SmartLine RMA803 Fieldbus Remote Indicator Assembly

Quick Start Installation Guide

34-ST-25-52, Revision 4, March 2020

This document provides descriptions

and procedures for the Quick

Installation of Honeywell’s family of

SmartLine Remote Indicator.

The SmartLine Remote Indicator is a

configurable intelligent field device

which functions as an output an d

status indicator for any Foundation

Fieldbus device on the same H1 link.

Table 1 lists the protocols, human

interface (HMI), materials, approvals,

and mounting bracket options..

For full details refer to the man uals

listed below for protocols , us er

Interface (HMI) operation, Install atio n,

configuration, calib ra ti on ,

maintenance, parts, and safety and

approvals etc. including options

Copyrights, Notices and

Trademarks.

Copyright 2020 by Honeywell

Revision 4, March 2020

Trademarks

SmartLine, RMA are U.S. registered

trademarks of Honeywell Inc.

FOUNDATION™ is a trademark of

the Fieldbus Foundatio n

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

Table of Contents

Documentation ........................................................................................ 1

Installation and Startup ........................................................................... 1

Installation Site Evaluation .......................................................... 1

Display Installation Precautions................................................... 1

Mounting Remote Indicator ......................................................... 1

Mounting Dimensions ............................................................................. 2

Bracket Mounting ......................................................................... 2

Wiring a Remote Indicator ...................................................................... 2

Wiring Procedure ......................................................................... 2

Fieldbus Network Wiring .............................................................. 2

Lightning Protection ..................................................................... 2

Supply Voltage Limiting Requirements .................................................. 2

Explosion-Proof Conduit Seal ................................................................. 2

Write Protect Jumper on Fo un dati on Fieldbus (FF) ............................... 3

Configuration Guid e ................................................................................ 3

