 ~ T-8: the times of

remeasurement

08-01-02 12:00

n - 1 T-0

HR : 0°00′00″

08-01-02 12:00

n - 1 T-1

HR : 0°00′00″

08-01-02 12:00

n - 0 T-2

HR : 20°00′01″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

18

horizontal angle.

⑥Repeat step ④~⑤ to

do the required

remeasurement

⑦Measurement is over.

Press ANG to enter into

Angle Measurement.

★The remeasure times is limited,the Max is 9. It will show

“E-09” if more remeasurement done.Press REP and restart.

★When do remeasurement,it will display “E-08” if

︱Measured Value- Average Value ︱≥ 30″. Press REP and

restart.

5. DISTANCE MEASUREMENT

Please confirm the cable can be connected with our Distance

Meter before measurement.

Operation Procedure

Display

①Press to enter into

the mode of distance

DIST 08-01-02 12:00

0.000 m

HR :157°33′58″

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

ANG 08-01-02 12:00

V : 81°54′21″

HR : 100°00′00″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

19

measurement

②Aim at Prism center.

③Press L/R to start SD

Measurement while press

ENT to stop.

④Press HOLD to start

HD Measurement while

press ENT to stop.

⑤Press % to start VD

Measurement while press

ENT to stop.

⑥Press 0SET to start

Tracking Measurement

while press ENT to stop.

