SmartLine RMA801 Installation Manual

SmartLine RMA801 HART/DE Remote Indicator Assembly

Quick Start Installation Guide

34-ST-25-63, Revision 5, March 2020

This document provides descriptions

and procedures for the Quick

Installation of Honeywell’s family of

SmartLine Remote Indicator.

The SmartLine Remote Indicator is a

configurable intelligent field device

which functions as an output an d

status indicator for any HART and

DE devices.

For full details refer to the man uals

listed below for protocols , us er

Copyrights, Notices and

Trademarks.

Copyright 2020 by Honeywell

Revision 5, March 2020

Trademarks

SmartLine, RMA are U.S. registered

trademarks of Honeywell Inc.

HART® is Trademarks of

FieldComm Group™

Interface (HMI) operat ion , Ins tallation,

configuration, calib ra ti on ,

maintenance, parts, and safety and

approvals etc. including options

Documentation

To access complete documentation, including language variants, scan

the QR code below using your smart phone/device or QR code scanner.

Go to the APP store for your free Smartphone QR scanner

Or you can follow the URL to access the online SmartLine HUB page.

The HUB page will contain direct links to open SmartLine product

documentation.

URL QR Code

https://hwll.co/SmartLineHUB

Table of Contents

Installation and setup .................................................................................1

Site evaluation............................................................................................1

Installation precau tio ns ..............................................................................1

Explosion-Proof Conduit Seal ....................................................................1

Mounting Remote indicator ........................................................................2

Mounting Dimensions ................................................................................2

Bracket Mounting .......................................................................................2

Wiring a Remote Indicator .........................................................................2

Terminal Block ...........................................................................................2

Wiring Connections and Power Up ............................................................3

Wiring procedure Options ..........................................................................3

DEVICE CONFIGURATION ......................................................................3

Appendix A. PRODUCT CERTIFICATIONS .............................................3