Appendix A. PRODUCT CERTIFICATIONS .......................................... 3

A1 European Directive Information (CE Mark) ........................... 3

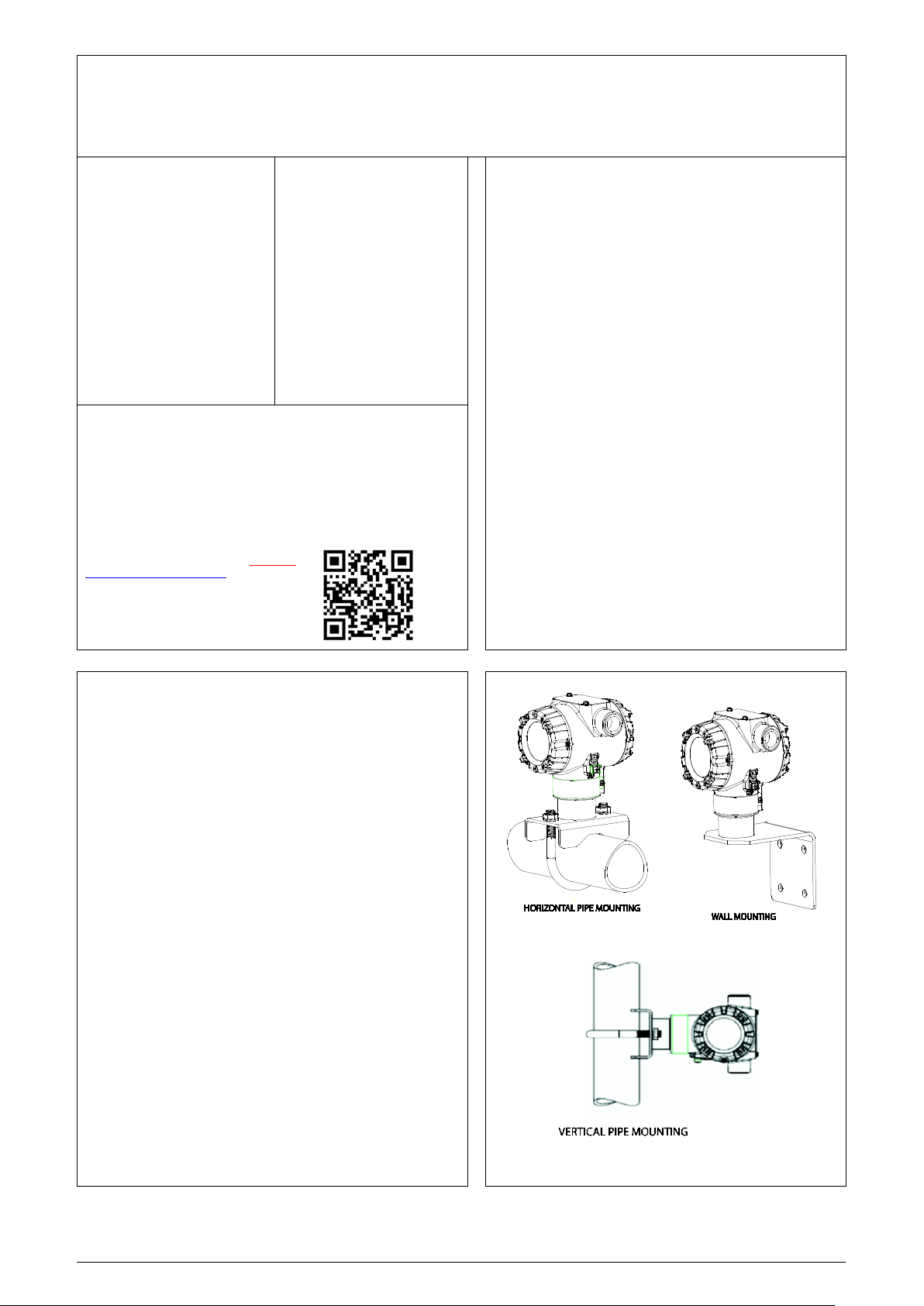

Figure 1: Typical Bracket Mounted Installations ..................................... 1

Figure 2: Pipe Mounting Bracket Secured to a Horizontal or Vertical

Pipe ......................................................................................................... 2