SD 08-01-02 12:00

22.000 m

HR :157°33′58″

HD 08-01-02 12:00

10.000 m

HR :157°33′58″

VD 08-01-02 12:00

3.000 m

HR :157°33′58″

DIST 08-01-02 12:00

20.00 m

HR :157°33′58″

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

20

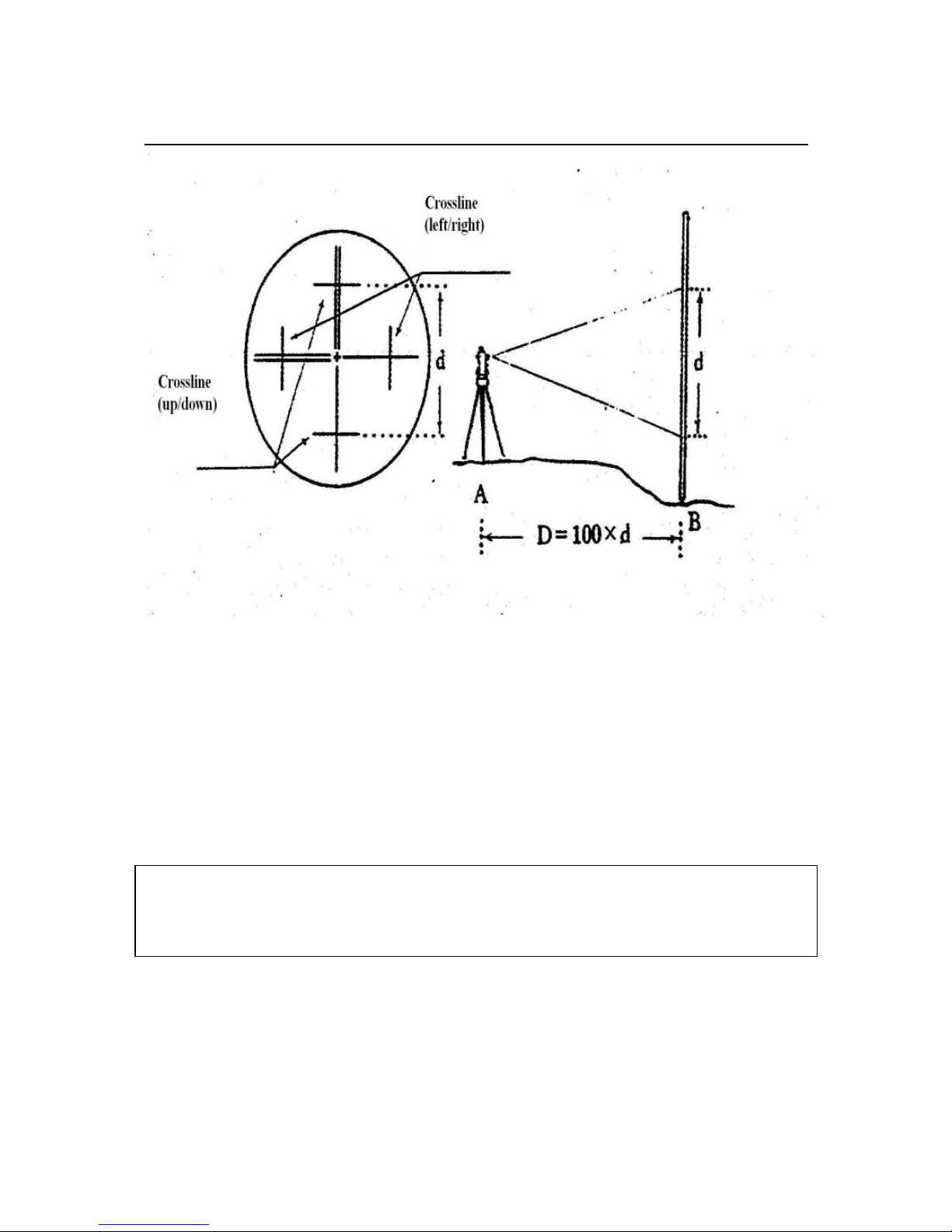

6. Distance Measurement through the

crossline in the telescope

Through the sightline (up/down or left/right) in the telescope

to measure the distance between the target and the

instrument.(Accuracy ≤ 0.4%D)

⑴ Place the instrument at point A,and place the leveling staff

at B.

⑵ Read the intercepted distance of the crossline(up/down or

left/right) on the leveling staff as “d”.

⑶The horizontal Distance between A and B is D(D= 100×d.)

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

21

Note: 100 means the Stadia Proportion Constant of the

instrument. (But because of such a low accuracy,it can not be

used to measure distance which requires high accuracy.)

7. Laser Measurement

7.1 Orientation Measurement

Find out the other points on the line of the two known

points ,which should be based on the known two points,this is

Attention:Please don’t watch the laser with eyes directly,

when it is turned on!

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

22

Laser Orientation Measurement.

Steps as bellows:

1.Leveling the instrument, then power on.

2.Aim at the target through the horizontal Tangent & Clamp

Screws.Turn on the laser.The other points can be found out with a

board which can make the laser focus together.

7.2 Angle Designment

Angle Designment is based on the line of two points,then

design a horizontal angle according with the requirement.

Steps as bellows:

1.Leveling the instrument, then power on.This must be done on a

fiducial point.

2.Aim at another fiducial point carefully,and set the horizontal

angle as 0°00′00″.

3.Move the telescope to make the horizontal angle be the required

value.Turn the laser on,the laser and the fiducial line will make

up an angle.

7.3 Zeith Measurement

Set a point as a standard, the laser will be set up vertically,this is

Zeith Measurement.

Steps as bellows:

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

23

1.Take away the eyepiece, fit on the diagonal eyepiece, and

locked.

2. Leveling the instrument, then power on.This must be done on a

fiducial point.

3. Circumgyrate the telescope to make the vertical angle to

0°00′00″,turn the laser on.Then move the foucsing screw to make

the facula minimum,loosenthe horizontal clamp screw, move the

telescope,the geometry center of the facula’s movig track is the

Vertical Direction.

7.4 Level Measurement

1. Leveling the instrument, then power on..

2. Lock the telescope after it is on the horizontal direction,aim at

the target carefully.Turn on the laser,the red laser line can be used

as level line.