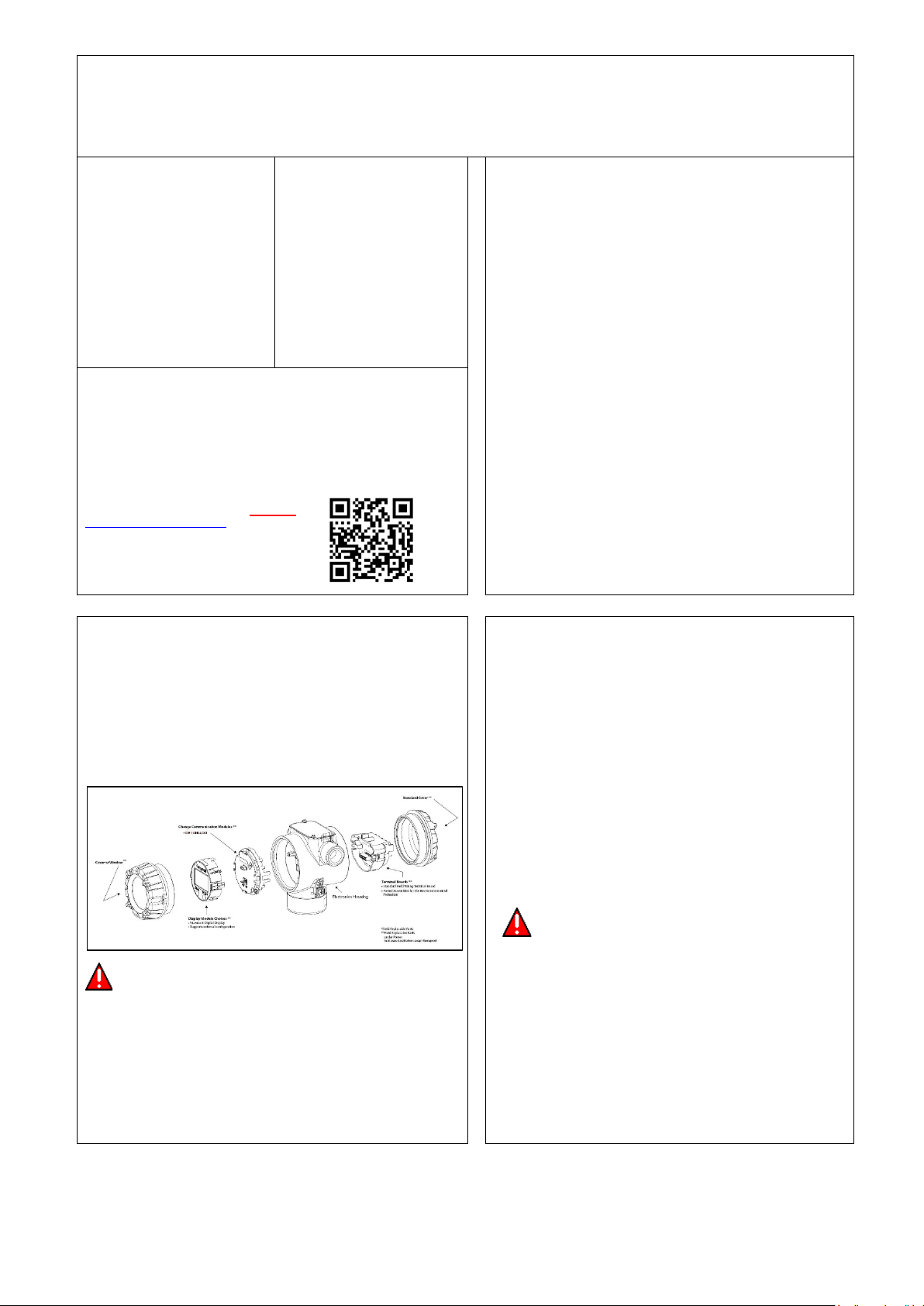

Figure 1: Electronics Housing Components ..............................................1

Figure 2: Typical Pipe Mounted Installations .............................................2

Figure 3: Pipe Mount - Horizontal Mounting Bracket .................................2

Figure 4: Pipe Mount - Vertical Mounting Bracket .....................................2

Figure 5: Remote Indicator Secured to a Wall Mounting Bracket .............2

Figure 6: DE/ANALOG Terminal Block ......................................................2

Figure 7: RMA801 Terminal Block .............................................................2

Figure 8: Remote Indicator connected to the negative loop wire ..............3

Figure 9: Remote Indicator connected to the negative loop wire ..............3

Figure 10: Remote Indicator connected to the positive loop wire .............3

Features and Options

The RMA801 Remote Indicator provides a means of remote-mounting a indicator (display)

that is associated with a Honeywell Smartline Transmitter or any transmitter operating in a

4-20 mA current loop.

The RMA801 is a DE/Analog Remote Indicator which can be connected anywhere along

the current loop.

For analog PV, the RMA801 measures the loop current and displays the equivalent PV

value on the display.

The RMA801 will auto configure when connected to Honeywell DE transmitters except

SMV800/3000when a database upload is performed.

This document provides the information for a quick setup. For detailed information, please

refer RMA801 user manual, 34-ST-25-62.

Figure 1: Electronics Housing Components

CAUTION

Temperature extremes can affect display quality. The display can go blank if the

temperature is below -20°C or above 70°C; ho wever, this is only a tem porary conditio n. The

display will again be readable when temperatures return to within operable lim its.

The device shall be operated by a t rained pr ofession al. It is the user /insta ller’s respo nsibility

to install the indicator in accordance with national and local code requirements. Conduit

entry plugs and adapters shall be suitable for the environment, shall be certified for the

hazardous location when required and accept able to the authority hav ing j urisdiction for the

plant

The RMA device is always connected in series with the transmitter. The current loop will

be broken if the RMA801 device is removed from the loop.

Installation and setup

ite evaluation

S

Evaluate the site selected for the Remote Indicator installation with respect to the

process system design specifications and Honeywell’s published performance

characteristics for your particular model. Some parameters that you may want to

include in your site evaluation can be found in the RMA801 user manual,

#34-ST-25-62

Installatio n pr ec au t i on s

Temperature extremes can affect display quality. The display can go blank if the

temperature is below -20°C or above +70°C; however, this is only a temporary

condition. The display will again be readable when temperatures return to within

operable limits.