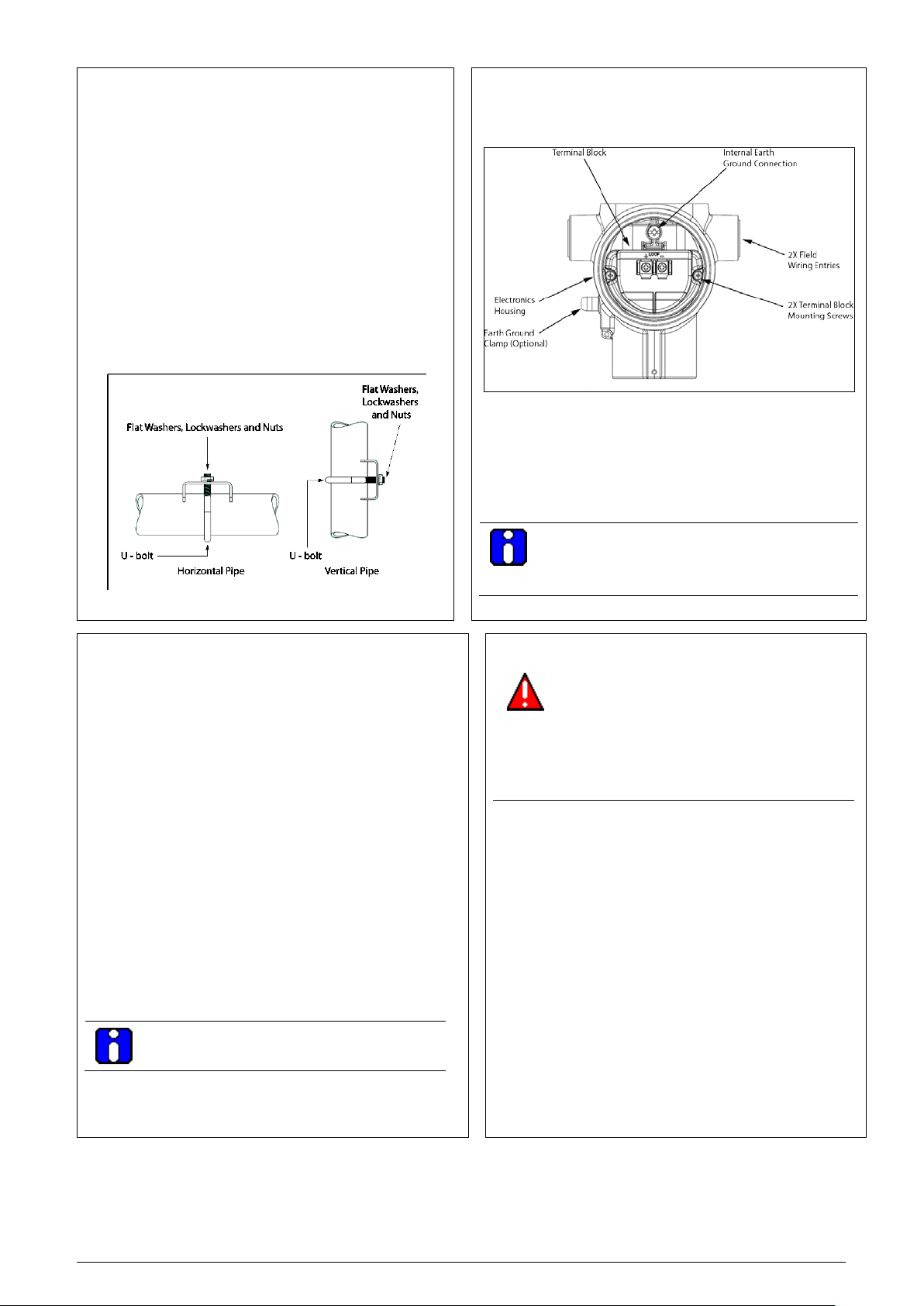

Figure 3: Two Position FF Terminal Block .............................................. 2

Figure 4: Fieldbus Write Protect ............................................................. 3

Installation and Startup

Installation Site Evaluation

Evaluate the site selected for the Remote Indicator installation with respect to

the process system design specifications and Honeywell’s published

performance characteristics for your particular model. Some parameters that

you may want to include in your site evaluation are:

• Environmental Conditions:

Display Installation Precautions

Temperature extremes can affect display quality. The display can go blank if

the temperature is belo w -20°C; however, this is only a temporary condition.

The display will again be readable when temperatures return to within

operable limits. The display update rate may increase at cold tempera tu re

extremes, but as with readability, normal updating resumes when

temperatures are within limits for full operability.

Mounting Remote Indicator

Summary

Remote Indicator models can be attached to a two-inch (50 millimeter)

vertical or horizontal pipe using Honey well ’s opt io nal pip e mou nti n g bra ck et .

Honeywell’s optional wall mounting bracket is also shown below.

Figure 1 shows typical bracket-mounted installations.

o Ambient Temperature

o Relative Humidity

• Potential Noise Sources:

o Radio Frequency Interference (RFI)

o Electromagnetic Interference (EMI)

• Vibration Sources

o Pumps

o Motorized System Devices (e.g., pumps)

o Valve Cavitation

• Process Parameters

o Temperature

o Maximum Pressure Rating

Figure 1: Typical Bracket Mounted Installations

RMA803 Fieldbus Quick Start Guide 1

Mounting Dimensions

Refer to Honeywell drawing number 50094836 for detailed electronic housing

dimensions. Refer to Honeywell drawing numbers 50095917 for detailed pipe

mounting dimensions and 50095918 for detailed wall mounting dimensions.

Abbreviated overall dimensions are also shown on the Specification Sheets for the

Remote Indicator models. This section assumes that the mounting dimensions have

already been taken into account and the mounting area can accommodate the Remote

Indicator.