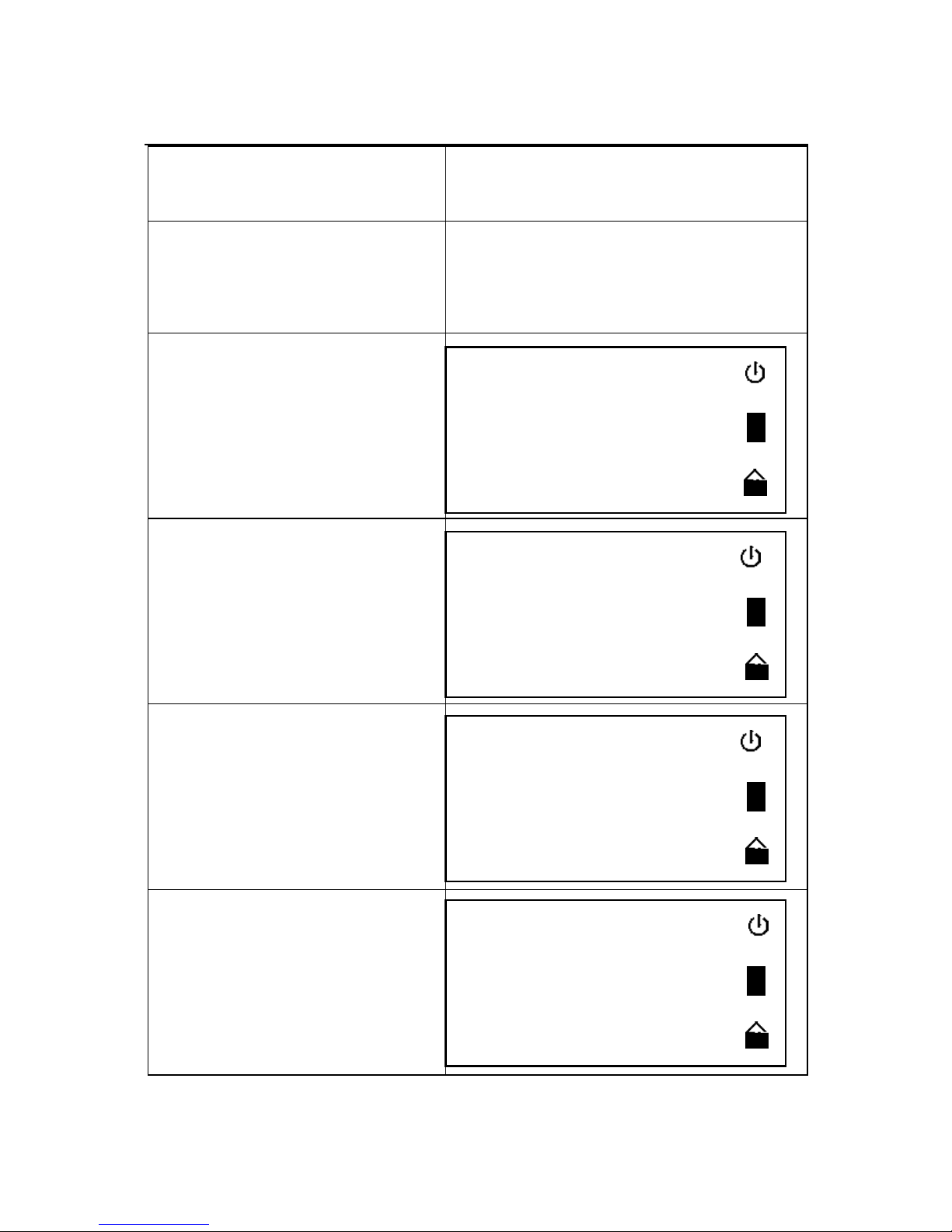

8. Parameter Setting Up

8.1 Enter into Setting up Parameter

Operation Procedure

Display

①Press ¤ and then press

ENT when in the angle

measurement mode to

08-01-02 12:00

SET-1

OFF

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

24

enter into Menu Mode.

② Press ◆ to choose

parameter which need to

be set up.

(Continuous press)

③Press▲、▼ to set up

parameter.

(Continuous press)

④Press ENT to save.

8.2 Setting up the Parameters

①SET-0:Power off Automatically

ON---The instrument will power off automatically if there is no

08-01-02 12:00

SET-1

OFF

08-01-02 12:00

SET-1

ON

ANG 08-01-02 12:00

V : 81°54′21″

HR :100°00′00″

★When Setting up Parameter, press ¤ to escape back to

angle measurement.The modified won’t be saved.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

25

operation within 30 minutes

OFF--- Not automatically power off

②SET-1:Compensator

ON---Turn on the compensator

OFF---Turn off the compensator

③SET-2:Position 0(Vertical Angle)

ON ---Zeith is 0°,the Horizontal will be 90° when turn left and

it will be 270° when turn right.