Explosion-Proof Conduit Seal

WARNING

When installed as explosion proof in a Division 1 Hazardous Location, keep

covers tight while the Remote Indicator is energized. Disconnect power to the

Remote Indicator in the non-hazardous area prior to removing end caps for

service.

When installed as non-incendive equipment in a Division 2 hazardous location,

disconnect power to the Remote Indicator in the non-hazardous area, or

determine that the location is non-hazardous before disconnecting or

connecting the Remote Indicator wires.

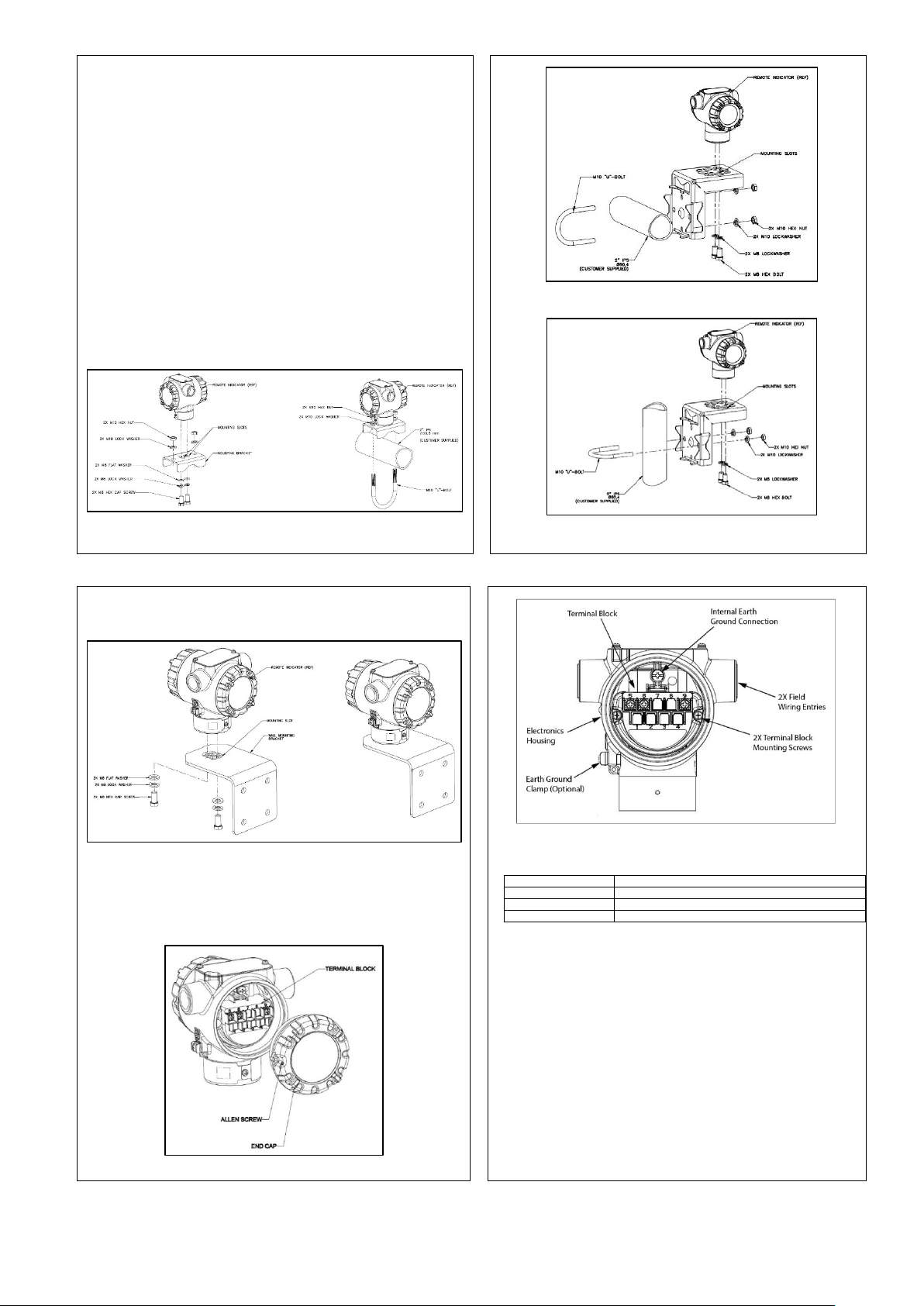

Mounting Remote indicator

Terminal No.