Bracket Mounting

If you are using an optional bracket, start with Step 1.

1. Align the two mounting holes in the Remote Indicator with the two slots in

the mounting bracket and assemble the (2) M8 hex cap screws, (2)

lockwashers and (2) flat washers provided. Rotate Remote Indicator

assembly to the desired position and torque the M8 hex cap screws to

27,0 Nm/20,0 Lb-ft maximum.

Pipe Mount Option: Refer to Figure 2

2. Position the bracket on a 2-inch (50.8 mm) horizontal or vertical pipe, and

install a “U” bolt around the pipe and through the holes in the bracket.

Secure the bracket with the nuts, flat washers and lock washers provided.

3. Wall Mount Option: Position the bracket on the mounting surface at the

desired location and secure the bracket to the mounting surface using the

appropriate hardware (Wall mounting hardware requirements to be

determined and supplied by the end user)

Wiring a Remote Indicator

Overview

The Remote Indicator is designed to operate as part of a Fieldbus Network.

Loop wiring is connected to the Remote Indicator by simply attaching the loop wires to the

terminals on the Remote Indicator terminal block in the Electronics Housing shown in Figure

3. Connect the Loop Power wiring shield to earth ground only at the power supply end.

Figure 3: Two Position FF Terminal Block

As shown in Figure 5, each Remote Indicator has an internal ground terminal. Optionally, a

ground terminal is also on the outside of the Electronics Housing. While it is not necessary

to ground the Remote Indicator for proper operation, doing so tends to minimize the

possible effects of noise on the output signal and affords protection against lightning and

static discharge. An optional lightning terminal block can be installed in place of the nonlightning terminal block for Remote Indicators that will be installed in an area that is highly

susceptible to lightning strikes. For this to be effective the instrument case must be

connected to earth ground.

ATTENTION

Wiring must comply with local codes, regulations and ordinances.

Grounding may be required to meet various approval body certifications,

for example CE conformity. Refer to Appendix A of this document for

details.

Figure 2: Pipe Mounting Bracket Secured to a Horizontal or Vertical Pipe

Wiring Procedure

1. See Figure 3, above, for parts locations. Loosen the end cap lock using a 1.5

mm Allen wrench.

2. Remove the end cap cover from the terminal block end of the Electronics

Housing.

3. Feed loop power leads through one end of the conduit entrances on either

side of the Electronics Housing. The Remote Indicator accepts up to 16 AWG

wire.

4. Plug the unused conduit entrance with a conduit plug appropriate for the

environment.

5. Feed both loop powered leads through the Ferrite core, 32301350-001, and

then back around and through a second time.

6. Connect both loop power leads to the loop terminals. Torque terminal screws

to 0,6 N.m (5.3 lbf.in) to 0.8 N.m (7.0 lbf.in).

Note. The remote Indicator is not polarity-sensitive.

7. Replace the end cap and secure it in place being careful not to damage the

ferrite core or wires.

Fieldbus Network Wiring

For Fieldbus network wiring concepts, see application notes such as Relcom Inc. Fieldbus

Wiring Guide.

Lightning Protection

If your Remote Indicator includes the optional lightning protection, connect a wire from the

Earth Ground Clamp (see Figure 3) to Earth Ground to make the protection effective. Use

a size 8 AWG or (8.37mm2) bare or green covered wire for this connection.

Explosion-Proof Conduit Seal

WARNING

When installed as explosion proof in a Division 1 Hazardous

Location, keep covers tight while the Remote Indicator is

energized. Disconnect power to the Remote Indicator in the nonhazardous area prior to removing end caps for service.

When installed as non-incendive equipment in a Division 2

hazardous location, disconnect power to the Remote Indicator in

the non-hazardous area, or determine that the location is nonhazardous before disconnecting or connecting the Remote

Indicator wires.