OFF---Zeith is 90°,the Horizontal will be 0° when turn left

④SET-3:Minimum Reading

1---Minimum Reading is 1"

5---Minimum Reading is 5"

10---Minimum Reading is 10"

20---Minimum Reading is 20"

⑤SET-4:Angle Unit

1---Set 360° as angle unit

2---Set 6400mil as angle unit

3---Set 400g as angle unit

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

26

9. Check & Adjustment

9.1 Check & Adjustment of Plate Vial

Check

① Rotate the instrument horizontally by loosening the Horizontal

Clamp Screw and place the plate vial parallel with the line

connecting leveling screw A and B, and then bring the bubble to

the center of the plate vial by turning the leveling screws A and B.

②Rotate the instrument 180°(200g)around its vertical axis.

Observe the bubble of plate vial. Fellow the steps below to adjust

it if the bubble is not in the center.

Remarks: SET-5 、 SET-6 、 SET-7 、 SET-8 、

SET-9means year,month,day,hour,minute(This is

optional )

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

27

Adjustment

① If the bubble of the plate vial moves from the center, bring it

half way back to the center by adjusting the leveling screw, which

is parallel to the plate vial. Correct the remaining half by

adjusting the screw of plate vial with adjusting pin.

② Confirm whether the bubble does is in the center by rotating

the instrument 180º.If not, repeat step ①.

③ Turn the instrument 180°(200g)and adjust the third screw to

center the bubble in the vial.

Half of deflection

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

28

9.2 Check & Adjustment of Circular Vial

Check

No adjustment is necessary

if the bubble of the circular

vial is in the center after

inspection and adjustment

of the plate vial.

Adjustment

If the bubble of the circular

vial is not in the center, bring

the bubble to the center by

using the adjusting pin to adjust

two bubble-adjusting screws.

9.3 Check & Adjustment of Optical Plummet

Check

①Set the instrument on the tripod and place a piece of white

paper with two perpendicular lines, then intersect drawn on it

directly under the instrument. Adjust the leveling screws so that

the center mark of the optical plummet coincides with the

intersection point of the cross on the paper.

Circular vial

Bubble-adjusting screw

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

29

②Rotate the instrument around the horizontal axis 180°(200g)

observe whether the center mark position coincides with the

intersection point of the cross. If the center mark always

coincides with intersection point, no adjustment is necessary.

Otherwise, the following adjustment is necessary.

Adjustment

①Take off protective cover of the optical plummet, you may see

four adjusting screws. Adjust four adjusting screws.

②Move woodscrew to make the center of optical plummet

coincides with ground point.

③Rotate the instrument around the vertical axis 180°(200g)

observe whether the center mark position coincides with the

intersection point of the cross. If the center mark always

coincides with intersection point, no adjustment is necessary.

Adjusting Screw (4 pcs)

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

30

Otherwise, repeat steps above mentioned.

9.4 Check & Adjustment of Inclination of Reticle

Check

①Set the instrument on a tripod and level it.

②Aim at target A with telescope(One point, 50m away).

③Observe point A moves along the vertical line of the reticle or

not by moving telescope up and down.. If so, no adjustment is

necessary. If not so, then need to adjust the reticle.

Adjustment

① Remove the eyepiece cover to expose the four reticle adjusting

screws.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

31

② Loosen the four reticle adjusting screws uniformly with an

adjusting pin. Rotate the reticle around the sight line and align the

vertical line of the reticle with point A. Tighten the reticle

adjusting screws.

③ Repeat the inspection and adjustment to see if the adjustment

is correct.

9.5 Check & Adjustment of discrepancy between

twice collimation errors(C)

Eyepiece

Reticle adjusting screws

Reticle adjusting screws

Note:Remember to check the index of the instrument after

adjusting.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

32

Check

① Set the instrument on a tripod and level it.

② Aim at cross line of the reticle of the collimator or a target

away. Observe left position and right position.

③ Calculate difference after getting horizontal angle reading (left

position) HI and(right position)HR

C =( HI – HR ± 180°)/2

If C ≤ 8",no adjustment is necessary;If C > 8",fellow these

steps to adjust it.

Adjustment

① Rotate fine motion screw in the right position and make the

reading is HR + C.