Description

5

Loop +ve

6

Loop -ve

9

DE COMM

Summary Remote Indicator models can be attached to a two-inch (50.8 millimeter) vertical

or horizontal pipe using Honeywell’s optional pipe mounting bracket. Honeywell’s optional

wall mounting bracket is also shown in figures below.

Mounting Dimensions

Refer to Honeywell drawing number 51455045* for detailed electronic housing dimensions.

Refer to Honeywell drawing numbers 32306827* for detailed pipe mounting dimensions,

50124813* for Detailed Pipe Angle mounting dimensions and 32306828* for detailed wall

mounting dimensions.

THE TRANSMITTER ENCLOSURE CAN BE ROTATED A TOTAL OF 90° FROM THE

STANDARD MOUNTING POSITION

* Honeywell drawings can be supplied on request.

Bracket Mounting

If you are using an optional bracket, start with Step 1.

1. Pipe Mount Option -Refer to Figure 2, Figure 3 and Figure 4. Align the two

mounting holes at the bottom of the Remote Indicator with the two slots in the

mounting bracket and assemble the (2) M8 hex cap screws, (2) lock washers

and (2) flat washers provided.

2. Rotate the Remote Indicator assembly to the desired position and torque the

M8 hex cap screws to 27,0 Nm/20,0 Lb-ft maximum

3. Position the bracket on a 2-inch (50.8 mm) horizontal or vertical pipe, and

install a “U” bolt around the pipe and through the holes in the bracket. Secure

the bracket with (2) M10 hex nuts, (2) flat washers and (2) lock washers

provided. Refer to Figure 4.

Figure 2: Typical Pipe Mounted Installations

Figure 3: Pipe Mount - Horizontal Mounting Bracket

Figure 4: Pipe Mount - Vertical Mounting Bracket

4.

Wall Mount Option – Refer Figure 5 Position the bracket on the mounting

surface at the desired location and secure the bracket to the mounting surface

using the appropriate hardware (Wall mounting hardware requirements to be

determined and supplied by the end user).

Figure 5: Remote Indicator Secured to a Wall Mounting Bracket

Wiring a Remote Indicator

Overview

The Remote Indicator is designed to operate in normal 4-20mA analog mode with HART

enabled transmitters across SmartLine Devices and DE transmitters except SMV 800/3000.

For improved noise performance, it is recommended to provide earth ground for both

transmitter and RMA housing.

Figure 6: DE/ANALOG Terminal Block

Terminal Block

The RMA801 has 3 terminals. Following table provides the connection details-

Three screw terminals suitable for wirings up to (16AWG)

• Shielded, twisted-pair cable such as Belden 9318 or equivalent must be used

for all signal/power wiring.

• The cable shield must be connected at only one end of the cable. Connect it to

the power supply side and leave the shield insulated at the transmitter side

and RMA side.

Note: If solid core wire is used strip insulation 1/4 in (6 mm). Once inserted under the

square washer the stripped portion should be contained under the square washer. If

multi-stranded wire is used, a ferrule is to be used and the stripped wire should be in

the insulated portion of the ferrule. The ferrule can be also be used on the solid core

wire.

Loop Terminals 5 & 6 shall be connected in series with the 4-20 ma loop for both

analog and DE modes. Additionally, third wire (Terminal 9) is required for DE

communication in DE mode only.

Loop wiring for analog and DE mode is shown in figure below.

After wiring the Transmitter as outline in the next sections, torque the screws to

Figure 7: RMA801 Terminal Block

NOTE:

1.1 Nm (10 lb-in)

Loading...

Loading...