Remote Indicator installed as explosion proof in Class I, Division 1, Group A Hazardous

(classified) locations in accordance with ANSI/NFPA 70, the US National Electrical

Code, with 1/2 inch conduit do not require an explosion-proof seal for installation. If 3/4

inch conduit is used, a LISTED explosion proof seal must be installed in the conduit,

within 18 inches (457.2 mm) of the Remote Indicator.

Supply Voltage Limiting Requirements

If your Remote Indicator complies with the ATEX 4 directive for self-declared

approval per 94/9EC, the power supply has to include a voltage-limiting device.

Voltage must be limited such that it does not exceed 9 to 32 V DC. Consult the

process design system documentation for specifics.

ATTENTION

FF power Supply along with the Terminators has to be used.

2 RMA803 Fieldbus Quick Start Guide

Write Protect Jumper on Foundation Fieldbus (FF)

ATTENTION:

WARNING! PERSONAL INJURY: Risk of electrical shock.

Failure to comply with these instructions could result in death or

Step

Action

Turn OFF Remote indicator power.

Electronics side of the Transmitter housing.

Module and pull it off.

behavior (Protected or Unprotected). See Figure 4 for jumper

On Foundation Fieldbus Remote Indicator there is no Failsafe jumper selection but there

is a Write Protect jumper.

The bottom jumper sets the Write Protect. The default setting is OFF (Un-protected).

When set to the On (Protected) position, Changed configuration parameters cannot be

written to the transmitter.

When set to the OFF (Un-protected) position, Changed configuration parameters can be

written to the transmitter.

precautions for handling electrostatic sensitive devices.

Disconnect power before proceeding. HAZARDOUS LIVE voltages

greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may be accessible.

Electrostatic Discharge (ESD) hazards. Observe

Configuration Guide

Table 1 shows the Advanced Display Configuration. Use these tables to configure the

transmitter.

Level 1 Level 2 Level 3

<Exit>

Diagnostics

Table 1 – Advanced Display Configuration

n/a n/a

Critical

Non-Critical

For details go to the

Diagnostics Menu table.

1

2

3

4

5

6

Loosen the end-cap lock, and unscrew the end cap from the

If applicable, carefully depress the tabs on the sides of the Display

Set the Write Protect jumper (Bottom jumper) to the desired

Screw on the end cap and tighten the end-cap lock.

Turn ON Remote Indicator power.

Image Description

Fieldbus SIM Mode = OFF

Write Protect = OFF (Not Protected)

Fieldbus SIM Mode = OFF

Write Protect = ON (Protected)

Fieldbus SIM Mode = ON

Write Protect = OFF (Not Protected)

Figure 4: Fieldbus Write Protect

Display Setup

Information

:

LCD Contrast

Common

Setup

Screen 1

Screen 2

…

Screen 8

Display

Elec Module

Model

Options

For details go to the Display

Setup Menu table.

Note that the Advanced

Display supports the

configuration of up to 8

different screens.

For details go to the

Information Menu table.

Appendix A. PRODUCT CERTIFICATIONS

A1 European Directive Information (CE Mark)

RMA800 SmartLine Remote Indicator Series EU Declaration of conformity (Document

#32302406), can be downloaded here: EU Declaration

RMA803 Fieldbus Quick Start Guide 3

A2. Hazardous Locations Certifications

MSG

CODE

AGENCY

TYPE OF PROTECTION

Electrical

Parameters

Ambient

Temperature

Explosion proof:

Class I, Divis ion 1, Groups A, B, C, D; T6. .T4

Class 2, Zone 21, A Ex tb IIIC T 95oC IP66 Db

Intrinsically Safe:

Class I Zone 0 AEx ia IIC T4 Ga

Non-Incendive

Class I Zone 2 AEx nA IIC T4 Gc

Enclosure: Type 4X/ IP66/ IP67

Standards: FM 3600: 2018; FM 3611: 2018 ; ANSI/ UL 60079-0: 2013; ANSI/

FM 3810: 2018;