② Remove the eyepiece cover to adjust two adjusting screws,

which makes reticle coincides

with cross line of collimator or one target away.

③ Repeat check and adjustment until C ≤ 8".

C =( HI – HR ± 180°)/2

9.6 Check & Adjustment of Vertical Index Difference

( i angle)

(Inspect the item after finishing the inspection and

adjustment of section 9.4 and 9.5.)

Check

① Set the instrument on a tripod and level it.

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

33

② Sight object A in left position and read the Vertical angle value

VI. Rotate the telescope. Sight object B in right position and read

the Verticail angle value VR.

③ Calculating, i=(VI+VR-360°)/2

④If i ≤10",no adjustment is necessary. If i >10", adjust it.

Adjustment

(Please adjust through the software if the differences between

the index is too big.)

Operation Procedure

Display

① Keep to press L/R to

power on until right screen

occurs. Loose L/R

② Rotate telescope and

make vertical angle

passing 0.

Enter into the mode of V

ANGLE 0 SET

V 0 S.E.T.

S.E.T.-301

V: 90°00′00″

STEP - 1

V: 270°00′00″

STEP - 2

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

34

③Aim at target (left

position). Press ENT

④ Aim at target (right

position).Press ENT

Power on automatically.

⑤Finish adjustment.

Repeat,if not within

standard.

9.7 Check & Adjustment of the laser confocal and

coaxial

(This step was done after finishing the inspection and

adjustment of Item 9.4 and 9.5)

Laser confocal

Send the laser after aiming at the target,and then check the

facula’s diameter.It should be minimum.If it is not,loose the

screw on the laser pedestal,and move the pedestal until the facula

be smallest.

Laser coaxial

The crossline should be in superposition with the facula after

aiming at the target.Make the facula in the center of the crossline

through the four screws on the pedestal.(as the picture below)

1

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

35

2 4

3

10. Technical Index

Telescope

Image Erect

Magnification 30×

Effective aperture 47mm

Resolving power 3.75″

Field of view 1°30′(26m/1000m)

Minimum focus 1m

Stadia ratio 100

Up,tighten screw 1,relax screw 3

Down,tighten screw 3,relax screw 1

Left,tighten screw 4,relax screw 2

Right,tighten screw 2,relax screw 4

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

36

Sight distance precision ≤0.4%D

Tube length 162mm

Angle Measurement

Measuring method photoelectric detection

by incremental encoder

Diameter of circle 79mm

Minimum reading 1″, 5″, 10″ , 20″Selectable

Measuring unit 360°, 400gon, 6400mil Selectable

Vertical angle0° Zenith0°, Horizontal0°Selectable

Accuracy 2″、5″、10″Selectable

Vial

Plate vial 30″/2mm

Circular vial 8′/2mm

Compensator

System Liquid-electric detection

Compensation range ±3′

Resolving power 1″

Optical Plummet

Image Erect

Magnification 3×

Focusing range 0.3m~∞

Field of view 5°

Display

Type LCD,Four lines,digital

Data Communication

Port RS-232C

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

37

On-board Battery

Power resource Rechargeable Ni-H battery

Voltage DC6V

Operation time BDC 1800mAh(about 20 hours)

Laser

Length of the wave 635nm

Power 10mW

Effective range(during daytime) 150m

Position error with the sight ≤5″

Power DC3.3V

Working temperature -10℃~+45℃

Operation Environment

Operating temperature -20℃~+45℃

Size & weight

Dimension 180mm×166mm×355mm

Weight 6.5kg

11. Packing List

Instrument

1pc

Battery

2pcs

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

38

Recharger

1pc

Plummet

1pc

Tool bag

1pc

Carrying case

1pc

Operator manual

1pc

12. Error Code Instruction

E-301 Memory Card-Error

E-302 VJ767-Error

SMART MAX GEOSYSTEMS CO.,LTD

www.smartmaxgeosystems.com info@smartmaxgeosystems.com

39

E-303 HJ767-Error

E-304 HY767-Error

E-305 HJ767-Error AND HY767-Error

E-108 Compensator-Error

E-08 Remeasurment

︱Measured Value- Average Value︱> 30″

E-09 Remeasurement times more than 9

Loading...

Loading...