FM 3616: 2011

Explosion proof:

Class I, Divis ion

Dust Ignition Pro of:

Class II, I II, Division 1, Groups E, F, G ; T4

Class I Zone 1 Ex d b IIC T4 Gb

Ex db IIC T4 Gb

Zone 21 Ex tb III C T 95

Ex tb IIIC T 95oC Db

Intrinsically Safe:

Ex ia IIC T4 Ga

Non-Incendive

Ex nA IIC T4 Gc

Enclosure:

Standards: CSA C22.2 No. 0: 2015; C SA C22.2 No. 30: 2016; CSA C22. 2

UL 12.27.01: 2017; A NSI/UL 50E: 2015

Flame-proof and Dust:

II 2 D Ex tb IIIC T 95oC Db

Intrinsically Safe:

Non-Incendive

Enclosure: Type IP66/ IP67

ALL

ALL

STANDARDS: EN 60079-0 : 2012+A11: 2013;

EN 60079-7: 2015;

Flame-proof:

Ex tb IIIC T 95oC Db

Intrinsically Safe:

Ex ia IIC T4 Ga

-50oC to 70oC

Non-Incendive

Ex ec IIC T4 Gc

Enclosure: IP66/ IP67

ALL

ALL

STANDARDS: IEC 60079-0: 2011; IEC 60079-1: 2014;

IEC 60079-11: 2011; IEC 60079- 7: 2015; IEC 60079-31: 2014

Flame-proof:

T6: -20oC to 65oC

Intrinsically Safe:

Ex ic IIC T4 Gc

Non-Incendive

Ex ec IIC T4 Gc

Enclosure: IP66/ IP67

ALL

ALL

STANDARDS: IEC 60079-0: 2011; IEC 60079-1: 2014;

IEC 60079-11: 2011; IEC 60079- 7: 2006; IEC 60079-31: 2013

Flame-proof:

T6: -20oC to 65oC

Intrinsically Safe:

STANDARDS: IEC 60079-0: 2011; IEC 60079-1: 2014;

IEC 60079-11: 2011; IEC 60079- 7: 2006; IEC 60079-31: 2013

A

FM

Approvals

(USA)

Dust Ignition Pro of:

Class II, I II, Division 1, Groups E, F, G ; T4

Class 1, Zone 1 , AEx d IIC T4 Gb

Class I, II , III, Division 1, Groups A, B, C,D,

E, F, G; T4

TM

Class I, Divis ion 2, Groups A, B, C, D; T4

T6: -50ºC to +65ºC

Note 1

T4, T5: -50 ºC to

85ºC

Note 2 -50 ºC t o 70ºC

Note 1 -50 ºC t o 85ºC

ALL ALL

UL 60079-1: 2015; FM 3610: 2018; ANSI/ UL 60079-11: 2014;

ANSI/ UL 60079-15: 2013; ANSI/ UL 60079-31 : 2015; FM C lass 3615: 2018;

CSA 14.2689056

1, Groups A, B, C, D ;T6..T4

o

C Db

T6: -50ºC to

Note 1

+65ºC

T4, T5: -50 ºC to

85ºC

B

CSA-

Canada

C ATEX

D IECEx

No. 94-M91; CSA C22. 2 No. 25: 2017;

CSA C22.2 No. 6101 0-1: 2017; CSA-C22.2No.157: 2016; C22.2 No. 213:

2017; C22.2 No. CSA 60079-0:2015; C22.2 No. 60079-1: 2 016; C22.2 No.

60079-11: 2014;C22.2 No. 600 79-15: 2016; C22.2 No. 60079-31: 2015;

ANSI/ ISA12.12.01 -2017; ANSI/ ISA 61010-1: 2016; ANSI/ UL 60079-0:

2013; ANSI/ UL 6007 9-1: 2015; ANSI/ UL 60079-11: 2014; ANSI/ UL

60079-15: 2013; ANSI / UL 60079-31: 2015; FM 3600: 2011; F M 3615:

2006; FM Class 3616: 2011; ANSI/ UL 913: 2015; UL 916: 2015; ANSI/

II 2 G Ex db IIC T6..T4 Gb

II 1 G Ex ia IIC T4 Ga

II 3 G Ex ec IIC T4 Gc

Note 1

Note 2 -50oC to 70oC

Note 1 -50oC to 85oC

EN 60079-1: 2014; EN 60079-11: 2012; EN 60079 -31: 2014;

Ex db IIC T6..T4 Gb

Note 1

Note 2

Note 1 -50oC to 70oC

T6: -50ºC to +65ºC

T4, T5: -50 ºC to 85ºC

T6: -50ºC to +65ºC

T4, T5: -50 ºC to 85ºC

B CSA-Canada

CSA 14.2689056

Class I, II , III, Division 1, Groups A, B, C, D,

E, F, G; T4

CSA 14.2689056

Class I, Divis ion 2, Groups A, B, C, D; T4

Class I Zone 2 Ex n A IIC T4 Gc

Ex db IIC T6..T5 Gb

CCoE/

P

PESO

Notes

1. Operating Parameters:

Voltage= 12 to 42 V Current= 25 mA

2. Intrinsically Safe Entity Parameters

For details see Control Drawing, 50089981.

Ex ia IIC T4 Ga

Enclosure: IP66/ IP67 ALL ALL

Type 4X/ IP66/ IP67

Note 2 -50oC to 70oC

Note 1 -50oC to 85oC

ALL ALL

Note 1

T5: -20oC to 85oC

Note 2 -20oC to 70oC

E SAEx

Ex db IIC T6..T5 Gb

Ex tb IIIC T 95oC Db

Ex ia IIC T4 Ga

T95oC,

Note 1

T5: -20oC to 85oC

Note 2 -20oC to 70oC

Note 1 --20oC to 85oC

A4. Marking ATEX D irective

a. General

The following information is provided as part of the labeling of the Remote

Indicator:

• Name and Address of the manufacturer

• The serial number of the Remote Indicator is located on the Meter Body

data-plate. The first two digits of the serial number identify the year (02) and

the second two digits identify the week of the year (23); for example,

0223xxxxxxxx indicates that the product was manufactured in 2002, in the

23rd week.

b. Apparatus Marked with Multiple Types of Protection

The user must determine the type of protection required for installation the

equipment. The user shall then check the box [ ] adjacent to the type of protection

used on the equipment certification nameplate. Once a type of protection has been

checked on the nameplate, the equipment shall not then be reinstalled using any of

the other certification types.

c. WARNINGS and Cautions

Non-Incendive / Non-Sparking (Division 2 and Zone 2 Environments):

WARNING – EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS

WARNING – DO NOT OPEN WHEN ENERGIZED

WARNING – OPEN CIRCUIT BEFORE REMOVING COVER

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2

Intrinsically Safe (Divisions 1, Zone 1 and Zone 2 Environments):

WARNING – EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY.

WARNING – DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE

IS PRESENT.

Explosion-Proof (Division 1 and Zone 1 Environments):

WARNING – DO NOT OPEN WHEN AN EXPLOSIVE GAS ATMOSPHERE

IS PRESENT.

WARNING – DO NOT OPEN WHEN ENERGIZED

“OPEN CIRCUIT BEFORE REMOVING COVER”

Flameproof (Division 1 and Zone 1 Environments):

WARNING – DO NOT OPEN WHEN ENERGIZED

General Requirements / Increased Safety (Zone 1):

All Protective Measures:

WARNING: FOR CONNECTION IN AMBIENTS ABOVE 60oC USE WIRE

RATED 105oC

4 RMA803 Fieldbus Quick Start Guide

A.3 Conditions of Use” for Ex Equipment”, Hazardous Location

Equipment or “Schedule of Limitations”:

a. Consult the manufacturer for dimensional information on the flameproof

joints for repair.

b. Painted surface of the RMA 800 series may store electrostatic charge and

become a source of ignition in applications with a low relative humidity less

than approximately30% relative humidity where the painted surface is

relatively free of surface contamination such as dirt, dust or oil. Cleaning of

the painted surface should only be done with a damp cloth.

c. The ambient temperature range, maximum process temperature and

applicable temperature class of the equipment is as follows:

RMA801: T4 for -50˚C < Ta < 85˚C

RMA803: T4 for -20˚C < Ta < 70˚C

d. The RMA800 series enclosure contains aluminum and is considered to

present a potential risk of ignition by impact or friction. Care must be

considered during installation and use to prevent impact or friction to avoid

impact.

e. If a charge-generating mechanism is present, the exposed metallic part on

the enclosure is capable of storing a level of electrostatic charge that could

become incendive for IIC gases. Therefore, the user/installer shall

implement precautions to prevent the buildup of electrostatic charge, e.g.

earthing the metallic part. This is particularly important if the equipment is

installed in a zone 0 location.

f. On installation, the RMA800 series shall be provided with supply transient

protection external to the apparatus such that the voltage at the supply

terminals of the RMA800 series does not exceed 140% of the voltage rating

of the equipment.

A.4 Control Drawing

RMA803 Fieldbus Quick Start Guide 5

34-ST-25-52, Rev. 4

2020 Honeywell International Inc.

ASIA PACIFIC (TAC) hfs-tac-support@honeywell.com

9015

EMEA, Phone: + 80012026455 or +44 (0)1202645583. FAX: +44 (0) 1344 655554

or (TAC) hfs-tac-support@honeywell.com

accurate and reliable as of this printing. However, we assume no responsibility for its use

Sales and Service

For application assistance, current specifications, pricing, or name of the nearest

Authorized Distributor, contact one of the offices below.

Australia Honeywell Limited, Phone: +(61) 7-3846 1255, FAX: +(61) 7-3840 6481

Toll Free 1300-36-39-36, Toll Free Fax: 1300-36-04-70

China – PRC – Shanghai, Honeywell China Inc. Phone: (86-21) 5257-4568,

Fax: (86-21) 6237-2826

Singapore, Honeywell Pte Ltd. Phone: +(65) 6580 3278. Fax: +(65) 6445-3033

South Korea, Honeywell Korea Co Ltd. Phone:+(822)799 6114. Fax:+(822) 792

Email: (Sales) sc-cp-apps-salespa62@honeywell.com

AMERICAS, Honeywell Process Solutions, Phone: 1-800-423-9883,

or 1-215/641-3610. (TAC) hfs-tac-support@honeywell.com.

Sales 1-800-343-0228. Email: (Sales) FP-Sales-Apps@honeywell.com

Knowledge Base search engine http://bit.ly/2N5Vldi

WARRANTY/REMEDY

Honeywell warrants goods of its manufacture as being free of defective materials and

faulty workmanship. Contact your local sales office for warranty information.

If warranted goods are returned to Honeywell during the period of coverage, Honeywell

will repair or replace without charge those items it finds defective. The foregoing is

Buyer's sole remedy and is in lieu of all other warranties, expressed or implied,

including those of merchantability and fitness for a particular purpose.

Specifications may change without notice. The information we supply is believed to be

While we provide application assistance personally, through our literature and the

Honeywell web site, it is up to the customer to determine the suitability of the product

in the application.

For more information

To learn more about SmartLine Devices, visit www.honeywellprocess.com

Or contact your Honeywell Account Manager

Process Solutions

Honeywell

1250 W Sam Houston Pkwy S

Houston, TX 77042

Honeywell Control Systems Ltd

Honeywell House, Skimped Hill Lane

Bracknell, England, RG12 1EB

Shanghai City Centre, 100 Jungi Road

Shanghai, China 20061

www.honeywellprocess.com

March 2020

Loading...

Loading...